Inorganic conductive terminal film and manufacturing method thereof

A conductive terminal, inorganic technology, used in conductive materials dispersed in non-conductive inorganic materials, equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, etc., can solve the problem of lead-containing substances harming human health and Living environment, thermal properties of inorganic conductive terminal film layer, bonding force of conductive materials, inconsistent thermal expansion coefficient, etc., to achieve the effect of benefiting human health, reliable mutual overlap, and large current carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Correspondingly, the embodiment of the present invention also provides a method for preparing an inorganic conductive terminal film, including the following steps:

[0055] S01. Weigh each component according to the formula of the above-mentioned inorganic conductive terminal film;

[0056] S02. Heat and melt bismuth oxide, zinc oxide, antimony trioxide, boric acid, aluminum oxide, magnesium oxide, quartz sand, lithium carbonate, and basic copper carbonate, grind and sieve after cooling, and add silver powder and ultrafine palladium powder Mix to obtain a substrate mixture;

[0057] S03. In the substrate mixture, add an organic medium accounting for 10-30% of the total weight of the substrate material and the liquid medium, and mix to obtain a mixed slurry;

[0058] S04. Provide a substrate, print the mixed paste on the substrate, perform drying and sintering treatment, and obtain an inorganic conductive terminal film.

[0059] Specifically, in the above step S01, the...

Embodiment 1

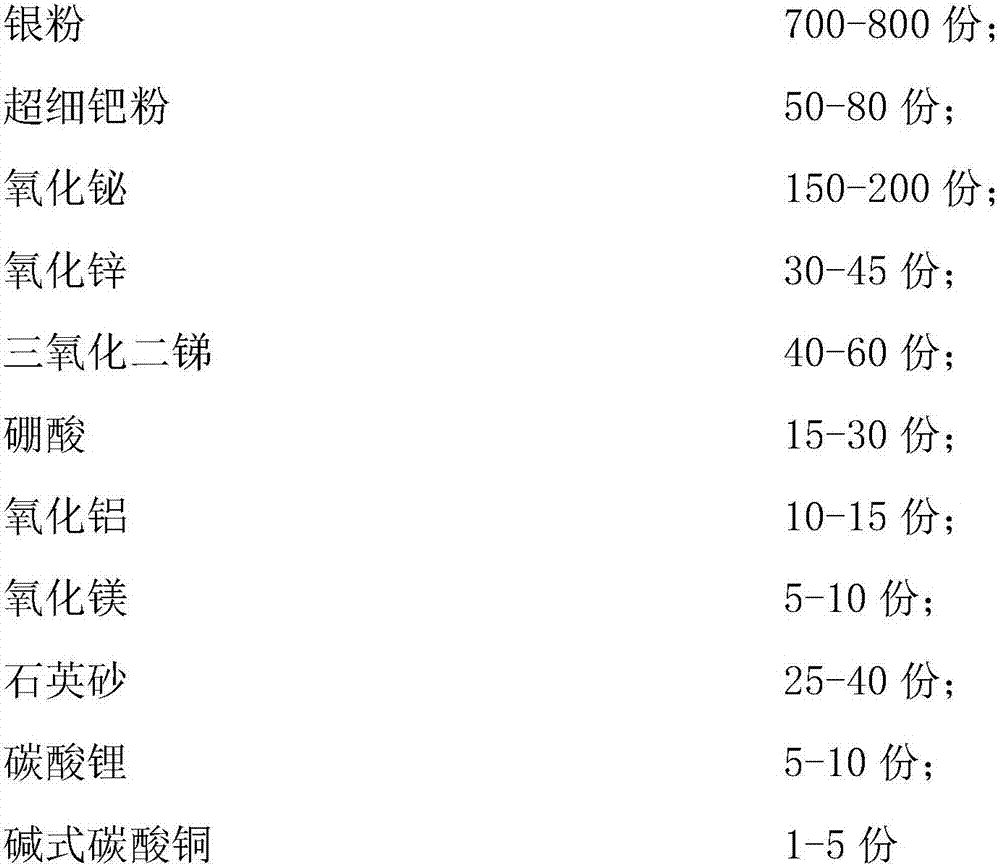

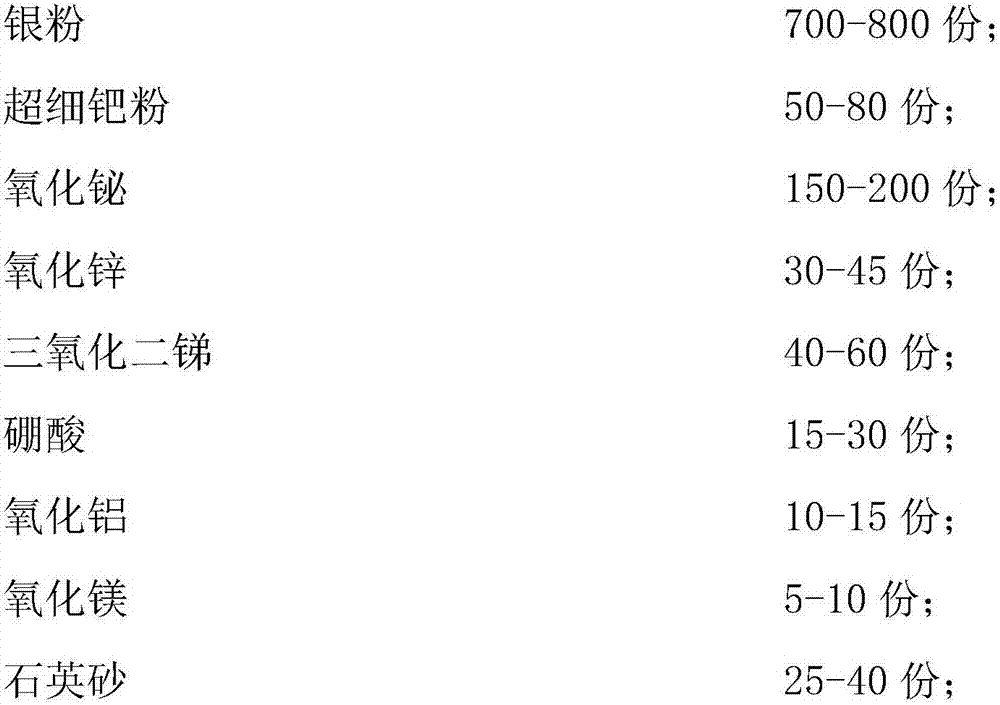

[0070] A kind of electrodeless electrode membrane (2000 grams), comprises base material and liquid medium, and described base material is made up of following raw material of following weight:

[0071]

[0072]

[0073] Described organic medium is the liquid organic medium that is made up of the following components of following percentage by weight:

[0074] Terpineol 95%;

[0075] Ethylcellulose 2.5%;

[0076] Silane coupling agent 2.5%,

[0077] The total weight is 450g.

[0078] The preparation method of the electrodeless electrode film comprises the following steps:

[0079] S11. Weigh each component according to the formula of the above-mentioned electrodeless electrode film;

[0080] S12. Stir bismuth oxide, zinc oxide, antimony trioxide, boric acid, aluminum oxide, magnesium oxide, quartz sand, lithium carbonate, and basic copper carbonate in a mixer, and melt the mixture at 1100°C for 60 minutes. The obtained mixture block is cooled and crushed, then ground...

Embodiment 2

[0084] In Example 2, the organic medium is a liquid organic medium composed of the following components in the following weight percentages:

[0085] Phenolic resin 90%;

[0086] Ethylcellulose 5%;

[0087] Rosin resin 5%.

[0088] Except that, others are the same as Example 1. The experiment was carried out according to the conditions of Example 1, and substantially the same results as Example 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com