Cutter ring of electroplated diamond hobbing cutter and processing technology of cutter ring

A technology of electroplating diamond and processing technology, which is applied in the direction of electrolytic coating, manufacturing tools, coating, etc., can solve the problems of increasing construction risk and engineering cost, reducing material toughness, frequent tool changes, etc., and achieves less impurities and high working life , The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

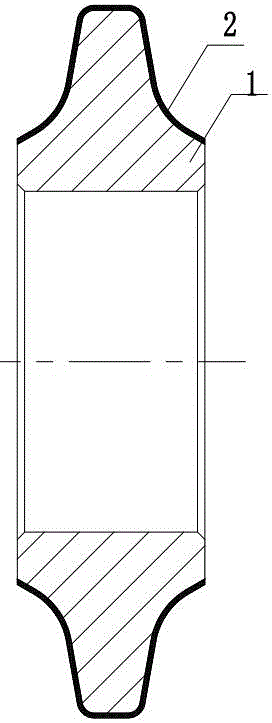

[0023] Such as figure 1 As shown, an electroplated diamond hob cutter ring of the present invention includes a cutter ring base 1 and a diamond wear-resistant layer 2 electroplated on the peripheral surface of the cutter ring base 1; wherein the mass percentage of each raw material of the cutter ring base 1 is They are: C is 0.38-0.48%, Si is 0.6-0.8%, Mn is 1.20-1.55%, Cr is 2.7-3.5%, Mo is 2.6-3.4%, V is 1.05-1.40%, impurity P≤0.02% , Impurity S≤0.02%, Fe balance.

[0024] The overall hardness of the knife ring base 1 is that the HRC of the knife ring base 1 is 53-57, and the impact toughness is 25-32 J / cm2.

[0025] A processing technology for an electroplated diamond hob cutter ring, comprising the following steps: a. The raw materials of the cutter ring base 1 are sequentially smelted in an electric furnace, refined, pre-forged, die forged, slowly cooled, annealed, and rough-processed to obtain a disc Shaped knife ring base 1 rough blank;

[0026] b. The rough blank of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com