Zirconia-based NOx sensor and preparation method thereof

A zirconia-based, sensor technology, used in instruments, scientific instruments, measuring devices, etc., can solve problems such as insufficient reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The above-mentioned preparation method of a sensor for measuring NOx concentration by AC impedance comprises the following steps:

[0032] Preparation of alumina substrates using recognized techniques;

[0033] Using thick film screen printing technology to print a Pt heating body on the surface of an alumina substrate to form a heating body;

[0034] Print two Pt leads on the surface of another alumina substrate;

[0035] Two alumina substrates are stacked and co-fired to prepare a heating body;

[0036] Coat one section of the two lead wires on the surface of the heating body with LSM slurry, dry, and sinter at 1200°C for 2 hours;

[0037] Coat the surface of alumina / LSM with zirconia slurry for 1 to 5 times; dry and sinter at 1200°C for 2 hours.

[0038] Compared with the prior art, the sensor prepared by the invention has a lower concentration detection function, and the preparation process is simple, which can reduce production costs and save resources. When wo...

Embodiment 1

[0040] The thickness of the aluminum oxide layer prepared by tape casting technology is 0.3 mm. Use thick film screen printing technology to print Pt heating body on the surface of one alumina substrate to form a heating body; print Pt lead wires on the surface of another alumina substrate; stack these two alumina substrates to prepare heating body.

[0041] Coat one section of the two leads on the surface of the heating body with LSM slurry, dry, and sinter at 1200°C for 2 hours; coat the surface of alumina / LSM with zirconia slurry for 5 times; dry, and sinter at 1200°C 2 hours. The thickness of the zirconia layer is 0.05mm, and the diameter of the LSM is 0.02mm

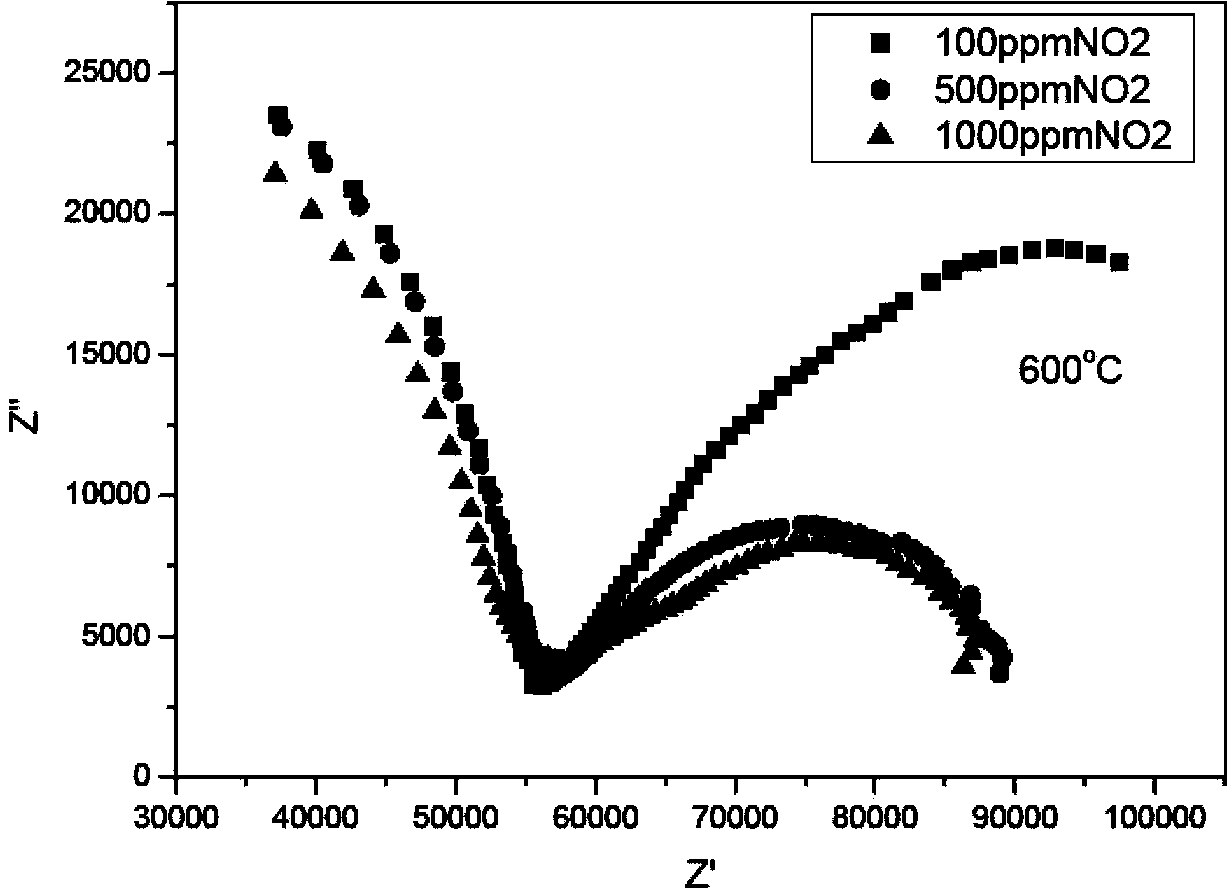

[0042] Test Example

[0043] Adopt the NOx sensor prepared by the present invention to different NO 2 Concentration was tested. from image 3 It can be seen from the figure that the NO from 0 to 1000ppm at 1 to 100Hz 2 can be distinguished.

[0044] This proves that the present invention provides a sensor fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com