Same-direction self-cleaned twin-screw extruder with baffle plates and processing method thereof

A technology of twin-screw extruders and baffles, applied to mixers with rotating stirring devices, chemical instruments and methods, mixers, etc., can solve the lack of main part of screw channel volume, high shear of kneading blocks, and product Unstable quality and other problems, to achieve the effect of strengthening the mixing and mixing and heat transfer process, improving the axial mixing effect, and saving energy and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

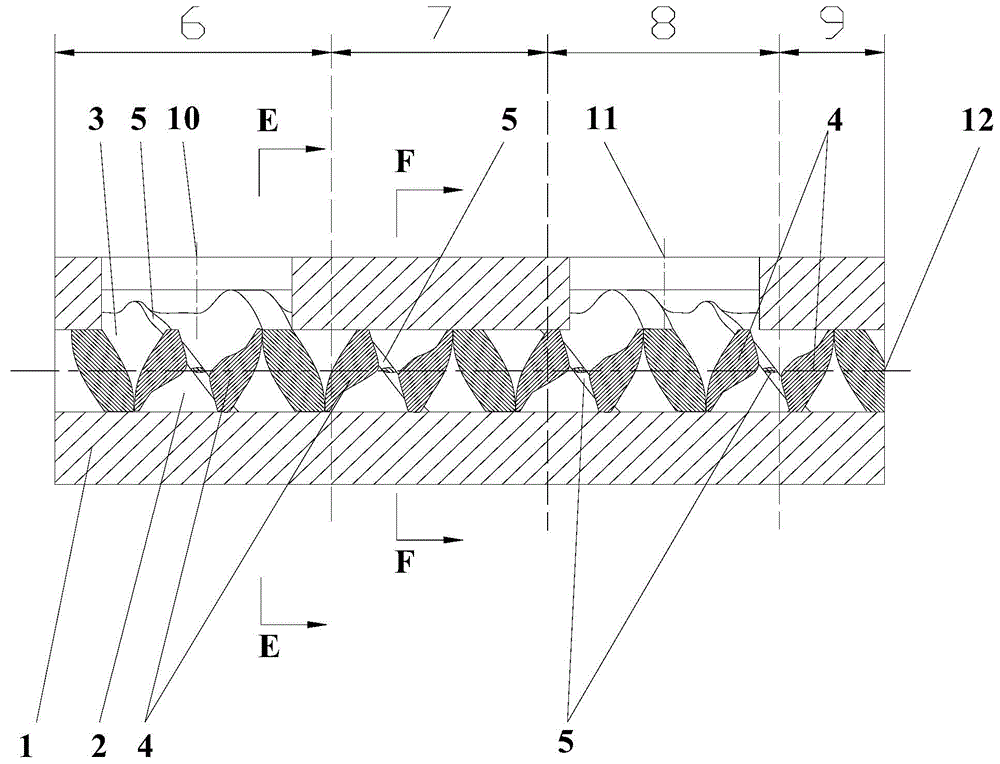

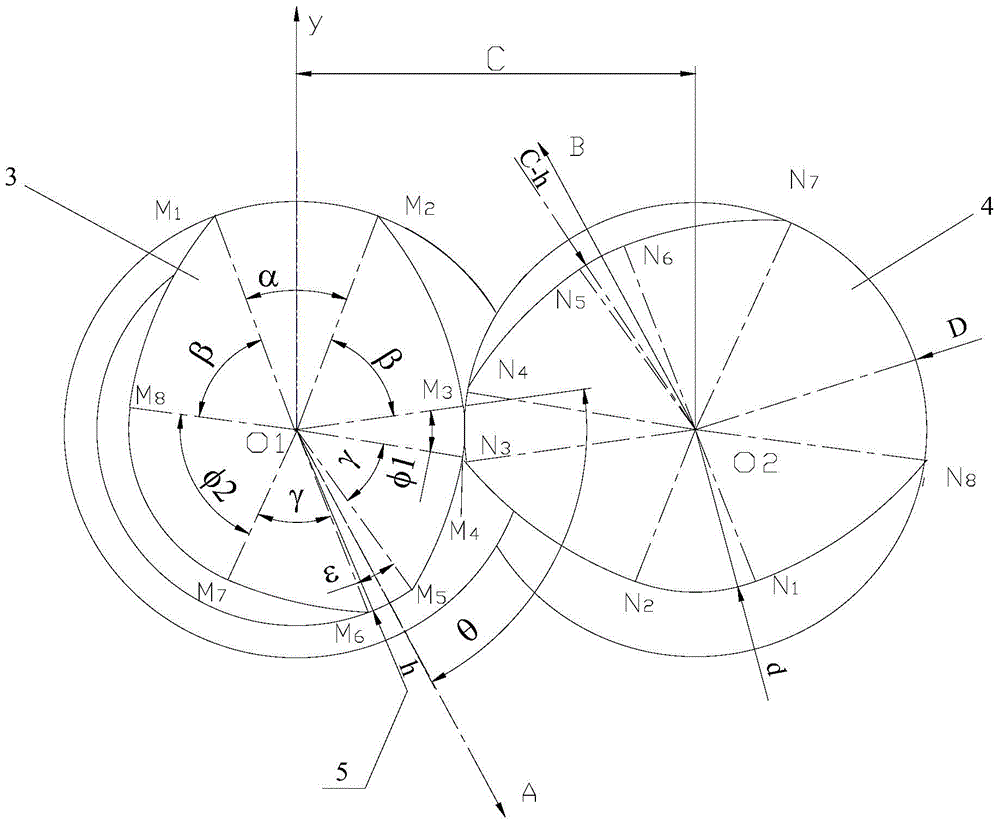

[0042] Such as Figure 1-7 As shown, in this embodiment, a co-directional self-cleaning twin-screw extruder with a baffle includes a barrel 1 and a screw mechanism, the screw mechanism is arranged in the inner chamber 2 of the barrel, and the screw mechanism includes intermeshing The first screw rod 3 and the second screw rod 4, the first screw rod is a single thread structure, and the second screw rod is a double thread structure; the screw groove of the first screw rod is provided with a baffle plate 5, and the height of the baffle plate is smaller than that of the first screw rod. The groove depth of the screw, the groove of the first screw forms a "8"-shaped hyperbolic flow disturbance flow line at the baffle (such as Figure 5 , 6 or shown in 7); the first screw and the second screw rotate at the same speed and keep meshing at all times, the thread structure of the first screw and the baffle form a self-cleaning mode between the screw grooves of the second screw, and the...

Embodiment 2

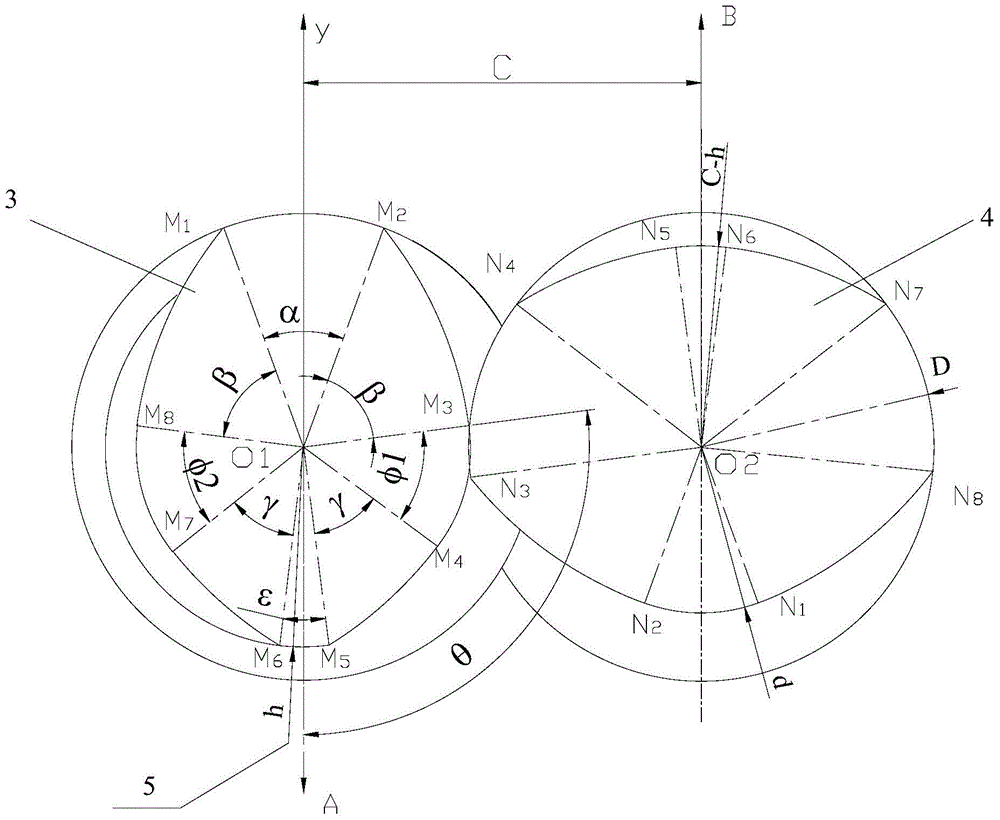

[0064] This embodiment is a co-rotating self-cleaning twin-screw extruder with baffles. Compared with Embodiment 1, the difference is that, with the change of the axial position of the baffles, the extreme The angle value is fixed; the structure of the screw mechanism and part of the barrel is as follows Figure 8 or Figure 9 shown.

Embodiment 3

[0066] This embodiment is a co-rotating self-cleaning twin-screw extruder with baffles. Compared with Embodiment 1, the difference is that, with the change of the axial position of the baffles, the extreme The angle value presents a nonlinear periodic change, and its functional relationship is as follows:

[0067] θ = θ min + ( θ max - θ min ) sin zπ L , 0 ≤ z ≤ L .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com