Method for refrigerating liquefied gas and installation therefor

A technology of liquefied natural gas and cooling method, which is applied in liquefaction, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of increasing production and achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

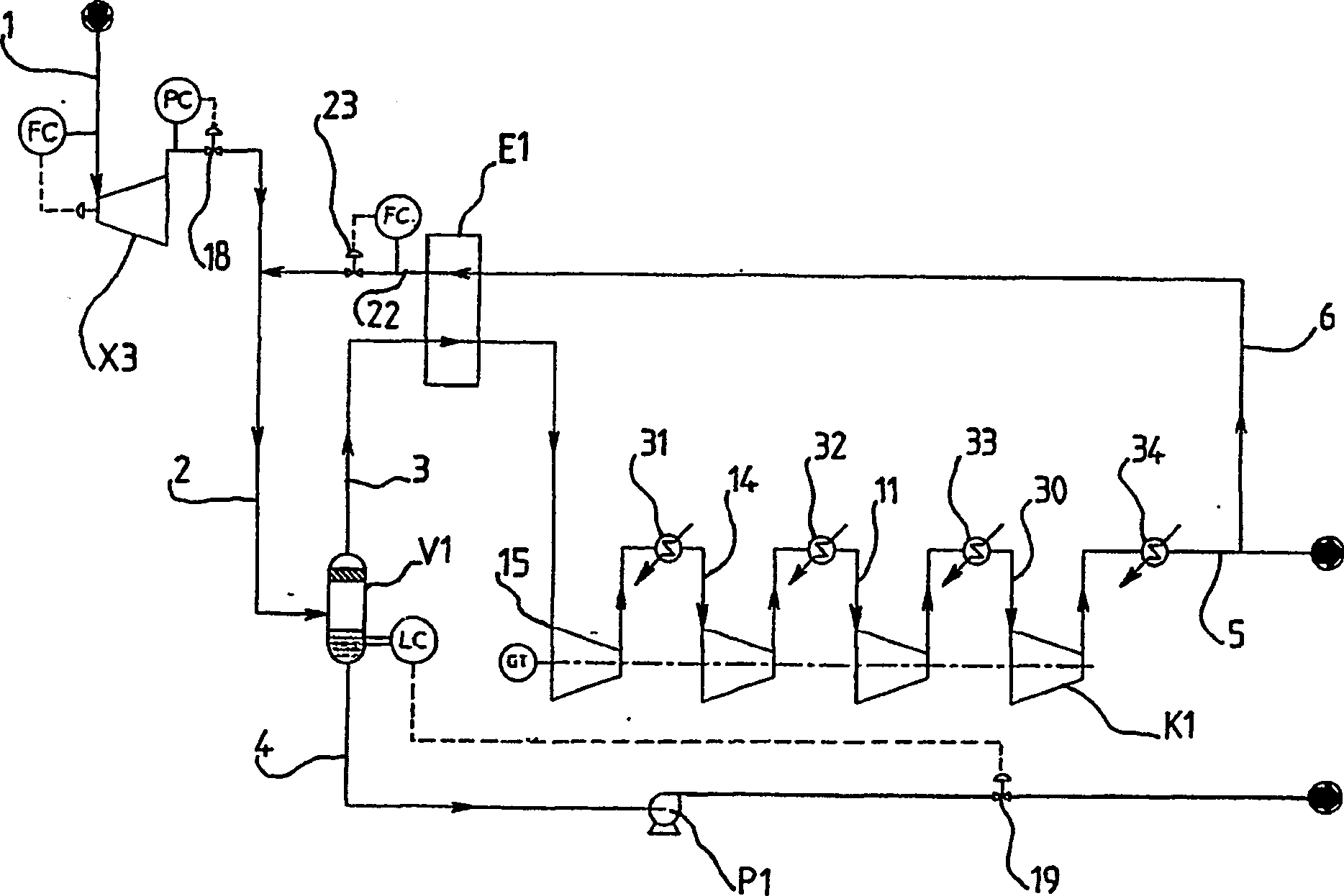

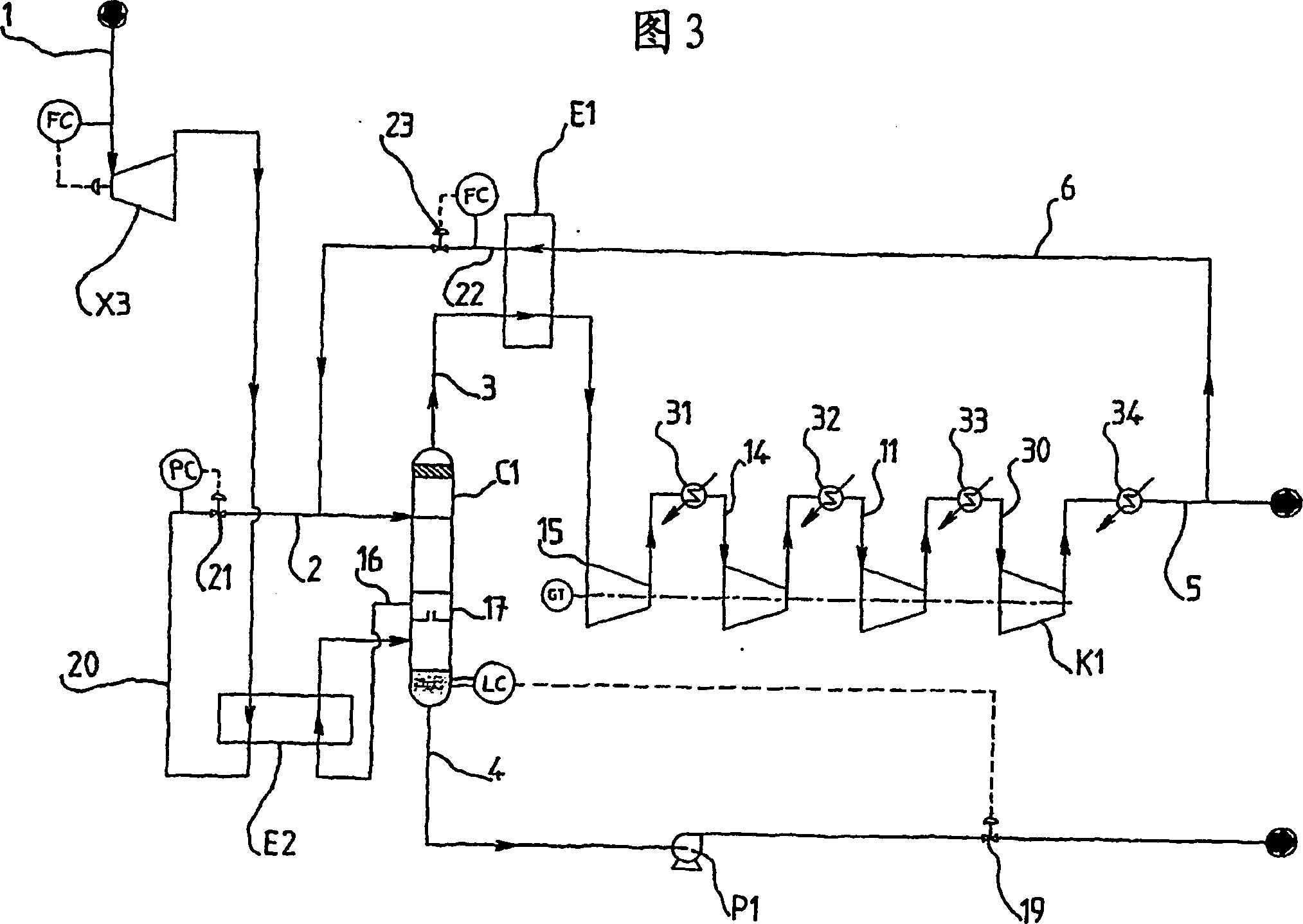

[0031] Some symbols can be seen in these 7 diagrams: "FC" stands for "Flow Controller", "GT" stands for "Gas Turbine", "GE" stands for "Generator", "LC" stands for "Liquid Level Controller" , "PC" stands for "Pressure Controller", "SC" stands for "Speed Controller", "TC" stands for "Temperature Controller".

[0032] For the sake of clarity and conciseness, the pipes used in the apparatus of Figures 1-7 are indicated by the same reference symbols as the gas fractions flowing therein.

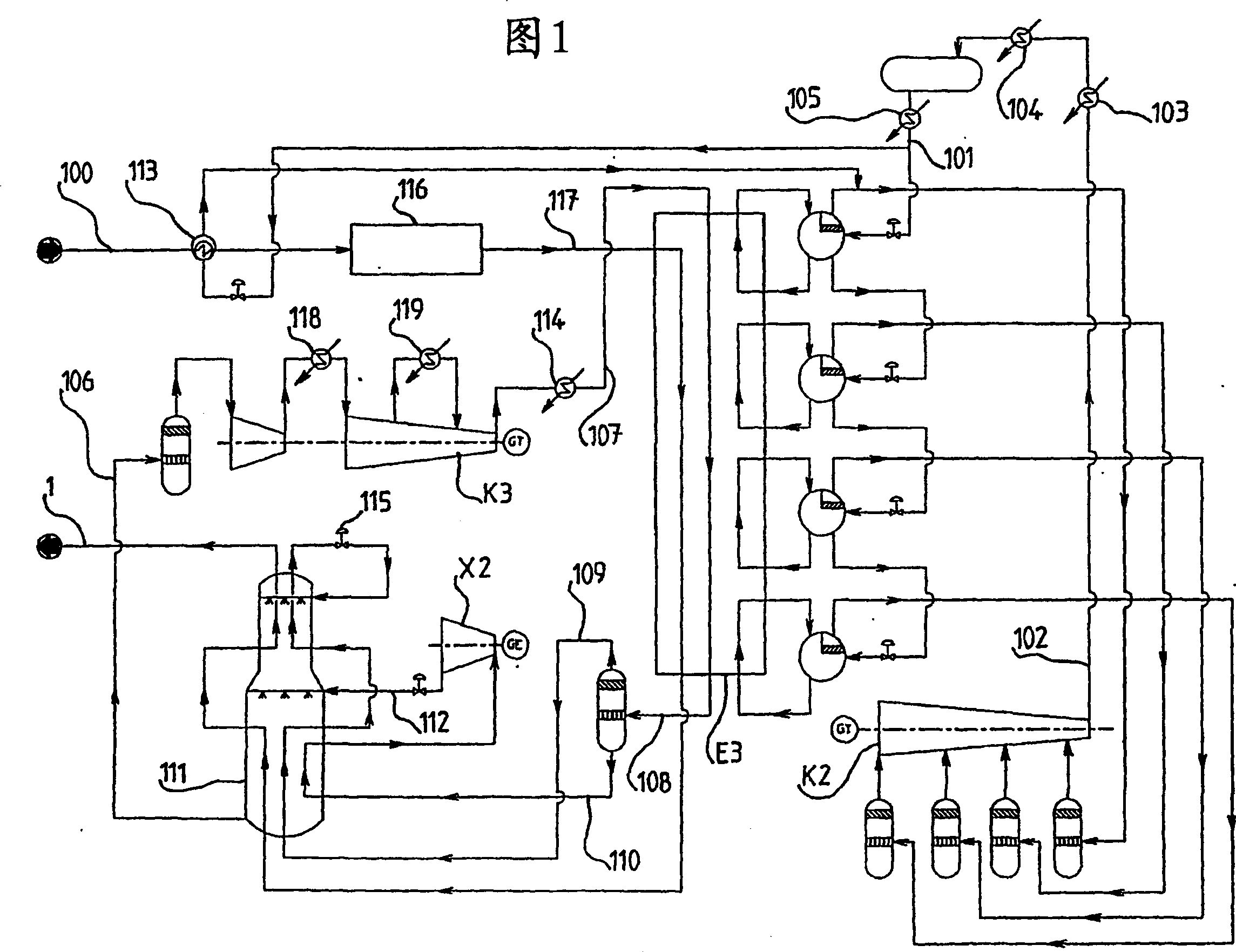

[0033] Referring to Figure 1, the apparatus shown is used in known manner to process a dry natural gas 100 free of sulfur and carbon to obtain a liquefied natural gas 1 at a temperature generally below -120°C.

[0034] The GNL liquefaction plant has two separate cooling circuits. The first cooling circuit 101 corresponds to a propane circuit, and a primary cooling of approximately -30° C. can be obtained by expansion and vaporization of liquid propane in an exchanger E3. The heated and expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com