Method for growing crystal optical fiber core in crystal cladding layer

A crystal fiber and crystal growth technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of easy cracking of cladding, low sol-gel efficiency, and undesired crystal cladding, and achieve consistent thermal expansion coefficients , good laser beam quality, avoid the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

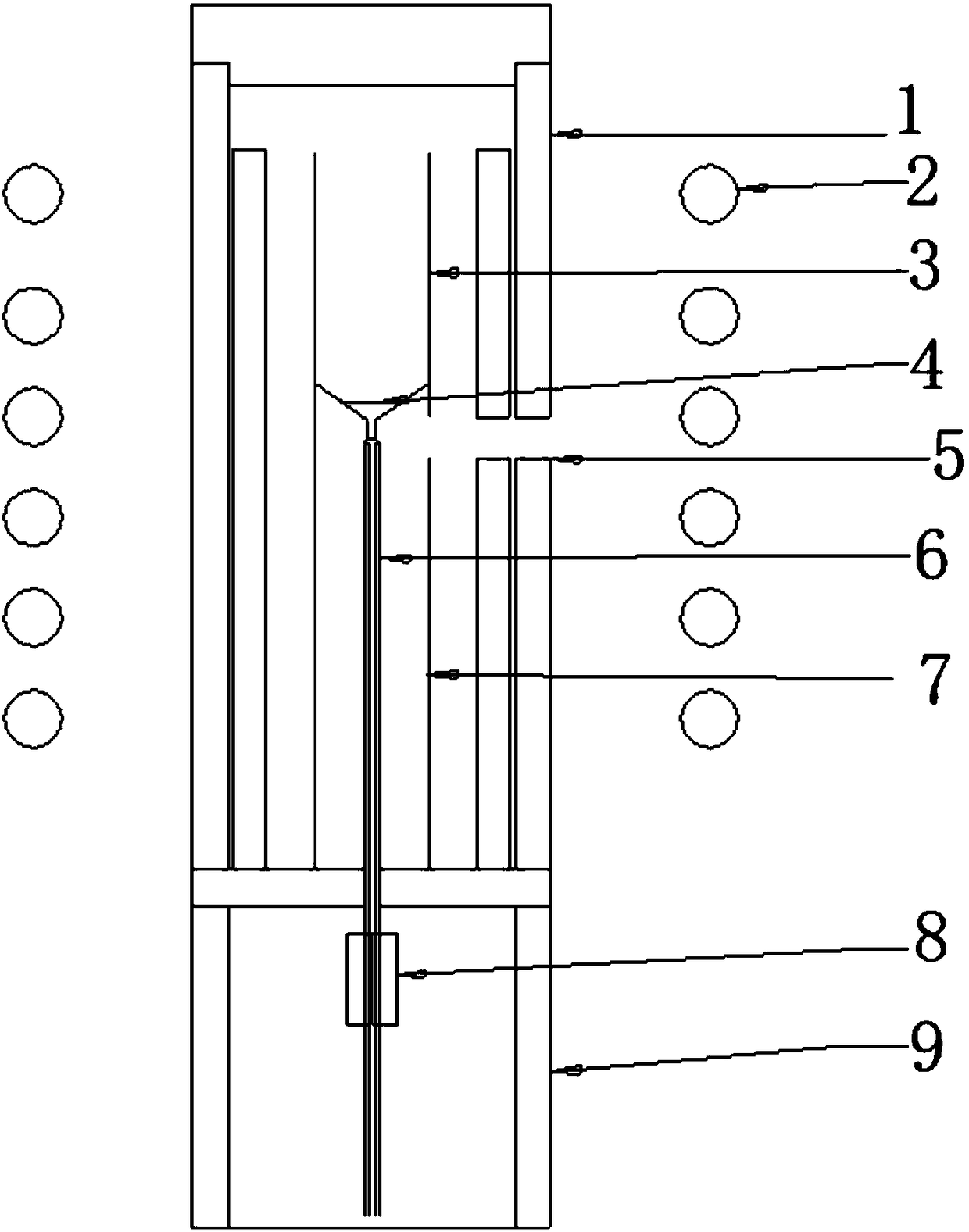

[0020] An all-crystal fiber and cladding manufacturing process adopts such as figure 1 The shown micro-drawing furnace device includes an insulation layer 1 arranged on the side wall of the furnace body, an induction coil 2 arranged outside the insulation layer 1, a quartz support column 9 arranged at the bottom of the furnace body, and a heater 3 is arranged above the quartz support column 9, There is a seed rod 8 inside, the transistor is installed on the seed rod 8 and passes through the heater 3, and an observation window 5 is set at the same height position of the rear heater 7 and the insulation layer 1.

[0021] The specific steps for making all-crystal fiber and cladding by using the above-mentioned device are as follows:

[0022] (1) Adopt the microporous crystal growth method to obtain the pure YAG microporous crystal 6 of length 40-160mm, the microporous crystal inner diameter is less than or equal to 1mm, or punch holes in the pure YAG crystal rod center to obtain ...

Embodiment 2

[0029] An all-crystal fiber and cladding manufacturing process adopts such as figure 1 The shown micro-drawing furnace device includes an insulation layer 1 arranged on the side wall of the furnace body, an induction coil 2 arranged outside the insulation layer 1, a quartz support column 9 arranged at the bottom of the furnace body, and a heater 3 is arranged above the quartz support column 9, There is a seed rod 8 inside, the transistor is installed on the seed rod 8 and passes through the heater 3, and an observation window 5 is set at the same height position of the rear heater 7 and the insulation layer 1.

[0030] The specific steps for making all-crystal fiber and cladding by using the above-mentioned device are as follows:

[0031] (1) Use the microporous crystal growth method to obtain pure YAG microporous crystals with a length of 40-160mm, and the inner diameter of the microporous crystals is less than or equal to 1mm, or punch holes in the center of the pure YAG cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com