Miniature dynamic osmotic water pressure sensor

A technology of pressure sensor and water penetration, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of affecting the measurement accuracy of the sensor, corroding the sensing surface of the stainless steel diaphragm, and the measurement cannot be carried out, so as to improve the effective Service life and long-term stability, improvement of dynamic frequency response and measurement accuracy, and prevention of soil penetration and water corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

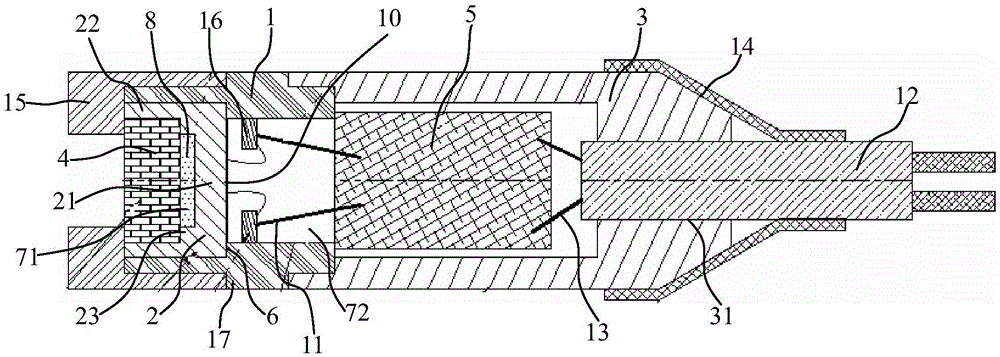

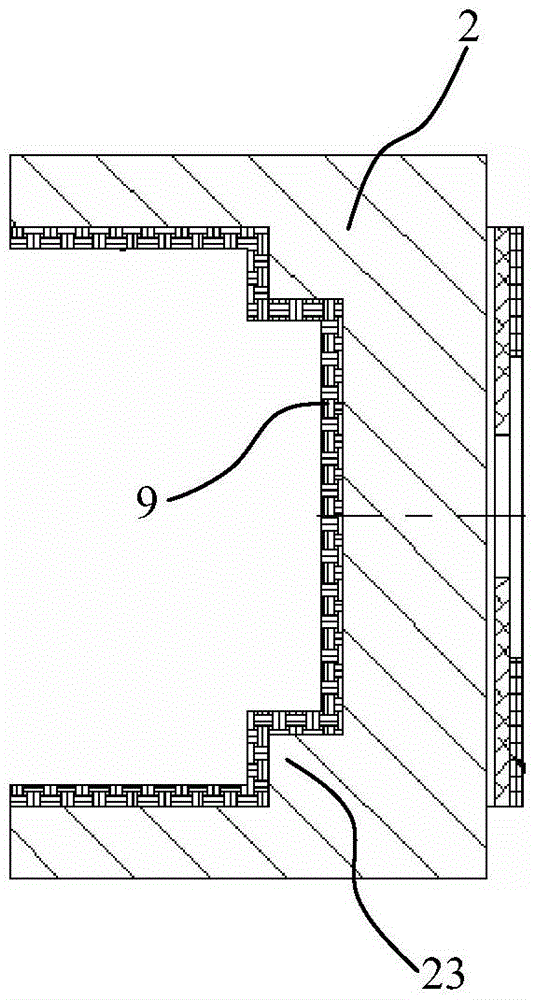

[0018] Embodiment: A miniature dynamic osmotic water pressure sensor, including a housing 1, a cup-shaped base 2 composed of a bottom plate 21 and a side plate 22 fixed to the circumference of the bottom plate 21, a stainless steel back cover 3, a permeable stone layer 4 and signal modulation Amplifying module 5, the middle part of the inner wall of the housing 1 has a stepped annular surface 6, thereby forming a connected pre-chamber 71 and a rear chamber 72, a flange 24 is located in the middle of the outer surface of the housing; the inner wall of the cup-shaped base 2 has steps Surface 23, a permeable stone layer 4 is installed on the step surface 23 of the cup-shaped base 2, thereby forming a permeable water chamber 8 between the permeable stone layer 4 and the bottom of the cup-shaped base 2; The base 2 is embedded in the front chamber 71 and installed on the stepped circular surface 6 of the housing 1; the stainless steel rear cover 3 is installed on one end of the housi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com