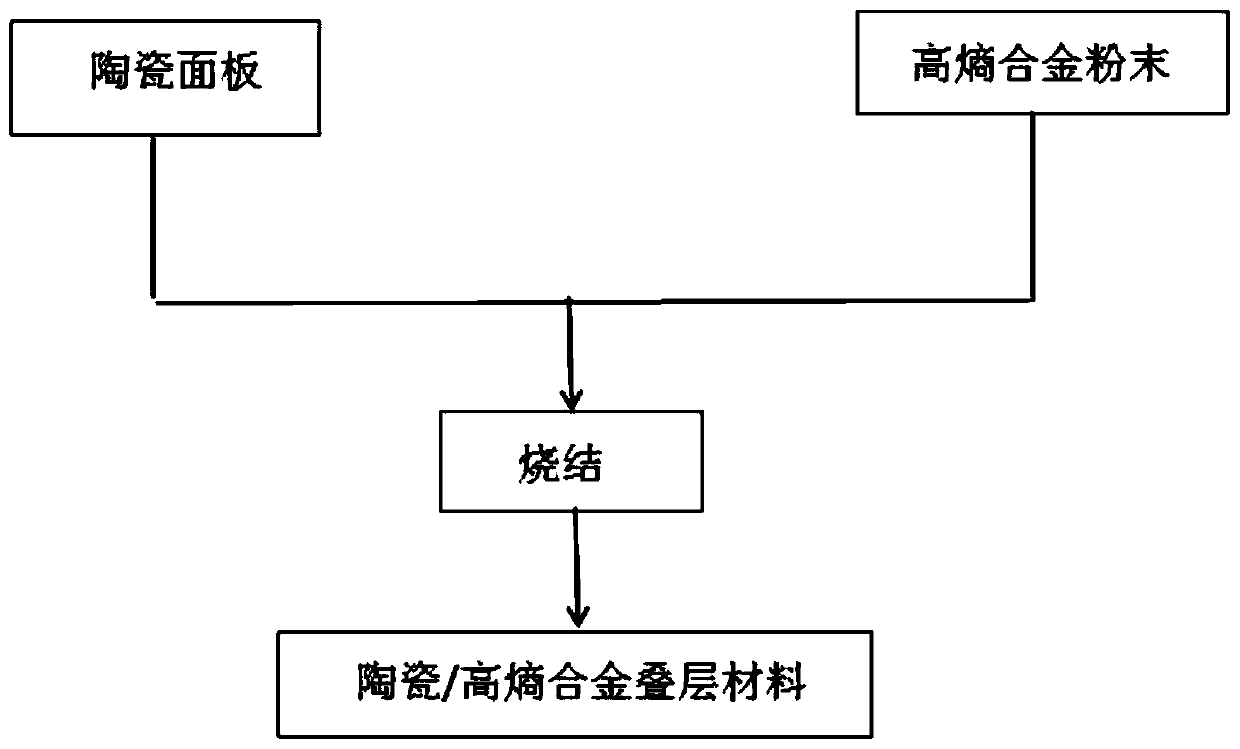

A kind of preparation method of ceramic/high entropy alloy laminated material

A technology of high-entropy alloys and laminated materials, applied in the field of ceramic/high-entropy alloy laminated materials and their preparation, can solve problems such as limited interface strength, decreased ballistic performance, and reduced composite armor's ballistic performance, and achieve high-energy resistance. Improving the impact performance and improving the secondary impact resistance, improving the effect of secondary impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The high-entropy alloy is composed of four elements: Co, Cr, Fe, and Ni. The ceramic panel is made of boron carbide ceramic material with a density of more than 95%.

[0026] This embodiment also provides a method for preparing the ceramic / high-entropy alloy laminate material, which includes the following steps:

[0027] Step 1: Select the high-entropy alloy powder of the appropriate system and prepare it by planetary ball milling. The molar percentage of metal element: Co, Cr, Fe, and Ni are mixed in a molar ratio of 3:3:3:1. The ball milling medium is stainless steel ball or Cemented carbide balls, ball-to-material mass ratio is 5:1, the speed of planetary ball mill is 200 rpm, and the total milling time is 20 hours.

[0028] Step 2: Put the boron carbide ceramic panel into the graphite mold, and spread the high-entropy alloy powder uniformly on the surface by the layering method, and the powder thickness is 0.1mm, and compacted.

[0029] Step 3: Put the mold into the sinter...

Embodiment 2

[0031] The high-entropy alloy is composed of five elements: Co, Cr, Fe, Ni, Al and Mn. The ceramic panel is a boron carbide-titanium diboride composite ceramic material with a density of more than 95%.

[0032] This embodiment also provides a method for preparing the ceramic / high-entropy alloy laminate material, which includes the following steps:

[0033] Step 1: Select the high-entropy alloy powder of the appropriate system and prepare it by planetary ball milling. The molar percentage of the elemental metal: Co, Cr, Fe, Ni, Al, Mn are mixed in a molar ratio of 35:20:20:10:15. The ball milling medium is stainless steel balls or cemented carbide balls, the mass ratio of the balls is 20:1, the speed of the planetary ball mill is 600 rpm, and the total milling time is 100 hours.

[0034] Step 2: Put the boron carbide-titanium diboride composite ceramic panel into the graphite mold, and spread the high-entropy alloy powder uniformly on the surface by the layering method, and the powde...

Embodiment 3

[0037] The high-entropy alloy is composed of five elements: Co, Cr, Fe, Ni and Al. The ceramic panel is made of titanium diboride ceramic material with a density of more than 95%.

[0038] This embodiment also provides a method for preparing the ceramic / high-entropy alloy laminate material, which includes the following steps:

[0039] Step 1: Select a suitable system of high-entropy alloy powder and prepare it by planetary ball milling, in which the percentage of elemental metal: Co, Cr, Fe, Ni, Al are mixed at 20% each, and the milling medium is stainless steel balls or cemented carbide balls , The ball-to-material mass ratio is 10:1, the speed of the planetary ball mill is 400 rpm, and the total ball milling time is 60 hours.

[0040] Step 2: Put the titanium diboride ceramic panel into the graphite mold, and spread the high-entropy alloy powder uniformly on the surface using the layering method, and the powder thickness is 10mm, and compacted.

[0041] Step 3: Put the mold into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com