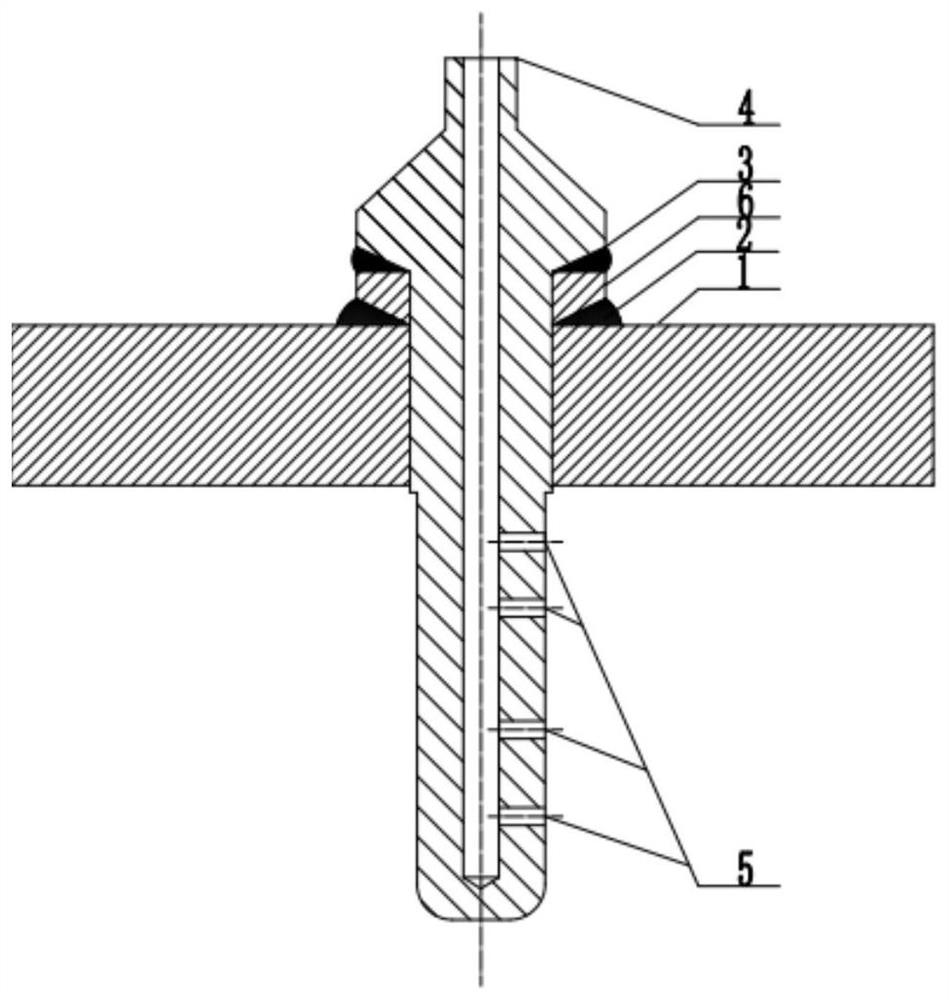

Steam sampling pipe device for high-temperature and high-pressure steam pipeline of thermal power plant

A high-temperature, high-pressure, steam pipeline technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of cracking, falling off, easy cracking, etc., and achieve the effect of improving reliability, high reliability, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

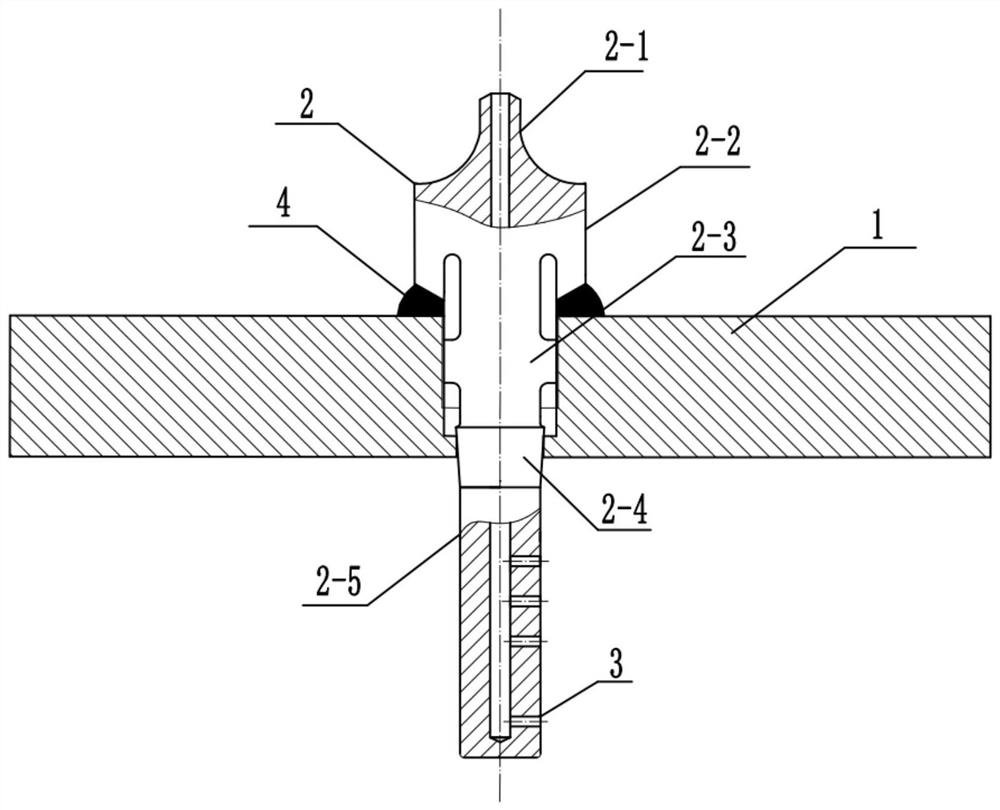

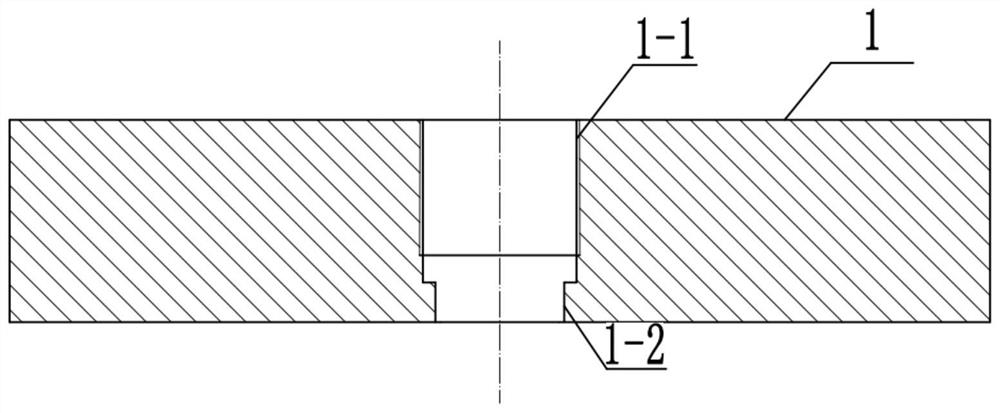

[0027] Implementation case: The original opening on the alloy steel pipe 1 is a full-diameter hole. Before installation, the upper part of the original opening of the alloy steel pipe 1 is reamed. The hole is coaxial with the inner wall of the upper nozzle of the alloy steel steam sampling pipe 2, and the diameter deviation of the upper nozzle of the newly reamed hole is less than 1 mm from the diameter of the upper nozzle of the alloy steel steam sampling pipe 2; The fine-toothed internal thread and the fine-toothed external thread of the small-diameter columnar body in the middle of the alloy steel steam sampling pipe 2 match the processing specifications of the internal thread on the inner wall of the reamed hole of the alloy steel pipe 1. The alloy steel steam sampling pipe 2 is screwed into the alloy steel pipe 1 through the outer thread of the small-diameter cylindrical outer thread in the middle part and the internal thread of the reaming inner wall of the alloy steel pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com