Repairing process and repairing tool for excircle crack conquassation of tires and carrier rollers of rotary kiln

A rotary kiln and crack technology, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of long time to replace rolling rings, huge loss of production stoppage, hidden dangers in production safety, etc., and achieve uniform hardness distribution, rapid construction, and reduced The effect of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

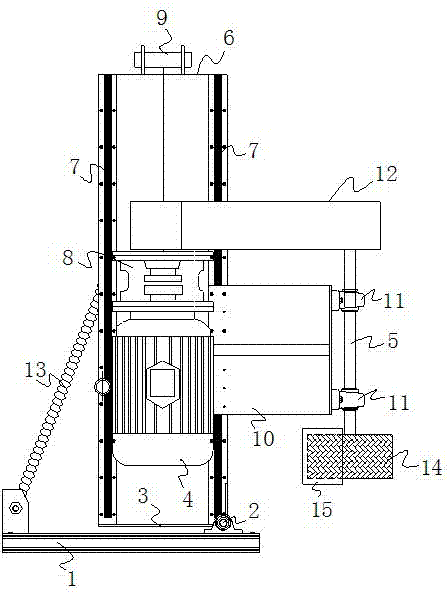

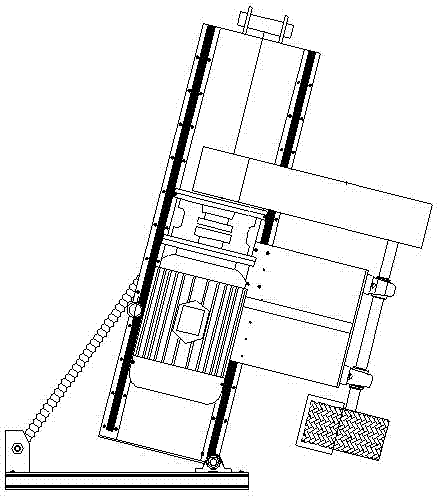

Image

Examples

Embodiment

[0026] Use a portable ultrasonic flaw detector to detect the cracked and crushed parts, determine the cutting range and depth, and make engineering confirmation records, and use a high-power plasma cutting torch to remove the cracks and crushed damaged parts. The construction efficiency of the plasma cutting torch is higher than that of oxyacetylene 4 times that of oxyacetylene, and the cost is only 1 / 3 of that of oxyacetylene. After cleaning the damaged part of the crack, the bevel is made on the damaged part and the undamaged part, that is, the joint part of the weld behind. The form of the bevel directly affects the surfacing welding. Make the wound surface into a flat concave shape. The angle of the groove is about 35 degrees relative to the radial plane of the rolling ring or supporting wheel, or about 35 degrees on the arc surface. The stress destroys the stress on the interface; 2 is to maximize the bonding surface between the weld and the base metal; 3 is to reserve a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com