Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Avoid unstable product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thirty-spice condiment and preparation method thereof

The invention relates to a thirty-spice condiment and a preparation method thereof. The thirty-spice condiment comprises star anise, clove, zanthoxylum, costustoot, dried orange peel, villous amomum, fennel, cinnamon, rhizoma kaempferiae, galangal, amomum tsao-ko, rhizoma zingiberis, hot pepper, liquorice, white pepper, allspice, angelica root, rosemary, thyme, bay, cumin, long pepper, fenugreek,coriander, wrinkled giant hyssop, lesser galangal, purple perilla, schisandra chinensis, turmeric and fructus galangae. The thirty-spice condiment provided by the invention has a simple production process and is a raw material suitable for specific foods; and as the components are proportioned scientifically, the condiment has stronger taste as well as color, aroma and taste superior to general condiments, the cooking dosage can be effectively reduced, the nutrient components of the condiment are increased, the original tastes of the raw materials are highlighted, the self odor of the food isremoved, specific aroma is released in a cooking process and the aims of heightening appetite and promoting digestion are achieved.

Owner:关保昌

Tea intelligent blending method and system

ActiveCN106525849AQuality assuranceSolve the ratio optimal solution problemInvestigation of vegetal materialMaterial analysis by electric/magnetic meansFood qualityVisible near infrared

The invention discloses a tea intelligent blending method and a system, and belongs to the technical field of food quality rapid evaluation. According to the tea intelligent blending method and system, multi-sensor information bionic evaluation technology is adopted, a machine vision module, a visible near-infrared light spectrum module, and an electronic nose module in the tea intelligent blending system are used for obtaining shape, color, smell, taste, and infused leaf characteristic evaluation information of tea firstly, standard tea sample machine self-learning training is adopted to establish a tea blending index standard database; obtaining and quantization of the above characteristic evaluation information of raw materials of blended tea are realized, a multiply-optimized combined model is established, and an optimal tea blending scheme is designed based on comprehensive consideration of the conformity with a standard tea sample and the cost of the blending scheme, so that tea quality is ensured, and the best benefits are achieved at the same time. The tea intelligent blending method is capable of solving problems such as unstable product quality caused by artificial tea blending, providing an optimal solution for blending of a plurality of tea samples, and providing an intelligent solving scheme for complex blended tea.

Owner:JIANGSU UNIV

Fermentation type lobster seasoning and making method thereof

InactiveCN101919525APromote decompositionFacilitate dissociationFood preparationChemistryFermentation broth

The invention discloses a fermentation type lobster seasoning and a making method thereof. The method comprises the steps of: carrying out pretreatment and enzymolysis with lobster leftovers as raw materials, then carrying out fermentation with Lactobacillus helveticus capable of producing dipeptidase and tripeptidase, concentrating and extracting to prepare a compound amino acid nutritious fermentation liquor containing the active functional component of taurine; and mixing the nutritious fermentation liquor with a mixed liquid prepared from various spice herbaceous plants through the steps of frying, decocting, stewing and boiling, adding a food additive for blending, homogenizing, sterilizing to prepare the liquid or sauce type lobster seasoning. By adopting a biological technology to make the lobster seasoning, the invention overcomes the technological bottleneck on limiting the development of the lobster seasoning industry and provides a normalized and standardized making method of the special lobster seasoning, thereby promoting the rapid development of the lobster industry.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

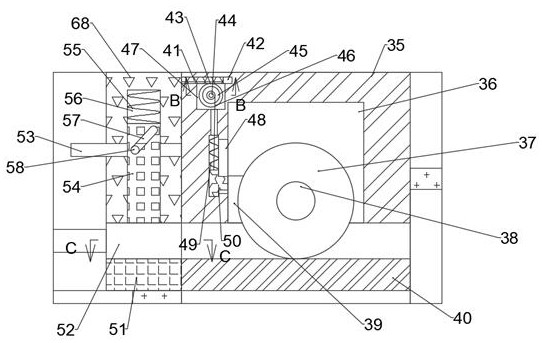

Multi-roller blanket belt type transfer printing device

ActiveCN103144420APrevent slippingAvoid unstable product qualityTransfer printingTransfer-treating textile partsAutomatic controlControl system

The utility model relates to a multi-roller blanket belt type transfer printing device, which comprises a center roller, a circular blanket belt, a guide roller, an online blanket belt cleaning and circulating system, a rectification device, a drying box and an automatic control system, wherein two ends of the center roller are fixed on a frame through bearings; a plurality of pressurizing rollers are distributed on the circumferential periphery of the center roller; a pressurizing device provides pressure for each of the pressurizing rollers independently; the circular blanket belt is wound on a plurality of supporting rollers and the plurality of pressurizing rollers; the pressurizing rollers is in pressurizing contact with the center roller through the blanket belt; a tensioning device provides tension for the blanket belt; the guide roller is arranged nearby an inlet and an outlet where the blanket belt is contacted with the center roller; the online blanket belt cleaning and circulating system is arranged in a circulation path of the circular blanket belt and comprises a blanket belt cleaning device, a scrapper and an oven; the rectification device is located on a guide roller nearby the inlet and then located in front of the inlet; the drying box is located at the outlet and then between a separation position of a fabric and a transfer printing carrier and a fabric rolling frame; and the automatic control system is used for controlling the speed of a spinning wheel, the tension of the blanket belt, the fabric and the transfer printing carrier, and the pressure of transfer rectification and pressurizing roller gradients.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

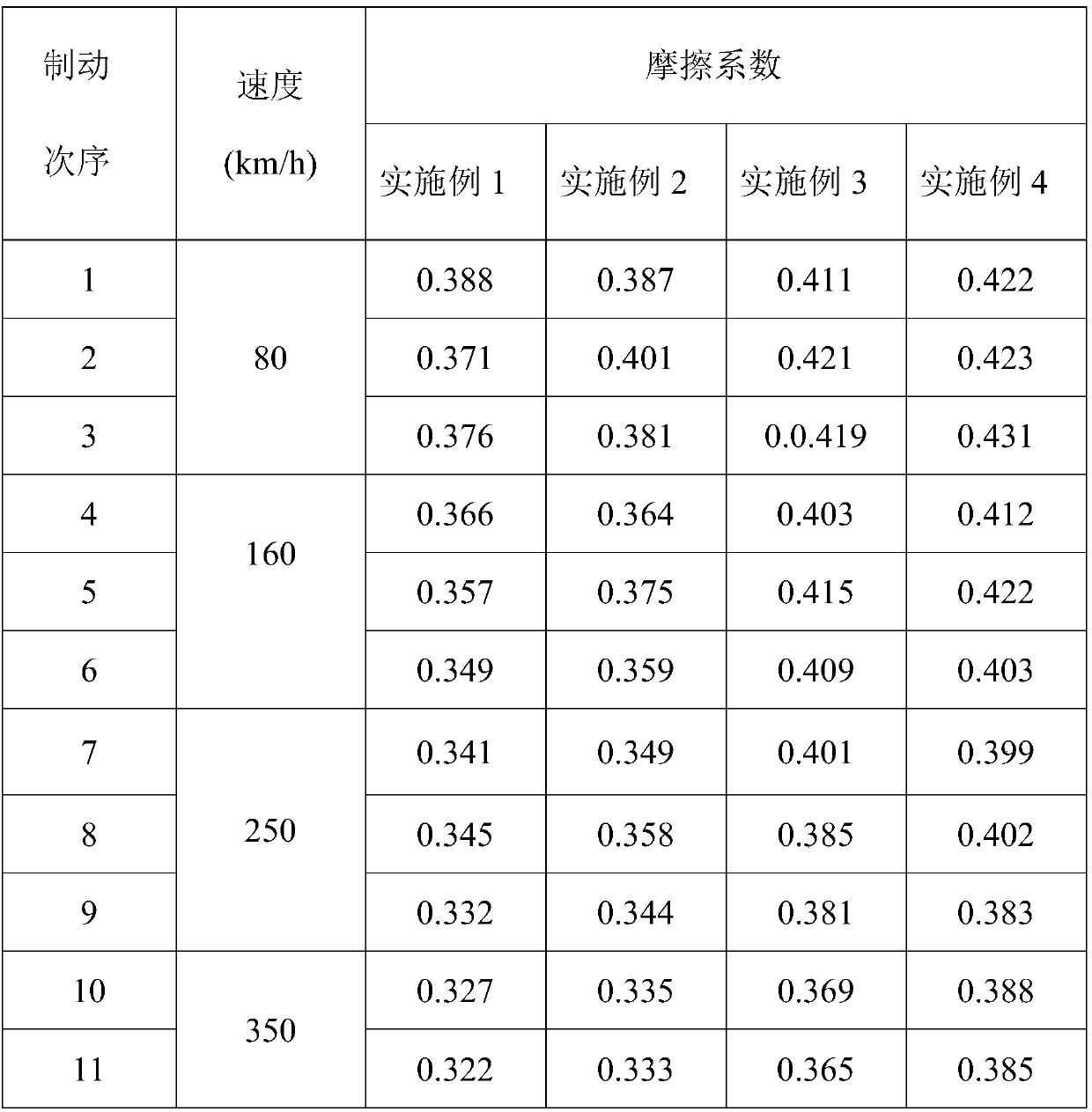

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

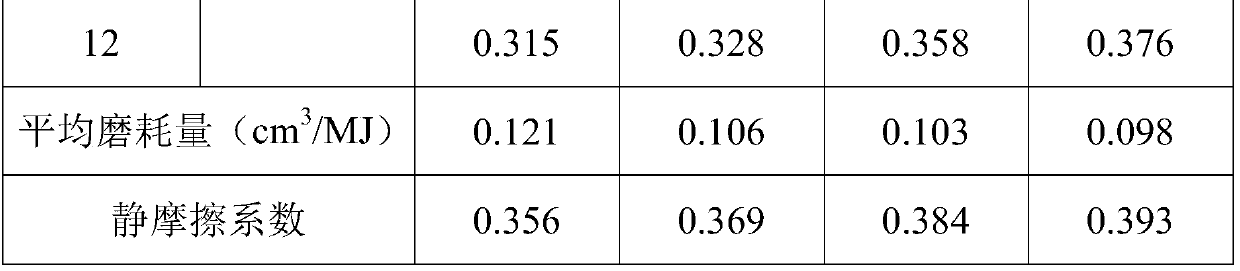

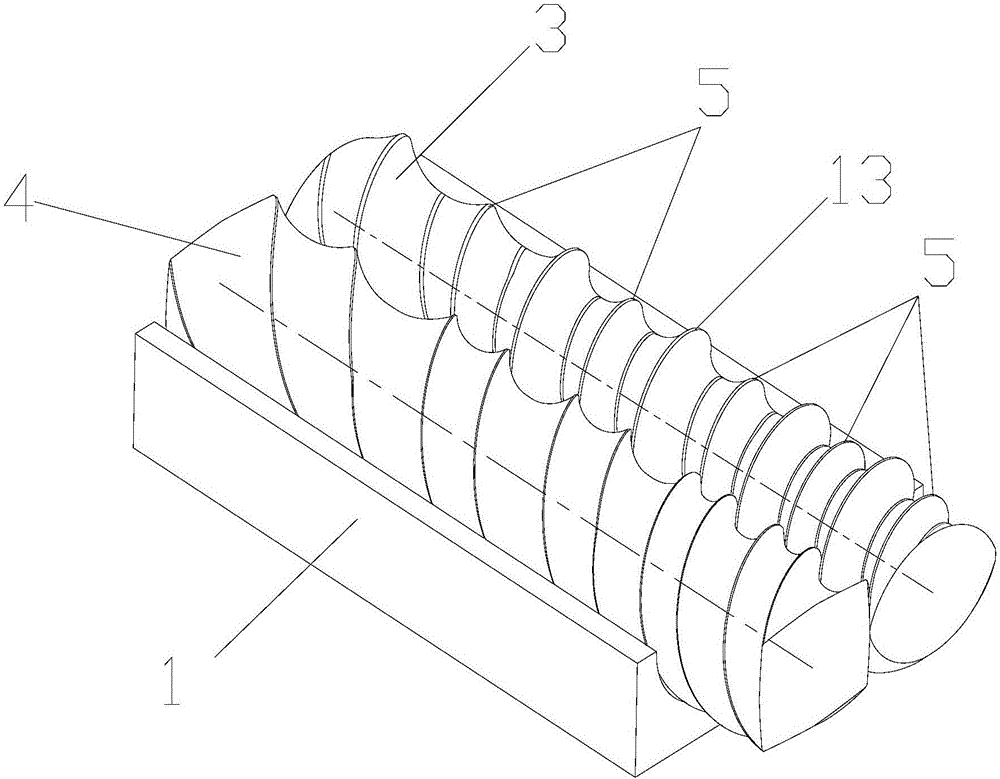

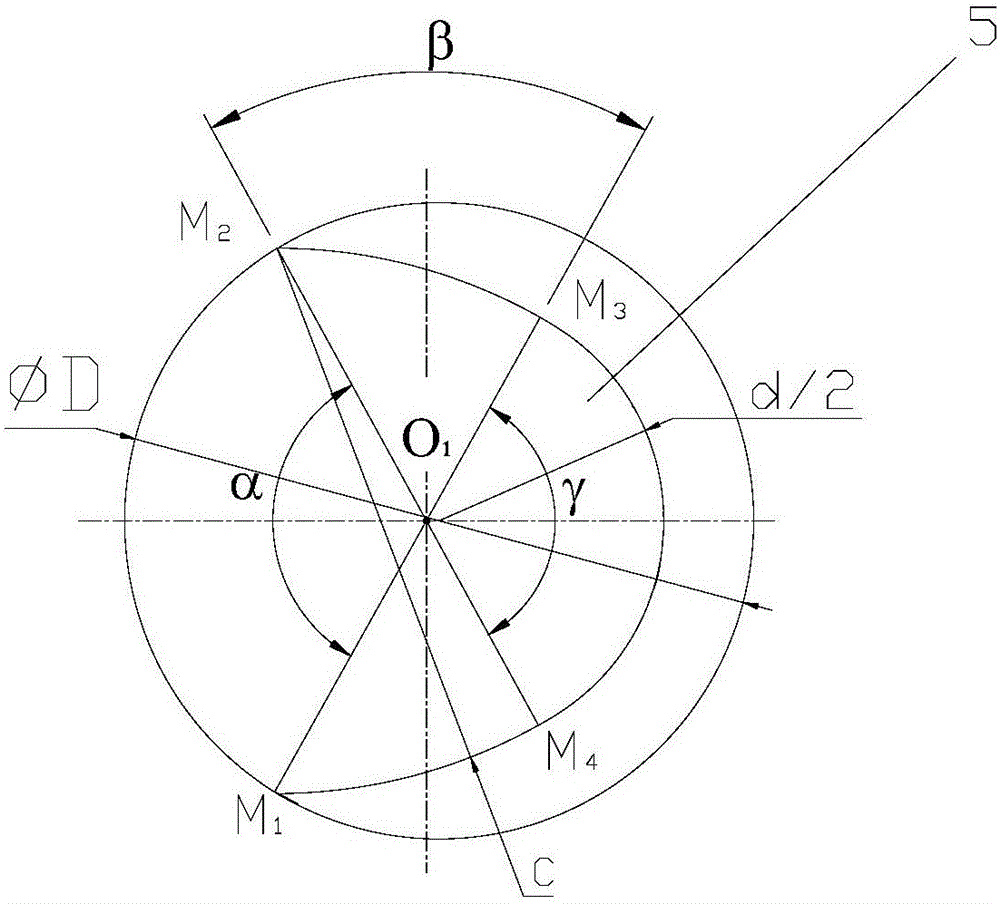

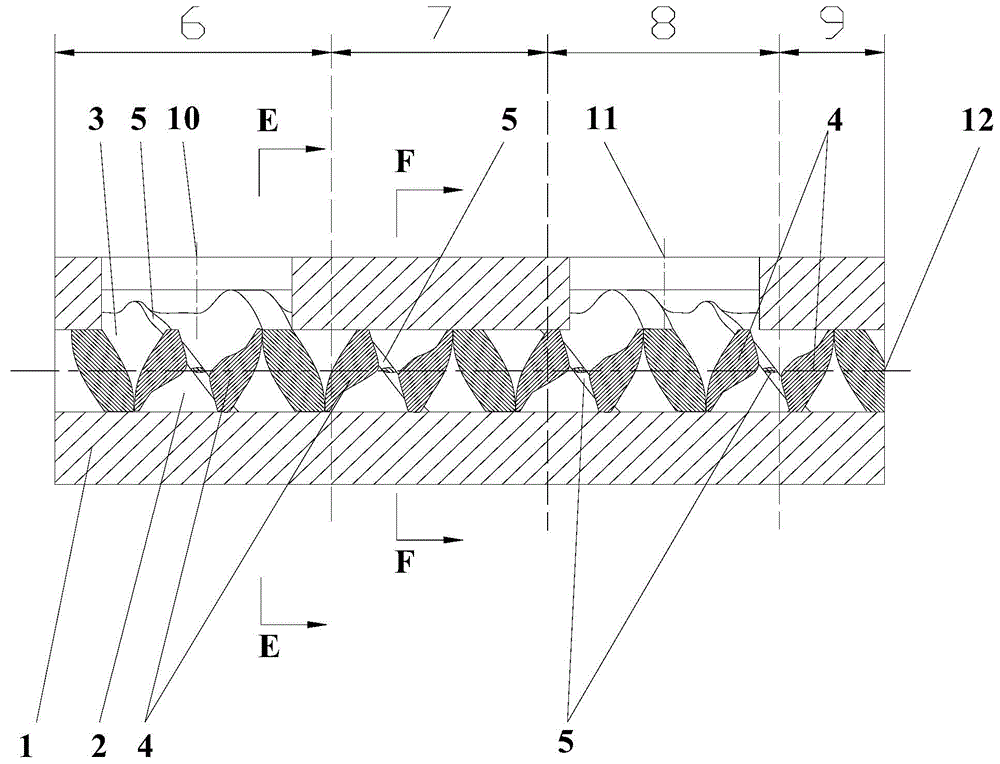

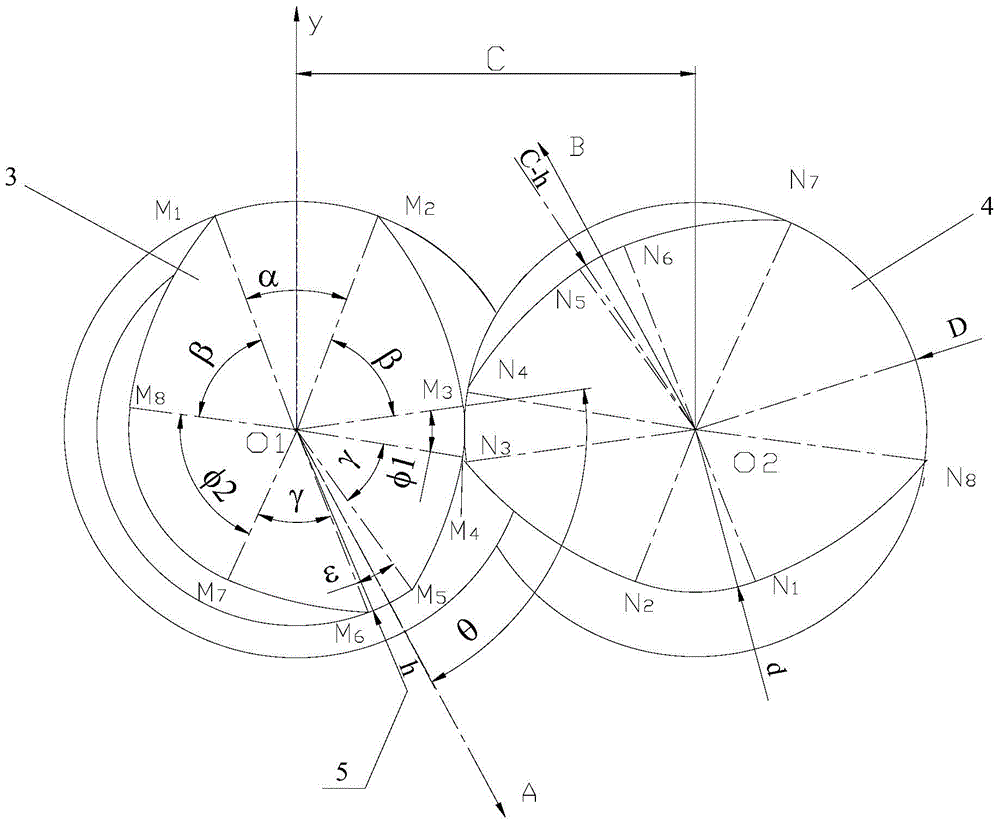

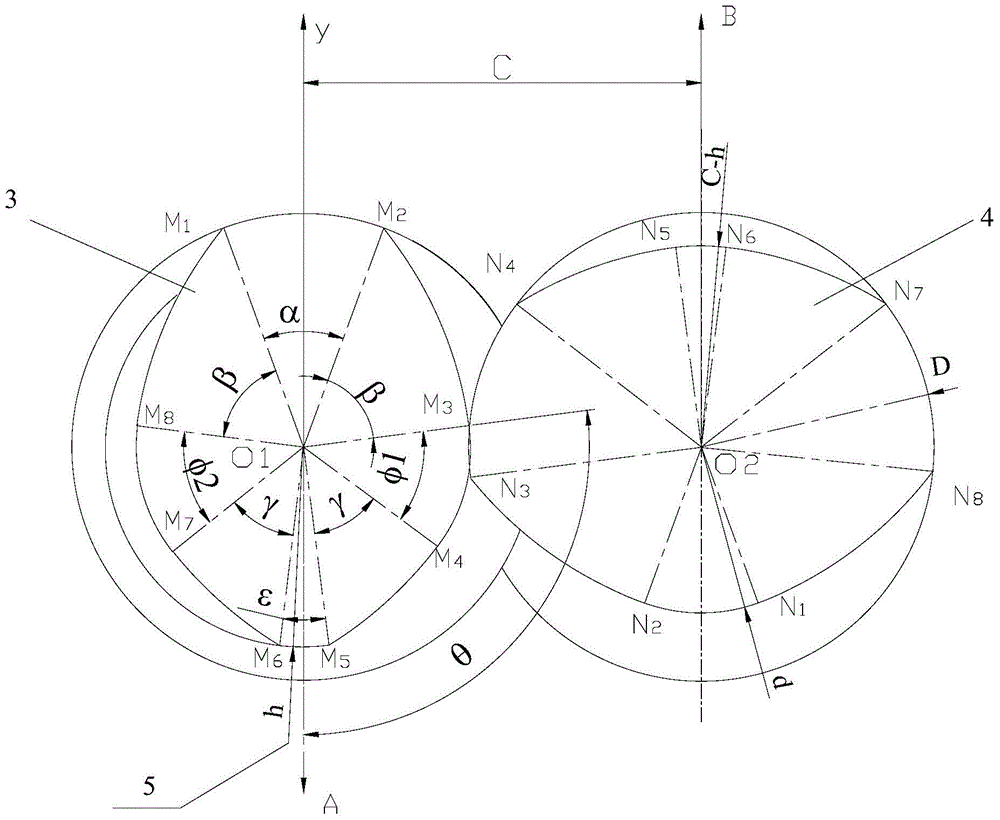

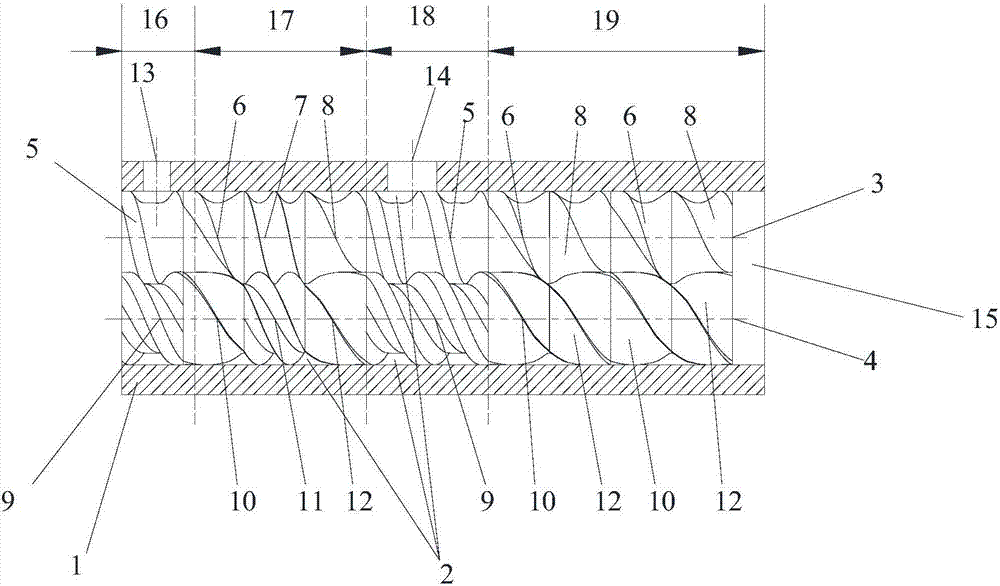

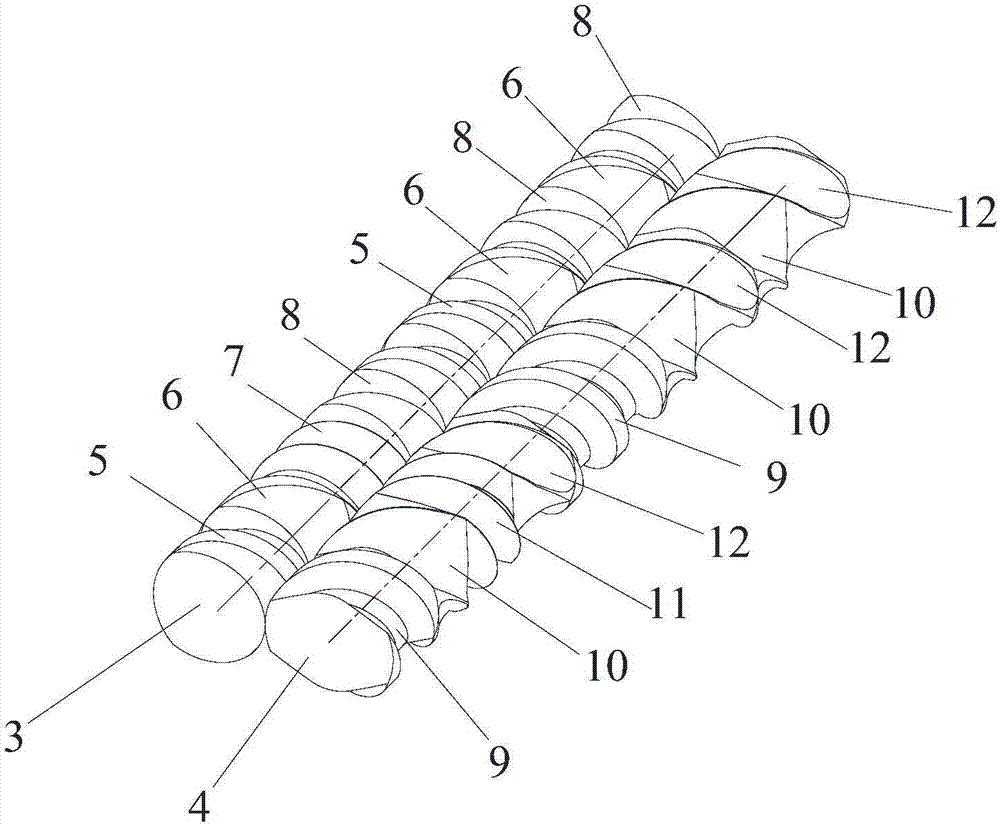

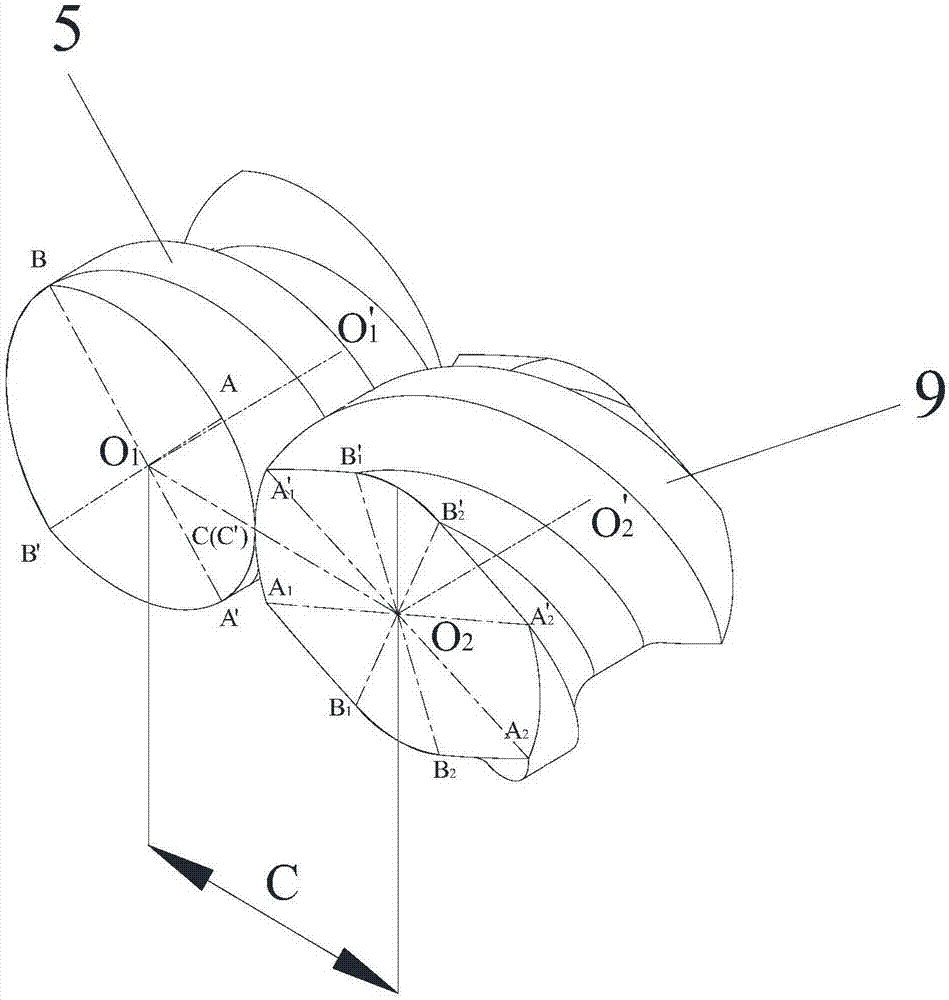

Embedded type short-screw-flight same-direction asymmetric multi-screw extruder and machining method thereof

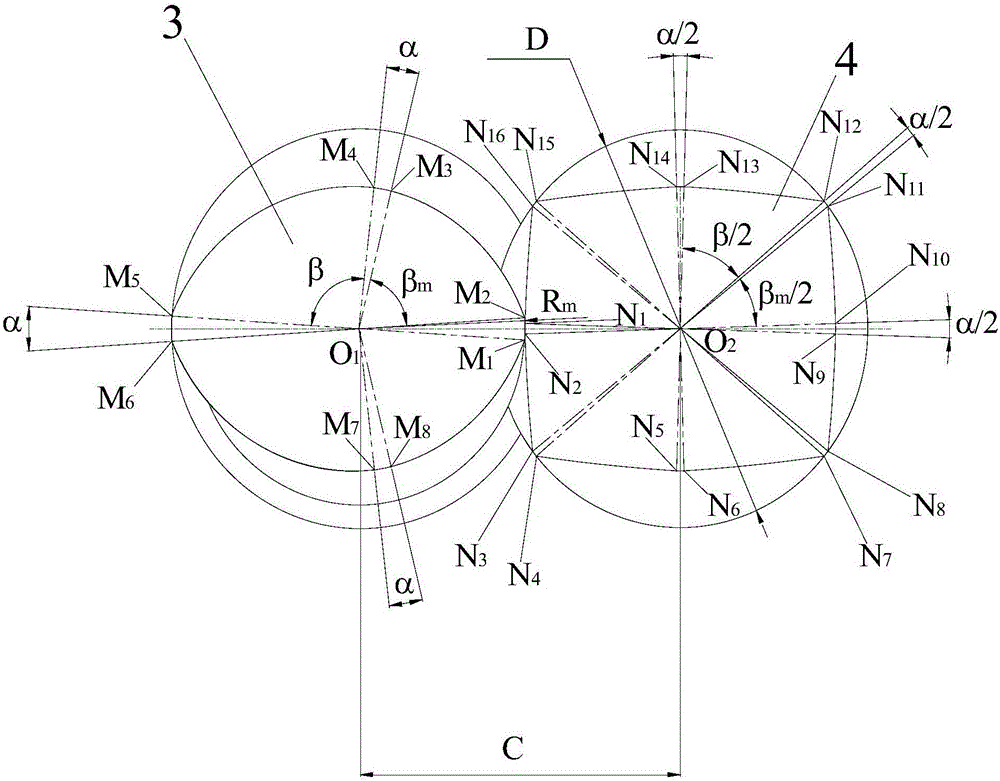

ActiveCN106476242AImprove delivery efficiencyAvoid unstable product qualityHomoclinic orbitEngineering

The invention discloses an embedded type short-screw-flight same-direction asymmetric multi-screw extruder and a machining method thereof. A screw mechanism in the extruder comprises a first screw and a second screw which are engaged with each other. The first screw is of a single-start thread structure, and the second screw is of a four-start thread structure. Embedded type short screw flights used as auxiliary screw flights are arranged in screw channel passageways each formed between two adjacent main screw flights in the first screw. The height of the auxiliary screw flights is smaller than or equal to the height of the main screw flights. According to the machining method of the embedded type short-screw-flight same-direction asymmetric multi-screw extruder, material conveying is achieved under the common effect of the axial positive displacement conveying force of the screw mechanism and the friction force between the first screw and the second screw. By means of the homoclinic orbit flow disturbance which is introduced through the embedded type short screw flights and shaped like the Arabic number '8', the whole-journey chaotic mixing in the screw channel passageways, the one-to-two topological chaotic effect formed by a passageway composed of the first screw and the second screw, the periodic compression and expansion effect generated by the passageways of the screw mechanism and the differential-speed rotation effect of the two screws are triggered, and the materials are sufficiently mixed, molten, mixed and plastified.

Owner:GUANGDONG IND TECHN COLLEGE

Method for microwave vacuum drying of edible bird's nests

InactiveCN103315294AIncrease productivityGuarantee product qualityDrying solid materials with heatFood preparationChemistryVacuum drying

The invention discloses a method for microwave vacuum drying of edible bird's nests. The method comprises the following steps of immersing raw edible bird's nests by RO water for 20-30min, manually and gently picking hair out of the edible bird's nests, carrying out secondary immersion of the edible bird's nests by clear water for 20-30min to obtain edible bird's nest cups, carrying out draining and setting of the edible bird's nest cups, drying them in a vacuum microwave dryer having a vacuum degree of 0.060Mpa and microwave power of 230KW for 30min, taking out the dried edible bird's nest cups in a cleaned work room, and carrying out grading, weighing and packaging. The method can effectively improve production efficiency, guarantee stable product quality, greatly improve a drying rate, solve the traditional drying method problem of unstable product quality and effectively improve production efficiency.

Owner:FUJIAN PINGANGE FOOD

Continuous alcoholysis and continuous transesterification recovery method of waste polyester material

ActiveCN110511137AImprove product qualityAvoid unstable product qualityOrganic compound preparationPreparation by ester-hydroxy reactionMolten stateRecovery method

The invention relates to a recovery method of a waste polyester material, particularly to a method for preparing dimethyl terephthalate (DMT) by chemically recovering waste polyester, and belongs to the technical field of waste polyester recycling. According to the method, a process comprising continuous feeding, continuous alcoholysis and continuous transesterification is adopted, such that materials are subjected to homogeneous alcoholysis in a molten state so as to achieve a short required alcoholysis time; more than two alcoholysis kettles are connected in series to carry out continuous alcoholysis, such that the alcoholysis product has stable quality; and the alcoholysis product continuously enters a transesterification kettle, and is subjected to a continuous transesterification reaction, and the EG generated by the transesterification reaction can be recycled in the alcoholysis step, such that the generation of side reactions and the unstable transesterification product qualityare avoided, and the purity and the yield of the waste polyester recovery product are greatly improved.

Owner:AVANTGARDE SHANGHAI ENVIRONMENTAL TECH CO LTD

Rhizopus strains, yeast strains, distiller's yeast containing same and production method for distiller's yeast

ActiveCN102041234AMeet different needsGuarantee standardized controlFungiMicroorganism based processesBiotechnologyMixed culture

The invention relates to rhizopus strains, yeast strains, distiller's yeast containing the same and a production method for the distiller's yeast. The invention relates to rhizopus oryzae strains CCTCC No: M209191 and CCTCC No: M209232, saccharomyces cerevisiae strains CCTCC No: M209190 and CCTCC No: M209231, and rice distiller's yeast containing the strains. The method for producing the rice distiller's yeast comprises the following steps of: inoculating the rhizopus strains and the yeast strains into a culture medium, and performing mixed culture to obtain mixed culture yeast; inoculating the rhizopus strains into the culture medium, and performing rhizopus culture to obtain pure yeast; and blending the pure yeast and the mixed culture yeast in a certain ratio to obtain the rice distiller's yeast. The rhizopus strains and the yeast strains have good adaptability during mixed culture. The method can meet different requirements of customers on mouthfeel, and meanwhile guarantees standard control of product quality.

Owner:ANGELYEAST CO LTD

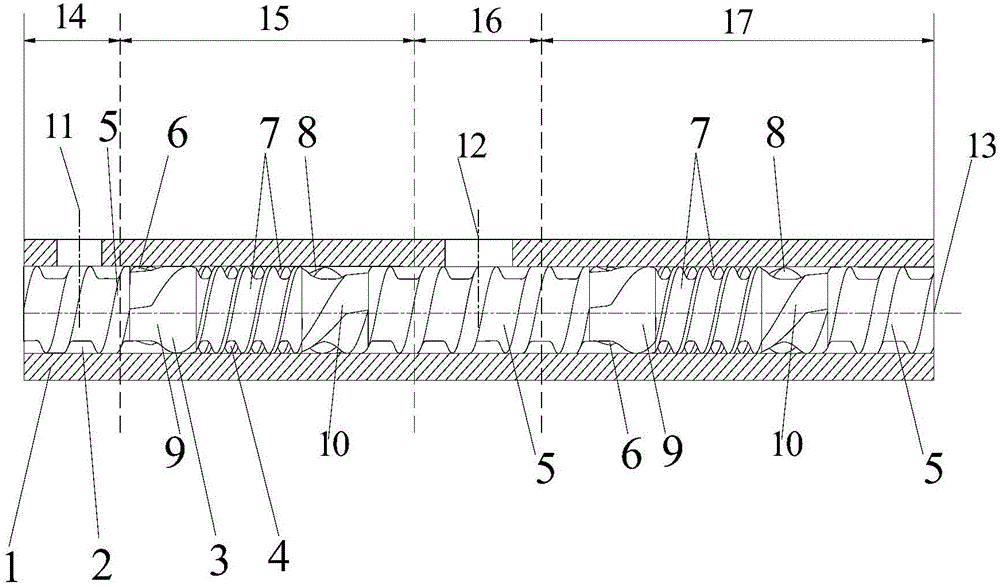

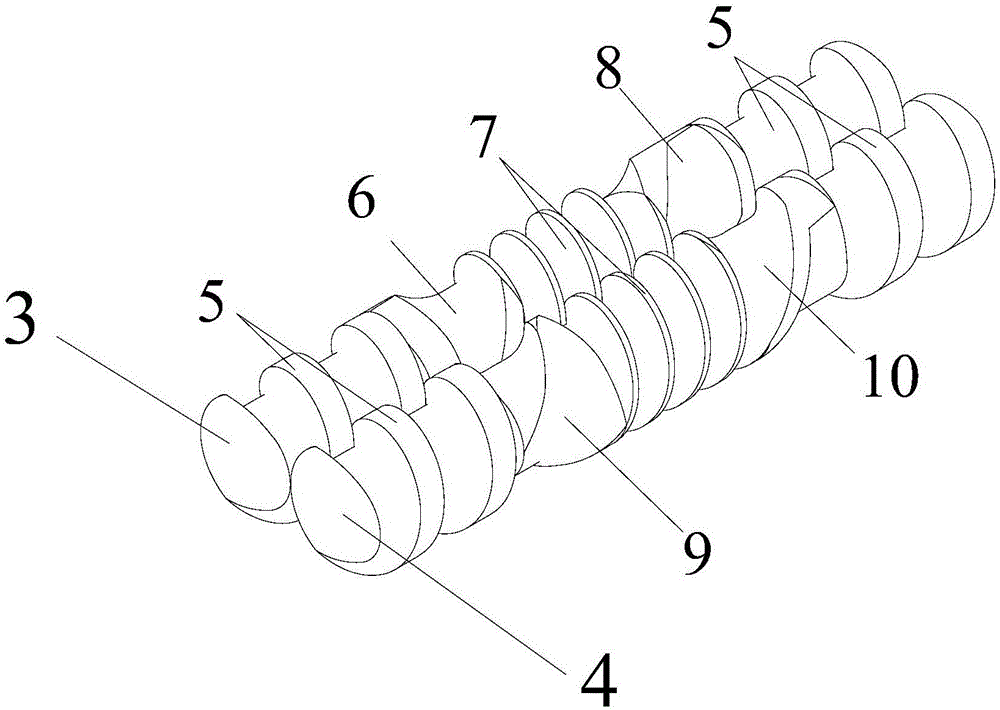

Homodromous self-cleaning double-screw extrusion machine with number of starts gradually changing and with whole-process self-cleaning function and machining method thereof

The invention discloses a homodromous self-cleaning double-screw extrusion machine with the number of starts gradually changing and with a whole-process self-cleaning function and a machining method thereof. A screw assembly of the extrusion machine comprises a first screw and a second screw, wherein the first screw and the second screw rotate at equal speed and in the same direction and are kept engaged. The first screw comprises a first single-start thread element, a first transitional element, a multi-start thread element, a second transitional element and a second single-start thread element which are connected in sequence. The second screw comprises a first single-start thread element, a third transitional element, a multi-start thread element, a fourth transitional element and a second single-start thread element which are connected in sequence. The machining method includes the steps that materials are conveyed through rotation of the first screw and the second screw, and constituents in the materials are promoted to be mixed through a structure of gradually changing numbers of starts of threads; a runner expands, contracts and expands again in sequence, so that the materials are divided, combined and divided again in the runner for chaotic mixing; self-cleaning is achieved through mutual wiping of the first screw and the second screw.

Owner:GUANGDONG IND TECHN COLLEGE

Same-direction self-cleaned twin-screw extruder with baffle plates and processing method thereof

ActiveCN104527025AImprove delivery efficiencyAvoid unstable product qualityTransportation and packagingRotary stirring mixersFistEngineering

Owner:GUANGDONG IND TECHN COLLEGE

LCM process DC resistance real-time monitoring method

InactiveCN1851451ALearn about curingAvoid unstable product qualityMaterial resistanceElectrical resistance and conductanceWaste product

The invention relates to LCM technology DC resistance real time monitoring method. It includes the following steps: pre-molding cross laying laser wire and inducing wire determine monitoring point; applying DC voltage to the two sides of the point and connecting ratio resistance to form divider circuit, measuring the voltage of the resistance that could be gathered and displayed by PC, the tested pre-molding body resistance would be gained after calculating; taking resin filling mould and recycling scanning all the monitoring points to judge the arrival of the resin flow peel; after filling mould, the pre-molding resistance of every monitoring point is increased, monitoring the alteration of the body resistance, the resin solidifying situation would be monitored. The invention could decrease defective percent, improve product quality, and effectively solve the product quality unstable problem in the producing of resin based compound material.

Owner:BEIHANG UNIV

Continuous nylon polymerization process

ActiveCN112062950AIncrease productivityOvercome the disadvantages of intermittent productionPlastic recyclingPolymer sciencePolyamide

The invention provides a continuous nylon polymerization process, which comprises the following polymerization raw materials in parts by mass: 5-60 parts of polymerization monomer dibasic acid and / ordibasic acid ester, 3-50 parts of diamine and 10-90 parts of reactive dispersion medium polyamide. According to the process, the raw materials are continuously added into a screw extrusion device in aweight metering or volume metering mode, so that the polymerization monomers react in the molten dispersion medium and are uniformly mixed; and then the mixture enters a subsequent polymerization device to be continuously polymerized until the nylon resin reaches the required molecular weight. According to the invention, melting reaction mixing of the raw materials is completed in the screw extrusion device, the bottleneck of melt polymerization production efficiency can be solved by utilizing the advantages of high heat dissipation and mixing efficiency of the screw extrusion device, and thenylon polymerization process is efficient, green and environmentally friendly.

Owner:CHENGDU 401 TECH CO LTD

Method for preparing tri(1,3-dichloro-2-propyl) phosphonate

ActiveCN108997416AHigh catalytic efficiencyEasy to recyclePhosphorus organic compoundsDistillationFire retardant

The invention provides a method for preparing tri(1,3-dichloro-2-propyl) phosphonate, which relates to the technical field of a preparation method of a fire retardant. The method adopts a self-made catalyst, and uses phosphorus oxychloride and 1,3-dichloro-2-propanol as a raw material, and adopts the following steps: phosphorus oxychloride, 1,3-1,3-dichloro-2- propanol and the self-made solid acidcatalyst are added to a reaction kettle, the materials are heated to the temperature of 100-160 DEG C for 4-6 hours, the generated hydrogen chloride gas is distilled under vacuum of -0.2-0 MPa, a crude product is washed with alkali, washed with water, and is subjected to underpressure distillation to remove water. A reaction equation is shown as the specification. The raw materials of the invention are easy to obtain, the catalyst has good catalytic performance, the product has high purity, the yield is high, the reaction is mild, the operation is simple, and the product is more suitable forindustrial production.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

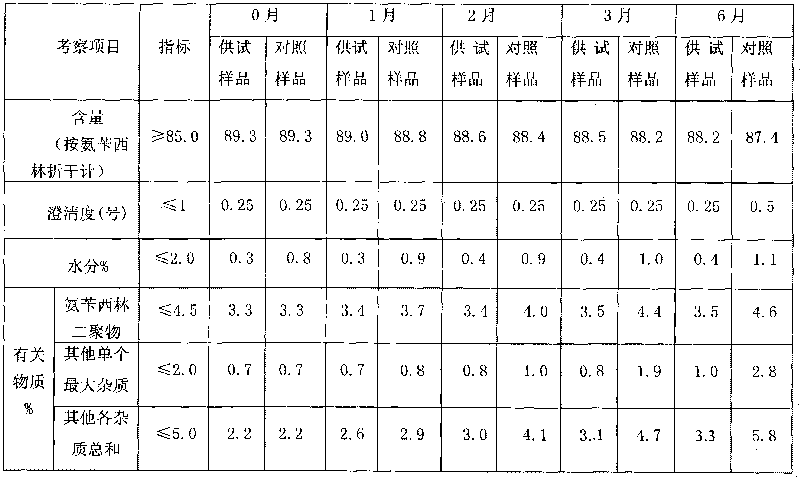

Method for preparing ampicillin sodium salt

ActiveCN101723957AOvercome the shortcomings of unstable product qualityHigh purityAntibacterial agentsOrganic chemistryOrganic solventSolvent

The invention discloses a method for preparing an ampicillin sodium salt. In the method, the general refrigerating and drying process has an additional post-treatment step of milling ampicillin sodium which is refrigerated and dried under vacuum into powder, filling the powder into a bipyramid, vacuumizing the bipyramid, heating the powder, keeping the temperature of the powder between 45 and 95 and the heat preservation time between 40 and 180 minutes and mixing the powder and separately packing the mixed powder. The method of the invention overcomes the drawback of instable quality of the products prepared by the traditional refrigerating and drying method and prepares high-purity, low-hygroscopicity and stable-quality ampicillin sodium raw material and preparation. The method is simple in process, avoids consuming a large amount of organic solvent like a solvent crystallization method and recovering the organic solvent and therefore has low cost.

Owner:华北制药集团先泰药业有限公司

Fusarium oxysporum BM201, compound pectinase produced by fusarium oxysporum BM201 and preparation method and application of compound pectinase

InactiveCN104498372AHigh removal rateIncrease productivityFungiMicroorganism based processesFusarium oxysporumChemistry

The invention provides fusarium oxysporum BM201, compound pectinase produced by the fusarium oxysporum BM201 and a preparation method and application of the compound pectinase. The fusarium oxysporum is fusarium oxysporum BM201; the Latin Name of the fusarium oxysporum is Fusarium oxysporum; the preservation number of the fusarium oxysporum is CGMCC No.9108. The Fusarium oxysporum BM201 provided by the invention is capable of simultaneously producing multiple pectinases such as polygalacturonase, pectate lyase, pectinesterase, cellulase and hemicellulase to form the compound pectinase. By virtue of coordinated proportion and mutual action of various enzymes in the compound pectinase, the removal rate of the peels of the fruits can be increased when the compound pectinase is utilized for removing peels of plants and fruits, and the production efficiency can be improved. The strain can be further used for decomposing waste residues such as fruit peels, so that the environmental pollution is alleviated, and the waste is recycled.

Owner:SHAOYANG UNIV +1

Co-rotating differential multi-screw extruding machine with gradually changing type thread number and machining method thereof

InactiveCN107031015AFacilitate interface updatesIncrease the exhaust areaDifferential equationEngineering

The invention discloses a co-rotating differential multi-screw extruding machine with the gradually changing type thread number and a machining method thereof. A first threaded rod in the extruding machine comprises two single-start thread elements, three single-start-gradually-changed-to-double-start transition thread elements, a double-start thread element and three double-start-gradually-changed-to-single-start transition thread elements; and a second threaded rod comprises two double-start thread elements, three double-start-gradually-changed-to-four-start transition thread elements, a four-start thread element and three four-start-gradually-changed-to-double-start transition thread elements. According to the machining method, a threaded rod mechanism achieves five enhancement mixing mechanisms by adopting the structure of the threaded rod mechanism, and conducts all-sided enhancement mixing on materials.

Owner:徐百平

Grafting reaction device and molten grafting reaction method

The invention discloses a grafting reaction device. The grafting reaction device comprises film casting equipment, grafting addition agent dispersion pre-reaction equipment and reactive extrusion grafting equipment, wherein the film casting equipment is used for extruding a premixed material in a mixed mode and casting the premixed material into a polymer film; the grafting addition agent dispersion pre-reaction equipment is used for dispersing grafting addition agents onto the polymer film and making the grafting addition agents have a pre-grafting reaction with the polymer film; the reactive extrusion grafting equipment is used for grafting functional monomers to a polymer molecule chain to form a graft polymer. According to the grafting reaction device, the polymer is cast to form the film, the grafting addition agents are dissolved in a dispersing agent and sprayed on the molten polymer film in a mist spray mode, the pre-grafting reaction happens to the surface of the molten polymer film, a grafting reaction is completely conducted in the reactive extrusion grafting equipment, a trace of the grafting addition agents are uniformly dispersed, the intercoupling probability of free radical active points of the polymer is lowered when the material is constantly sheared in a screw rod and an interface is updated so that the occurrence probability of crosslinking side reactions can be lowered, and the graft polymer which is high in grafting ratio, small in fisheye quantity and small in smell is obtained.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Continuous nylon polymerization method

ActiveCN112390945AIncrease productivityOvercome the disadvantages of intermittent productionPlastic recyclingPolymer sciencePolyamide

Owner:CHENGDU 401 TECH CO LTD

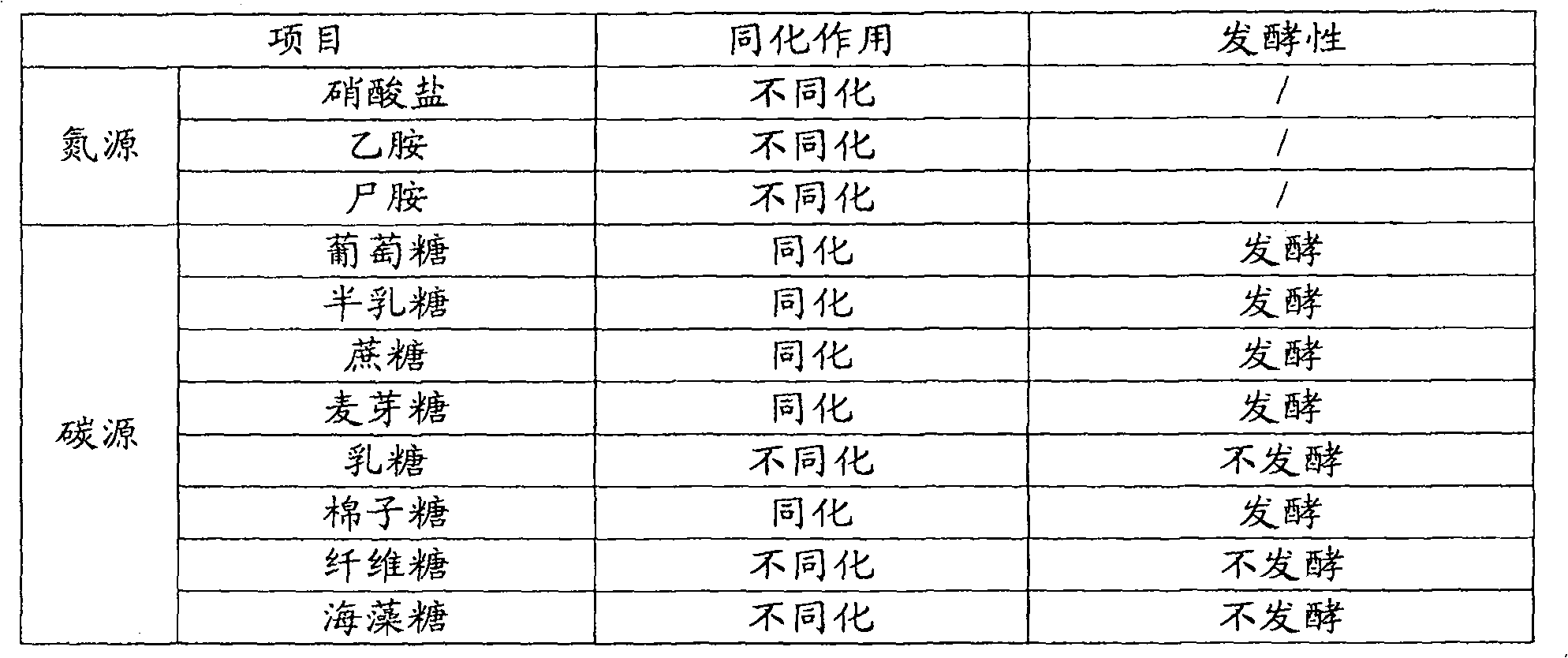

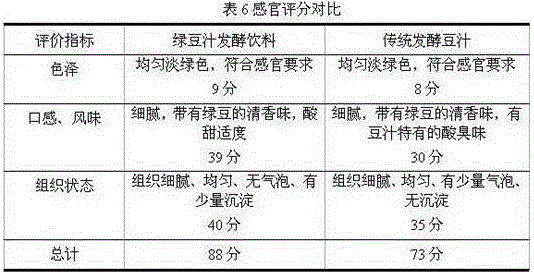

Lactobacillus lactis subsp.Lavtis LLY003, and applications thereof in living bacterium-type mung bean juice fermented beverage

ActiveCN106399164AGrow fastIncrease acidityBacteriaMicroorganism based processesNutritionFood flavor

The invention discloses Lactobacillus lactis subsp.Lavtis LLY003. Nutritional requirement of Lactobacillus lactis subsp.Lavtis LLY003 is simple, it is suitable for Lactobacillus lactis subsp.Lavtis LLY003 to grow in mung bean starch supernate prepared via only adding of a carbon source, and Lactobacillus lactis subsp.Lavtis LLY003 is capable of achieving key effects in bean juice fermentation. Lactobacillus lactis subsp.Lavtis LLY003 is capable of growing rapidly in bean juice fermentation, generating acid, and simplifying fermentation process, is suitable for production under existing conditions of the domestic manufacturers, and is capable of shortening production period. Pure bacterium fermentation of bean juice is capable of increasing safety factor and nutritional value of bean juice greatly; and flavor substances generated via lactobacillus metabolism are capable of improving the flavor of bean juice. Lactobacillus lactis subsp.Lavtis LLY003 is capable of maintaining the natural faint scent of mung bean; and the obtained living bacterium-type mung bean juice fermented beverage is a functional beverage high in nutritional value.

Owner:JINZHOU MEDICAL UNIV

Preparation method of rose ferment fermented with pure strains

PendingCN108902951AAvoid unstable product qualityImproves antioxidant activityFood scienceFlavorLactobacillus plantarum

The invention discloses a preparation method of rose ferment fermented with pure strains, and belongs to the technical field of food processing. The rose ferment is prepared from roses as a main raw material by the following steps: adding white granulated sugar and water, performing uniform mixing, performing sectional inoculation with patent strains lactobacillus plantarum and saccharomyces cerevisiae, and performing fermentation in a sealed container. The obtained rose ferment stock solution is free of artificially synthesized pigments, spices and preservatives, has a natural rose red color,strong and pure rose fragrance and sour, sweet and fresh mouthfeel, and has the effects of regulating intestinal florae, beautifying skin, keeping youthfulness and the like after being drunk for a long term.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Automatic control system and method for controlling reflux of light component removal rectifying tower

ActiveCN103418156AAvoid wastingAvoid unstable product qualityDistillation regulation/controlAutomatic controlEngineering

The invention provides an automatic control system for controlling the reflux of a light component removal rectifying tower. The automatic control system comprises a reflux drum communicated with a rectifying tower, an executing mechanism arranged on a discharge pipeline of the reflux drum and used for regulating the reflux ratio of fractions in the reflux drum, a pressure controller for acquiring the pressure value of the rectifying tower and providing the pressure control variable for a signal selector according to the pressure value, a temperature controller for acquiring the temperature value of the reflux drum and providing the temperature control variable for the signal selector according to the temperature value, and the signal selector for receiving the pressure control variable and the temperature control variable, and selecting one of the variables to control the opening of the executing mechanism. Through the correlation of the temperature and the pressure parameter in the system with the action of the discharge valve of the reflux drum, the action of the discharge valve is controlled in real time according to the state in the system, so that the product quality unstability or the material waste due to excessive emission is avoided.

Owner:BLUESTAR BEIJING TECH CENT +1

Automatic water transfer printing equipment for canvas shoes batch

InactiveCN112477392AHigh degree of automationAvoid unstable product qualityTransfer printingOther printing apparatusWater transferManufacturing engineering

The invention discloses automatic water transfer printing equipment for canvas shoe batch which. The automatic water transfer printing equipment comprises a transfer printing box, and a transfer cavity is formed in the transfer printing box; a first communicating cavity penetrating through the inner wall of the upper side of the transfer cavity is formed in the inner wall of the upper side of thetransfer cavity, and a first sliding groove cavity with a rightward opening is formed in the inner wall of the left side of the transfer cavity; a first electric sliding rail, a second electric sliding rail and a third electric sliding rail with forward openings are arranged on the inner wall of the rear side of the transfer cavity, and a second communicating cavity penetrating through the inner wall of the right side of the transfer cavity is formed in the inner wall of the right side of the transfer cavity; and a feeding device is arranged in the second electric sliding rail. According to the automatic water transfer printing equipment, transfer paper is mechanically intercepted through the equipment, and floats on the surface of water; the shoes are fixed to the designated positions, and then water transfer printing can be conducted on the vamps of the shoes; since the equipment automation degree is high, the product quality instability due to manual manufacturing is avoided; meanwhile, the water transfer printing efficiency can be greatly improved, the production period is shortened, and the production cost is reduced.

Owner:胶州市硕通针织有限公司

Production method of bulk ingredient-expanded sinking aquatic feed

InactiveCN107149056ANo drying process requiredImprove ripenessWorking-up animal fodderFood additivePrill

The invention relates to a production technology of sinking aquatic feed molded by carrying out extruding expansion and ring die pelletizing on a bulk ingredient. The production technology comprises the steps of carrying out efficient tempering and extruding expansion on mixed powder which is free from a heat-sensitive component and a feed additive, so as to cure the bulk ingredient, cooling, finely crushing and then adding the heat-sensitive component and the feed additive; after that, tempering, pelletizing and molding. The sinking aquatic feed processed by the method has the advantages of high curing degree, stable quality, easy quality control, and less loss of the heat-sensitive component compared with expanded sinking pellet feed; furthermore, a ring die pelletizing process is adopted in granule formation, so that an aquatic feed expander and a drying machine do not need to be arranged, and steam consumption is further greatly reduced; the formula is wide in adaptability, and high-starch formula sinking feed is easily produced.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Bio-organic fertilizer for watermelon planting and production method thereof

InactiveCN107082688AIncrease productionImprove qualityExcrement fertilisersBioloigcal waste fertilisersMicrobial agentAdditive ingredient

The invention provides bio-organic fertilizer for watermelon planting, prepared from the following raw materials according to a weight proportion: 20 to 30 parts of kitchen waste, 20 to 30 parts of cottonseed meal, 5 to 10 parts of peanut shell, 4 to 8 parts of chicken manure, 10 to 15 parts of sawdust, 5 to 10 parts of sugar residue, 3 to 5 parts of rapeseed cake powder, 0.1 to 1 part of microbial agent, 0.01 to 0.05 part of plant growth promoter and 1 to 2 parts of trace element; the bio-organic fertilizer for watermelon planting is comprehensive and balanced in nutritional ingredient, and is easy to absorb by watermelon crops, thus enhancing the drought resisting and disease-and-pest-resisting capabilities of the watermelon crops and improving the yield and quality of watermelons. The invention also provides a production method of the bio-organic fertilizer for watermelon planting; by adopting the production method, the technical problems that during organic fertilizer production by using biomass resources, raw material characters are instable, and material decomposing is not thorough are solved, the fertilizer efficiency of the organic fertilizer is improved, and meanwhile the pollution of wastes to pollution is avoided.

Owner:TAICANG LVFENG BIOLOGICAL ORGANIC FERTILIZER CO LTD

Production method of high-purity furfuryl alcohol

InactiveCN102417494AUnique methodIncrease production capacityOrganic chemistryHydrogen pressureControl system

The invention relates to a production method of furfuryl alcohol, in particular to a production method of high-purity furfuryl alcohol. The method is characterized by comprising the following steps of: uniformly mixing furfuryl alcohol with a catalyst; boosting to 7-9 MPa with an injection pump; preheating to 130-150 DEG C with a preheater and entering a reaction tower; starting a hydrogen compressor; raising the hydrogen pressure from 1 MPa to 7-9 MPa; controlling the bottom temperature of the reaction tower at 190-205 DEG C through the steam amount of the preheater; controlling the top temperature of the tower to be lower than 145 DEG C through the tower top cooling water amount; controlling the pressure of a system at 7.4-7.9 MPa through the return hydrogen amount; reacting the furfuryl alcohol and hydrogen in the reaction tower under control; cooling with a condenser and feeding into a high-pressure separator; discharging crude furfuryl alcohol from the lower part of the main high-pressure separator; discharging the crude furfuryl alcohol into a temporary storage groove through a low-pressure separator; and settling the crude furfuryl alcohol for 24 hours, separating the catalyst out by using the separator, and entering continuous rectification to obtain high-purity furfuryl alcohol of which the purity is over 98.5 percent. In the production method, low free furfuryl alcohol is produced, high intensity is achieved, and the production procedure is environmentally-friendly and free from three wastes.

Owner:KOCEL GROUP +1

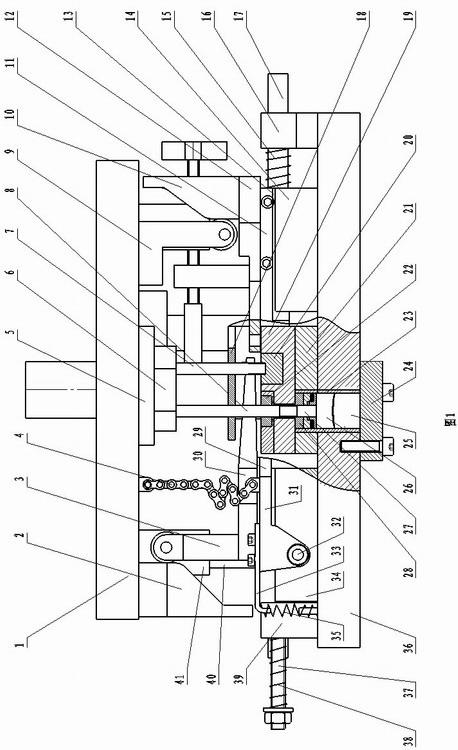

Explosion proof aluminous shell stamping forming die of capacitor

InactiveCN101770873AAvoid wastingSolve the problem that adjustment maintenance affects productionShaping toolsCapacitor manufactureEngineeringMachine tool

The invention discloses an explosion proof aluminous shell stamping forming die of a capacitor. A clamp thereof is movably installed in a clamp guide seat through a clamp slide block, a return spring is installed between the clamp slide block and the clamp guide seat, a driving piece and a driven piece are installed between an upper template and the clamp slide block, the clamp guide seat is provided with a clamp return limitation piece, and a flexible traction piece is connected between the clamp return limitation piece and the upper template; a feeding piece thereof is movably installed in a feeding piece guide seat through a feeding piece slide block, a return spring is installed between the feeding piece slide block and the feeding piece guide seat, a driving piece and a driven piece are installed between the upper template and the feeding piece slide block, and a feeding limitation plate which extends into a moving space of the clamp slide block is also connected to the feeding piece slide block. Compared with the prior art, the invention has the advantages of simple structure and convenient maintenance and can be conveniently installed on an ordinary punch machine to use so as to replace a special explosion proof aluminous shell stamping forming machine tool.

Owner:梁惠新 +1

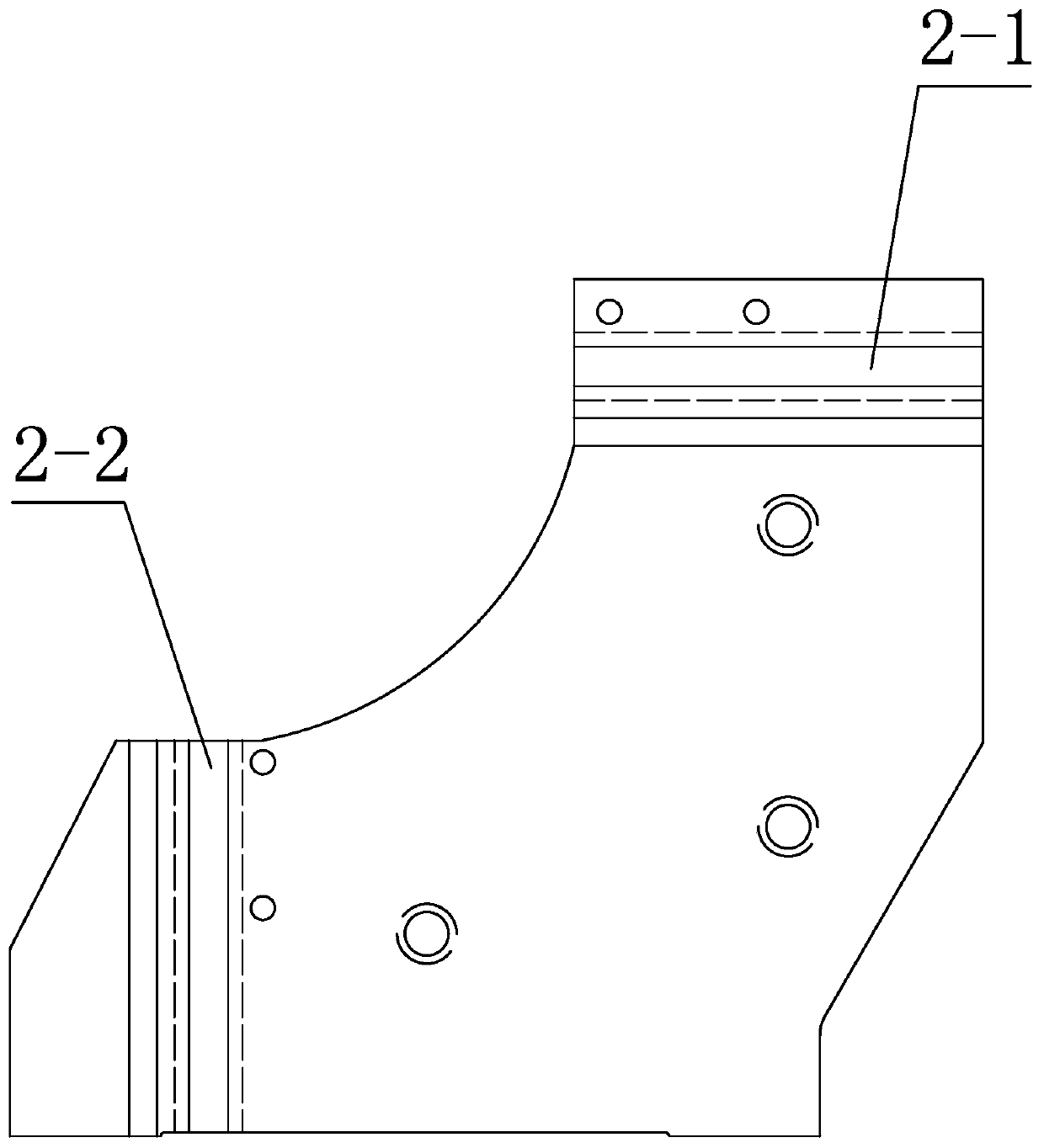

Bearing ring grinding tool and method

InactiveCN110774069ASolve the problem of unstable grinding qualityImprove grinding qualityRevolution surface grinding machinesGrinding drivesStructural engineeringIndustrial engineering

The invention discloses a bearing ring grinding tool and a method, and relates to the field of bearing manufacturing. The bearing ring grinding tool and the method solve the problems in the prior artthat when the inner surface of a bearing ring is ground, process parameters cannot be fixed, the tool adjustment time is long, and the part machining quality is unstable. The end face of a positioningdatum reference scale panel is provided with a scale disc, a pivot base is fixed to the positioning datum reference scale panel through a main positioning pin and an auxiliary positioning pin, and anadjustment knob comprises a first cylinder, a second cylinder and a pointer; the second cylinder is eccentrically arranged on the end face of the first cylinder, the pointer is arranged on the outercircumference of the first cylinder, the adjustment knob is installed on the positioning datum reference scale panel, a centering shaft is installed on the adjustment knob, the outer diameter of the centering shaft is the same as the size of the outer circle of a machined ring, a horizontal pivot is slidably installed in a horizontal pivot slot, and a vertical pivot is slidably installed in a vertical pivot slot. The bearing ring grinding tool and the method are used for stabilizing and improving the grinding quality of the inner surface of the ring.

Owner:AVIC HARBIN BEARING

Control method with deviation rate adjustment function

InactiveCN104714565APrecise adjustment and controlSolve product instabilityLevel controlEngineeringLiquid level sensor

The invention provides a control method with a deviation rate adjustment function, and belongs to the field of mineral separation control. The control method is realized through a laser liquid level sensor, a PLC and a pneumatic adjustment valve, wherein the input of the pneumatic adjustment valve is connected with the output of the PLC, the input of the PLC is connected with the output of the laser liquid level sensor, the laser liquid level sensor is arranged inside a floating cell, and the pneumatic adjustment valve is connected with an ore pulp input pipe. By the adoption of the control method, adjustment control is accurate and the phenomena of unstable production and unstable product quality can be avoided.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Preparation method and device for powdery fatty acid methyl ester sodium sulfonate

InactiveCN105254540AUniform appearance and sizeAvoid unstable product qualitySulfonic acids salts preparationEvaporation by sprayingSulfonateCold air

The invention relates to a preparation method and device for powdery fatty acid methyl ester sodium sulfonate. The invention aims at providing the method capable of realizing the MES granularity basically identical to that of washing powder. The device has the characteristic of a simple and compact structure. The preparation method for powdery fatty acid methyl ester sodium sulfonate has the technical scheme that the preparation method for powdery fatty acid methyl ester sodium sulfonate is carried out according to the following steps that (1) water-containing MES materials are conveyed to an atomizer to be dried; (2) a powder body enters a cooling section, is cooled by cold air and is then discharged from the bottom of a tower; (3) a powdery fatty acid methyl ester sodium sulfonate product is obtained. The preparation device of the powder fatty acid methyl ester sodium sulfonate comprises a cyclone separator, a cloth bag dust remover and a drying tower, wherein the atomizer is arranged between a sedimentation section and a drying section; a plurality of hot air inlets are formed between the drying section and a cooling section; exhaust openings are sequentially communicated with the cyclone separator and the cloth bag separator; the bottom of the cooling section is provided with a cold air inlet; the bottom end of the cooling section is also sequentially communicated with a fluidized bed, a crushing machine and a powder cabin through pipelines.

Owner:JIAXING ZANYU TECH DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com