Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Transfer-treating textile parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

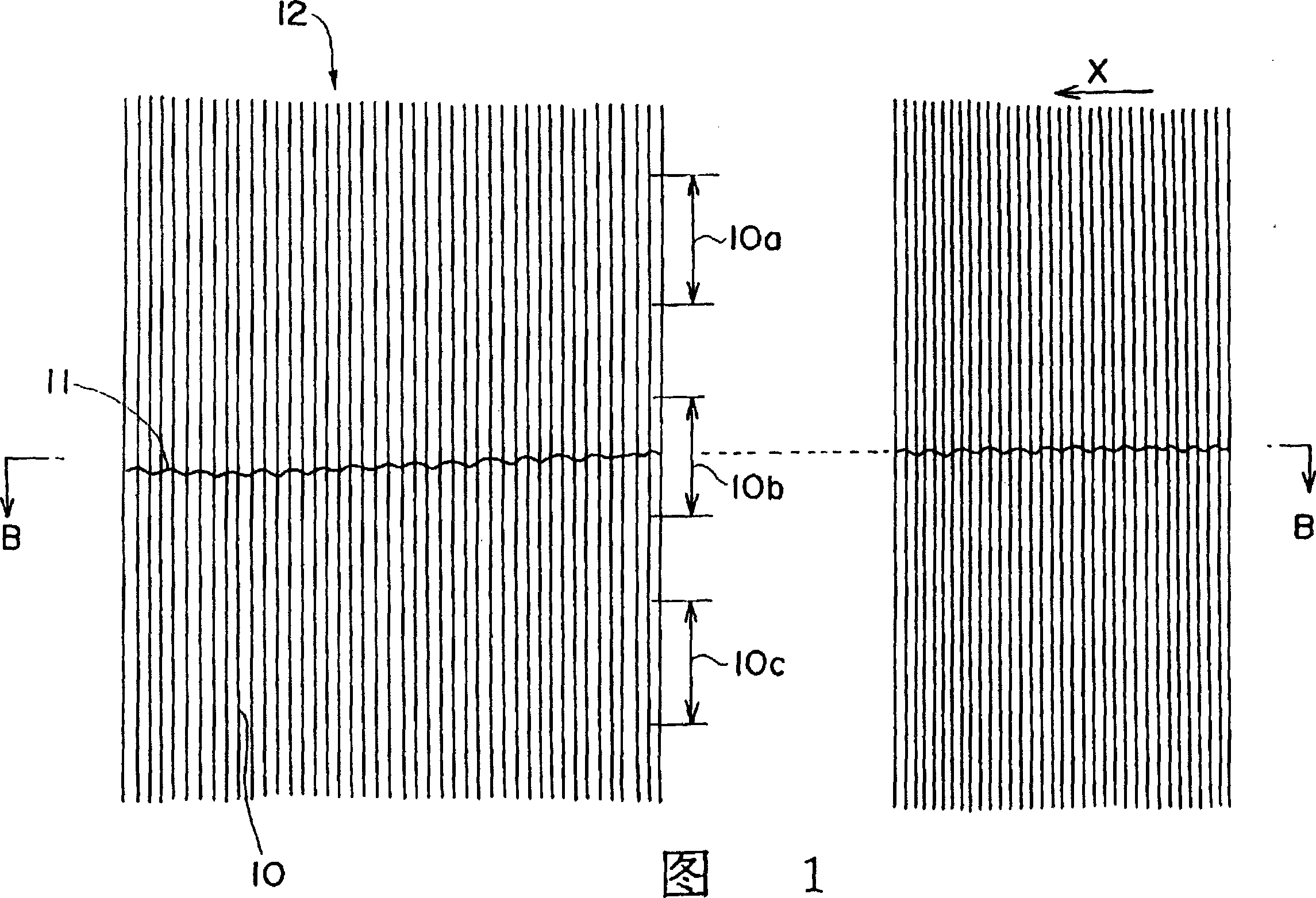

Realistically textured printed flocked fabrics and methods for making the fabrics

InactiveUS7229680B1Improve visual effectsDegree of reductionLiquid surface applicatorsLamination ancillary operationsEngineeringTransfer printing

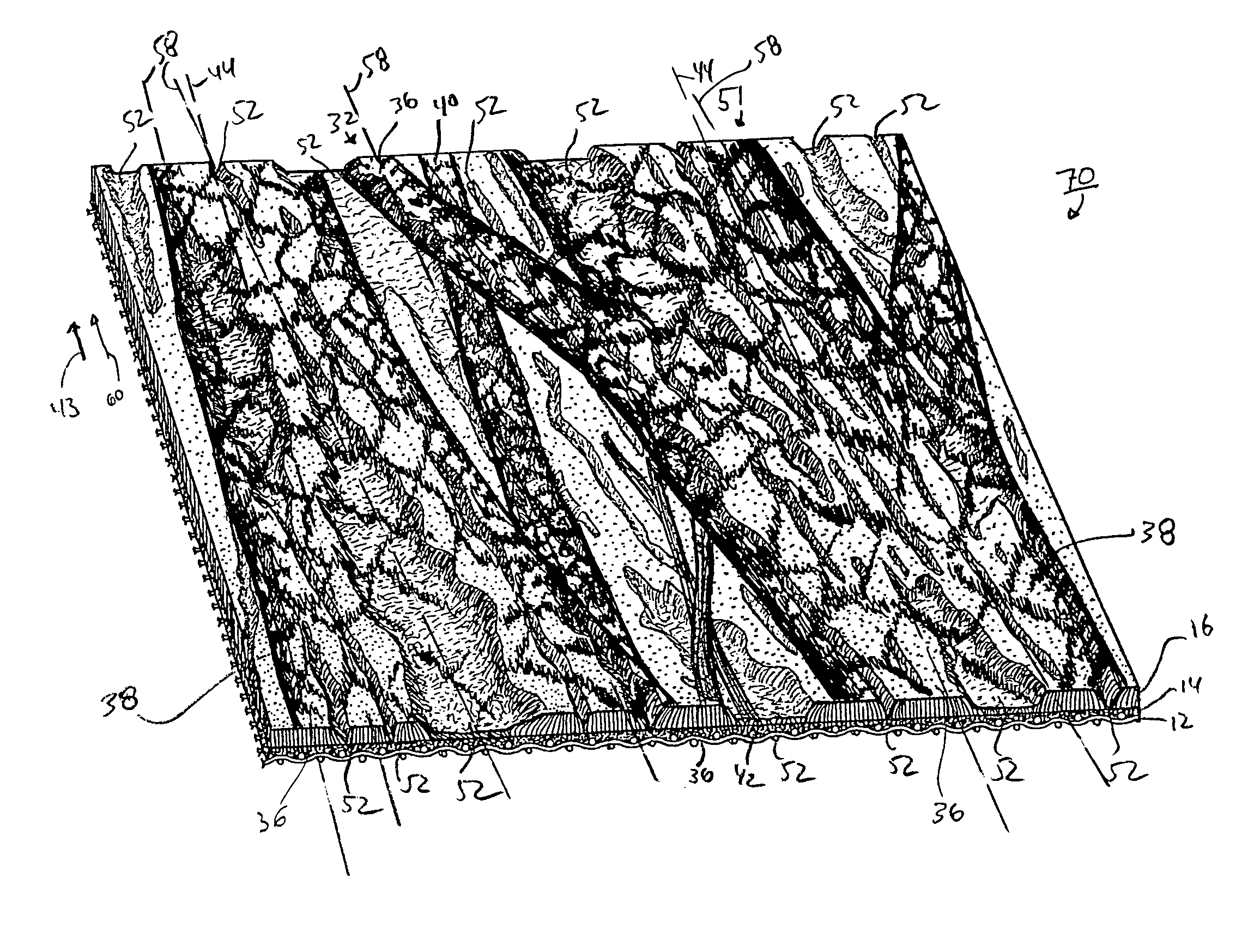

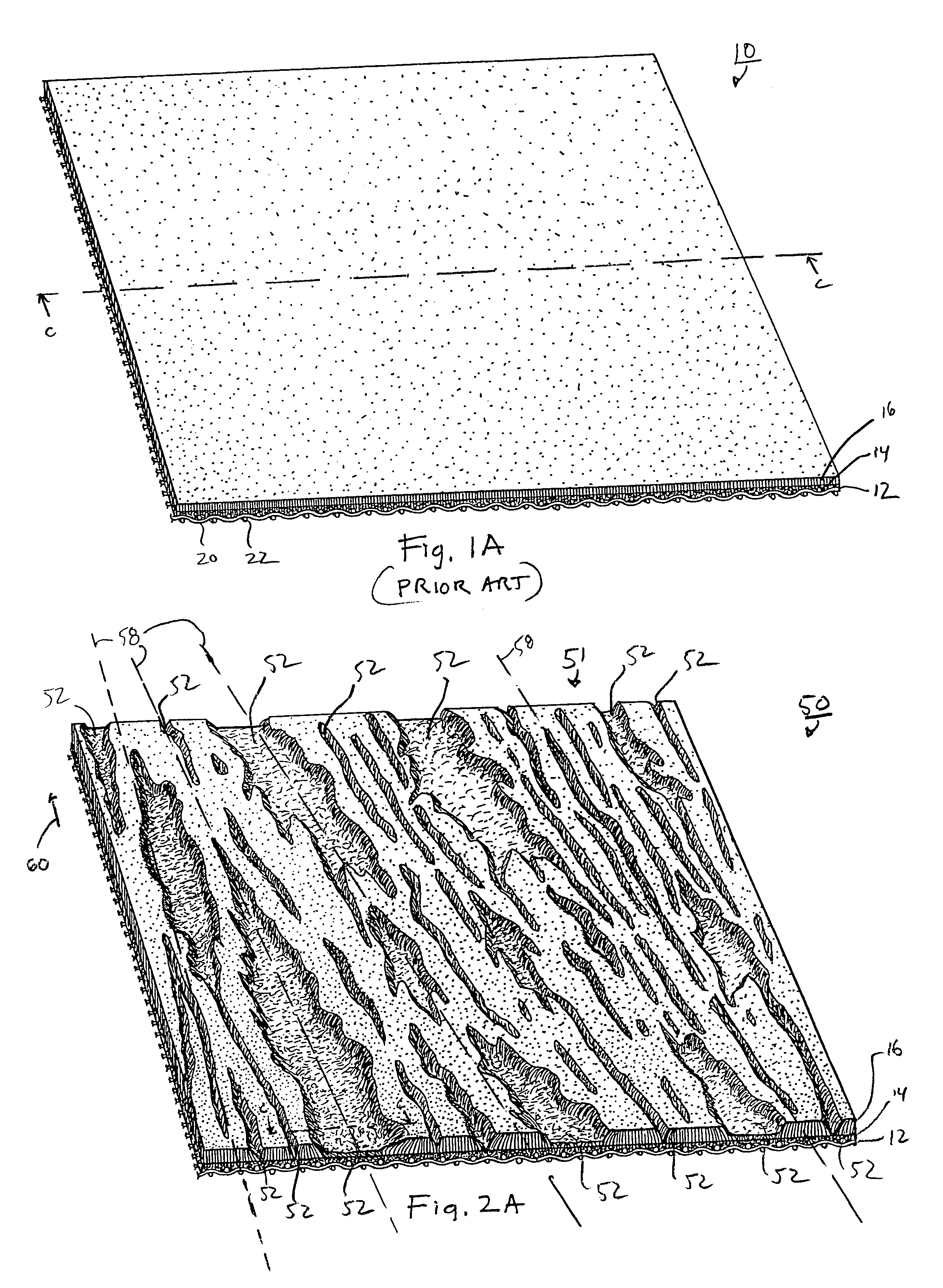

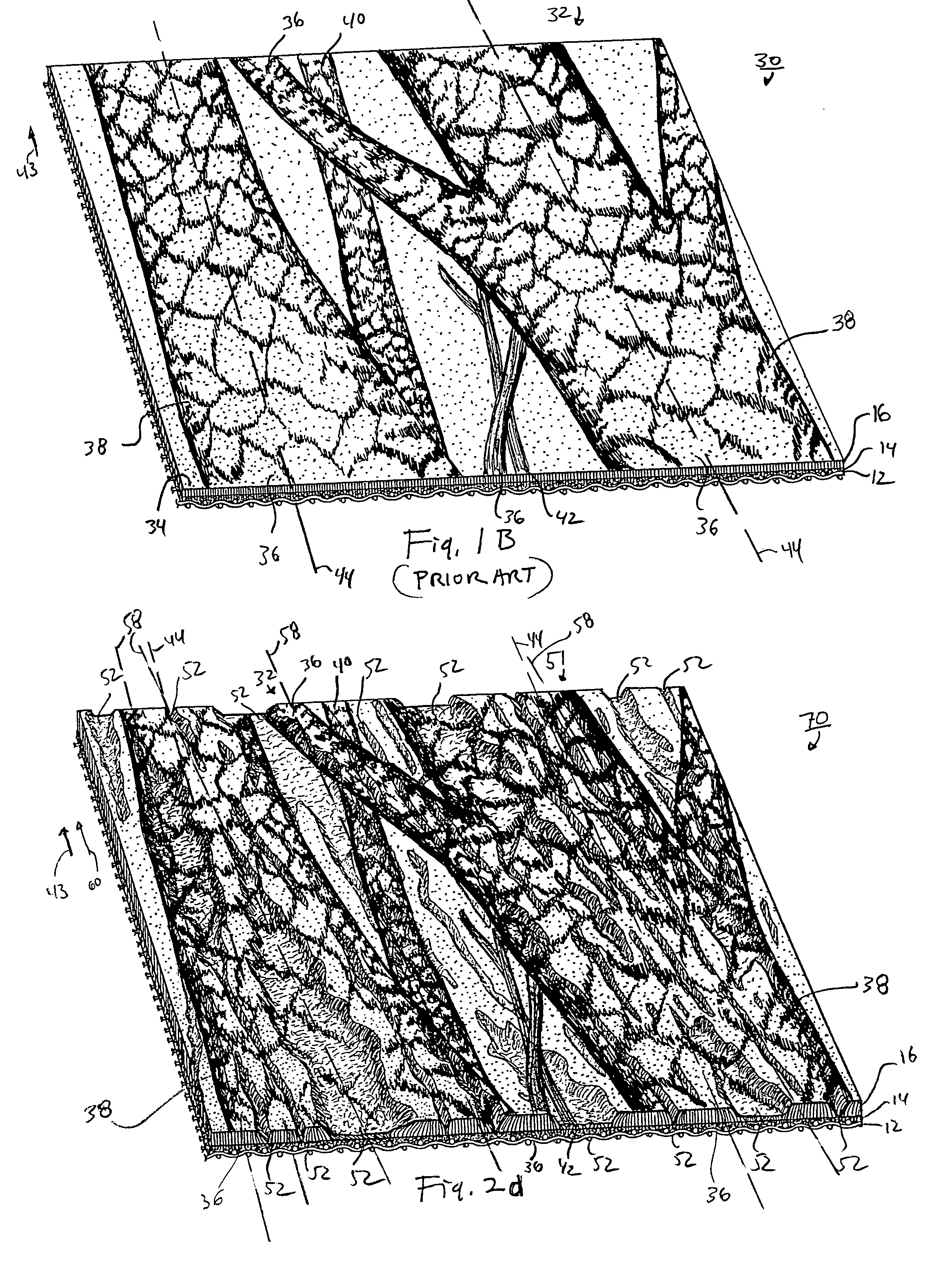

The present invention is directed to unique flocked pile fabrics and methods for producing such fabrics. The fabrics provided according to one embodiment of the invention include an embossed pattern, characterized by a plurality of elongated depressions in the surface of the pile fabric, and a superimposed printed pattern, characterized by a scene or illustration including a plurality of visual features having elongated shapes. The inventive embossed, printed pile fabrics, having a superimposed embossed and printed pattern, advantageously superimpose the embossed pattern and the printed pattern upon the pile fabric so that the embossed pattern imparts a three-dimensional texture to the scene or illustration or pattern comprising the printed pattern. The texture provided by the embossed pattern can impart a visual effect to the scene or illustration which can render it more realistic than a similar scene or illustration printed upon a conventional unembossed pile fabric. In one embodiment, this unique texturing effect is accomplished by substantially aligning the longitudinal axes of the elongate features of the printed pattern and the elongate features of the embossed pattern. The pile fabric provided by the invention can be produced by utilizing a plurality of embossing and printing techniques. In one embodiment, the embossing technique comprises air embossing, and the printing technique comprises paper transfer printing utilizing a paper transfer sheet. The fabrics provided by the invention are especially useful as camouflage fabrics. Such fabrics typically include a printed scene or illustration representing a sylvan setting dominated by visual features such as trees, branches, bushes, leaves, flowers, berries, grass, rocks, moss, etc.

Owner:MICROFIBERS

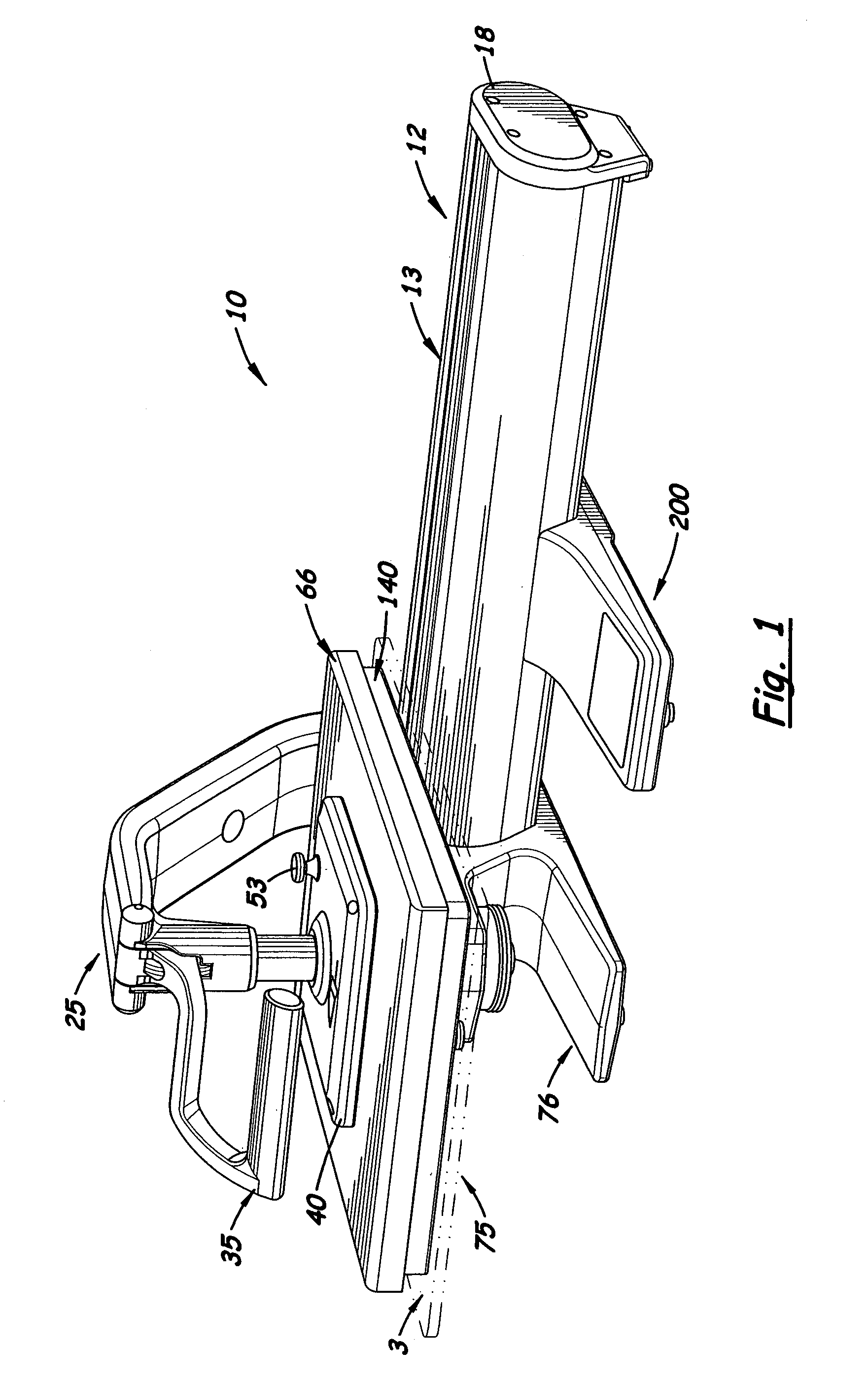

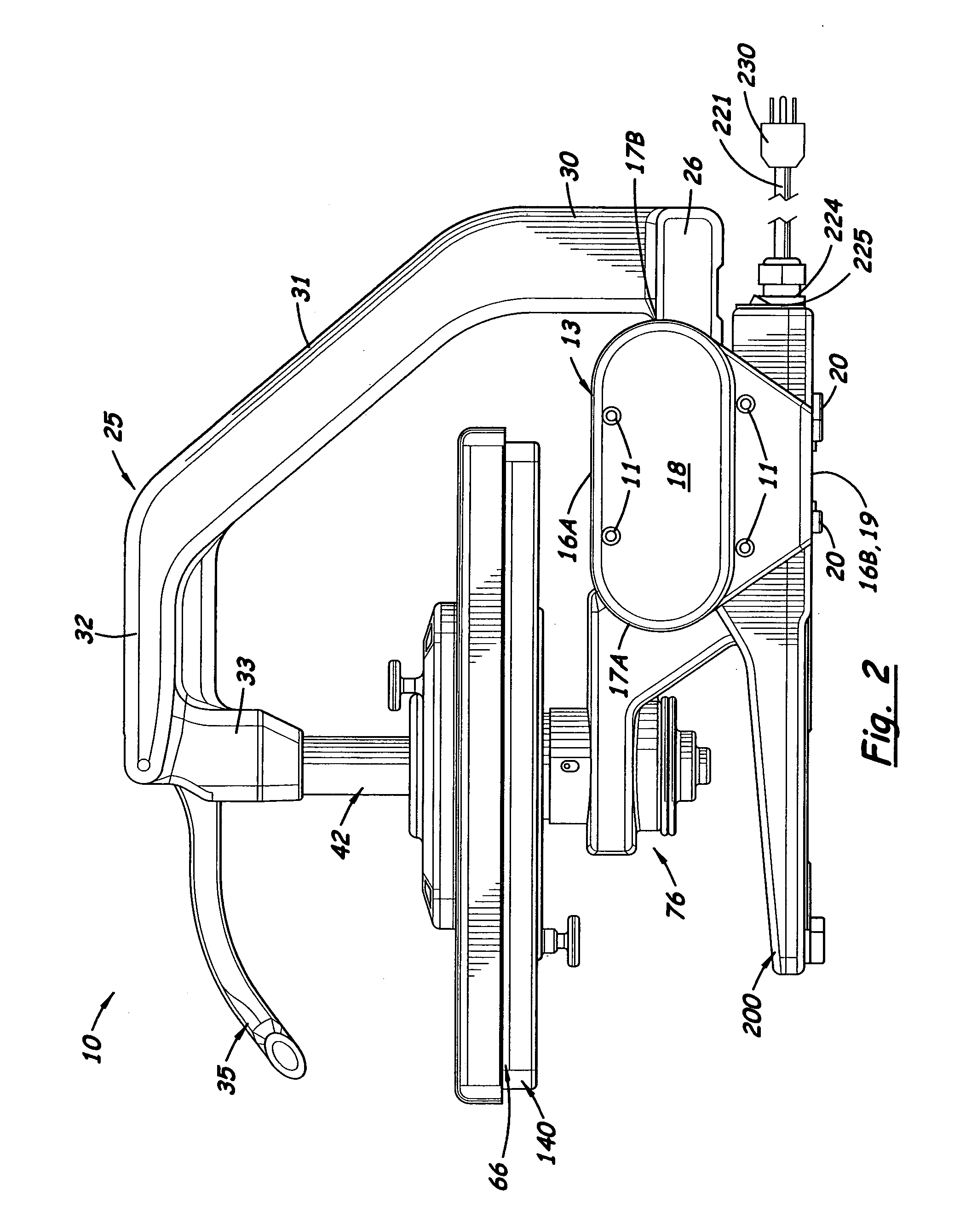

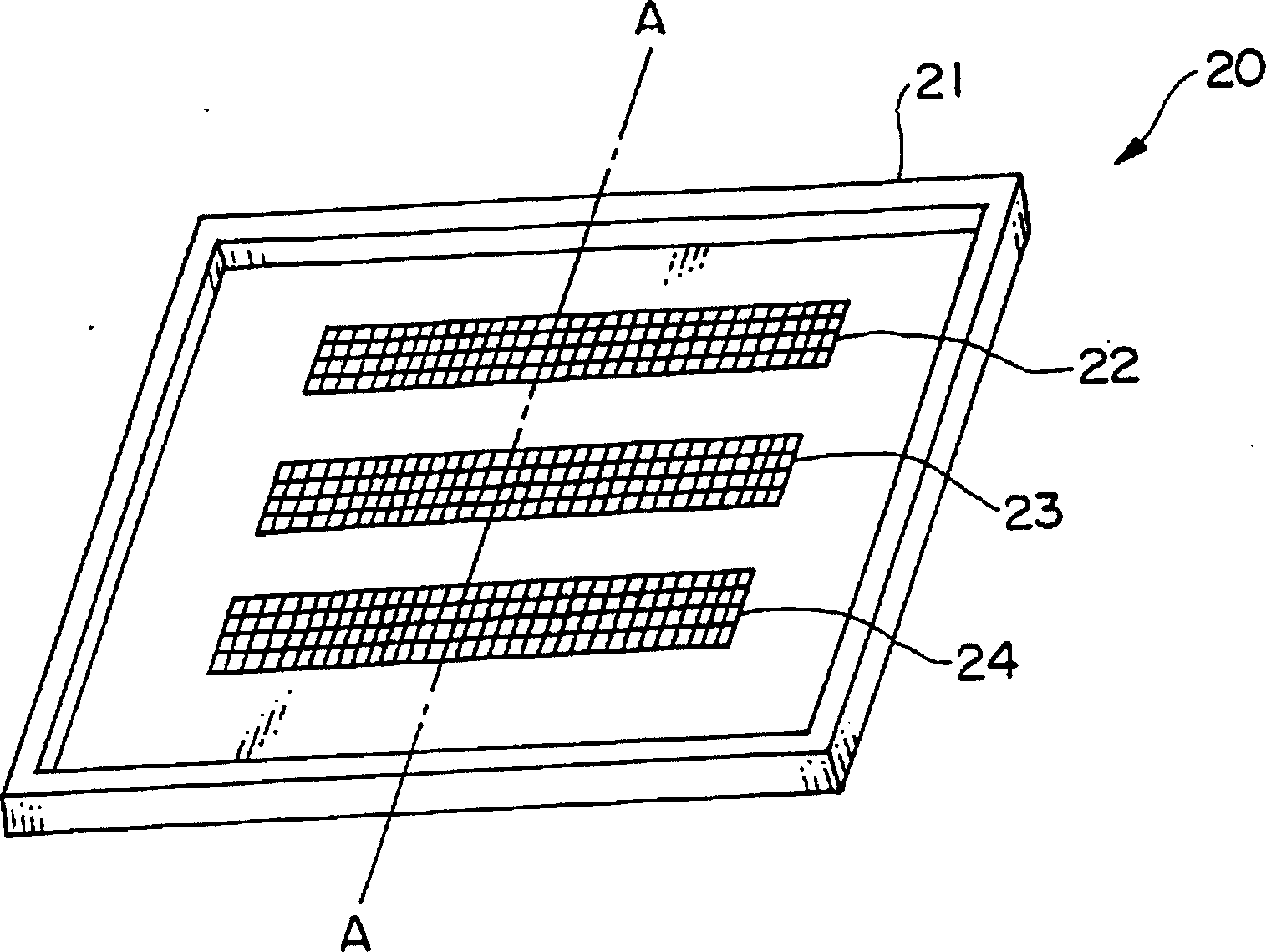

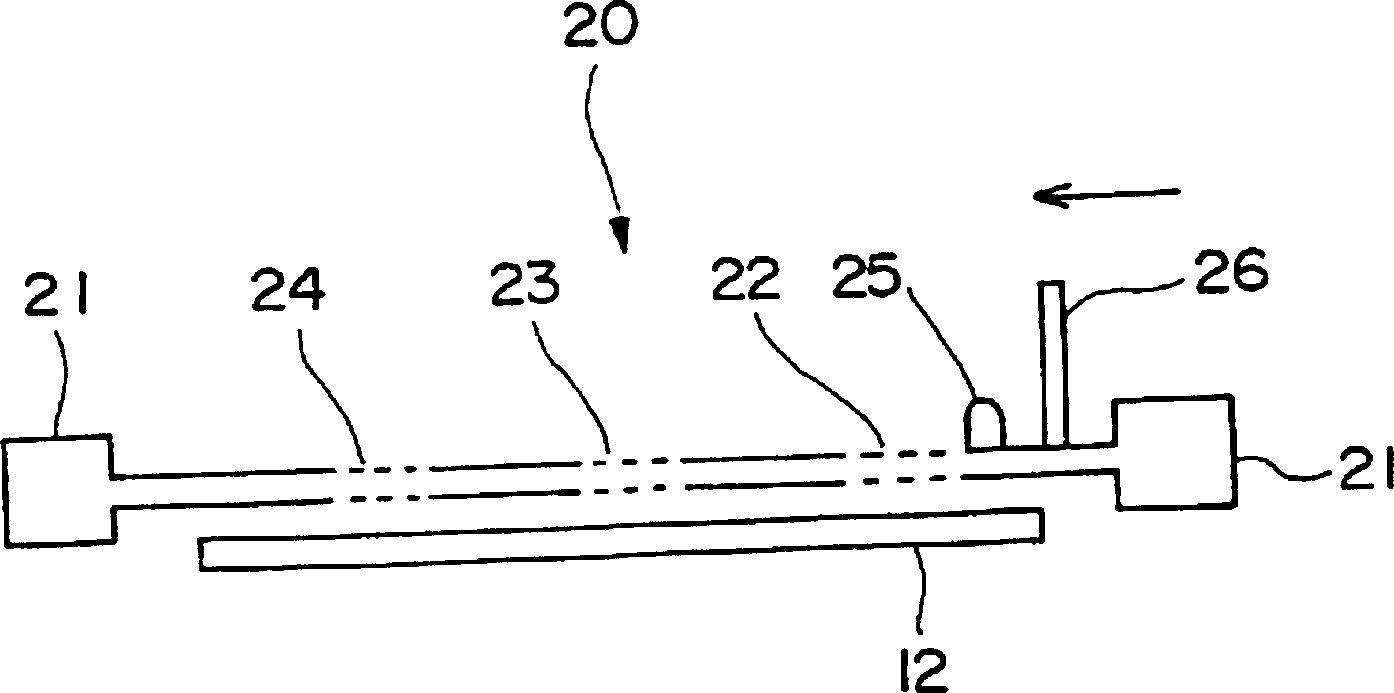

Modular lateral heat press machine

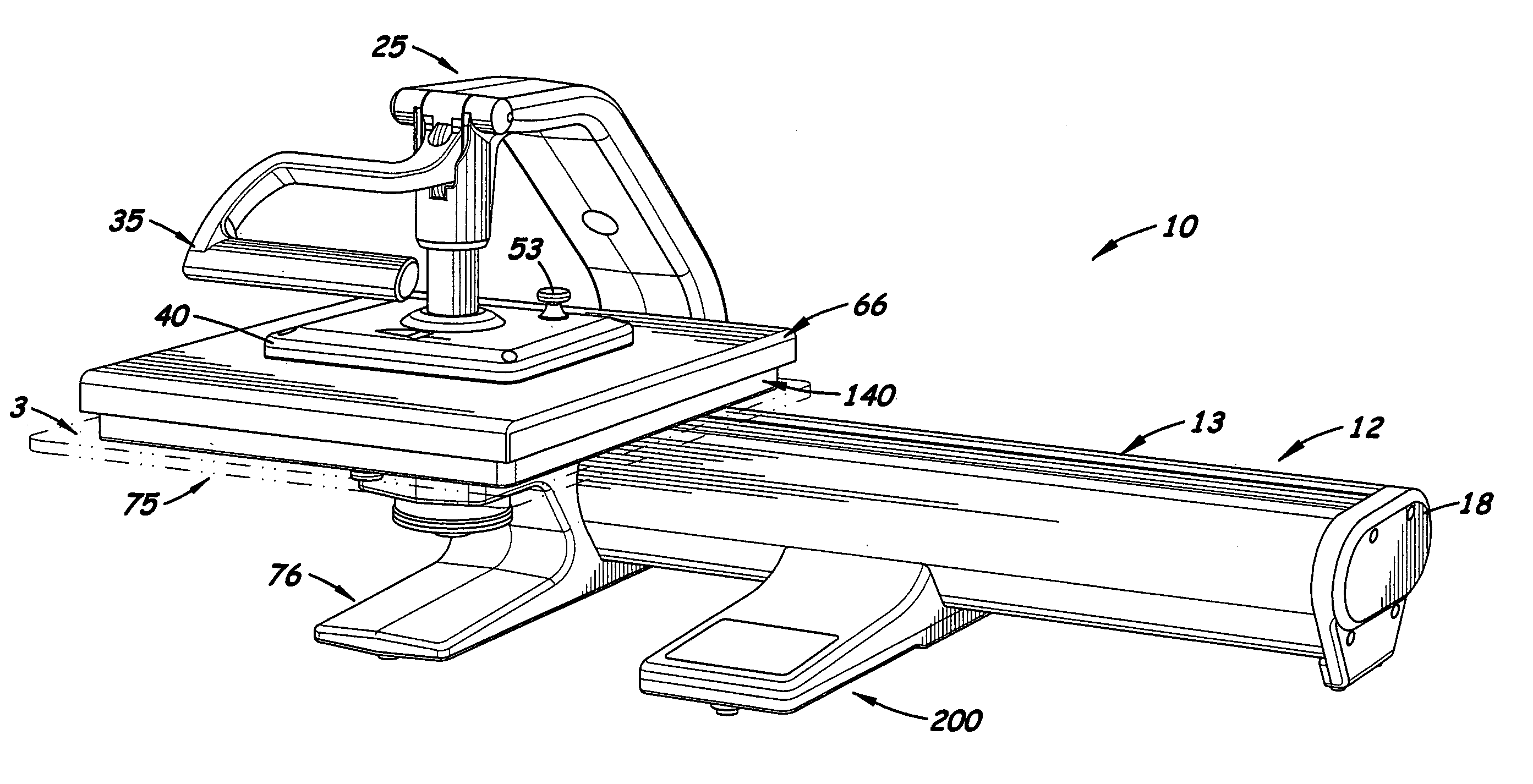

InactiveUS7185584B1Easy to useEasily and quickly exchangedTransfer printingPlywood pressesEngineeringWorkstation

A lightweight, portable lateral heat press machine that allows an operator to quickly and economically transfer graphic characters or images using an ink transfer paper process or a sublimation process, or vinyl onto the surface of a garment or an object. The device includes a vertical aligned sliding arm assembly perpendicularly aligned to a horizontally aligned chassis assembly. Attached to the chassis assembly is at least one workstation assembly and a console. The workstation assembly includes a pedestal with an exchangeable, horizontally aligned lower platen that may be selectively rotated and locked in portrait or landscape orientation and a height and pressure adjustment feature. The sliding arm assembly extends upward and forward and includes a heated, upper platen attached to a manually operated plunger. The console contains the controls for operating the heating element inside the upper platen and a timer. In a second embodiment, a second workstation assembly is provided which enables the operator to slide the arm assembly between workstations thereby enabling the operator to setup one workstation as the pressing procedure is being performed on the other.

Owner:PREMIUM INCENTIVES

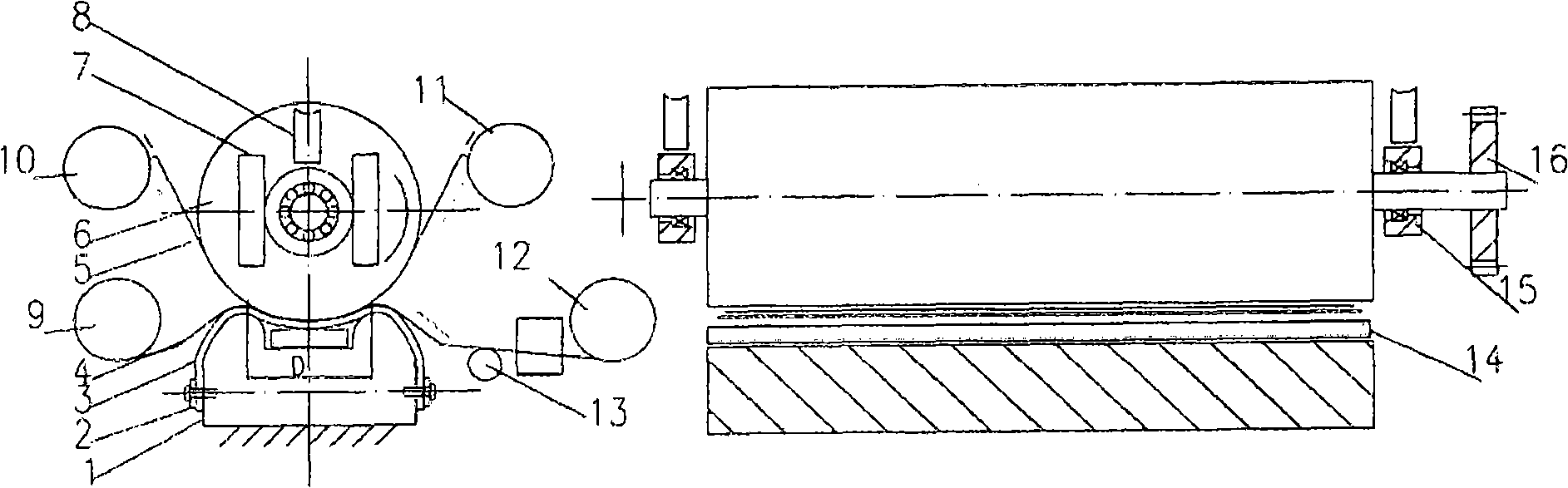

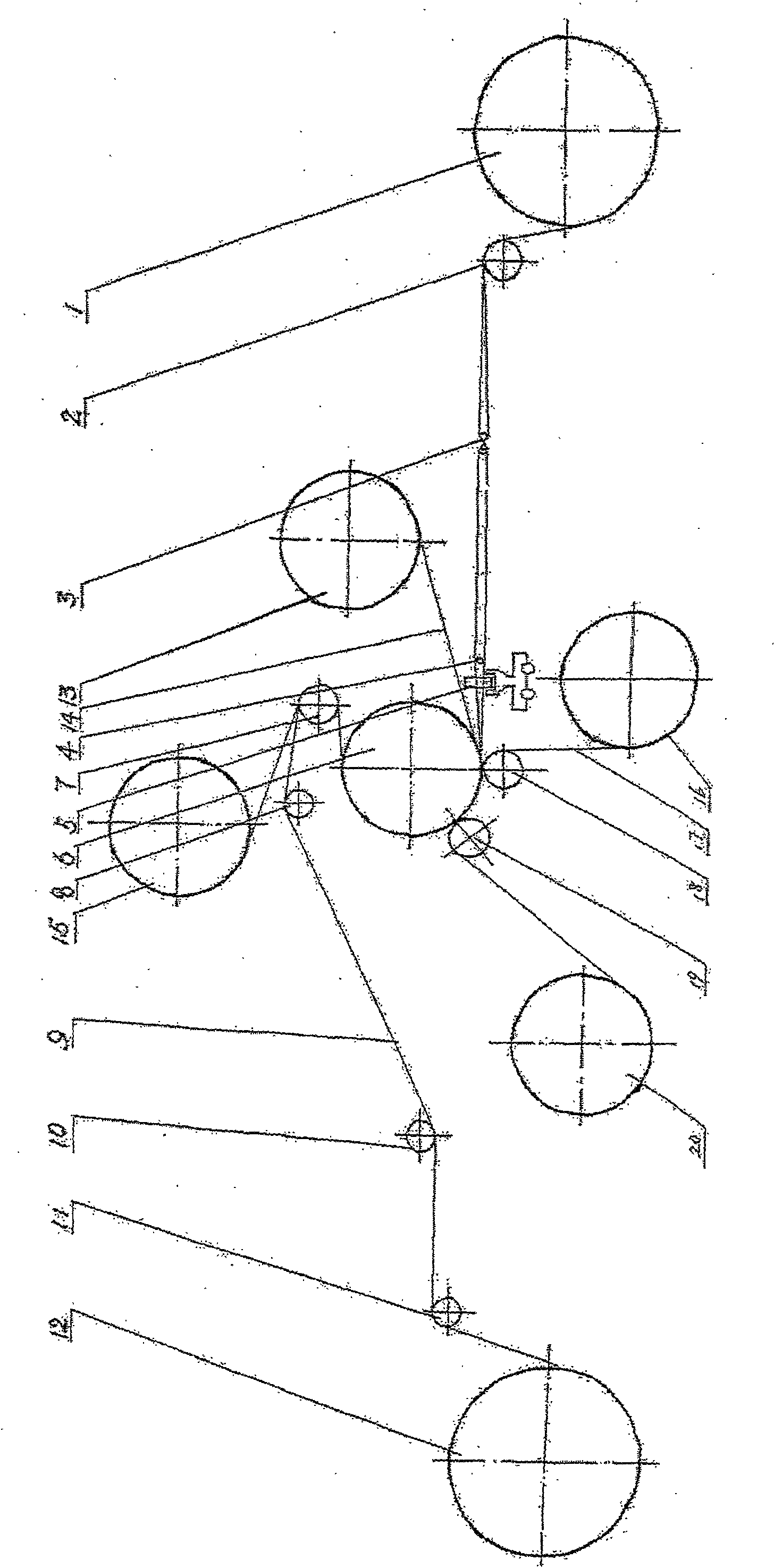

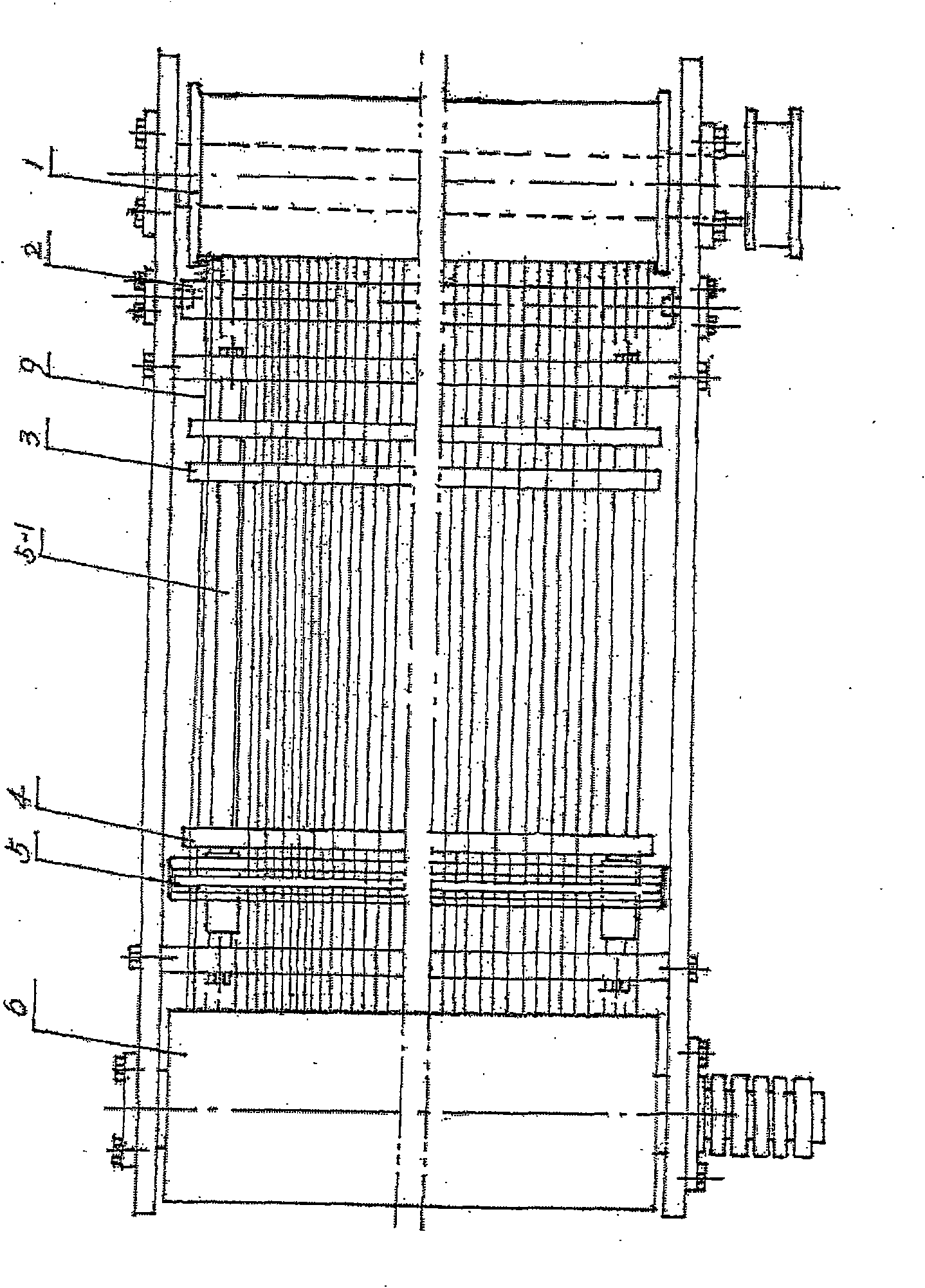

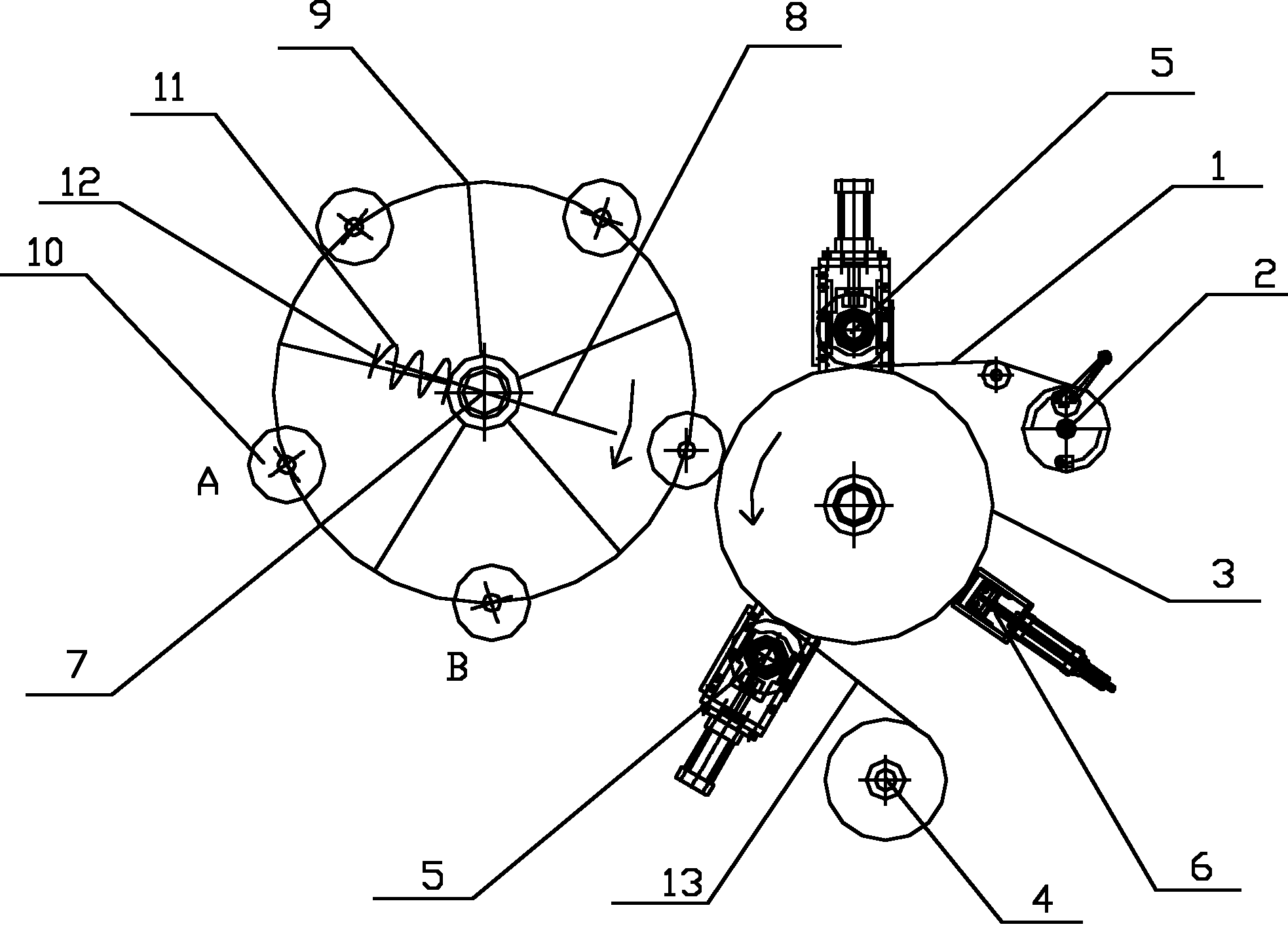

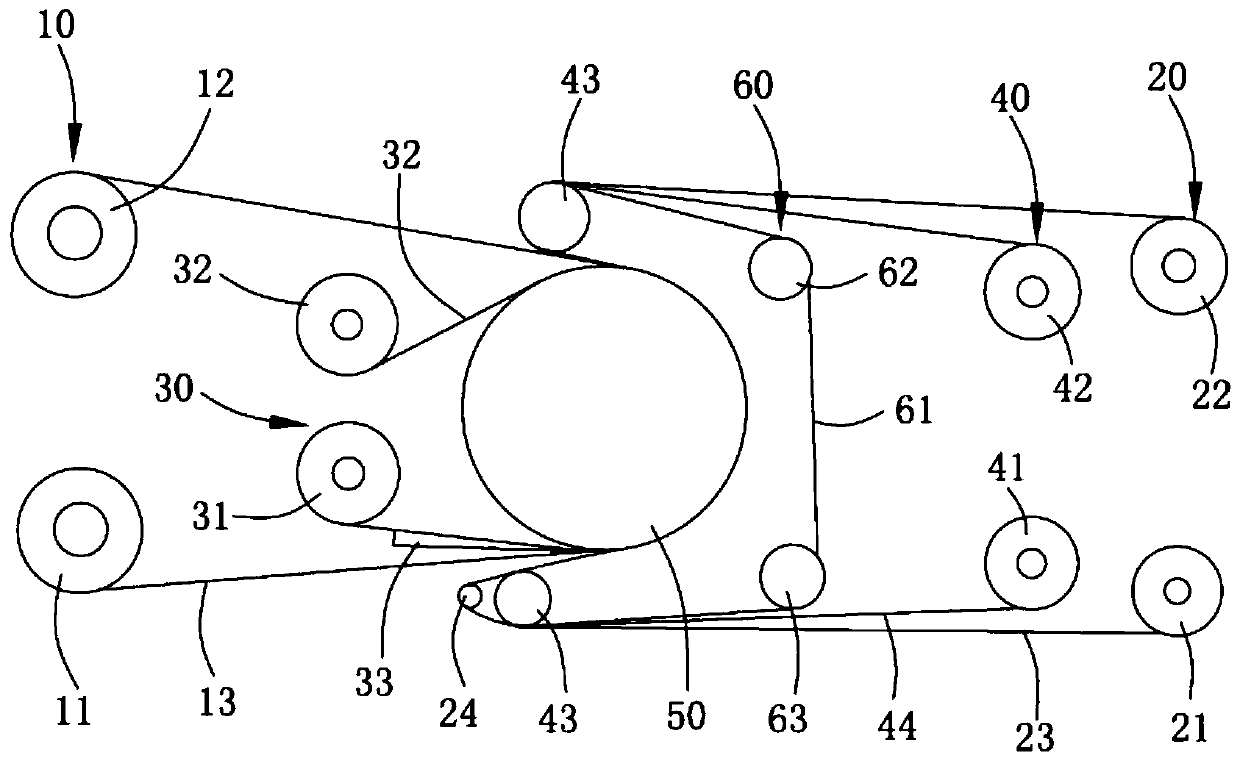

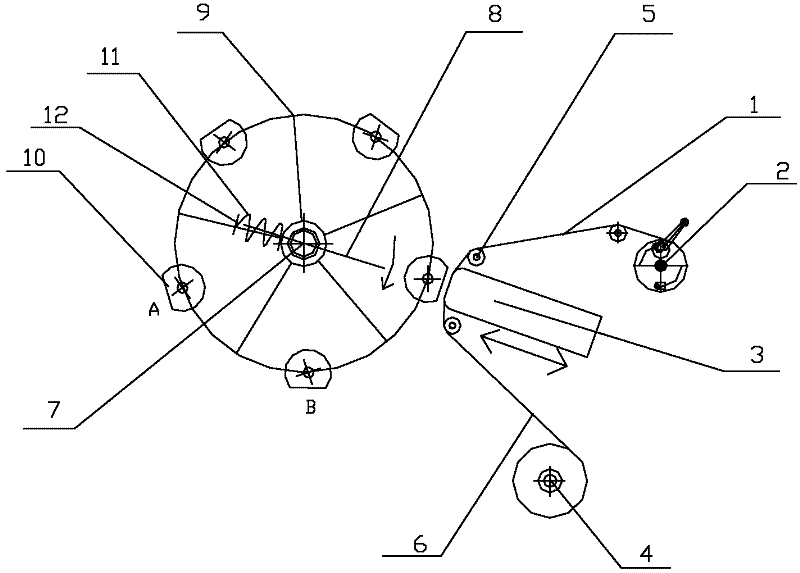

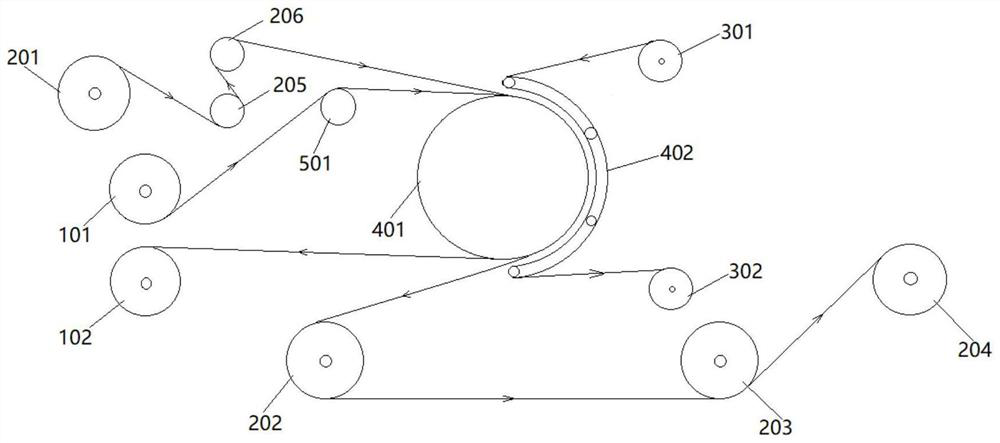

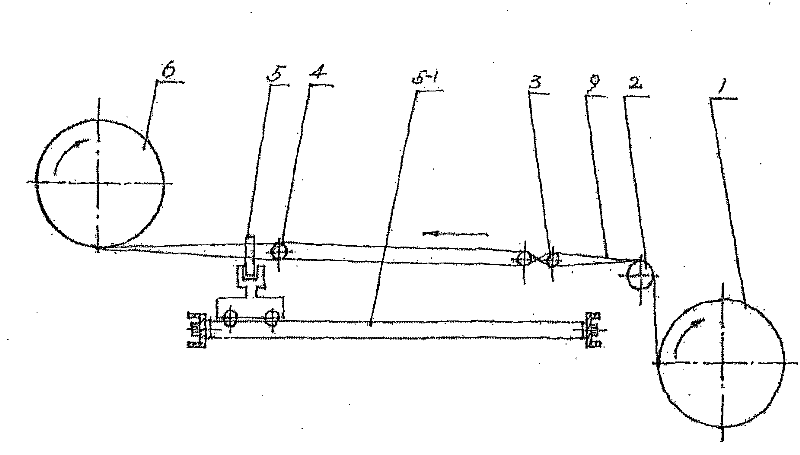

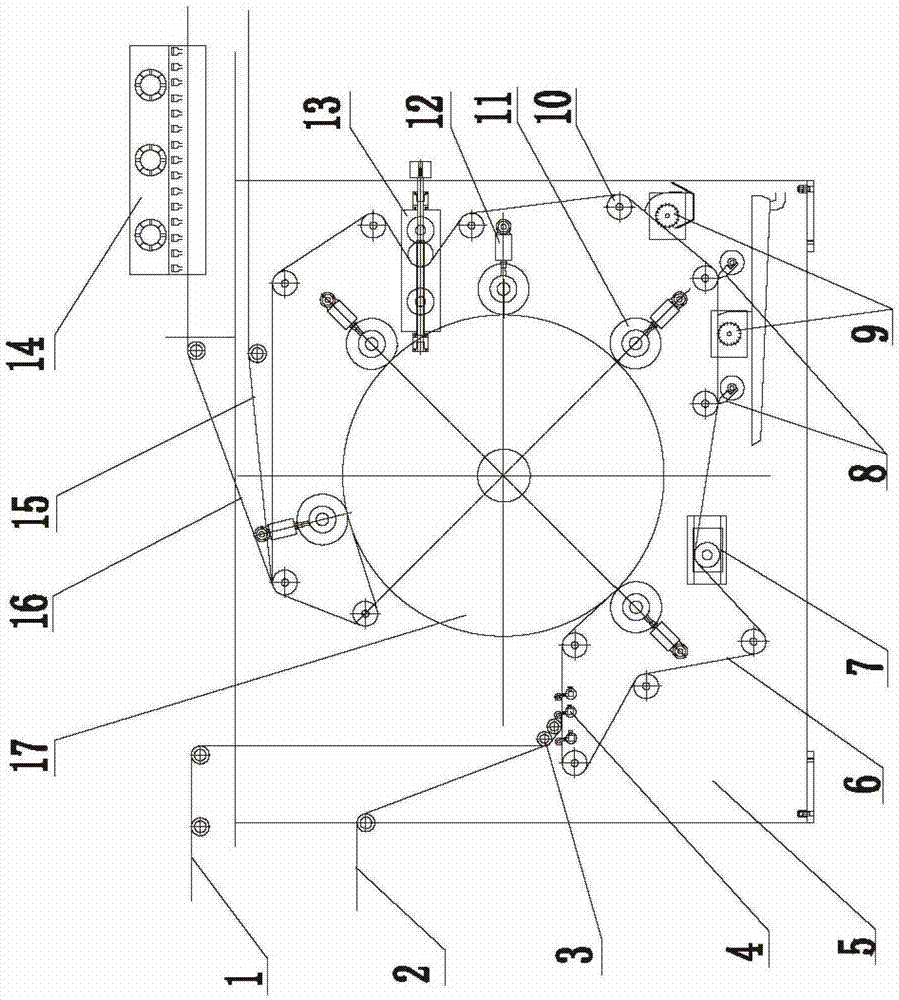

Multi-roller blanket belt type transfer printing device

ActiveCN103144420APrevent slippingAvoid unstable product qualityTransfer printingTransfer-treating textile partsAutomatic controlControl system

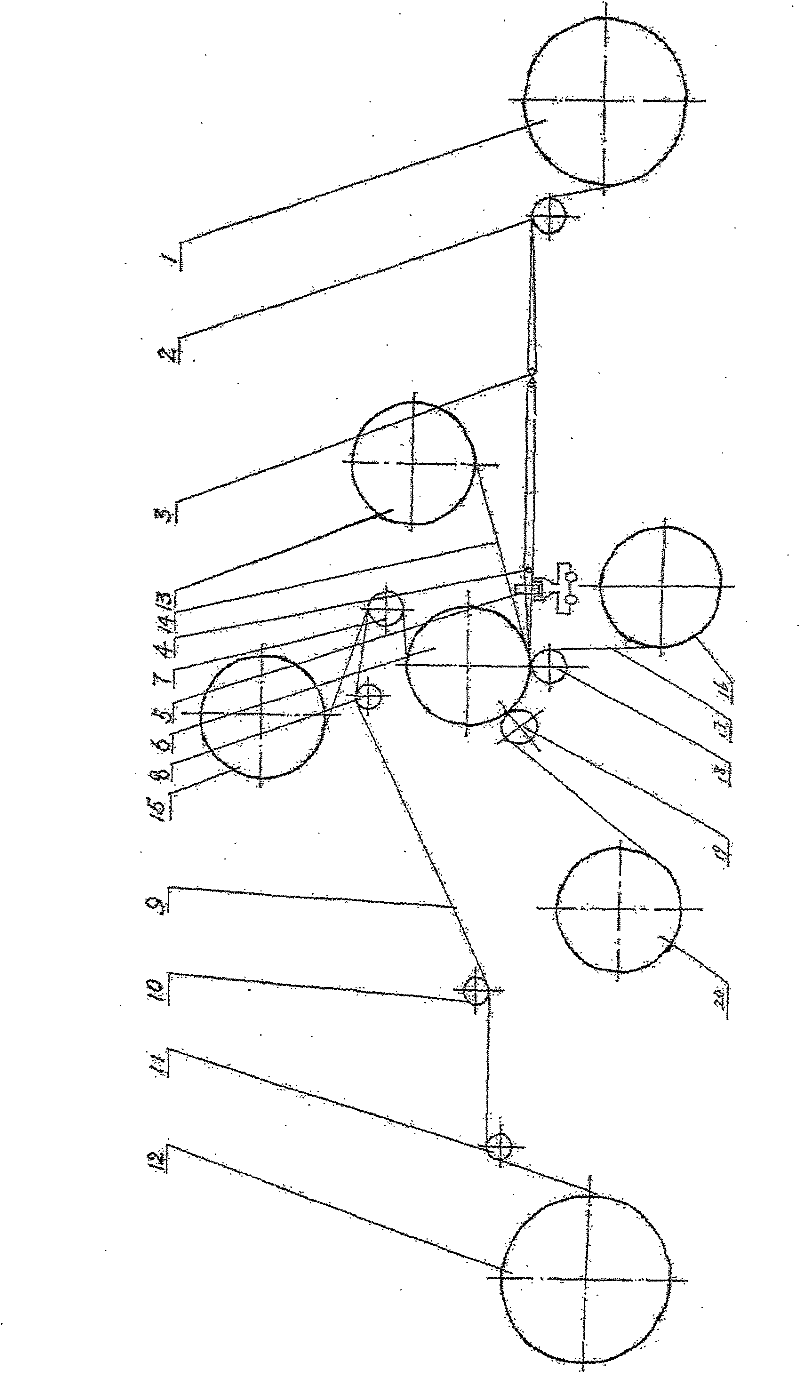

The utility model relates to a multi-roller blanket belt type transfer printing device, which comprises a center roller, a circular blanket belt, a guide roller, an online blanket belt cleaning and circulating system, a rectification device, a drying box and an automatic control system, wherein two ends of the center roller are fixed on a frame through bearings; a plurality of pressurizing rollers are distributed on the circumferential periphery of the center roller; a pressurizing device provides pressure for each of the pressurizing rollers independently; the circular blanket belt is wound on a plurality of supporting rollers and the plurality of pressurizing rollers; the pressurizing rollers is in pressurizing contact with the center roller through the blanket belt; a tensioning device provides tension for the blanket belt; the guide roller is arranged nearby an inlet and an outlet where the blanket belt is contacted with the center roller; the online blanket belt cleaning and circulating system is arranged in a circulation path of the circular blanket belt and comprises a blanket belt cleaning device, a scrapper and an oven; the rectification device is located on a guide roller nearby the inlet and then located in front of the inlet; the drying box is located at the outlet and then between a separation position of a fabric and a transfer printing carrier and a fabric rolling frame; and the automatic control system is used for controlling the speed of a spinning wheel, the tension of the blanket belt, the fabric and the transfer printing carrier, and the pressure of transfer rectification and pressurizing roller gradients.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

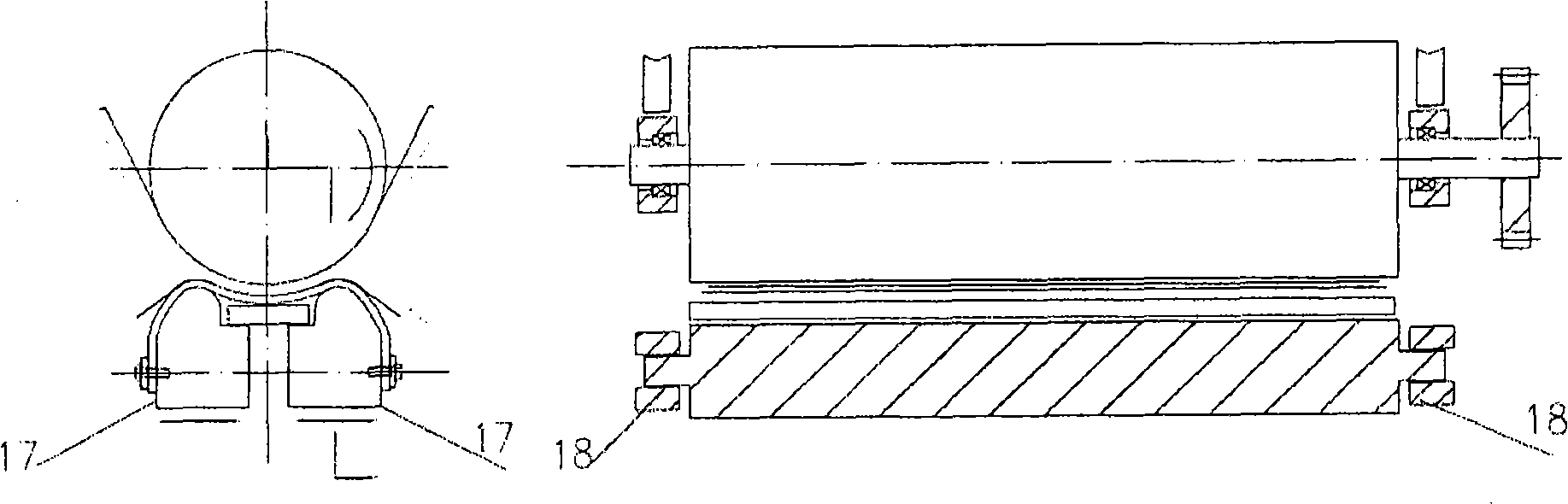

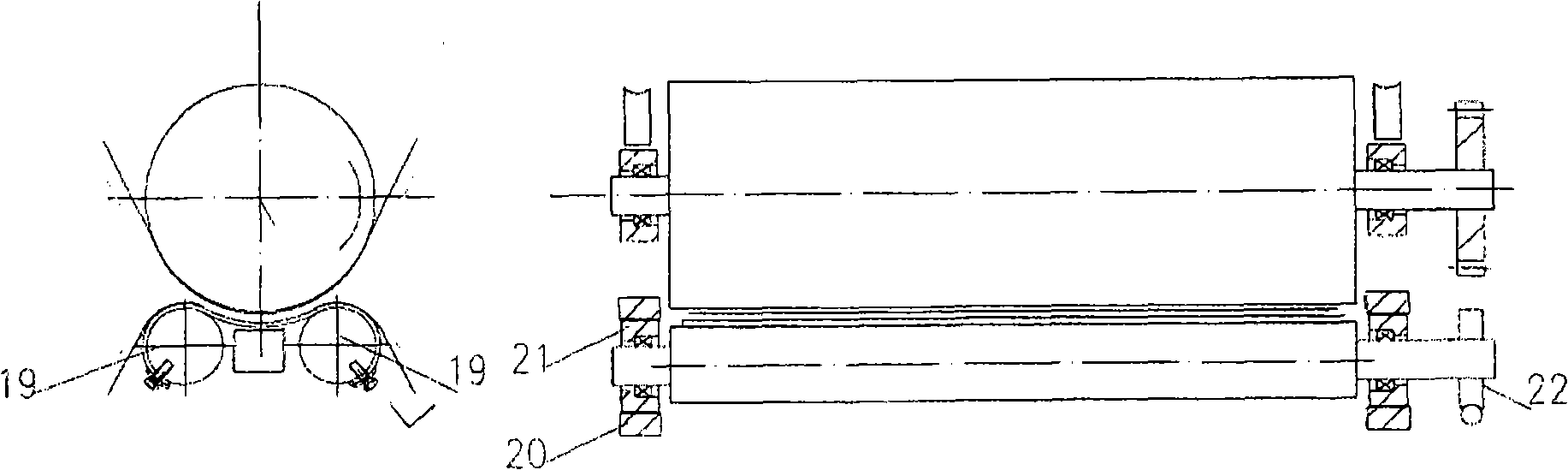

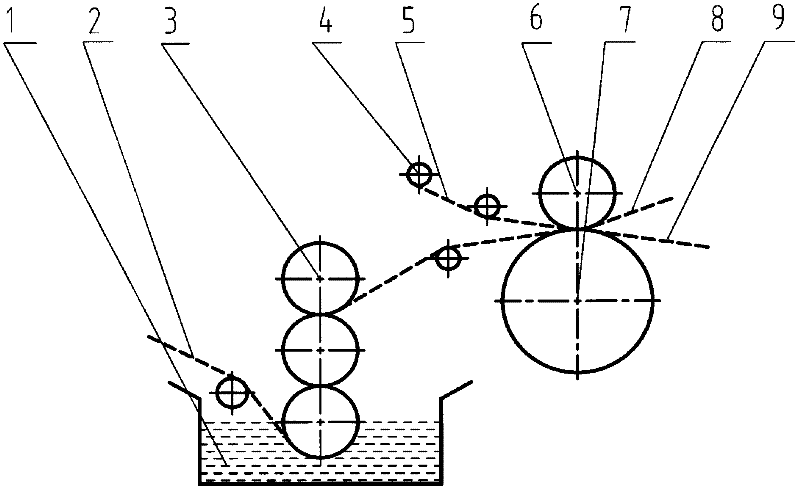

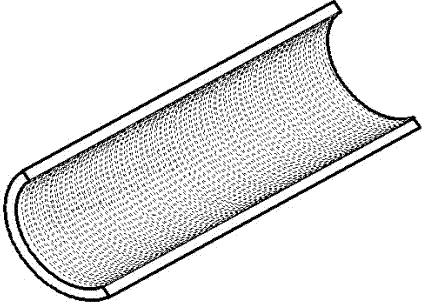

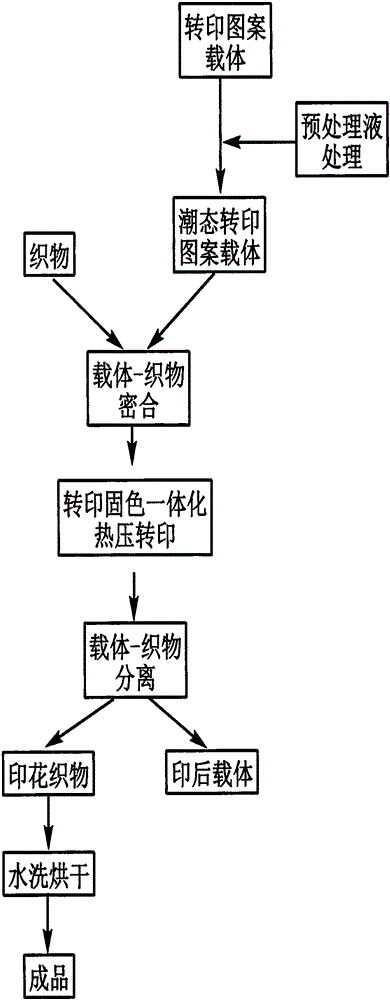

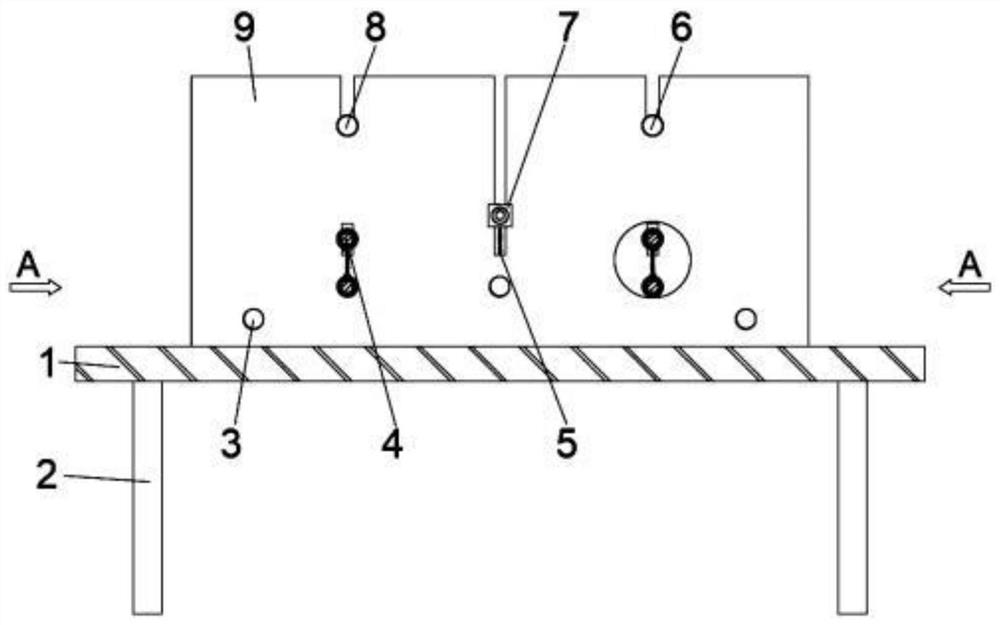

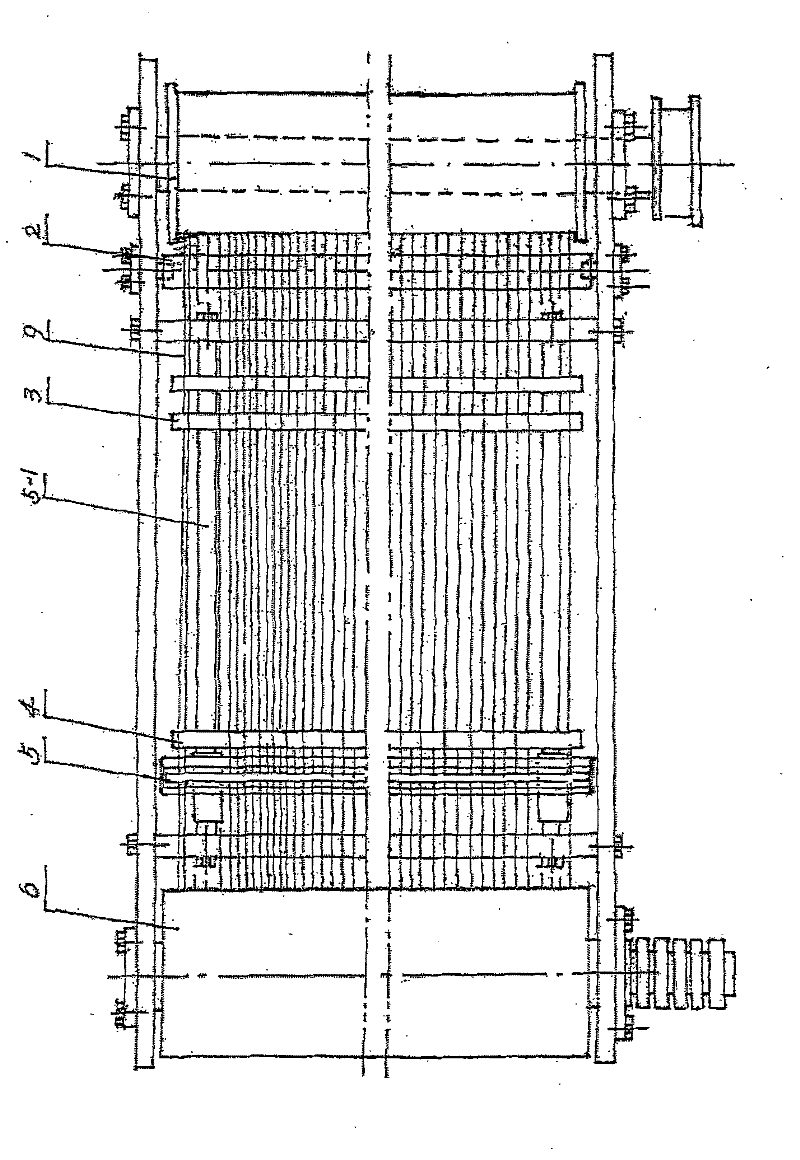

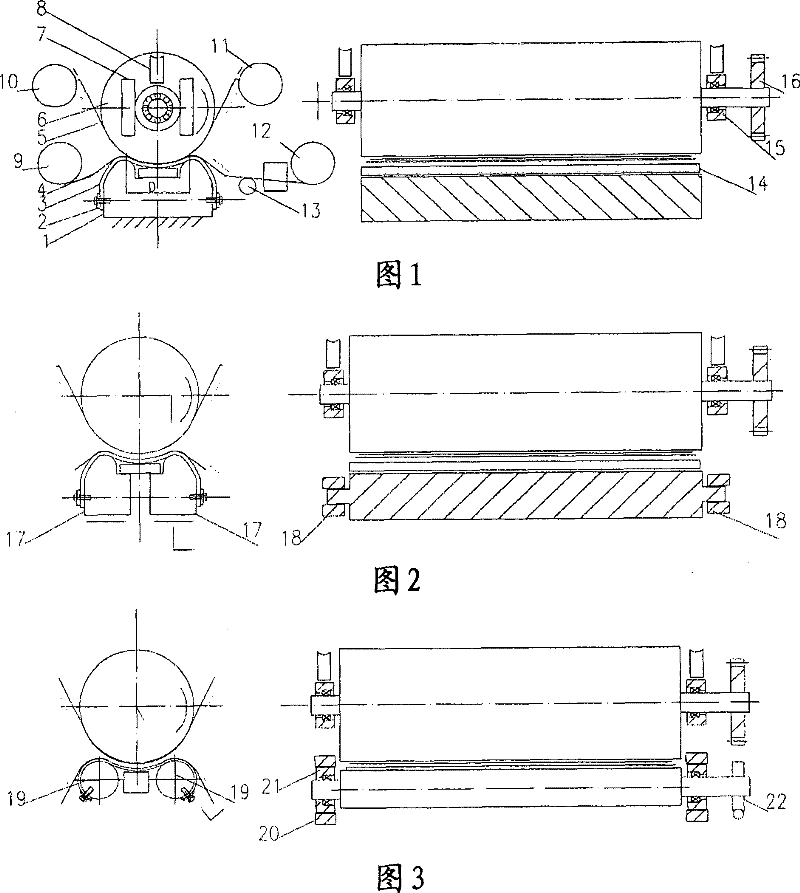

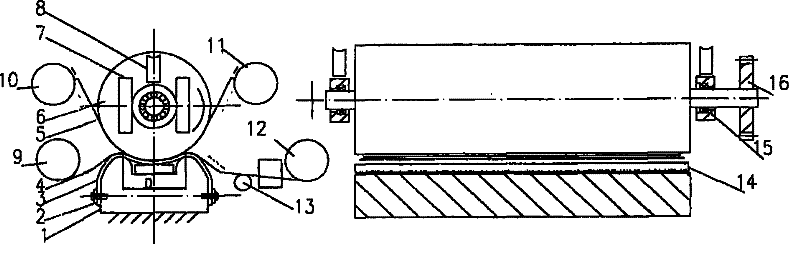

Transfer printing device for cold-transfer decorating machines

ActiveCN101513790AIncrease pressureMaximum stapling lengthTransfer printingTransfer-treating textile partsDrive wheelEngineering

The invention provides a transfer printing device for cold-transfer decorating machines, which comprises a base, a fixing clamp plate, a transfer printing belt, a transfer printing roller, a pressurization device, a bearing block and a driving wheel, wherein the transfer printing roller is a circular roller; two ends of a central shaft of the transfer printing roller are supported by a bearing and the bearing block and are connected with the pressurization device; the driving wheel connected with a drive mechanism is arranged beside the bearing at one end of the central shaft; the base is a concave rigid base fixed on a frame; the transfer printing belt is fixedly connected with the left and right sides of the concave rigid base by the fixing clamp plate; the transfer printing roller can rotate around the central shaft and move up and down relative to the transfer printing belt; and the acting surfaces of the transfer printing roller and the transfer printing belt fit each other, wherein the transfer printing belt stays still in a transfer printing process, and a cooling device is arranged between the transfer printing belt and the concave rigid base. As the transfer printing belt stays still, the transfer printing belt and the rotating transfer printing roller can form steady decorating pressure. Meanwhile, the flexibility of the transfer printing belt determines that a decorating area between the transfer printing belt and the transfer printing roller can be increased according to decorating requirements, thus enough transfer printing time required by a decorating process can be ensured.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

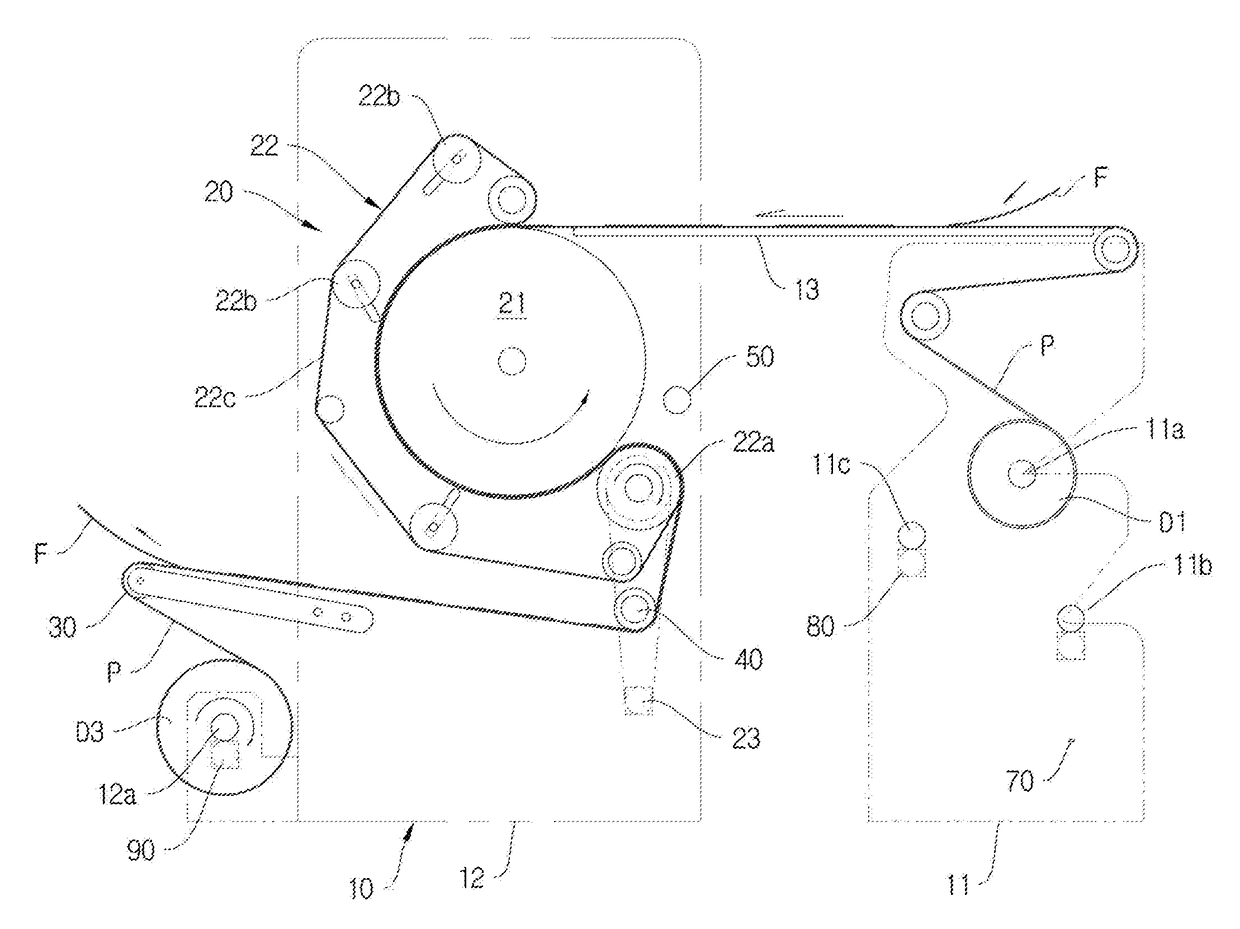

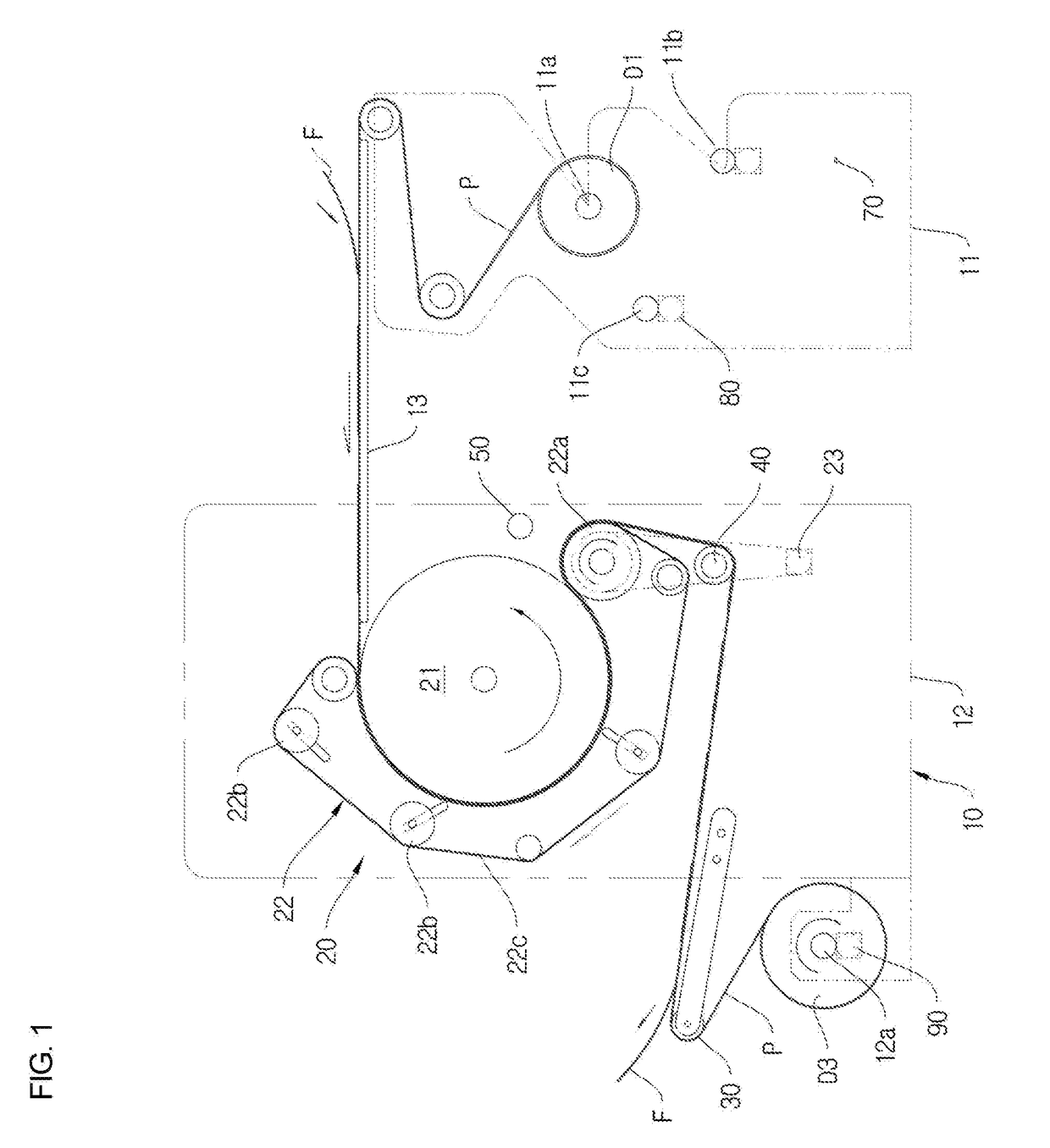

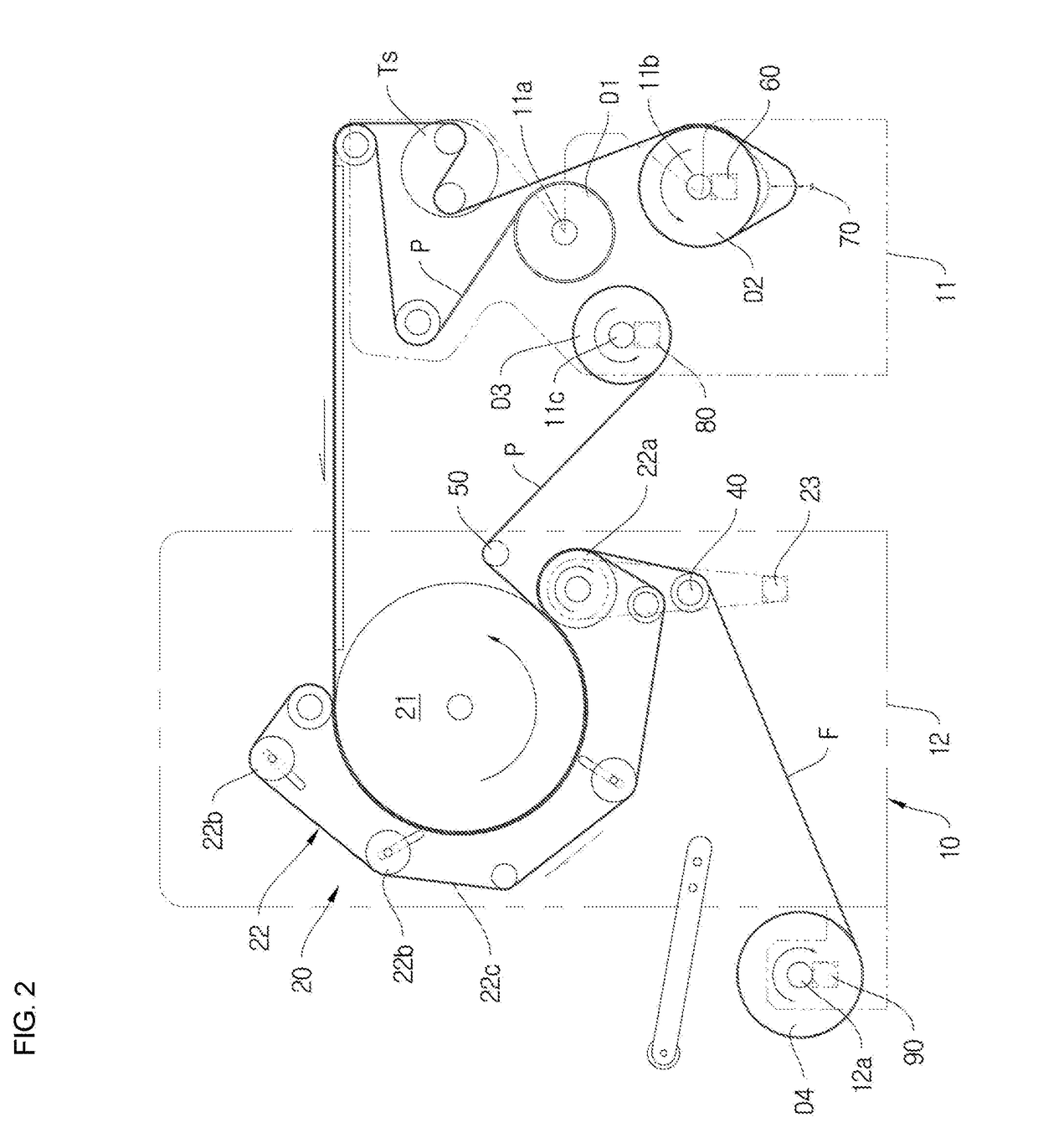

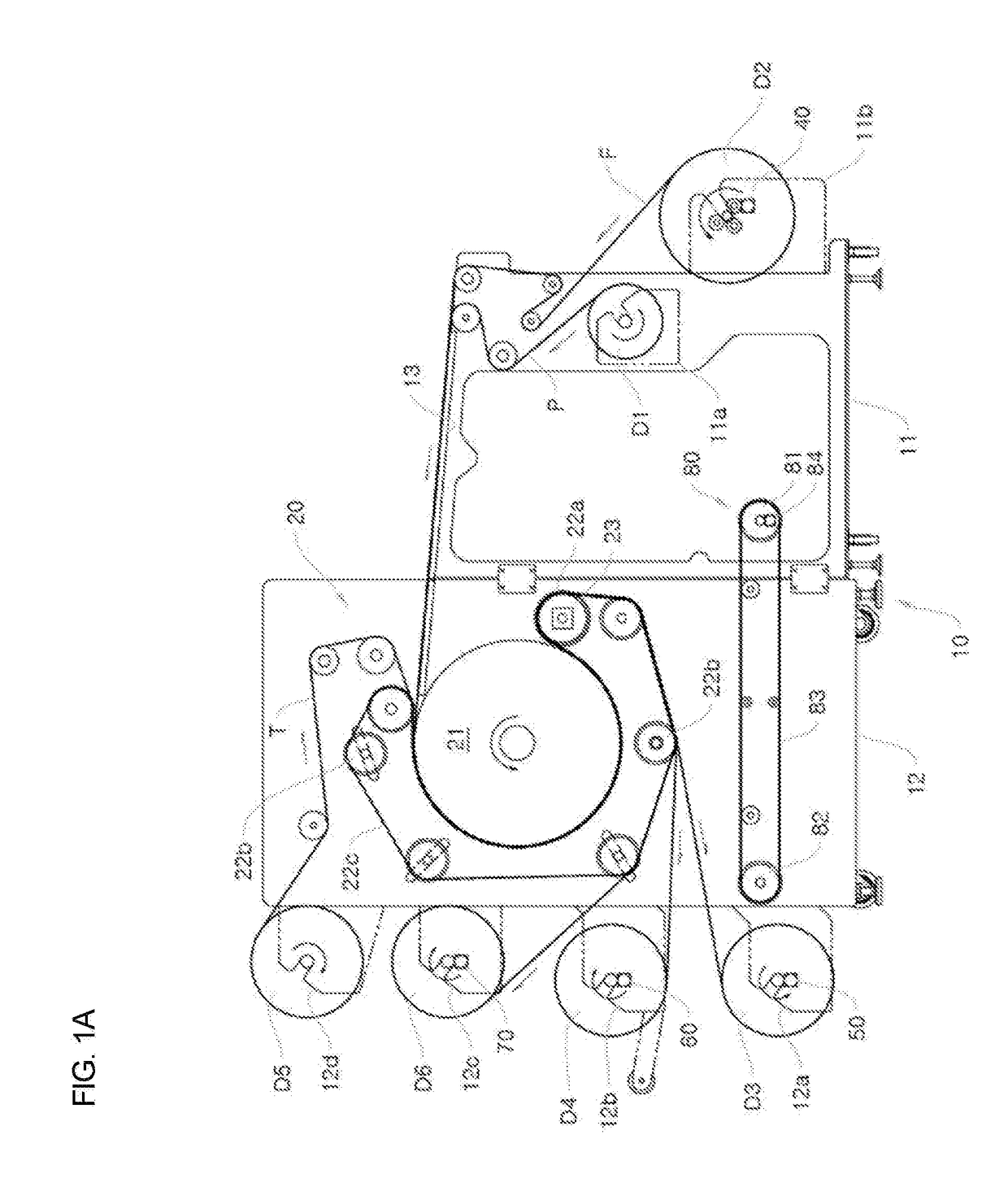

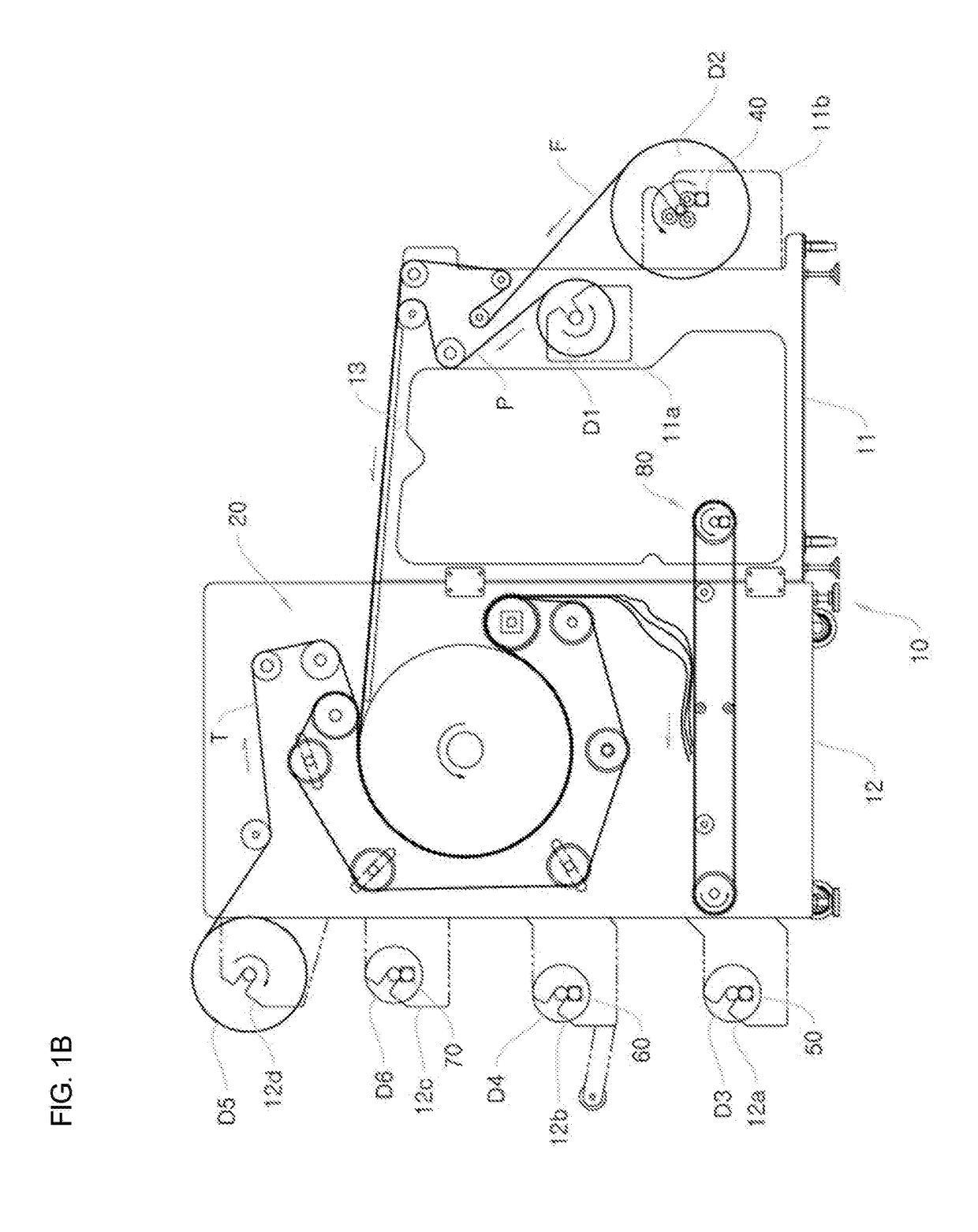

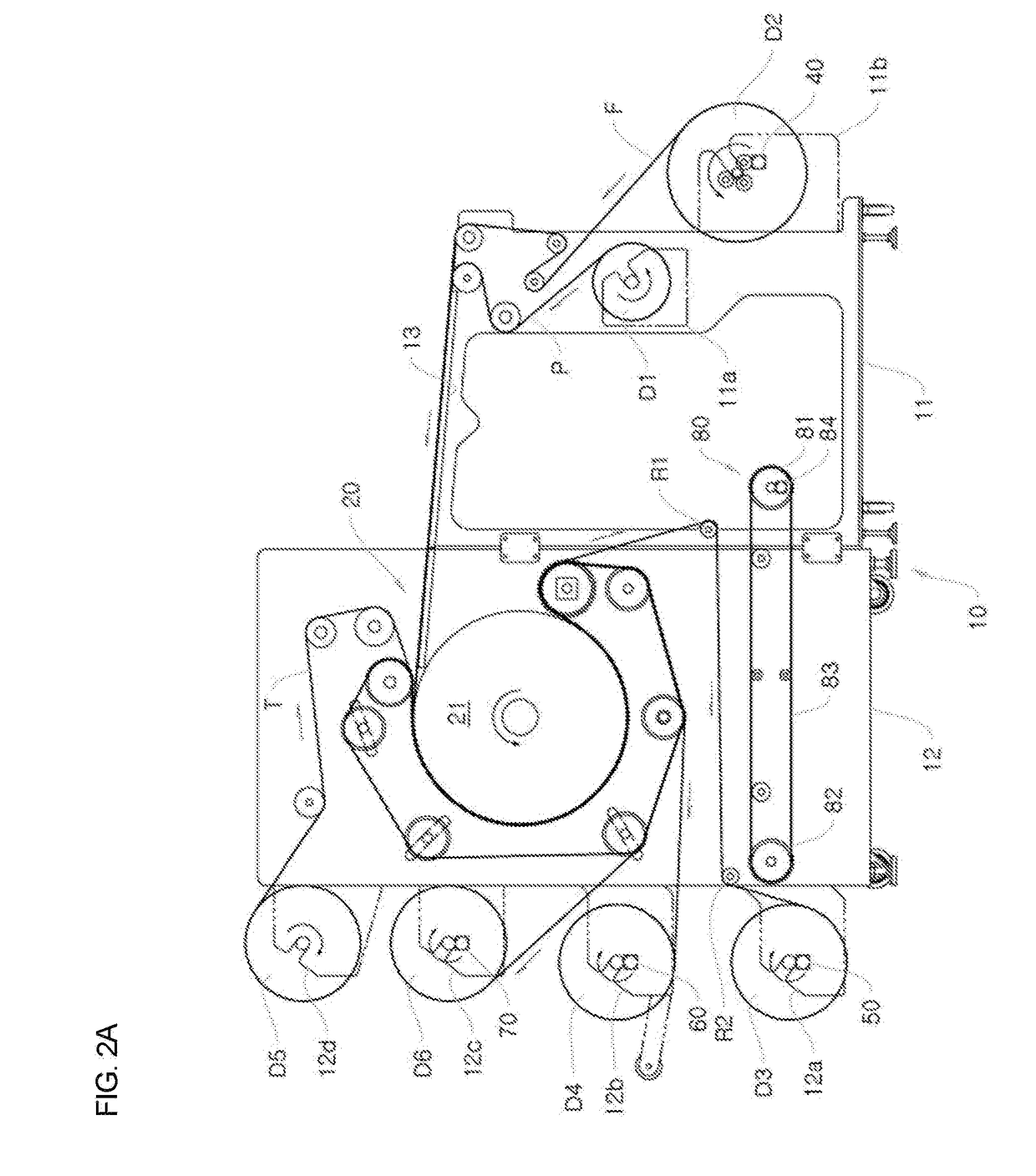

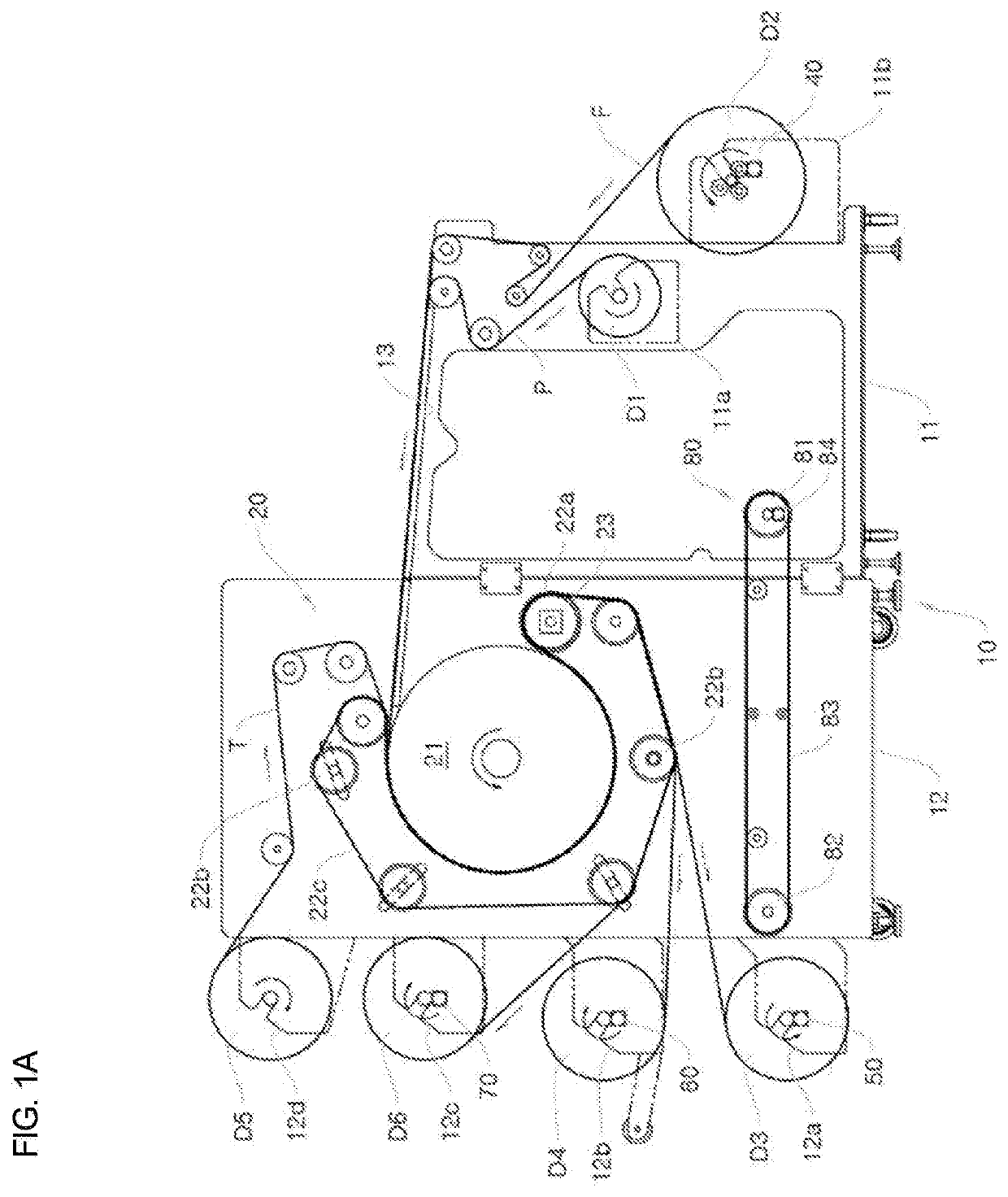

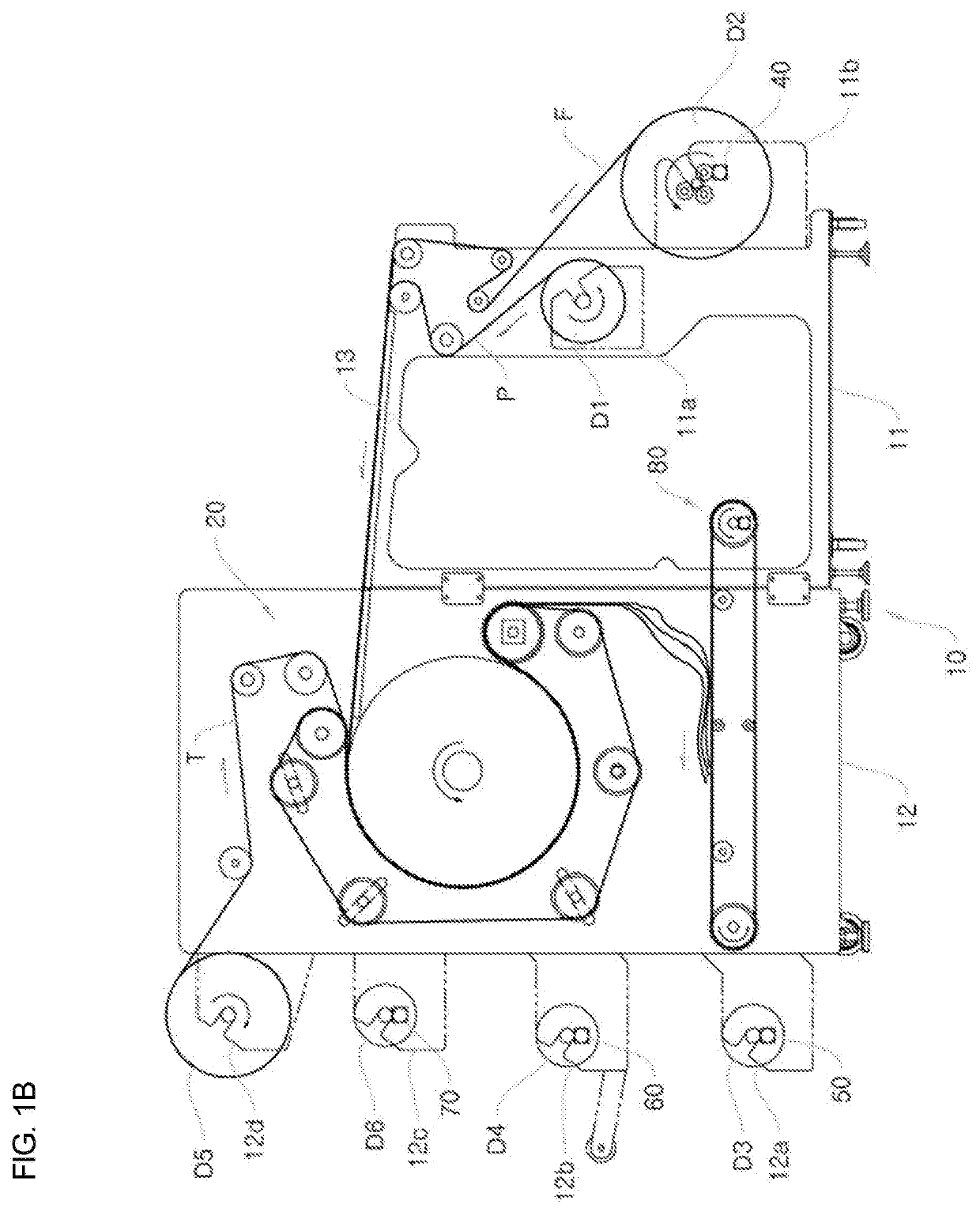

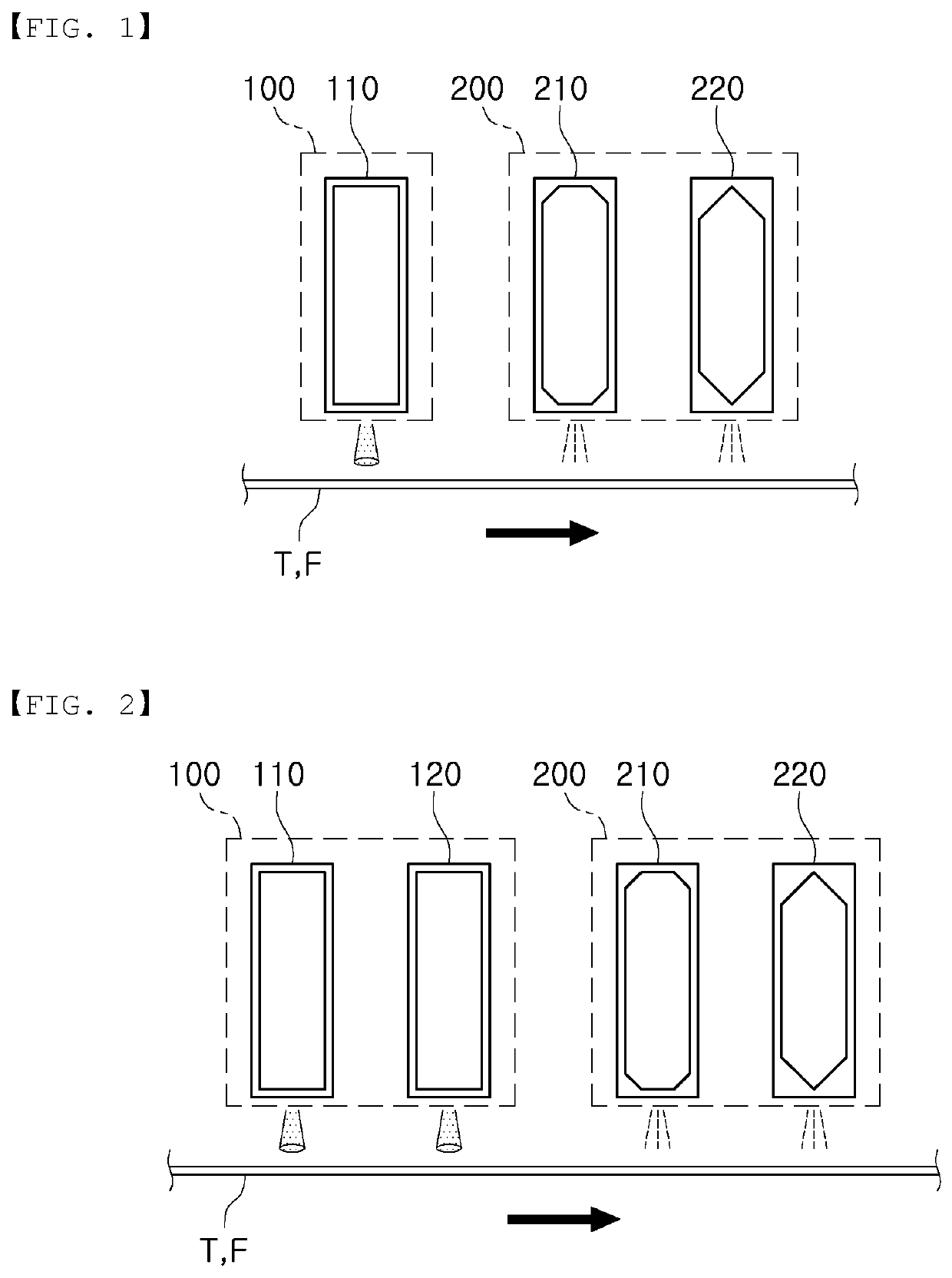

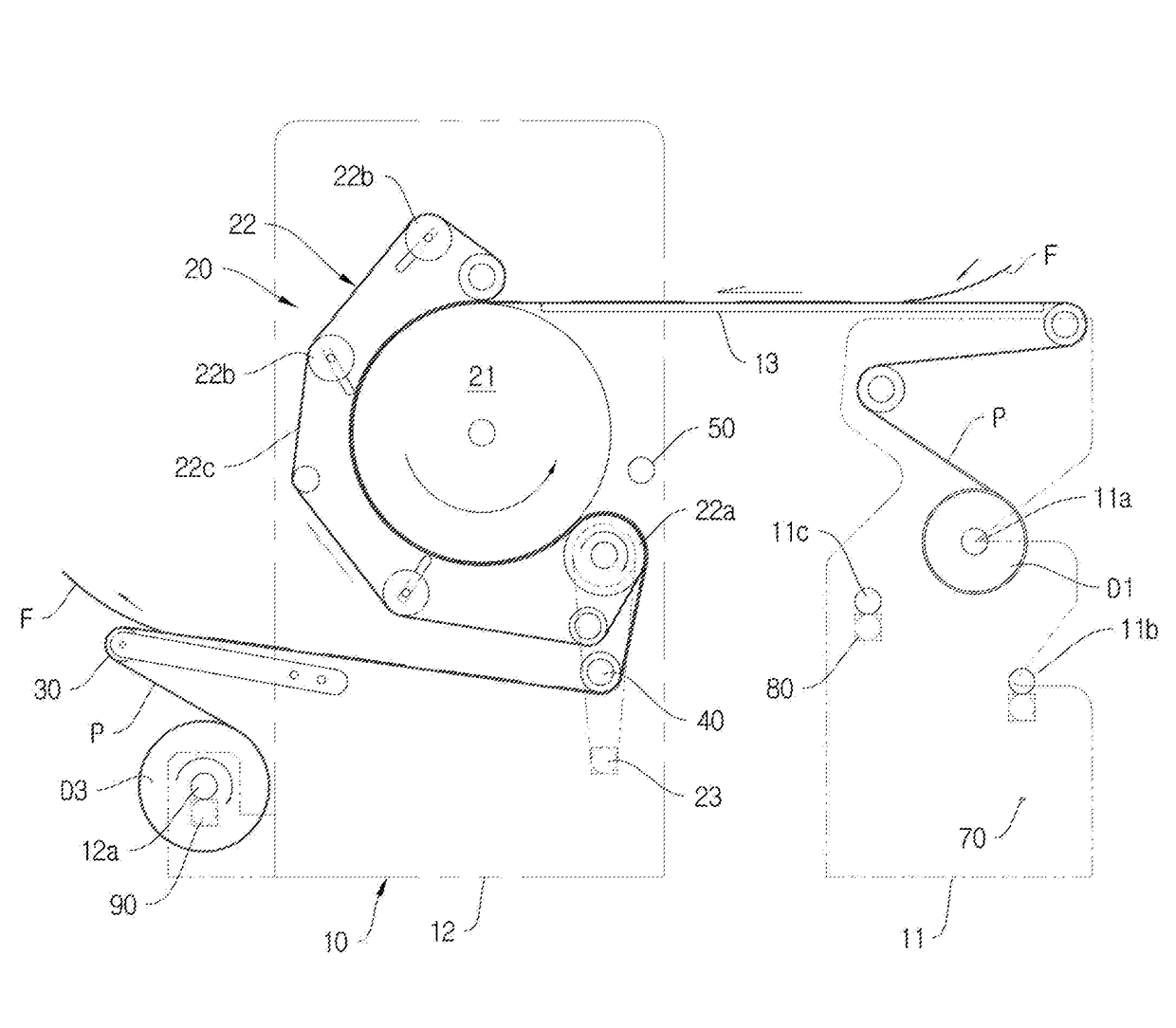

Hybrid transfer machine

ActiveUS20170144431A1Improve versatilityImprove space utilizationTransfer printingTransfer printing processMechanical engineeringIndustrial engineering

A hybrid transfer machine includes a body, a fabric supply drum driving means, a fabric detection sensor, a take-up transfer paper drum driving means, a thermal transfer unit, a piece-mode roller, a take-up main drum driving means, a main guide roller, and a roll-mode roller. The body includes a first body, a second body, and a worktable. The fabric supply drum driving means drives a fabric supply drum. The fabric detection sensor detects fabric, and controls an operation. The take-up transfer paper drum driving means drives the take-up transfer paper drum. The thermal transfer unit heats the fabric and transfer paper. The piece-mode roller rotatably guides the transfer paper. The take-up main drum driving means drives the take-up fabric drum or take-up transfer paper drum. The main guide roller guides the transfer paper or the fabric. The roll-mode roller guides the transfer paper.

Owner:KYUNGIL TECH

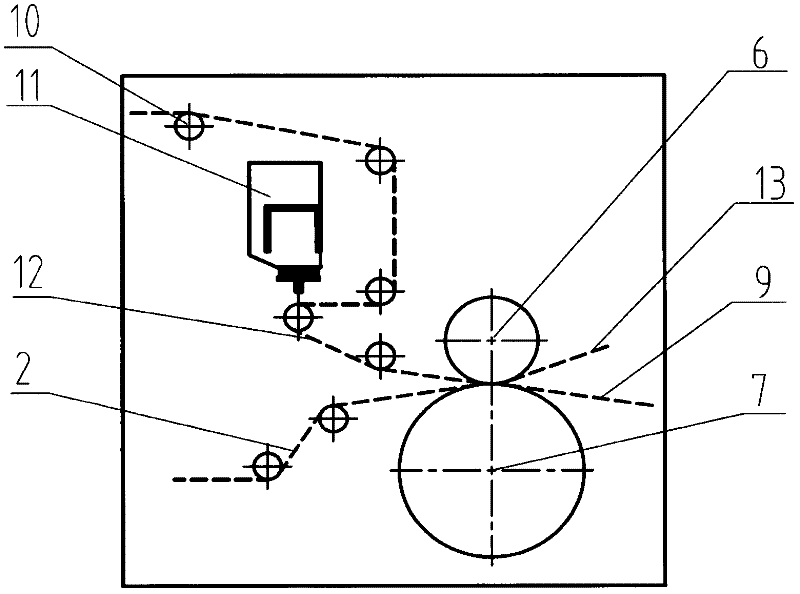

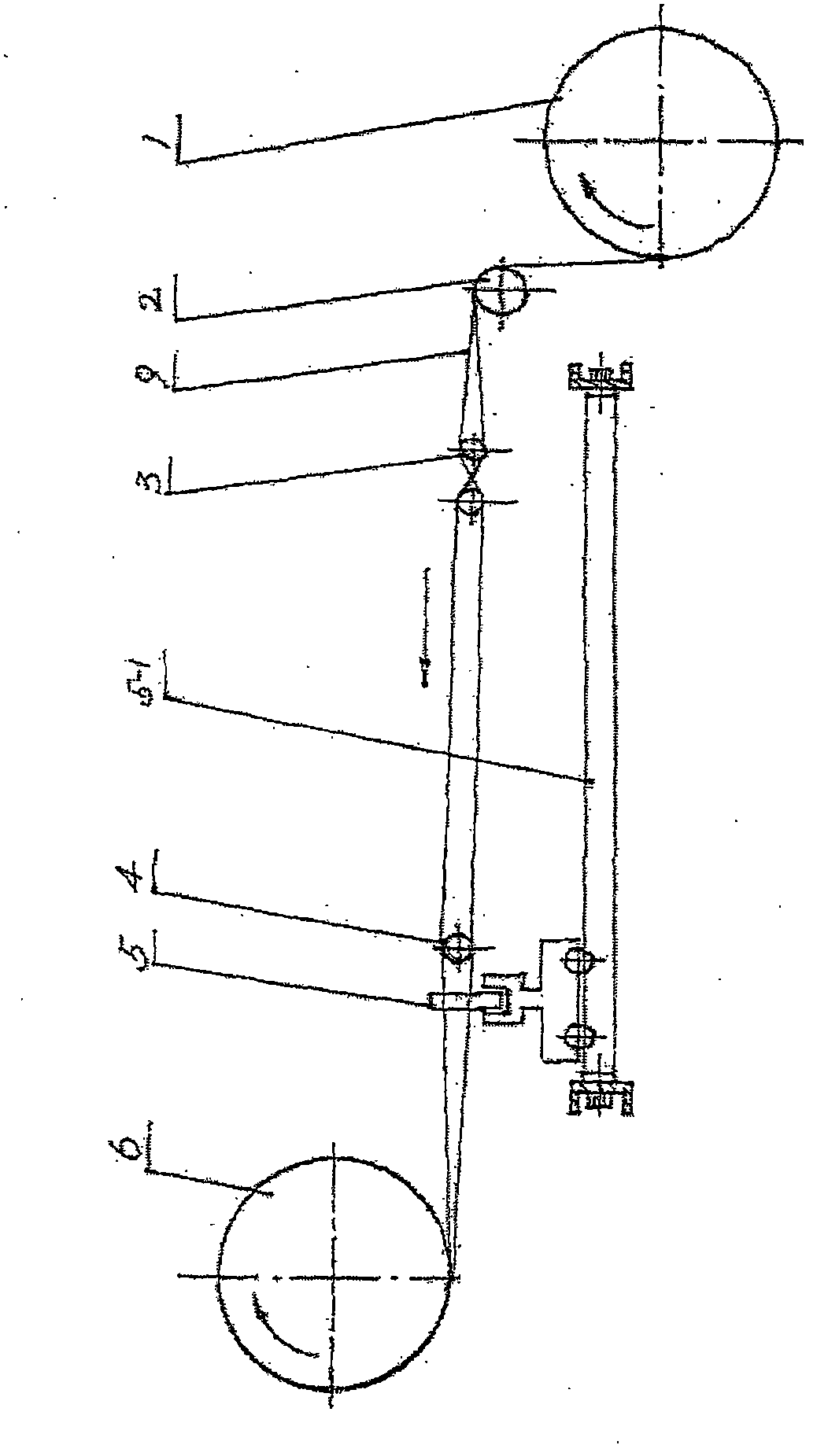

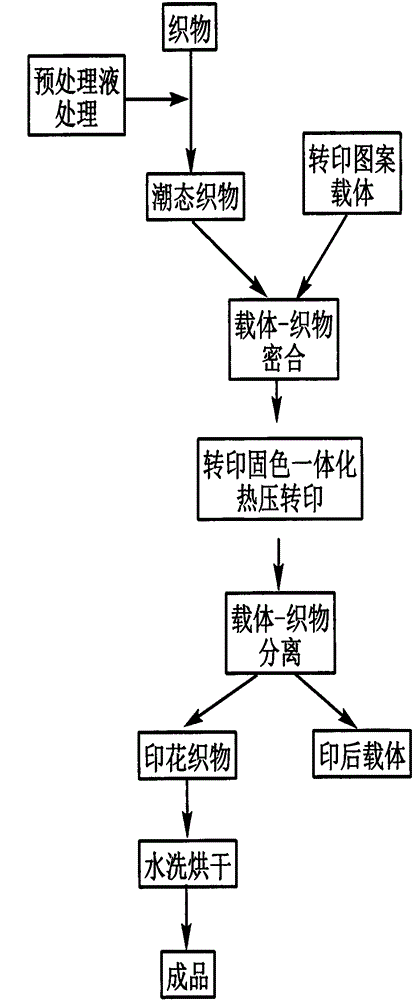

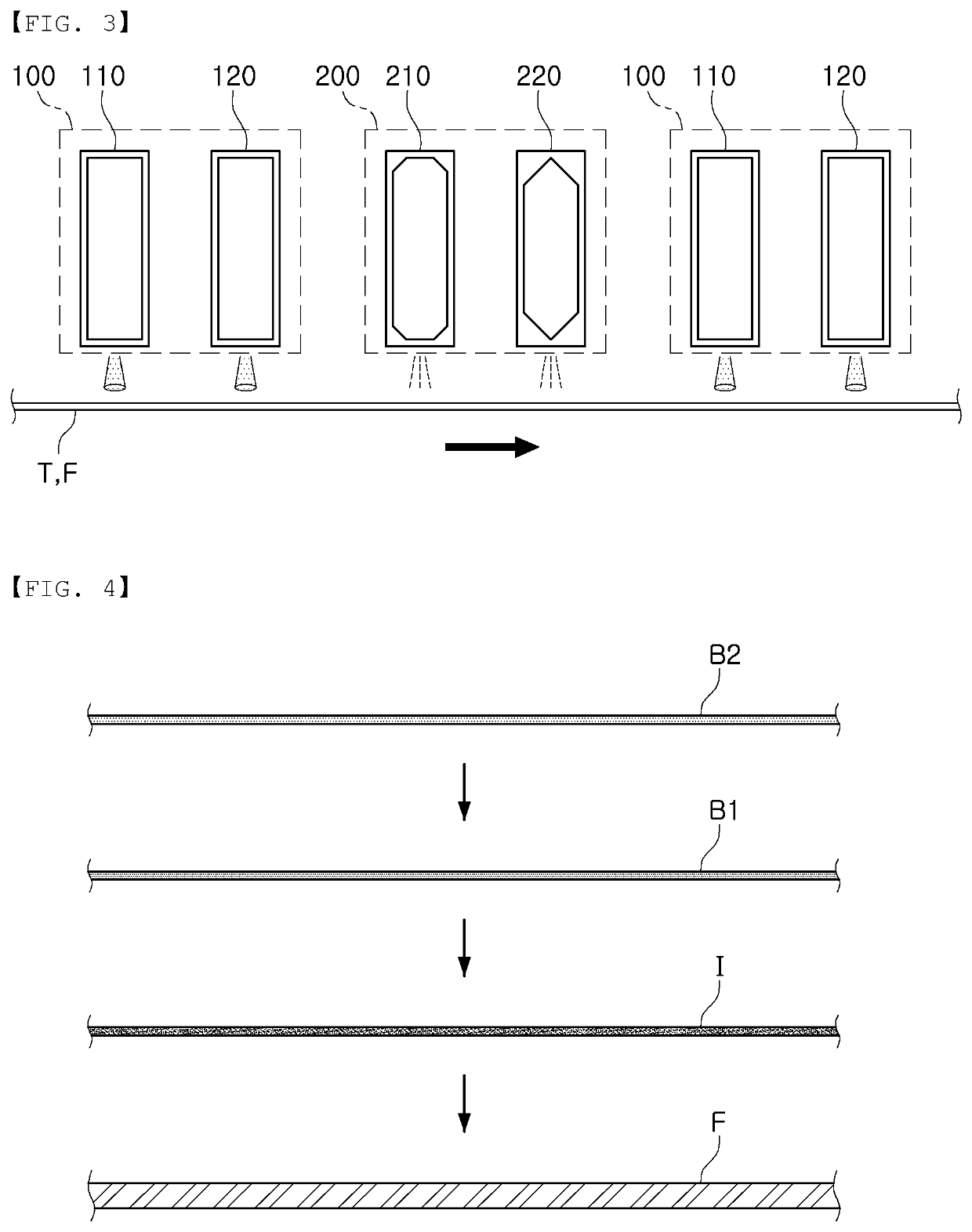

New pretreatment method for transfer printing

The invention relates to a new pretreatment method for transfer printing. In the invention, the original padding treatment method applying pretreatment liquid to the fabric to be printed is changed, and a pretreatment method applying the pretreatment liquid to transfer printing paper is adopted. The treatment method comprises the following steps: a transfer printing carrier (the substrates include paper, plastic film and aluminum foil) is treated with the pretreatment liquid through the pretreatment equipment of a transfer printing machine; the side of the transfer printing carrier, with the dye pattern, is required to be treated by the pretreatment liquid; after the treatment, the side of the transfer printing carrier, with the dye pattern, and the fabric to be printed are mutually fitted, and the transfer printing is completed through transfer printing equipment. The pretreatment method solves the problems of original treatment methods that the fabric is easy to have the defects of elongation, offgrain, shrinkage, etc., and the pattern of the printed fabric is distorted, and the product quality is seriously affected.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Printing machine used for ventilating and cooling T-shirt fabric

InactiveCN104512098AEasy to reuseImprove surface cleanlinessCylinder pressesTransfer printingPulp and paper industryAluminum foil

The invention relates to a printing machine used for ventilating and cooling T-shirt fabric, which comprises: a cloth placing roller, a conveyor belt, a tension cloth guiding roller group, a wetting roller group, a printing compression roller and a drying drum roller group which are sequentially arranged along a cloth running path, and an embossing roller that matches the printing compression roller, the printing machine is characterized in that one side of the embossing roller is provided with an aluminum foil transfer paper unwinding roller, the other side is provided with an aluminum foil transfer paper washing roller group, and the aluminum foil transfer paper washing roller group is provided with at least one hairbrush groove. The aluminum foil transfer paper washing roller group arranged on the printing machine can timely wash the aluminum foil transfer paper after the transfer print is finished, and is convenient for recycling use of next time, the arrangement of the hairbrush groove makes the aluminum foil transfer paper able to experience washing twice, and the surface clearness is higher.

Owner:SUZHOU OUBBOO FASHION CO LTD

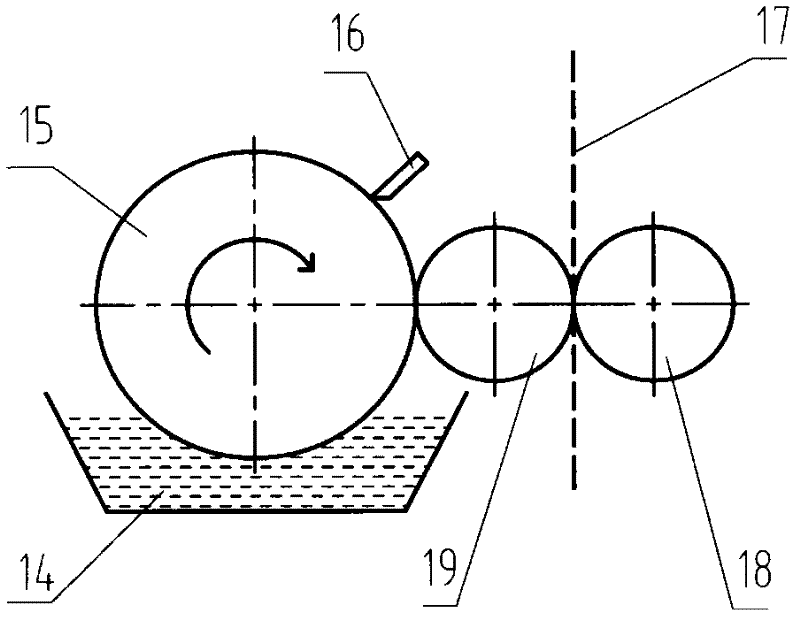

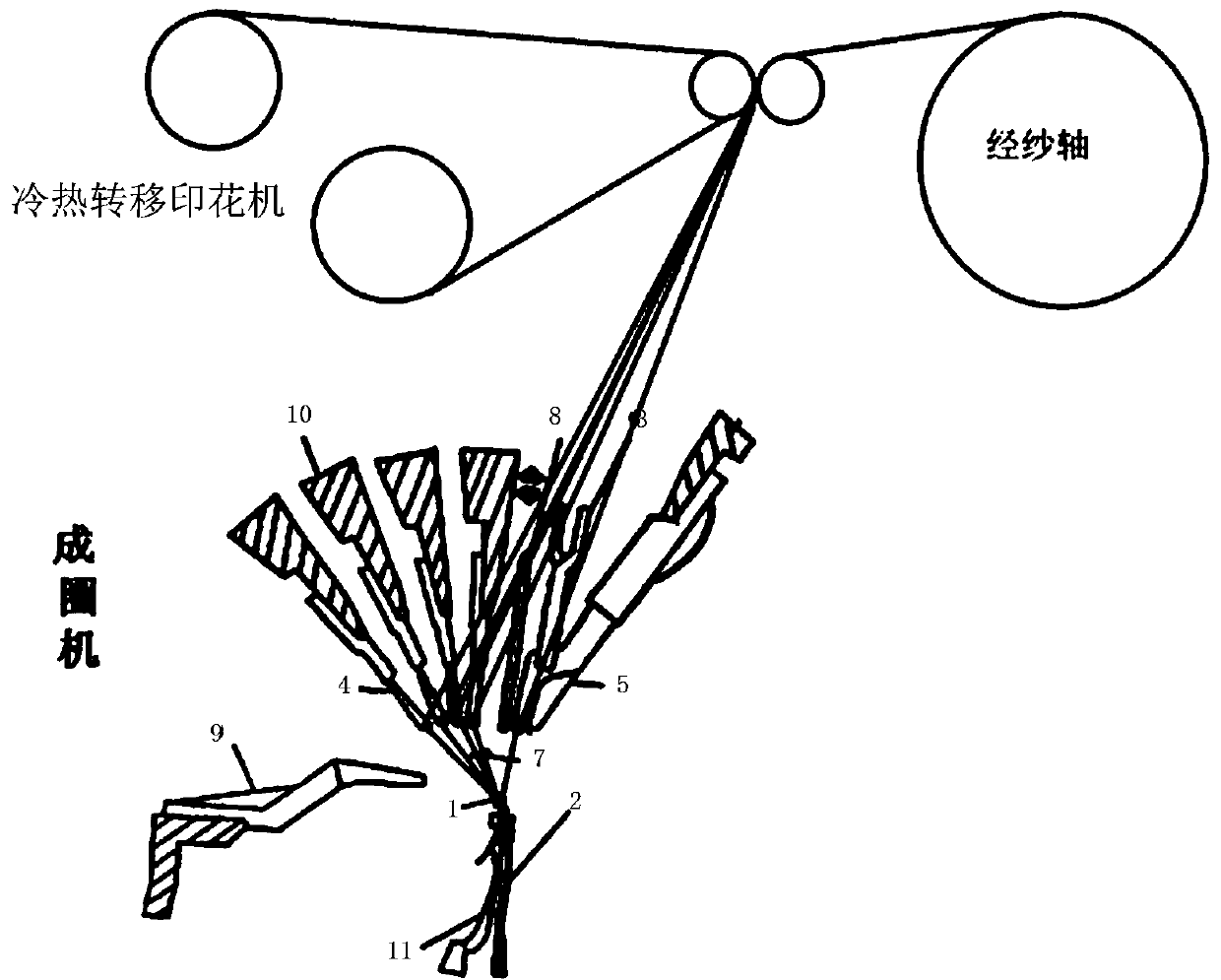

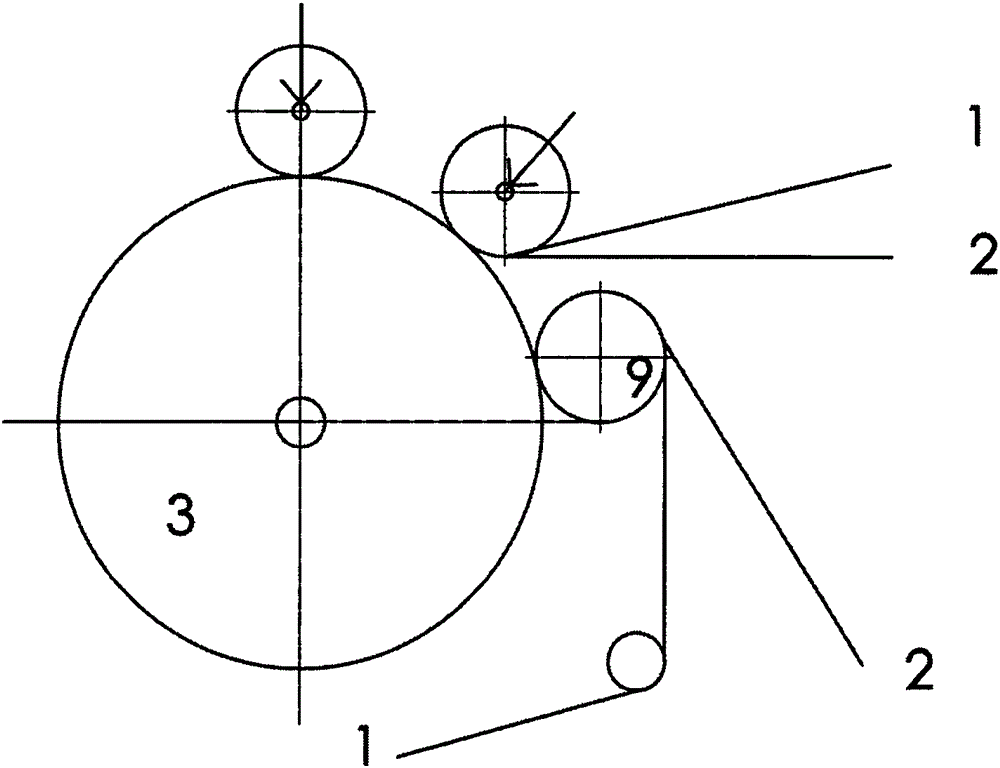

Heat transfer warp decorating machine

InactiveCN101885261AGlossy and movingTransfer printingMoving yarn parts treatmentPulp and paper industryHeat transfer

The invention relates to a heat transfer warp decorating machine, which comprises a warp beam, a hot roller and a decorating warp beam arranged along the process. The heat transfer warp decorating machine further comprises decorating paper of which the back side is adhered to the circumferential surface of the hot roller and the front side is adhered to the warp; and the distance between the decorating warp beam and the hot roller can be adjusted. As the distance between the decorating warp beam and the hot roller can be adjusted, the heat transfer warp decorating machine can adjust the color misregistration of the warp to adapt to various patterns and obtain cloth with more attractive luster.

Owner:WUJIANG NEW DEV TEXTILE

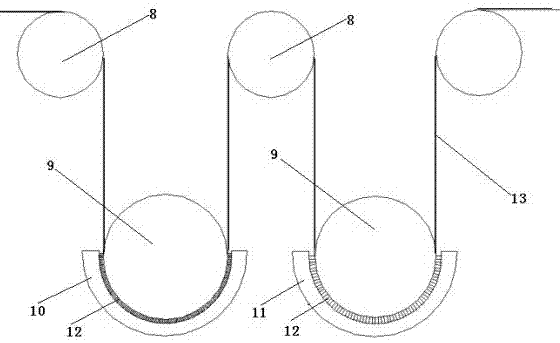

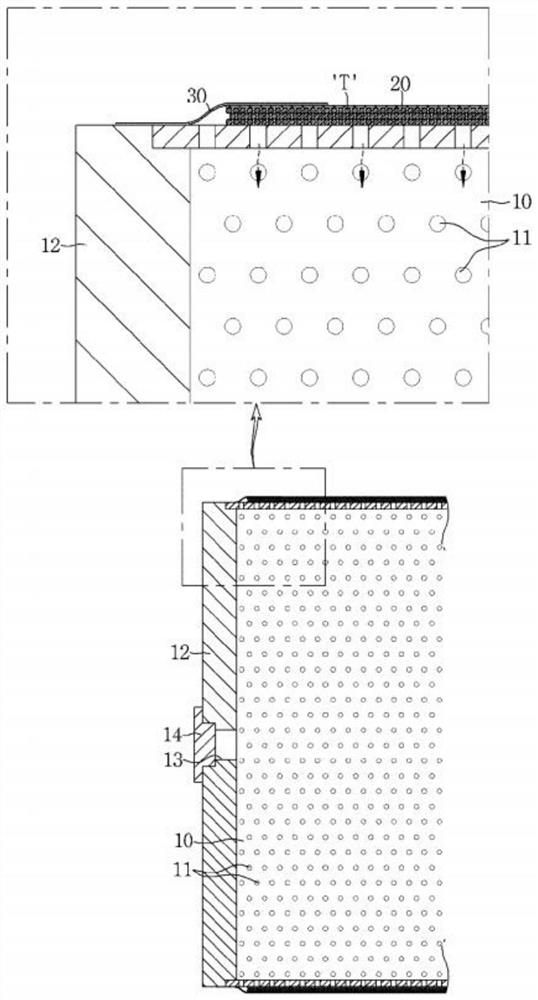

Pile fabric transfer printing device

InactiveCN103042820ASolve the problem of not vertical hairImprove Cloth EffectsTransfer printingTransfer-treating textile partsVacuum pumpingEngineering

The invention relates to a pile fabric transfer printing device which includes a cloth feeding mechanism, a printing mechanism and a winding mechanism. The printing mechanism includes a printing chamber in which a heating roller is arranged, a feeding roller is arranged along a cloth feeding direction of the heating roller and a paper delivery roller, a first draw-out roller and a second draw-out roller are arranged along a cloth draw-out direction of the heating roller. The fabrics are windingly arranged on a plurality of cloth feeding rollers, the feeding roller, the heating roller, the first draw-out roller, the second draw-out roller and the winding mechanism in sequence. Printing paper is wound round the feeding roller through a paper feeding roller, printing paper and the fabrics are wound around the heating roller together, and the printing paper is wound around a paper collecting roller through the paper delivery roller. The pile fabric transfer printing device is characterized in that a vacuum pile absorbing device is arranged on the upper portion of the printing chamber and the vacuum pile absorbing device includes vacuum pumping port, a plurality of high pressure tuyeres and water-cooling tuyeres which are arranged in sequence along a direction from the first draw-out roller to the second draw-out roller. The pile fabric transfer printing device solves the problem that piles of a cloth surface are not upright after a pile fabric is subjected to transfer printing and improves cloth surface effects after a pile fabric is subjected to transfer printing.

Owner:夏美顺

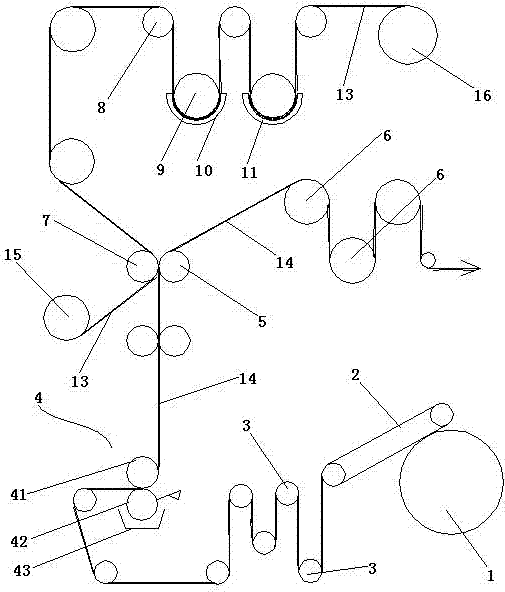

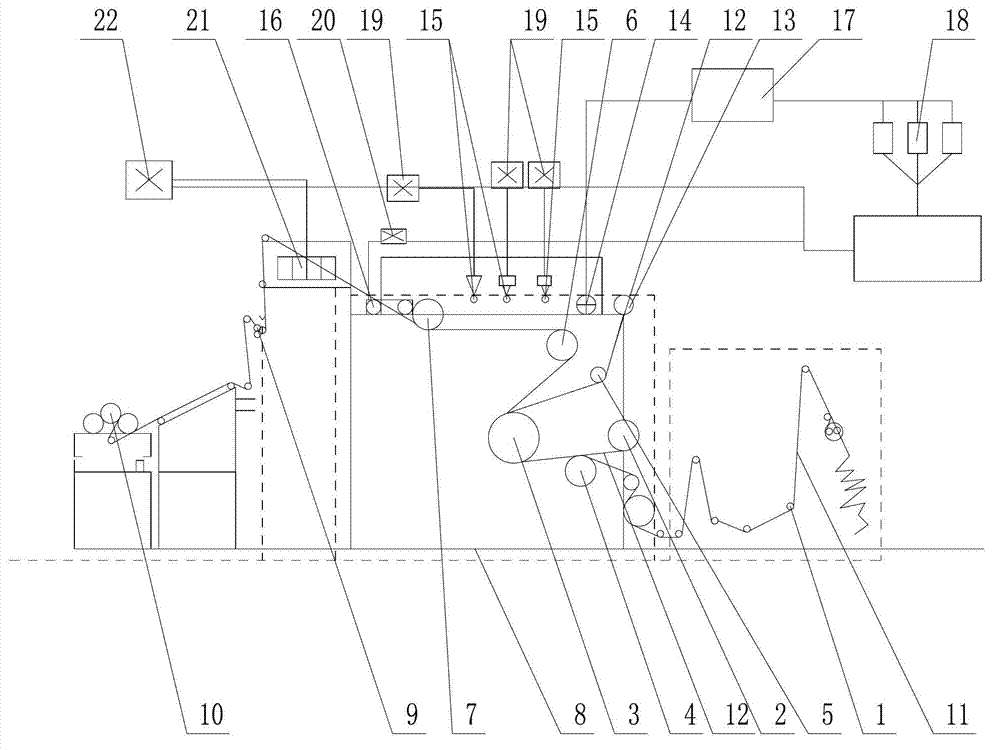

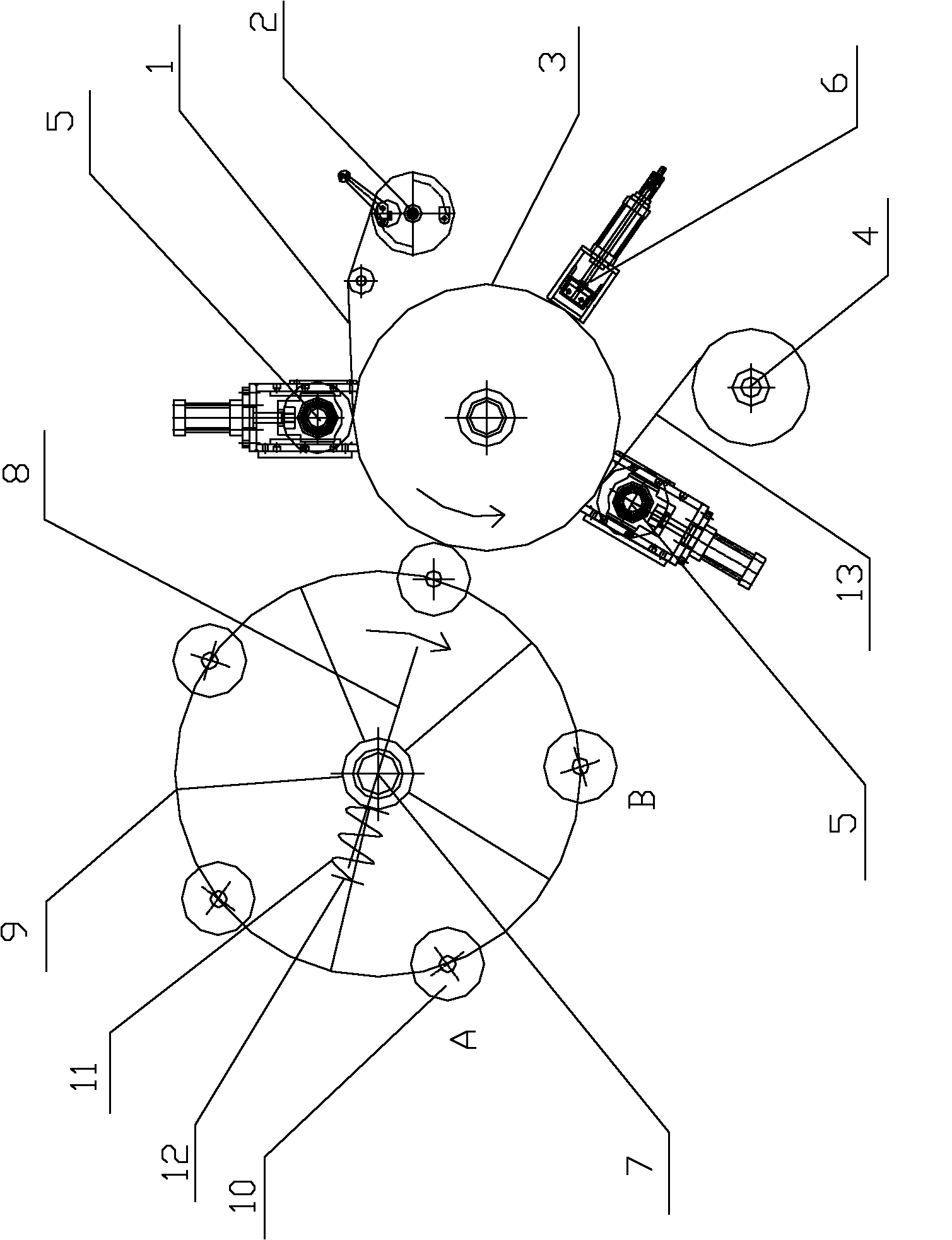

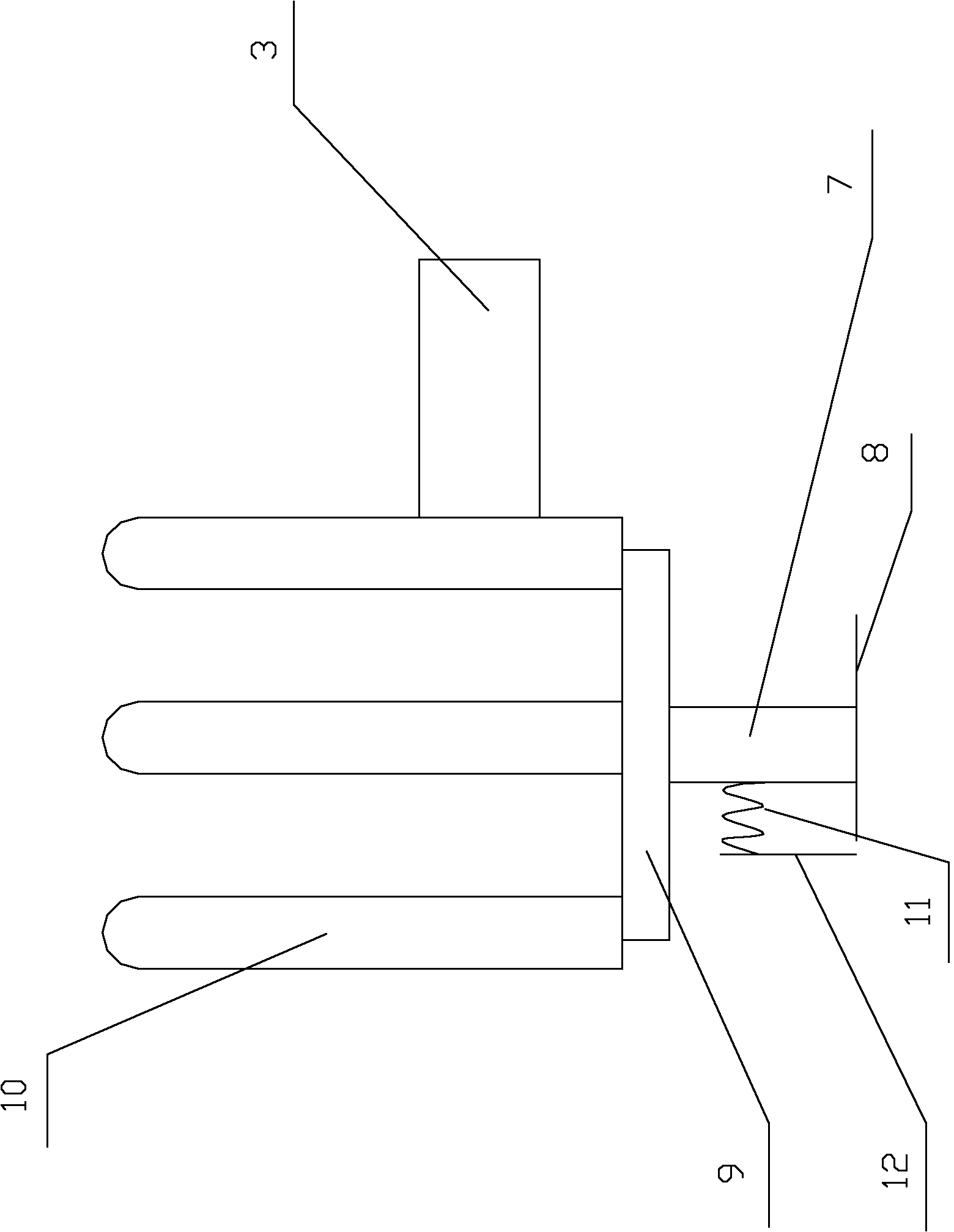

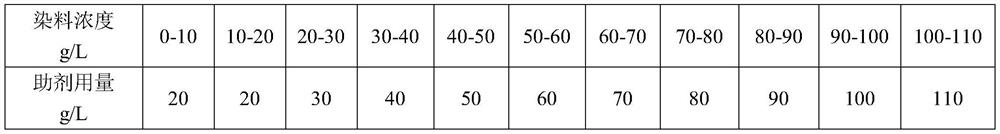

Knitting machine for synchronization of online cold-heat transfer printing and pattern weaving function and application method thereof

InactiveCN108396457AEasy to operateReduce laborCrochetingTransfer printing processTextile printerIndustrial Ethernet

The invention provides a knitting machine for synchronization of online cold-heat transfer printing and pattern weaving function and an application method thereof, and is intended to solve the problems with processing time and pollution emission restraining in the whole process of textile printing and dyeing of apparel, thus rejuvenating textile industry. The knitting machine is free of pollution,high in efficiency and good in intelligence. Advanced control system and expert system are employed; online data are acquired and monitored quickly; various process parameters are set and adjusted; remote fault diagnosis is performed; machine networked control, diagnosis and management are implemented via the internet, industrial Ethernet and field bus; the knitting machine is simpler and more convenient to operate, less manpower is used, and maintenance cost is lowered.

Owner:ZHONGYUAN ENGINEERING COLLEGE

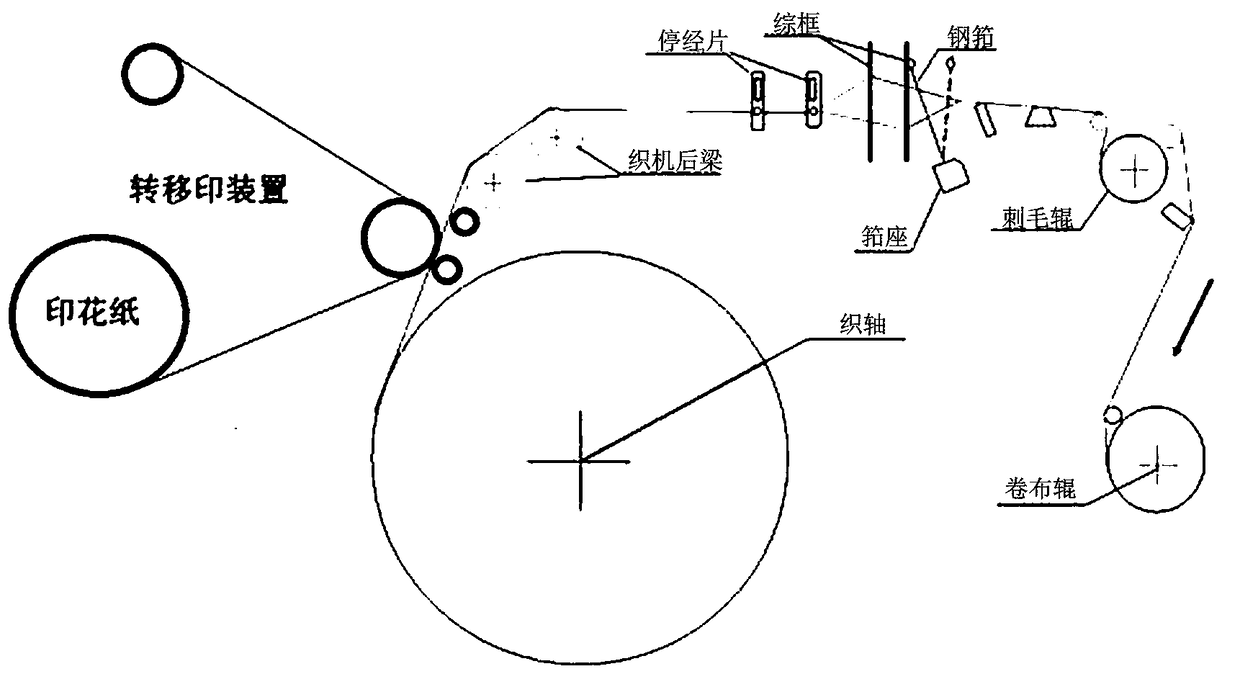

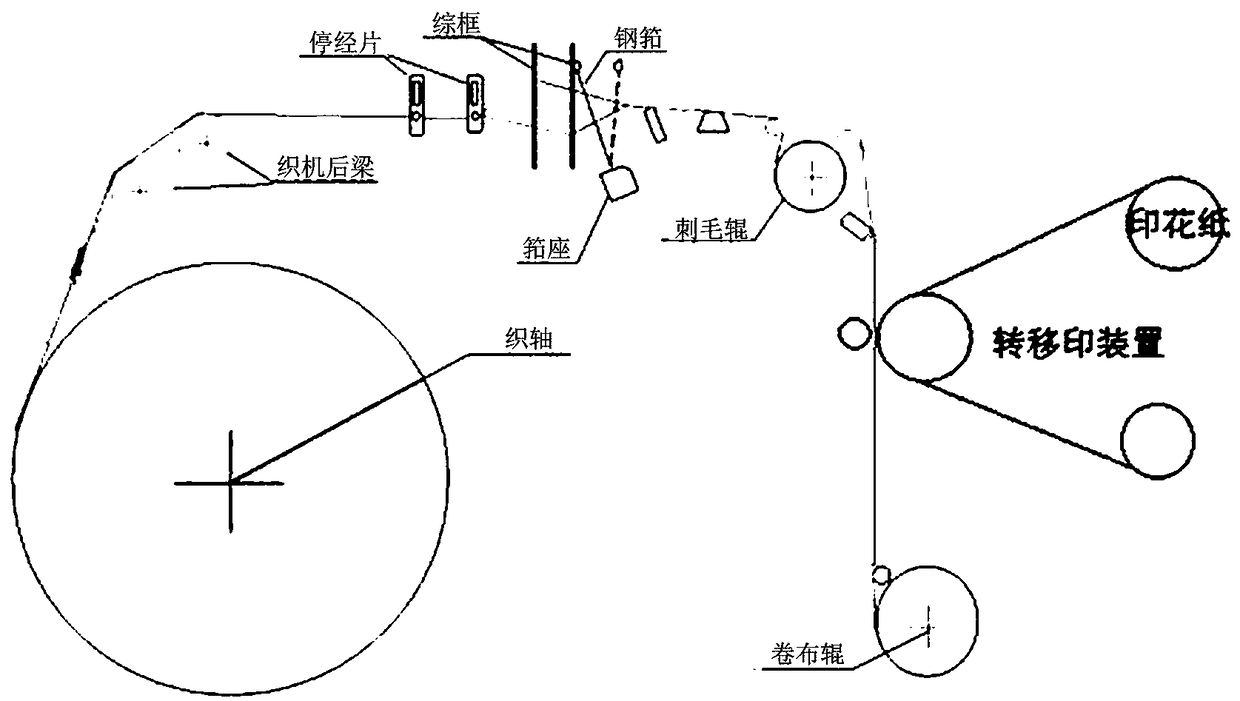

Weaving machine with synchronous online cold-heat transfer printing and dyeing and pattern weaving functions and use method thereof

InactiveCN108486747AAvoid processing timeEasy to operateTransfer printingAuxillary apparatusYarnEngineering

The invention discloses a weaving machine with synchronous online cold-heat-transfer printing and dyeing and pattern weaving functions and a use method thereof. The method includes the steps of conducting non-desizing slurry sizing preprocessing through shaft piece yarn plasmas and ultrasonic waves to prepare a slurry shaft, conducting drawing-in, putting the product on the weaving machine body, directly conducting printing and dyeing and synchronous weaving on warp between a rear beam and a weaving shaft and between a heald frame and the rear beam through an online cold-heat-transfer printingand dyeing device according to the design or the requirements of clients for patterns, design and colors and dermatoglyphic patterns of clothes for weaving the cloth, taking the cloth from the textile machine body, inspecting the cloth and conducting sizing. The current technology advantage of the weaving machine with the processing speed lower than 0.3 m / min is sufficiently used, dyeing, printing and weaving are synchronously completed, and the printing and dyeing time and place are saved; since the specific surface area of yarn directly distributed in the hot environment is larger than thatof cloth, warp vertically changes the position at high speed on the weaving machine, and the energy and time consumption for drying the yarn is lower than the energy and time consumption for drying the cloth.

Owner:ZHONGYUAN ENGINEERING COLLEGE

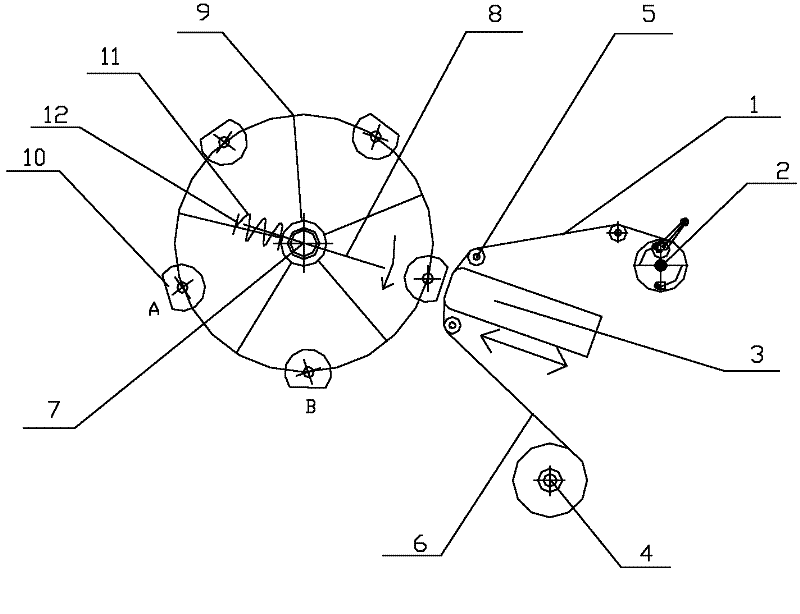

Heat transfer production process of silk socks

InactiveCN102133825AWith continuous productionWith thermal transfer productionDuplicating/marking methodsTransfer-treating textile partsSOCKSProcess engineering

The invention discloses a heat transfer production process of silk socks, relating to the field of mark heat transfer in the production process of silk socks. For solving the problem of heat transfer incapability of thin and high-temperature-unresisting textiles, such as silk socks, and the like, the operation initialization position of the machine is divided into the configuration of three different process parameters, i.e. a transfer part, a preheating part and acting time and pressure, and through the design, the heat transfer production process has the advantages of continuous production and the heat transfer production on thin and high-temperature-unresisting textiles.

Owner:刘磊

Integrated transfer printing of dye transfer and baking color fixation

ActiveCN102797175BImprove the efficiency of transfer printing productionOvercome the defects of thermal decomposition into aromatic amine substancesTransfer printingTransfer printing processEngineeringMoisture

An integrated transfer printing of dye transfer and color fixing by baking, which combines transfer printing and color fixing into one process, and adds a heating mechanism for baking and color fixing to the transfer printing device of the transfer printing machine, while satisfying the original transfer printing function Complete the color-fixing task of transfer fabric under certain conditions. The main process parameters in the integrated transfer printing of dye transfer and baking color fixation are dyestuff, moisture content, transfer pressure, temperature and time. The integrated transfer printing can overcome the shortcomings of the fabric color fixing process in the existing cold transfer printing, and improve the quality and output of the transferred fabric.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

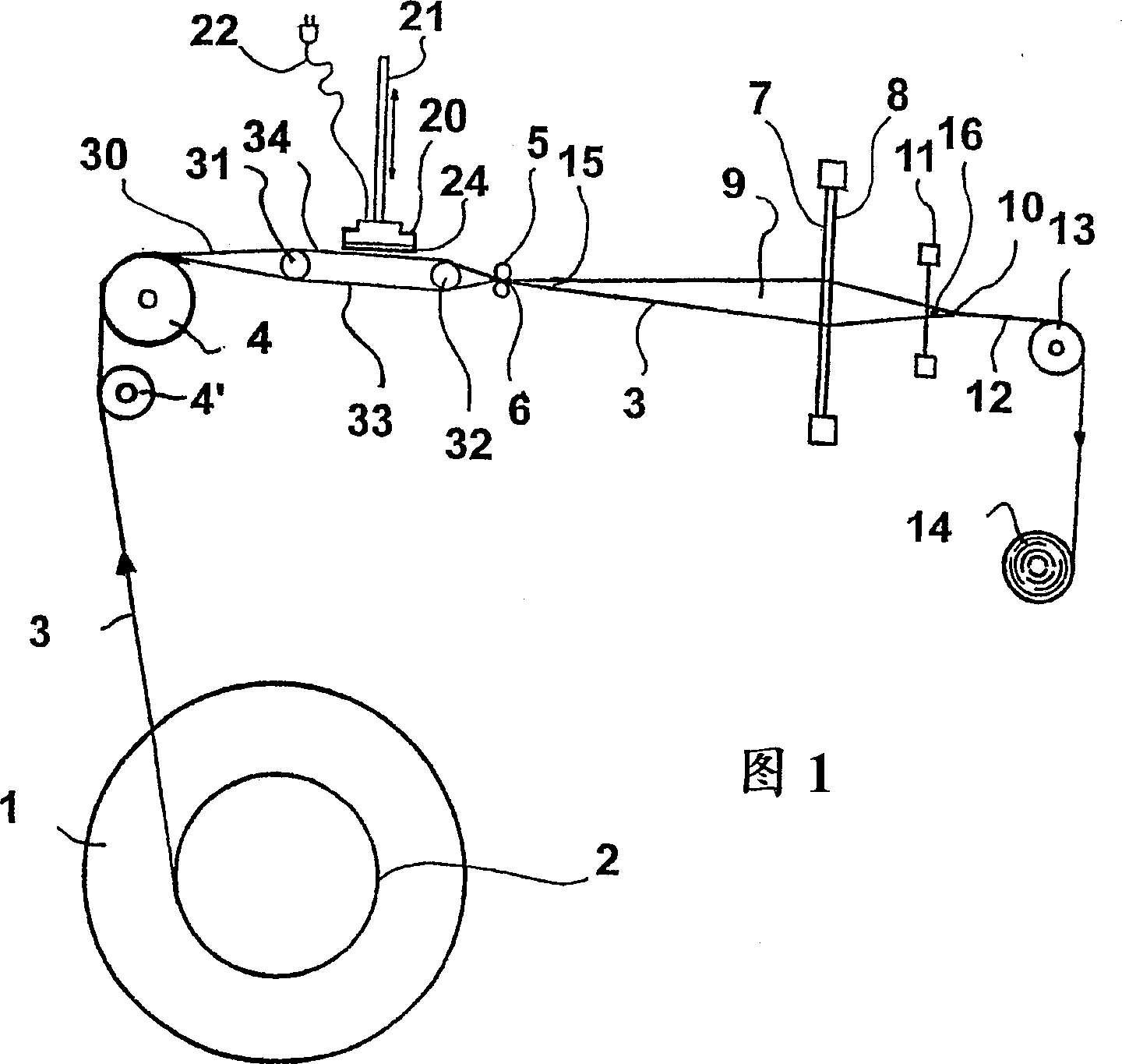

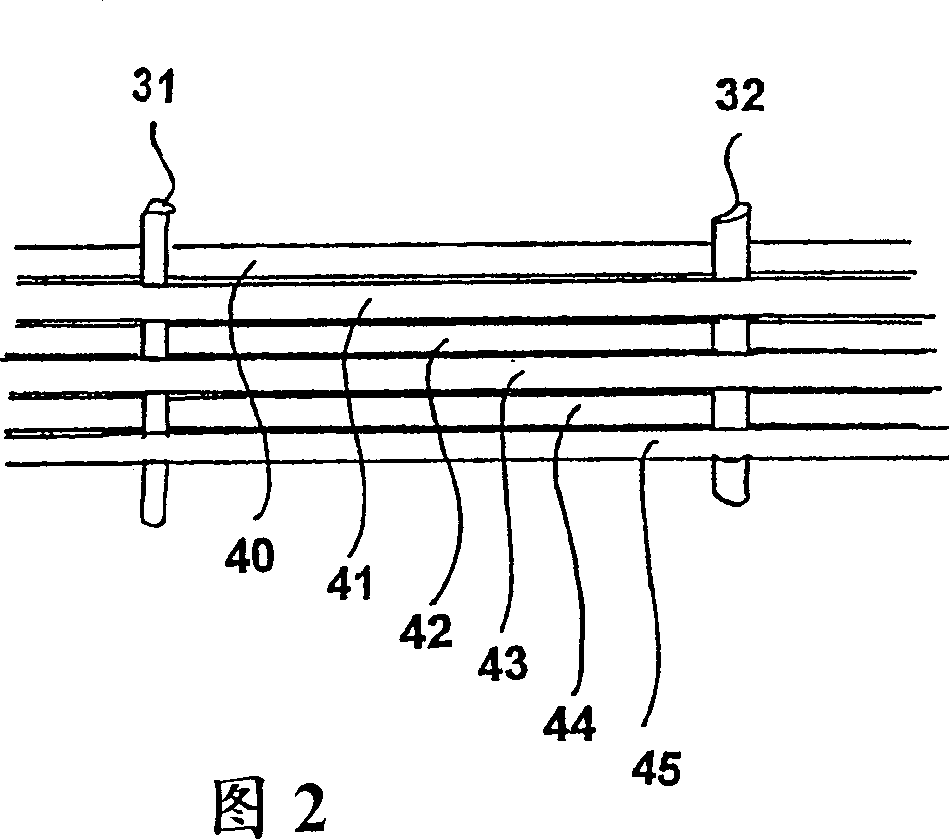

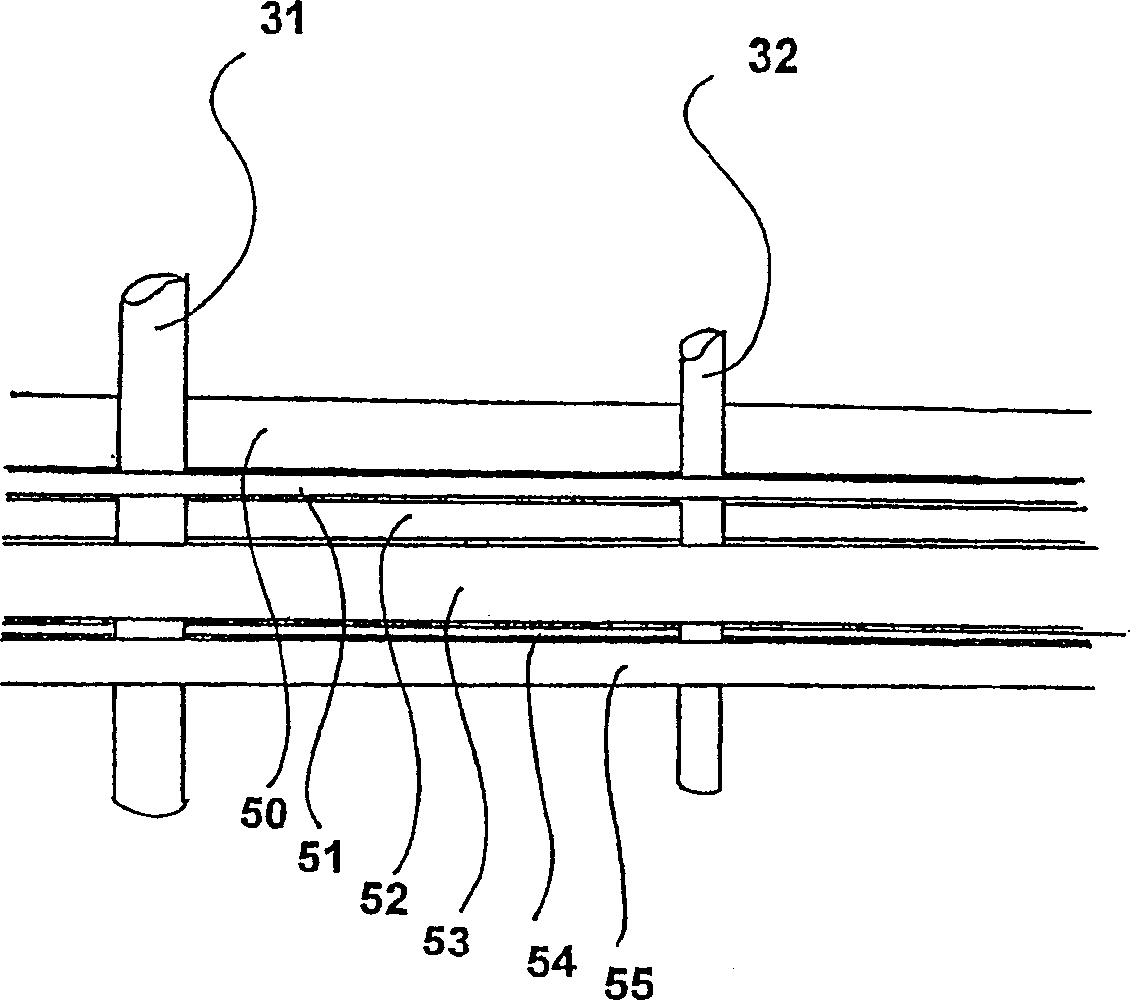

Method for obtaining woven fabric

InactiveCN1342226ALow elastic modulusIncrease changeLoomsMoving yarn parts treatmentEngineeringWeft yarn

The invention concerns a method for obtaining a woven fabric which consists in: continuously unwinding from a single warp beam (1), a set of parallel warp yarns (3); passing said set on a whip-roll (4); forming a shed (9) using heald means (7, 8), said shed being defined in the forward movement direction of the warp, at the input through an opening stitch (15) of the shed, and on the other side through a face stitch (10); inserting a weft yarn (16) in the shed in the proximity of the face stitch (10) to form a fabric; and finally uniformly pulling and batching the resulting fabric; method which consists, in the proximity of the shed opening stitch, in heating the warp yarns (3), and then cooling said warp yarns in the shed before they reach the heald means (7, 8), characterised in that only part (34) of the warp yarns is heated.

Owner:CORTECS LTD

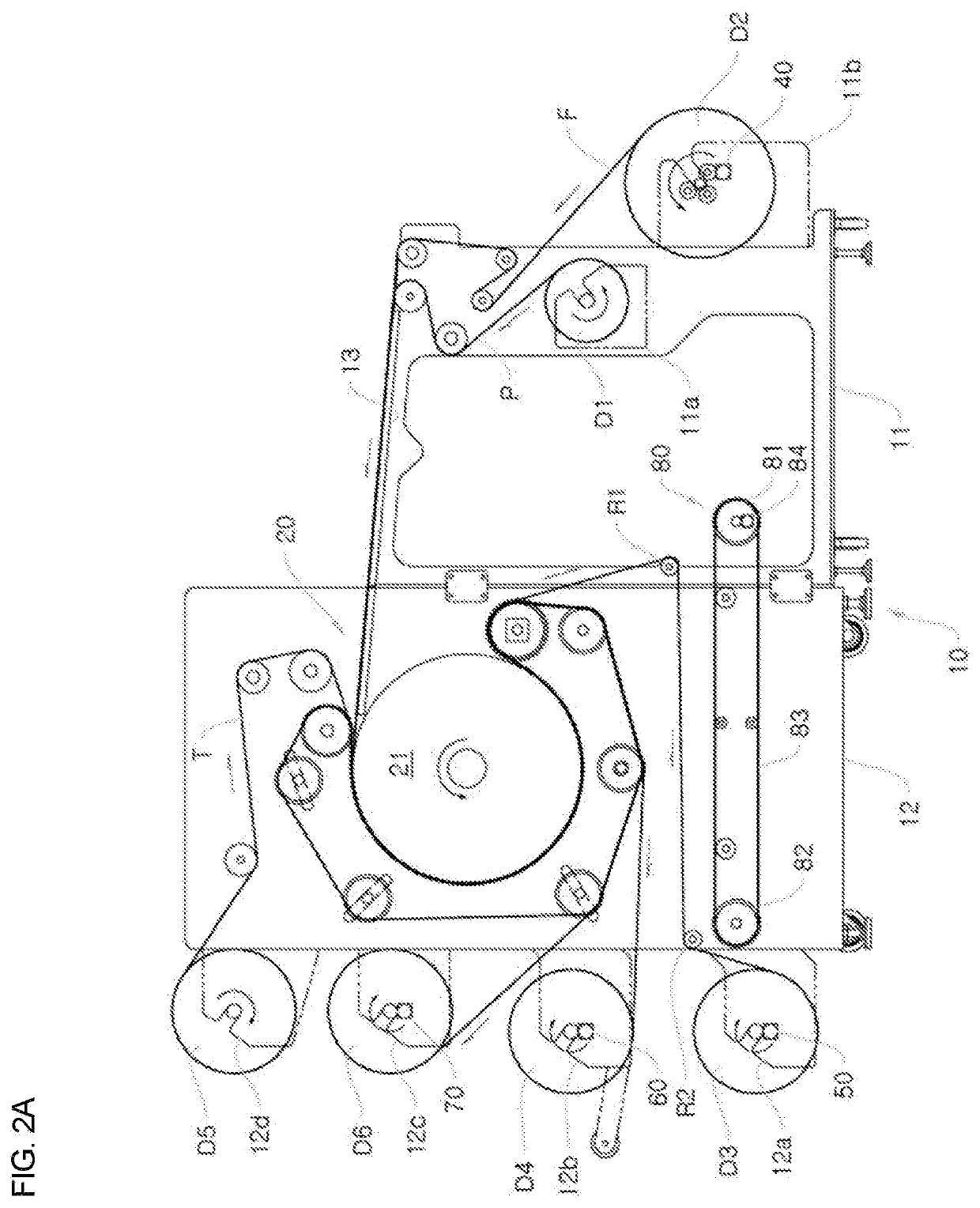

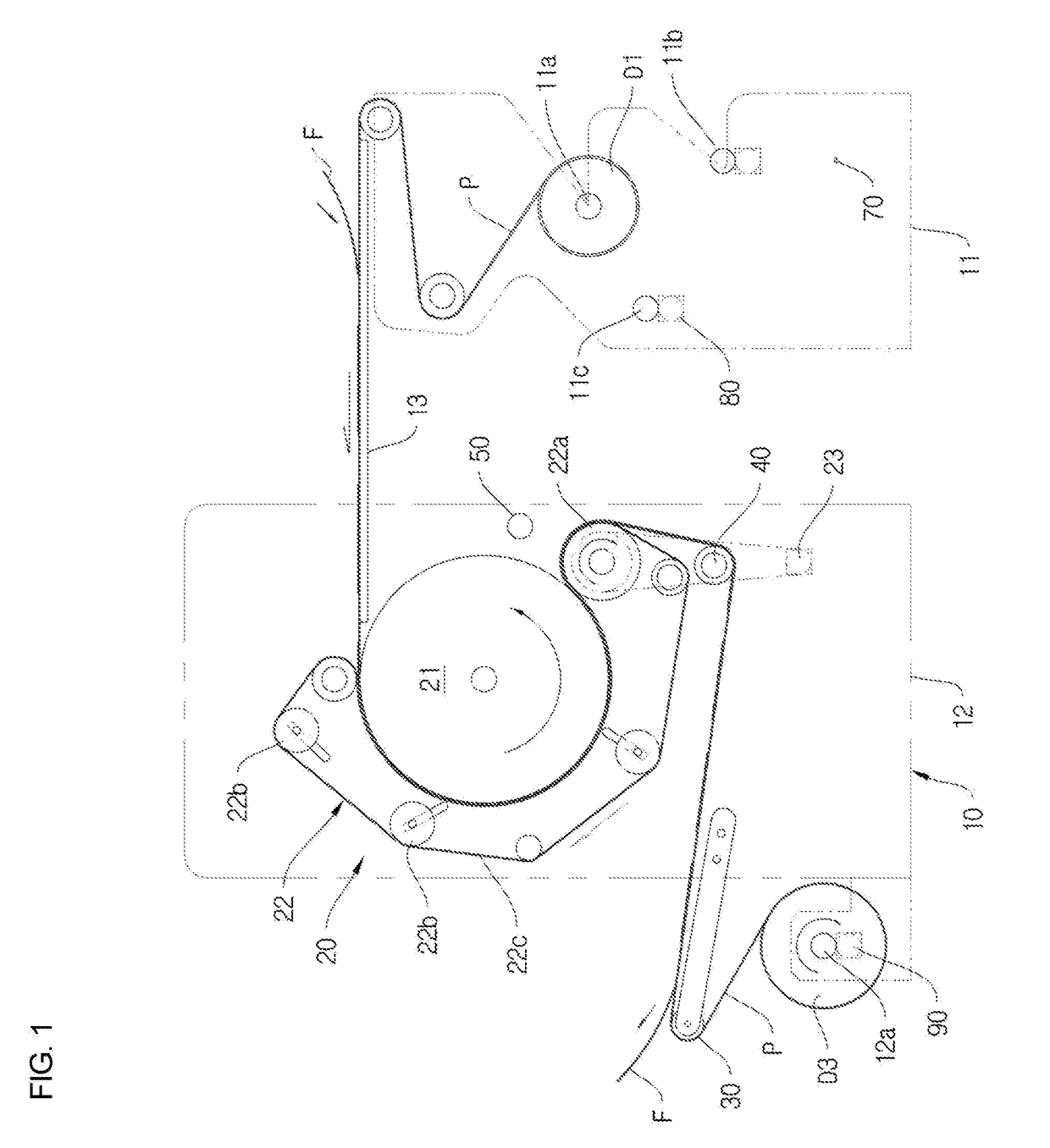

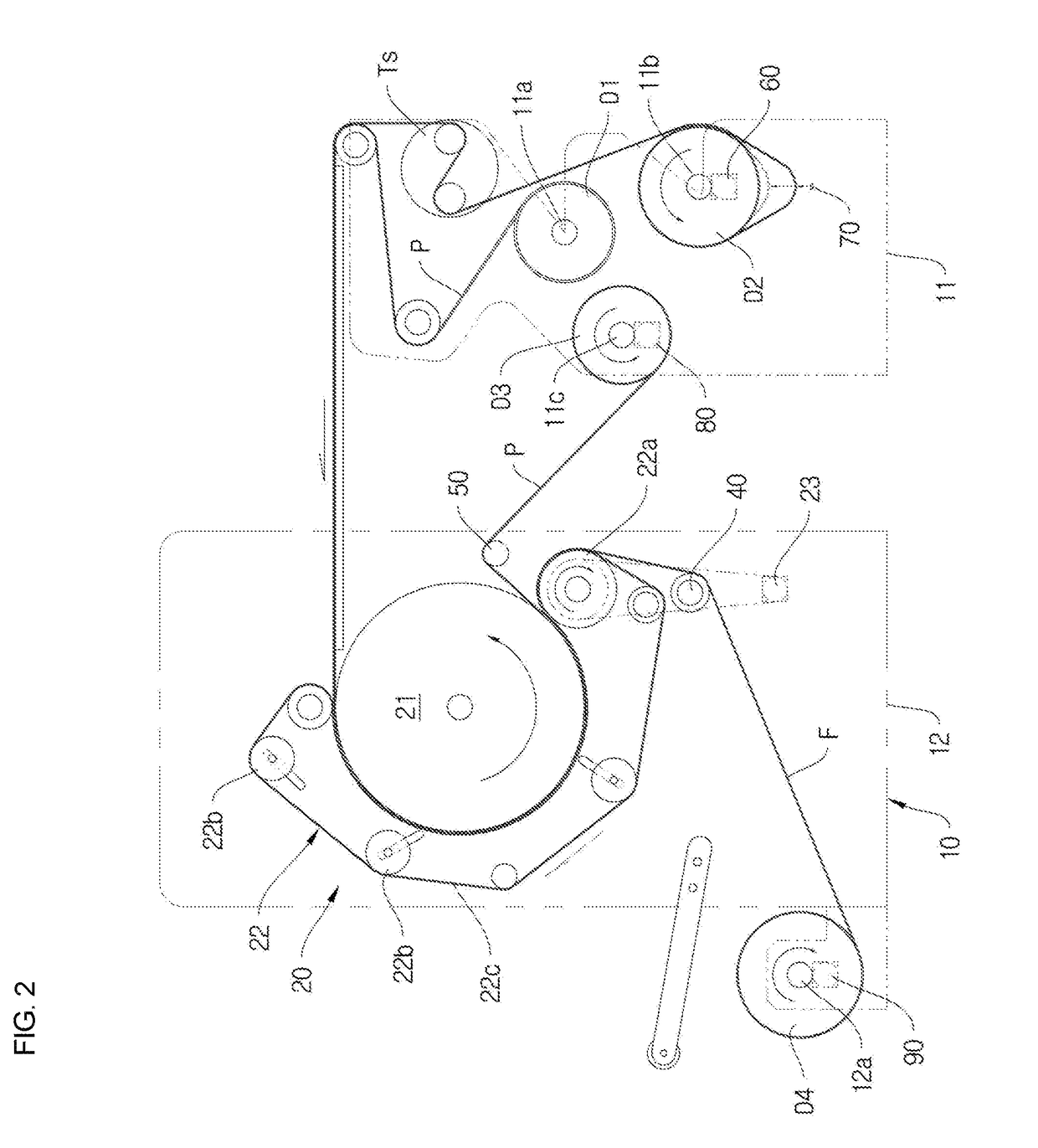

Hybrid transfer machine

ActiveUS20190047280A1Easy to operateRapidly and conveniently performedTransfer printingOther printing apparatusEngineeringThermal transfer

A hybrid transfer machine includes: a body including a first drum installation part, a second drum installation part, a first body, a second body, and a worktable; a first drive means configured to allow wound fabric to be unwound; a thermal transfer unit configured to be installed in the second body, and to press and heat the fabric and transfer paper; a piece-type roller arm configured to be installed in the second body, and to guide the transfer paper to the third drum installation part; a second drive means configured to allow the transfer paper to be wound; a third drive means configured to allow the fabric to be wound; and a conveyer configured to be installed in the body, and to transfer the fabric and the transfer paper to the third and fourth drum installation parts.

Owner:KYUNGIL TECH

Transfer tie-dyeing method and nylon-cotton lace fabric prepared by same

ActiveCN113265804AIncrease profitVarious forms of expressionTextile/flexible product manufactureDyeing processPolymer scienceEngineering

Owner:福州华冠针纺织品有限公司

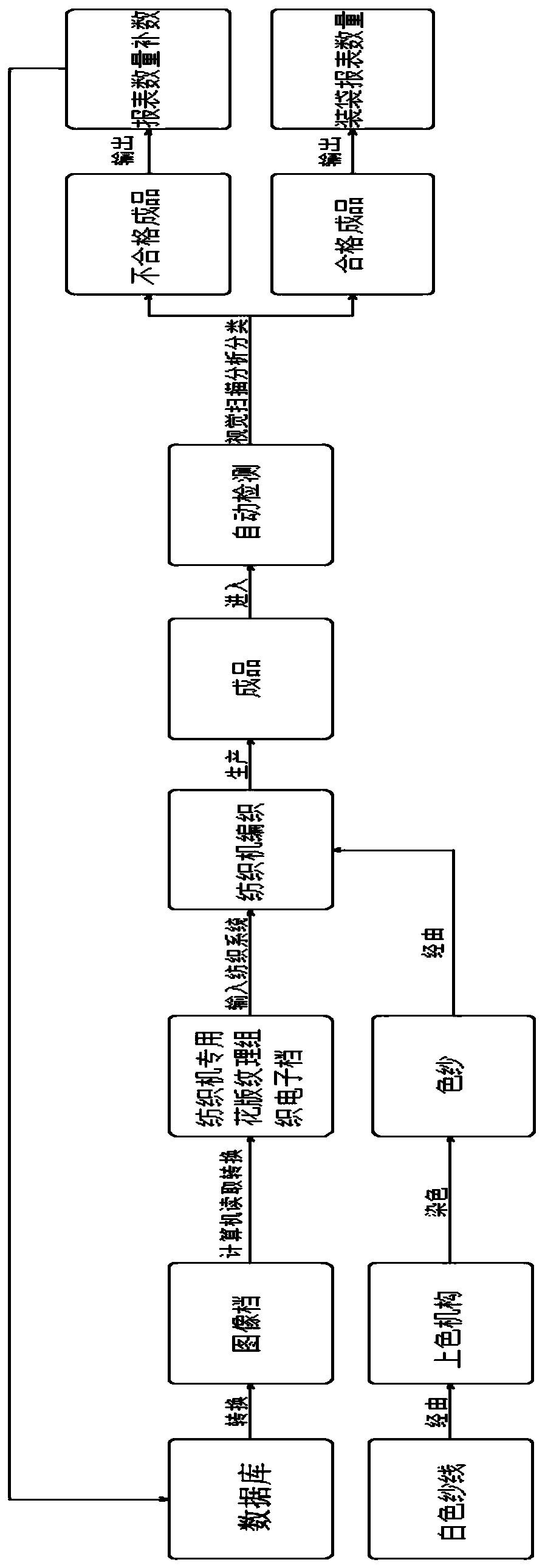

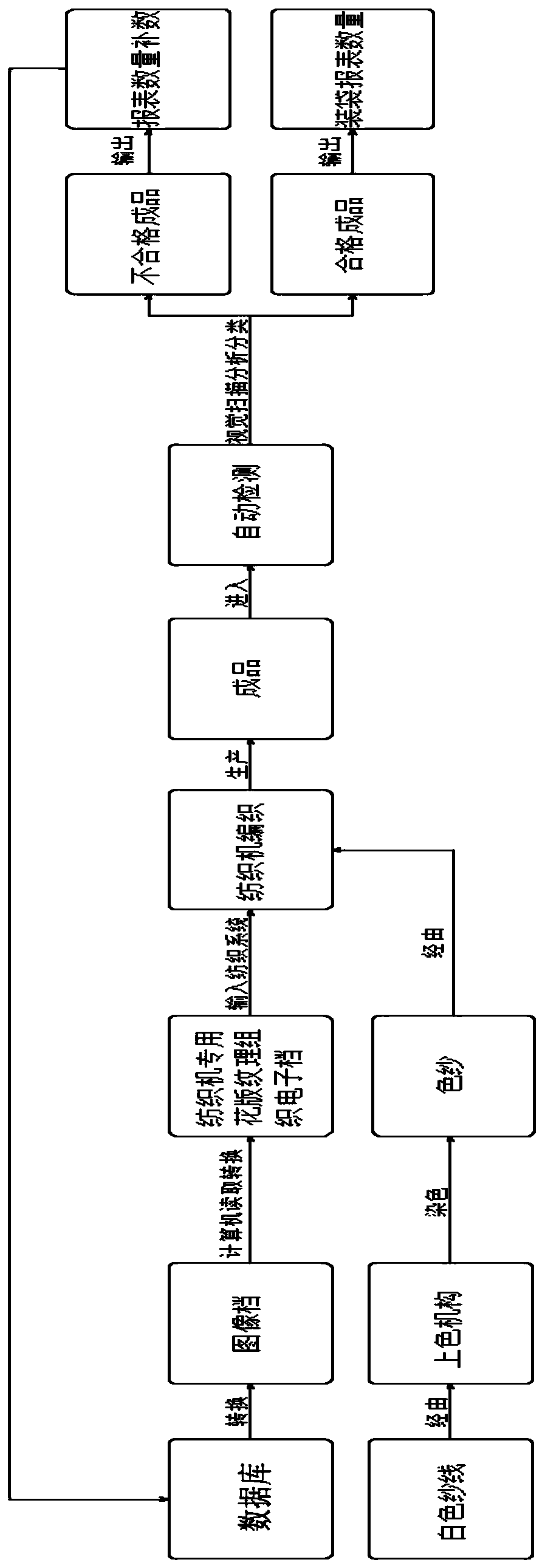

Preparation method of color anti-counterfeiting code cloth label

The invention discloses a preparation method of a color anti-counterfeiting code cloth label. The preparation method comprises a step 1, establishing a database; a step 2, converting data informationinto an image file; a step 3, converting the image file into a pattern plate texture organization electronic file special for a textile machine; a step 4, performign waterless yarn dyeing, including:(1) dyeing first color paper and second color paper; and (2) transferring the colors of the first color paper and the second color paper to the yarns; a step 5, weaving an anti-counterfeiting code; feeding the dyed yarns into the textile machine such that the textile machine organizes an electronic file according to the pattern plate texture and weaves the anti-fake plaiting label in a warp-wise mode; and a step 6, analyzing the data in the step 1 and the cloth labels woven in the step 5 by adopting automatic detection equipment, classifying qualified products and unqualified products, ensuring the qualification of the products, and making sub-packaging and detailed reports. According to the invention, the color diversity of the anti-counterfeiting code is increased, and the anti-counterfeiting effect is improved; and the anti-counterfeiting code cloth label is thinned, so that the softness of the anti-counterfeiting code cloth label is improved. Meanwhile, the production efficiency ishigh, the production loss is low, and safety and environmental protection are achieved.

Owner:白复华

Stocking sheathing tube for silk stocking heat transfer machine

InactiveCN102490458ASolve the problem of poor printing fastnessTransfer printingTransfer-treating textile partsEngineeringHeat transfer

The invention discloses a stocking sheathing tube for a silk stocking heat transfer machine and relates to the field of marking heat transfer in the production process of silk stockings, solving the problems that heat transfer cannot be applied to light and thin textiles incapable of resisting high temperature, such as silk stockings and the like and the printing fastness is poor due to non-uniformity of pressure. According to the stocking sheathing tube for the silk stocking heat transfer machine, which is provided by the invention, a plane is formed in the direction of the preheated stocking sheathing tube, which is opposite to an ironing head, and is matched with a surface plane of the ironing head. Due to the adoption of the design, the stocking sheathing tube has the advantages of continuous production and heat transfer production on the light and thin textiles incapable of resisting the high temperature as well as uniformity for printing fastness.

Owner:刘磊

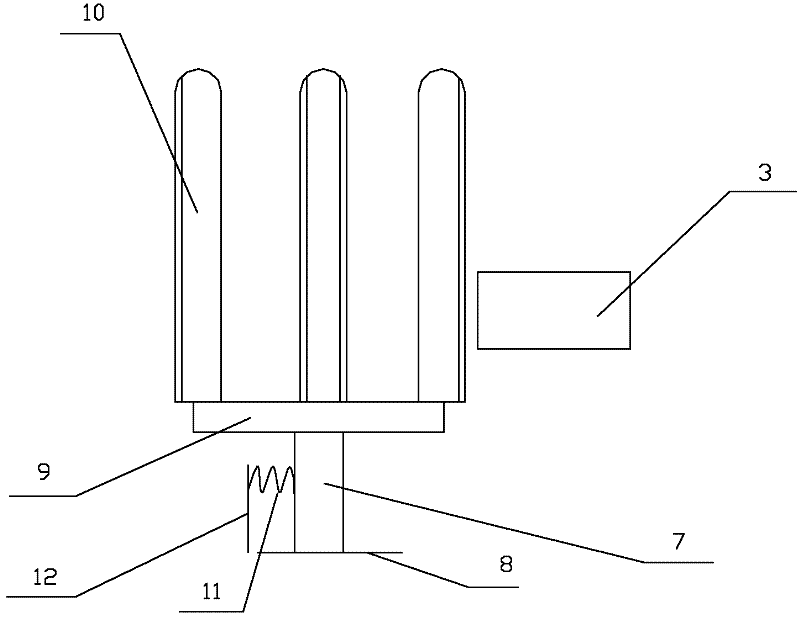

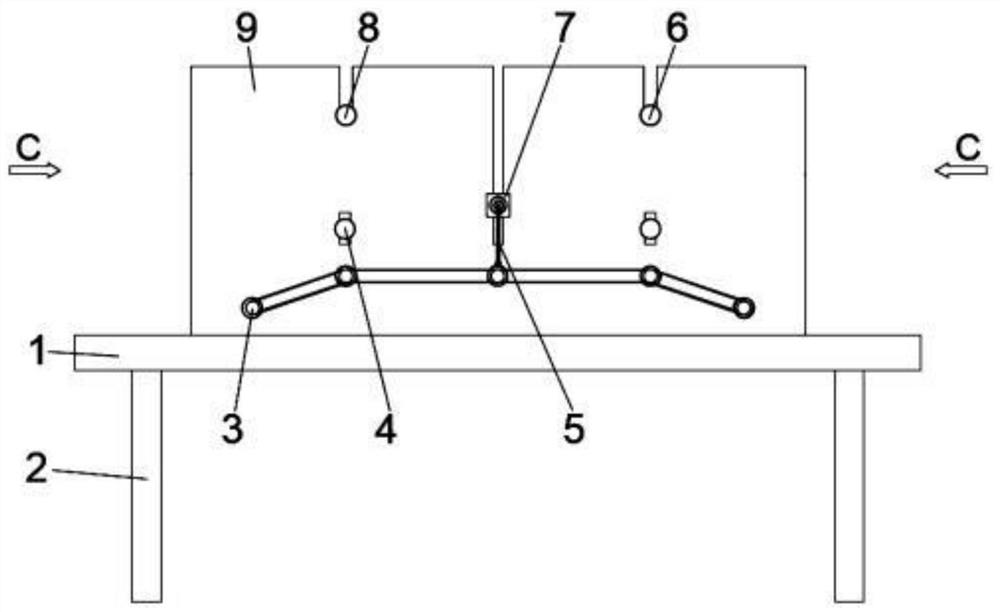

Waxing device for garment textile machines

ActiveCN109056237BUse levelingEasy to apply continuouslyTransfer-treating textile partsFabric parts treatmentMechanical engineeringIndustrial engineering

The invention provides a waxing device for a clothing textile machine, which comprises a cloth rotating roller, a membrane rotating roller and side support plates; the top of the main table is fixed and symmetrically provided with two side support plates. The invention provides a waxing device for clothing textile machines. By providing a film-exiting rotary roll, when it is necessary to apply some patterns and patterns, the long-rolled diaphragm with the pattern is first wound on the film-exiting rotary roll. On the outside, then place the two ends of the film-out rotating roller in the openings on the top side of the two side support plates, and put one end of the diaphragm through the bottom of the two diaphragm rotating rollers and stick it upwards on the outer side of the film-receiving rotating roller. Then install the wax stick. At this time, the diaphragm will be attached to the top of the textile cloth. When smearing, the No. 1 motor and No. 2 motor drive the textile cloth and the diaphragm to rotate synchronously. At this time, the wax stick will also pass through the vacant pattern on the diaphragm. Applied on a textile cloth to obtain the desired pattern, the diaphragm is smoother to use and easier to apply continuously.

Owner:安徽方玺宠物用品有限公司

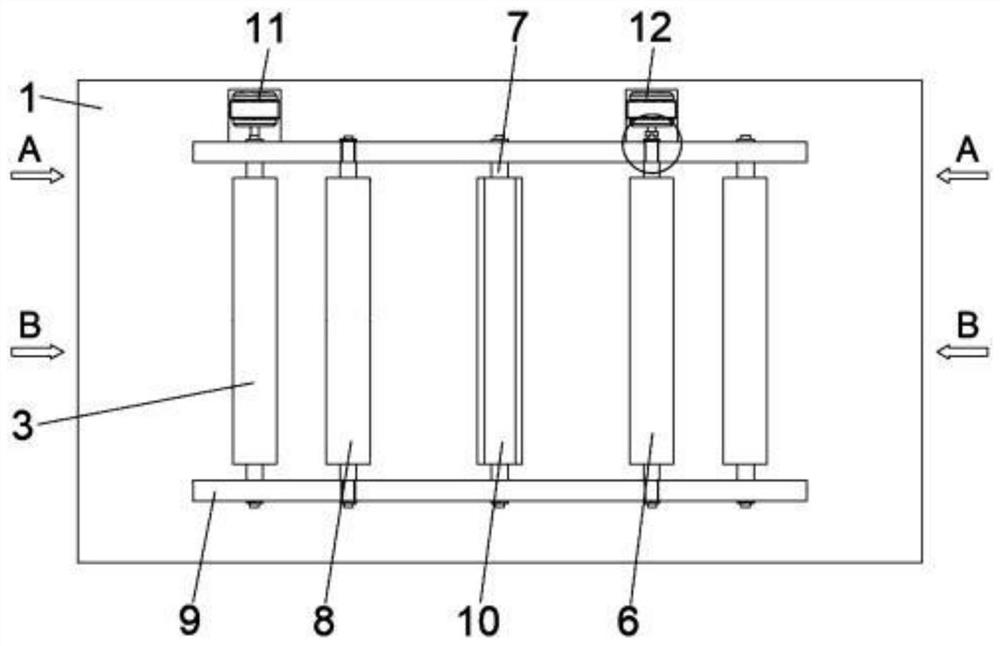

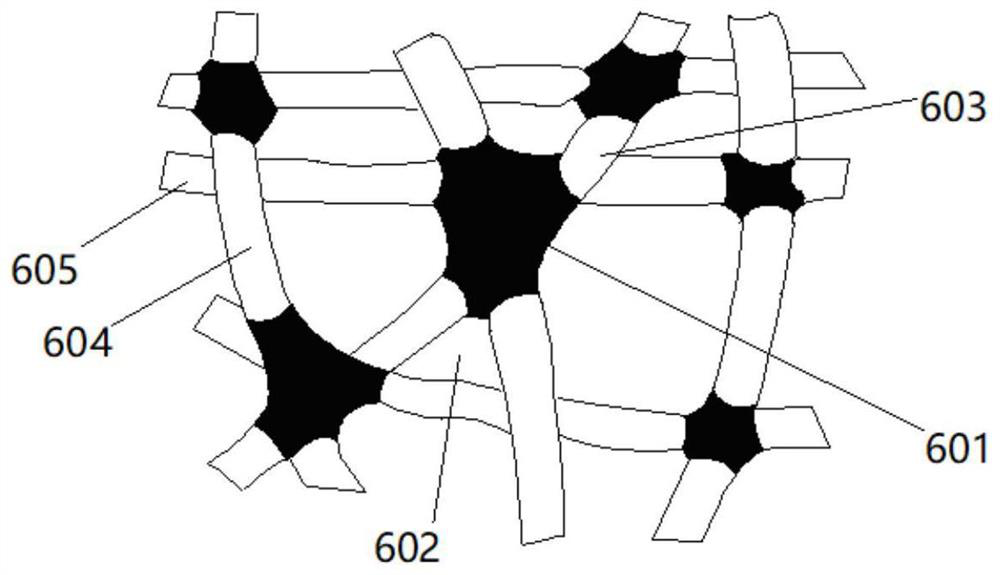

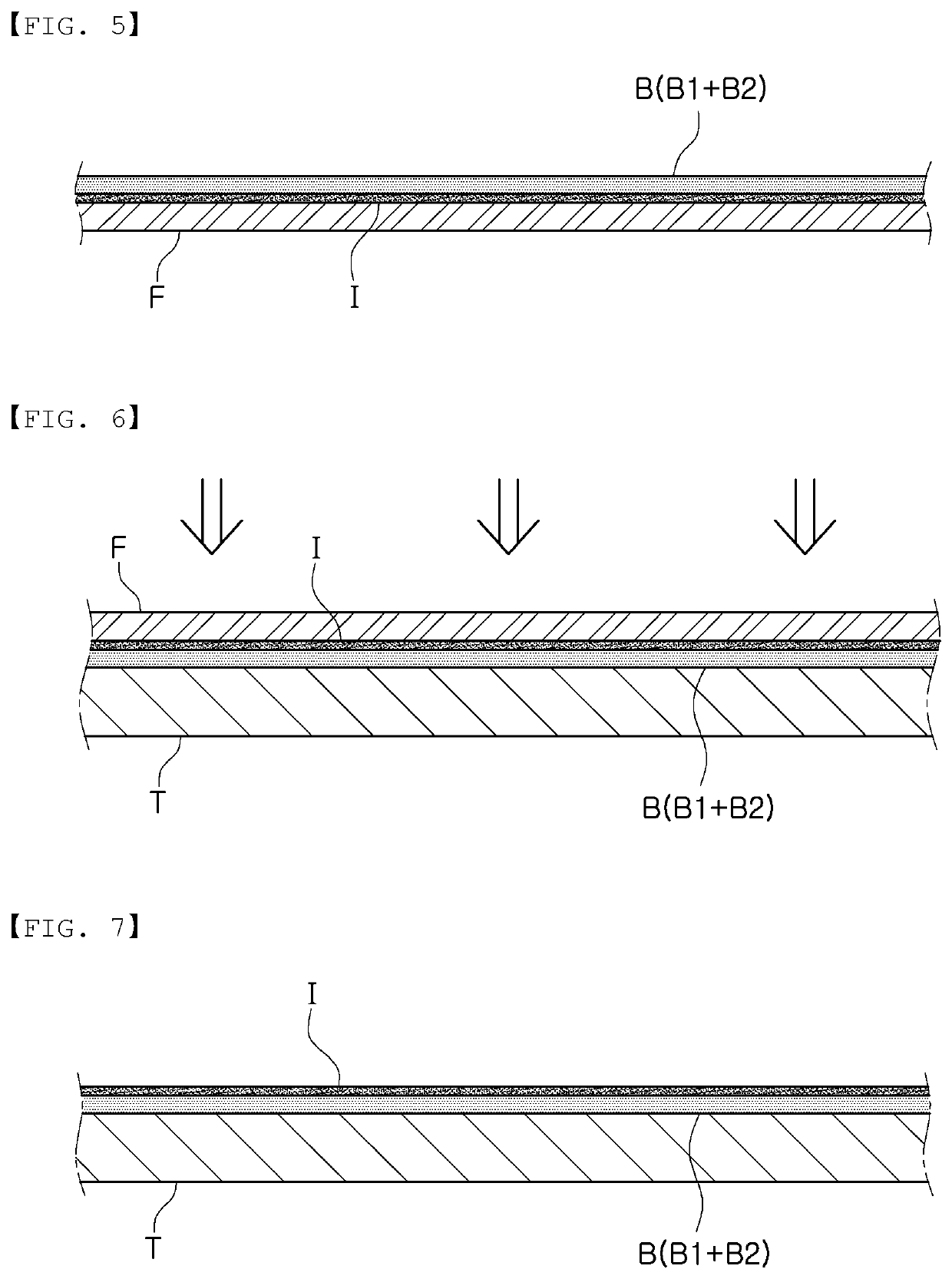

Heat transfer printing method and equipment for fiber texture network sandwich

PendingCN111775551ARelieve shrinkage stressSmall shrinkageTransfer printingDuplicating/marking methodsFiberSurface wrinkling

The invention provides a heat transfer printing method and equipment for a fiber texture network sandwich. The heat transfer printing method comprises the steps that the fiber texture network sandwichand transfer printing paper are attached together and rotate around a heating roller at the same speed, the fiber texture network sandwich and the transfer printing paper are heated to a heat transfer printing temperature through the heating roller, so that dye on the transfer paper is transferred onto the fiber texture network sandwich; longitudinal stress and transverse stress are applied to the fiber texture network sandwich subjected to transfer printing treatment; and the heat transfer printing temperature ranges from 180 DEG C to 250 DEG C, and the heat transfer printing heating time ranges from 5 s to 50 s. According to the heat transfer printing method and equipment for the fiber texture network sandwich, longitudinal stress and transverse stress are applied to the fiber texture network sandwich subjected to heat transfer printing, so that shrinkage stress, caused by heat transfer printing, of the fiber texture network sandwich is eliminated, the fiber texture network sandwichis smooth, shrinkage is reduced, and the situation of surface wrinkling or unevenness is avoided.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Hybrid transfer machine

ActiveUS10946638B2Easy to operateRapidly and conveniently performedTransfer printingOther printing apparatusProcess engineeringMechanical engineering

A hybrid transfer machine includes: a body including a first drum installation part, a second drum installation part, a first body, a second body, and a worktable; a first drive means configured to allow wound fabric to be unwound; a thermal transfer unit configured to be installed in the second body, and to press and heat the fabric and transfer paper; a piece-type roller arm configured to be installed in the second body, and to guide the transfer paper to the third drum installation part; a second drive means configured to allow the transfer paper to be wound; a third drive means configured to allow the fabric to be wound; and a conveyer configured to be installed in the body, and to transfer the fabric and the transfer paper to the third and fourth drum installation parts.

Owner:KYUNGIL TECH

Printer

ActiveUS20220143979A1Improve printing qualityEasily and conveniently performedInking apparatusTypewritersFiberComputer printing

A printer according to the present invention includes an ink head unit for spraying ink through a head, and an adhesive head unit for spraying an adhesive material through the head.Specifically, by including the adhesive head unit configured to spray a plurality of adhesive materials through a plurality of heads, respectively, the present invention enables use of an inkjet type print head in forming patterns on a fiber fabric, paper, a transfer film, or the like, and thus enables various designs and printing on a fiber fabric including a blended fiber fabric; paper; a transfer film; or the like through processing digital type image and data and can ensure excellent print quality, and can enhance the printing speed while achieving easy and convenient printing.

Owner:KOSTECH INC

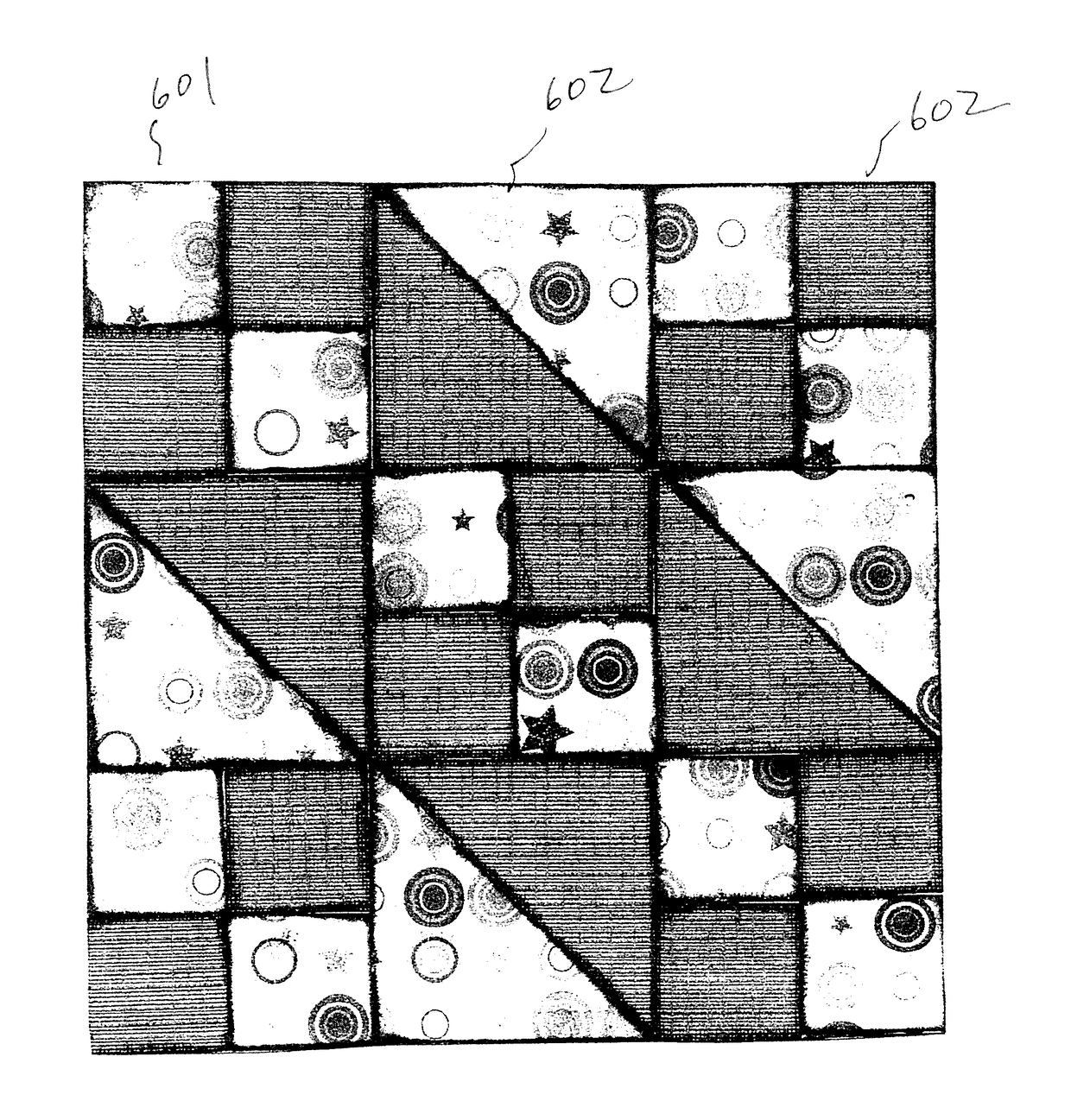

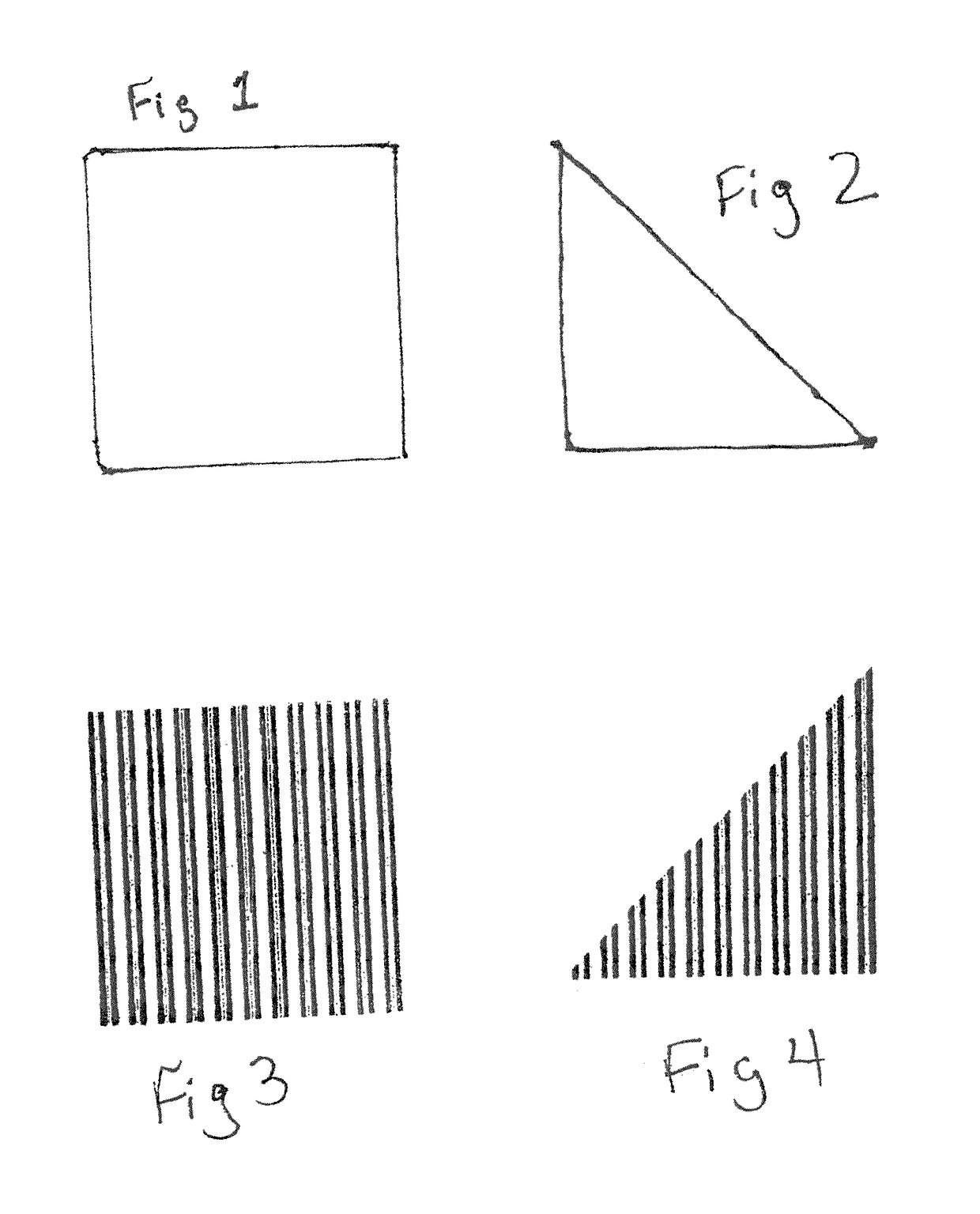

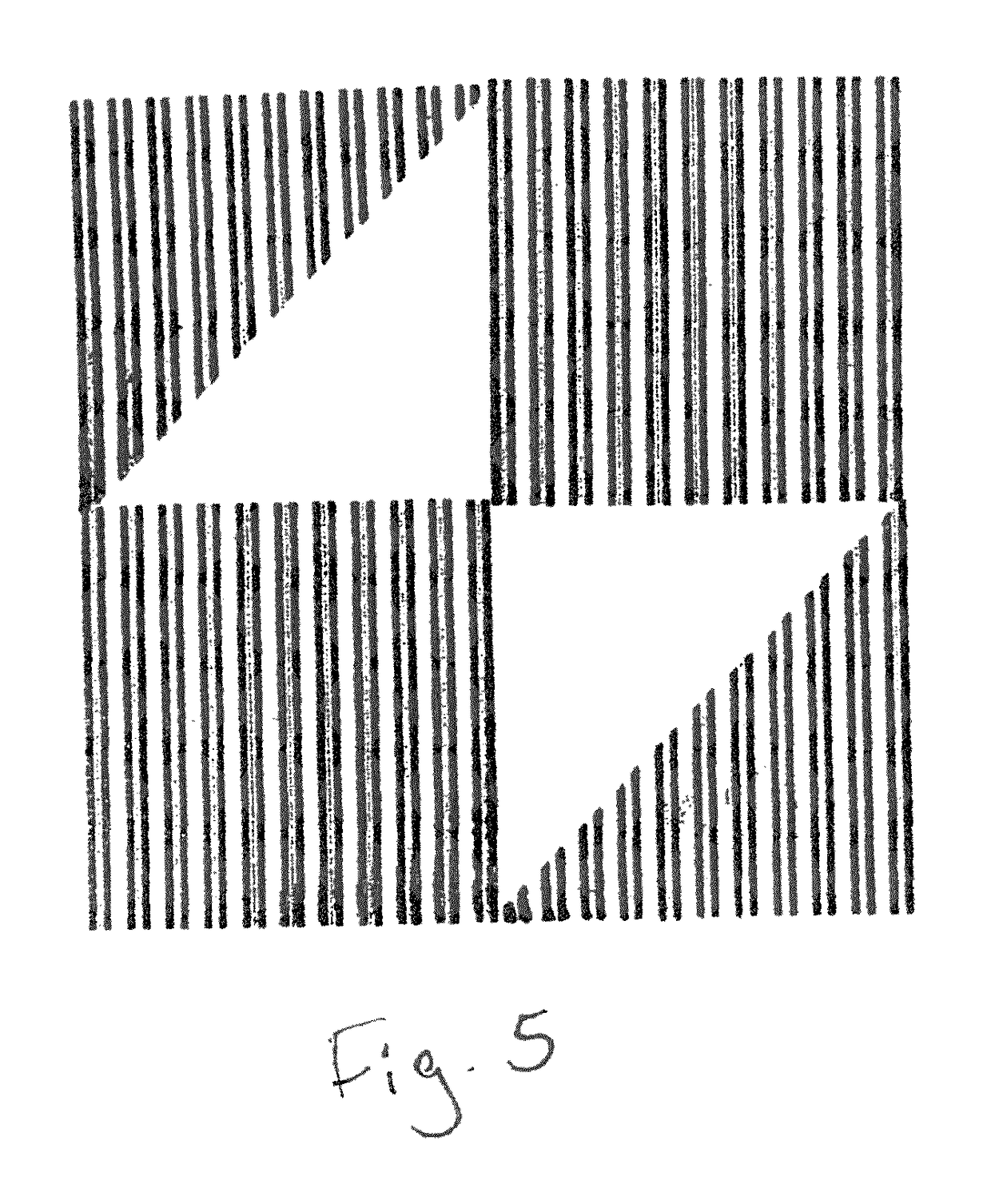

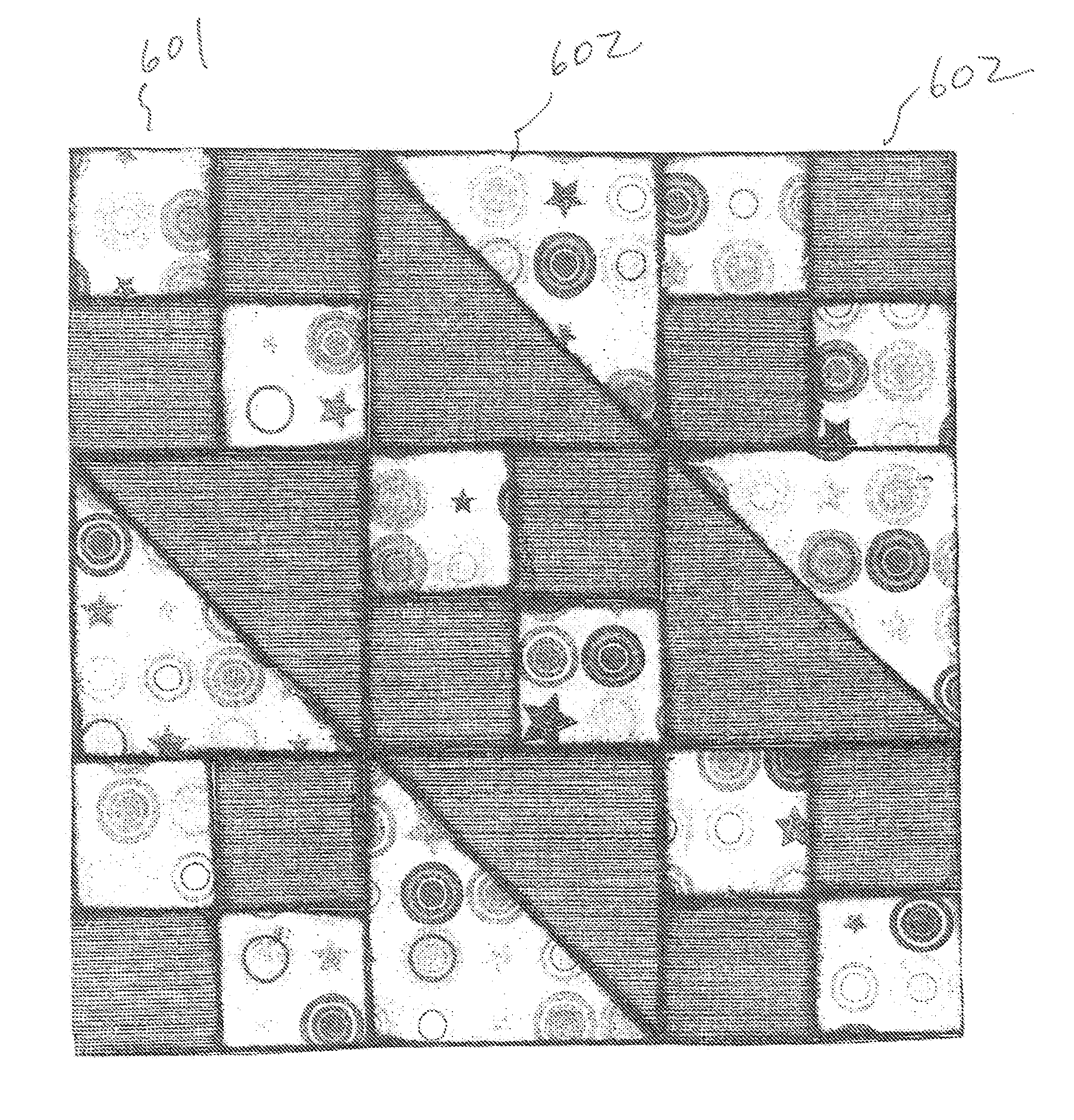

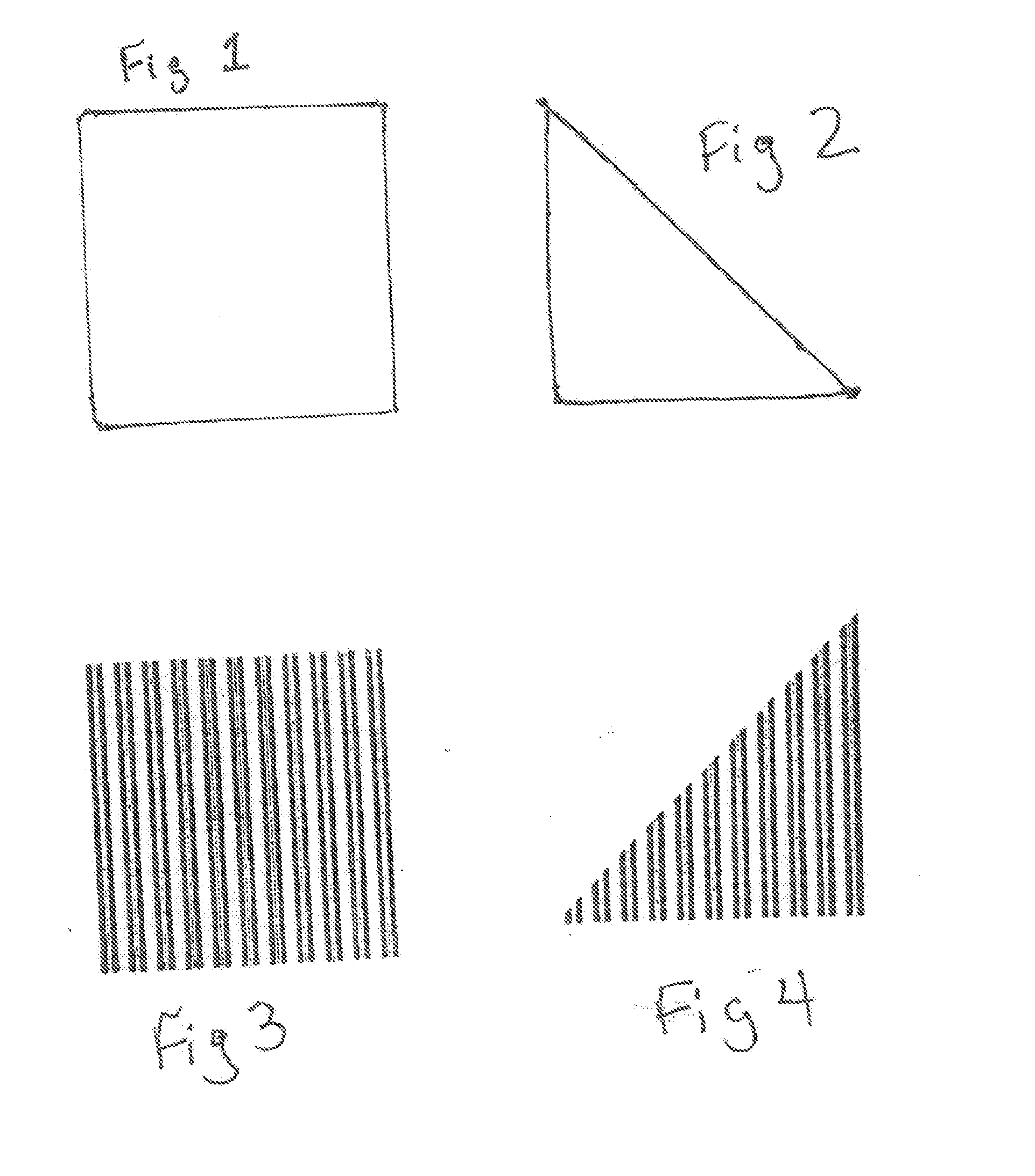

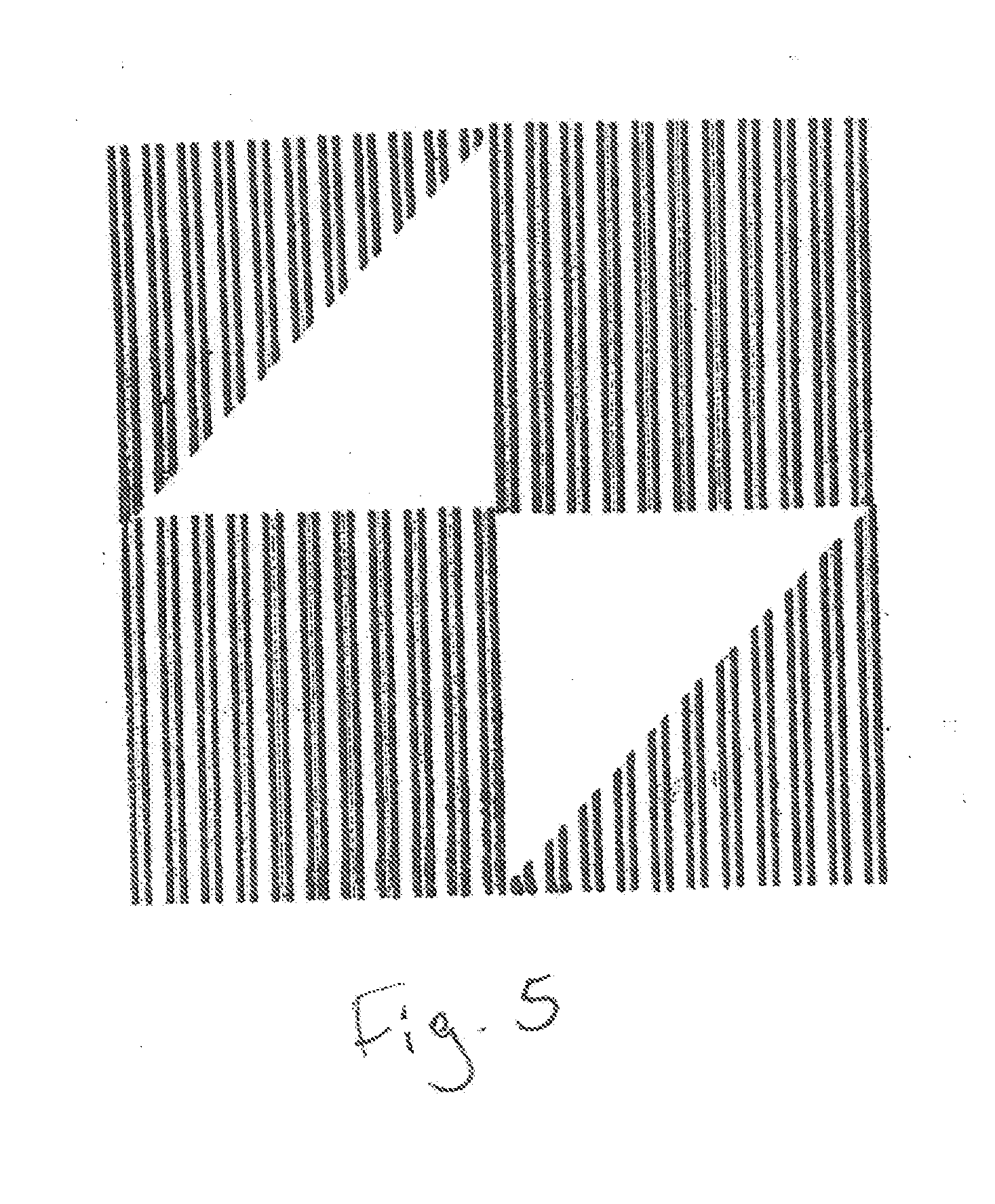

Method and system of creating a quilted product

A method and system of creating a quilted product. A method for the creation of a quilted product includes using a first stamp to apply a coloring liquid to a blank surface to create a first quilted piece. Then, a second stamp is used to apply a coloring liquid to a blank surface to create a second quilted piece. The second quilted piece is adjacent to the first quilted piece such that it abuts against the first quilted piece. Neither the first stamp nor the second stamp comprise an added allowance.

Owner:BUTLER ANN MARIE

Method and System of Creating a Quilted Product

A method and system of creating a quilted product. A method for the creation of a quilted product includes using a first stamp to apply a coloring liquid to a blank surface to create a first quilted piece. Then, a second stamp is used to apply a coloring liquid to a blank surface to create a second quilted piece. The second quilted piece is adjacent to the first quilted piece such that it abuts against the first quilted piece. Neither the first stamp nor the second stamp comprise an added allowance.

Owner:BUTLER ANN MARIE

A thermal transfer warp printing machine

InactiveCN101885261BGlossy and movingTransfer printingMoving yarn parts treatmentColor shiftEngineering

The invention relates to a thermal transfer warp printing machine, which comprises a warp beam arranged along the flow, a heat roller, and a printing warp beam, and also includes a machine whose reverse side is bonded to the circumferential surface of the heat roller and the front side is bonded to the warp thread. For printing paper, the distance between the printing warp beam and the heating roller can be adjusted. The present invention provides a thermal transfer warp printing machine whose distance between the printing warp beam and the heating roller can be adjusted, so that the color displacement difference of the warp can be adjusted to adapt to various patterns, and weave cloth with more luster.

Owner:WUJIANG NEW DEV TEXTILE

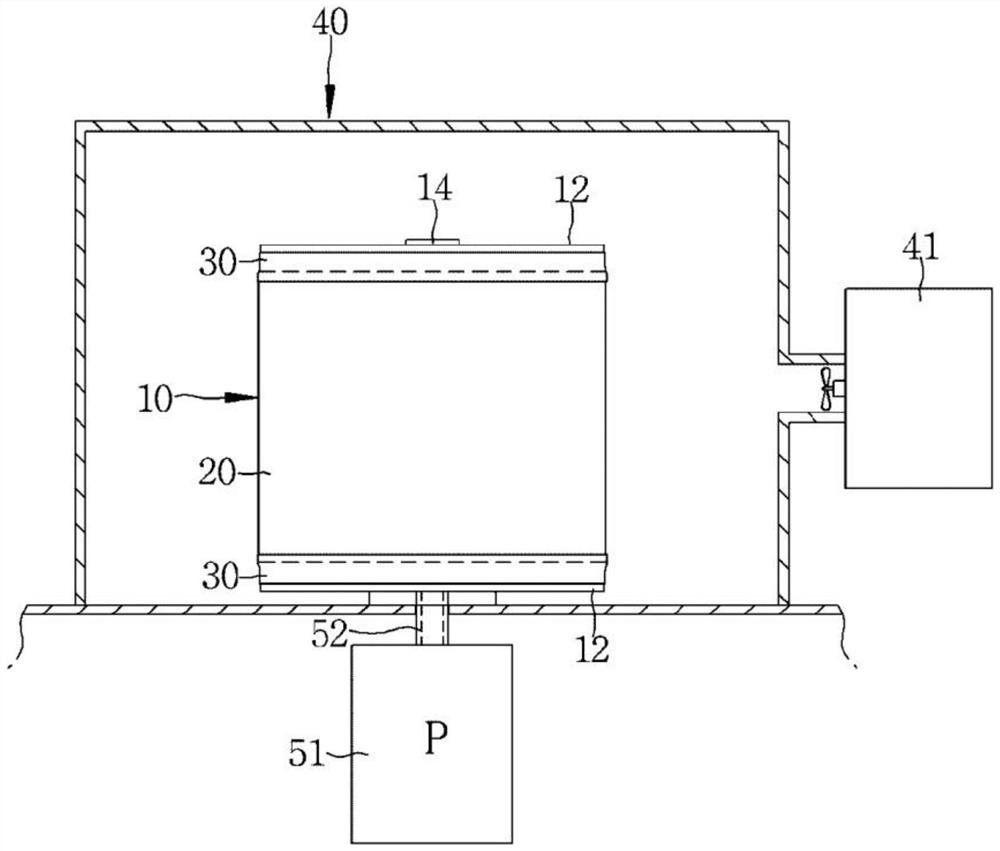

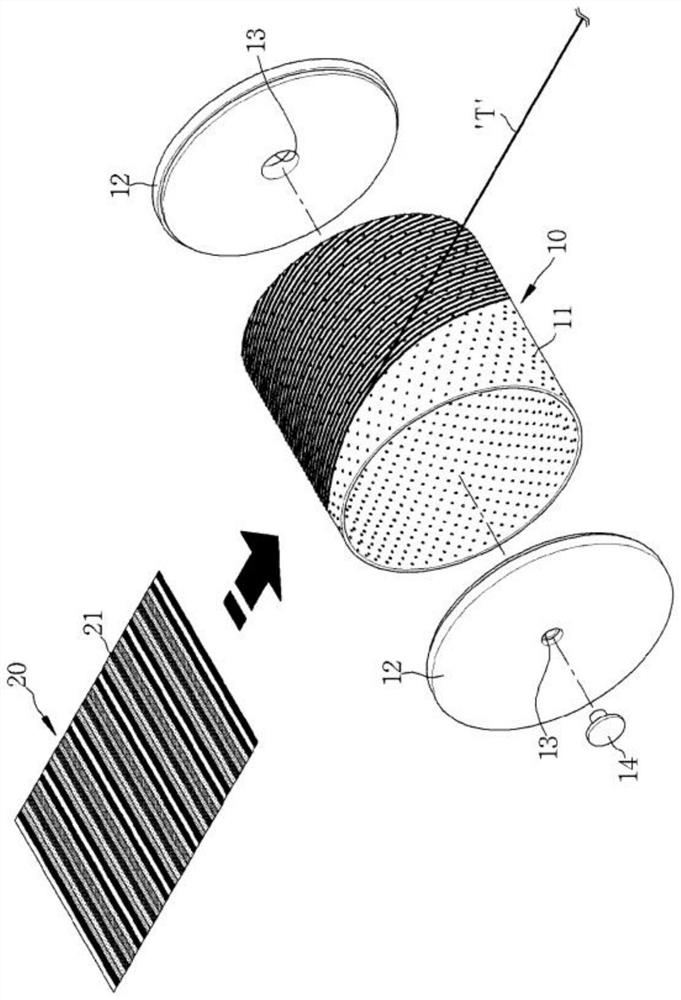

Apparatus and method for dyeing waterless precursor using vacuum transfer, and precursor manufactured according to dyeing method

PendingCN114729502AFast dyeing processTransfer printing processTextile treatment machine partsPolymer scienceVacuum pressure

The present invention relates to an apparatus and a method for dyeing a waterless precursor using vacuum transfer, and a precursor manufactured according to the dyeing method, in which a precursor is wound around a tub in which a plurality of small holes are formed, and a transfer film coated with a dye of a color to be dyed is covered on the precursor, and then the precursor is subjected to high-temperature heating inside a vacuum chamber while the transfer film is coated with a dye of a color to be dyed. The present invention relates to an anhydrous precursor dyeing method using vacuum transfer, comprising the steps of: (S1) winding a precursor on the outside of a tub, and (S2) applying vacuum pressure to the inside of the tub so that the dye applied to a transfer film can be transferred to the precursor and dyed; (S2) covering a transfer film coated with dye on the outer surface of the precursor wound on the barrel; (S3) heating the precursor in a state in which the precursor and the transfer film are attached to the tub, thereby heating the precursor; and (S4) air is sucked in through the inner space of the barrel, and vacuum pressure is formed through the small holes of the barrel.

Owner:ASSEMS

Colored hair manufacturing process and colored hair thus manufactured

A process for manufacturing colored hair is disclosed. This process comprises the steps of applying a color sizing agent to hair material, semi-drying the color sizing agent applied to the hair material, winding a vapor feeding member comprised of a net member and a moisture-contained member around an area of the hair material where the color sizing agent is applied, winding an evaporation adjusting member for adjusting the quantity of evaporation of the moisture around the vapor feeding member from outside thereof, and permeating and fixing the color sizing agent to the applied area of the hair material by heating the vapor feeding member, thereby, hair at least partly applied with a desired color or color shade is obtained.

Owner:ADERANS CO LTD

Hybrid transfer machine

ActiveUS9776390B2Improve efficiencyImprove utilizationTransfer printingTransfer printing processPulp and paper industryThermal transfer

A hybrid transfer machine includes a body, a fabric supply drum driving means, a fabric detection sensor, a take-up transfer paper drum driving means, a thermal transfer unit, a piece-mode roller, a take-up main drum driving means, a main guide roller, and a roll-mode roller. The body includes a first body, a second body, and a worktable. The fabric supply drum driving means drives a fabric supply drum. The fabric detection sensor detects fabric, and controls an operation. The take-up transfer paper drum driving means drives the take-up transfer paper drum. The thermal transfer unit heats the fabric and transfer paper. The piece-mode roller rotatably guides the transfer paper. The take-up main drum driving means drives the take-up fabric drum or take-up transfer paper drum. The main guide roller guides the transfer paper or the fabric. The roll-mode roller guides the transfer paper.

Owner:KYUNGIL TECH

Multi-roller blanket transfer printing device

ActiveCN103144420BPrevent slippingAvoid unstable product qualityTransfer printingTransfer-treating textile partsAutomatic controlControl system

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Transfer printing device for cold-transfer decorating machines

ActiveCN101513790BIncrease pressureMaximum stapling lengthTransfer printingTransfer-treating textile partsEngineeringTransfer printing

The invention provides a transfer printing device for cold-transfer decorating machines, which comprises a base, a fixing clamp plate, a transfer printing belt, a transfer printing roller, a pressurization device, a bearing block and a driving wheel, wherein the transfer printing roller is a circular roller; two ends of a central shaft of the transfer printing roller are supported by a bearing and the bearing block and are connected with the pressurization device; the driving wheel connected with a drive mechanism is arranged beside the bearing at one end of the central shaft; the base is a concave rigid base fixed on a frame; the transfer printing belt is fixedly connected with the left and right sides of the concave rigid base by the fixing clamp plate; the transfer printing roller can rotate around the central shaft and move up and down relative to the transfer printing belt; and the acting surfaces of the transfer printing roller and the transfer printing belt fit each other, wherein the transfer printing belt stays still in a transfer printing process, and a cooling device is arranged between the transfer printing belt and the concave rigid base. As the transfer printing beltstays still, the transfer printing belt and the rotating transfer printing roller can form steady decorating pressure. Meanwhile, the flexibility of the transfer printing belt determines that a decorating area between the transfer printing belt and the transfer printing roller can be increased according to decorating requirements, thus enough transfer printing time required by a decorating process can be ensured.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com