Method for preparing hierarchical pore titanium-silicon TS-1 molecular sieve

A TS-1 and molecular sieve technology, applied in the direction of molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic metal phosphates, etc., can solve the problems of difficult control conditions, poor experiment repeatability, cumbersome operation, etc., to reduce generation, prevent precipitation, and expand applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0139] According to one embodiment of the present application, the method for preparing the hierarchically porous TS-1 molecular sieve is as follows:

[0140] a) Mix titanate-based polyester polyol with organic base template, silicon source, water, etc. according to a certain ratio to obtain a gel mixture. Preferably, the gel mixture has the following molar ratio:

[0141] TiO 2 / SiO 2 =0.005~0.1;

[0142] Organic base template / SiO 2 =0.01~10;

[0143] h 2 O / SiO 2 =5~500;

[0144] The silicon content in the silicon source is SiO 2 In terms of moles, the titanium content in titanic acid polyester polyol is calculated as TiO 2 The number of moles; the content of the organic base template is based on the number of moles of N atoms.

[0145] b) subjecting the gel mixture obtained in step a) to an aging process, which can be omitted or carried out under stirring or static conditions, the aging temperature is 0-120°C, and the time is 0-100 hours;

[0146] c) Put the gel mi...

Embodiment 1

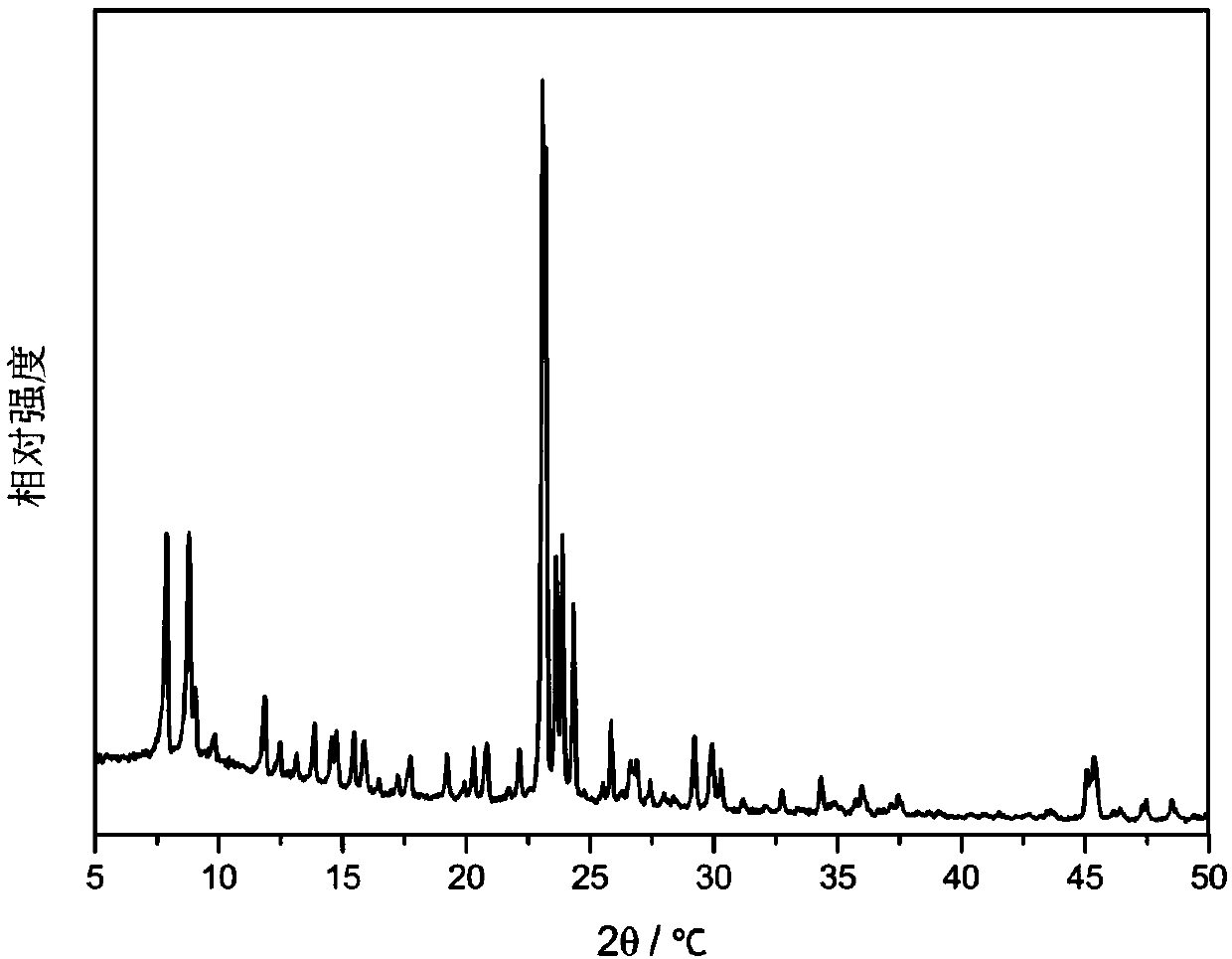

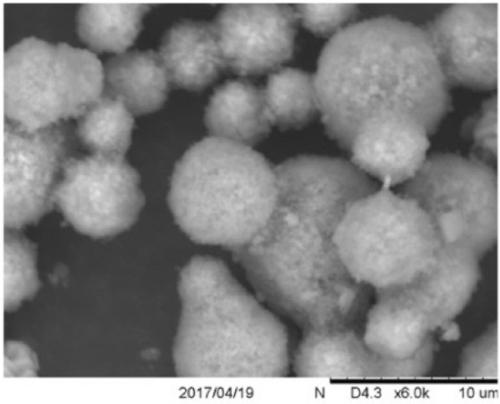

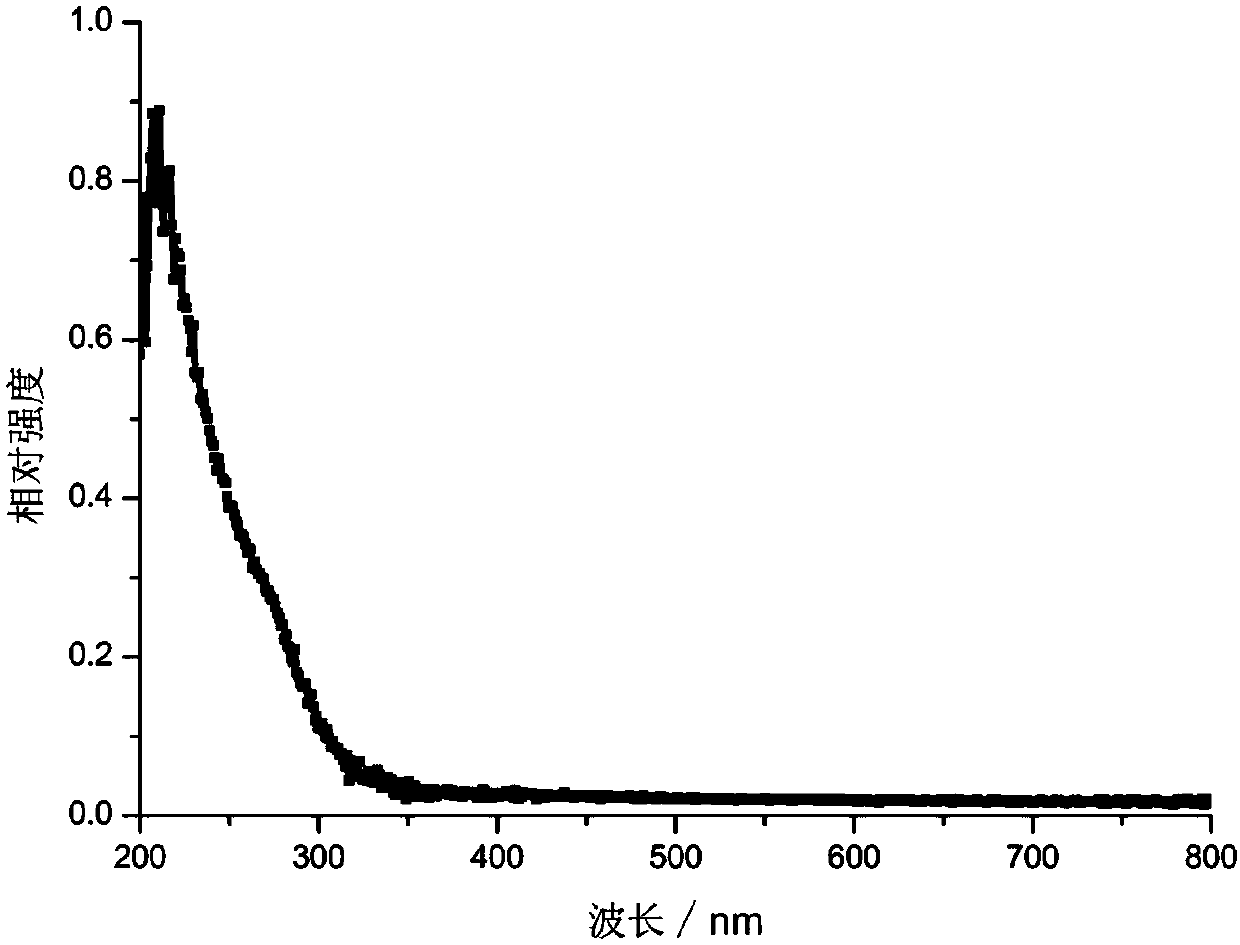

[0157] The types and molar amounts of each raw material, crystallization temperature and time, XRD crystal form and external specific surface results are shown in Table 1 below.

[0158] In Example 1, the specific batching process is as follows: add 6.76g tetrapropylammonium hydroxide (25wt.%) aqueous solution, 1g white carbon black, 10g water to 0.14g ethylene glycol titanate polyester, mix well, and stir at room temperature 2 hours, and then transferred to a stainless steel autoclave. At this time, the molar ratio of each component of the synthesis system is 0.05[Ti(OCH 2 CH 2 O) 2 ] 20 :SiO2 2 :0.5TPAOH:50H 2 O. The autoclave was sealed and placed in an oven at a constant temperature of 170°C for crystallization under autogenous pressure for 2 days. After the crystallization, the solid product was centrifuged, washed with deionized water until neutral, and dried in air at 110°C to obtain a multi-order pore TS-1 molecular sieve. Get the sample of this former powder a...

Embodiment 2-13

[0165] Specific ingredients, materials, reaction conditions and analysis results are shown in Table 1 below. The synthesis process is similar to Example 1. Other analysis results of the product are shown in Table 1 below.

[0166] Raw material composition and crystallization condition of table 1 embodiment 2-13

[0167]

[0168]

[0169] In Table 1, R is selected from the group formed by the loss of x hydrogen atoms in hydrocarbon compounds, ethyl, propyl, butyl, polyethylene glycol, terephthalyl, etc., x is 2-6 between.

[0170] The crystallization in Examples 1 to 13 is static crystallization.

[0171] Wherein, the preparation method of the titanate-based polyester polyol in Example 2 to Example 13 is the same as the preparation method of the titanate glycol polyester in Example 1, the difference is that 5g of ethylene glycol is replaced by 6.1 g 1,3-propanediol, 5g glycerol, 7.2g 1,4-butanediol, 9.5g 1,6-hexanediol, 11.1g terephthalenediol, 9.3g 1,4-cyclohexanediol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com