Crystal silicon solar cell aluminum paste with high conductivity

A solar cell, high-conductivity technology, applied in conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve problems such as poor appearance and boiling performance of aluminum films, and achieve reduced warpage, humidity and heat resistance. Good performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

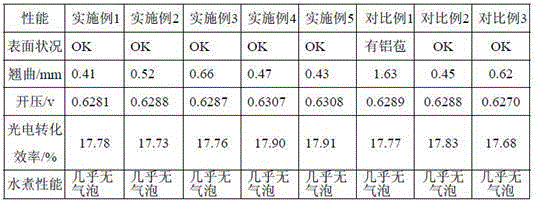

Examples

Embodiment 1

[0022] The formulation components of the high-conductivity crystalline silicon solar cell aluminum paste include, by weight percentage: 65% of aluminum powder, 1% of lead-free glass powder, 30% of organic vehicle, 3% of anti-warping additive and 1% of auxiliary agent.

[0023] Among them, aluminum powder specifications: oxygen content 0.2%. Based on the total weight of aluminum powder, the particle size mix is: 30% aluminum powder A of less than 2 μm, 30% B of 3-5 μm aluminum powder and 40% of C 6-8 μm aluminum powder. The lead-free glass powder components include by weight percentage: Bi 2 o 3 30%, B 2 o 3 20%, SiO 2 8%, ZnO30%, Sb 2 o 3 6.4%, ZrO 2 0%, V 2 o 5 5%, Al 2 o 3 0.5%, BaO0.1% and SrO0%.

[0024] The organic vehicle components include by weight percentage: ethyl cellulose 7%, cellulose acetate butyrate 5%, phenolic resin 5%, terpineol 41%, butyl carbitol acetate 18.7%, tributyl citrate 16% ester, 4% diethylene glycol butyl ether, 3% pump oil and 0.3% w...

Embodiment 2

[0026] 70% aluminum powder, 3.5% lead-free glass powder, 24.4% organic vehicle, 2% anti-warping additive and 0.1% additive.

[0027] Among them, aluminum powder specification: oxygen content is 0.25%. Based on the total weight of aluminum powder, the particle size mix is: 10% of aluminum powder less than 2μm, B80% of 3-5μm aluminum powder and 10% of 6-8μm aluminum powder C. The lead-free glass powder components include by weight percentage: Bi 2 o 3 40%, B 2 o 3 13%, SiO 2 15%, ZnO10%, Sb 2 o 3 10%, ZrO 2 1%, V 2 o 5 3%, Al 2 o 3 5%, BaO2% and SrO1%.

[0028] The formulation components and percentages of the organic vehicle are the same as in Example 1; anti-warping additive: ThP 2 o 7 and UP 2 o 7 Equal mass mixing, and surface treatment by borate coupling agent; additives are composed of sodium polydimethylcarboxylate, cetylpyridine, dipalmitoyl ethylenediamine and modified urea thixotropic agent.

Embodiment 3

[0030] Aluminum powder 75%, lead-free glass powder 5%, organic vehicle 17.5%, anti-warping additive 0.5% and auxiliary agent 2%.

[0031] Among them, aluminum powder specification: oxygen content is 0.30%. Based on the total weight of aluminum powder, the particle size mix is: 20% of aluminum powder A of less than 2 μm, 70% of B of 3-5 μm aluminum powder and 10% of C of 6-8 μm aluminum powder. The lead-free glass powder components include by weight percentage: Bi 2 o 3 50%, B 2 o 3 10%, SiO 2 12%, ZnO14.5%, Sb 2 o 3 5%, ZrO 2 3%, V 2 o 5 1%, Al 2 o 3 3%, BaO1%, SrO0.5%.

[0032] The formulation components and percentages of the organic vehicle are the same as in Example 1; anti-warping additive: HfW 2 o 8 , surface treated with polyvinylpyrrolidone; additives consist of dioctyl sodium adipate, sodium stearate, polyether defoamer and polyamide wax micropowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com