Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Consistent coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

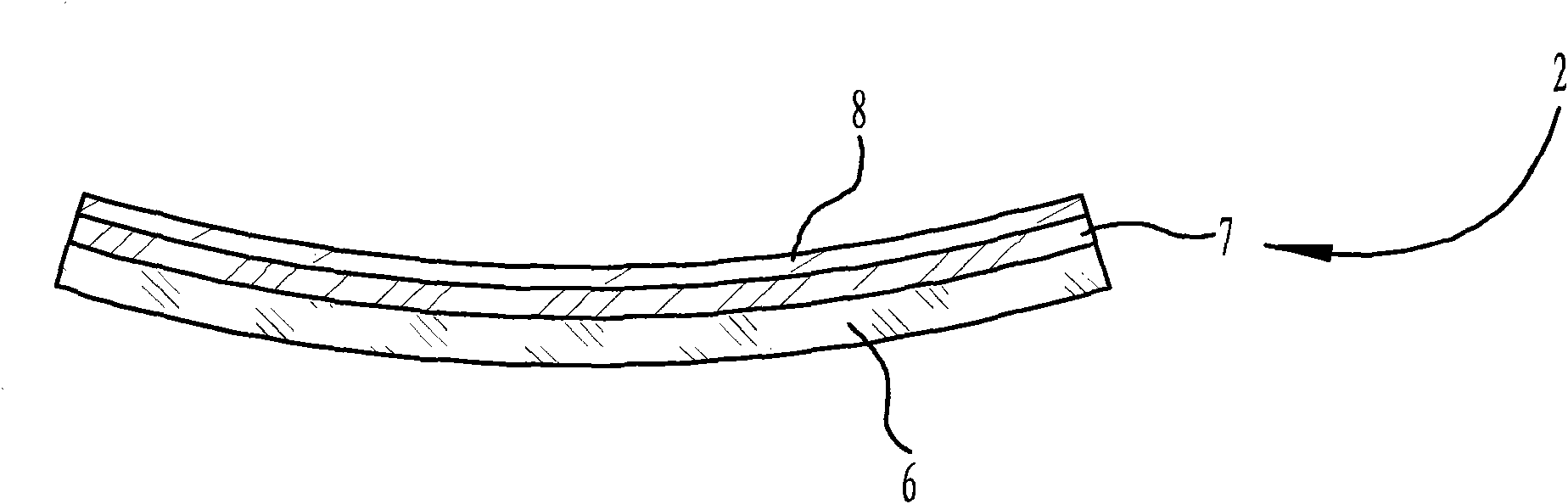

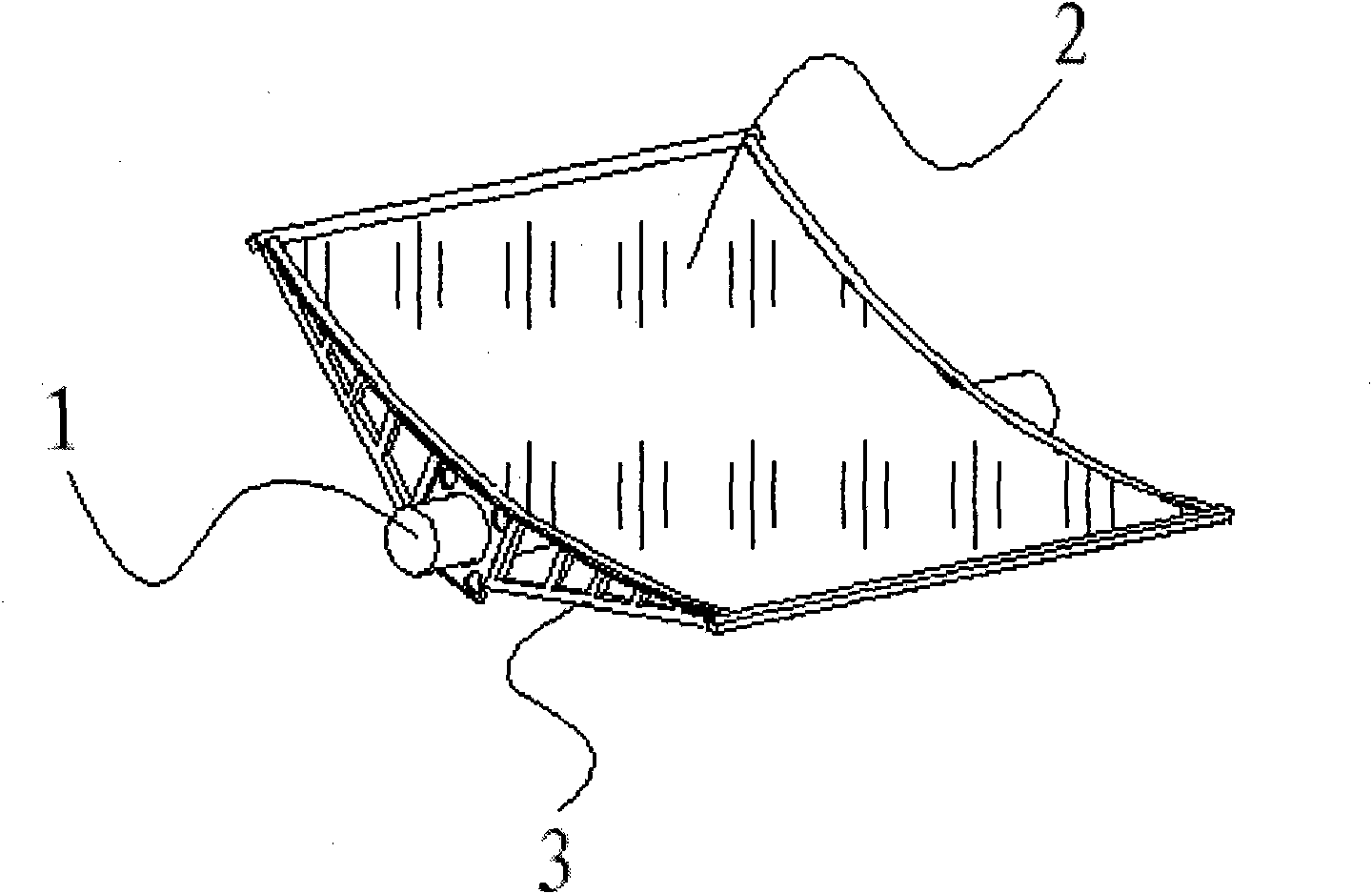

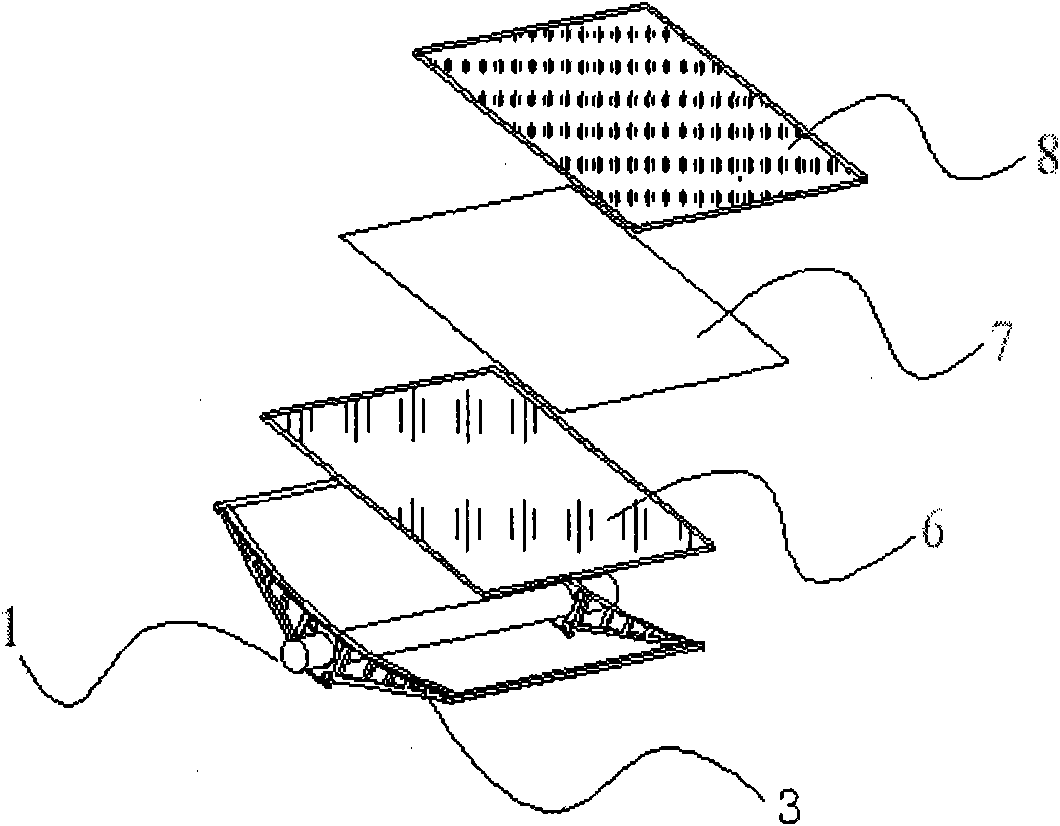

Curved mirror reflector and production method thereof

ActiveCN102759765AStable structureCombine tightly and evenlyMirrorsLayered productsOptoelectronicsFlat glass

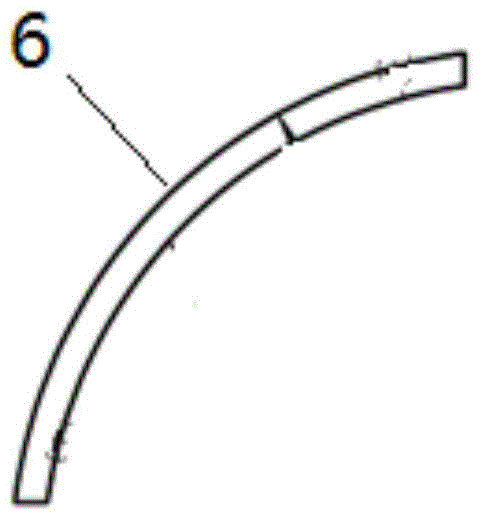

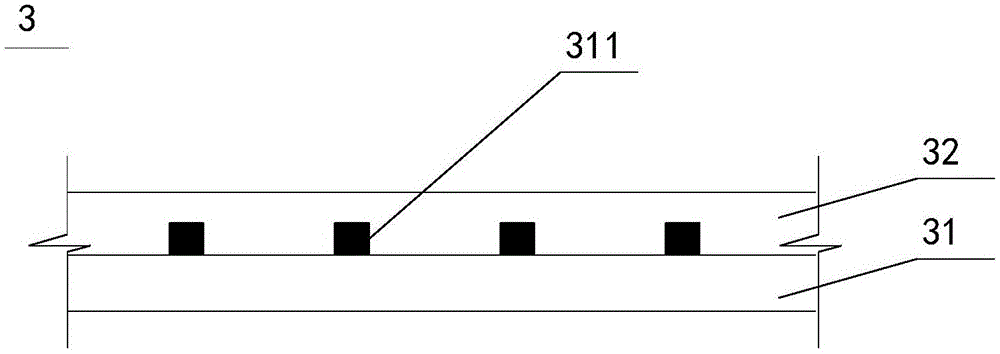

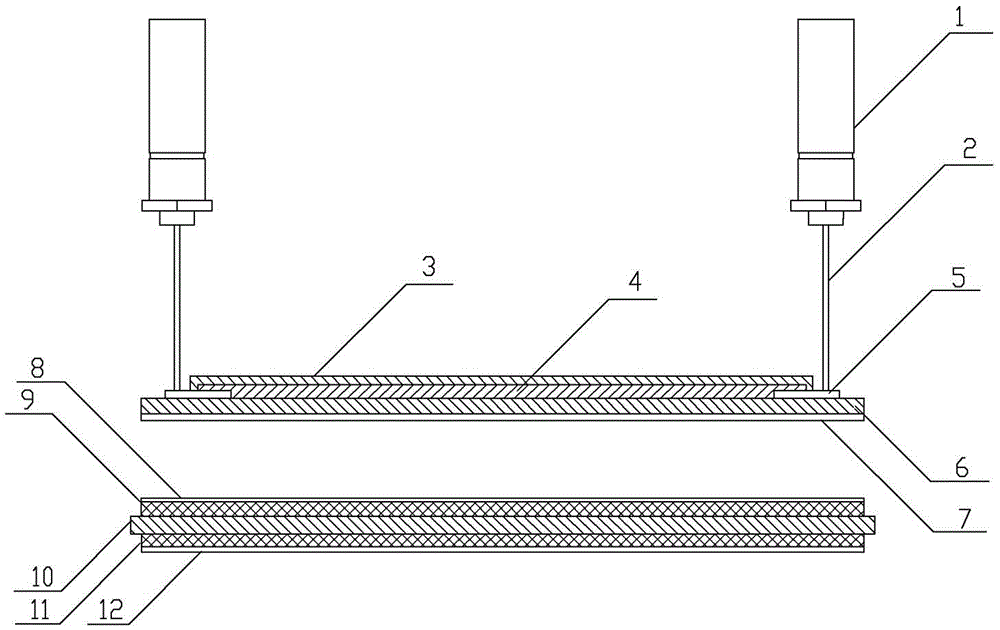

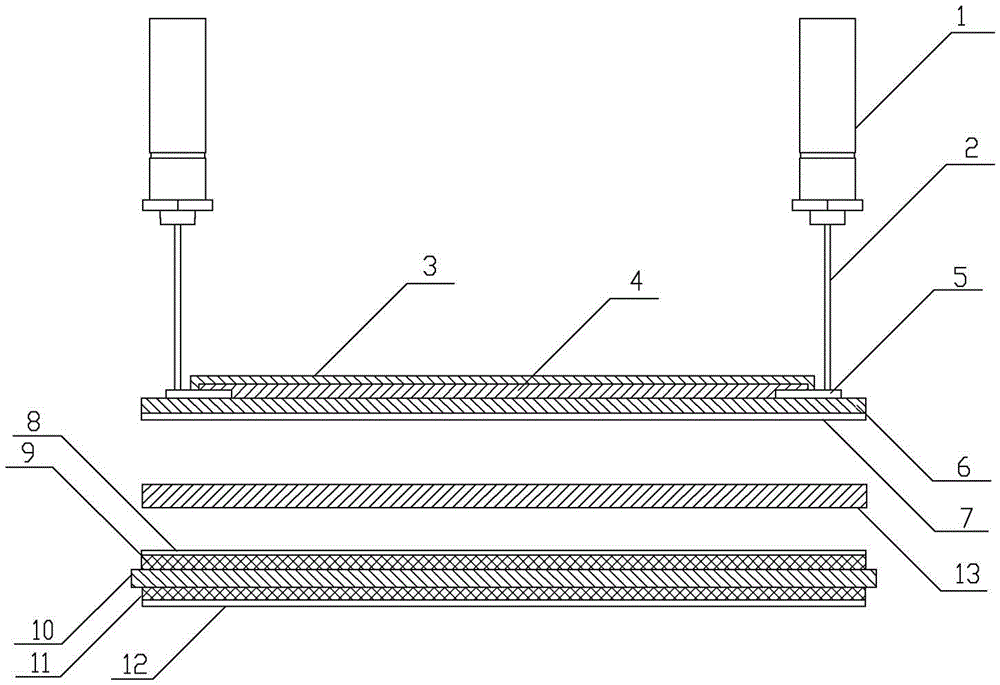

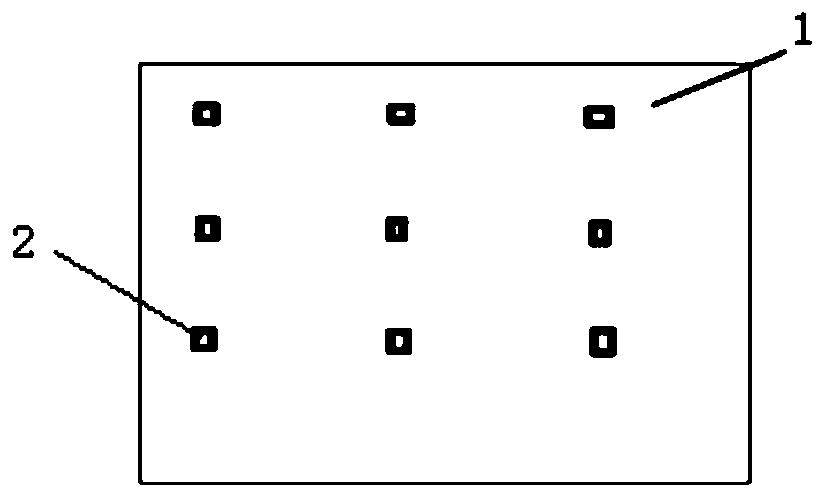

The invention provides a curved mirror reflector (2), which comprises a flat glass structure (6), a middle bonding layer (7) and a flat glass mirror (8), wherein the flat glass structure (6) and the flat glass mirror (8) are processed by non-edging and / or non-tempered common glass; the middle bonding layer (7) is located between the flat glass structure (6) and the flat glass mirror (8), and is bent and deformed under support of a mould through a mechanical manner, and the bent and deformed flat glass structure (6), the middle bonding layer (7) and the flat glass mirror (8) are solidified and bonded to a composite curved surface structure through a heating and / or normal-temperature solidification manner. The curved mirror reflector (2), provided by the invention, can be widely applied in all kinds of fields of solar thermal collection and focus and solar thermal power generation.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

Joining method of SiC ceramic through combining nano-impregnated transient co-crystal phase with chemical vapor infiltration as well as prepared ceramic connector

The invention belongs to the technical field of ceramic joining and discloses a joining method of SiC ceramic through combining a nano-impregnated transient co-crystal phase with chemical vapor infiltration as well as a prepared ceramic joining part. The method comprises the following steps: firstly, mixing SiC powder with Al2O3-Re2O3, adding a solvent and a ball milling medium for mixing and drying to obtain mixed powder; granulating the mixed powder and spreading the granulated powder between two pieces of polished SiC to form a sandwich structure; putting a sample with the sandwich structure into a heat treatment furnace, raising the temperature to 1000 to 1400 DEG C for heat treatment in a vacuum or protective atmosphere, adding organic carbon silane doped with filler and carrying outchemical vapor infiltration at 1300 to 1600 DEG C to obtain a joining part of the SiC ceramic. According to the joining method disclosed by the invention, low-temperature pressure-free joining of theSiC ceramic is realized by combining the nano-impregnated transient co-crystal phase with the chemical vapor infiltration and the leakage rate at the joint reaches 0 to 1*10<-10> Pa.L / s.

Owner:GUANGDONG UNIV OF TECH

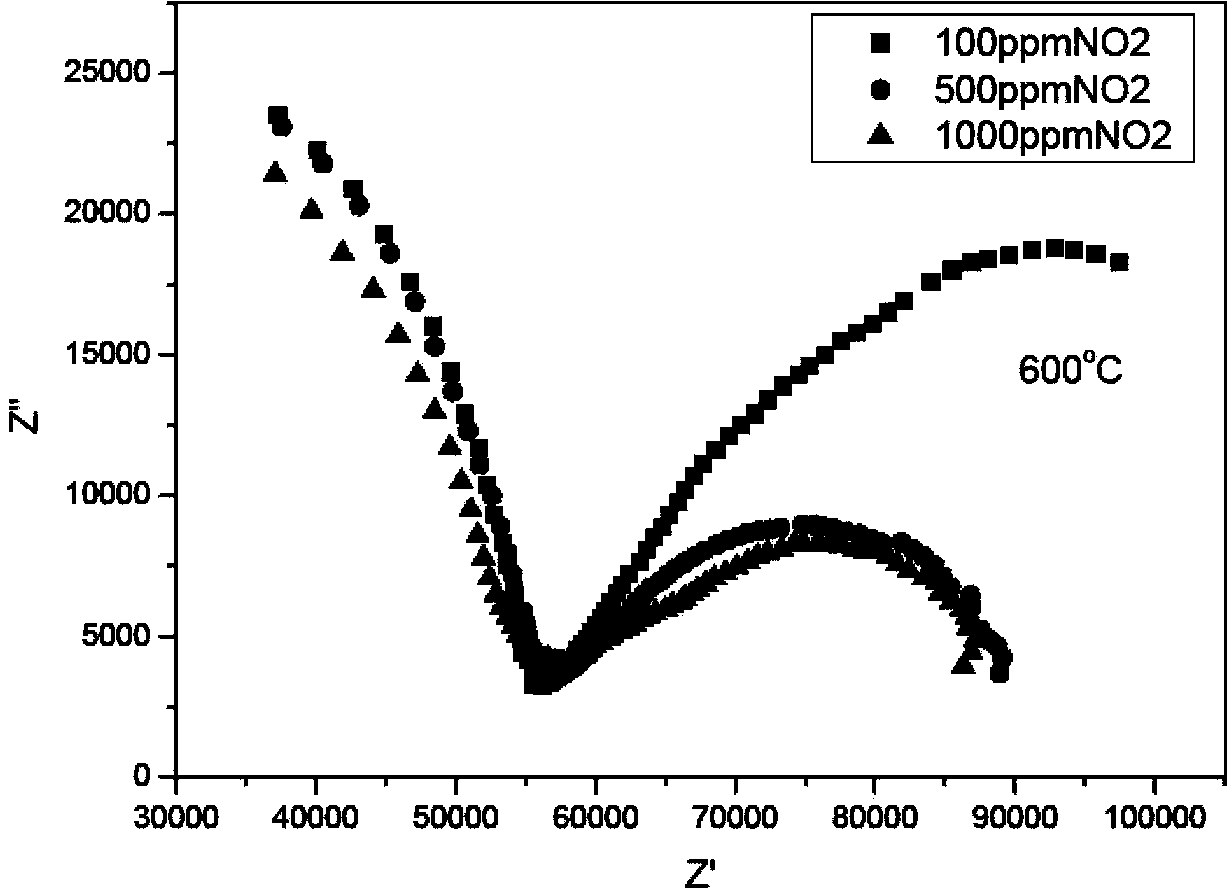

Zirconia-based NOx sensor and preparation method thereof

InactiveCN103884740AConsistent coefficient of thermal expansionGood heat matchingMaterial analysis by electric/magnetic meansWhole bodyResource saving

The invention provides a sensor for measuring the concentration of NOx through measuring the alternating current (AC) impedance, and a preparation method thereof. The preparation method comprises the following steps: adopting an alumina cast sheet forming technology to laminate and burn multiple layers of heating units into a whole body so as to form an authentic direct heating structure; covering the surface of the alumina heating body with a Pt wire and a sensitive body, wherein the sensitive body is arranged on an insulation layer and is composed of a Pt wire, a zirconia layer, and (LaSr<1-x>)MnO3(LSM) and the x is in a range of 1 to 0. When the zirconia-based NOx sensor is in a normal work state, the work voltage (VW) is 10 to 50 mV, and the heating voltage (VH) is 12 V. The detectable range of NOx concentration is 0 to 500 ppm, the response time is less than 2 seconds, and the sensor is suitable for detecting NOx with a low concentration. The sensor can detect NOx with a lower concentration, and has the advantages of simple preparation technology, reduction on production cost, and resource saving.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

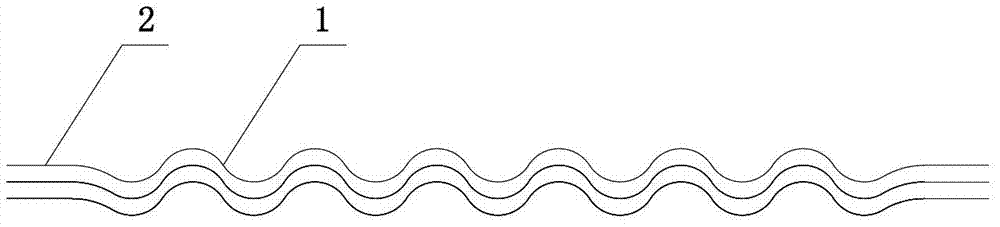

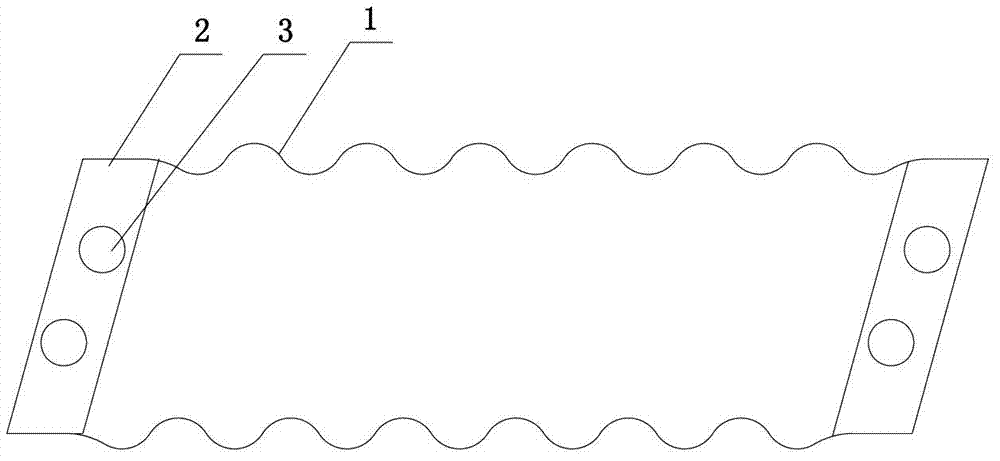

Structure and method for conductive connection between copper materials or between copper material and other components

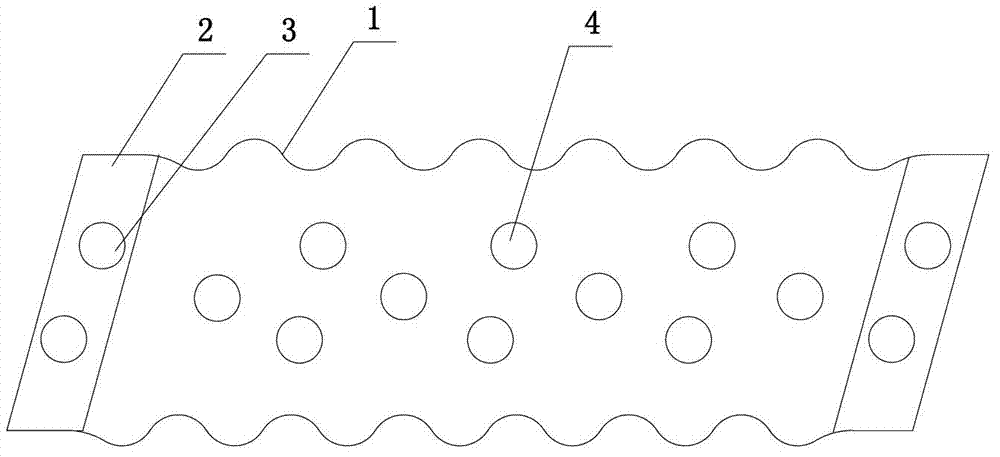

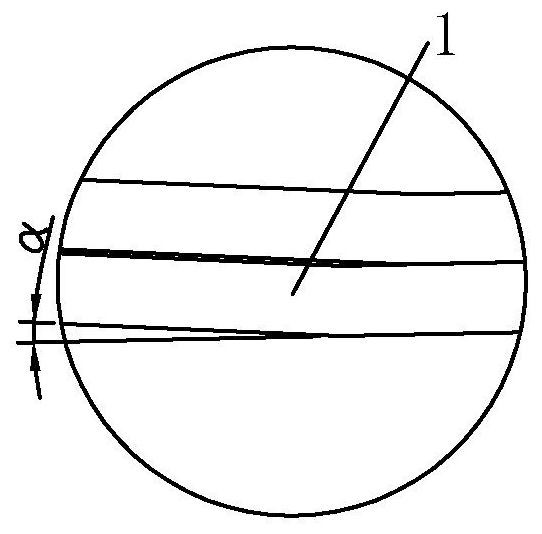

InactiveCN102738600AFully contactedClosely connectedLine/current collector detailsClamped/spring connectionsState of artWave shape

The invention relates to a connection technology between copper materials or between a copper material and other components, in particular to a structure and method for conductive connection between copper materials or between a copper material and other components. A multi-layer copper foil flexible connection structure is connected between the copper materials or between the copper material and other components, the copper foil flexible connection structure is a multi-layer structure formed by superposing wave-shaped or snake-shaped or unfolded spiral copper foil strips, the middle wave-shaped or snake-shaped or unfolded spiral copper foil strips are in a free layering state, and two ends of the wave-shaped or snake-shaped or unfolded spiral copper foil strips of the multi-layer structure are directly connected to the copper materials or other components. The structure and method for conductive connection disclosed by the invention solve the problems of unsatisfactory conductive performance, low reliability and the like of the prior art, the copper foil flexible connection which has a simple structure and high reliability and is convenient to maintain is adopted, and the conductive connection structure not only has a good conductive performance, but also has good heat compensation ability and a vibration isolation effect.

Owner:江西九星铜业有限公司

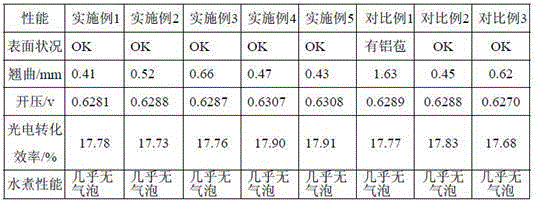

Crystal silicon solar cell aluminum paste with high conductivity

InactiveCN105225722AGood compatibilityConsistent coefficient of thermal expansionNon-conductive material with dispersed conductive materialSemiconductor devicesSilicon solar cellMaterials science

The invention discloses crystal silicon solar cell aluminum paste with high conductivity. The crystal silicon solar cell aluminum paste comprises the following formula components in percentage by weight: 65%-78% of aluminum powder, 1%-5% of lead-free glass powder, 15%-30% of an inorganic carrier, 0.5%-3% of a warp-resistant additive and 0.1%-3% of an assistant, wherein the oxygen content of the aluminum powder is less than 0.4% in percentage by weight. After the solar cell aluminum paste prepared from the formula components is subjected to silk-screen printing and high-temperature sintering, the open-circuit voltage can be improved; and the photoelectric conversion efficiency of a cell slice is improved. Meanwhile, the solar cell slice is good in appearance; and an aluminum film is smooth, does not generate an alumina bead or an aluminum bract, is small in warping degree and good in boiling resistance, and completely conforms to the requirements on the crystal silicon solar cell aluminum paste on the market.

Owner:JIANGSU HOYI TECH

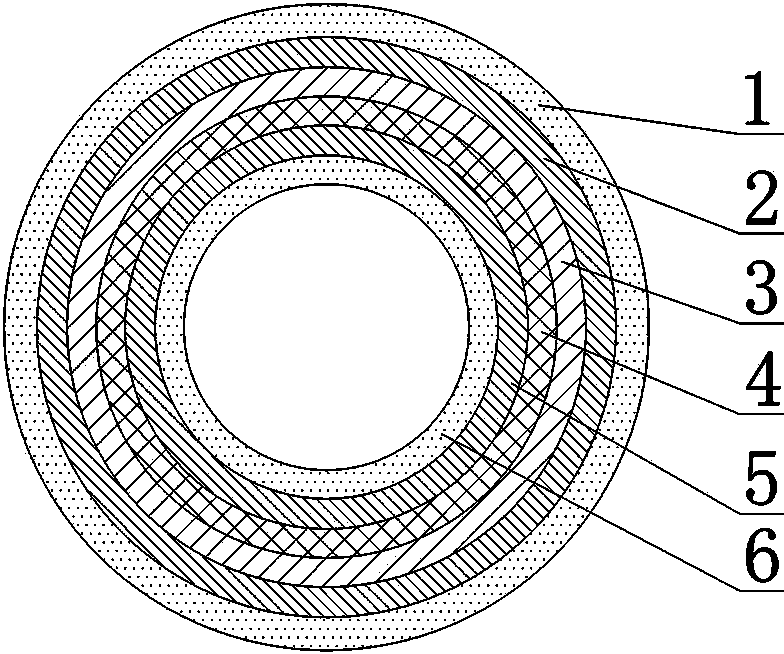

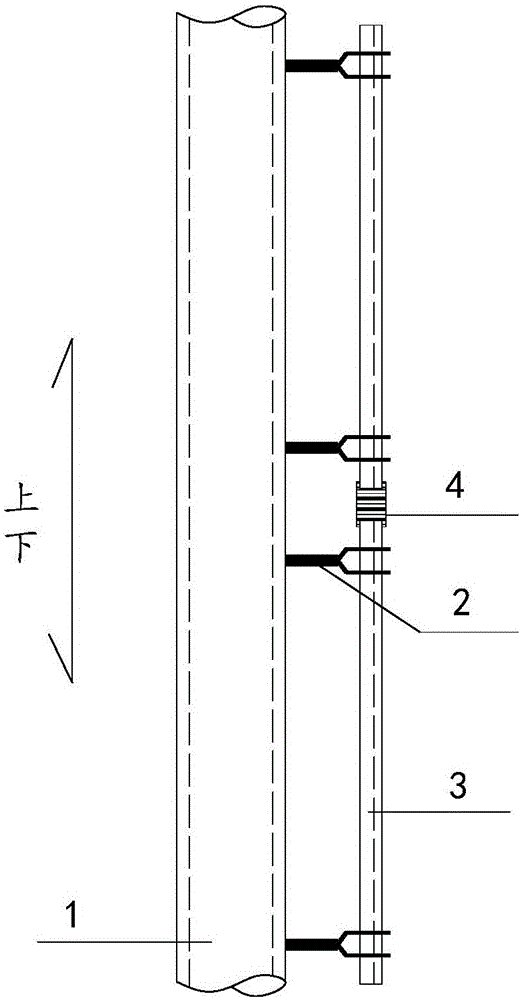

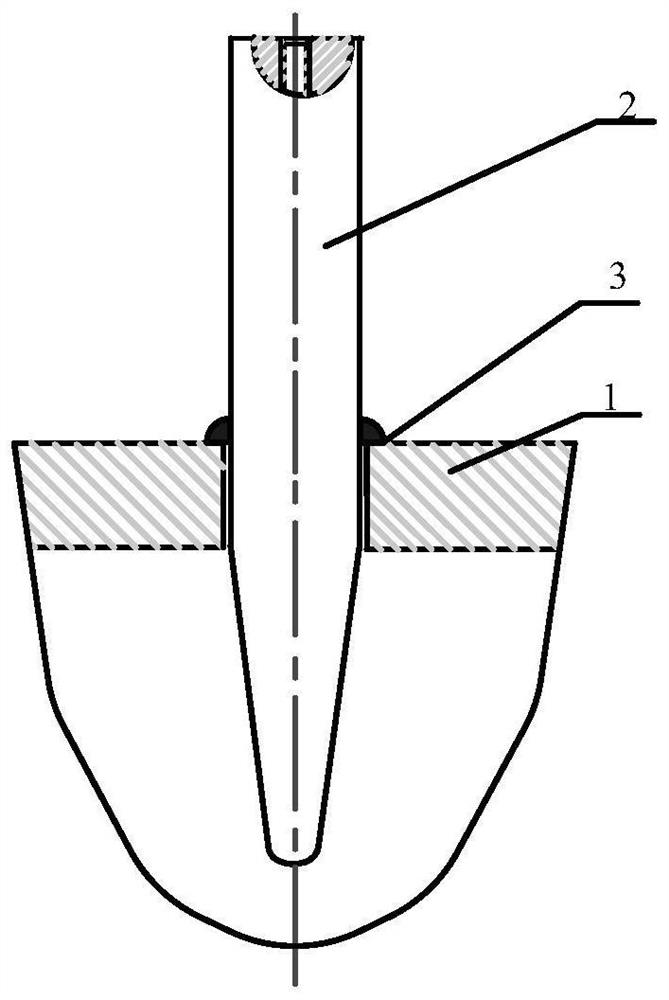

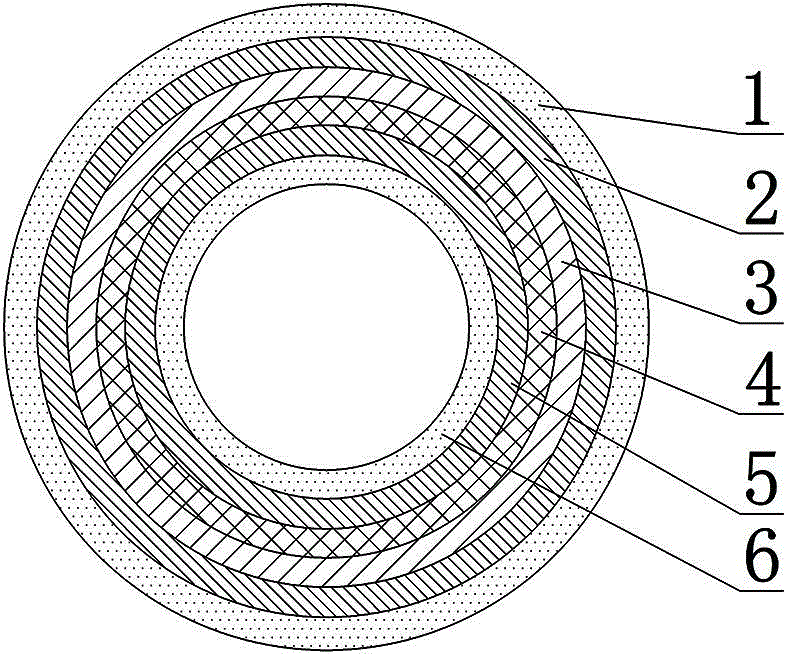

Heat preservation and intelligent anticorrosion oil pipe for high sulfur natural gas well

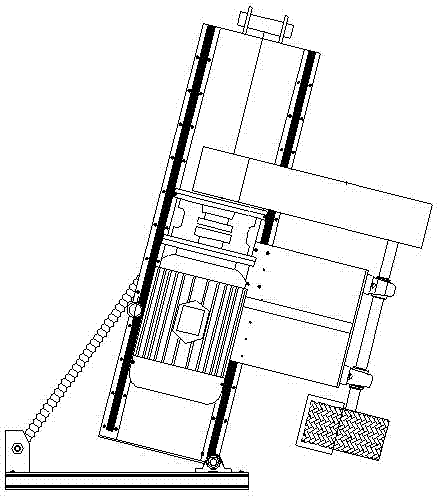

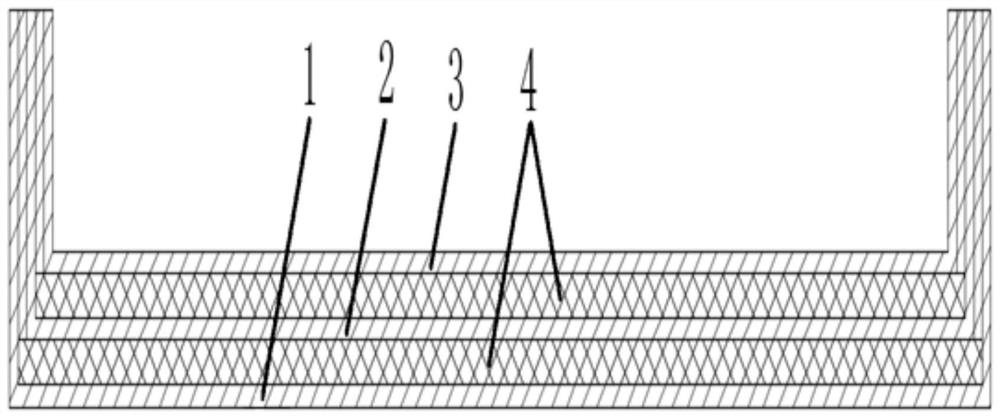

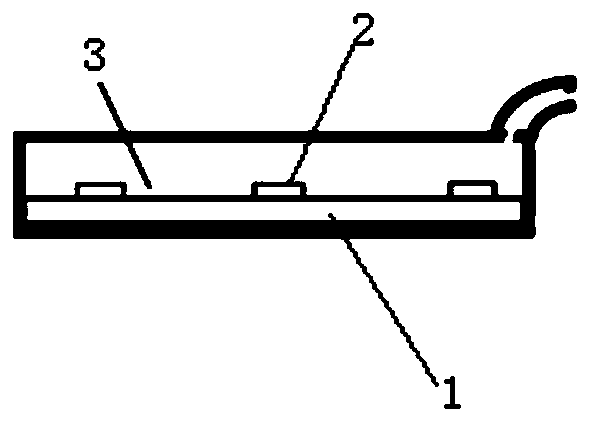

ActiveCN103821460AAnti-stressWith insulationDrilling rodsSynthetic resin layered productsThermal dilatationEngineering

The invention discloses a heat preservation and intelligent anticorrosion oil pipe for a high sulfur natural gas well. The heat preservation and intelligent anticorrosion oil pipe is composed of six layers which are an inner anticorrosion anti-drag layer (6), an inner intelligent anticorrosion layer (5), a heat preservation layer (4), a supporting layer (3), an outer intelligent anticorrosion layer (2) and an outer anticorrosion anti-drag layer (1) in sequence; the inner intelligent anticorrosion layer (5) is wrapped outside the inner anticorrosion anti-drag layer (6); the heat preservation layer (4) is wrapped outside the inner intelligent anticorrosion layer (5); the supporting layer (3) is wrapped outside the heat preservation layer (4); the outer intelligent anticorrosion layer (2) is wrapped outside the supporting layer (3); the outer anticorrosion anti-drag layer (1) is wrapped outside the outer intelligent anticorrosion layer (2). The heat preservation and intelligent anticorrosion oil pipe has the beneficial effects that the oil pipe has excellent thermal stability and non-corrosibility; each functional layer has the capacities of compression resistance, heat preservation, intelligent anticorrosion, drag reduction and attaching prevention respectively; the coefficients of thermal expansion of the functional layers are the same; the problem that heat preservation and anticorrosion materials for conventional heat preservation and anticorrosion tubular products are easy to fall off is solved.

Owner:SOUTHWEST PETROLEUM UNIV

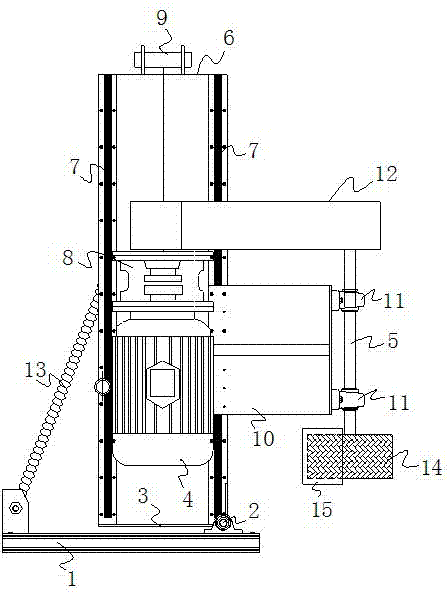

Repairing process and repairing tool for excircle crack conquassation of tires and carrier rollers of rotary kiln

The invention relates to a repairing process and a repairing tool for excircle crack conquassation of tires and carrier rollers of a rotary kiln. According to the invention, a flux-cored wire, of which the tensile strength is 585, is used for padding and isolating; padding, isolating and cladding are conducted twice on a circle of a plano-concave groove, wherein the current is 190, the voltage is 22, and the welding seam is required to be 10 mm higher than the upper part of a groove base metal; then a solid core wire, of which the yield strength is 580, is used for replacing the flux-cored wire to caulk and restore the size, wherein the integral appearance of a concave welding bead is required to be kept during the build-up welding process; segmental welding is adopted on the basis to restore the size; finally, a temper bead is additionally capped; when the size is restored through build-up welding, the internal stress can be lowered to the minimum value, and build-up welding is fulfilled; and on-site heat treatment is carried out immediately. Therefore, the repairing process and the repairing tool have the advantages that the integration of welding material and base metal can be better; the distribution of metallographic structures and hardness is uniform; impact of vertical welding is avoided; the construction is fast; the welding strength is high; the ductility and the toughness are good; wear-resistant, corrosion-resistant, heat-proof, shock-proof and crack-resistant capabilities are excellent; stop time in cement enterprises is reduced; and the production efficiency is improved.

Owner:水文文

Method for joining nano-impregnated transient eutectic phase with SiC ceramic as well as ceramic prepared by method and application

ActiveCN109437910AAchieve connectionNo void defectOptical rangefindersNuclear energy generationMetallurgySolvent

The invention belongs to the technical field of ceramic joining and discloses a method for joining a nano-impregnated transient eutectic phase with SiC ceramic. The method comprises the following steps: taking mixed powder A of SiC powder and Al2O3-MxOy as a joining material, wherein MxOy is Ho2O3 or CeO2; adding a solvent and a ball milling medium into the mixed powder A for mixing and drying, then spreading powder obtained by granulating obtained mixed powder B between two pieces of polished SiC to form a sandwich structure; then carrying out isostatic cool pressing treatment, and pressurizing to 0.01 to 0.1MPa in a vacuum or atmosphere protection; raising the temperature to 600 to 1000 DEG C and insulating I; raising the temperature again to 1450 to 1600 DEG C and insulating II at the pressure of 200 to 500 MPa, and joining to obtain the nano-impregnated transient eutectic phase joined SiC ceramic. The method disclosed by the invention realizes low-temperature and low-pressure joining of the SiC ceramic, and the leak rate of the joining part reaches 0 to 1*10<-8> Pa.L / s.

Owner:GUANGDONG UNIV OF TECH

Method for growing crystal optical fiber core in crystal cladding layer

ActiveCN108456926AConsistent coefficient of thermal expansionAvoid heat stressPolycrystalline material growthBy pulling from meltHigher PowerCapillary action

The invention relates to a method for growing a crystal optical fiber core in a crystal cladding layer. The method comprises the following steps: (1) obtaining a microporous crystal with a length of 40 to 160 mm by adopting a microporous crystal growing method, wherein the inner diameter of the microporous crystal is less than or equal to 1 mm, or obtaining the microporous crystal provided with micropores by perforating the center of a crystal rod with a machining method; (2) mounting the microporous crystal obtained in the step (1) on a micro pull-down furnace seed rod; (3) putting 1 to 2 g of a raw material into a crucible; (4) heating and melting the raw material in the crucible; (5) lifting up the seed rod to enable the microporous crystal to be in contact with a small hole in the bottom of the crucible, and allowing a melt in the crucible to enter the holes of the microporous crystal under the action of the gravity and the capillary action; (6) controlling the temperature of a post-heater to be reduced to room temperature at a cooling rate of 100 to 300 DEG C / h, so as to complete the whole crystal growing process. Compared with the prior art, the method has the advantages thata crystal core and the crystal cladding layer are seamlessly connected to obtain uniform refractive index distribution, so that a high-power crystal optical fiber laser device can be obtained.

Owner:TONGJI UNIV

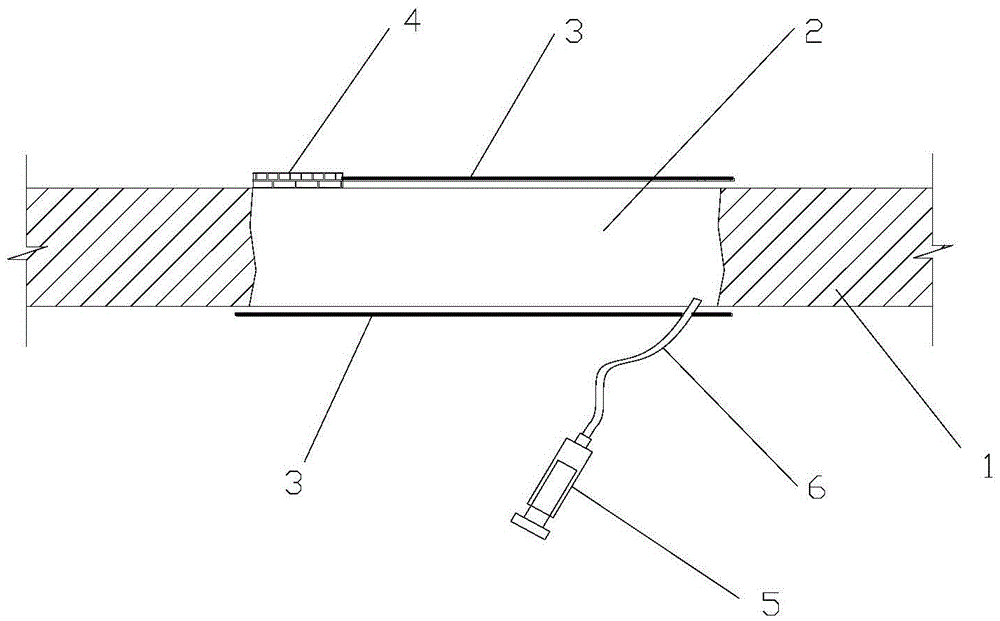

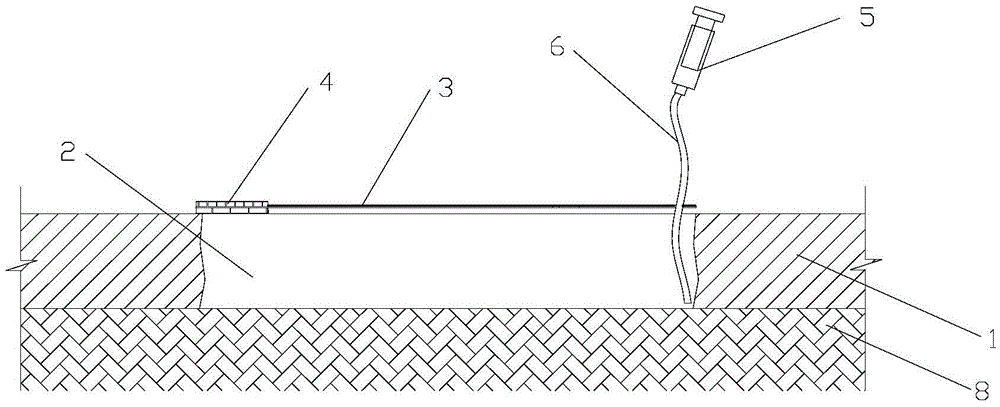

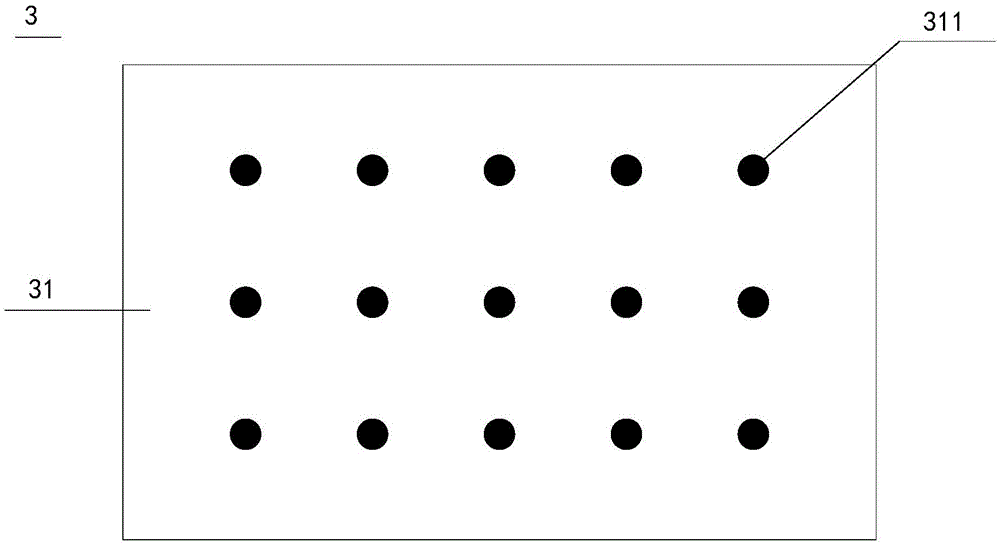

Microbial deposition of calcium carbonate to plug cracks in cast-in-place concrete slabs or bottom slabs

ActiveCN104196131BConsistent coefficient of thermal expansionImprove permeabilityBuilding constructionsFloor slabRebar

The invention discloses a method for plugging a cast-in-situ concrete slab or base-plate crack with microbe-sedimented calcium carbonate. The method includes preparation of plugging materials, plugging of the cast-in-situ concrete slab crack and plugging of the cast-in-situ base-plate crack. A method for preparation of the plugging materials includes preparation of calcium source solutions, preparation of nutrient salt solutions and preparation of microbial solutions; a method for plugging of the cast-in-situ concrete slab crack includes that the pressure grouting mode is adopted on base of the crack, the top surface and bottom surface of the plugged crack are sealed with rubber tapes, and water solutions are ensured to flow out with bacteria filtered within the crack; a rubber hose is inserted in the bottom of the other end of the crack, and an injector is connected with the rubber tube; the injector is utilized to inject the microbial solutions, the nutrient salt solutions and the calcium source solutions with the volume ratio of 1:1:1, and fluid is ensured to seep from the position of a gauze; grouting work is repeated once every 24 hours for 5 days; the gauge, the rubber tube, the injector and the sealing rubber tapes are removed. By the method, problems of durability of rusting and the like caused by exposure of steel bars inside plates can be effectively solved.

Owner:SHANDONG JIANZHU UNIV

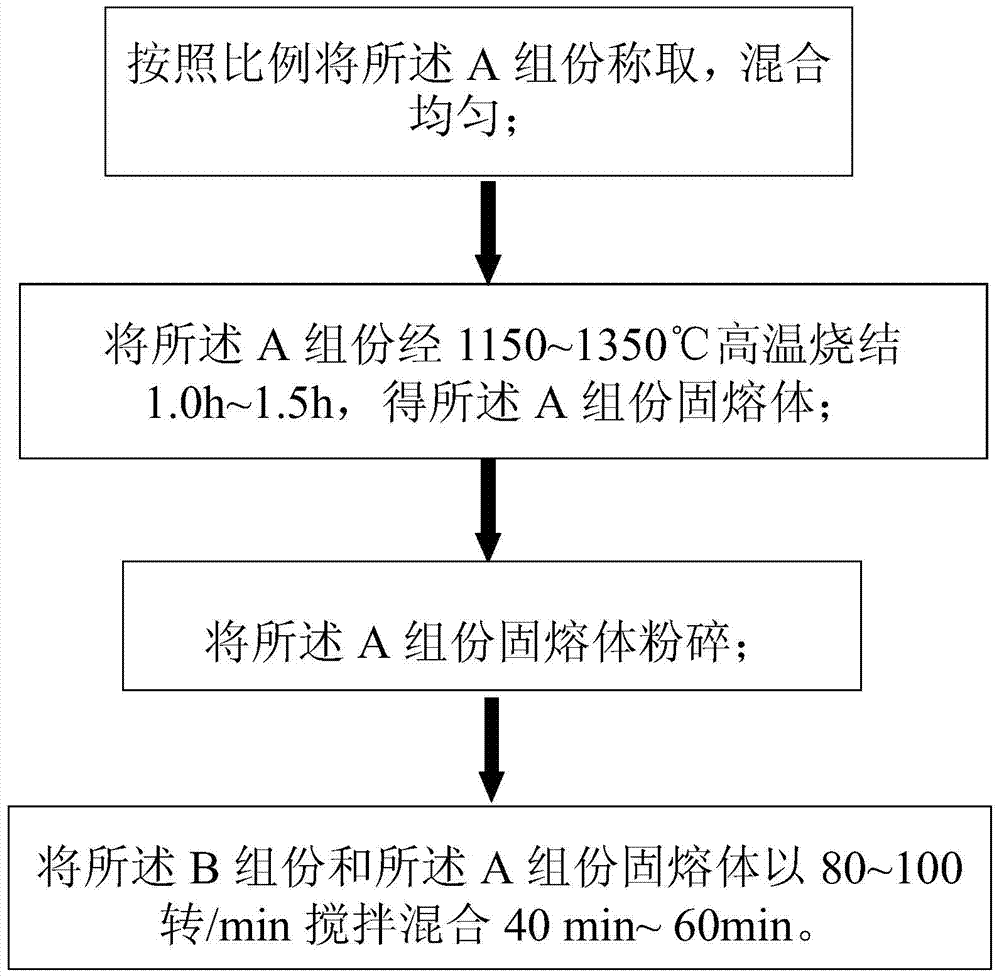

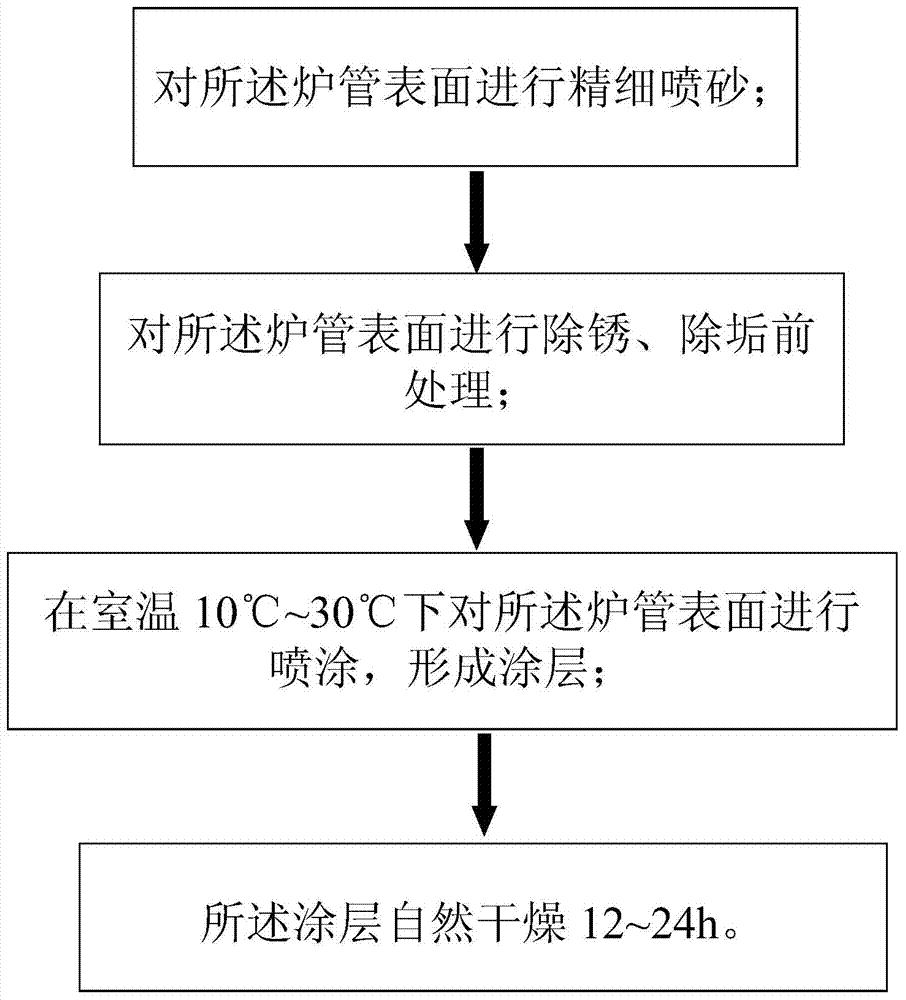

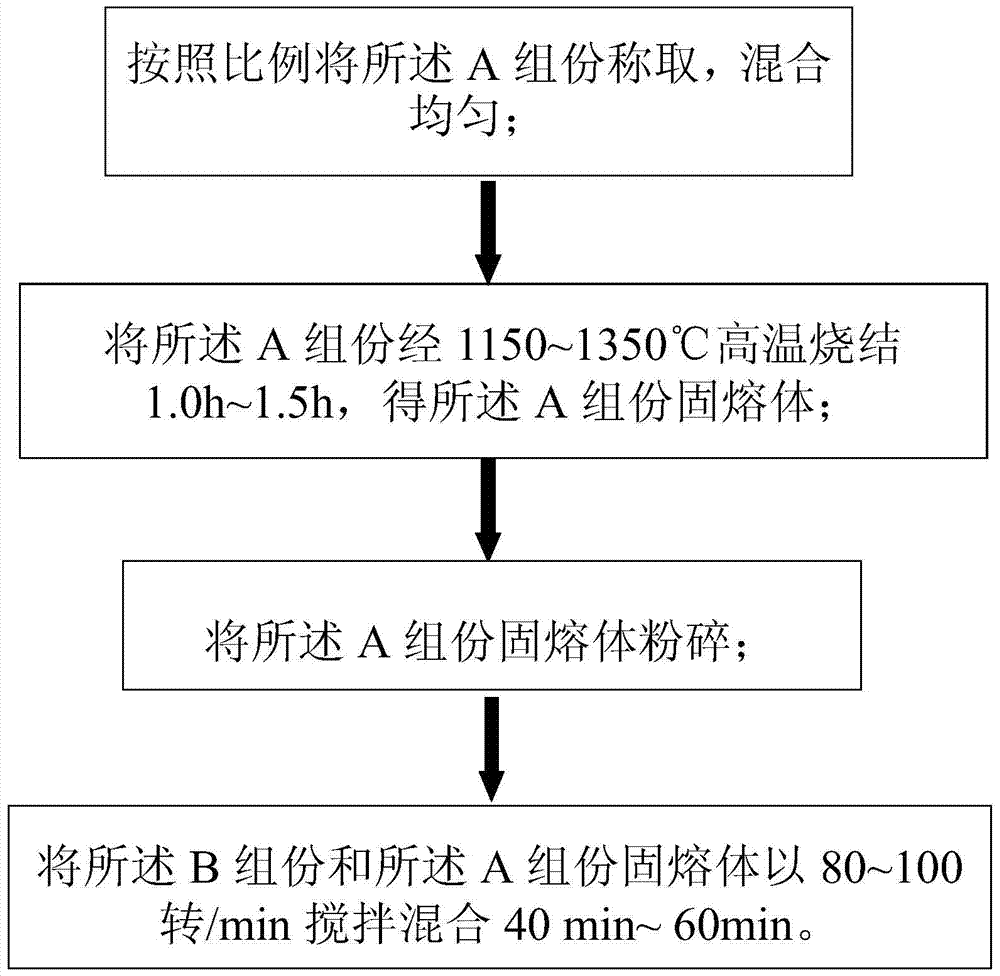

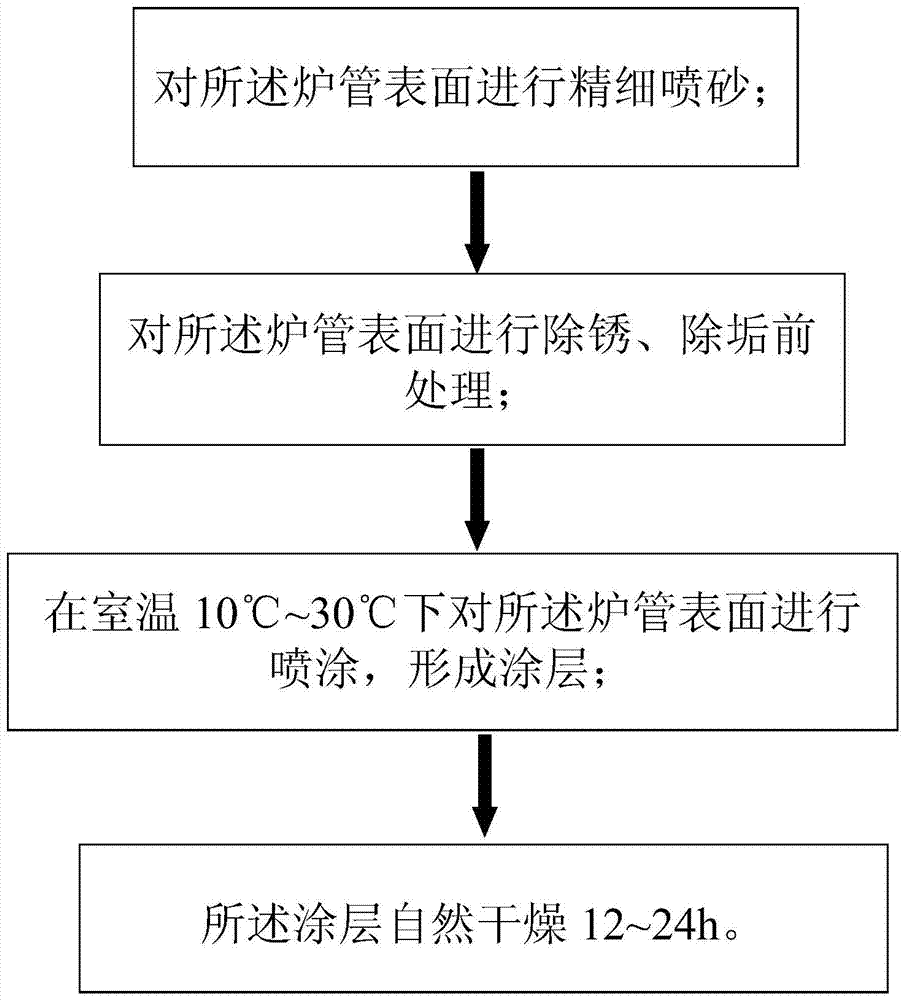

High radiant ceramic coating for heating furnace tube as well as preparation method and using method thereof

InactiveCN104744973AHigh temperature oxidation resistanceCorrosion resistantChemical industryPretreated surfacesRadiative transferCeramic coating

The invention discloses a high radiant ceramic coating for a heating furnace tube as well as a preparation method and a using method thereof. The high radiant ceramic coating for the heating furnace tube comprises a component A and a component B, wherein the component A is a metallic oxide mixture which is 30-35% of the total amount and the component B is a temperature resistant bonder which is 65-70% of the total amount. The high radiant ceramic coating provided by the invention has the functions of anti-high temperature oxidation and anticorrosion, prolongs the service life of the furnace tube, increases the heat transfer on the surface of the furnace tube, increases the heat exchange efficiency, reduces the fuel consumption of the heating furnace and reaches the energy saving purpose; under the condition of not changing the device structure, the high radiant ceramic coating reinforces the radiative transfer, is few in investment, rapid in effect, simple in construction and good for industrial popularization.

Owner:马麟

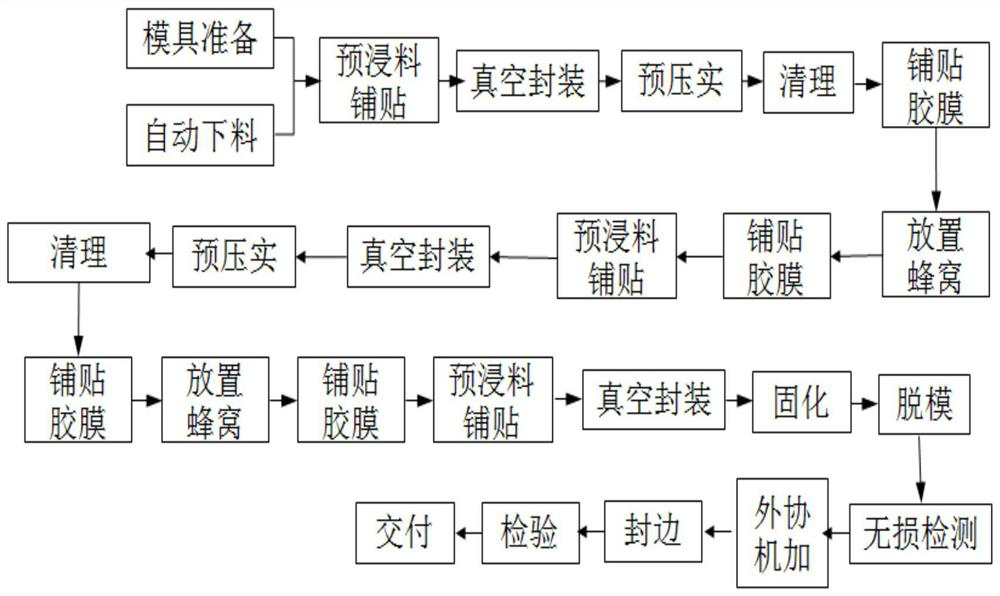

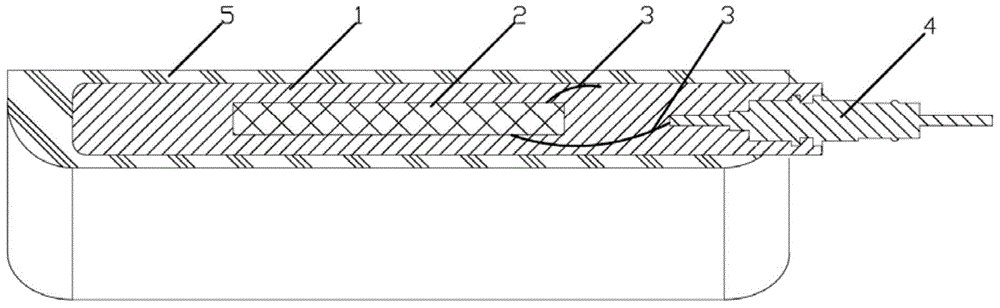

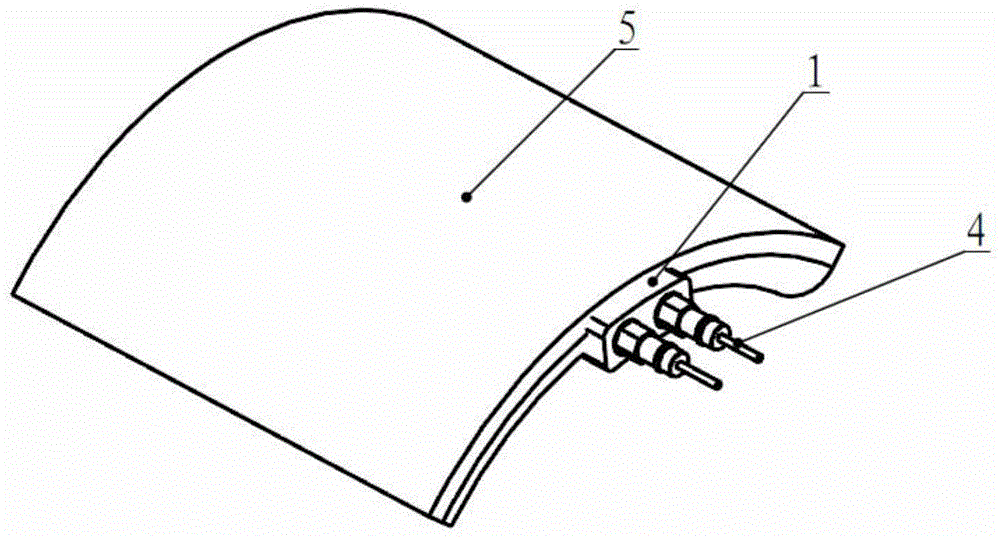

Method for integrally forming C sandwich panel antenna housing

The invention discloses a method for integrally forming C sandwich panel antenna housing. The method comprises the following steps: (1), preparing prepregs; (2), carrying out die pretreatment; (3), laying and pasting an outer skin; (4), laying and pasting honeycombs and a middle skin; (5), laying and pasting honeycombs and an inner skin; (6), curing; (7), demolding; and (8), machining and formingholes. According to the method for integrally forming the C sandwich panel antenna housing is simple; mixed materials with glass fibers or quartz fibers and epoxy resin or cyanic acid resin or bismaleimide resin are used as prepregs; aramid paper honeycombs and same-system adhesive films are used as main raw materials; a pre-compaction step is added after the skins are laid and pasted; bubbles among the prepregs are completely eliminated; meanwhile, resin fusion is more sufficient; curing is carried out after three layers of skins and two layers of honeycombs are laid and pasted; the thermal expansion coefficients of the prepregs are consistent; the stress in the curing process is small; the planeness of the panel antenna housing can be guaranteed; the method has few operation steps; the usage of autoclaves can be reduced; the energy consumption is reduced; and the production cost is reduced.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

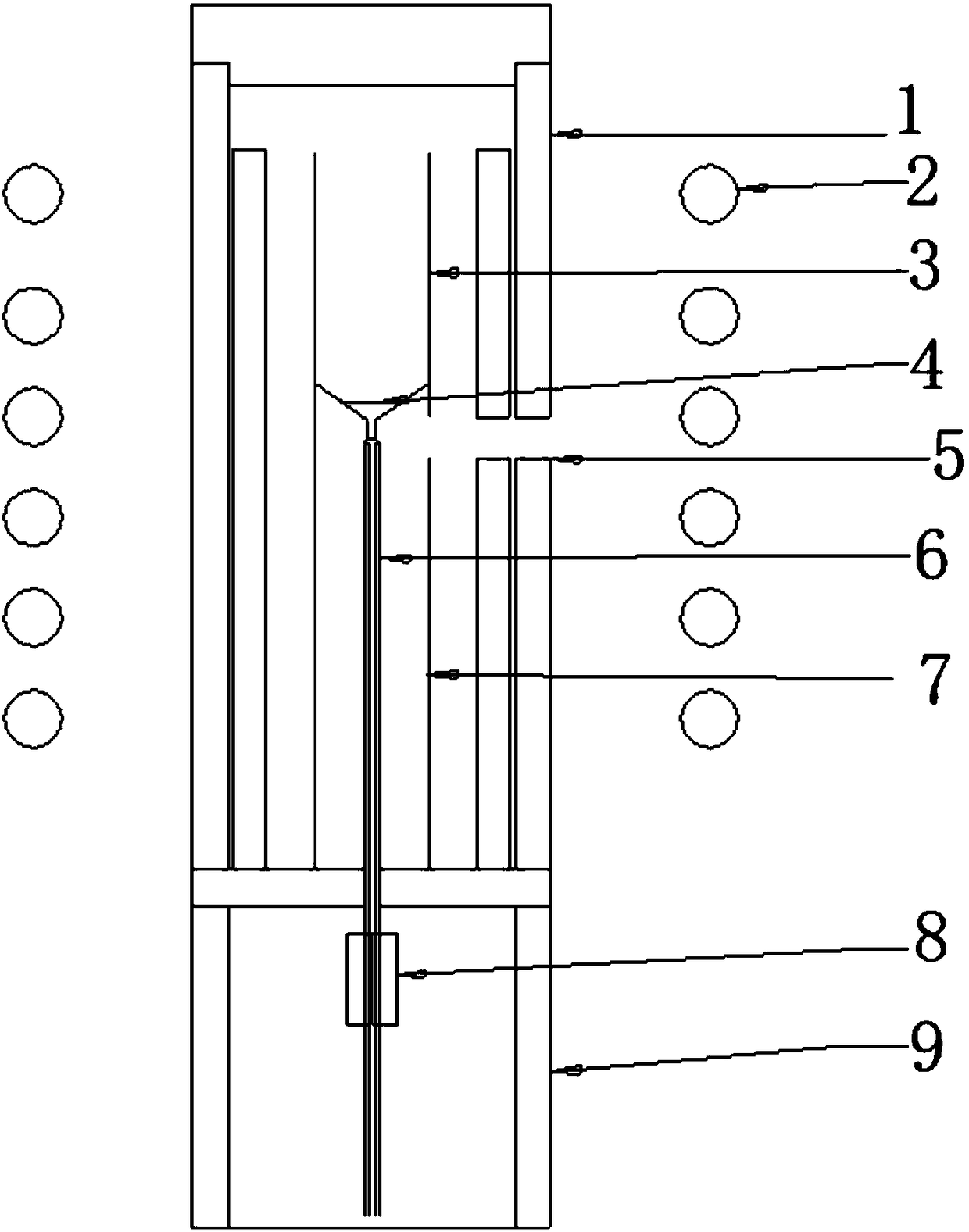

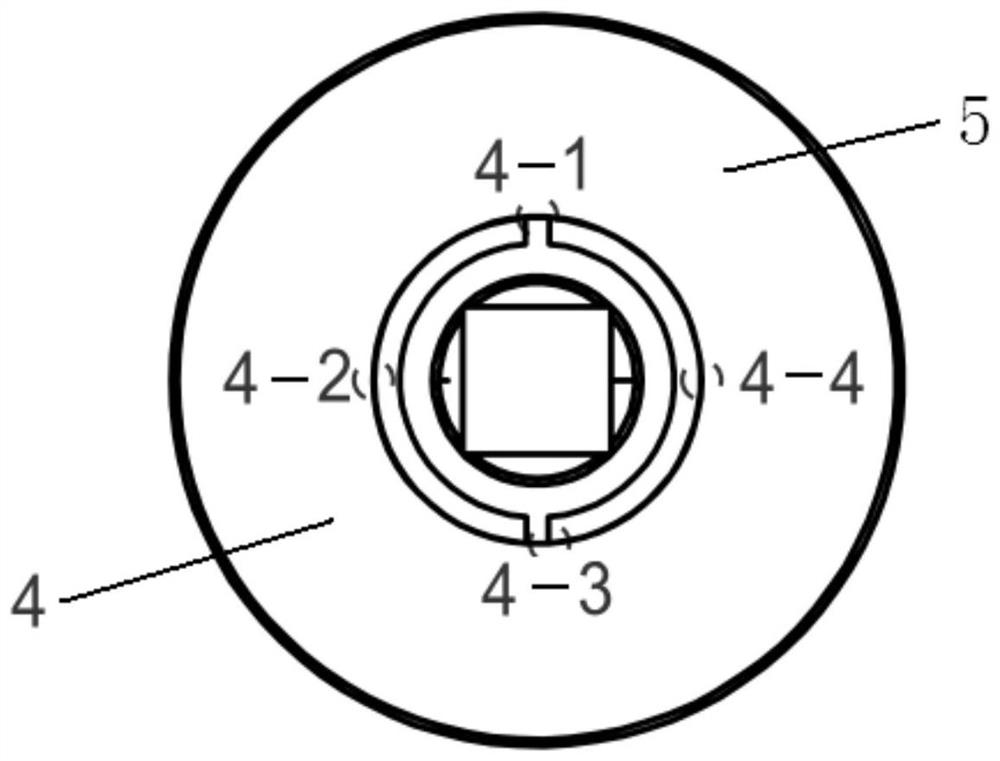

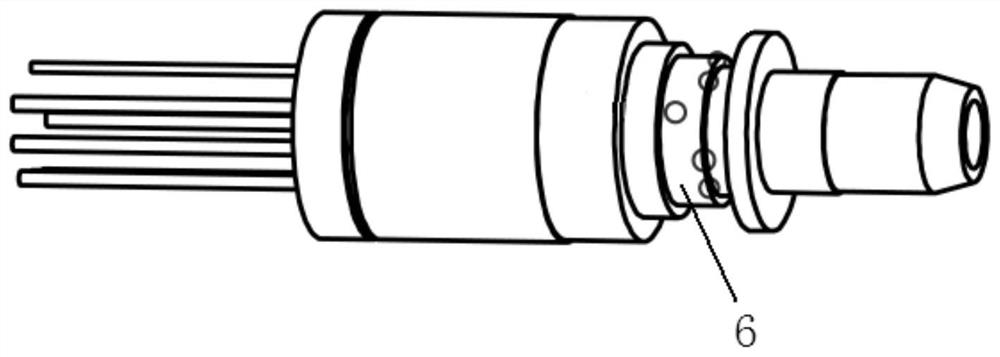

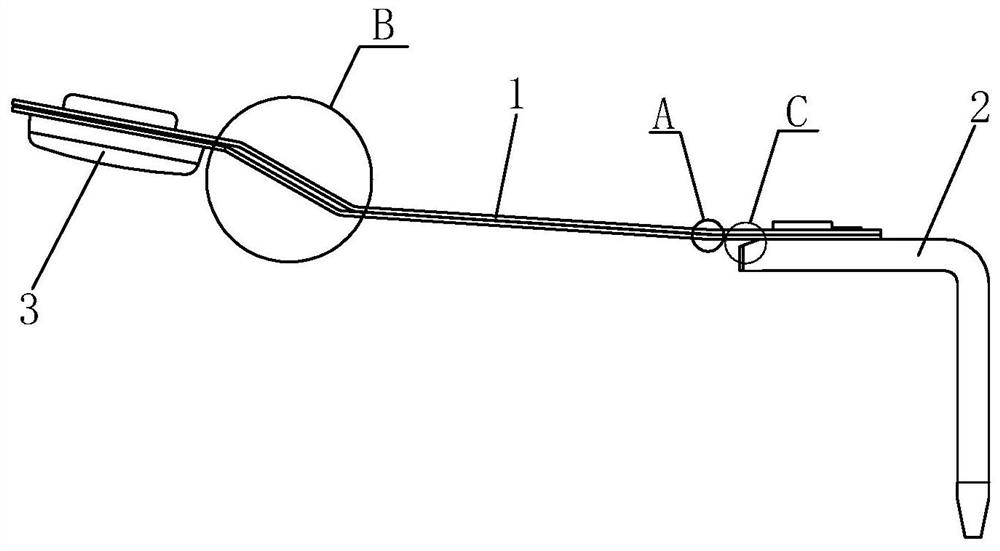

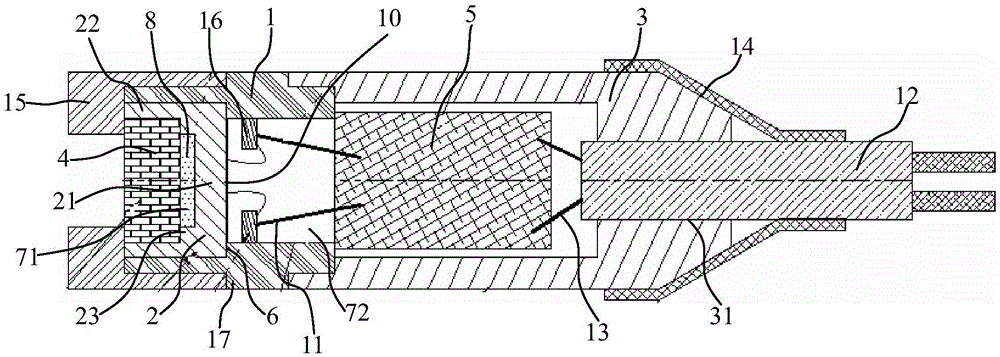

Packaging method for while-drilling acoustic wave transducer

Provided is a packaging method for a while-drilling acoustic wave transducer. The while-drilling acoustic wave transducer comprises a rubber layer, an outer shell, a piezoelectric ceramic crystal and an electric connector, wherein the piezoelectric ceramic crystal and the electric connector are packaged in the outer shell. The packaging method comprises the following steps that (1), an electrode of the piezoelectric ceramic crystal and the electric connector are connected with each other through a lead and placed in a mold; (2), packaging materials are prepared, and the packaging materials are identical with the piezoelectric ceramic crystal in thermal expansion coefficient; (3), the mold is filled with the packaging materials which are heated to the melting point, the outer shell is formed after the packaging materials are cooled and solidified, and the packaging materials, the piezoelectric ceramic crystal and the electric connector are made to be packaged into a whole; and (4), the rubber layer is laid on the outer side of the outer shell. By means of the packaging method, it is guaranteed that the piezoelectric ceramic crystal in the transducer cannot be damaged in the packaging process, the rubber layer is laid on the outer side of the outer shell of the while-drilling acoustic wave transducer so as to resist vibration, and installation of the transducer is facilitated.

Owner:CHINA NAT OFFSHORE OIL CORP +1

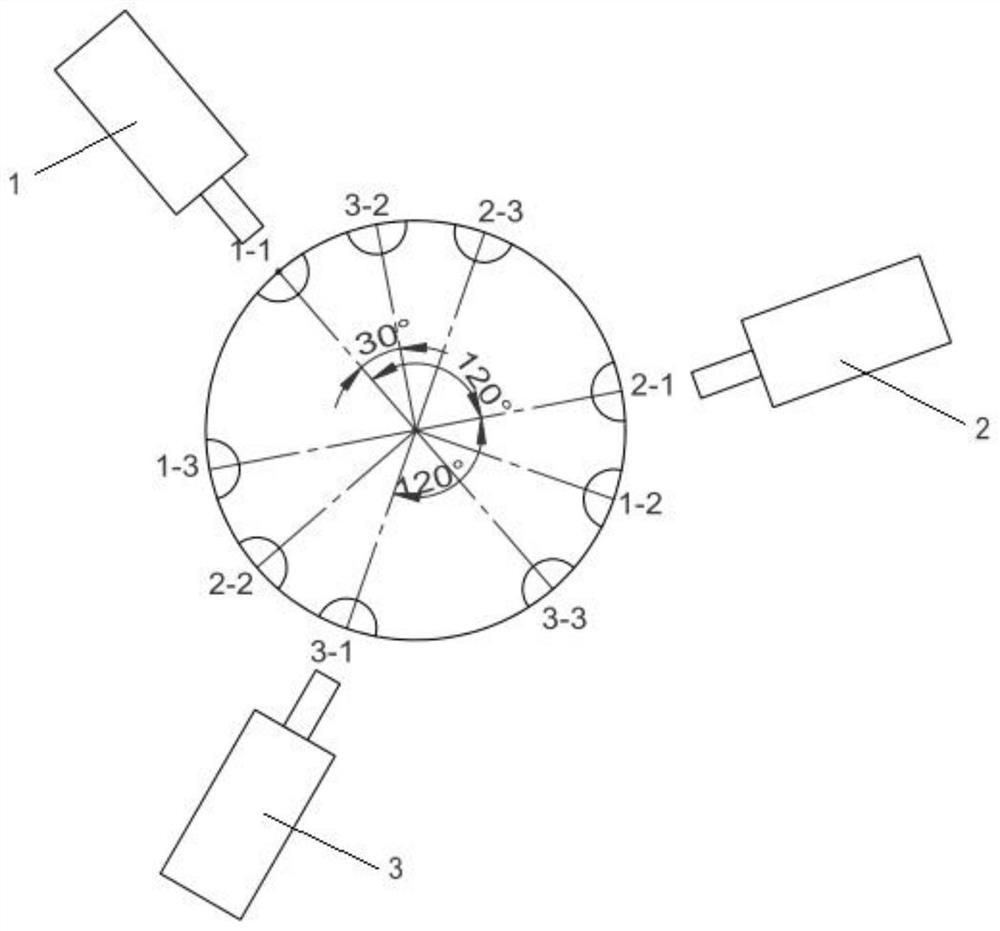

Mounting and welding method for controlling tracking errors of coaxial optical devices

ActiveCN111805082AImprove performanceSuitable for mass productionLaser beam welding apparatusEngineeringOptical communication

The invention relates to the field of optical communication, in particular to a mounting and welding method for controlling tracking errors of coaxial optical devices. The mounting and welding methodfor controlling the tracking errors of the coaxial optical devices comprises the following steps of (1), mounting the optical devices; (2), mounting an isolator; (3), welding a pipe body; and (4), welding a plug pin. On the premise of ensuring correct mounting operation, a laser coupling welding process of the pipe body and the plug pin is adjusted, spot welding is adopted, each group of three welding spots are respectively welded by three welding guns, energy is uniformly distributed, stress pulling is consistent so that light path deviation cannot be caused, the welding spots welded by the plug pin are distributed in a plum blossom shape, welding symmetry can be increased, and sufficient stress release is guaranteed, so that performance of the devices is greatly improved, the power variation range along with the external environment temperature is reduced, the high-low temperature power errors of the coaxial devices are better controlled within the standard range, the rejection rateis reduced, the cost is low, and thus the mounting and welding method is suitable for batch production of coaxial products.

Owner:DALIAN CANGLONG OPTOELECTRONICS TECH

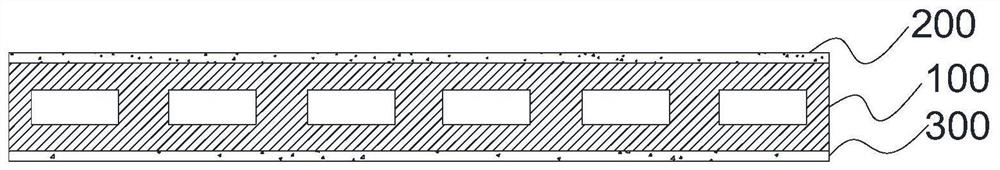

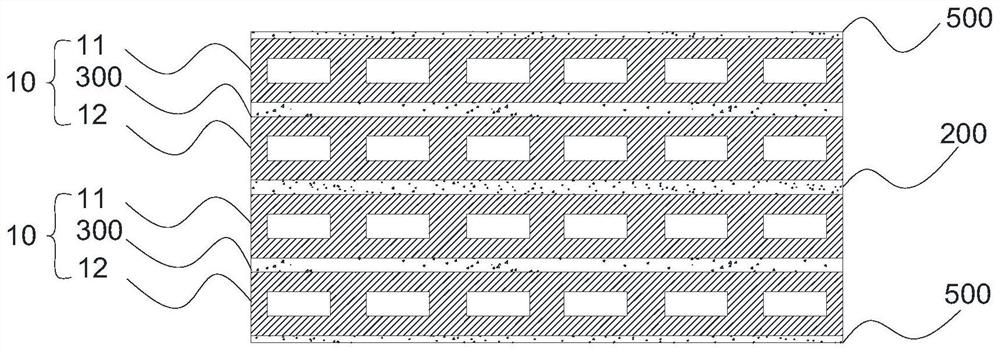

Solid oxide fuel cell stack and preparation method thereof

ActiveCN113488689AReduce thermal stressImprove long-term stabilityFinal product manufactureFuel cellsThin membraneElectrical battery

The invention discloses a solid oxide fuel cell stack and a preparation method thereof, and relates to the technical field of fuel cells. An electrolyte membrane layer and a ceramic connector membrane layer are formed by coating a porous ceramic framework, then back-to-back hot-pressing stacking is performed, and alternate impregnation is performed to obtain a negative electrode and a positive electrode, so that each repetitive unit of the cell stack comprises a negative electrode layer, an electrolyte membrane layer and a positive electrode layer which are sequentially arranged; and the anode layer in each repeating unit is connected with the cathode layer in the adjacent repeating unit through the ceramic connector film layer to form a cell stack structure in which the anode layers and the cathode layers are alternately stacked. The structure has abundant three-phase interfaces, the electrochemical performance of the cell is outstanding, the electrolyte and the connector are both compact ceramic films, the ohmic impedance is small, and the power output of the cell stack is high; and the ceramic connector with the thermal expansion coefficient consistent with that of the porous ceramic framework is adopted, the thermal stress is small, the thermal cycle performance of the cell stack is good, the oxidation corrosion problem does not exist, and the long-term stability of the cell stack can be improved.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV +1

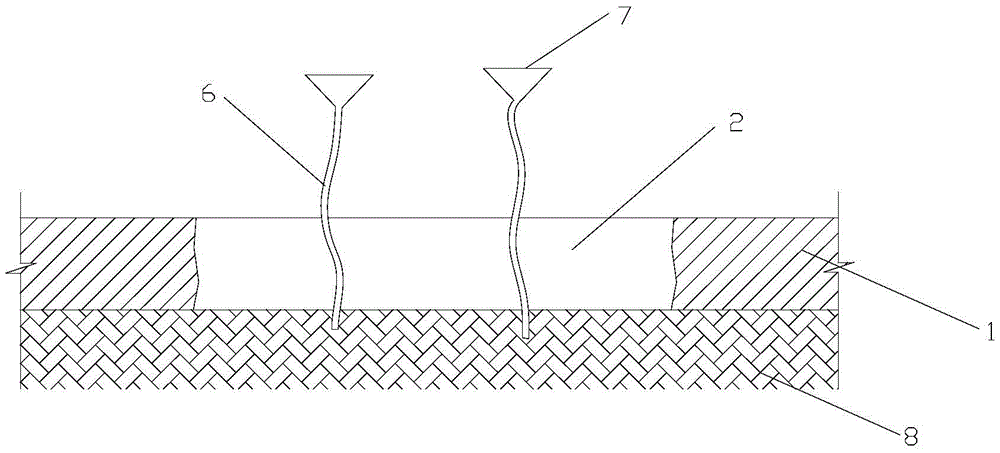

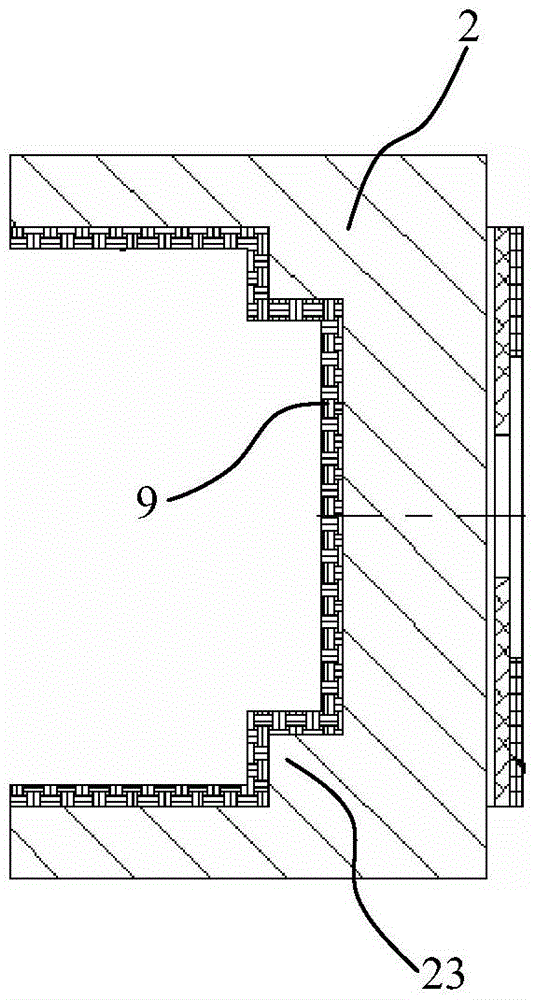

Semitransparent and ultrathin bone china curtain wall used for enveloping outside building and mounting method thereof

InactiveCN105003011ASolve the strength problemGuaranteed StrengthCovering/liningsWallsArchitectural glassKeel

The invention discloses a semitransparent and ultrathin bone china curtain wall used for enveloping outside a building and a mounting method thereof. The curtain wall comprises at least one building glass bone china curtain wall block, and each building glass bone china curtain wall block comprises a building glass layer and a bone china layer which are connected into a whole in a stacked manner. The building glass layers guarantee strength of the curtain wall and improve the defect that the bone china layers are insufficient in strength, so that the curtain wall solves the problem of strength and gives visual effect of the bone china layers into play. In addition, the building glass bone china curtain wall blocks are mounted on a keel through connecting claws, thereby being easy to operate, mount and replace, and construction can be realized only through simple dry-hanging. A rubber gasket is arranged at a position where each connecting claw is connected with the corresponding building glass bone china curtain wall, so that fastening is guaranteed while hard contact and extrusion damage to the building glass bone china curtain wall blocks is avoided. Each two adjacent building glass bone china curtain wall blocks are sealed by adopting a flexible rubber sealing strip, so that free thermal expansion of the curtain wall is ensured.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Power Thick Film Resistors

ActiveCN103632779BConsistent coefficient of thermal expansionOvercome crackingResistor cooling/heating/ventillationNon-adjustable resistorsElectricityHeat conducting

The invention discloses a power thick-film resistor which comprises a resistor substrate provided with a printed internal electrode and a resistor both on one surface as well as a printed back electrode on the other surface, wherein a heat-conducting plate is arranged on the surface of the back electrode of the resistor substrate in a matching manner, and is a porcelain substrate of which the inner surface and the outer surface are fixedly coated with an inner heat-conducting fin and an outer heat-conducting fin respectively; the surface of the inner heat-conducting fin is plated with a nickel layer; the nickel layer is oppositely welded and fixed with the back electrode on the resistor substrate in a matching manner. The porcelain substrate of which the inner surface and the outer surface are coated with the inner heat-conducting fin and the outer heat-conducting fin in a welding manner is welded on the surface of the back electrode of the resistor substrate to serve as the heat-conducting plate, and the heat-conducting fins on the two surfaces cancel out each other due to temperature distortion so as to enable the thermal expansion coefficient of the heat-conducting plate to be basically the same as that of the resistor substrate, so that the problem that the resistor substrate cracks due to the inconsistent thermal expansion coefficient during the use of the resistor substrate in a large size resistor is solved; the power thick-film resistor has the advantages that under the condition of the same size, the resistor is larger in power compared with a conventional resistor, the stable performance is realized, and the temperature distortion cannot be caused.

Owner:BDS ELECTRONICS

A method of nano-impregnated transient eutectic phase-connected SIC ceramics and its prepared ceramics and applications

ActiveCN109437910BAchieve connectionNo void defectOptical rangefindersNuclear energy generationCeramicMaterials science

The invention belongs to the technical field of ceramic connection and discloses a method for connecting SiC ceramics by nano impregnating transient eutectic phase. The method is to combine SiC powder and Al 2 o 3 -M x o y The mixed powder A is used as the connecting material, the M x o y = Ho 2 o 3 or CeO 2 , the mixed powder A is added to the solvent and the ball milling medium, mixed and dried, and the obtained mixed powder B is granulated, and the powder is spread in the middle of two polished SiC to form a sandwich structure; Under the protection of the atmosphere, pressurize 0.01-0.1MPa, first raise the temperature to 600-1000°C for heat preservation Ⅰ, then raise the temperature to 1450-1600°C for heat preservation Ⅱ, the heat preservation pressure is 200-500MPa, and connect to obtain nano-impregnated transient eutectic phase connection SiC ceramics. The invention realizes the low-temperature and low-pressure connection of SiC ceramics, and the leakage rate of the connection reaches 0-1×10 ‑ 8 Pa·L / s.

Owner:GUANGDONG UNIV OF TECH

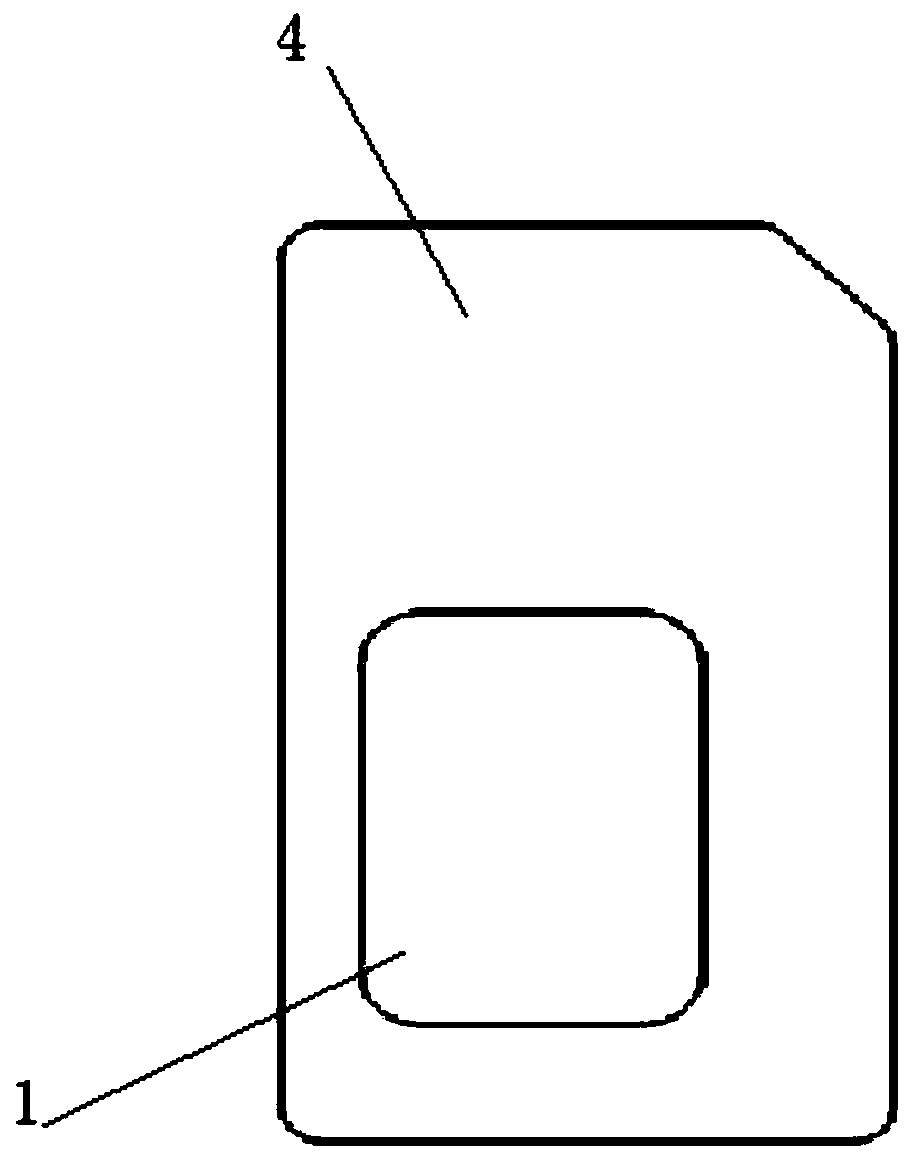

Electronic chip packaging structure and method

PendingCN111081561ALow costHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesComputer hardwareElectronic chip

The invention provides an electronic chip packaging method in order to eliminate the cost disadvantage of the prior art. With the electronic chip packaging method adopted, the production cost of a whole process is effectively reduced. The electronic chip packaging method is characterized by comprising the following steps of: a, obtaining a finished product carrier, and forming a groove in the finished product carrier; b, mounting a chip on a substrate; and c, mounting the substrate with the chip into the groove.

Owner:姜凤明 +1

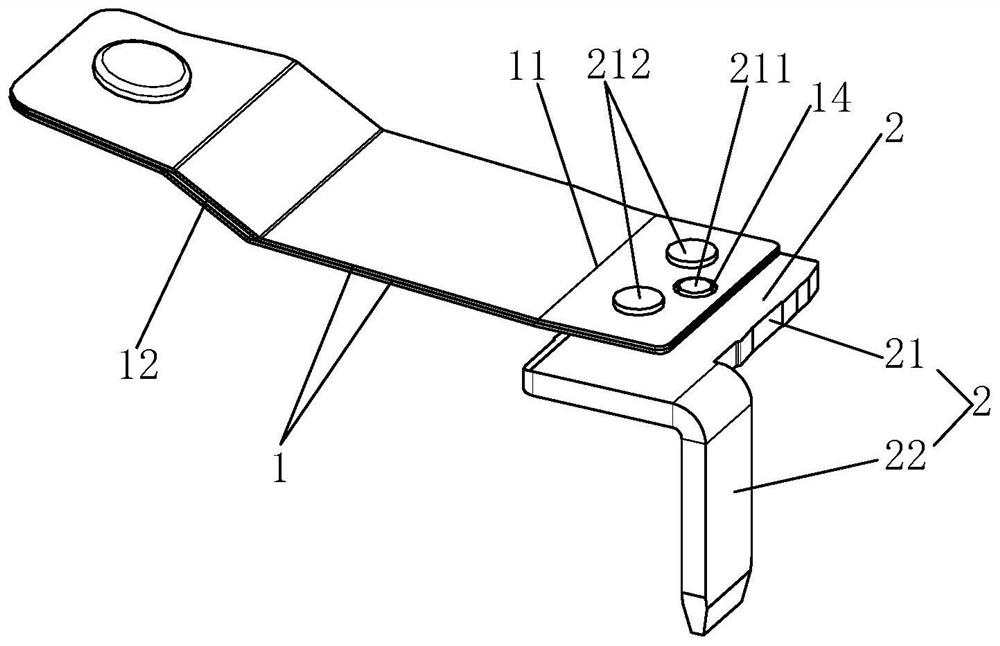

Movable spring assembly of relay and electromagnetic relay

PendingCN114551163AConsistent coefficient of thermal expansionLow mechanical stressElectromagnetic relay detailsThermal dilatationEngineering

The invention discloses a movable spring assembly of a relay and an electromagnetic relay, the movable spring assembly comprises at least two movable spring sheets, a movable spring leading-out sheet and a movable contact, the at least two movable spring sheets are stacked together, one end of each movable spring sheet is fixedly connected with the movable spring leading-out sheet, and the other end of each movable spring sheet is fixedly connected with the movable contact. The other ends of the at least two movable reeds are fixedly connected with the movable contact respectively; and the shapes and the unfolding sizes of the at least two movable reeds are consistent or basically consistent. According to the invention, the at least two movable reeds can share one blanking die during punch forming, the thermal expansion coefficients of the movable reeds are consistent, and the mechanical stress and thermal stress are small, so that the action and release parameters of the relay are stable.

Owner:ZHANGZHOU HONGFA ELECTROACOUSTIC CO LTD

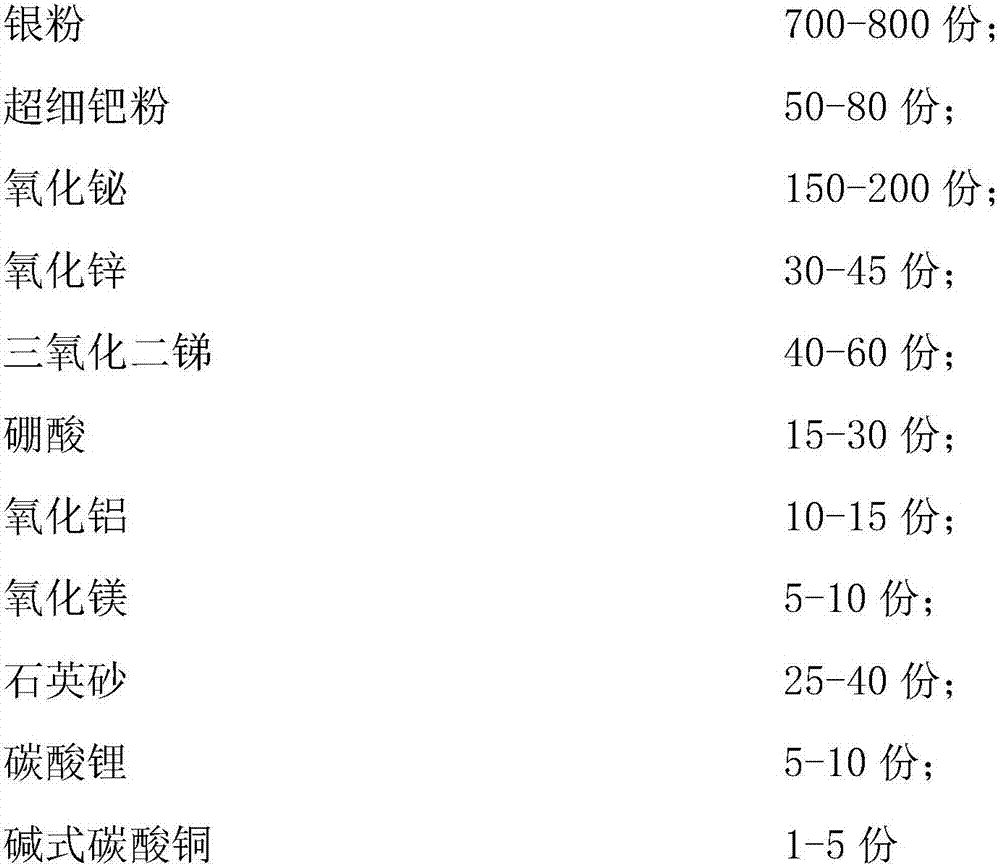

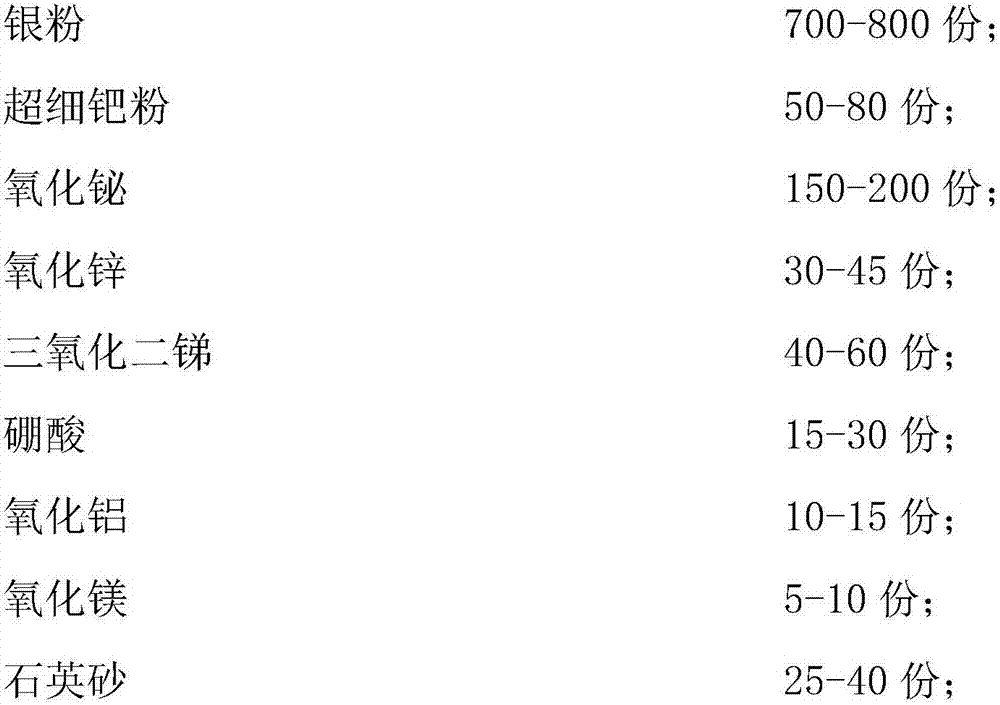

Inorganic conductive terminal film and manufacturing method thereof

InactiveCN107274959ALap each other firmlySmall coefficient of thermal expansionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersLiquid mediumBasic copper carbonate

The invention provides an inorganic conductive terminal film produced from a matrix material and liquid medium. The matrix material is composed of the following raw materials in parts by weight: 700-800 parts of silver powder; 50-80 parts of ultrafine palladium powder; 150-200 parts of bismuth oxide; 30-45 parts of zinc oxide; 40-60 parts of antimony trioxide; 15-30 parts of boric acid; 10-15 parts of alumina; 5-10 parts of magnesium oxide; 25-40 parts of quartz sand; 5-10 parts of lithium carbonate; and 1-5 parts of basic copper carbonate, wherein the particle size of the ultrafine palladium powder is smaller than 500 mesh.

Owner:陶志斌

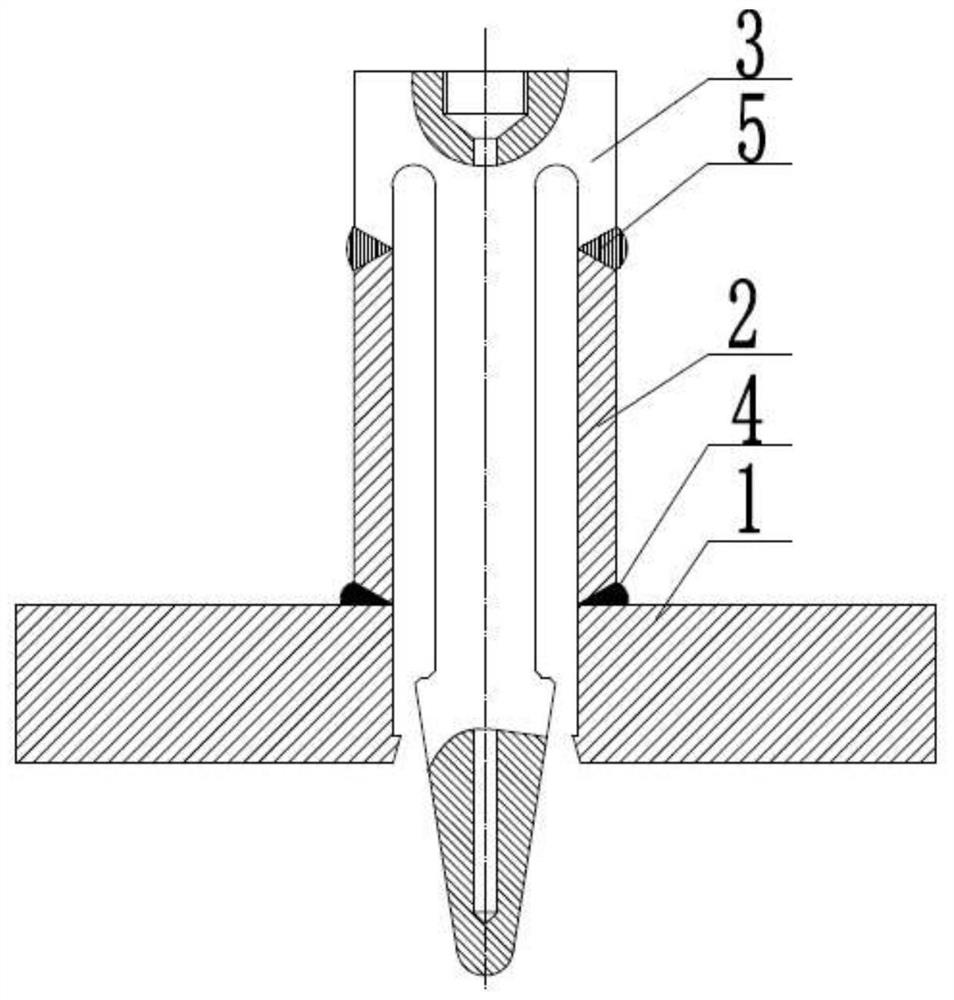

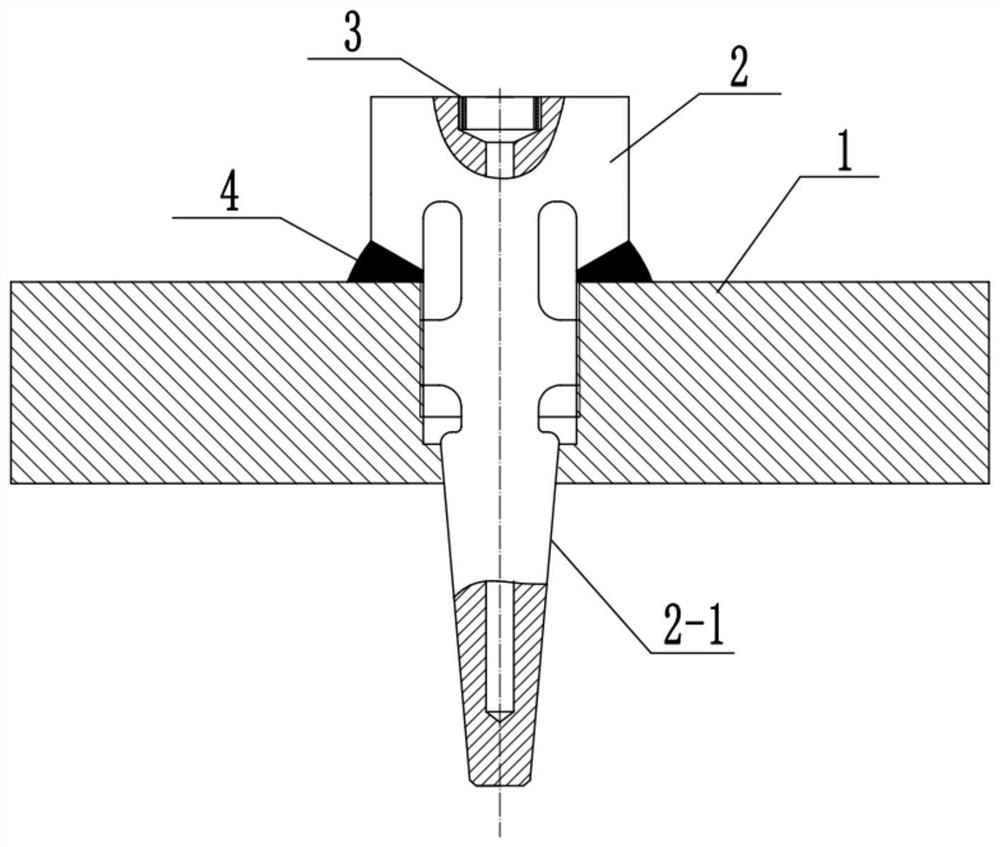

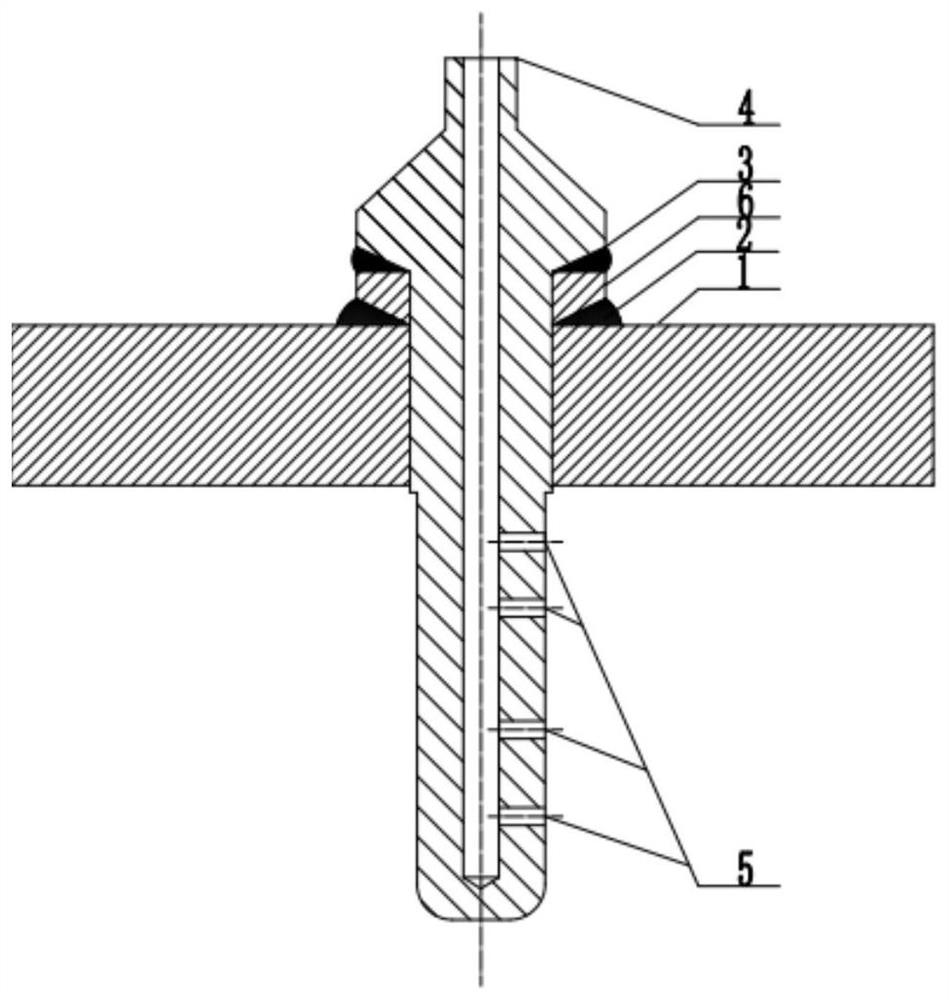

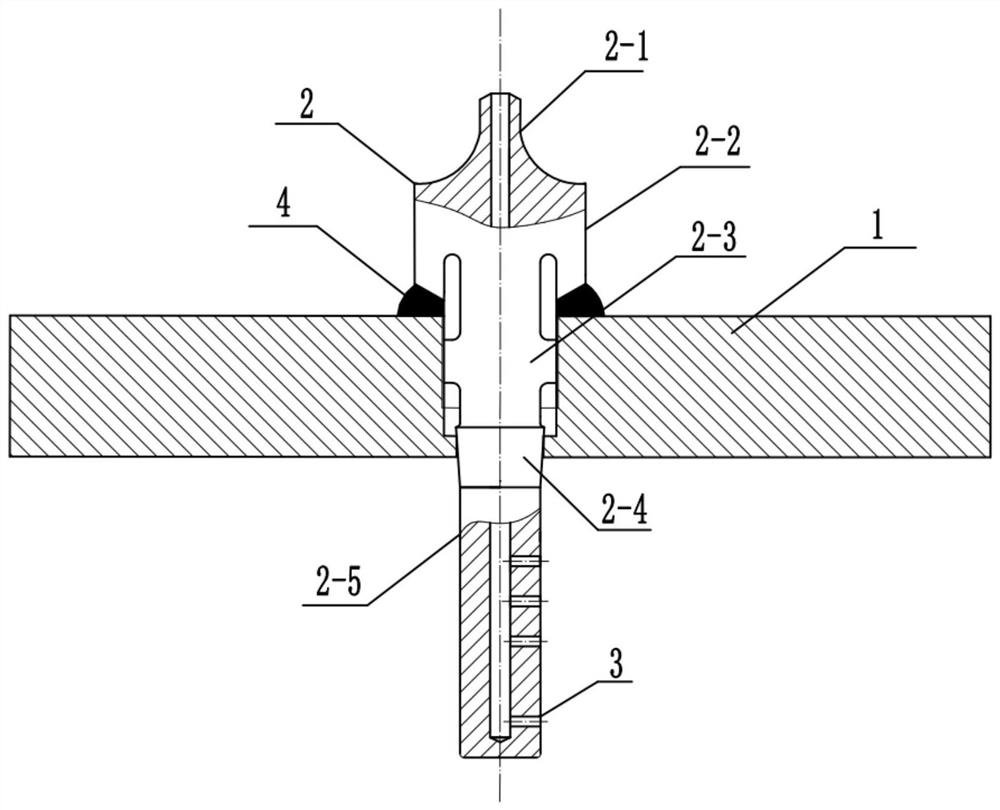

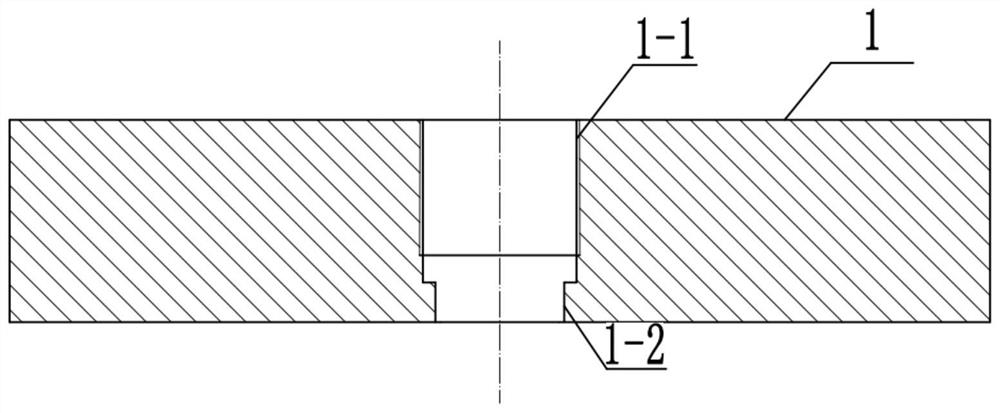

Temperature measuring point sleeve device for high-temperature and high-pressure steam pipeline of thermal power plant

PendingCN112798120AEliminate weak interfacesConsistent coefficient of thermal expansionThermometer detailsFillet weldThermodynamics

The invention discloses a temperature measuring point sleeve device for a high-temperature and high-pressure steam pipeline of a thermal power plant, which is characterized in that a columnar hole and a circular boss with an inclined surface which are communicated with each other are arranged on the side wall of an alloy steel pipeline from outside to inside, and a columnar hole internal thread is arranged on an inner wall of the columnar hole; an alloy steel temperature measuring point sleeve comprises an upper large-diameter cylindrical body, a middle small-diameter cylindrical body and a lower conical body which are connected in sequence; the upper large-diameter columnar body is located on the upper portion of the columnar hole and welded through the same steel fillet weld, the middle small-diameter columnar body is located in the columnar hole, the lower conical body is located in the circular boss with the inclined face, the bottom of the lower conical body extends into the alloy steel pipeline, and external threads are formed in the periphery of the middle small-diameter columnar body; and the top of the alloy steel temperature measuring point sleeve is provided with a temperature measuring element connecting hole. The device is large in rigidity and not prone to vibration, the influence of a weak interface of a dissimilar steel weld joint and the axial pressure of a middle thread of an alloy steel temperature measuring point on an alloy steel pipeline and an alloy steel temperature measuring point sleeve fillet weld is eliminated, and safety and reliability of the sleeve are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

A heat-insulating intelligent anti-corrosion tubing for high-sulfur natural gas wells

ActiveCN103821460BAnti-stressWith insulationDrilling rodsSynthetic resin layered productsThermal dilatationEngineering

The invention discloses a heat preservation and intelligent anticorrosion oil pipe for a high sulfur natural gas well. The heat preservation and intelligent anticorrosion oil pipe is composed of six layers which are an inner anticorrosion anti-drag layer (6), an inner intelligent anticorrosion layer (5), a heat preservation layer (4), a supporting layer (3), an outer intelligent anticorrosion layer (2) and an outer anticorrosion anti-drag layer (1) in sequence; the inner intelligent anticorrosion layer (5) is wrapped outside the inner anticorrosion anti-drag layer (6); the heat preservation layer (4) is wrapped outside the inner intelligent anticorrosion layer (5); the supporting layer (3) is wrapped outside the heat preservation layer (4); the outer intelligent anticorrosion layer (2) is wrapped outside the supporting layer (3); the outer anticorrosion anti-drag layer (1) is wrapped outside the outer intelligent anticorrosion layer (2). The heat preservation and intelligent anticorrosion oil pipe has the beneficial effects that the oil pipe has excellent thermal stability and non-corrosibility; each functional layer has the capacities of compression resistance, heat preservation, intelligent anticorrosion, drag reduction and attaching prevention respectively; the coefficients of thermal expansion of the functional layers are the same; the problem that heat preservation and anticorrosion materials for conventional heat preservation and anticorrosion tubular products are easy to fall off is solved.

Owner:SOUTHWEST PETROLEUM UNIV

Miniature dynamic osmotic water pressure sensor

ActiveCN103674396BHigh dynamic frequency responseHigh measurement accuracyFluid pressure measurement by electric/magnetic elementsEngineeringLinearity

Owner:昆山昆博智能感知产业技术研究院有限公司

Steam sampling pipe device for high-temperature and high-pressure steam pipeline of thermal power plant

PendingCN112834291AEliminate weak interfacesConsistent coefficient of thermal expansionWithdrawing sample devicesFillet weldThermodynamics

The present invention discloses a steam sampling pipe device which is characterized in that a columnar hole and a circular boss which are communicated with each other are formed in the side wall of an alloy steel pipeline from outside to inside, and columnar hole internal threads are formed in the inner wall of the columnar hole; the alloy steel steam sampling pipe comprises a steam sampling pipe connecting pipe, an upper large-diameter cylindrical body which is positioned at the upper part of a cylindrical hole in the side wall of the alloy steel pipeline, is welded and connected by adopting a same steel fillet weld and is provided with a single V-shaped groove at the bottom, a middle small-diameter cylindrical body which is positioned in the cylindrical hole in the side wall of the alloy steel pipeline and is provided with an external thread, a cone-shaped body having the lower part being in contact with the circular boss of the alloy steel pipeline in an abutting manner, and a cylindrical body which is provided with a steam sampling hole and extends into the alloy steel pipeline; and the steam sampling pipe connecting pipe is connected with a steam sampling pipe system. The device is high in rigidity and not prone to vibration, and influences of weak interfaces of dissimilar steel weld joints and axial pressure of threads in the middle of the alloy steel steam sampling pipe on fillet weld joints of the alloy steel pipeline and the alloy steel steam sampling pipe are eliminated.

Owner:XIAN THERMAL POWER RES INST CO LTD

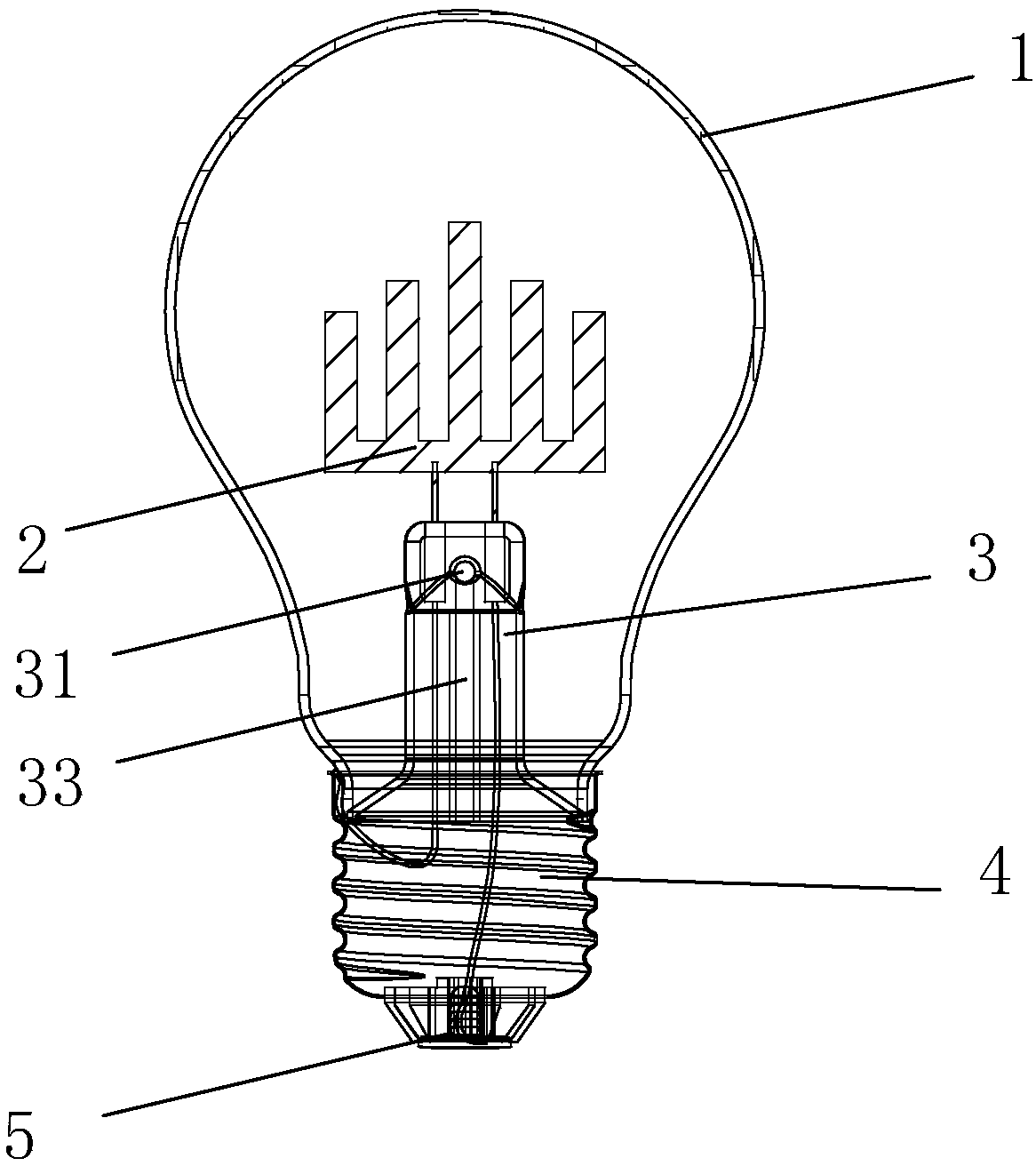

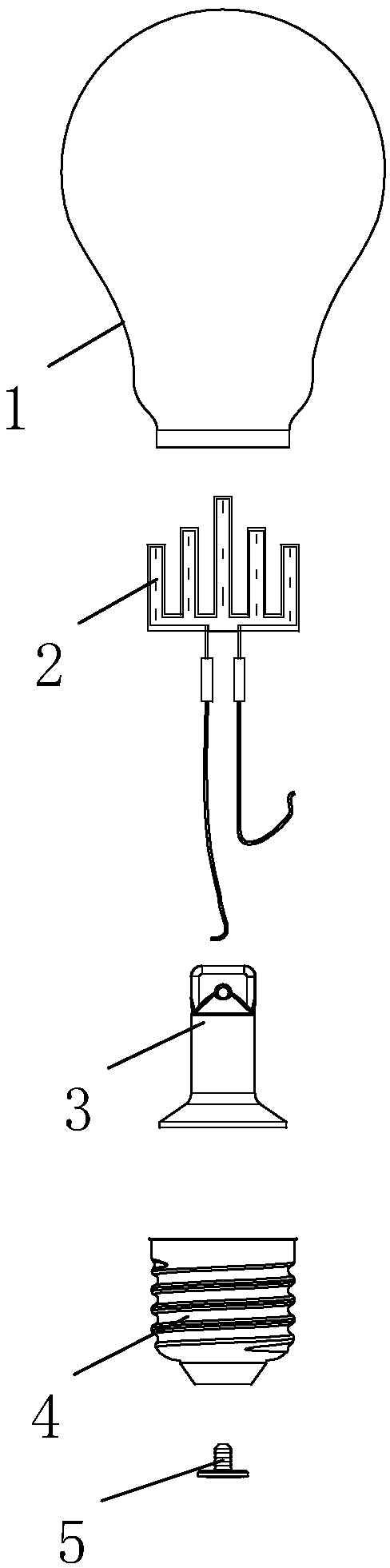

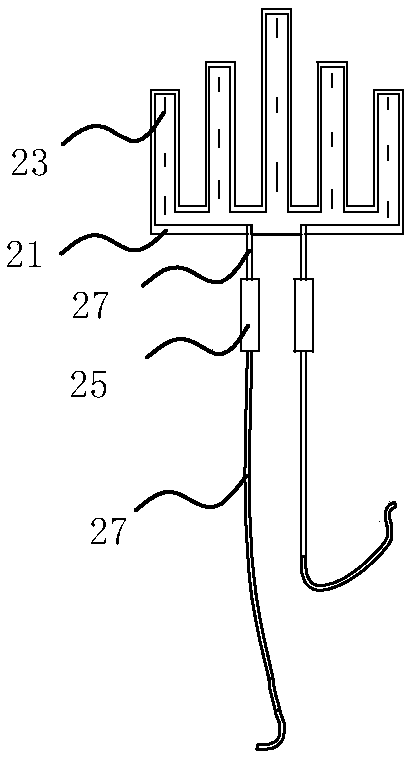

Full glass bulb LED lamp and assembling method thereof

PendingCN109058781AReduce heatExchangeLighting heating/cooling arrangementsSemiconductor devices for light sourcesLight fluxEngineering

The invention discloses a full glass bulb LED lamp and an assembling method thereof. The full glass bulb LED lamp comprises a bulb case, a lamp holder, a light source module and a stem. The stem is ina hollowed column shape, and a horn-shaped opening is formed in the bottom end of the stem. An air inflation hole is formed in the upper end of the stem and further communicates with an exhaust rod.The exhaust rod is arranged inside the stem and further extends downwards to the opening. The light source module comprises a substrate, LED light sources, a driving IC and a guide line. The LED lightsources and the driving IC are packaged on the substrate and are further connected through the guide line. The guide line comprises a dumet wire and a nickel wire. According to the full glass bulb LED lamp and the assembling method thereof, a traditional driving board is omitted, the number of heat sources is reduced, and the mode that the air inflation hole and the exhaust rod are matched for heat radiating is adopted, so that the whole lamp is excellent in heat radiating effect, the bearing power upper limit and light flux upper limit of the whole lamp are increased, the number of structural parts is small, manufacturing and assembling efficiency is high, cost is low and the core competitiveness is good.

Owner:LEEDARSON IOT TECH INC

A kind of high-radiation ceramic coating for heating furnace tube and its preparation and application method

InactiveCN104744973BHigh temperature oxidation resistanceCorrosion resistanceChemical industryPretreated surfacesRadiative transferCeramic coating

The invention discloses a high radiant ceramic coating for a heating furnace tube as well as a preparation method and a using method thereof. The high radiant ceramic coating for the heating furnace tube comprises a component A and a component B, wherein the component A is a metallic oxide mixture which is 30-35% of the total amount and the component B is a temperature resistant bonder which is 65-70% of the total amount. The high radiant ceramic coating provided by the invention has the functions of anti-high temperature oxidation and anticorrosion, prolongs the service life of the furnace tube, increases the heat transfer on the surface of the furnace tube, increases the heat exchange efficiency, reduces the fuel consumption of the heating furnace and reaches the energy saving purpose; under the condition of not changing the device structure, the high radiant ceramic coating reinforces the radiative transfer, is few in investment, rapid in effect, simple in construction and good for industrial popularization.

Owner:马麟

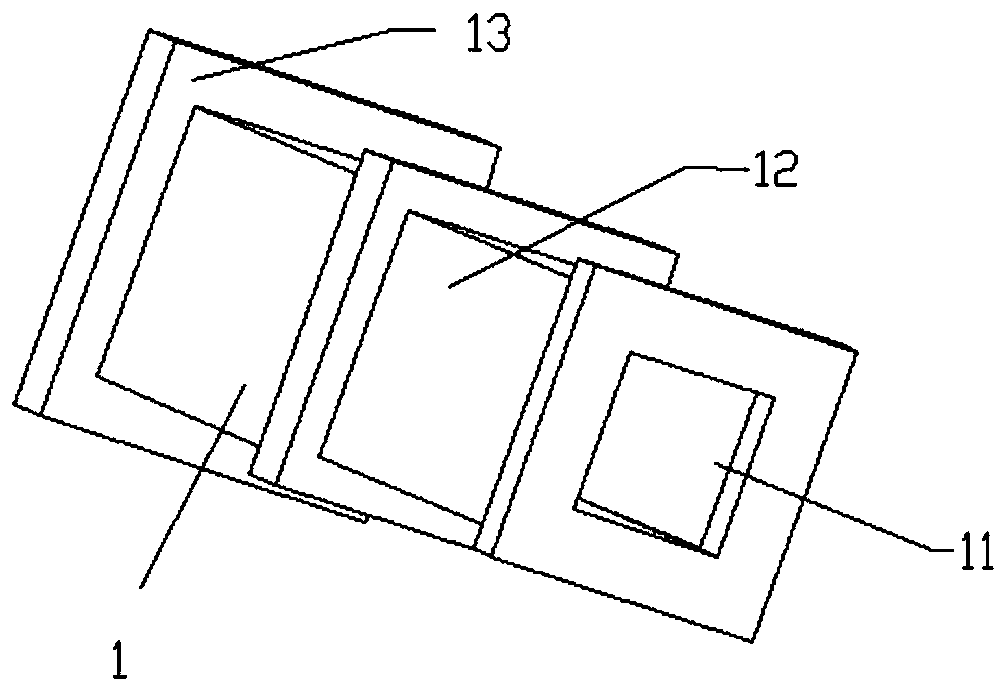

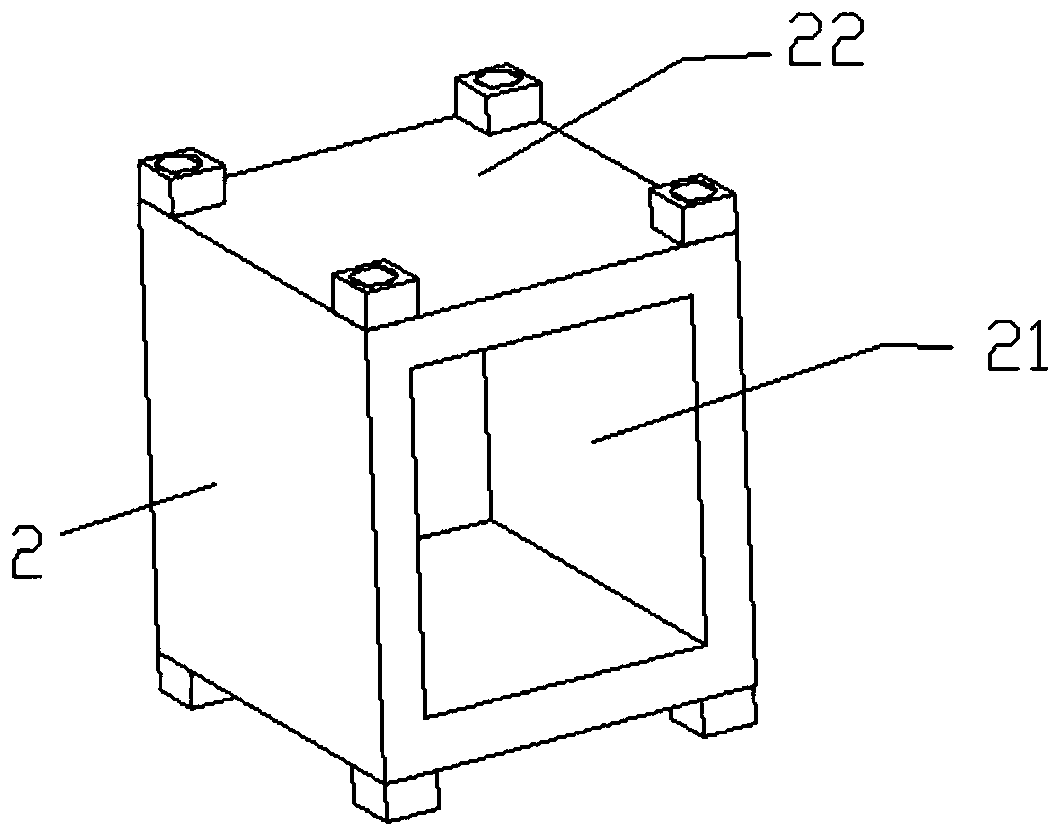

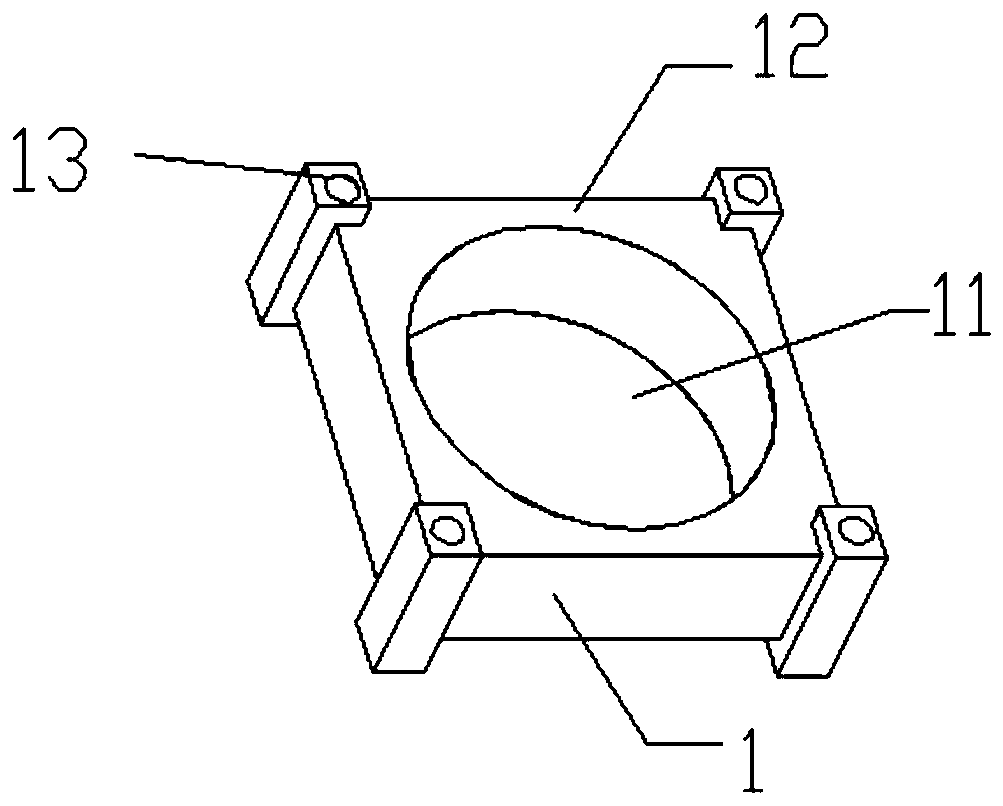

A Fluxgate Magnetic Sensor with a Magnetic Core Skeleton Structure

ActiveCN108872888BReduce weightLow priceMagnetic field measurement using flux-gate principleTemperature resistanceElectrical and Electronics engineering

The invention belongs to the technical field of sensors and concretely relates to a flux gate magnetic sensor with a novel magnetic core skeleton structure. An inner frame and an outer frame are adopted to cooperate with each other, a magnetic core wound by an excitation coil is arranged in a first chamber in the inner frame, an induction coil is wound around the inner frame, and a feedback coil is wound around the outer frame, so uniformity of a feedback field can be ensured. Moreover, the cooperation between the inner and outer frames enables installation to be easier, the later calibrationwork to be easier, and facilitates batch production. Meanwhile, the frames made from PEEK, which is lighter, cheaper and easier to process compared with materials of a conventional sensor, and the frames also has the advantages of electrical insulation, high temperature resistance, light weight, high tensile strength, basic consistence between thermal expansion coefficients and enameled wires, etc.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI +1

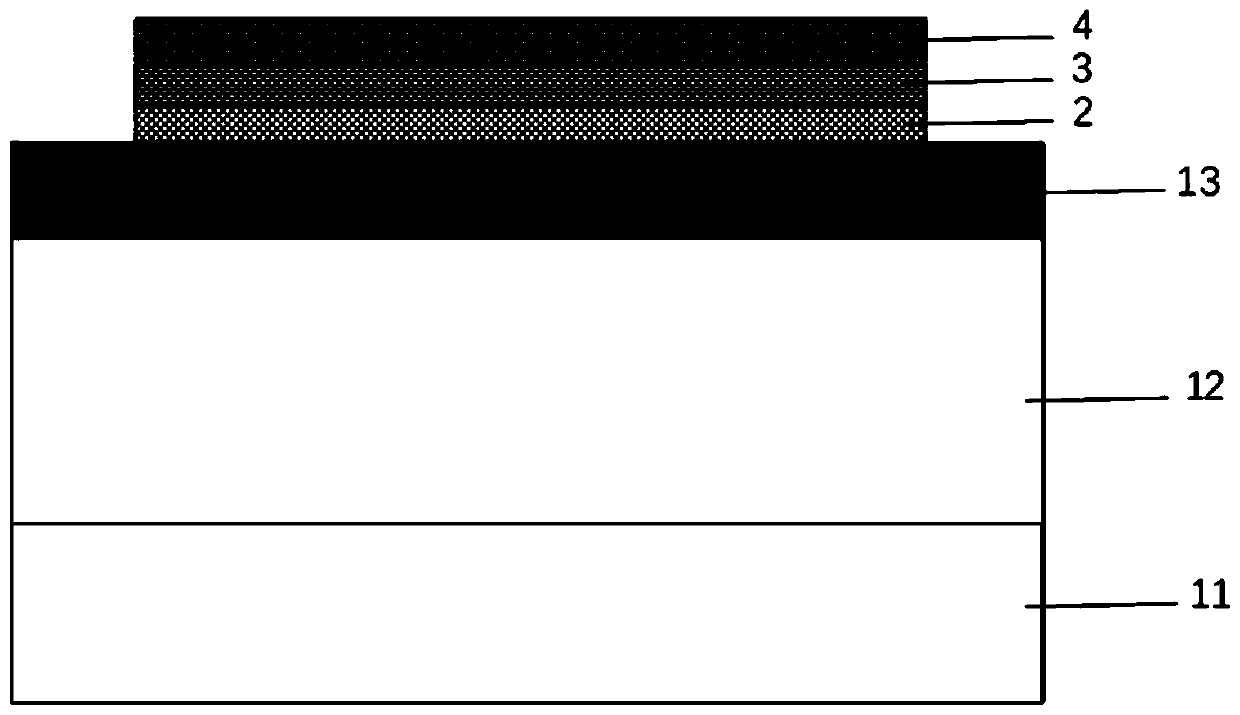

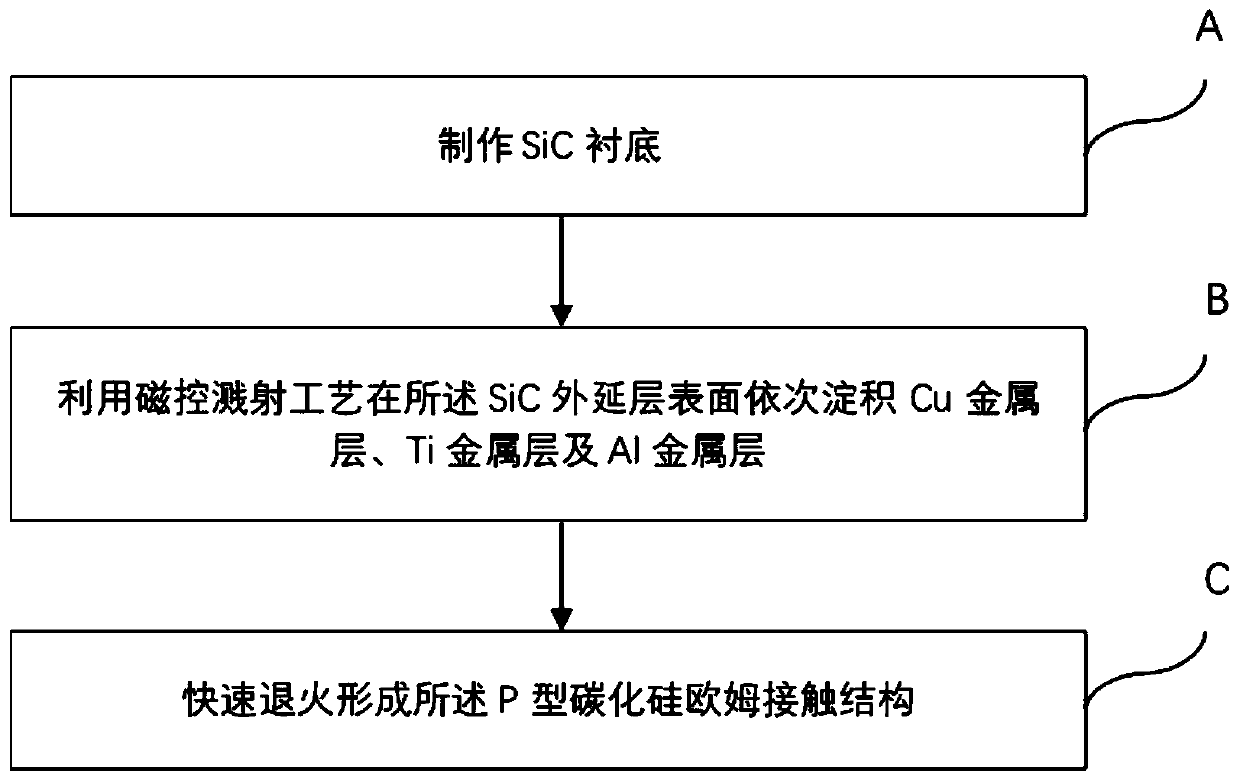

P-type silicon carbide ohmic contact structure and manufacturing method thereof

PendingCN110854189AImprove reliabilityConsistent coefficient of thermal expansionSemiconductor devicesCarbide siliconThermal dilatation

The invention relates to a P-type silicon carbide ohmic contact structure and a manufacturing method thereof. The manufacturing method comprises the following steps: selecting a SiC epitaxial substrate, sequentially depositing a Cu metal layer, a Ti metal layer and an Al metal layer on the surface of the substrate by a magnetron sputtering process, and rapidly annealing to form the P-type siliconcarbide ohmic contact structure. According to the invention, Cu metal material is used in the P-type silicon carbide ohmic contact structure, and can be combined with the power element crimping packaging technology of sintered copper. Both ohmic contact and packaging adopt Cu metal having the same thermal expansion coefficient and more applicability, thus being conducive to improve the reliabilityof the device and save the process cost.

Owner:HANGZHOU DIANZI UNIV

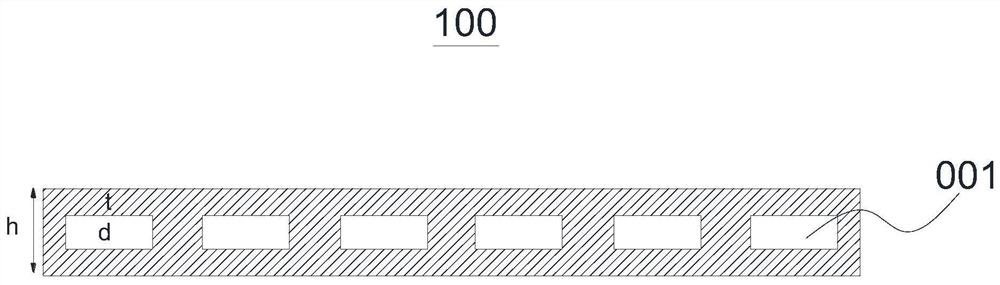

Preparation method of zirconium oxide and aluminum oxide tape casting green body co-sintered sheet layer

ActiveCN111792932AInsulation matchingMatching of sintering characteristicsThermal dilatationNano al2o3

The invention discloses a preparation method of a zirconium oxide and aluminum oxide tape casting green body co-sintered sheet layer. According to the preparation method, enstatite (the main componentis Mg2[Si2O6]Fe2[Si2O6]) is selected; the thermal expansion coefficient of enstatite is 13.5 ppm / k, the addition amount of enstatite is 42%, the addition amount of nano Al2O3 is 58%, the thermal expansion coefficient of enstatite can be consistent with the that of zirconium oxide, and meanwhile, the insulation property, the sintering characteristic, the strength and the compatibility of enstatitecan be matched. The problems that the insulating property is reduced and the sintering property, strength and compatibility are not matched due to co-sintering at present are solved.

Owner:镇江锆源传感科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com