Power Thick Film Resistors

A thick film resistor, power technology, applied in resistors, non-adjustable metal resistors, resistor cooling/heating/ventilation devices, etc., can solve the problem of slow heat dissipation, unstable performance and large size of power thick film resistors problems, to achieve the effect of improving the bonding effect, high resistance power and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

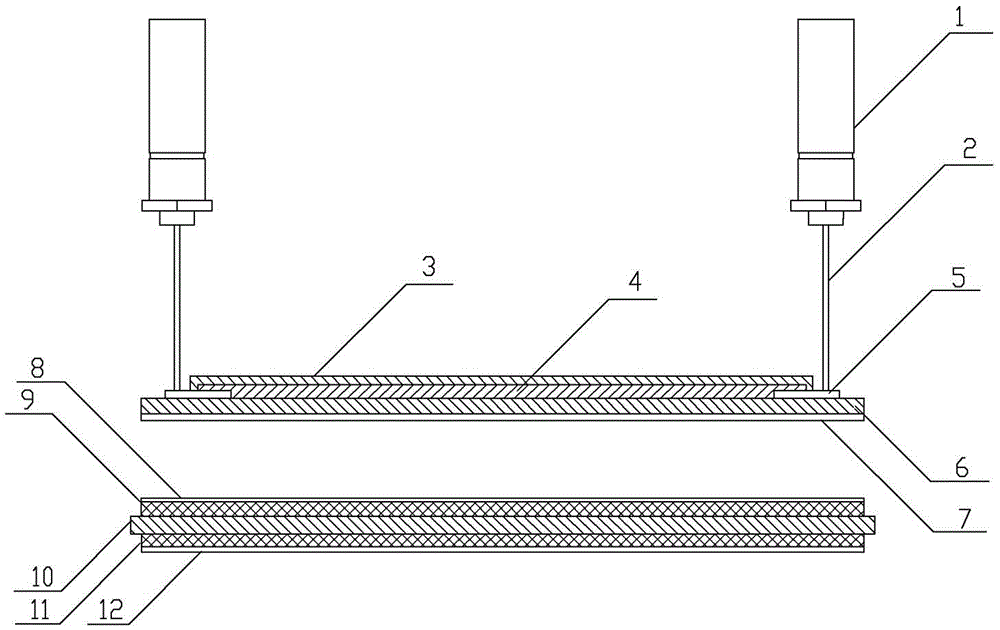

[0014] Such as figure 1 As shown, the product uses an alumina plate or an aluminum nitride plate as the resistance substrate 6, adopts a thick film screen printing process, and screen-prints the internal electrode 5 and the resistor 4 on the upper surface of the resistor substrate 6, and the surface of the resistor 4 is printed with a glaze The protective layer 3, the back electrode 7 is printed on the lower surface of the resistance substrate 6, and the internal electrode 5 is connected to the external terminal 1 through the lead wire 2. The surface of the resistance substrate back electrode 7 is welded and fixed with a heat conduction plate, and the heat conduction plate includes a porcelain substrate 10 (aluminum oxide plate or aluminum nitride plate), the inner and outer surfaces of the porcelain substrate 10 are respectively welded with the inner heat conduction sheet 9 and the outer heat conduction sheet 11, the surface of the inner heat conduction sheet 9 is plated with ...

Embodiment 2

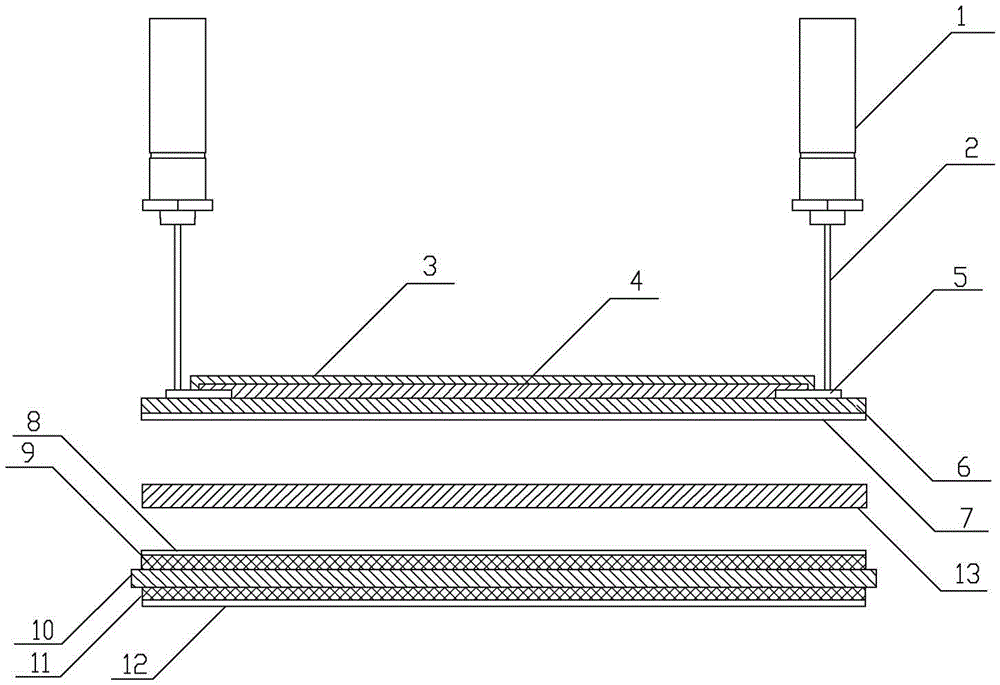

[0016] Such as figure 2 As shown, including the entire structure of Embodiment 1, in order to further increase the heat conduction speed, a layer of heat conducting sheet 13 is added between the back electrode 7 of the resistance substrate and the nickel layer 8 of the heat conducting plate, and the heat conducting sheet 13 is made of copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com