Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163results about "Fabric parts treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Patterned textile product

InactiveUS20050106355A1Layered productsControl devices for washing apparatusEngineeringFloor covering

A textile substrate is patterned by the selective application of various dyes to the substrate surface in a way that provides desirable, visually apparent enhancements in the area of pattern detail, definition, and color range, through the use of a novel patterning system, including the application of various chemical agents, that makes such enhancements possible. In one embodiment, the patterning system described herein is capable of producing pile-faced textile substrates, useful as floor coverings, that exhibit a unique combination of desirable pattern attributes that have been identified and measured using novel techniques specifically developed for these substrates and pattern attributes.

Owner:MILLIKEN & CO

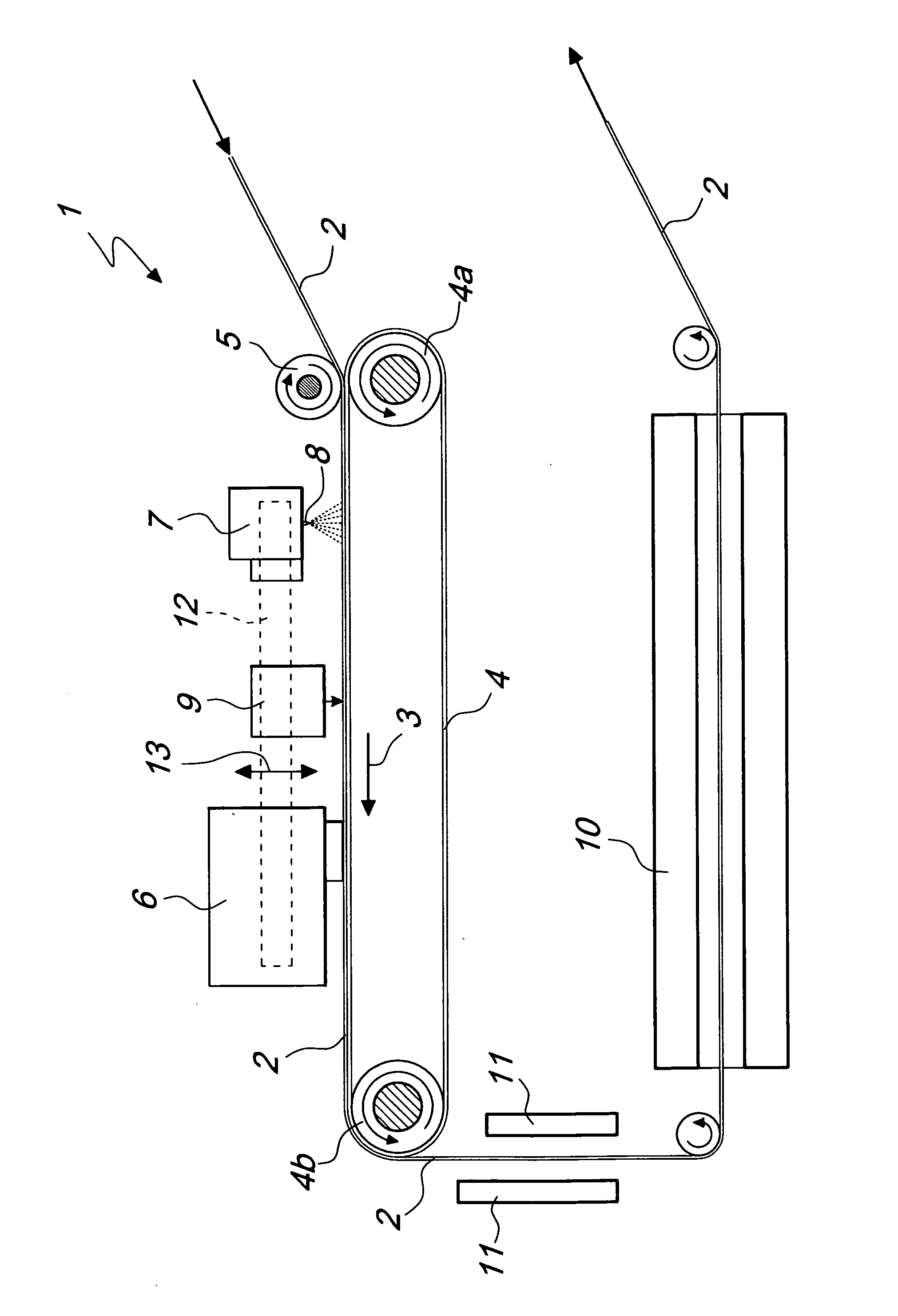

Method and apparatus for digital inkjet printing of materials, particularly sheet-like materials such as fabrics, hides or the like

InactiveUS20050206711A1Low costDuplicating/marking methodsTypewritersEngineeringMechanical engineering

Owner:MILINI PAOLO

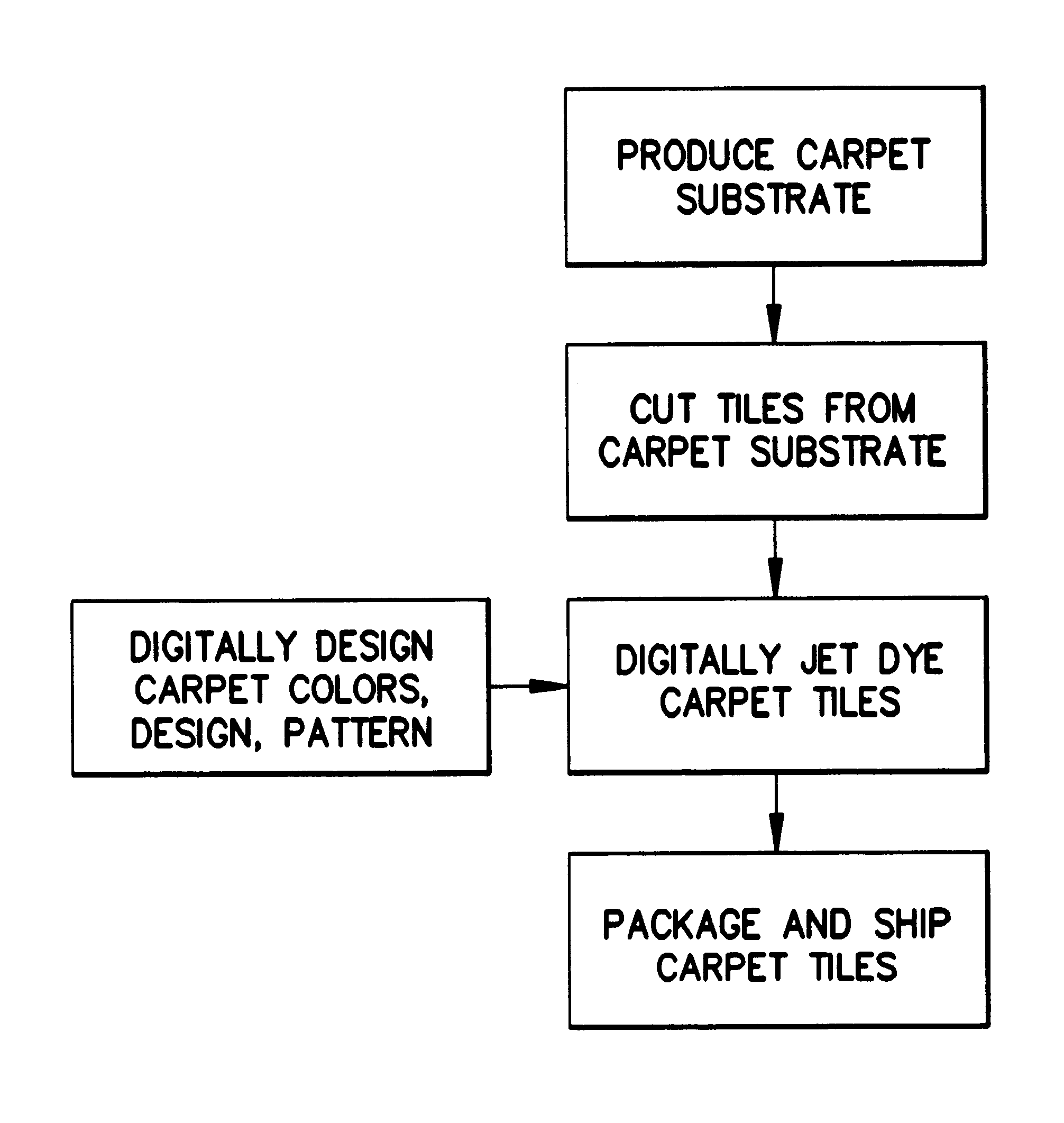

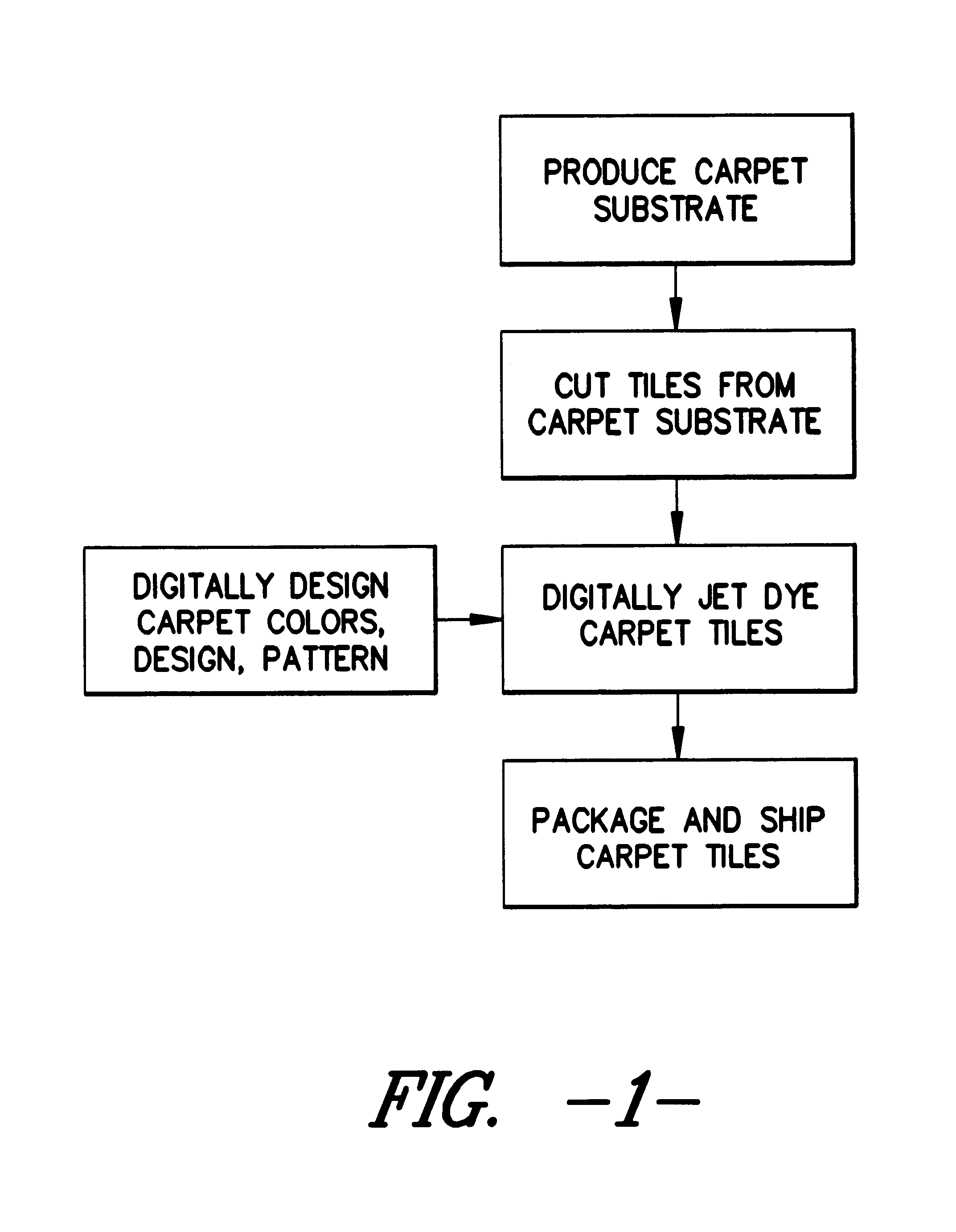

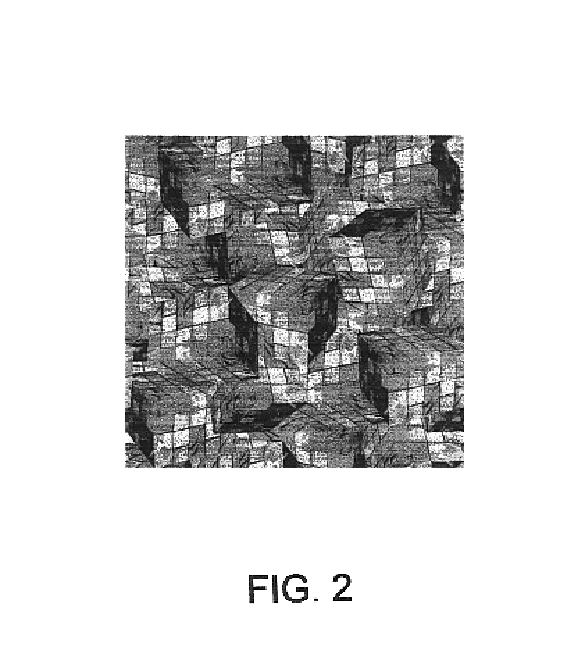

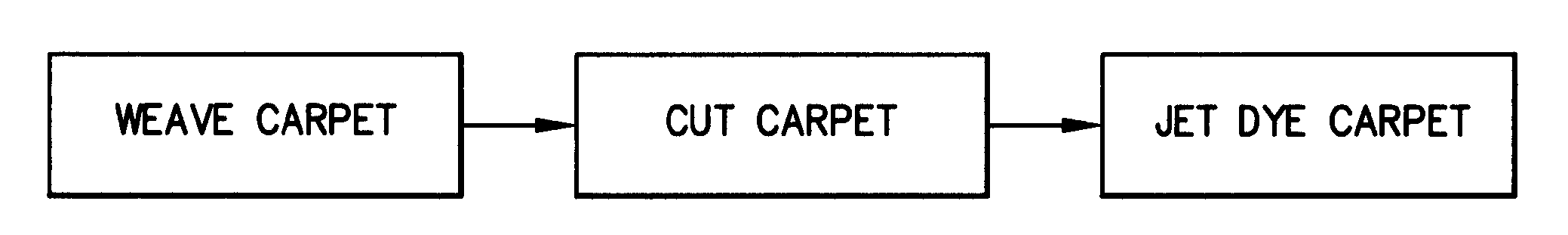

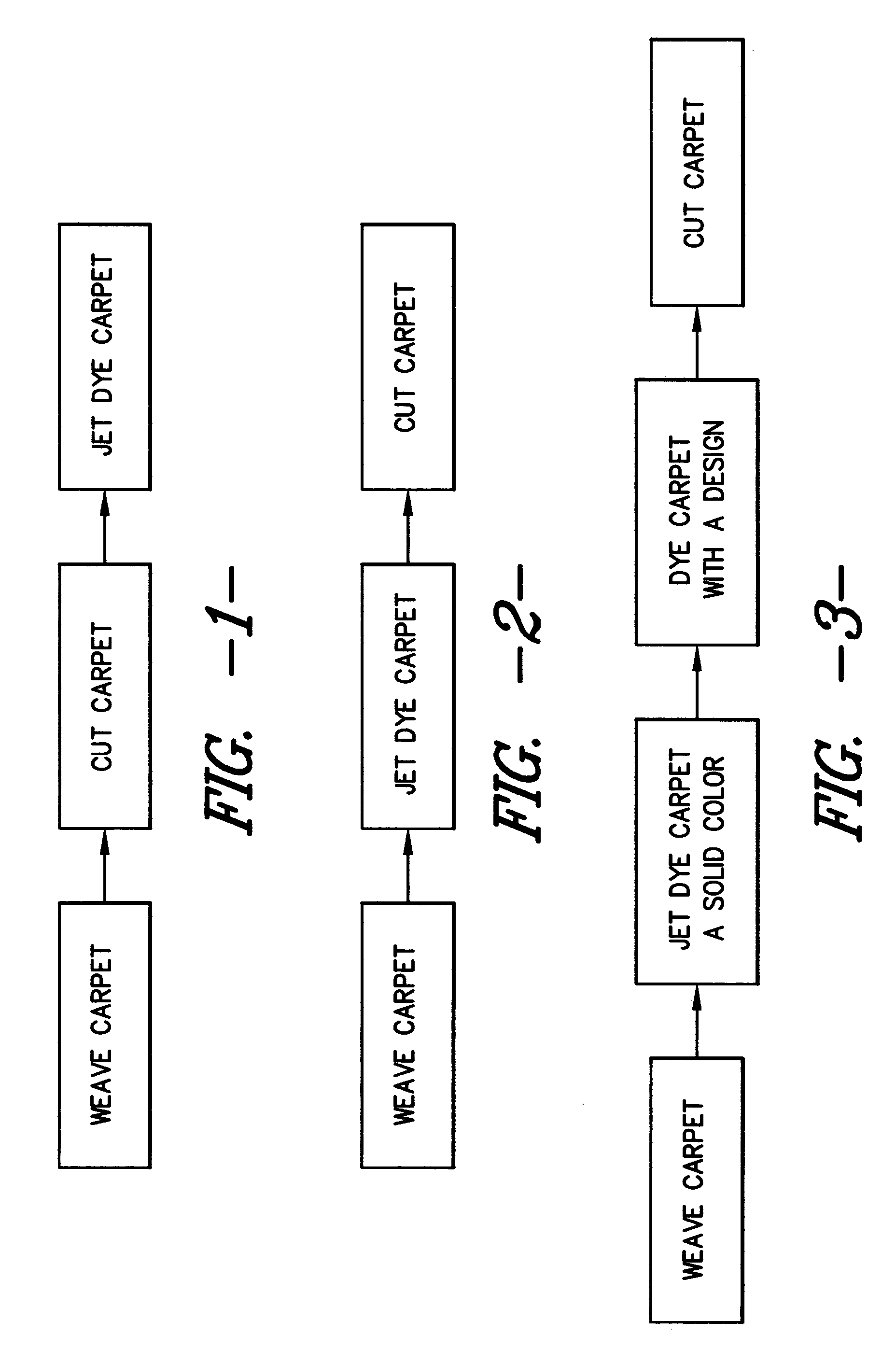

Method for producing digitally designed carpet

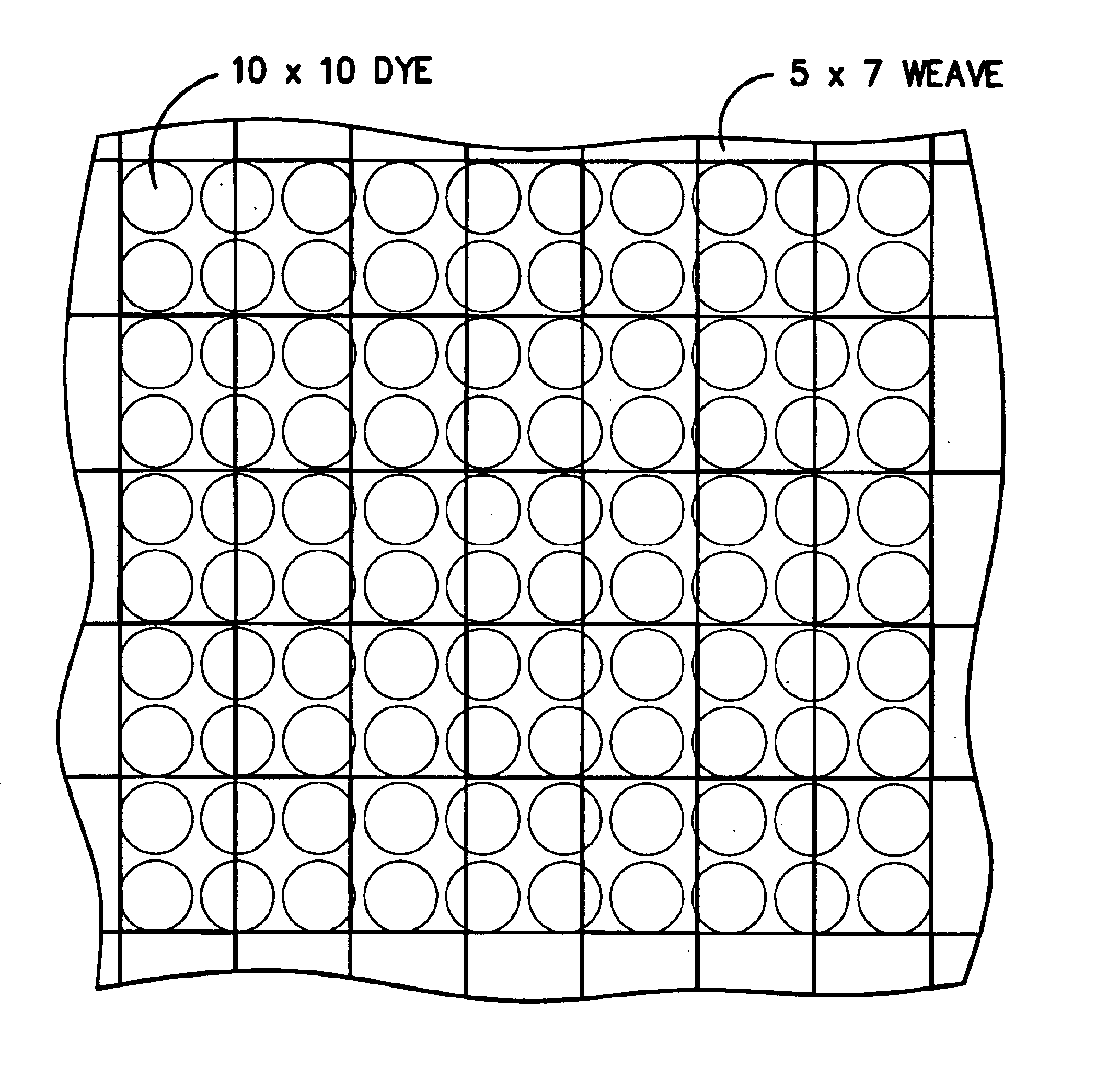

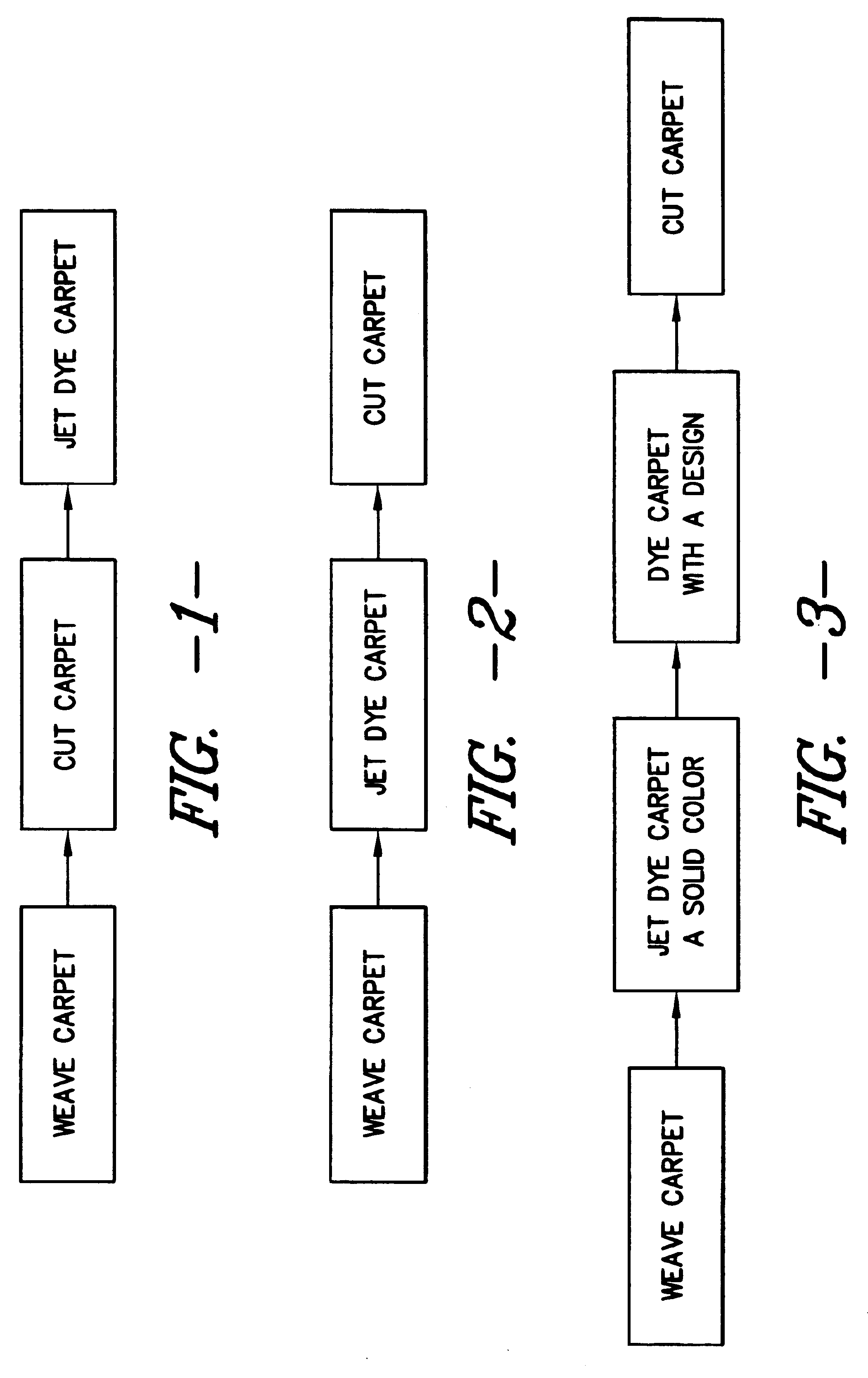

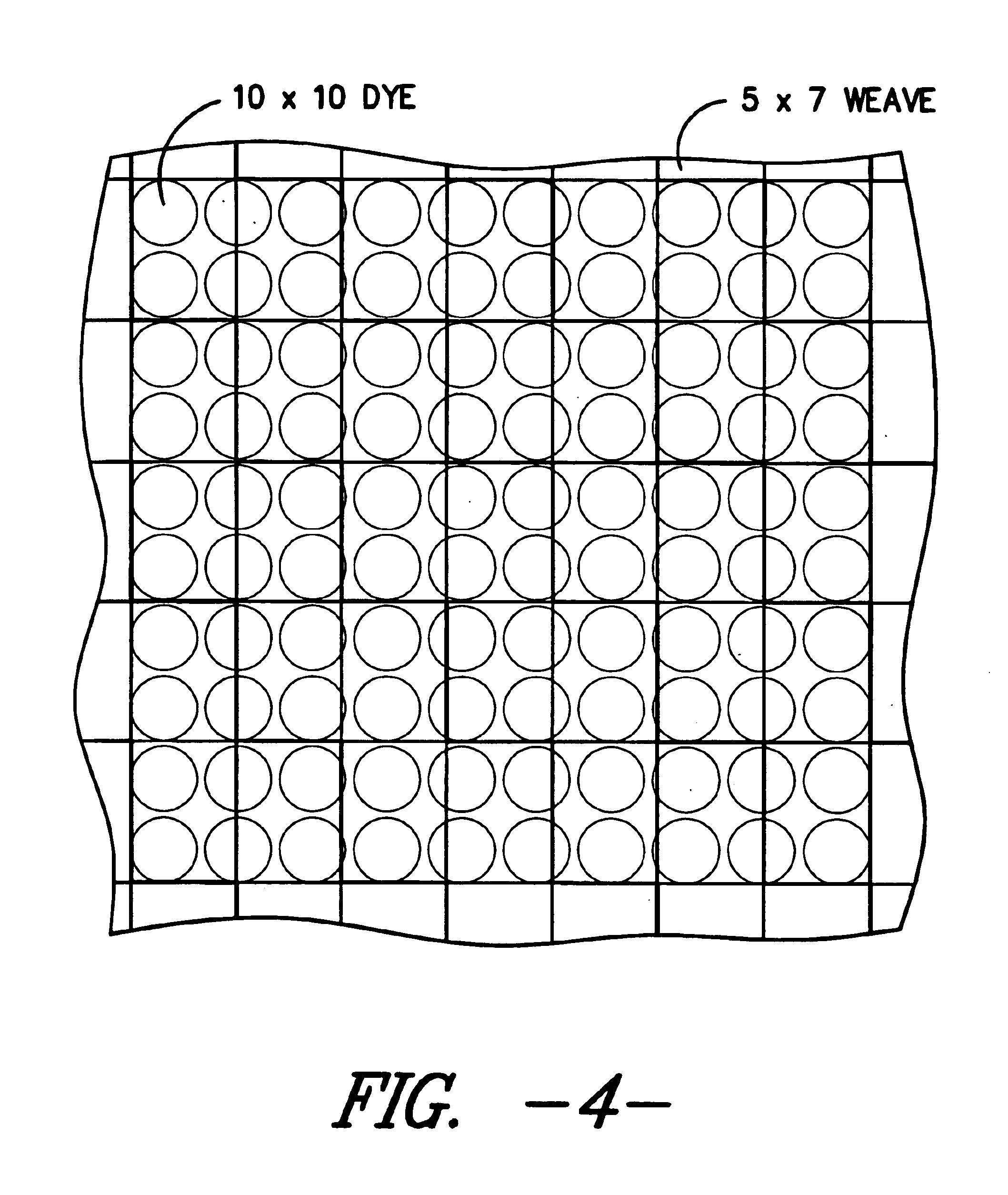

Exciting new optically engaging and controversial three dimensional simulating illusionary digital designs which generate emotional responses and photo-realism shock effects are produced by digitally creating a design or pattern and dying and / or printing the digitally created design using digitally controlled dying or printing equipment on flooring, such as, modular carpet tiles, area rugs, runners, rugs, carpets, floor mats, or the like. In accordance with the preferred embodiment of the present invention, a carpet tile substrate is cut into individual carpet tile blanks which are jet injection dyed with digitally created designs, colors, patterns, and / or the like which provide excellent seamability, look, feel, wear, and allow for true or accurate registration of three dimensional like, complex, complicated, intricate designs heretofore unknown in the carpet industry.

Owner:MILLIKEN & CO

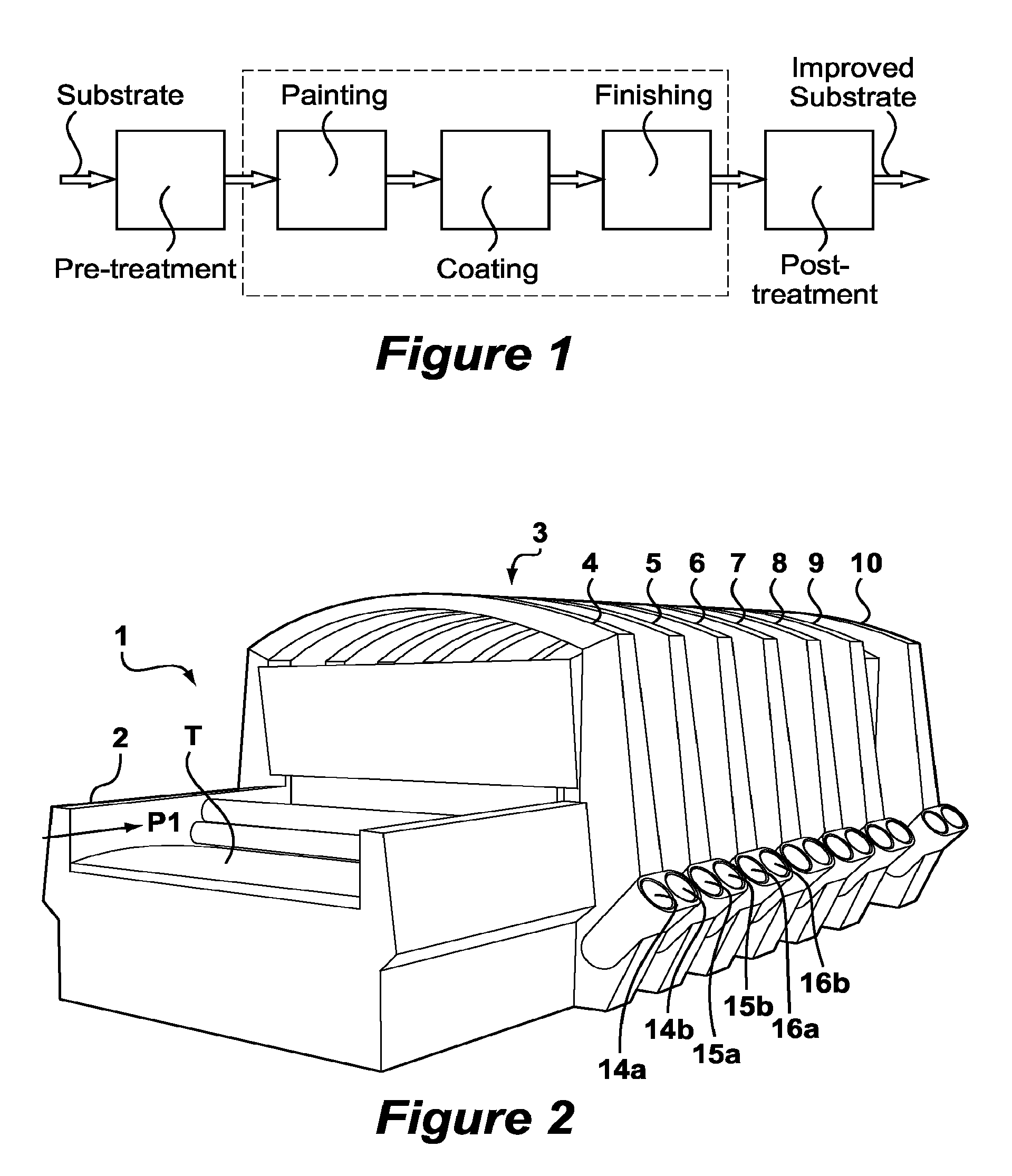

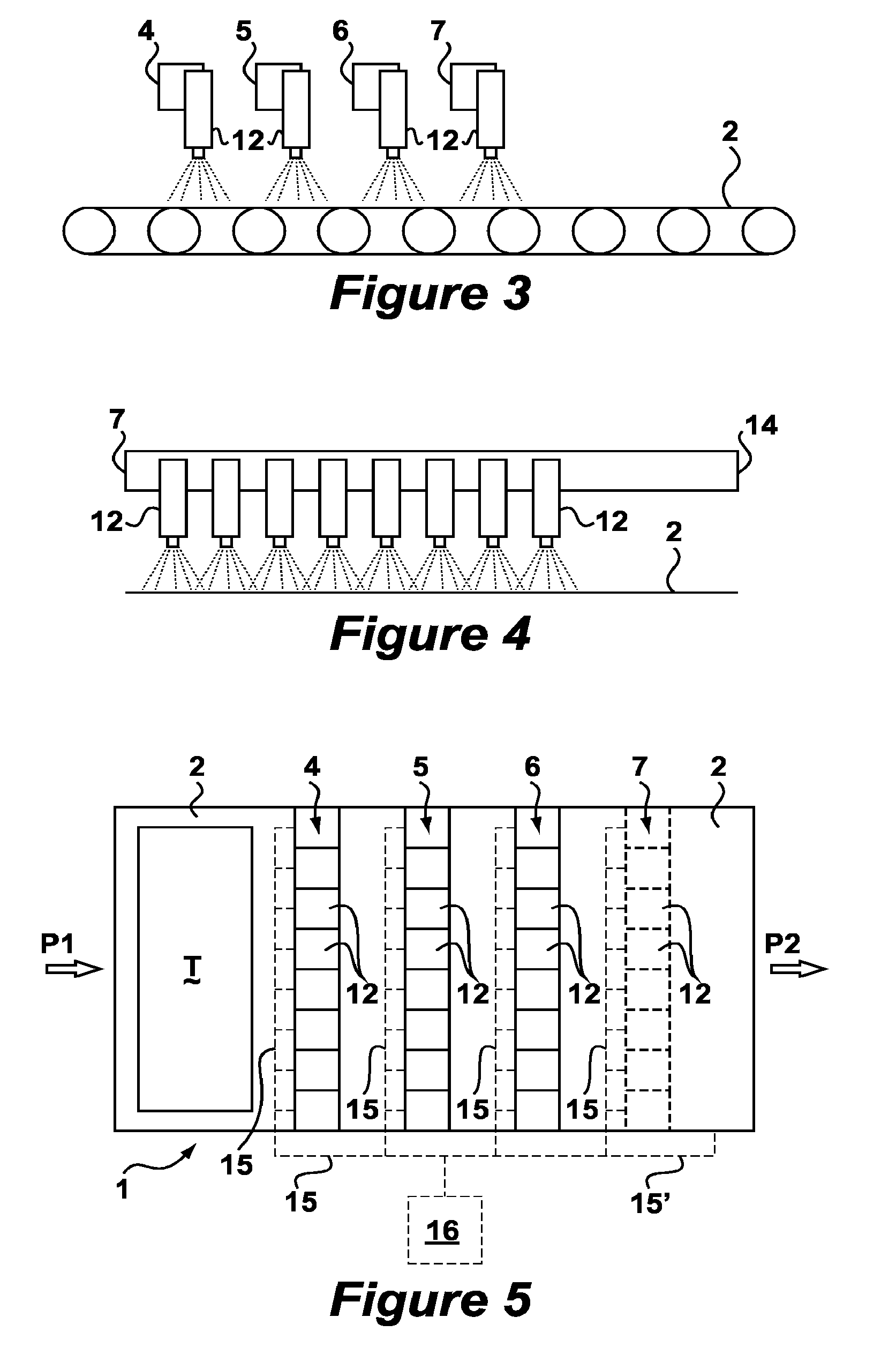

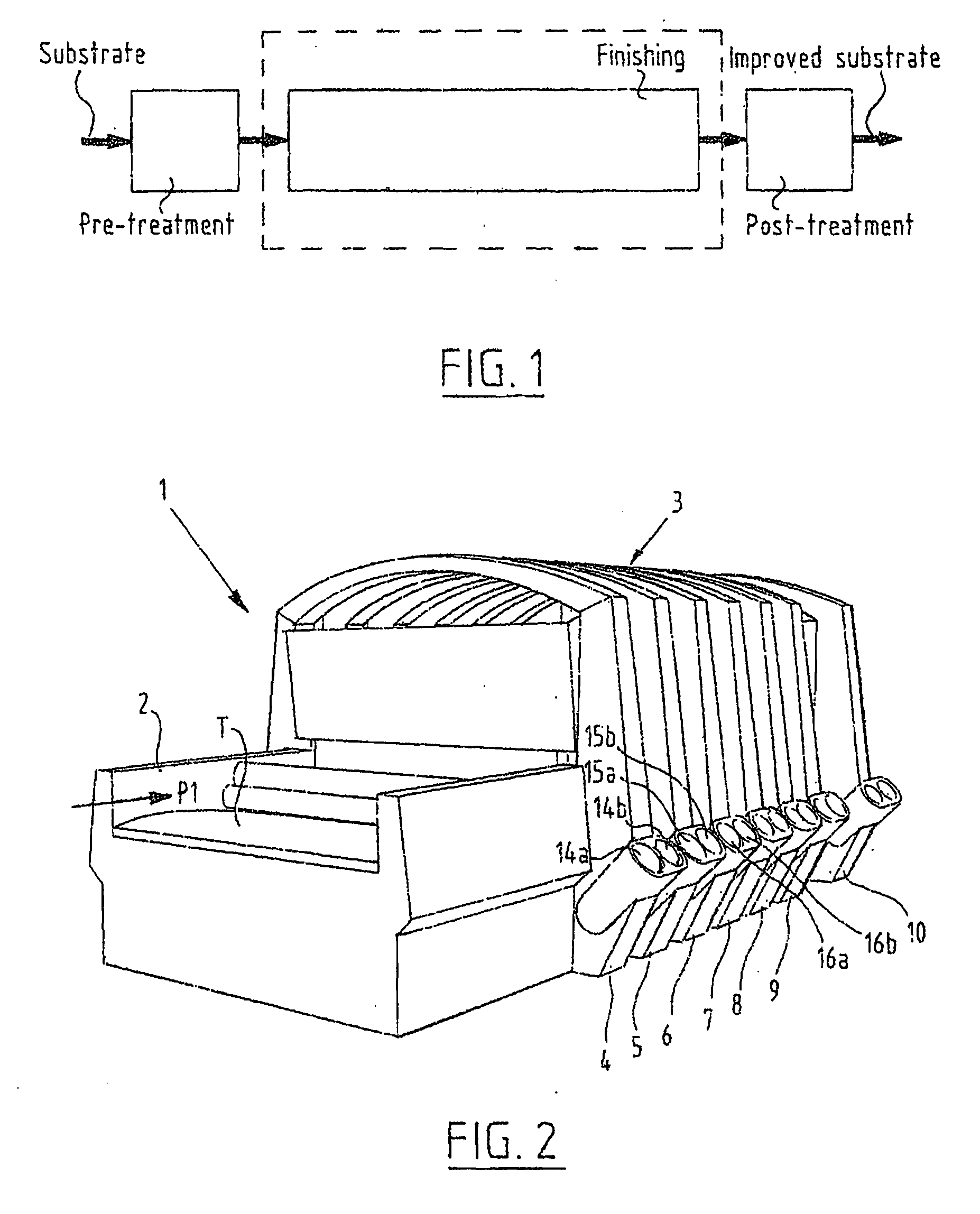

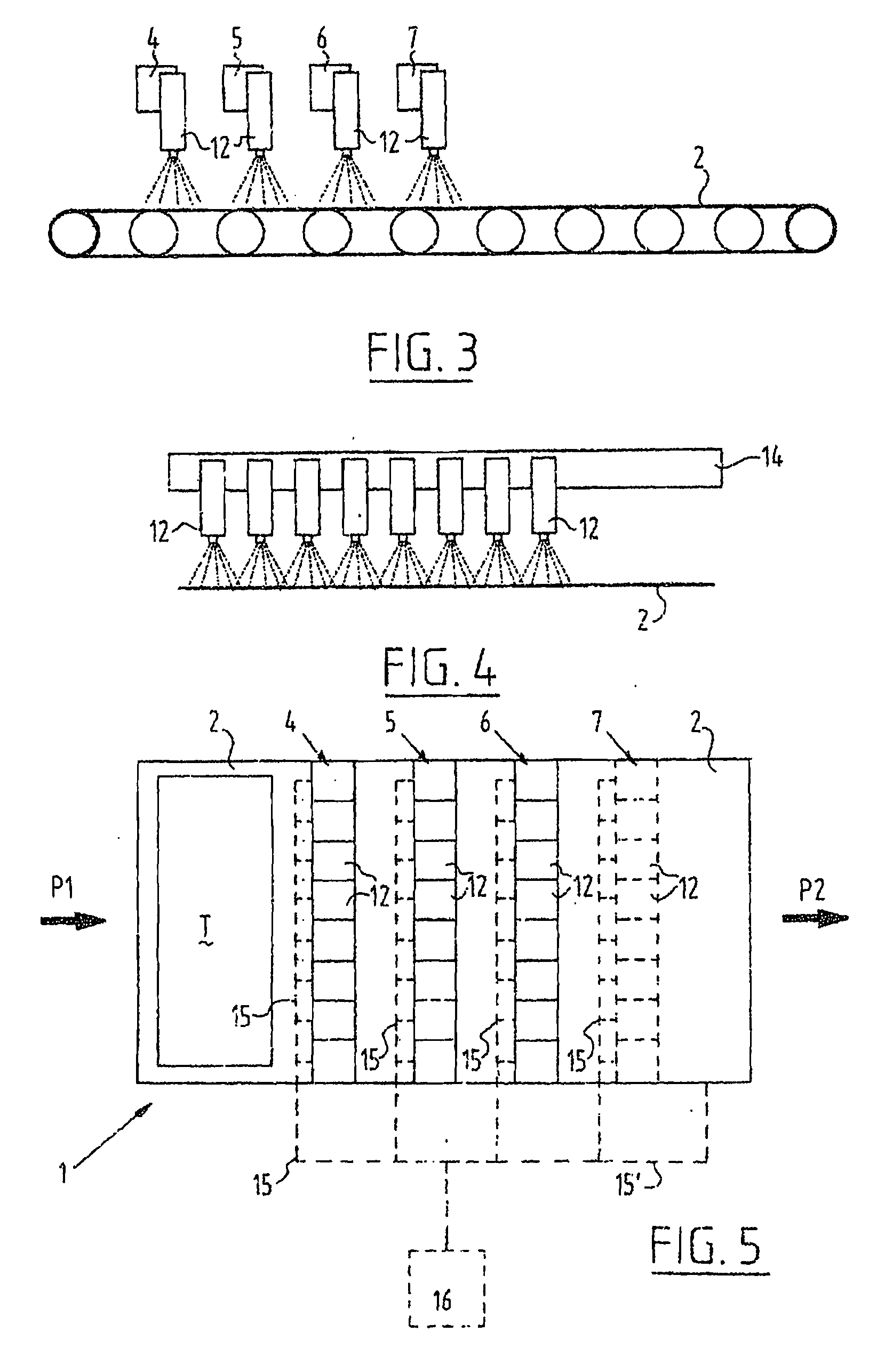

Method for Providing a Localised Finish on Textile Article

A method of producing a textile article having a localised finish is described. The method comprises providing a continuous supply of a textile substrate, providing an array of digital nozzles, supplying a finishing composition to the nozzles and selectively depositing the finishing composition from the nozzles in a series of droplets to deposit a first predetermined pattern of droplets on a selected area of the substrate to endow a functional characteristic on the selected areas. In this way, it is possible to ensure that only those areas receive the finishing composition that ultimately require it. Usage of valuable chemicals and process time can hereby be reduced.

Owner:TEN CATE ADVANCED TEXTILES BV

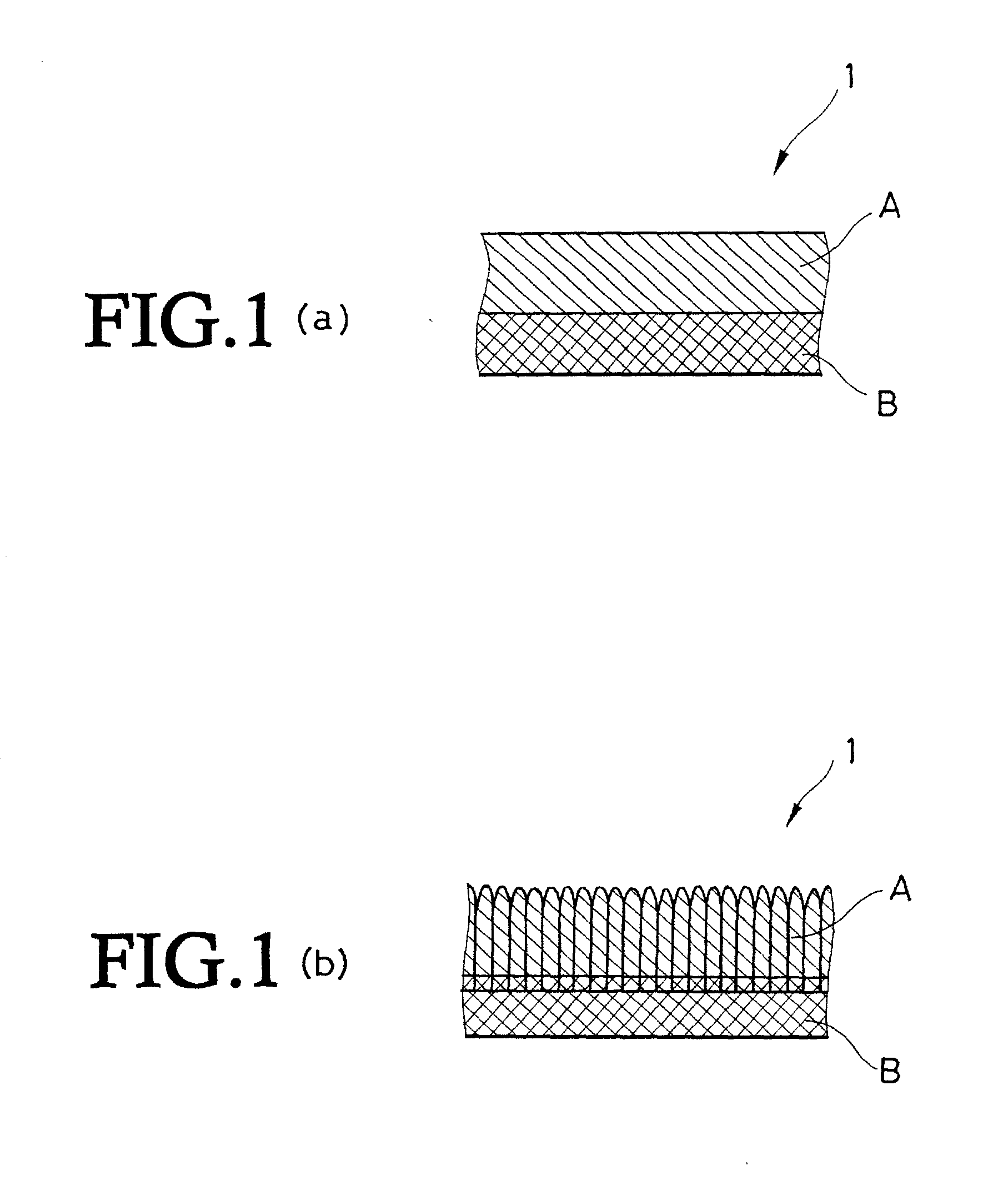

Fabric for use in ink-jet printing, a method for preparing such fabric and printed goods made by ink-jet printing of the fabric

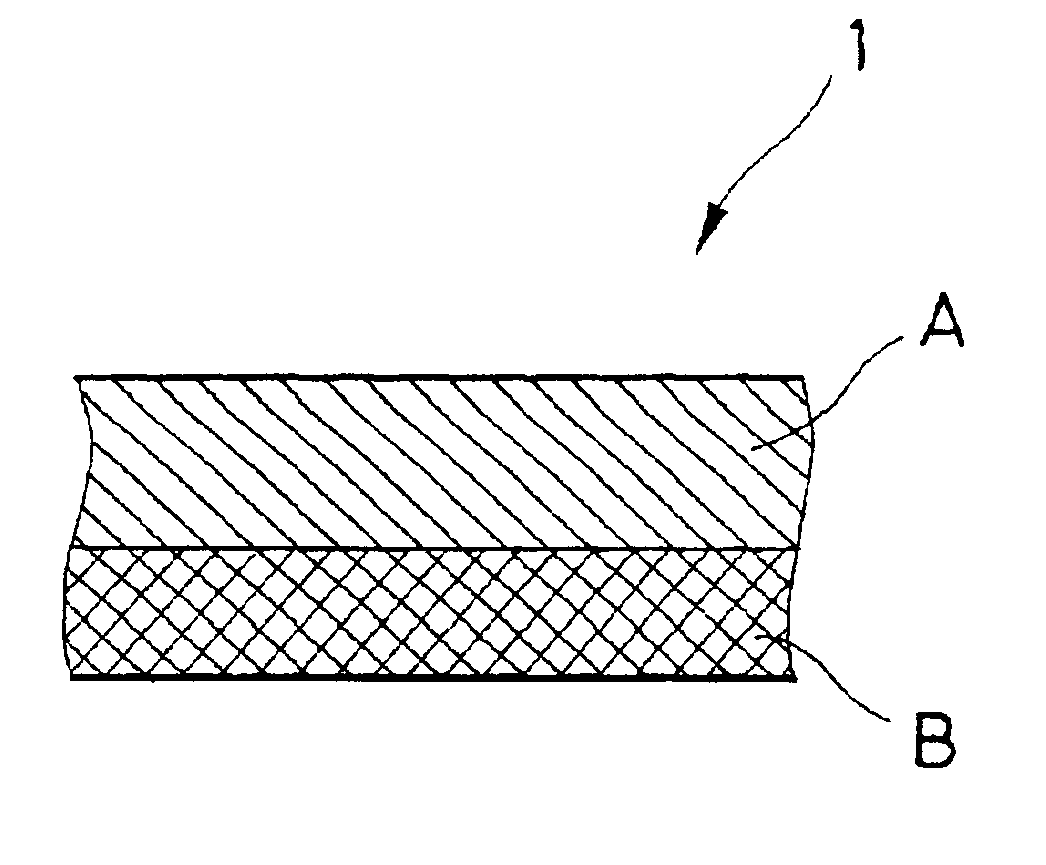

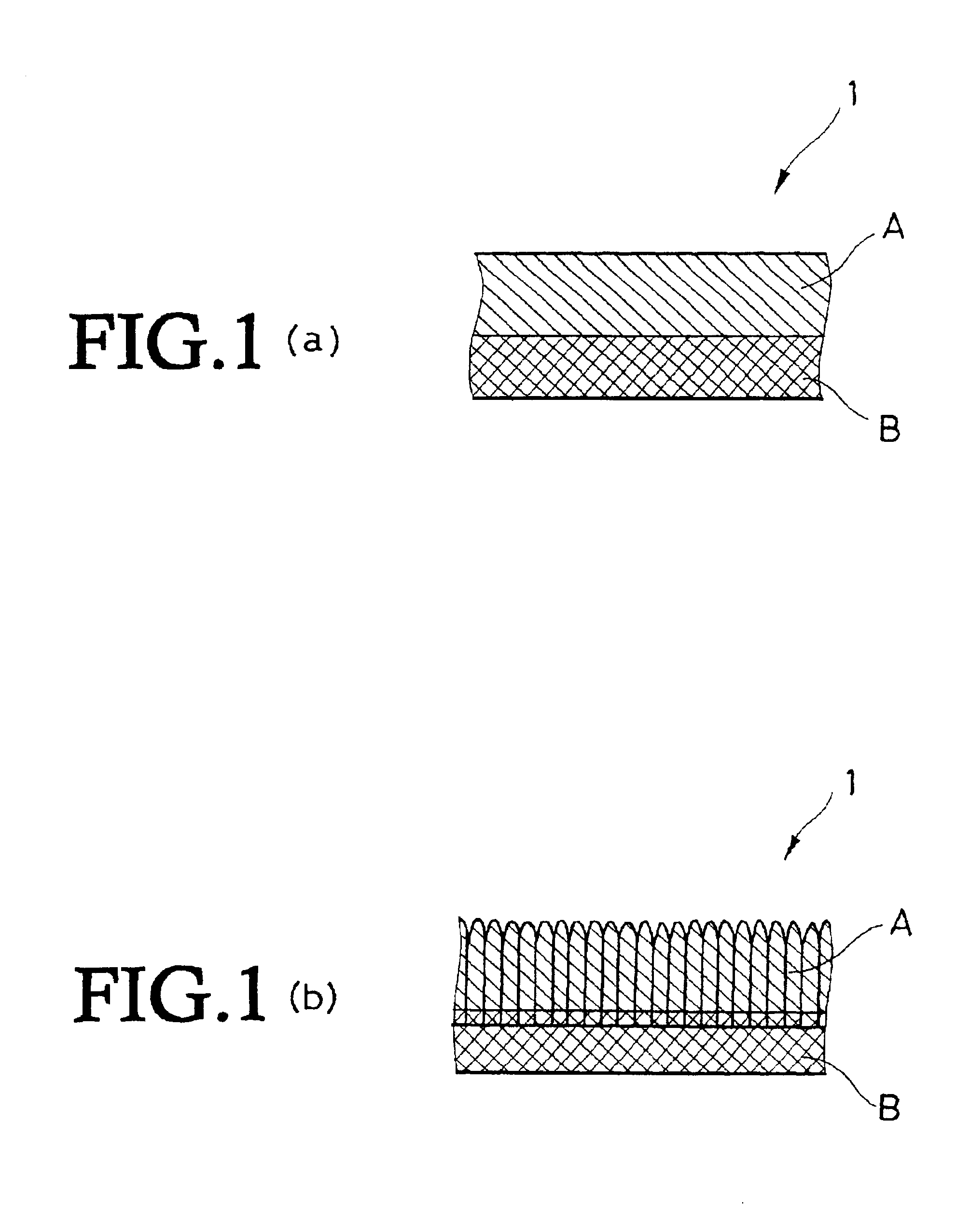

It is an object of the present invention is to provide fabric for use in ink-jet printing that can prevent not only "ink bleeding", but also "white exposure", "nonuniform coloration" and "back staining". A further object of the present invention is the provision of fabric for use in ink-jet printing, consisting of two textures-napped and ground, which can be evenly ink-jet printed with no variation in color between both, while preventing the occurrence of "white exposure", "nonuniform coloration" and "back staining". Fabric for use in ink-jet printing composed of synthetic fiber or fiber containing synthetic fiber, consisting of two textures-napped and ground, the preparation of which comprises penetration of the ground texture with at least two types of solutions-one containing an ink holding agent of high wettability to synthetic fiber and the other containing an ink holding agent of low wettability to synthetic fiber, and penetration of the napped texture with a solution containing an ink holding agent of high wettability to synthetic fiber (represented as A in the same figure).

Owner:SEIREN CO LTD

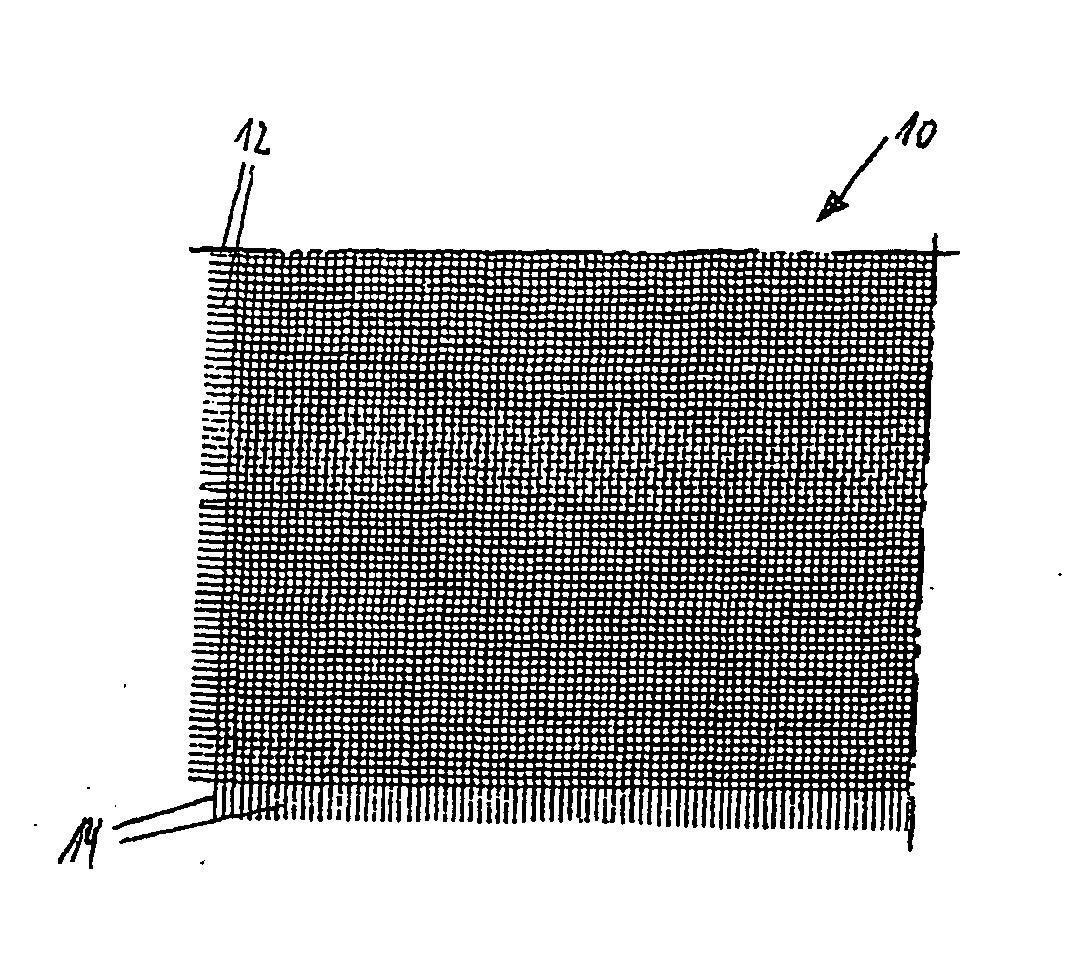

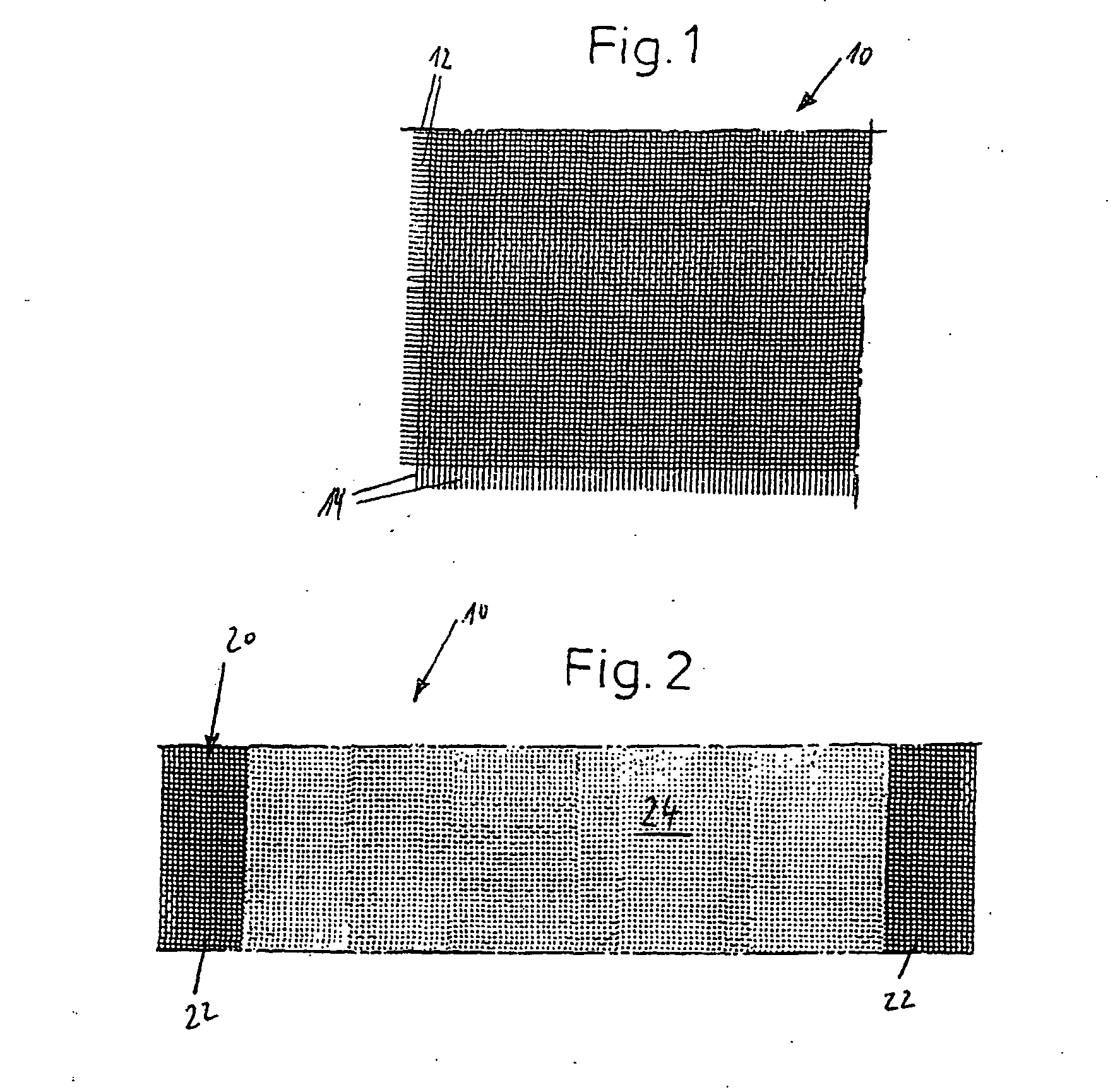

Patterned carpet and method

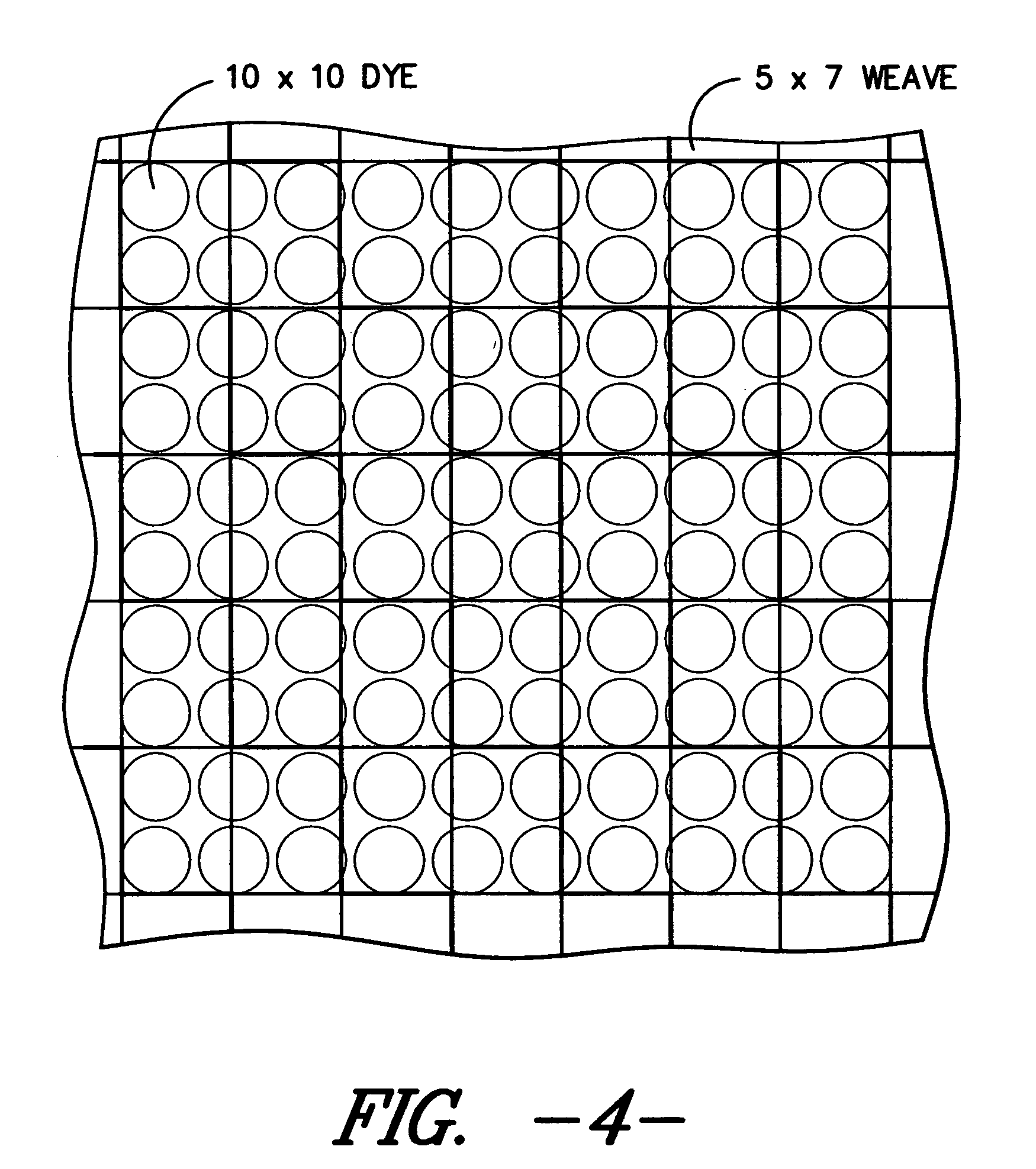

InactiveUS6884493B2Designed withImprove finenessFibre treatmentSynthetic resin layered productsYarnScreen printing

Owner:MILLIKEN & CO

Patterned textile product

A textile substrate is patterned by the selective application of various dyes to the substrate surface in a way that provides desirable, visually apparent enhancements in the area of pattern detail, definition, and color range, through the use of a novel patterning system, including the application of various chemical agents, that makes such enhancements possible. In one embodiment, the patterning system described herein is capable of producing pile-faced textile substrates, useful as floor coverings, that exhibit a unique combination of desirable pattern attributes that have been identified and measured using novel techniques specifically developed for these substrates and pattern attributes.

Owner:MILLIKEN & CO

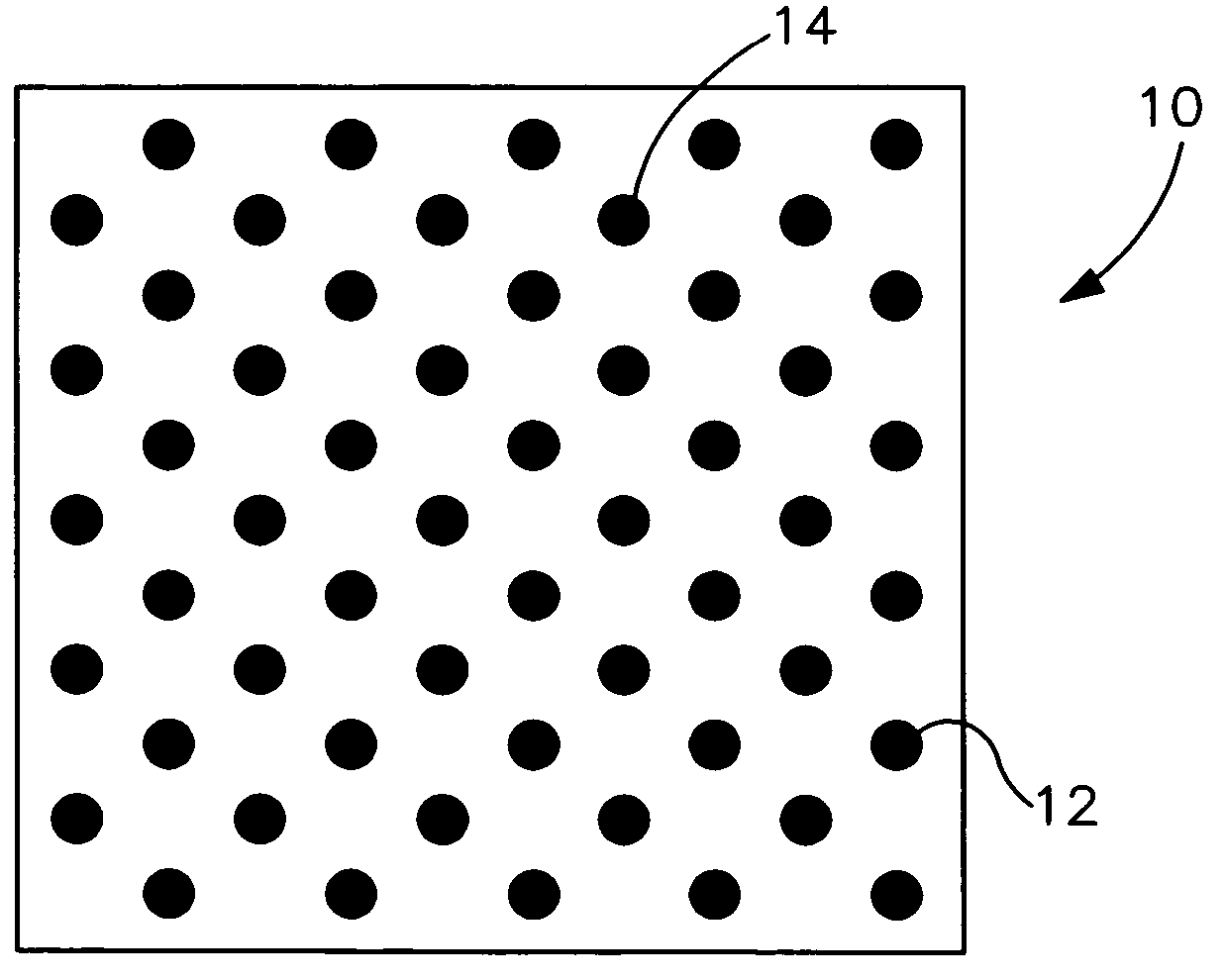

Patterned application of activated carbon ink

An odor control substrate that is applied with an activated carbon ink is provided. The activated carbon ink is applied in a pattern that covers from about 25% to about 95% of the surface area of the substrate. Although not covering the entire surface, the present inventors have discovered that the activated carbon ink is still capable of providing good odor reduction qualities to the substrate. To further enhance the aesthetic appeal of the odor control substrate to a consumer, one or more colored inks may also be applied the substrate in a pattern that may or may not overlap with the activated carbon ink pattern. The colored ink(s) may contrast well with the activated carbon ink to provide an overall design that is more aesthetically than otherwise would be provided by a uniform coating of activated carbon ink.

Owner:KIMBERLY-CLARK WORLDWIDE INC

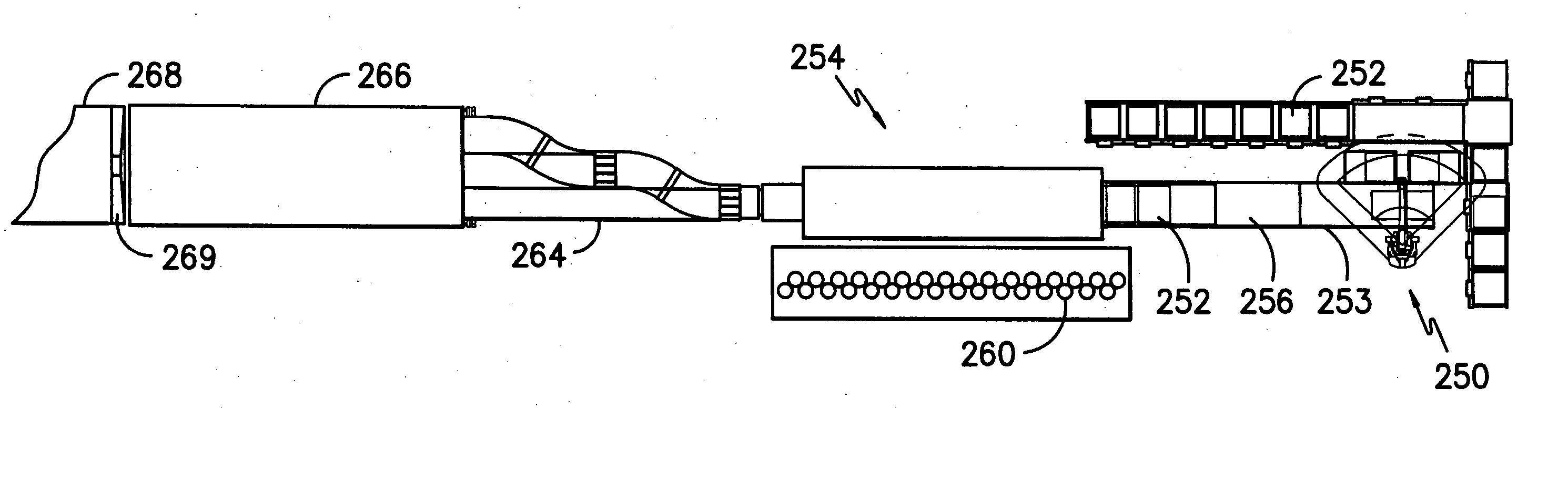

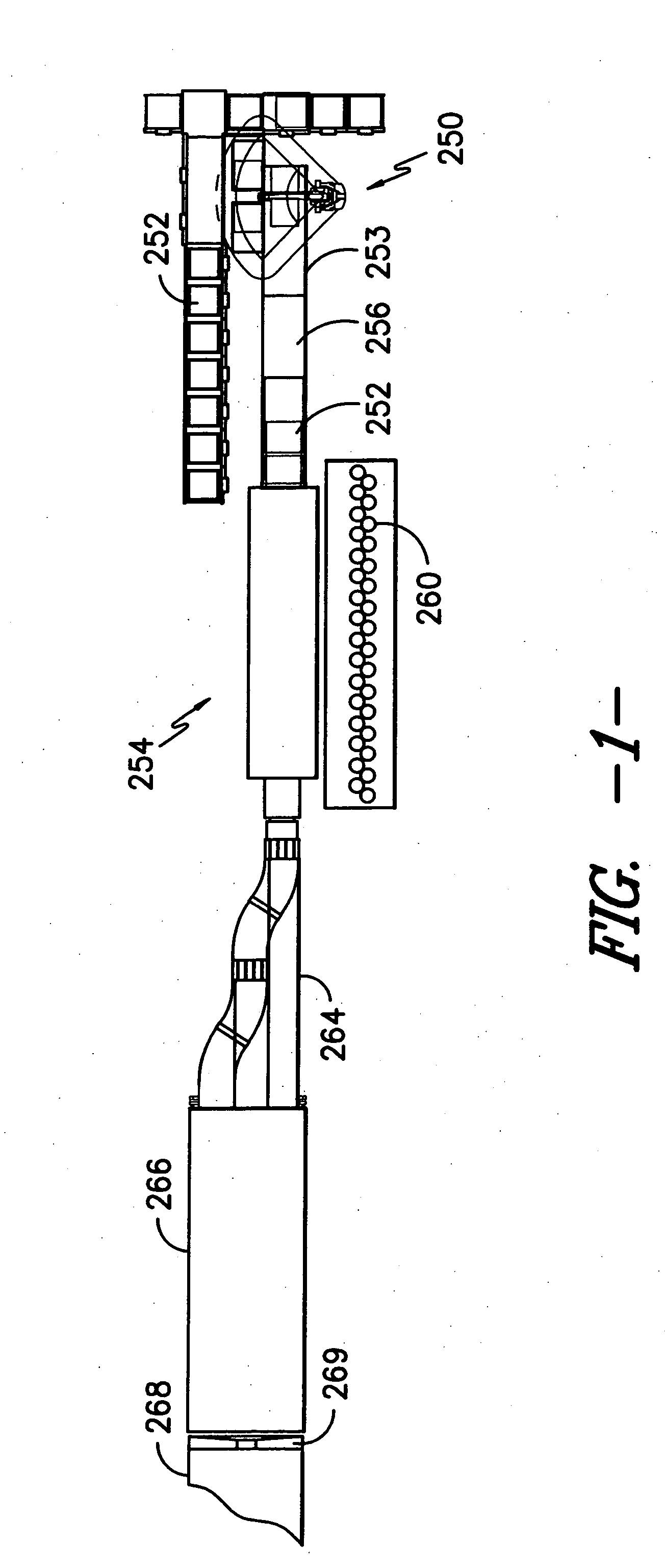

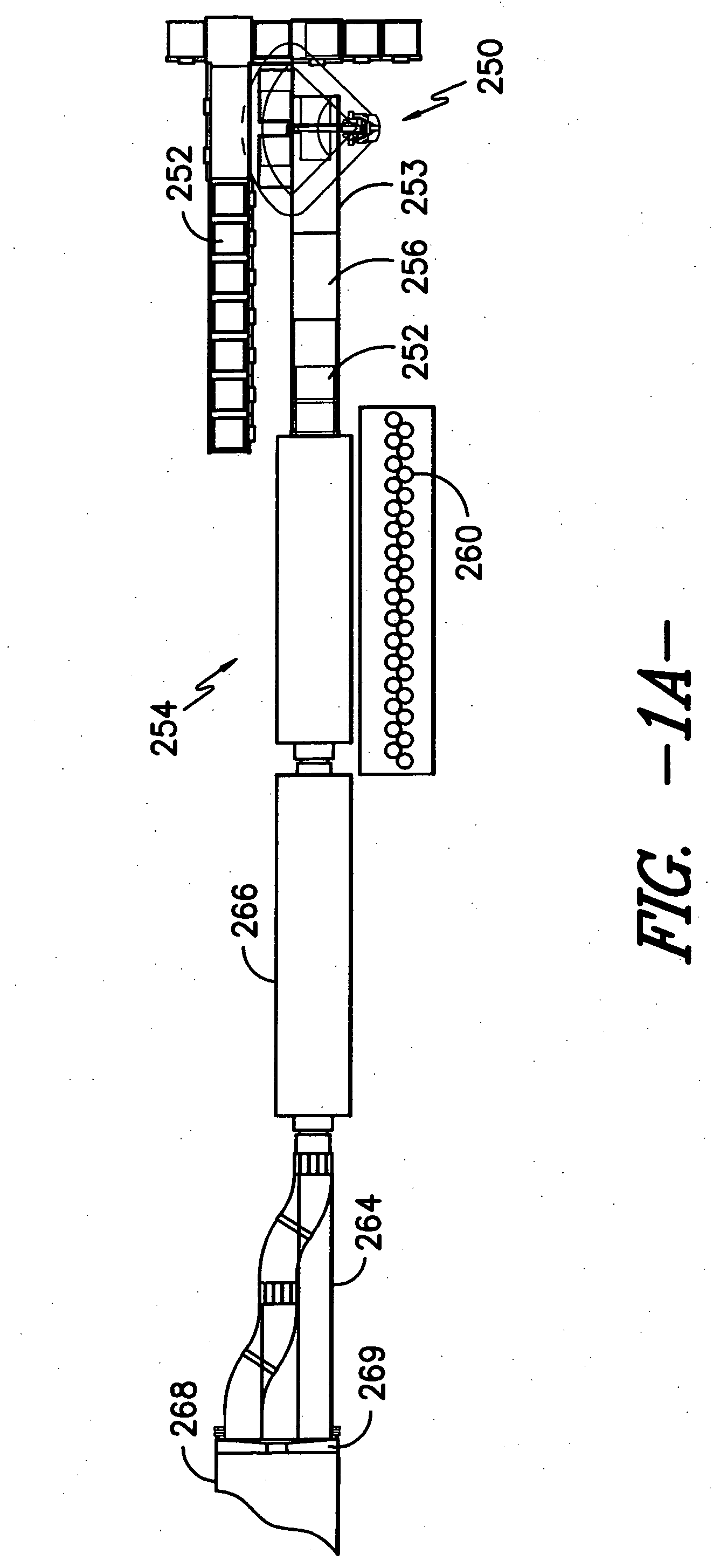

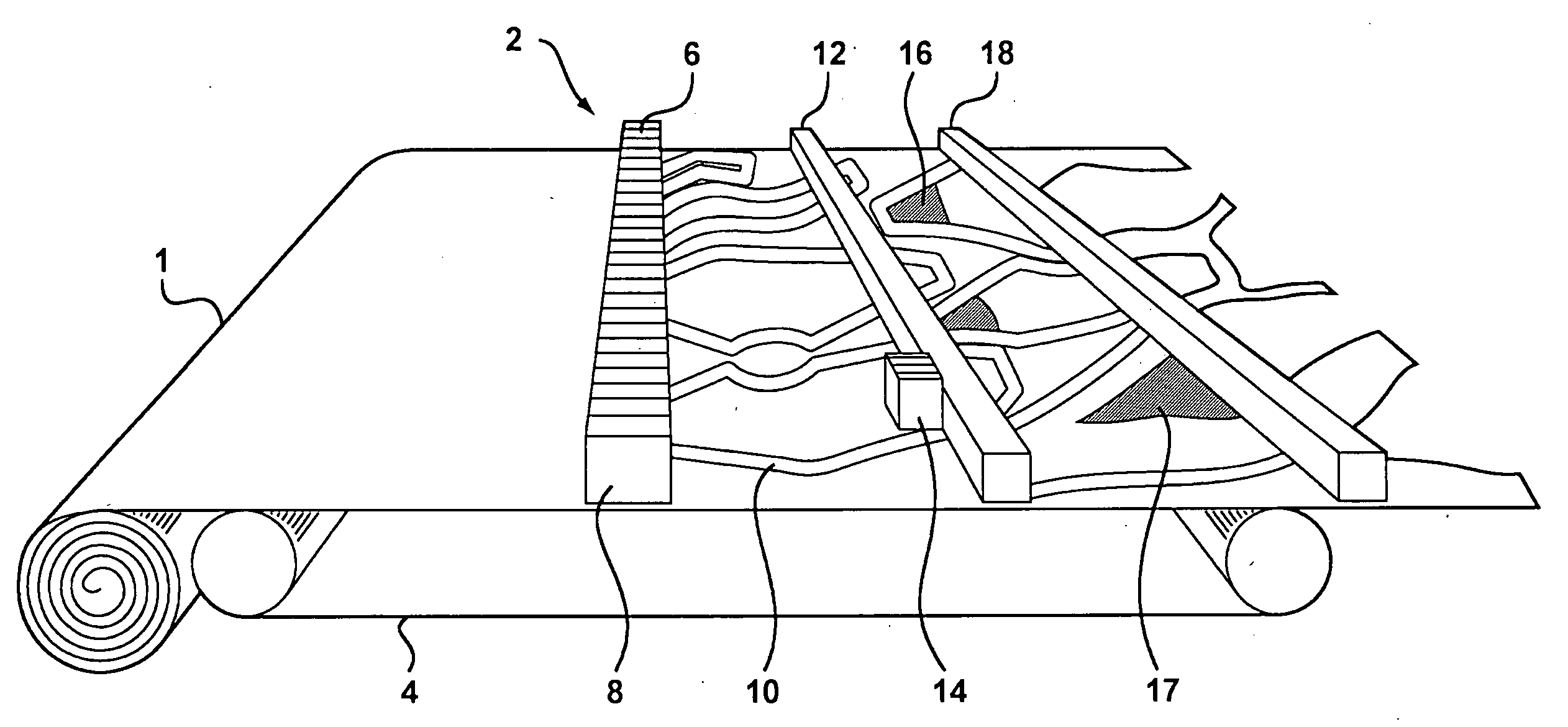

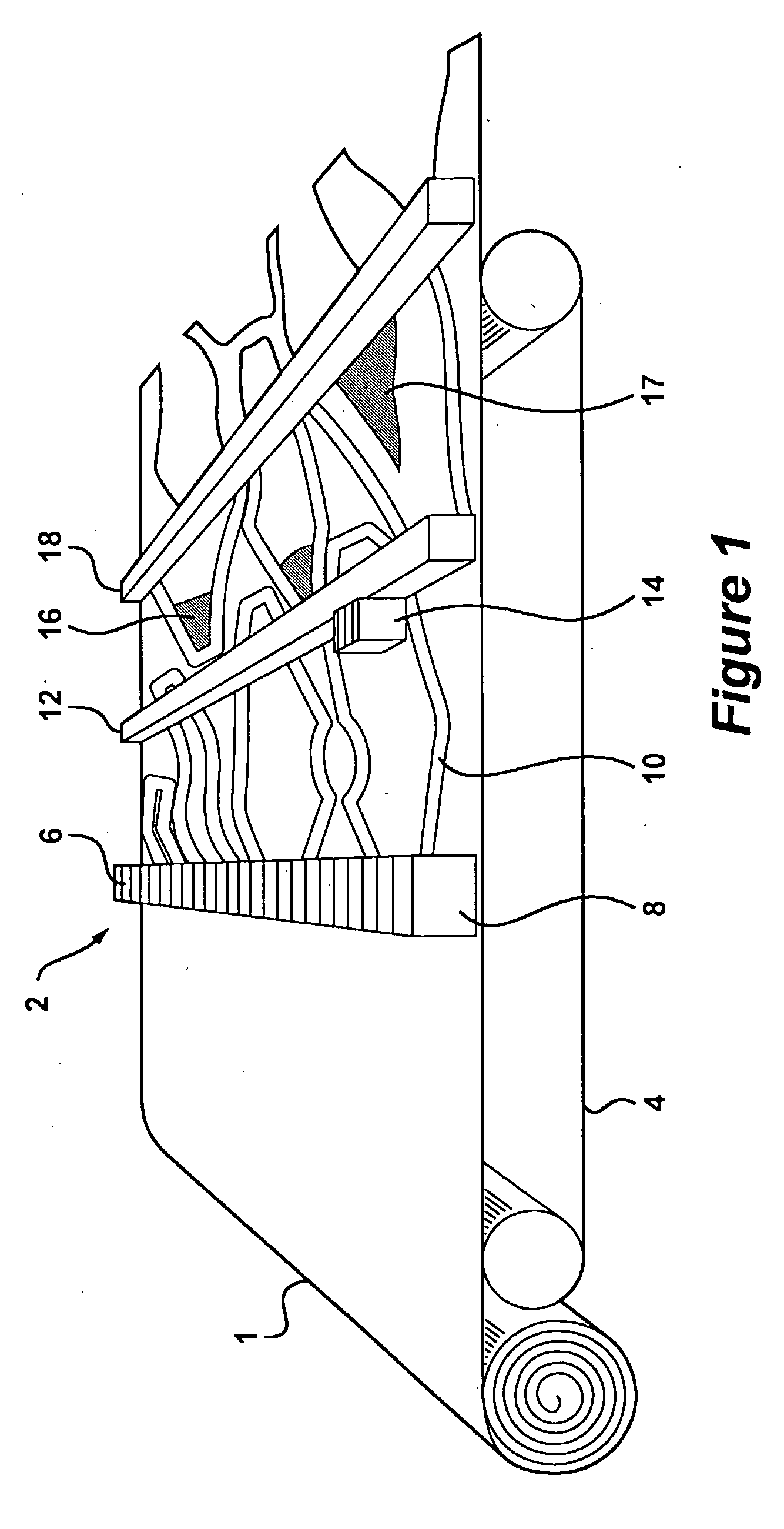

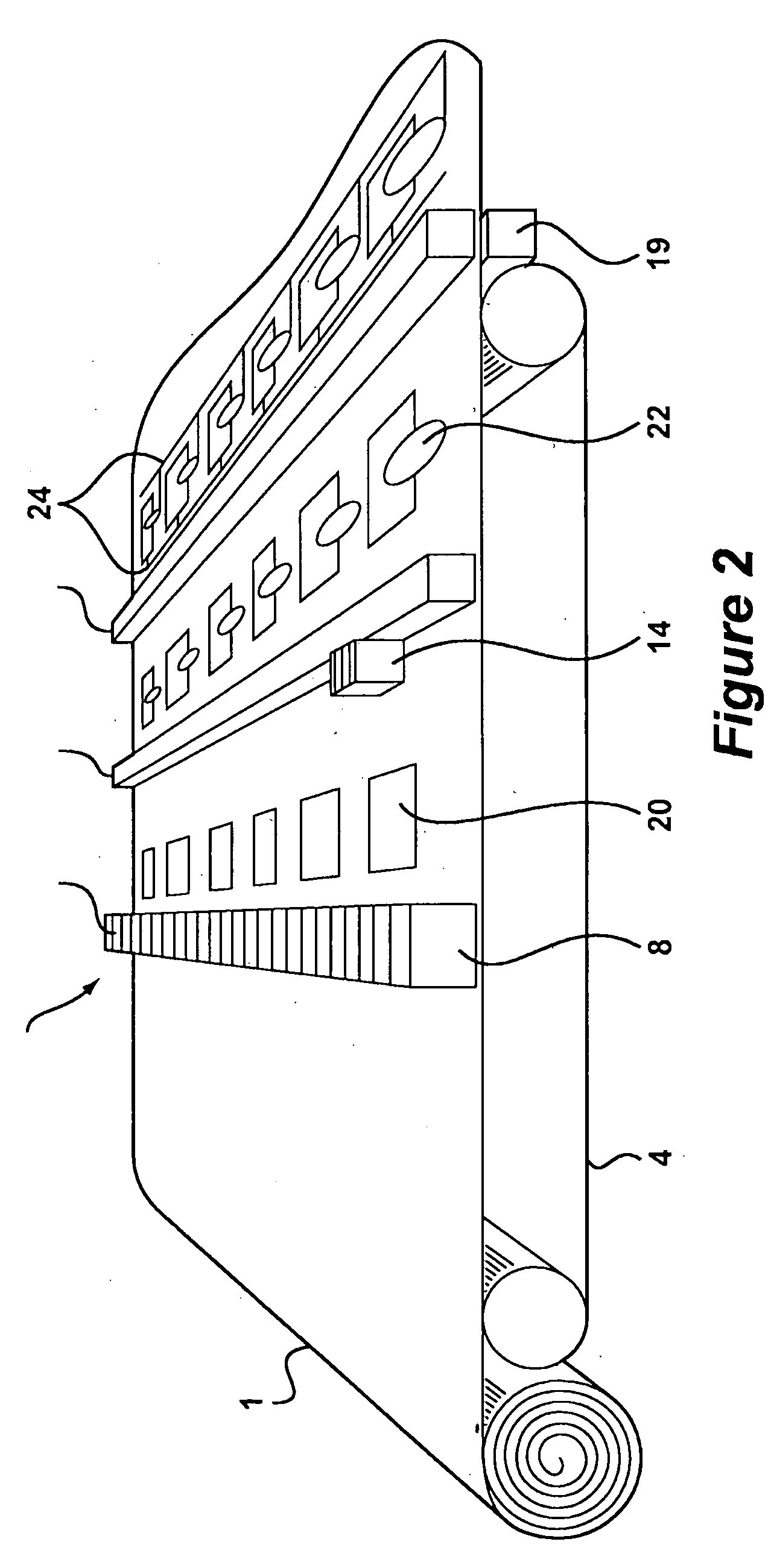

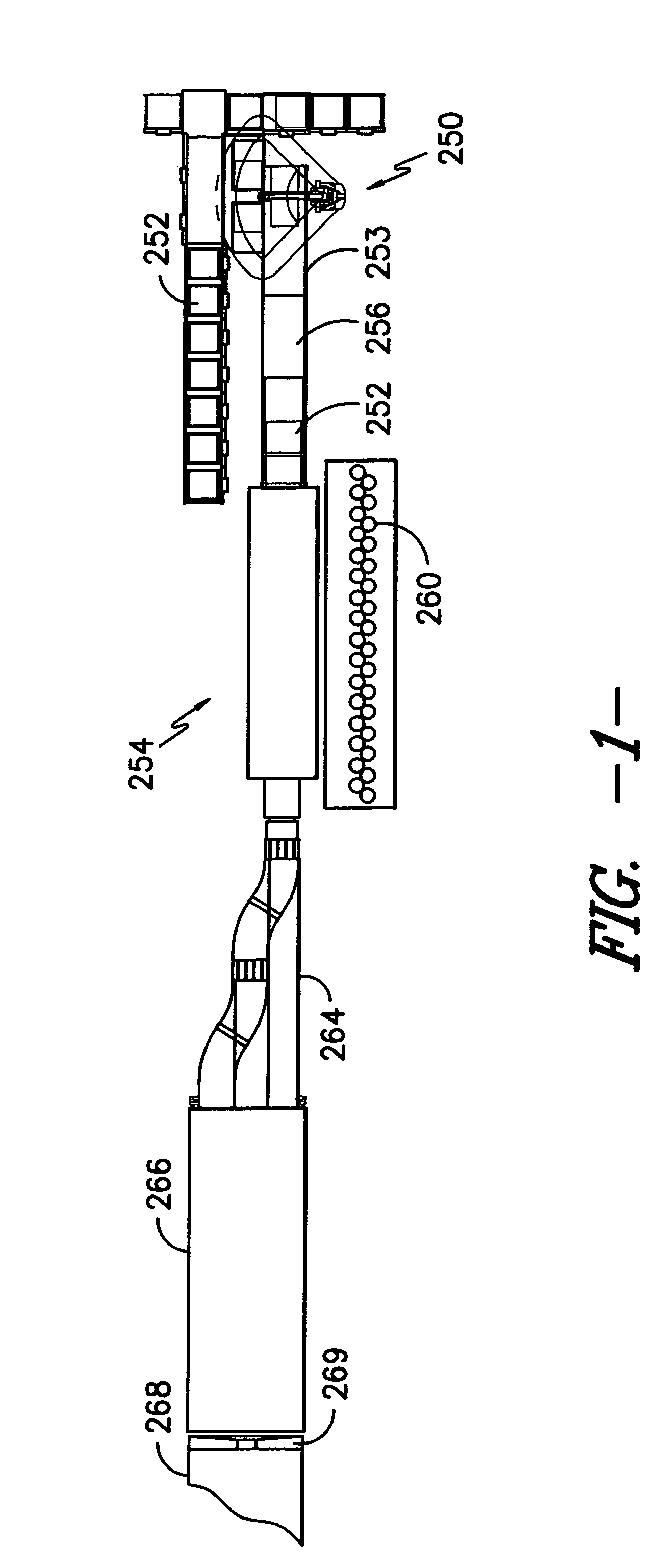

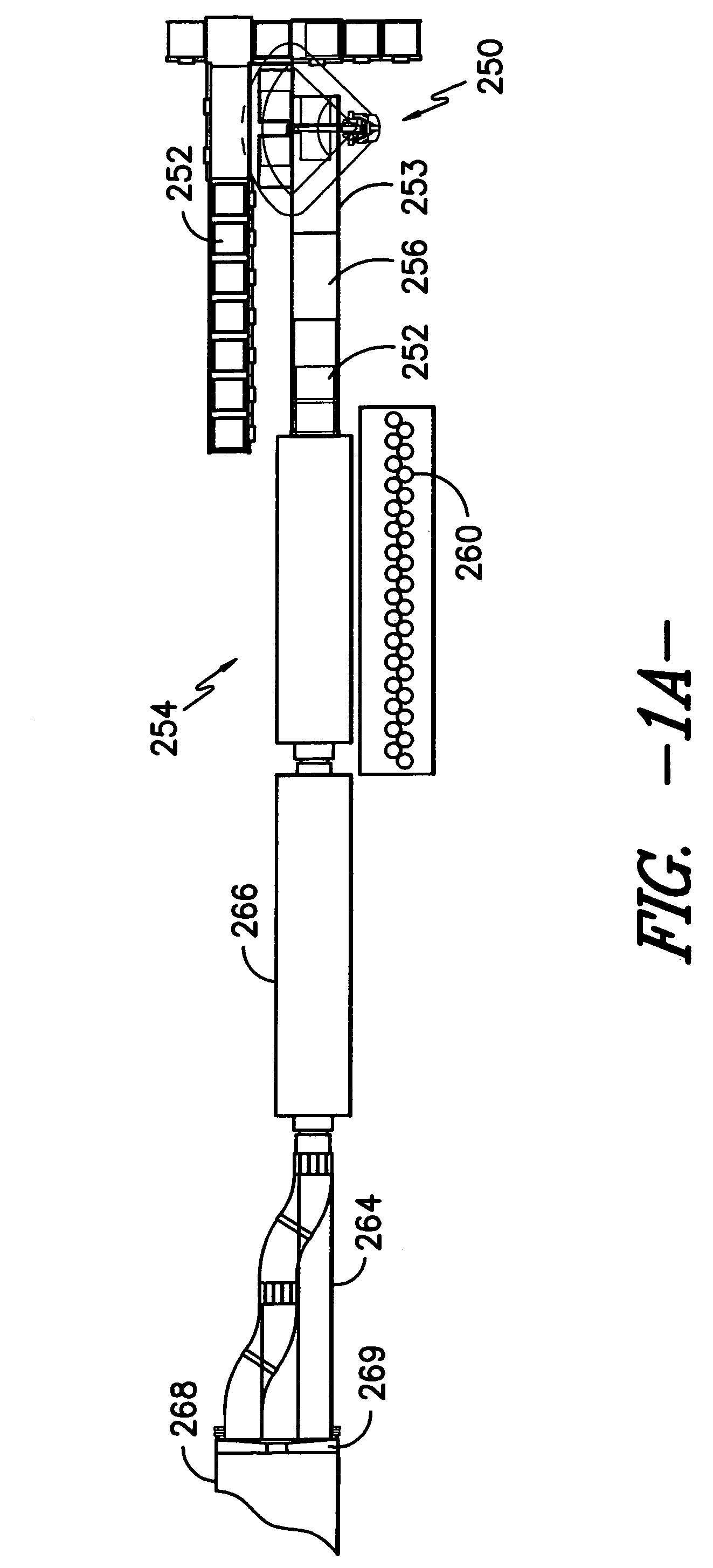

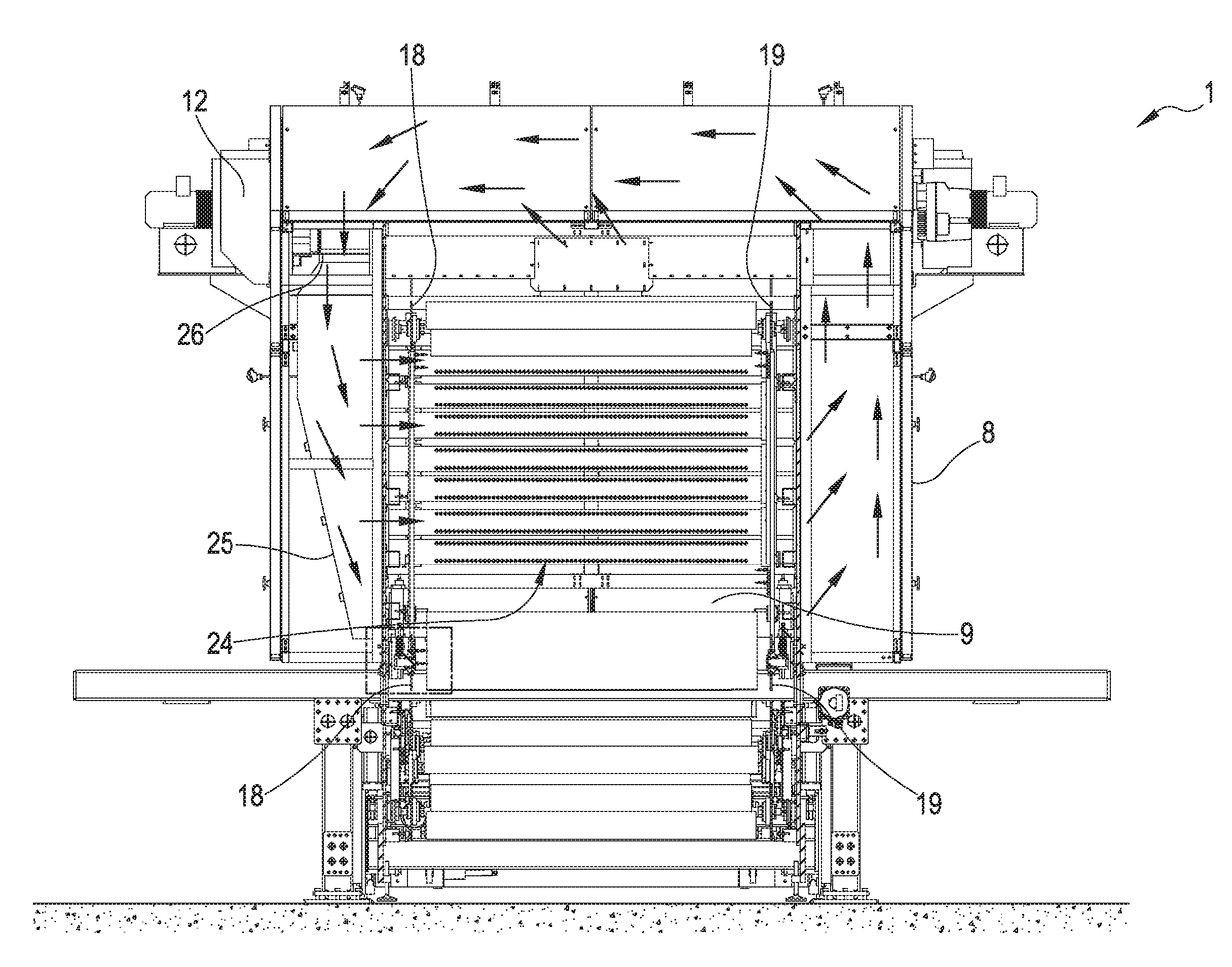

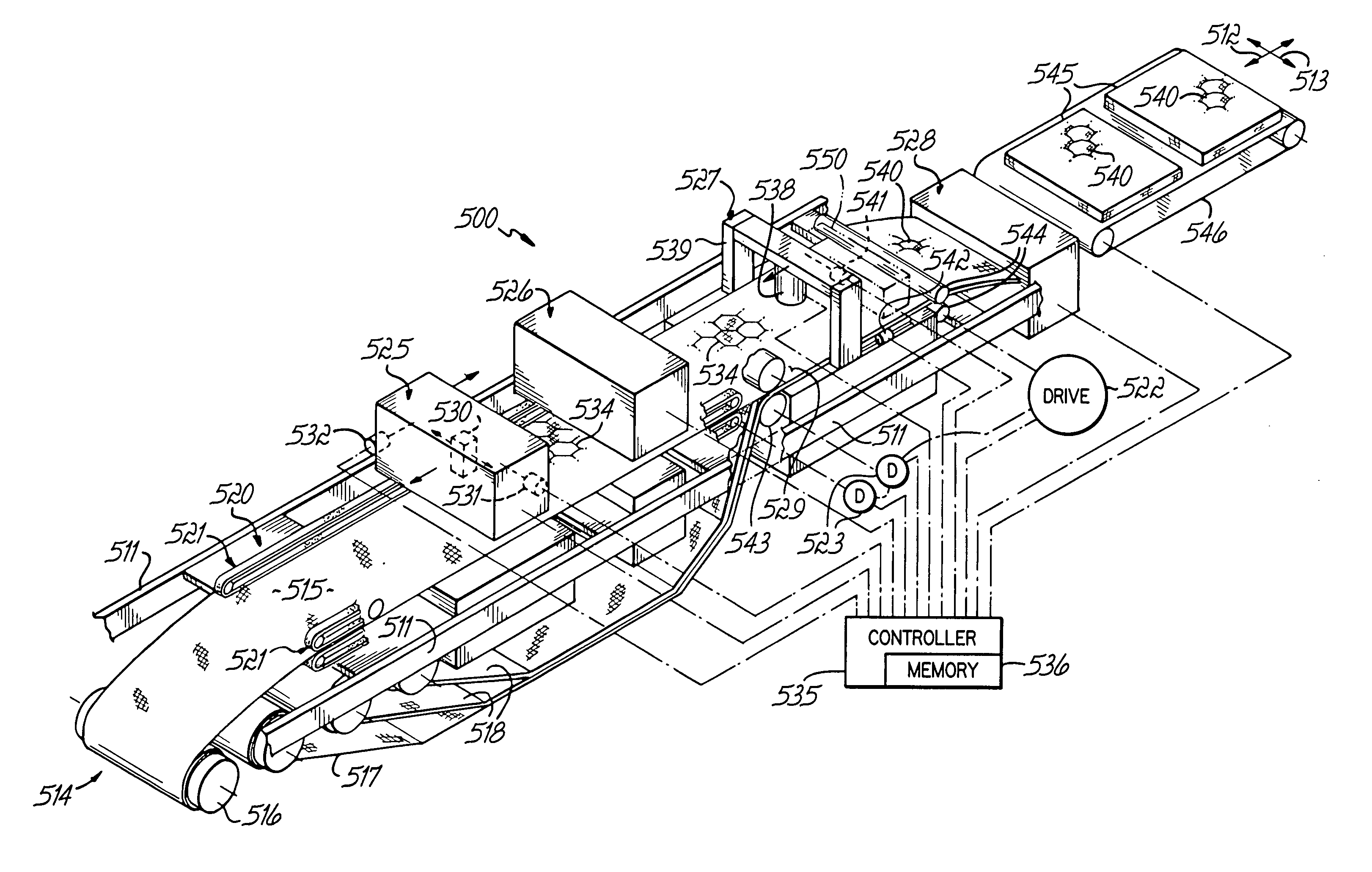

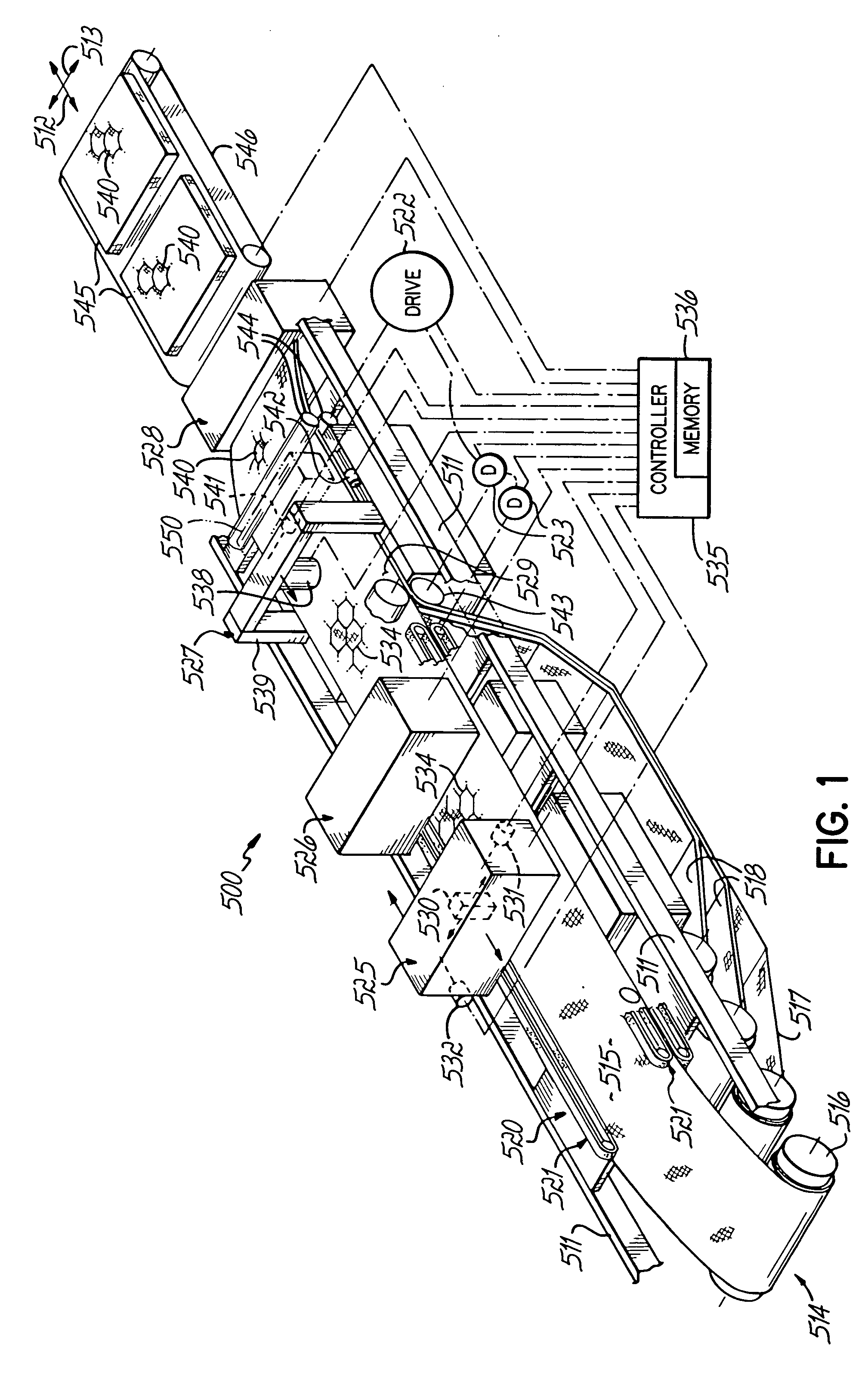

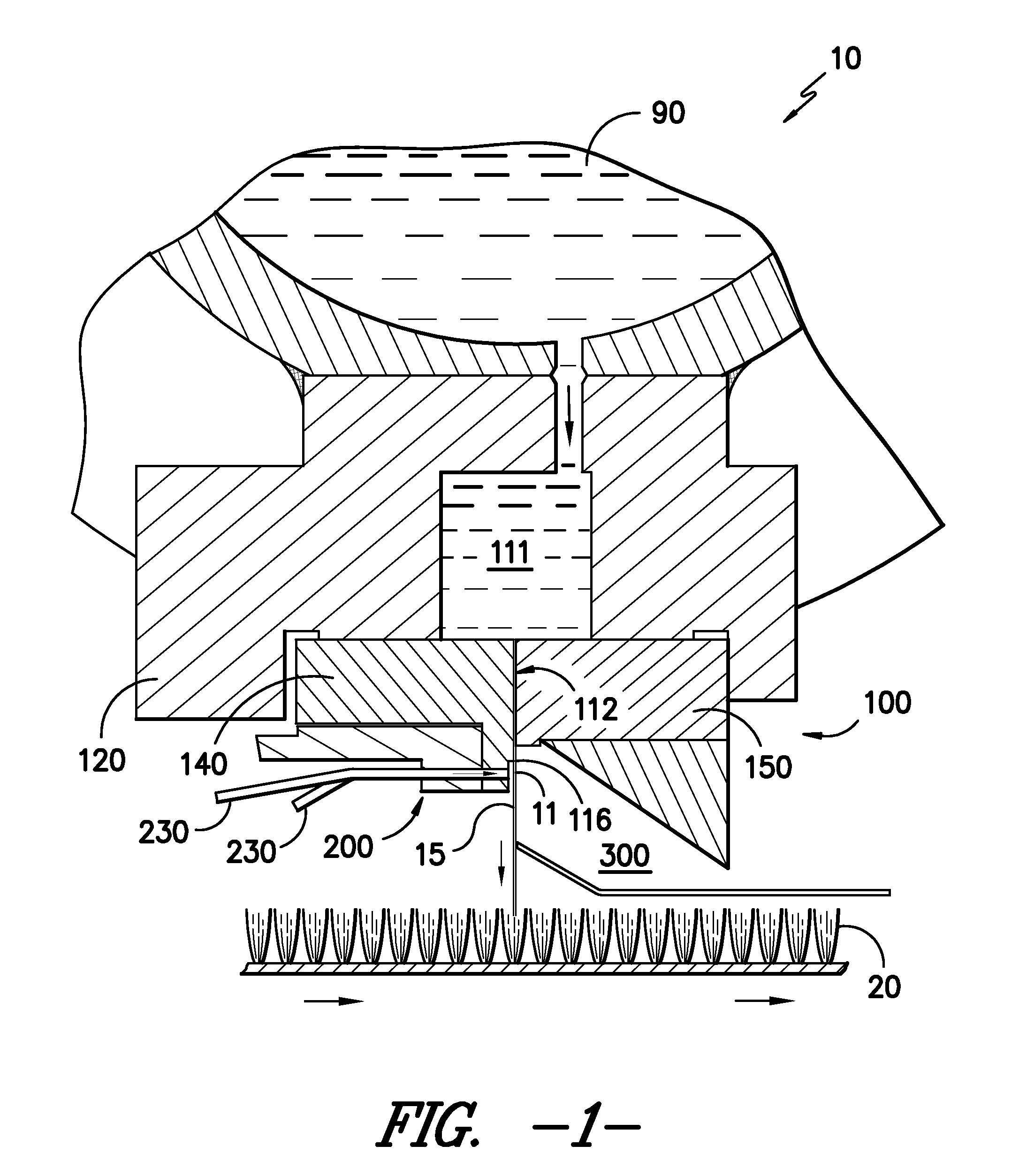

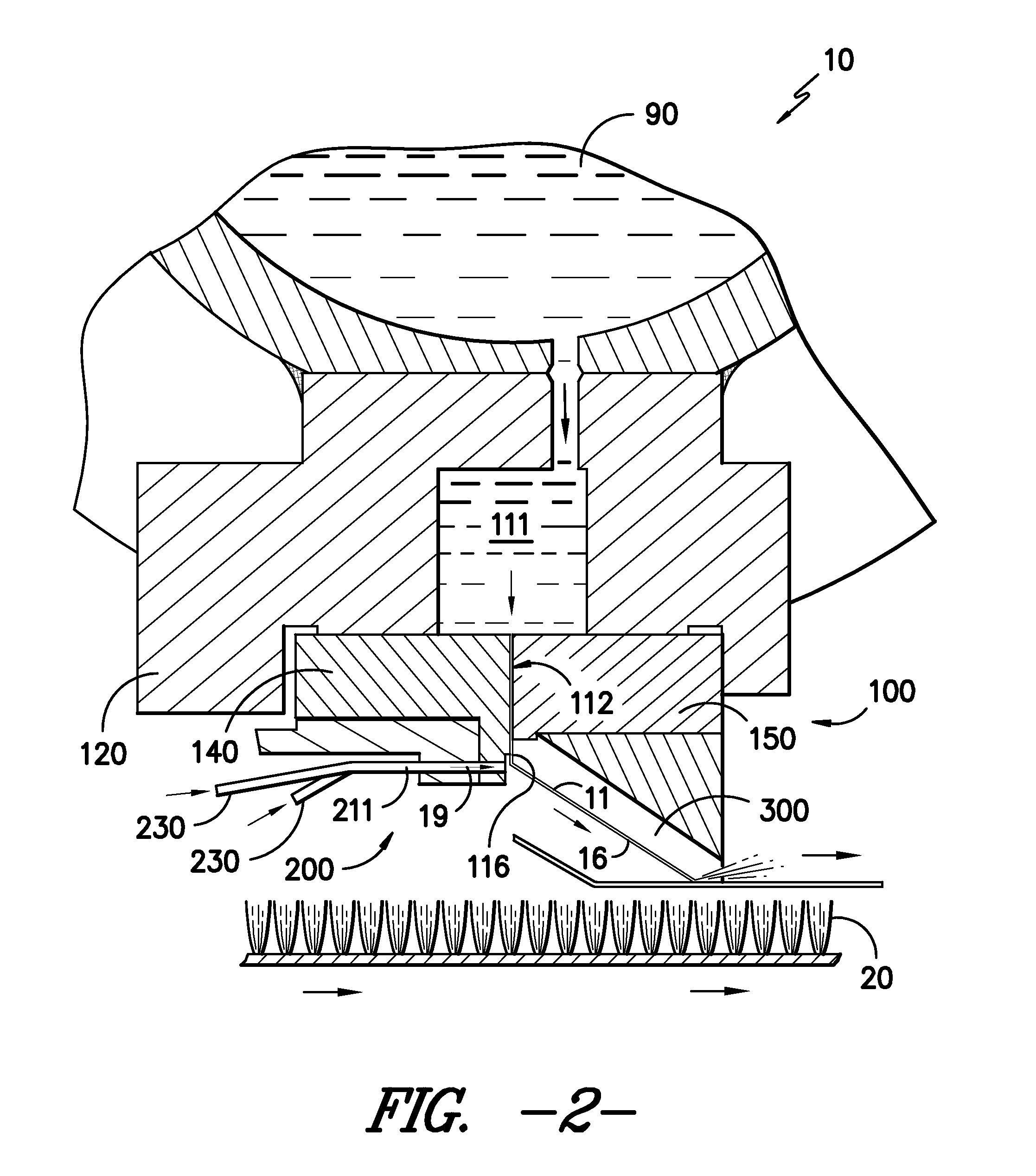

Printing and quilting method and apparatus

InactiveUS6848846B2Efficiently and economicallySave a lot of costRecording apparatusOrnamental textile articlesData fileEngineering

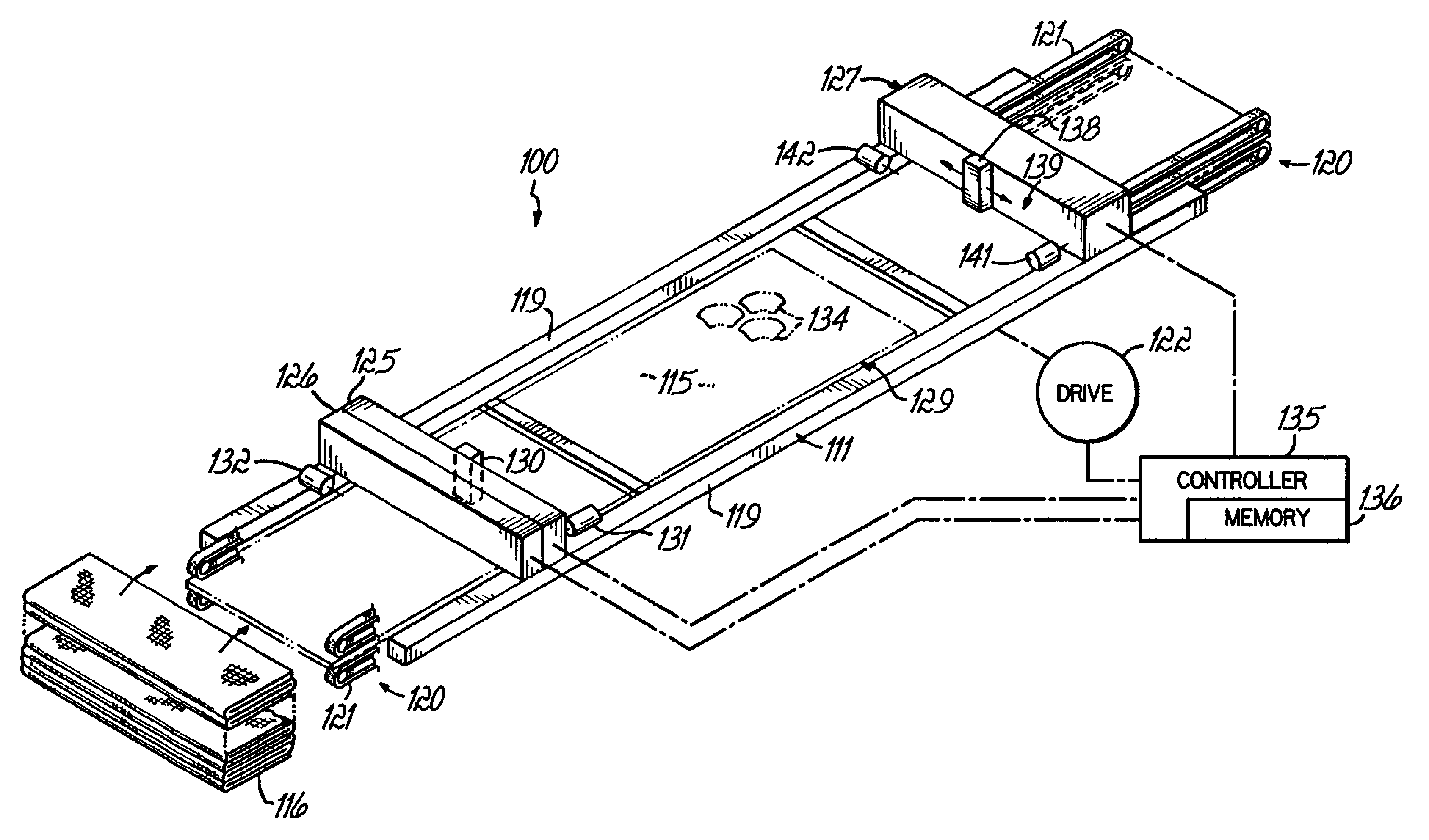

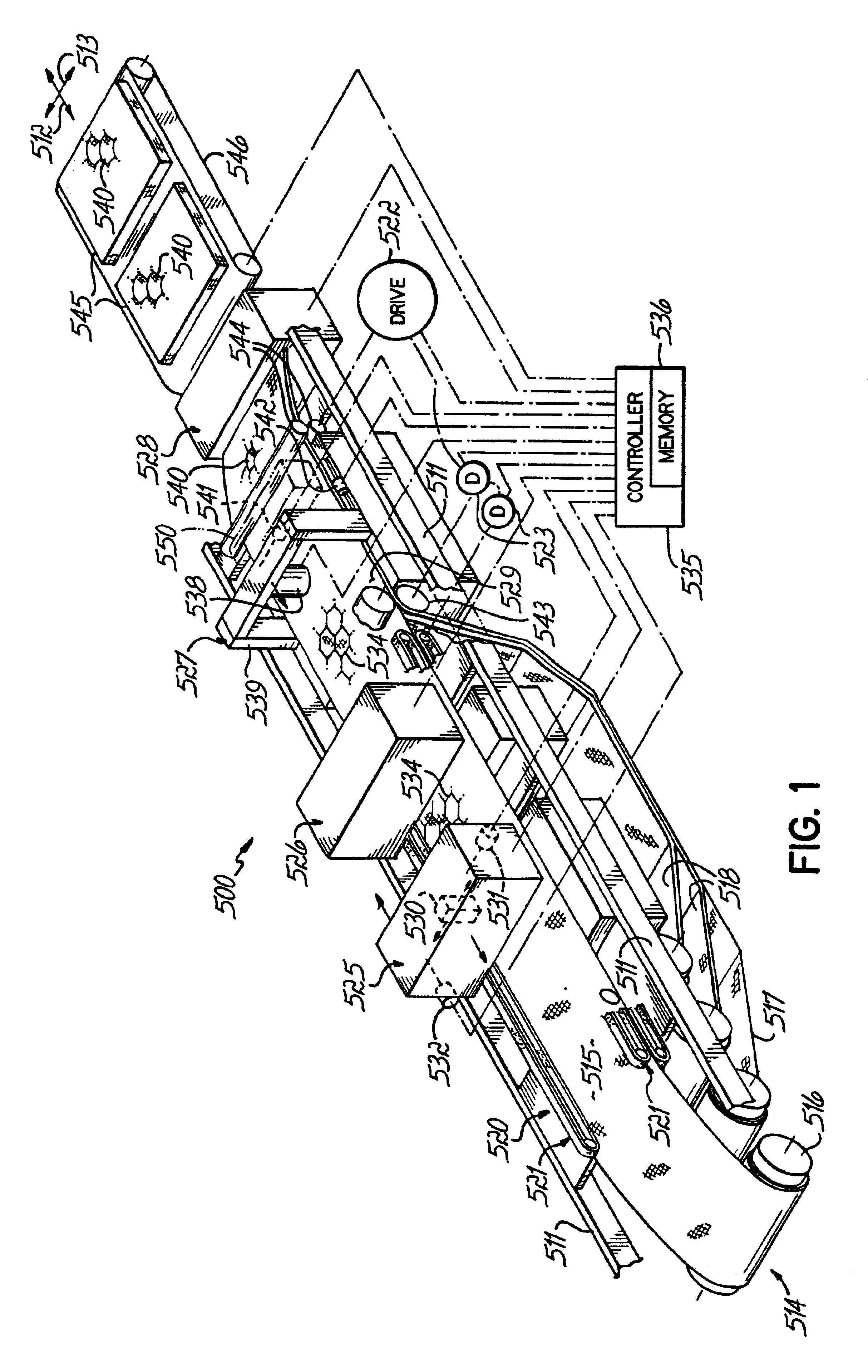

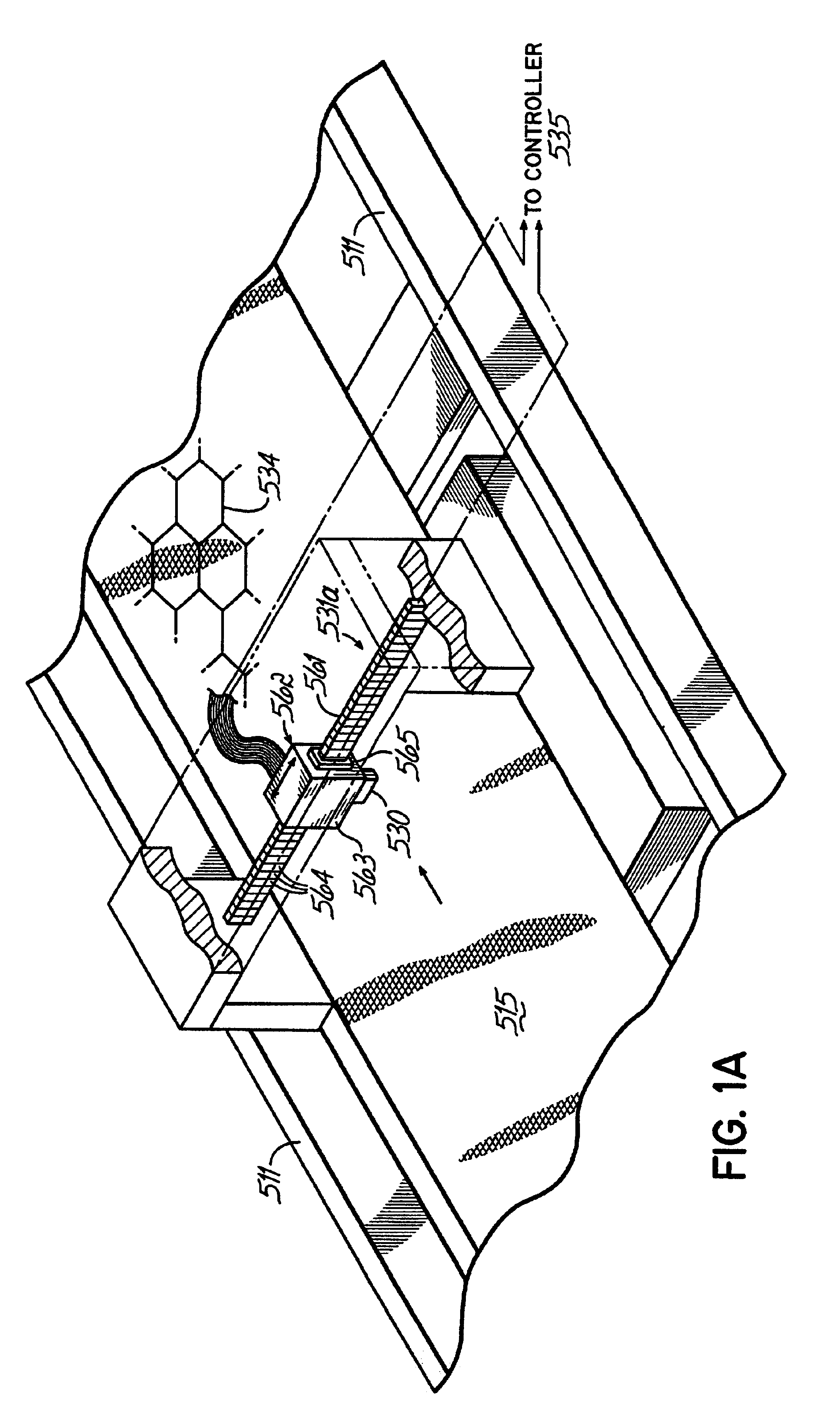

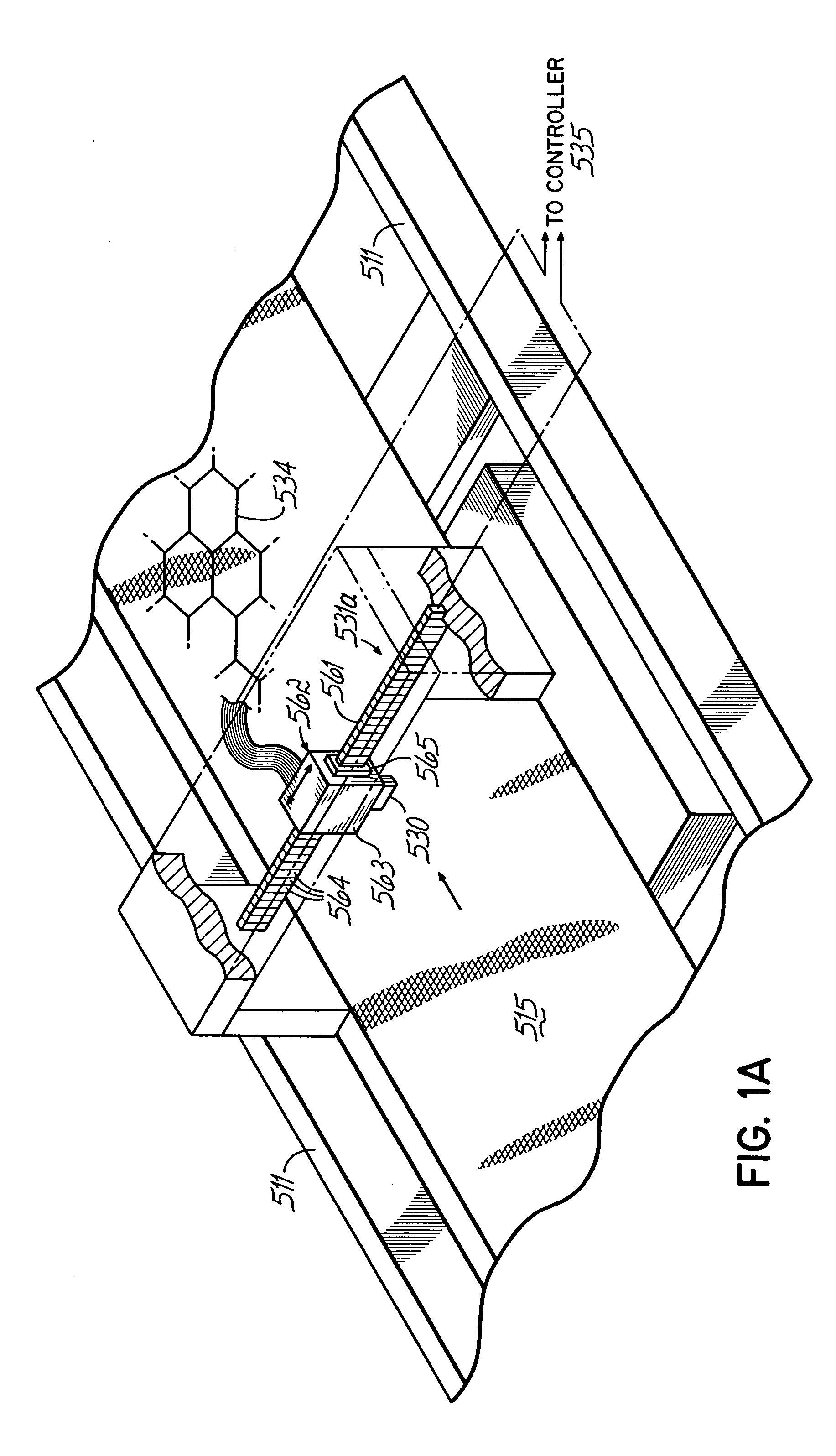

A quilting machine (10, 100, 200, 300, 400, 500, 600) is provided with a printing station (20, 125, 225, 325, 425, 525, 611, 626, 631) and a quilting station (44, 127, 227, 327, 427, 527, 627, 632). The printing station is located either in line and preferably upstream of the quilting station, with a conveyor (520) extending through each of the stations to convey a web of quilting material through the machine, or is off of the quilting line such that the material with a pre-applied pattern thereon is transferred, preferably in web form, to the line of the second station for the application of a pattern in registration with the first applied pattern. At the quilting station, registration longitudinal and transverse registration is measured and skewing or rotation of the material is determined. Opposite transverse sides of the material are differently adjusted to orient and register the material. A master batch controller (90, 135, 235, 335, 435, 535) assures that the proper combinations of printed and quilted patterns are combined to allow small quantities of different quilted products to be produced automatically along a material web. Ticking is preprinted with a plurality of different patterns, organized and communicated by the computer so that a print head can scan the material and print different patterns of different panels (32) across the width of a web. Identifying data (40) for matching the panels of a mattress product can be provided in data files printed on the fabric. Cutting and slitting of the panels from each other and the quilting and combining of the panels for assembly of a mattress product can be carried out manually or automatically using the data.

Owner:L & P PROPERTY MANAGEMENT CO

Non-woven fabric with surface subjected to local water repellency treatment and preparation method and application thereof

InactiveCN106192268AImprove drynessReduce manufacturing costFabric parts treatmentSurface layerNonwoven fabric

The invention discloses a non-woven fabric with a surface subjected to local water repellency treatment. The non-woven fabric comprises a base material layer used as a surface layer of a heath care product, and after one surface of the base material layer is subjected to local water repellency treatment, a local water repellency region is formed on the surface. The invention further discloses a preparation method and application of the non-woven fabric. The surface of the non-woven fabric is subjected to local water repellency treatment, the water retention rate of the non-woven fabric used as the surface layer or the contact area between the non-woven fabric and skin is adjusted by adjusting the area ratio of a hydrophilic region to the water repellency region, therefore, the use experience is improved, and experience comfort is enhanced.

Owner:CHANGZHOU WISDOM NONWOVENS TECH

Printing and quilting method and apparatus

InactiveUS20050051071A1Efficiently and economicallyHighly efficient and economical and high and mannerLeather sewingOrnamental textile articlesProduction lineData file

A quilting machine (10, 100, 200, 300, 400, 500, 600) is provided with a printing station (20, 125, 225, 325, 425, 525, 611, 626, 631) and a quilting station (44, 127, 227, 327, 427, 527, 627, 632), either on the same or a different production line. Ticking is preprinted with a plurality of different patterns, organized and coordinated by the computer so that a print head can scan the material and print different patterns of different panels (32). Identifying data (40) for matching the panels of a mattress product can be provided in data files and codes can be printed on the fabric. Panels can be matched and assembled into products based on the codes, and quilting, cutting, slitting and other operations can be controlled by printed codes and other data. The quilting and combining of the panels for assembly of a mattress product can be carried out manually or automatically using the data.

Owner:L & P PROPERTY MANAGEMENT CO

Patterned carpet and method

InactiveUS20050056337A1Maximize utilizationImprove efficiencyFibre treatmentWoven fabricsYarnScreen printing

Color, pattern, design, and / or the like is applied by means of a jet dye process, or any other secondary or post pattern application process, including but not exclusively, silk screen printing and rotary printing, etc., to a carpet substrate, where the yarn in the carpet is all white (no dye applied) or where the yarn is pre-dyed with a single or multiple colors or where the yarn is treated chemically. The carpet can, for example, be made with any conventional loom weaving process or hand weaving process, for example Wilton, Axminster, spool, spool gripper, and Chenille looms, hand gun tufted, or any other conventional method.

Owner:MILLIKEN & CO

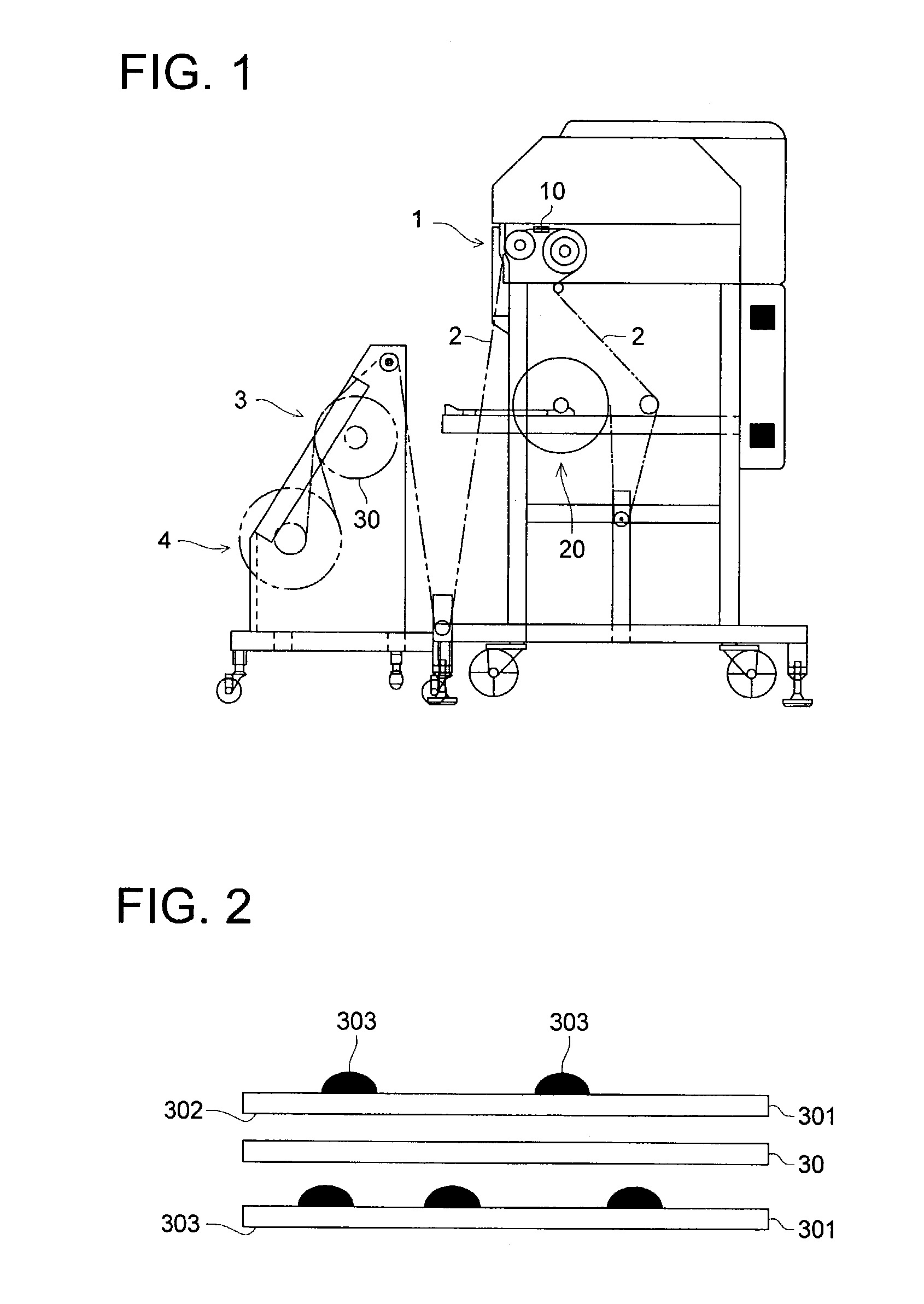

Production process and production equipment for pure cotton fabric with white space effect

InactiveCN103215830AUniform and natural whitening effectReduce pollutionTextile storage in wounded formDyeing processPulp and paper industryReactive dye

A production process and production equipment for pure cotton fabric with white space effect. The production process includes pretreatment, lye padding, dye paste scraping, stack cooling and fixation, and floating color washing. The dye paste scraping step refers to scraping a reactive dye paste on the back of pure cotton fabric subjected to lye padding. The stack cooling and fixation step refers to rolling up the pure cotton fabric scraped with the reactive dye paste; in the rolling process, isolating membranes are introduced to separate each layer of the cotton fabric, so that the reactive dye paste on the back of the pure cotton fabric to gradually diffuses, permeates, adsorbs to a right side, and finally reacts into bonds to fix the color. As the reactive dye is in a paste shape, diffusivity and permeability of the dye are limited to a certain extent that only part of the dye can reach the right side of the pure cotton fabric; in addition, the pure cotton fabric has bump woven texture; therefore, uniform and natural white space effect is formed on the right side.

Owner:HUAHAN QUANZHOU NEW FABRIC DEV

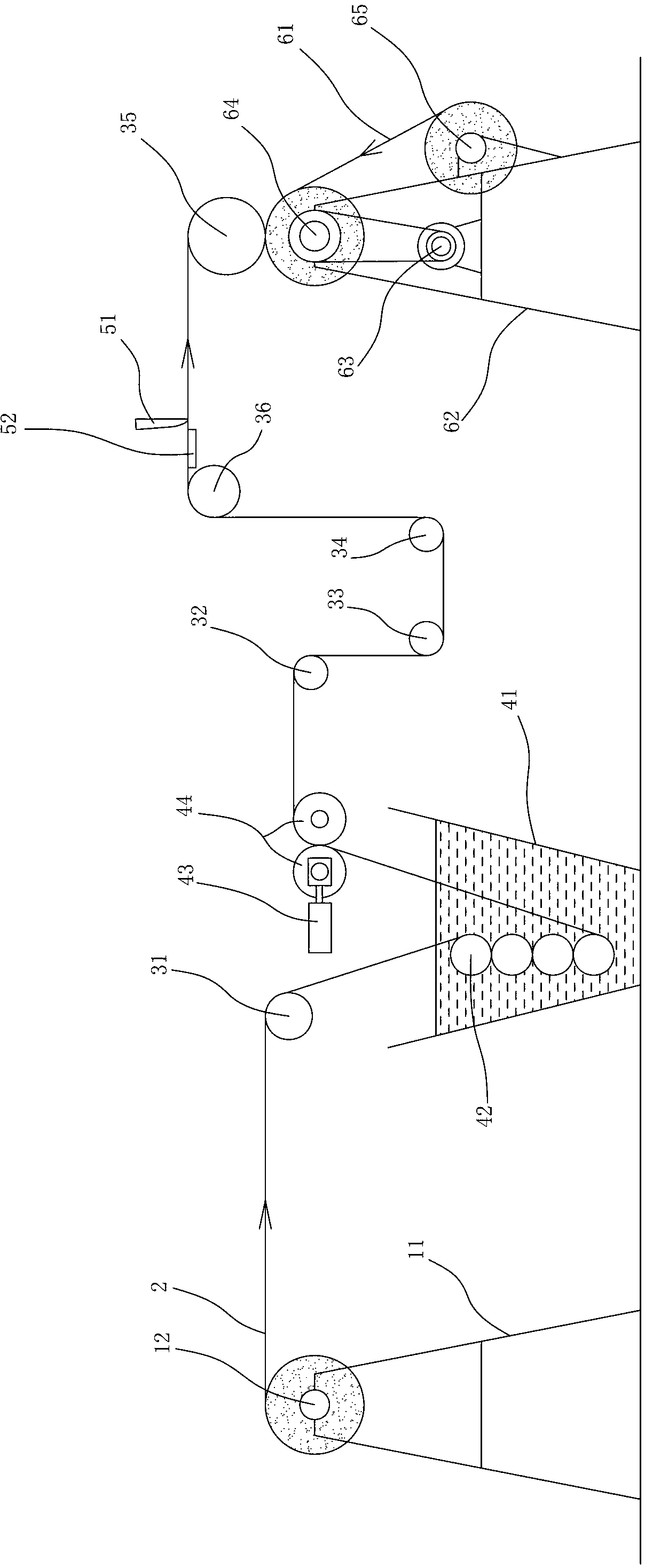

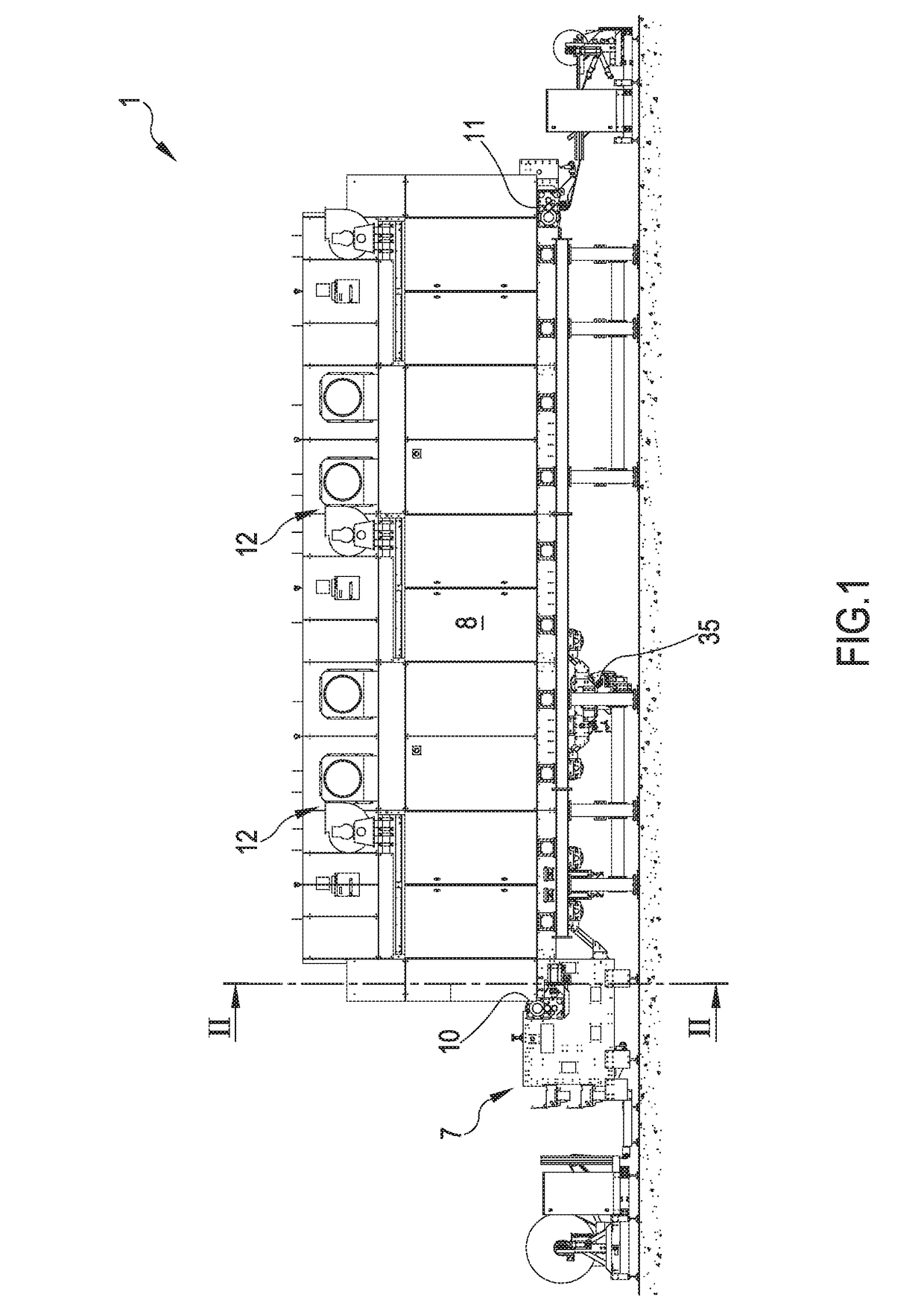

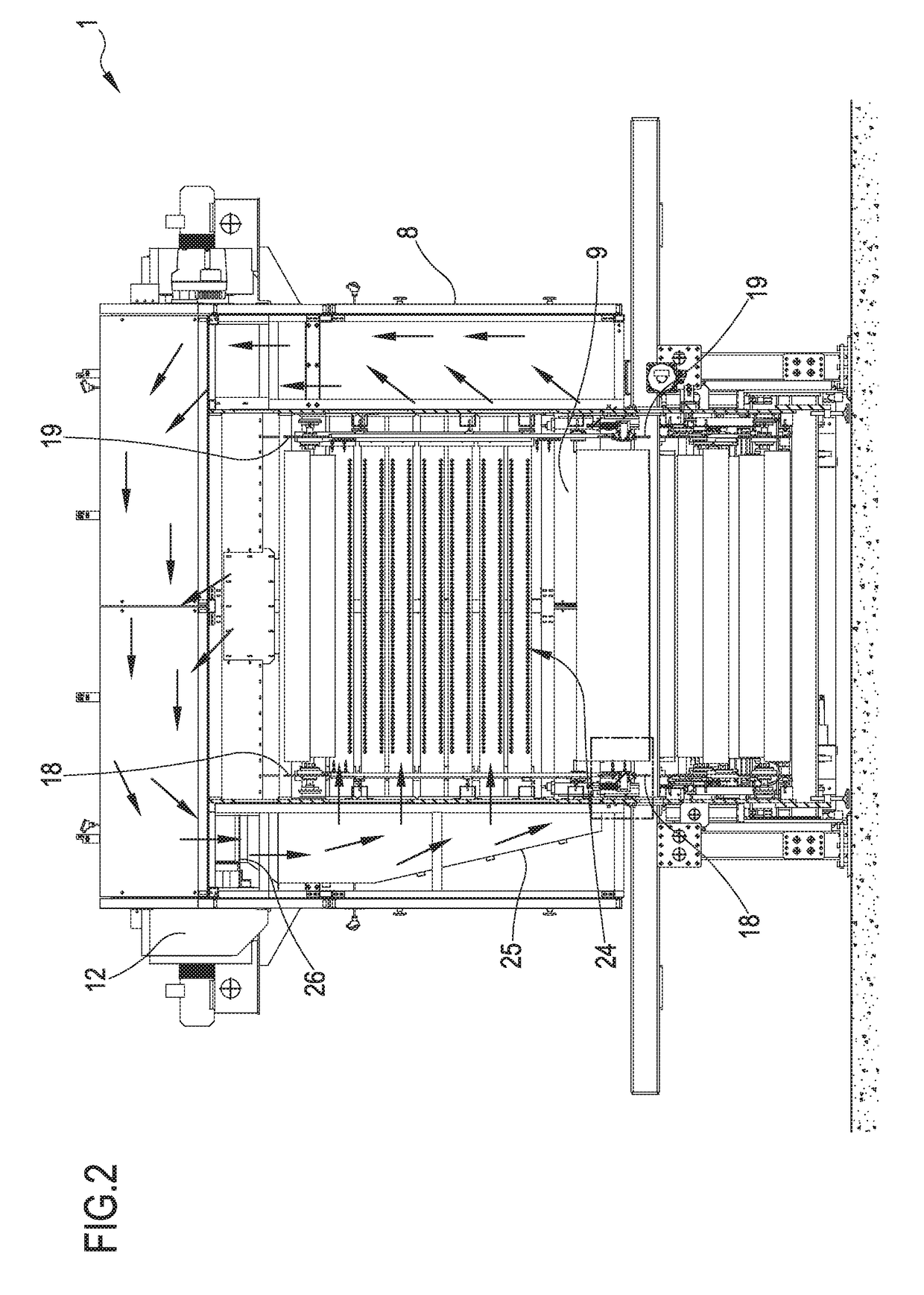

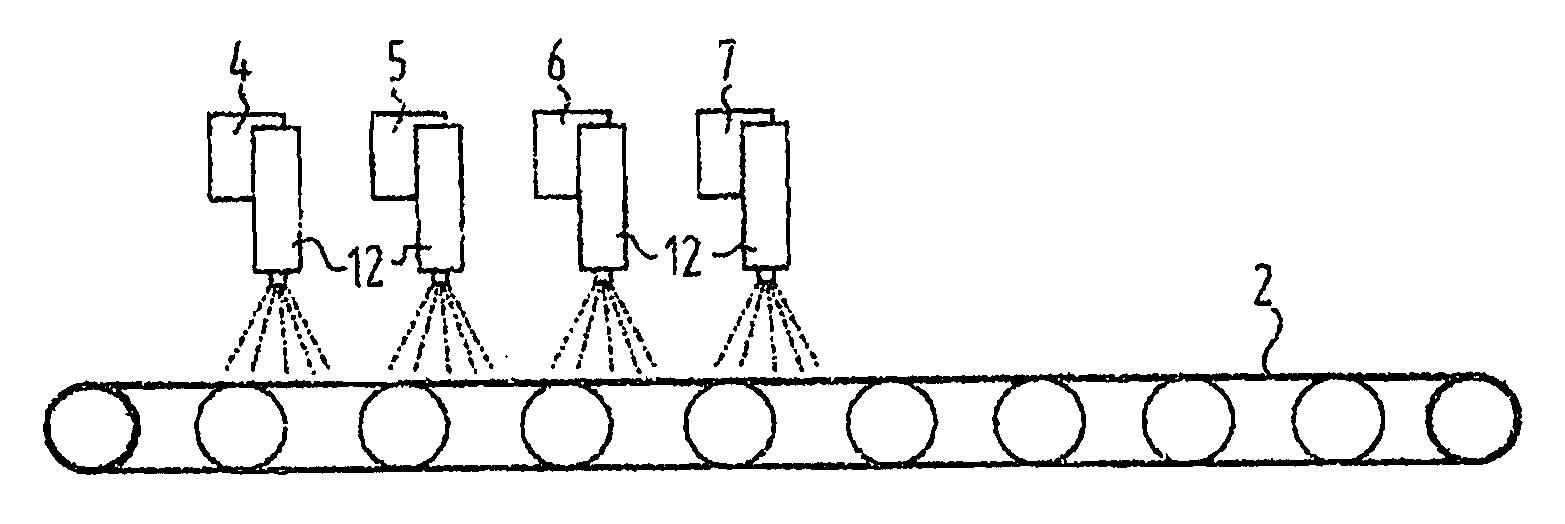

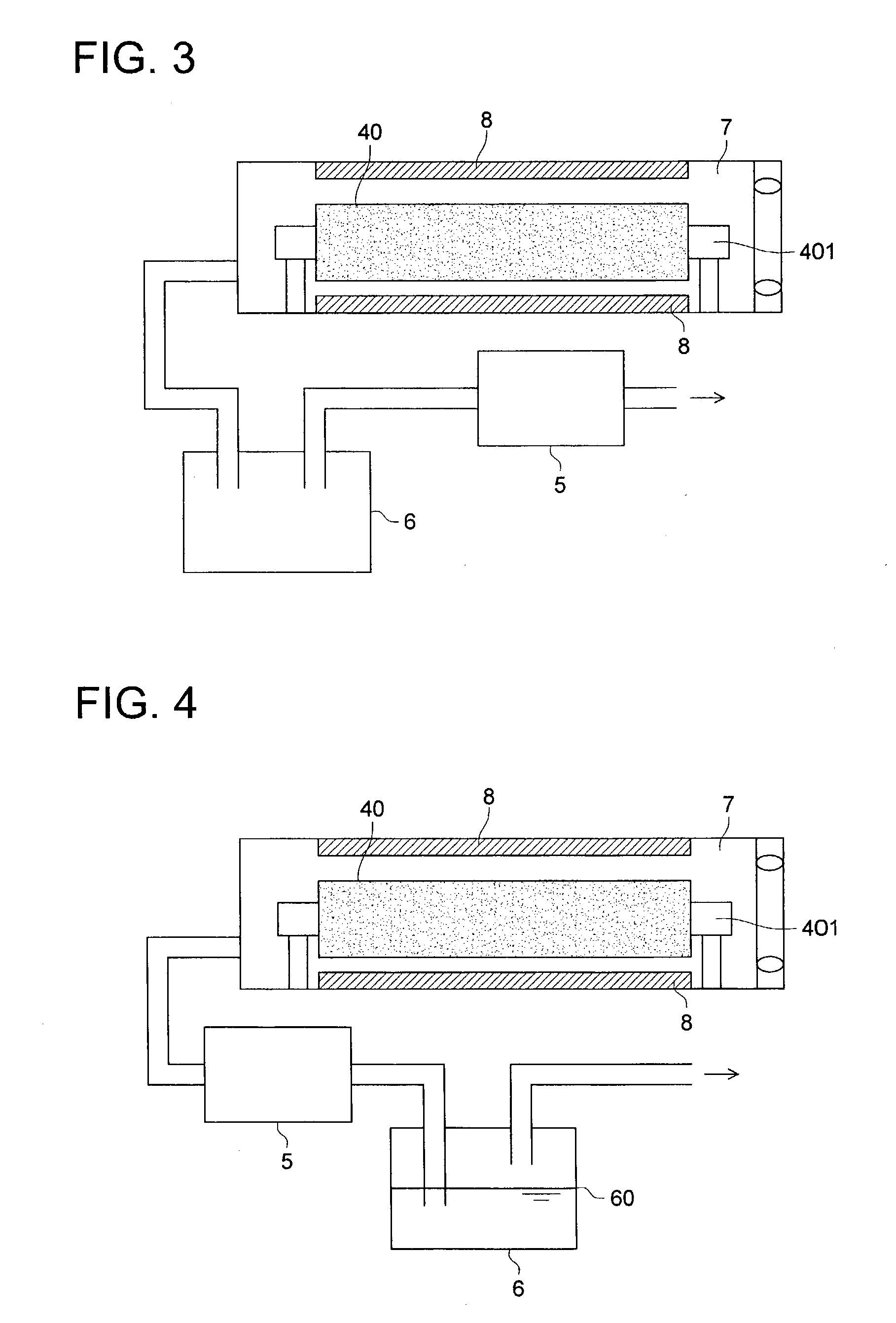

System for production-line printing on wet web material

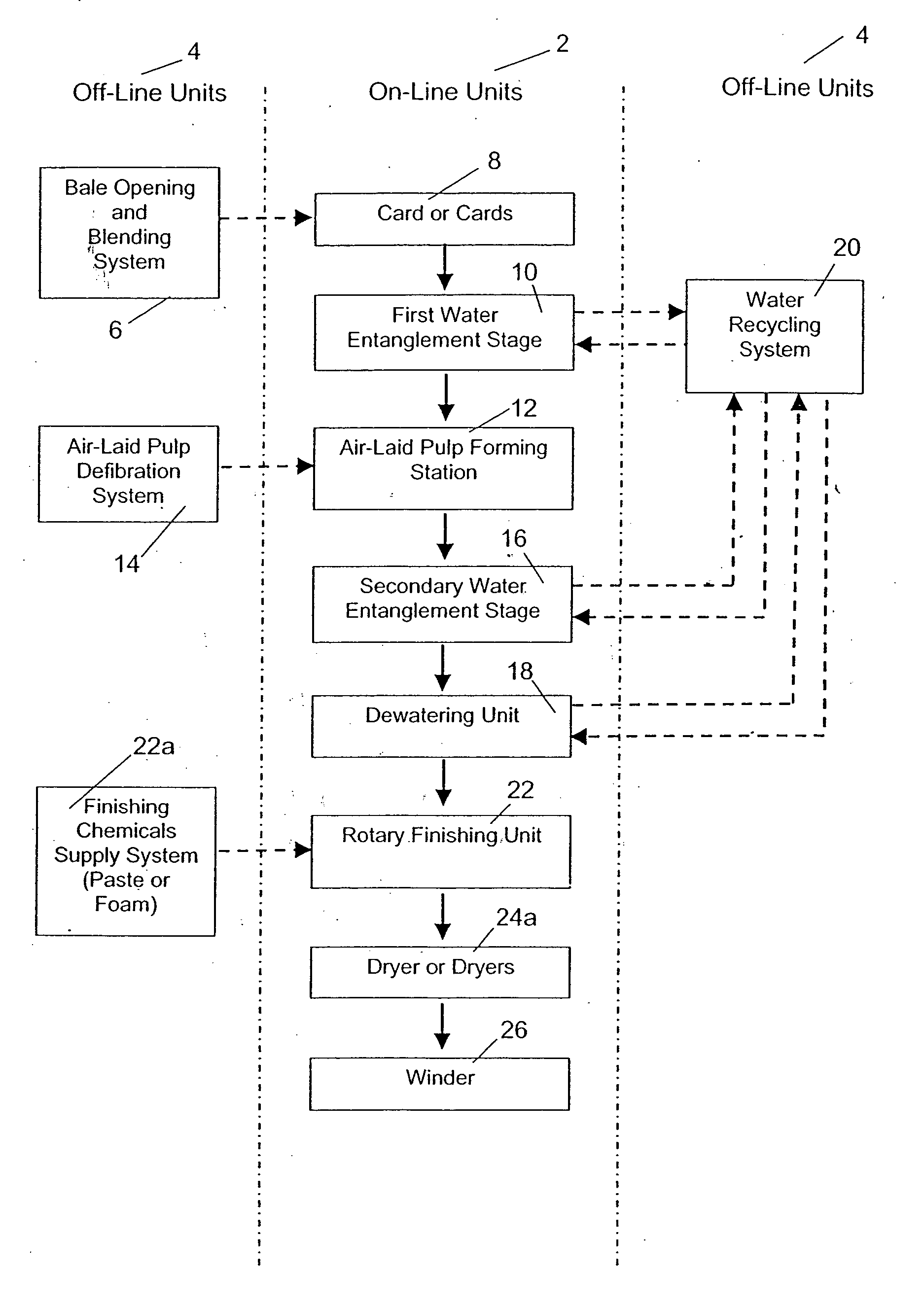

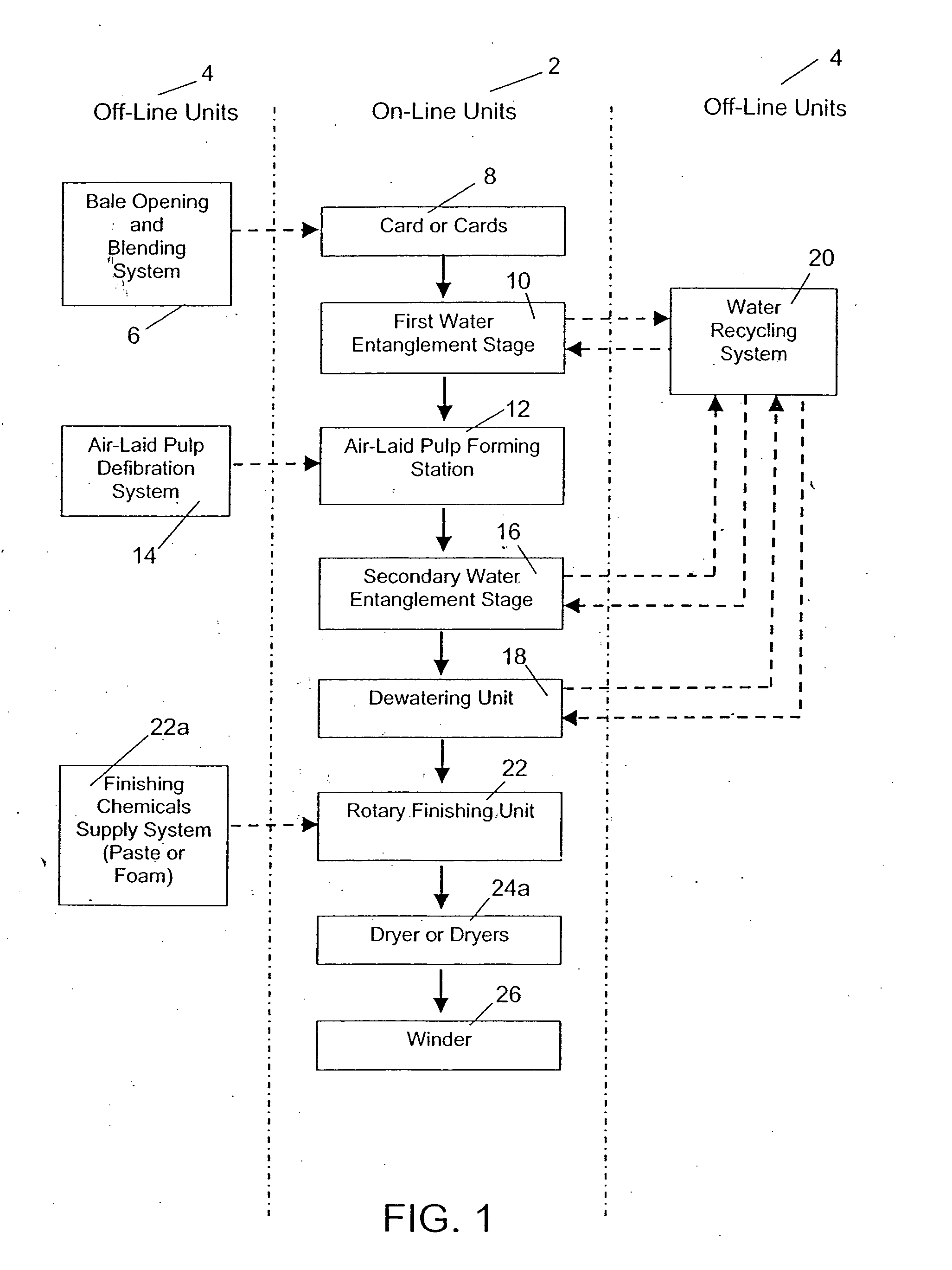

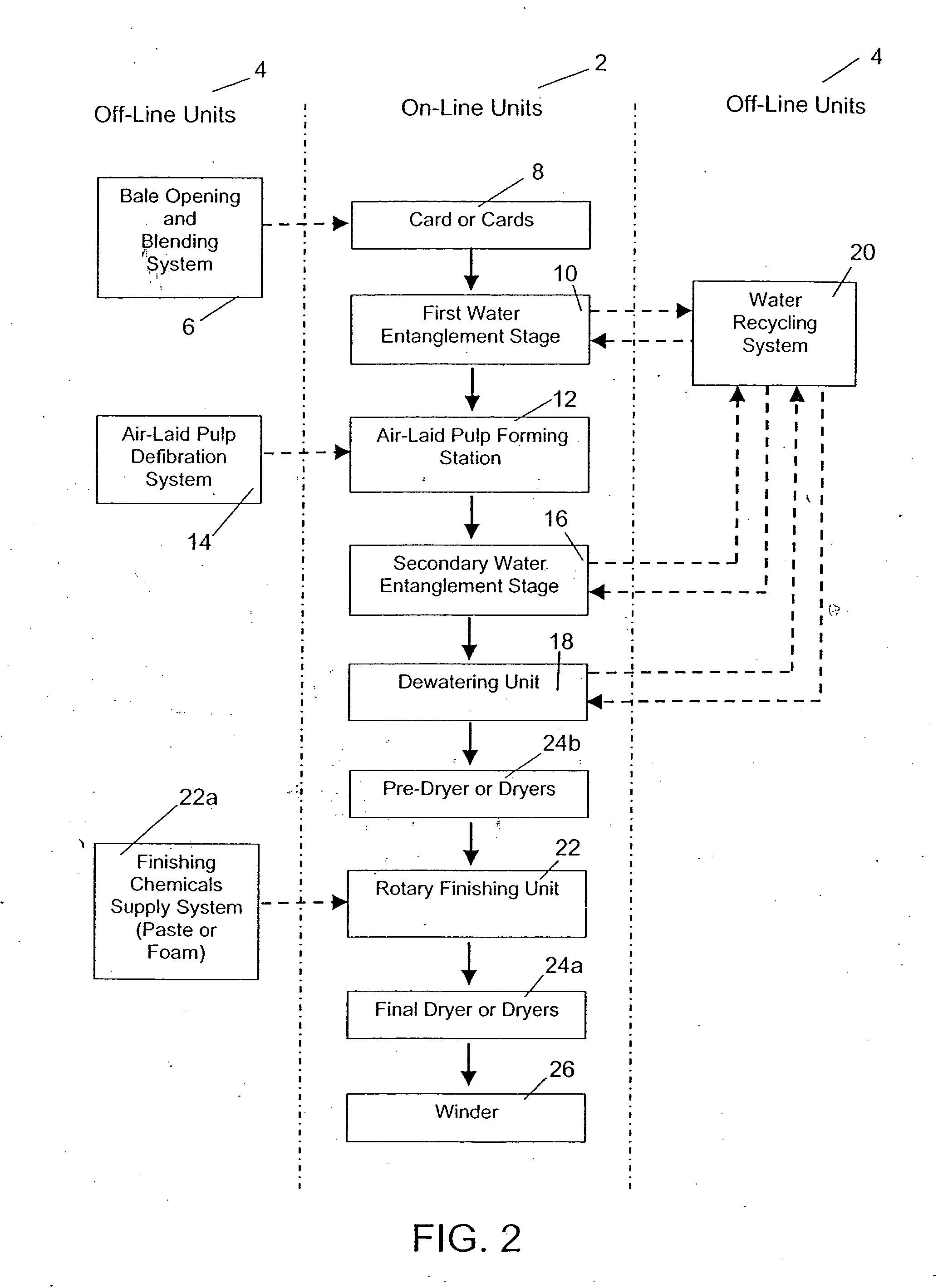

The present invention is method and system for applying a finish to non-woven fabric as part of the production line, during the production process, and provides for the selective application of, for example, colorants so as to produce patterns or graphic designs to the non-woven fabric before completion of the drying process.

Owner:N R SPUNTECH IND

Composition, method and device for digitally coating textile

InactiveUS20110033691A1Good varietyImprove solubilitySucessive textile treatmentsLayered productsFlocculationEmulsion

A finishing composition is described for deposition by dot-on-demand inkjet technique onto a textile substrate. The composition comprises a solution, dispersion or emulsion of a functional finishing agent in a vehicle, wherein the size of particles in the dispersion or emulsion of the finishing composition is less than about 2 microns. By ensuring sufficient fineness of the particles, effective and reliable droplet deposition may proceed without clogging. Of significance, the composition should not be subject to flocculation or sedimentation during use.

Owner:TEN CATE ADVANCED TEXTILES BV

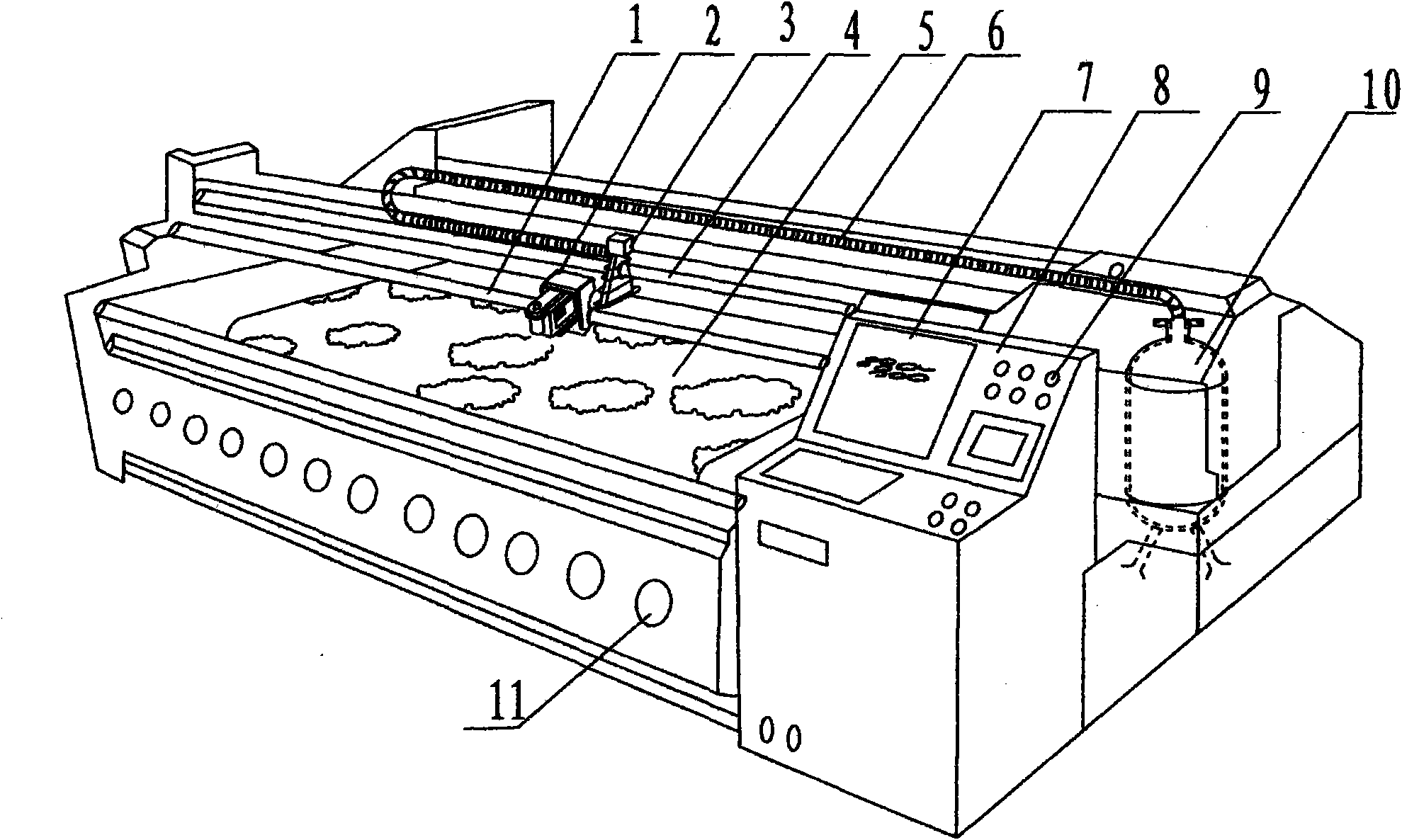

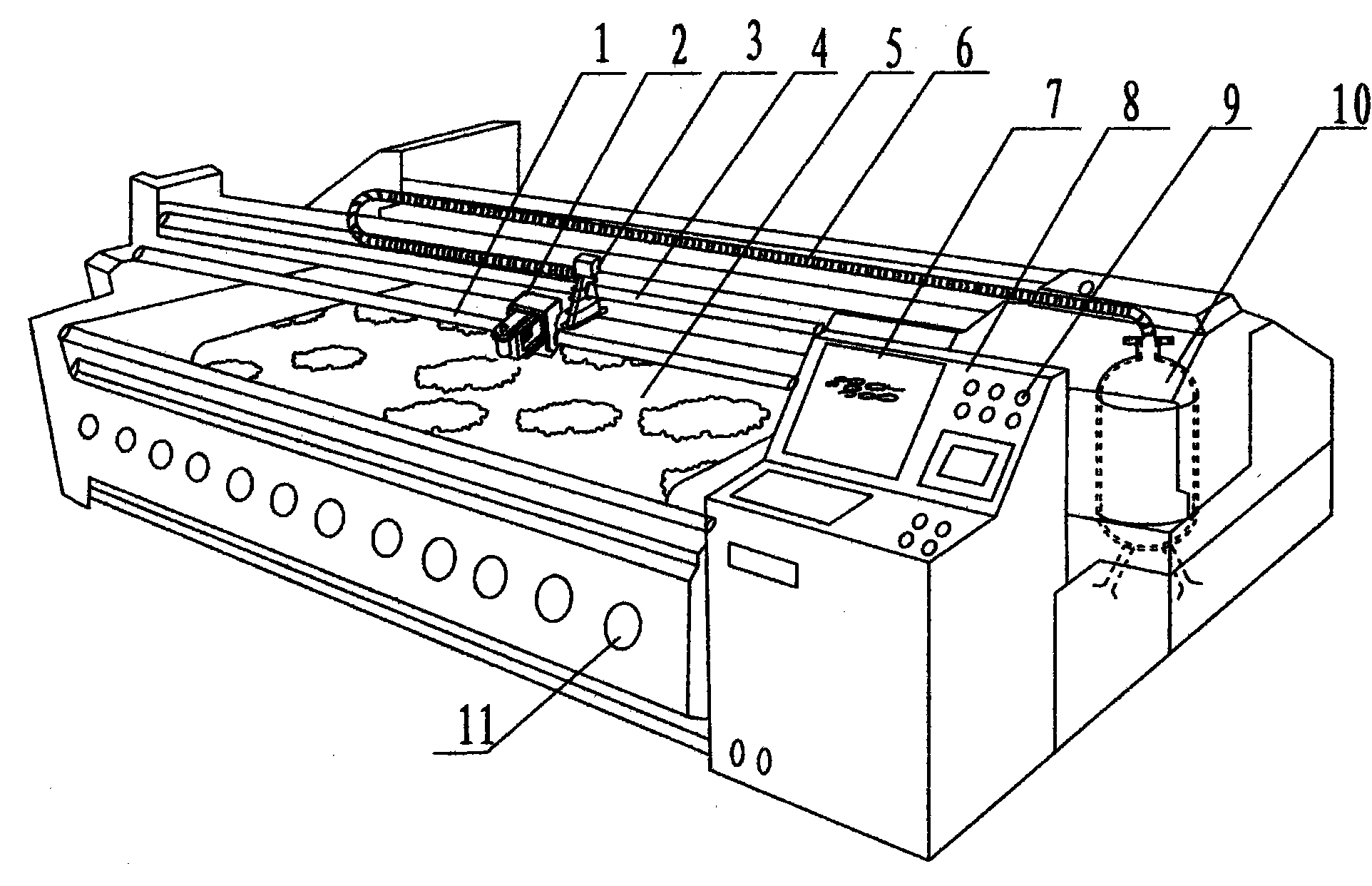

Fabric printing and dyeing device with electron accelerator mechanism

InactiveCN102009534AImprove dyeing effectIncrease apparent depthTypewritersOther printing apparatusElectron radiationColor printing

The invention provides a fabric printing and dyeing device, comprising a printing head guide rail, an ink jet type color printing head, a control cabinet display screen, a control cabinet, an exhaust fan and an electronic accelerator mechanism, wherein the electronic accelerator mechanism comprises an electronic accelerator launching gun, a launching gun guide rail, a radial transmission channel and an electronic accelerator; the printing head guide rail is arranged to be vertical to an advancing direction of a fabric during printing and dyeing, and the launching gun guide rail is arranged in parallel to the printing head guide rail. When the fabric is longitudinally wound forwards, the fabric is firstly modified through high-velocity electron radiation below the launching gun of the electronic accelerator, and then printed and dyed by the ink jet type color printing. The fabric printing and dyeing device can improve the dyeing property of the fabric and obviously improve the dyeing color fastness, and can be used for only dyeing the parts of the fabric, to be cut, therefore dyes are saved and waste water treatment is reduced.

Owner:LANYAN GROUP

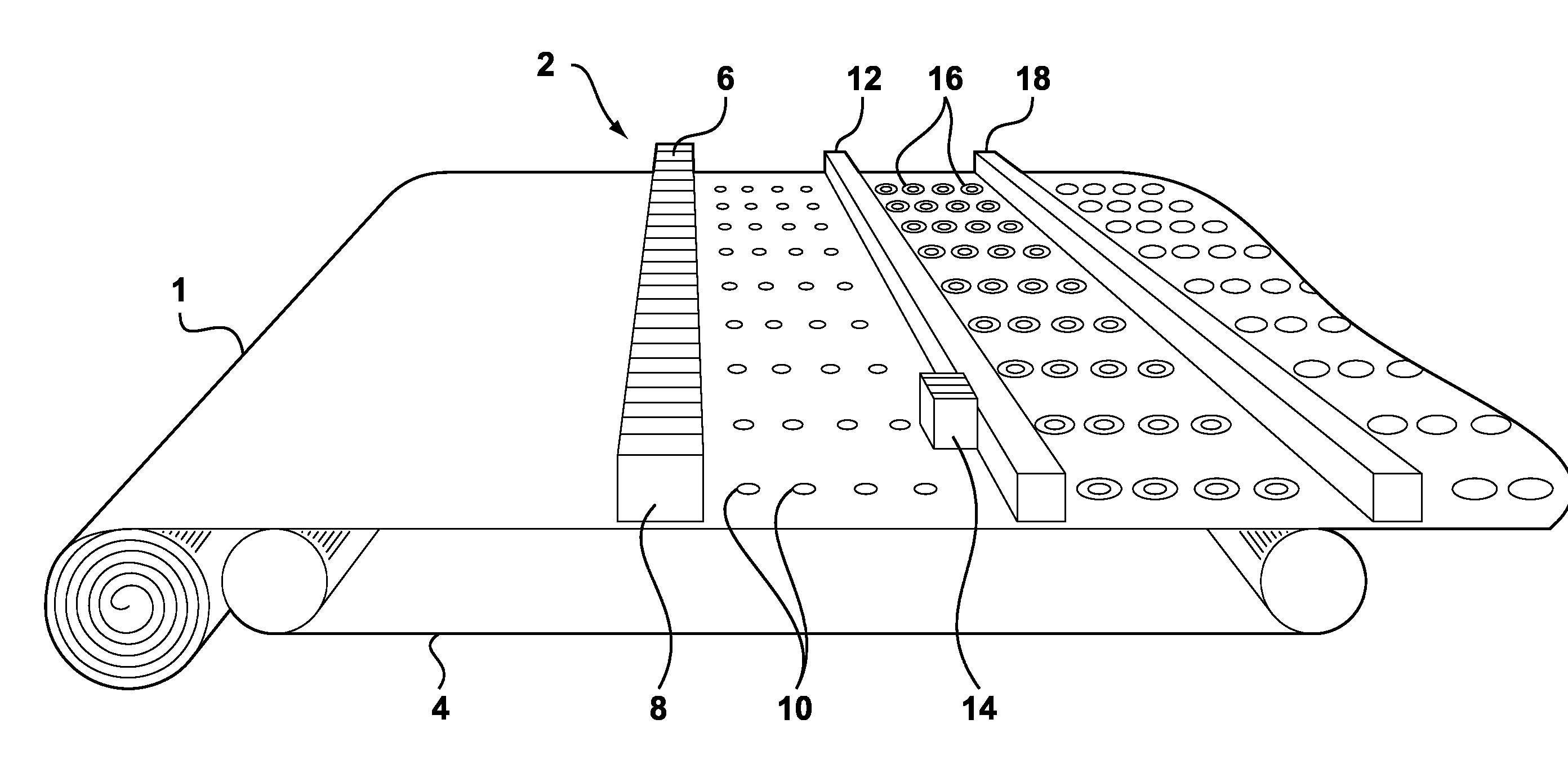

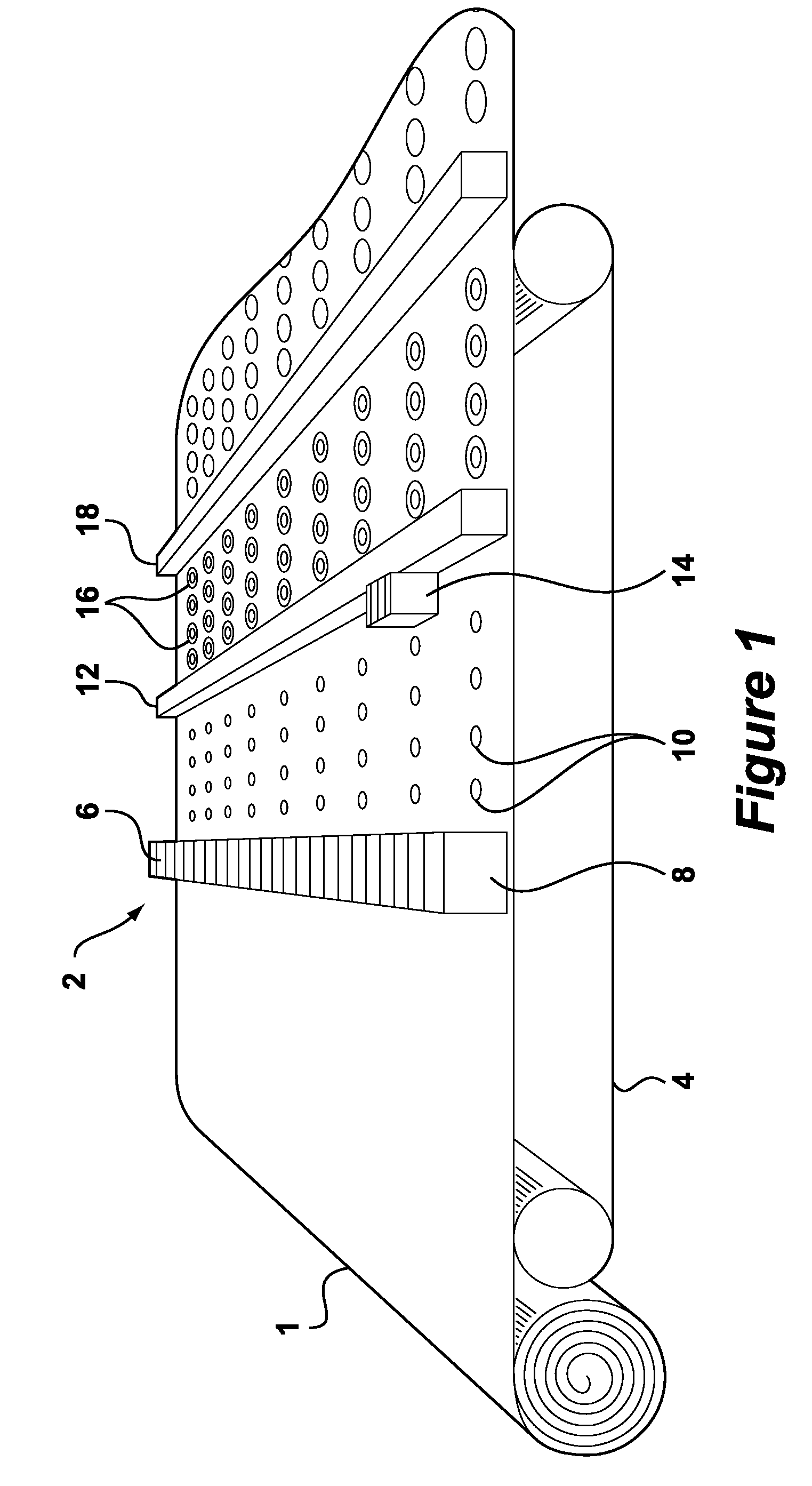

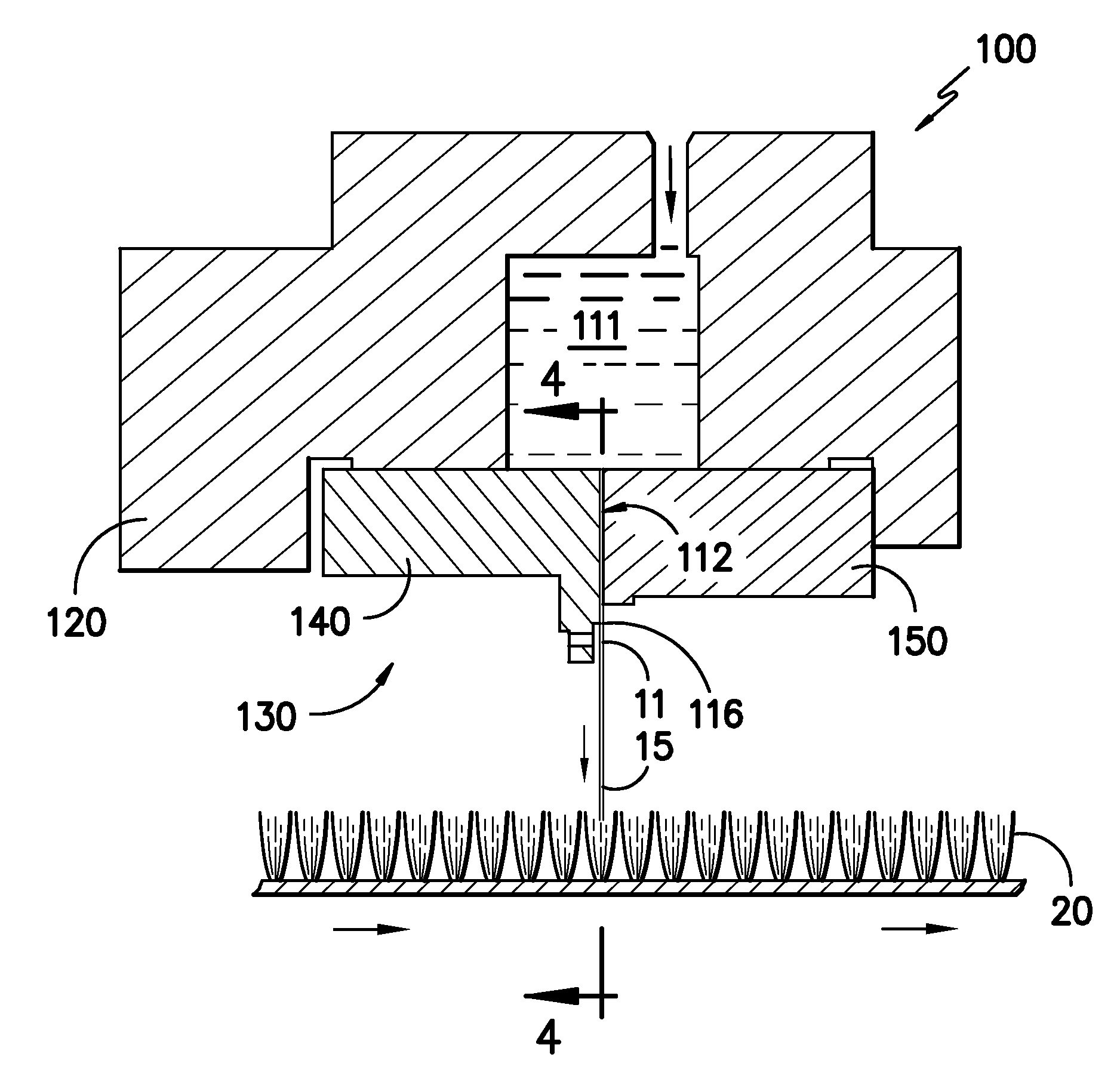

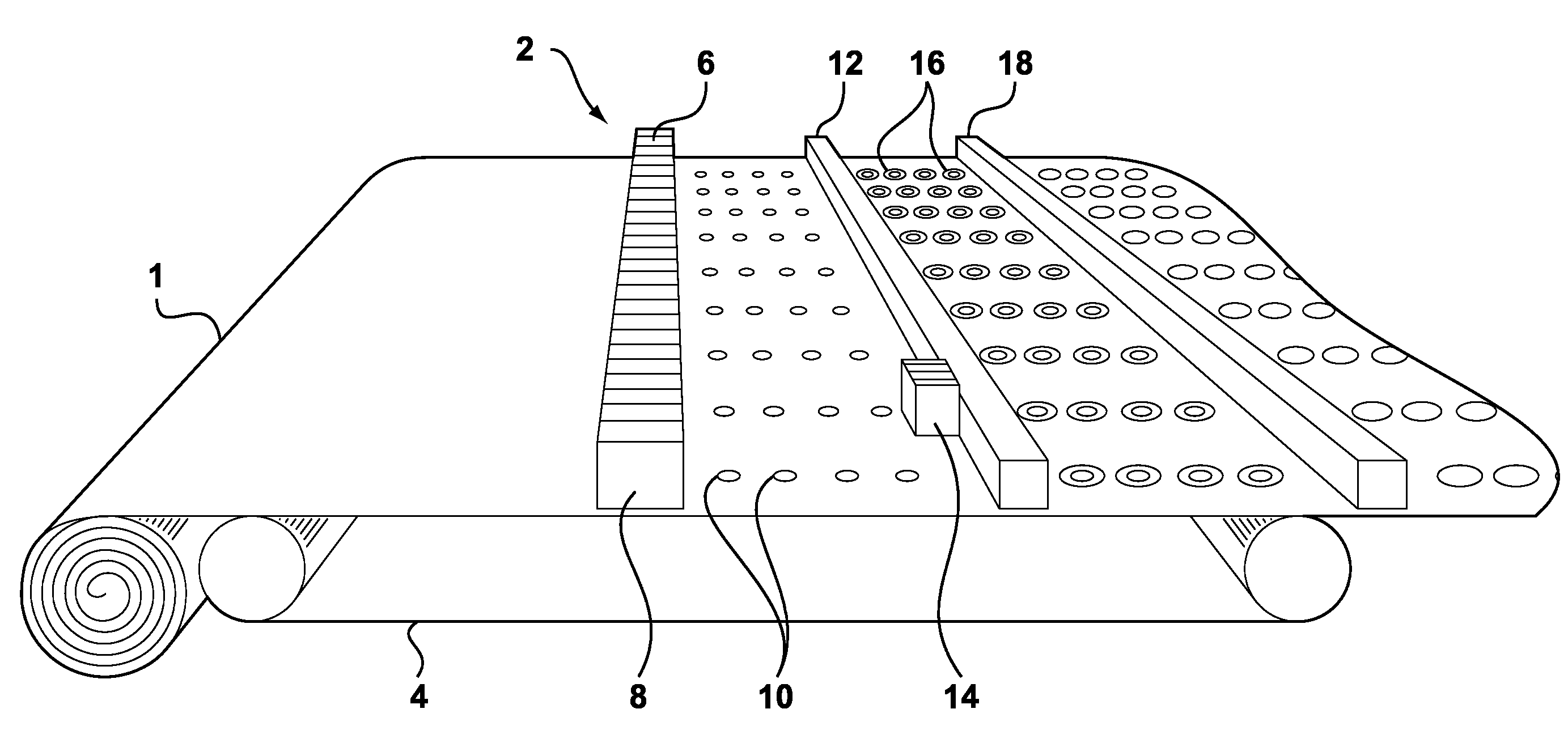

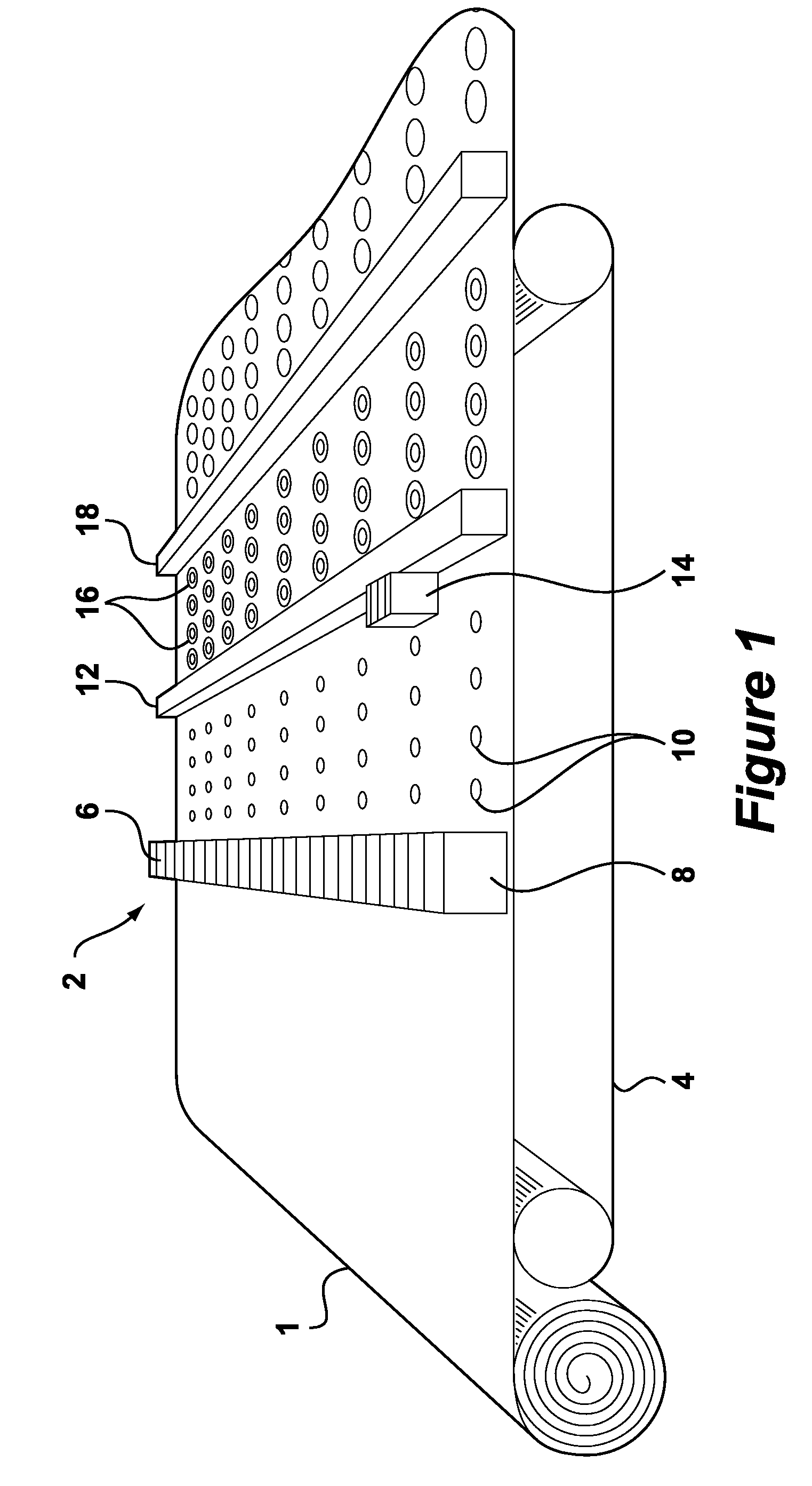

Method of Depositing Materials on a Textile Substrate

InactiveUS20090142552A1Accurate packagingGood varietyLayered productsDecorative surface effectsEngineeringNozzle

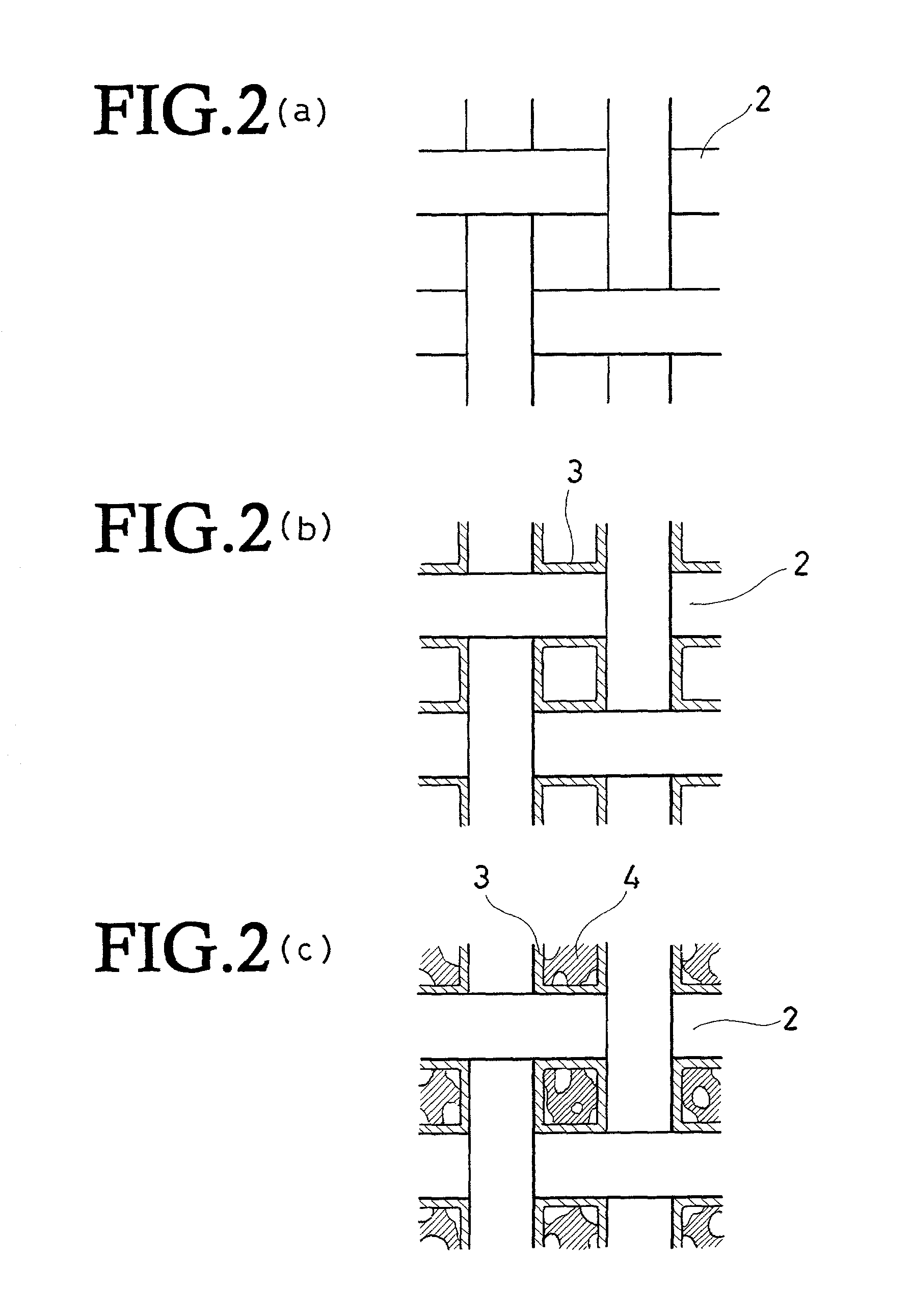

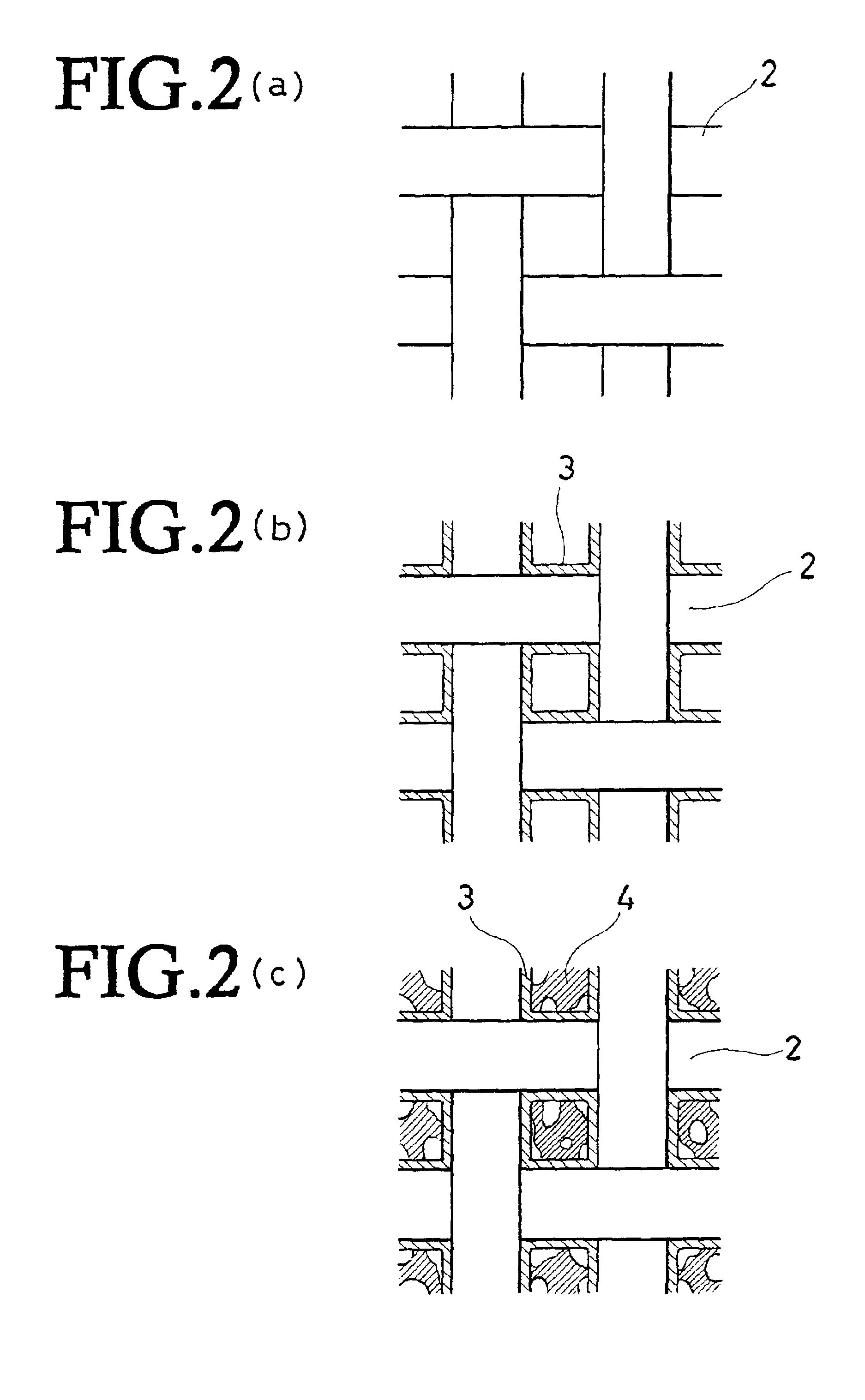

A method of providing deposits of a functional composition on a textile substrate (1) is described. The method comprises providing a supply of the textile substrate (1); providing a first digital nozzle; supplying a functional composition to the first nozzle; providing a second digital nozzle; supplying an encapsulating composition to the second nozzle; selectively depositing the functional composition from the first nozzle to form a series of functional droplets (10) on the substrate (1); and selectively depositing the encapsulation composition from the second nozzle to form a series of encapsulation droplets (16) to at least partially cover the functional droplets (10). In this way, quantities of highly specific functional compositions or “agents” may be precisely deposited at those locations where they are required and may subsequently be covered by an encapsulation composition.

Owner:TEN CATE ADVANCED TEXTILES BV

Fabric for use in ink-jet printing, a method for preparing such fabric and printed goods made by ink-jet printing of the fabric

It is an object of the present invention is to provide fabric for use in ink-jet printing that can prevent not only “ink bleeding”, but also “white exposure”, “nonuniform coloration” and “back staining”. A further object of the present invention is the provision of fabric for use in ink-jet printing, consisting of two textures—napped and ground, which can be evenly ink-jet printed with no variation in color between both, while preventing the occurrence of “white exposure”, “nonuniform coloration” and “back staining”. Fabric for use in ink-jet printing composed of synthetic fiber or fiber containing synthetic fiber, consisting of two textures—napped and ground, the preparation of which comprises penetration of the ground texture with at least two types of solutions—one containing an ink holding agent of high wettability to synthetic fiber and the other containing an ink holding agent of low wettability to synthetic fiber, and penetration of the napped texture with a solution containing an ink holding agent of high wettability to synthetic fiber (represented as A in the same figure).

Owner:SEIREN CO LTD

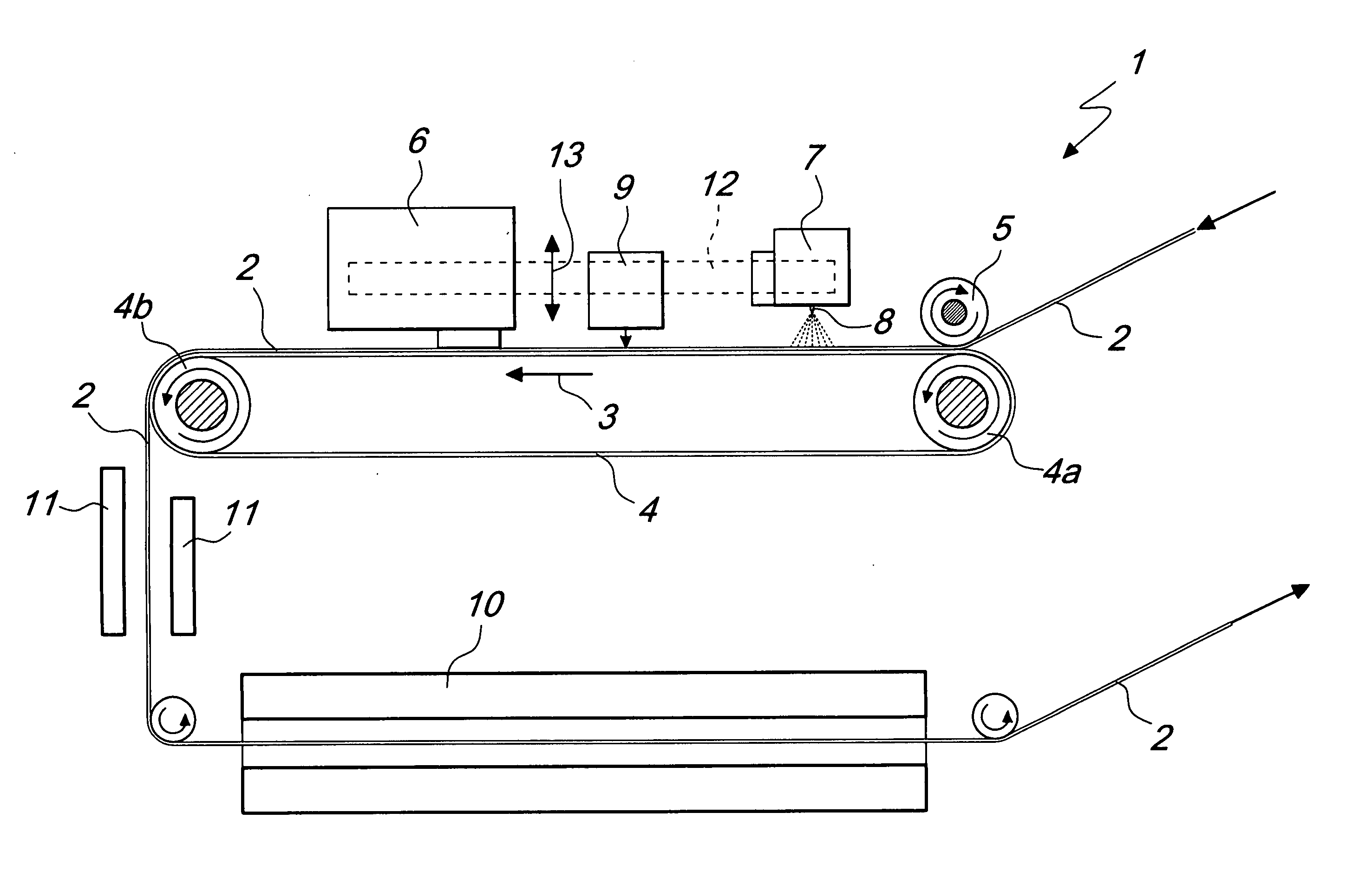

Treating a fibrous material for printing

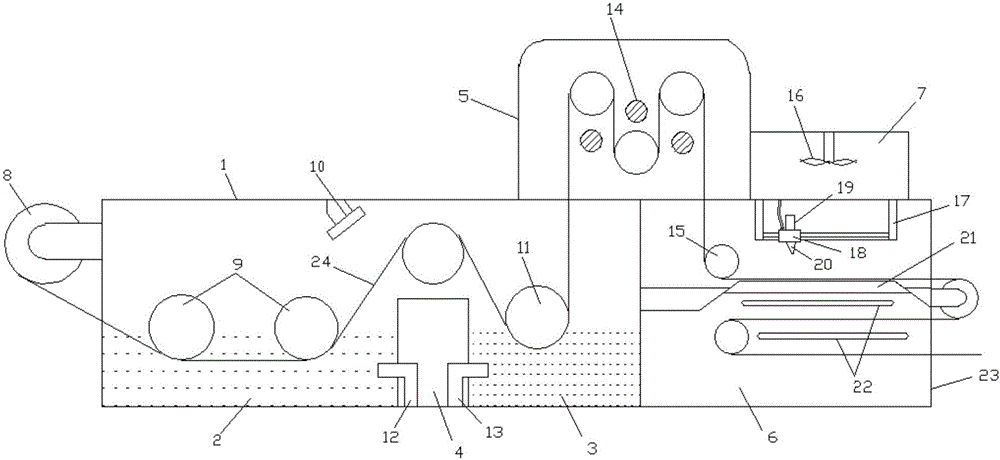

An apparatus and method for treating a sheet fibrous material to be printed with ink. The apparatus includes a conveyor belt movable along a closed path including an operative section defining a plurality of bends, an inlet station that receives the sheet fibrous material and adheres a first side of the material to an exposed surface of the conveyor belt, a drying station placed at the operative section and configured to at least partially dry the sheet fibrous material, and an applicator for applying a wet treatment agent to the material prior to drying.

Owner:MS PRINTING SOLUTIONS SRL

Printing and quilting method and apparatus

InactiveUS7063028B2Efficiently and economicallyHighly efficient and economical and high and mannerOrnamental textile articlesSewing-machine elementsProduction lineData file

A quilting machine (10, 100, 200, 300, 400, 500, 600) is provided with a printing station (20, 125, 225, 325, 425, 525, 611, 626, 631) and a quilting station (44, 127, 227, 327, 427, 527, 627, 632), either on the same or a different production line. Ticking is preprinted with a plurality of different patterns, organized and coordinated by the computer so that a print head can scan the material and print different patterns of different panels (32). Identifying data (40) for matching the panels of a mattress product can be provided in data files and codes can be printed on the fabric. Panels can be matched and assembled into products based on the codes, and quilting, cutting, slitting and other operations can be controlled by printed codes and other data. The quilting and combining of the panels for assembly of a mattress product can be carried out manually or automatically using the data.

Owner:L & P PROPERTY MANAGEMENT CO

Wax printing process of pattern shell fabric and equipment for wax printing process

ActiveCN106049114AImprove early work efficiencyEasy to recycleSucessive textile treatmentsTextile treatment machine arrangementsWaxEngineering

The invention discloses a wax printing process of a pattern shell fabric and equipment for the wax printing process. The wax printing process comprises the following steps: firstly preparing a dye-resistant agent, and simultaneously carrying out preprocessing on a shell fabric, wherein the preprocessing comprises the steps of bleaching the shell fabric by virtue of plant ash, cleaning, drying, coating one surface of the shell fabric with paste, drawing stripes or patterns on the surface which is not coated with the paste, and coating the drawn stripes or patterns with the dye-resistant agent, then dyeing the shell fabric, and dewaxing the shell fabric; and finally carrying out ironing on the dewaxed shell fabric. The wax printing process of the pattern shell fabric has the beneficial effects that the shell fabric produced by virtue of the wax printing process is divided into a front surface and a back surface, the quality of printed patterns can be improved by virtue of the dye-resistant agent, wax stripes are fine, and the dye-resistant agent is easy to recover.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

Apparatus and method for pretreating and printing textile surfaces

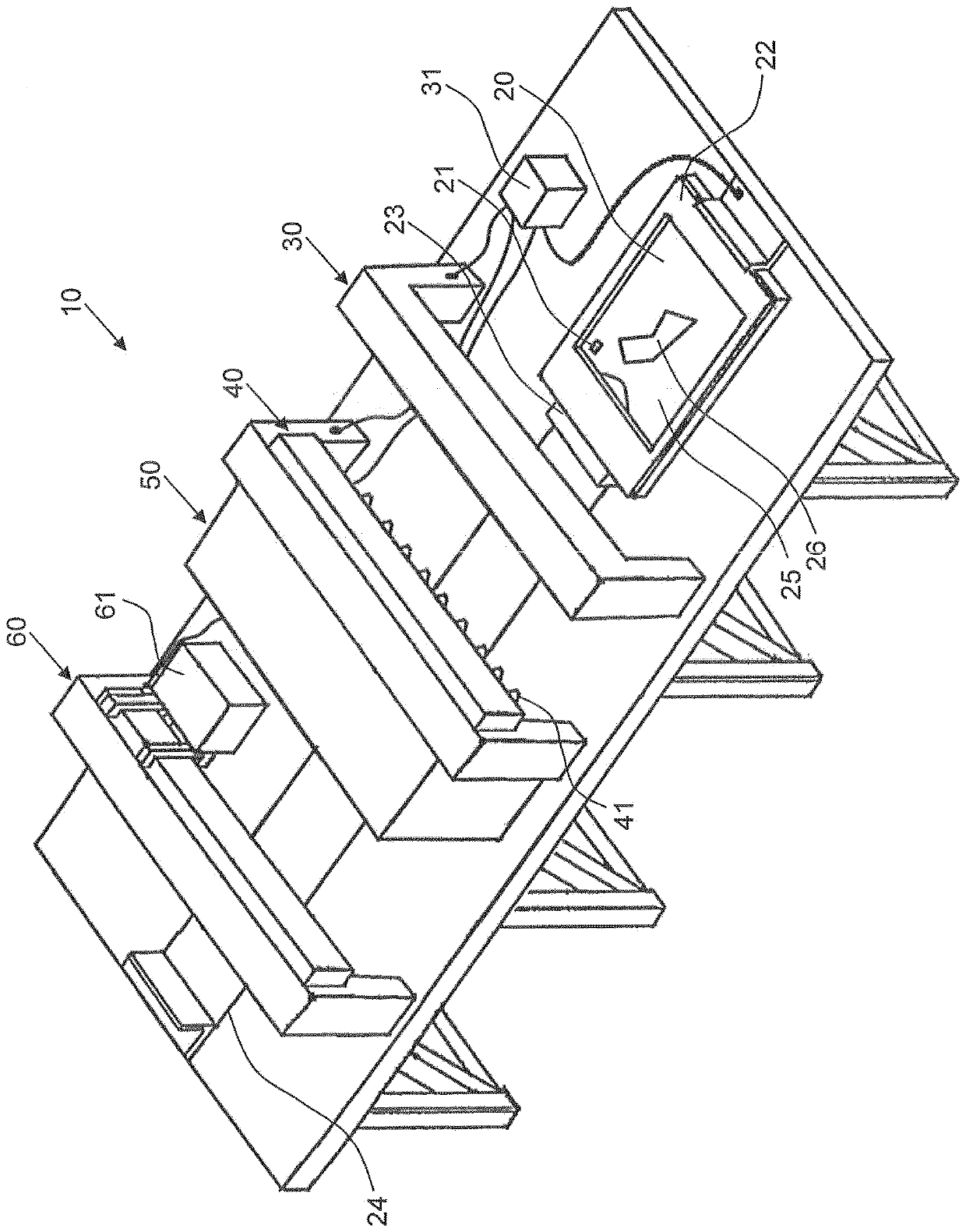

ActiveCN108025563AReduce wearFast and even movementDuplicating/marking methodsTypewritersPolymer scienceIdentification device

The invention relates to an apparatus and a method for pretreating and printing textile surfaces. For this purpose, at least one pallet (22) for accommodating and retaining a textile article (20) to be printed on a printing face, a pretreatment device (40) which allows the textile article to be pretreated, prior to it being printed, by applying a pretreatment fluid to the textile article in a pretreatment area, a printing device (60) comprising at least one printhead (61) that allows a printed image to be printed onto the textile article in the pretreatment area, a moving device (23) which allows the at least one pallet to be displaced relative to the pretreatment device and the printing device, and a programmable control device (31) which allows the printing device, the pretreatment device and / or the moving device to be controlled, are provided. An identification device (30) which can identify the textile article and is connected to the programmable control device is provided in frontof the pretreatment device, and depending on the identified textile article, the pretreatment area can be applied individually to a subarea of the printing face of the textile article.

Owner:易安技术有限责任公司

Method for Providing a Flame Retardant Finish of a Textile Article

InactiveUS20090280706A1Precise positioningUniform layersFireproof paintsLiquid surface applicatorsEngineeringFire retardant

A method of producing a textile article having a flame retardant finish comprising: providing a continuous supply of a textile substrate having a width; providing an array of digital nozzles over the width of the textile article; supplying a flame retardant formulation to the nozzles; and selectively dispensing the flame retardant formulation from the nozzles in a series of droplets to deposit a predetermined pattern of droplets on the substrate.

Owner:TEN CATE ADVANCED TEXTILES BV

Apparatus and method for controlled application of liquid streams to a substrate

InactiveUS20120034388A1Simple systemConvenient ArrangementSpray nozzlesLiquid/solution decomposition chemical coatingEngineering

An improved system for application of liquid streams to a substrate. The system incorporates open face flow channels for carrying the liquid away from fully enclosed flow segments prior to discharge along an unconstrained flow path. The present invention further provides an improved, self-aligning modular assembly for delivery of impingement jet to the liquid streams for diverting the direction of the liquid streams. The present invention further provides an improved arrangement for collection of the deflected liquid in response to application of the impingement jet without excess residue build-up.

Owner:LOVE III FRLIN S +4

Method of depositing materials on a textile substrate

A method of providing deposits of a functional composition on a textile substrate (1) is described. The method comprises providing a supply of the textile substrate (1); providing a first digital nozzle; supplying a functional composition to the first nozzle; providing a second digital nozzle; supplying an encapsulating composition to the second nozzle; selectively depositing the functional composition from the first nozzle to form a series of functional droplets (10) on the substrate (1); and selectively depositing the encapsulation composition from the second nozzle to form a series of encapsulation droplets (16) to at least partially cover the functional droplets (10). In this way, quantities of highly specific functional compositions or “agents” may be precisely deposited at those locations where they are required and may subsequently be covered by an encapsulation composition.

Owner:TEN CATE ADVANCED TEXTILES BV

Image forming method and image forming system

An image forming method comprising the steps of: forming an image by jetting an ink comprising a high-boiling point solvent onto a textile; and removing the high-boiling point solvent from the image-formed textile by drying the fabric under depressurized condition.

Owner:KONICA CORP

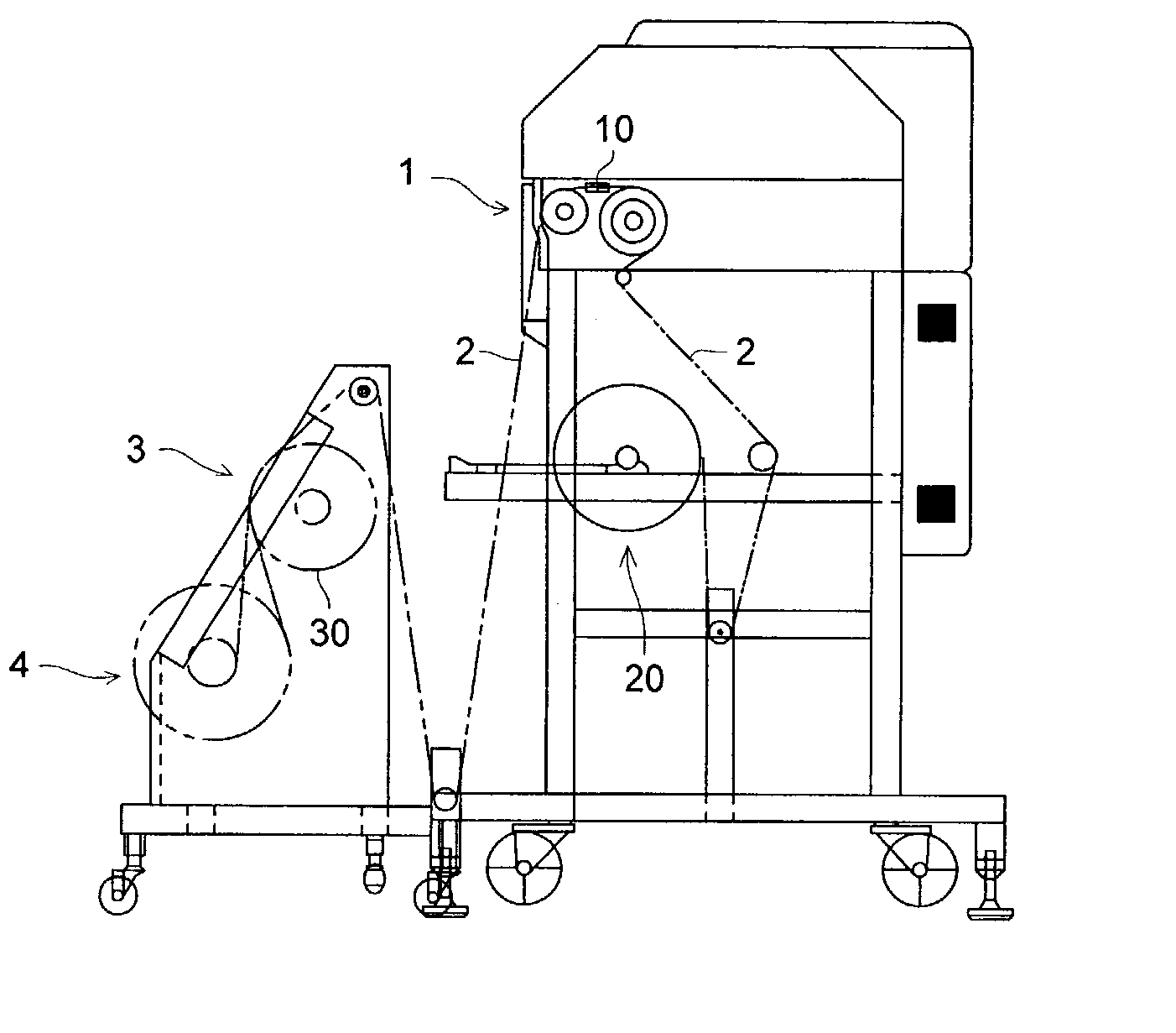

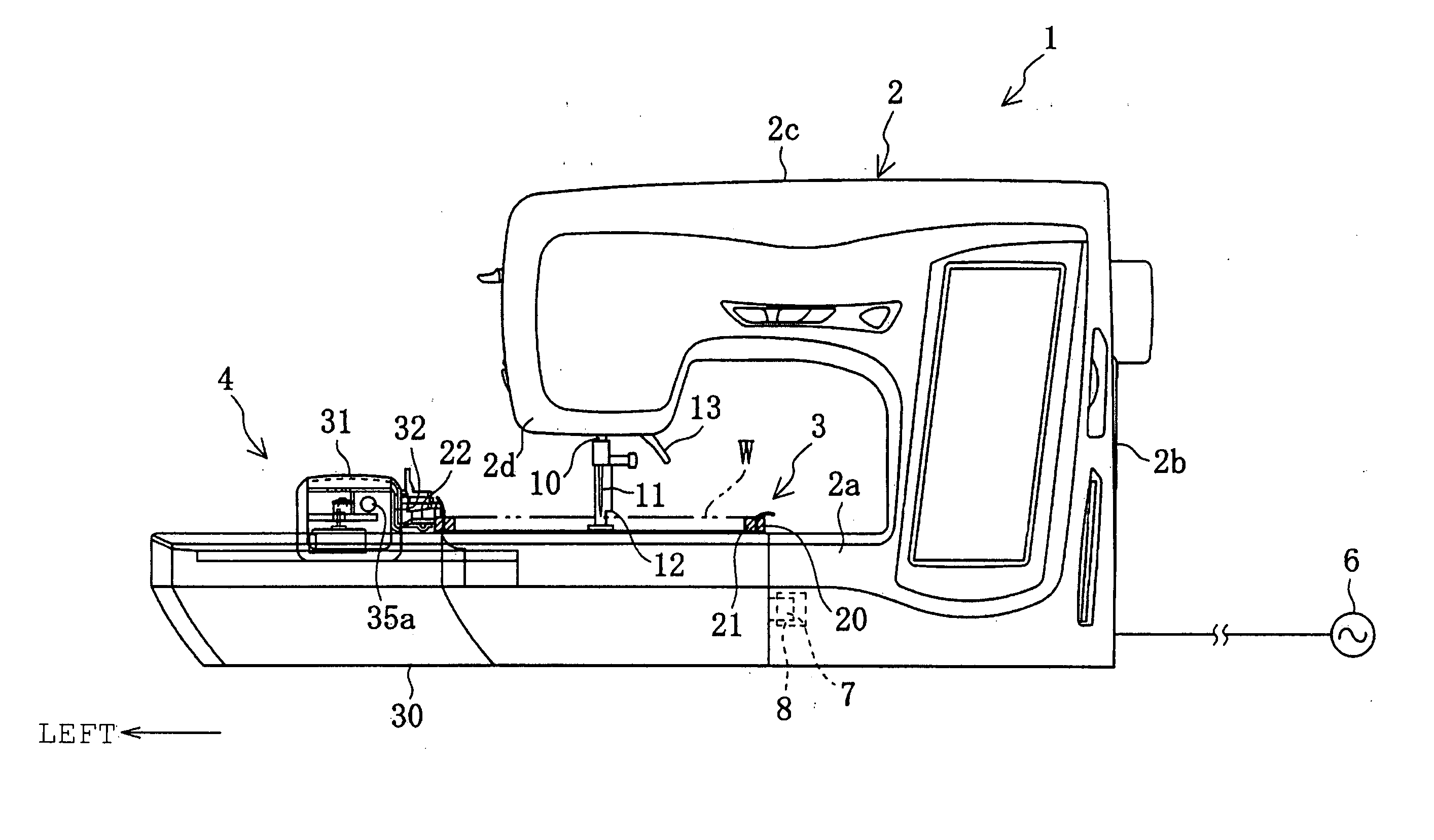

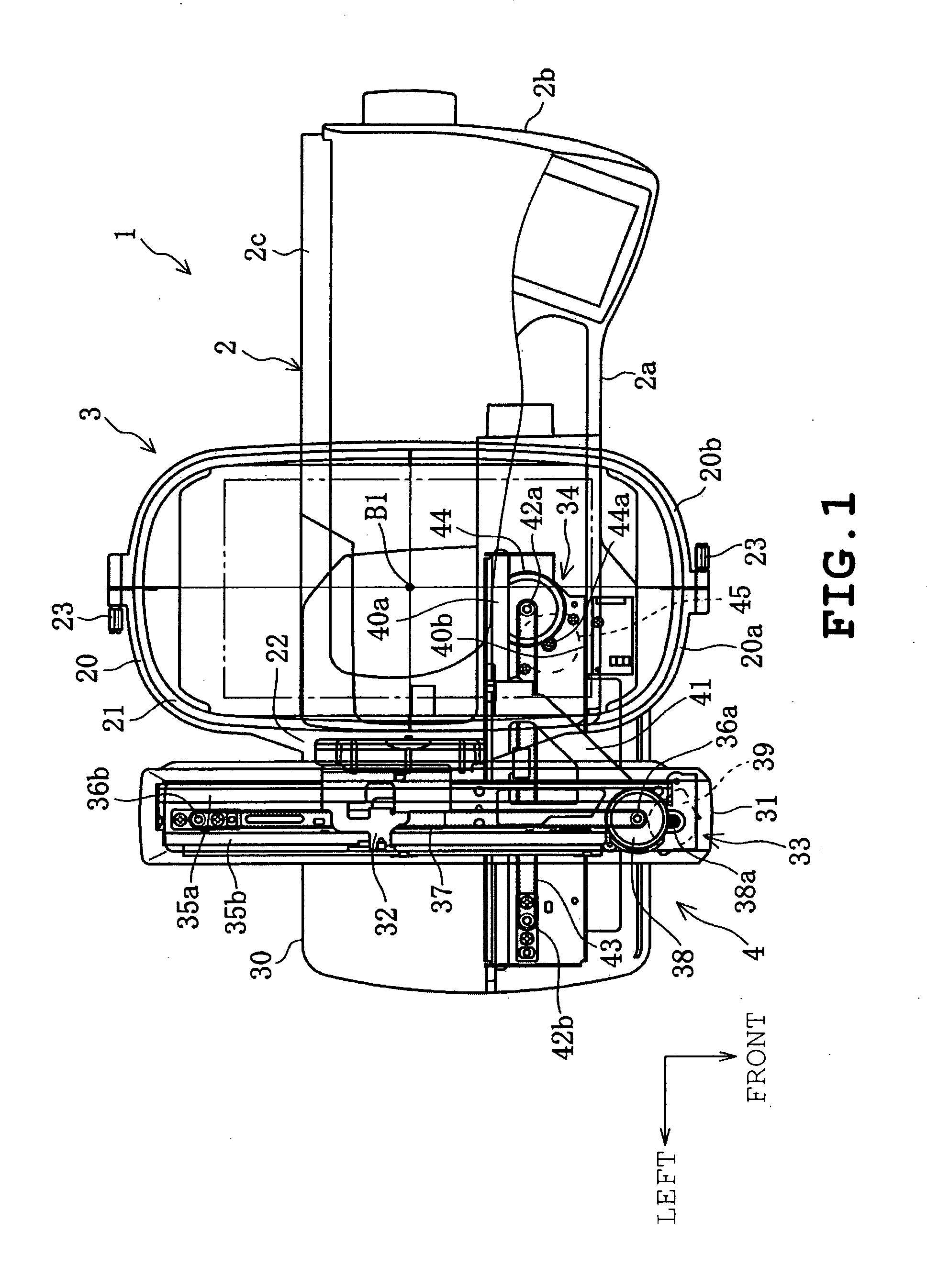

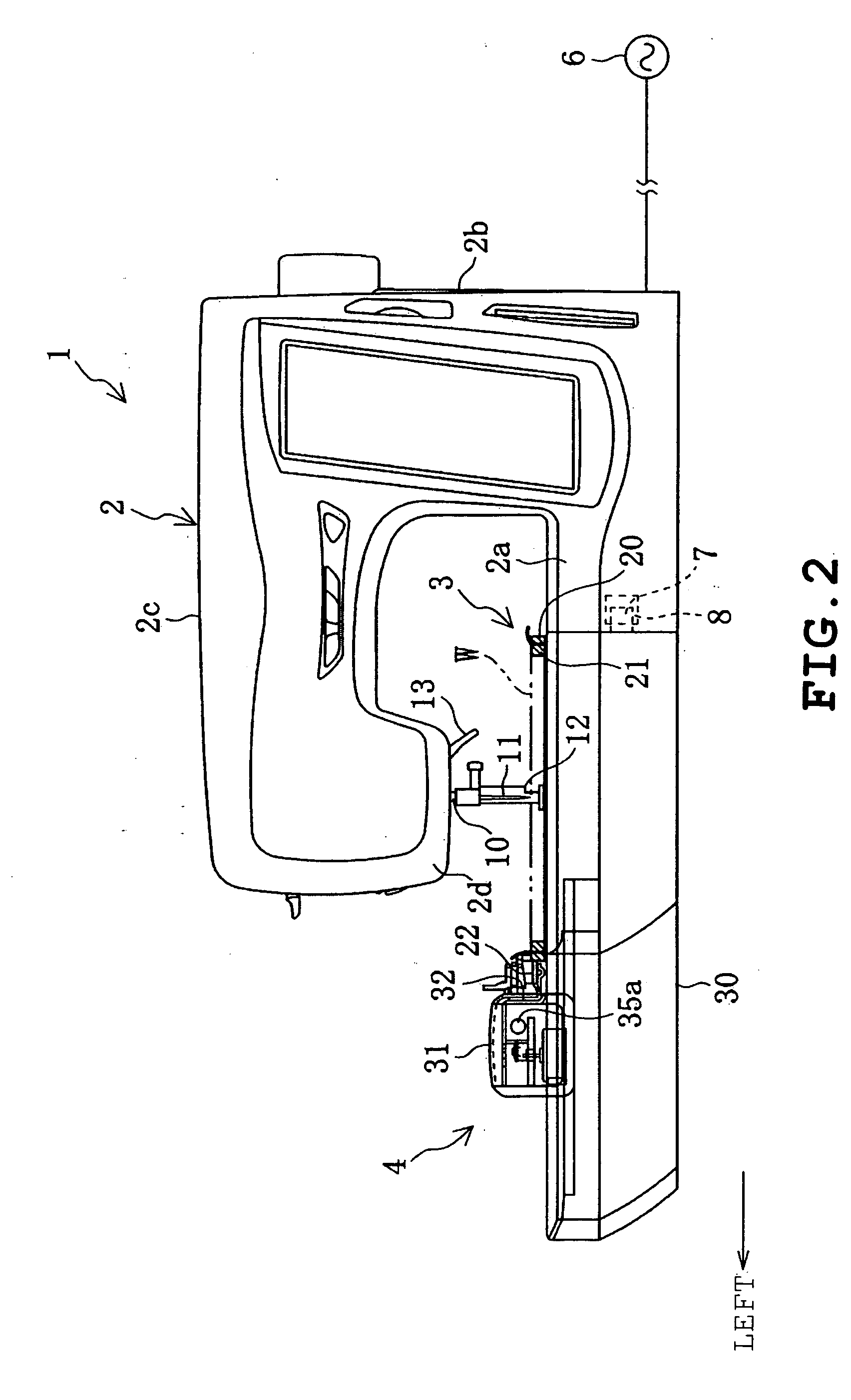

Printable Embroidery Machine

InactiveUS20070204775A1Reduce manufacturing costReduce sizing costsProgramme-controlled sewing machinesTypewritersEngineeringMechanical engineering

A printable embroidery machine (1), including a machine body (2) capable of sewing a workpiece cloth (W), a cloth holding frame (3) holding the workpiece cloth (W) to be sewn, and a frame drive unit (4) having a mounting part (4a) detachably attached to the machine body (2), and coupled to the cloth holding frame (3) to independently move the cloth holding frame in two horizontal directions perpendicular to each other. An ink-jet type printer (5) is detachably attached to the mounting part (4a) of the frame drive unit (4) separated from the machine body (2). The workpiece cloth (W) on the cloth holding frame (3) moved by the frame drive unit (4) can be printed by the printer (5).

Owner:BROTHER KOGYO KK

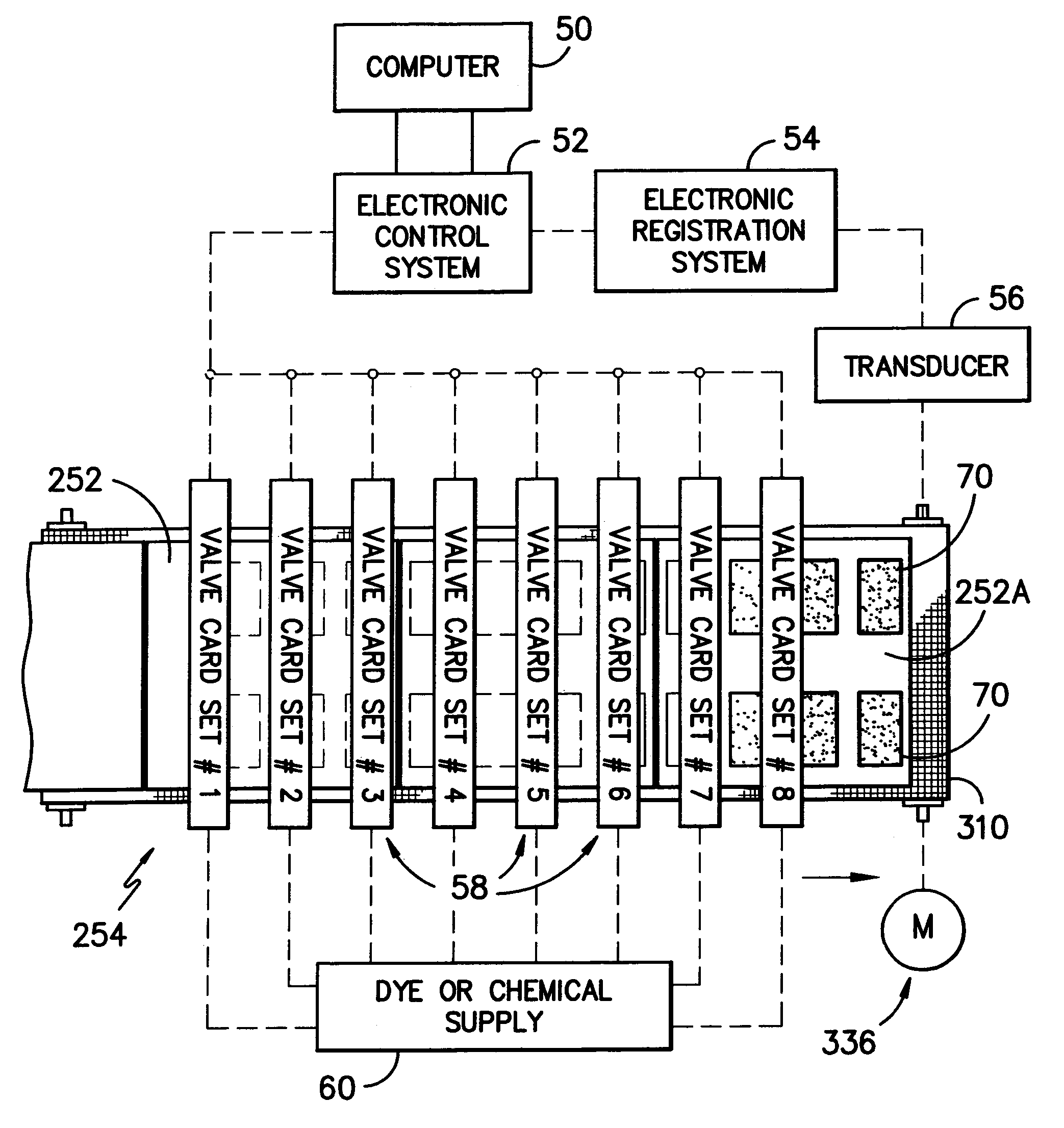

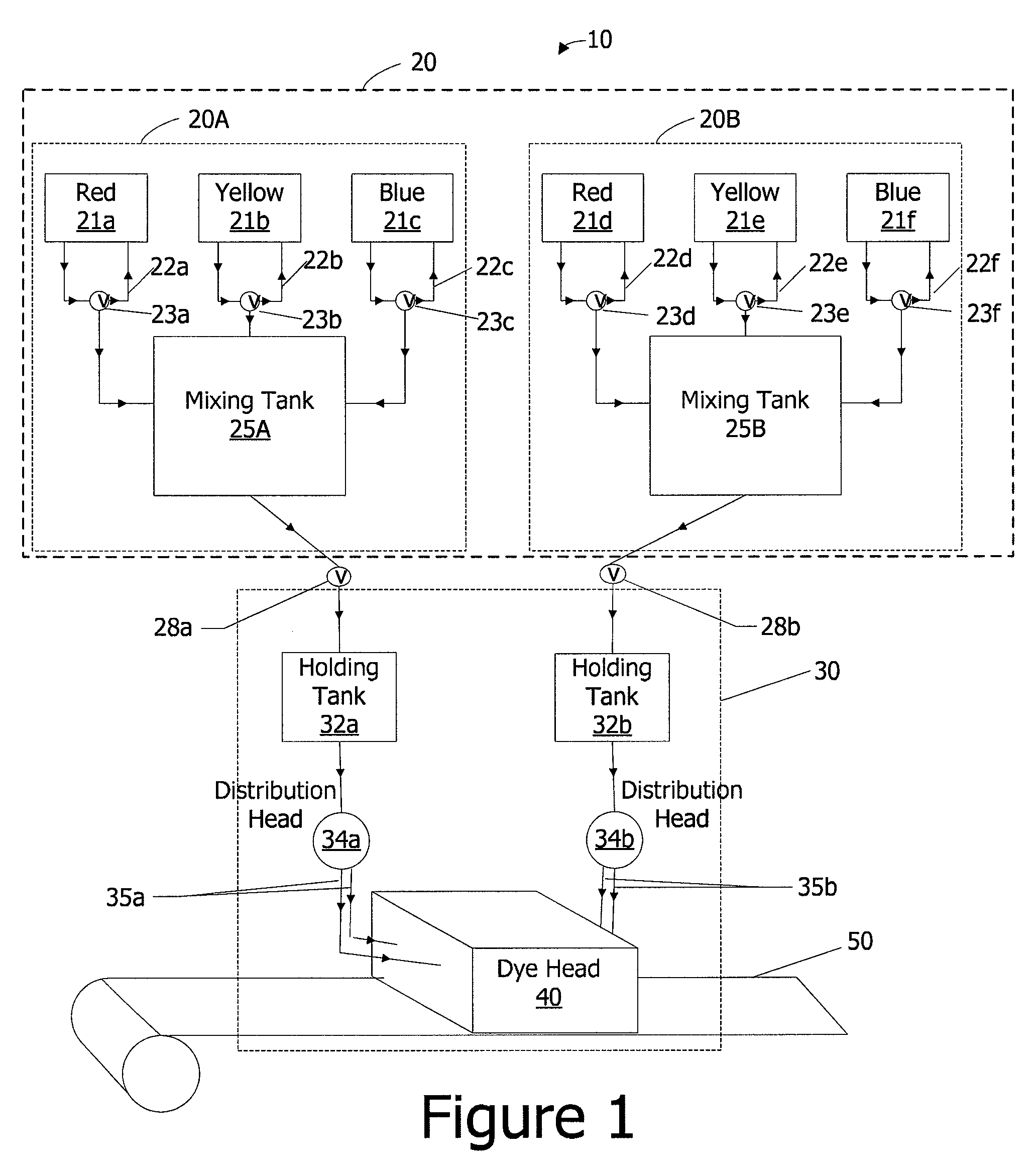

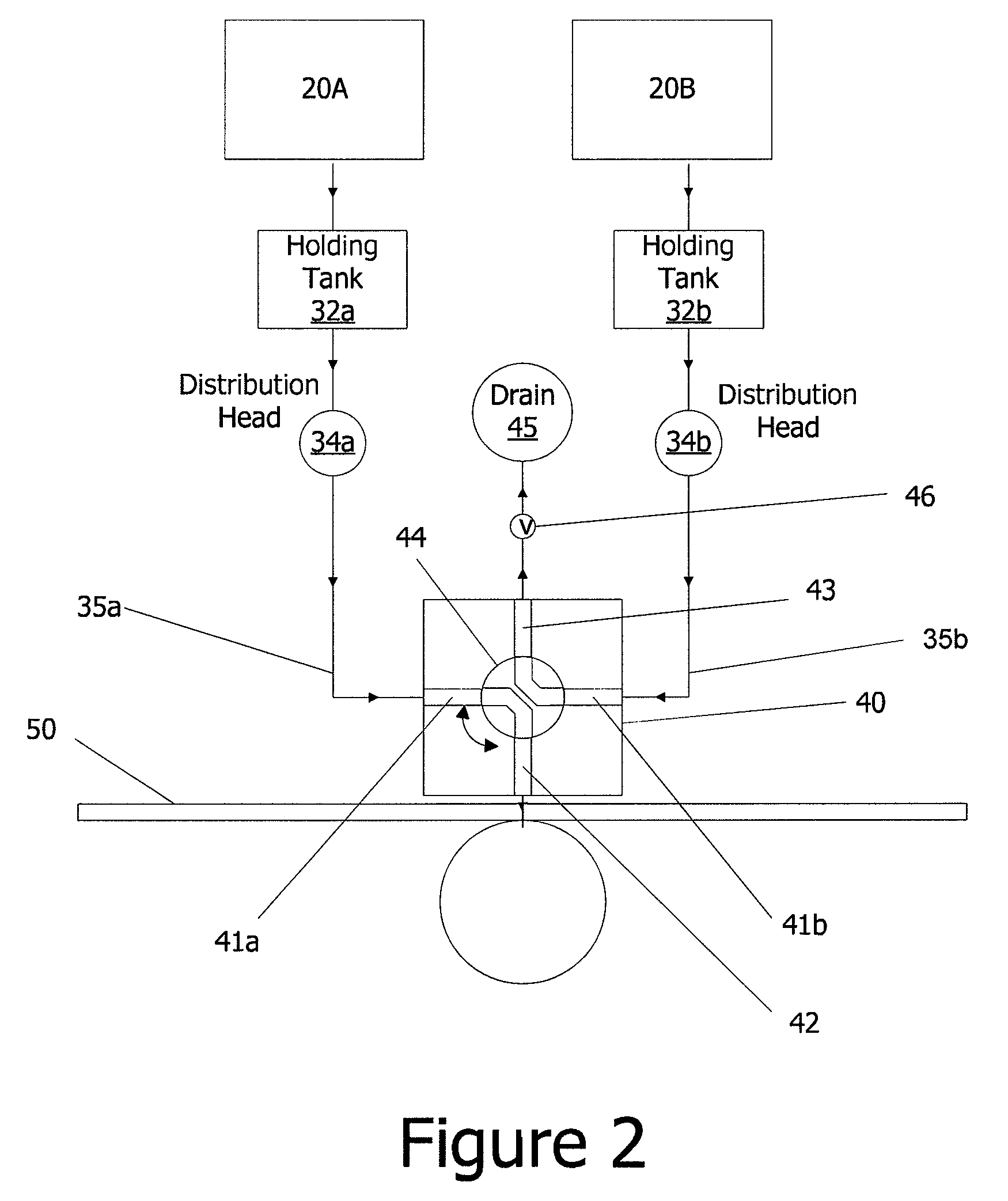

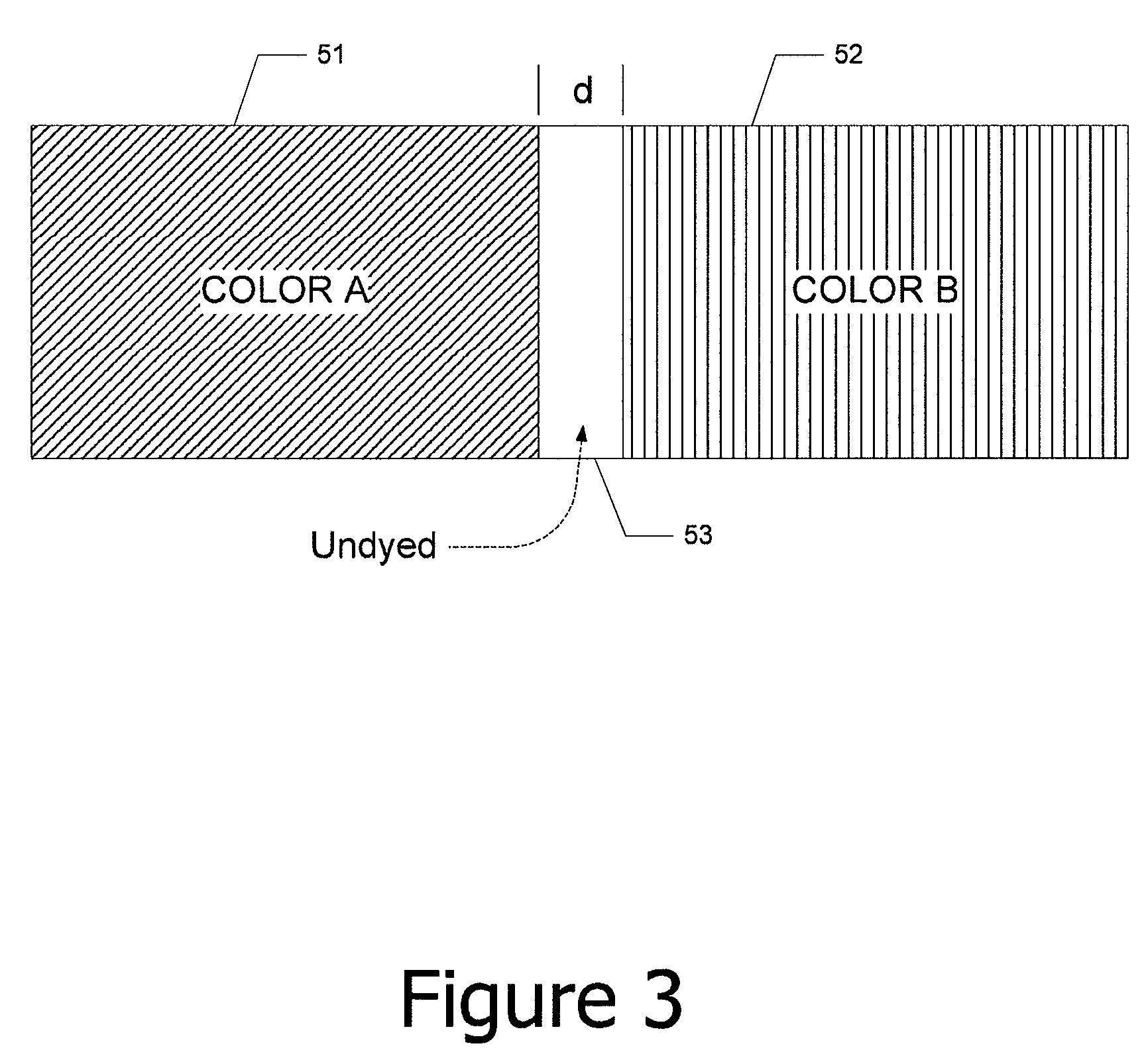

Carpet dyeing systems and methods

ActiveUS8082057B2Reducing unacceptable visual effect of blendingReduce the amount requiredLayered productsFibre treatmentChange colorOrder processing

Embodiments of the present invention provide systems and methods for “dye-to-order” carpet manufacturing that address deficiencies in the carpet manufacturing industry, some of which are discussed above. In one embodiment, an improved manufacturing system is provided that allows manufacturers to change colors “on the fly” (e.g., within a single roll) with minimal waste. In another embodiment, a dye-to-order processing system is provided that maps multiple orders to undyed carpet rolls such that usage of the undyed carpet rolls is optimized.

Owner:ALADDIN MFG CORP

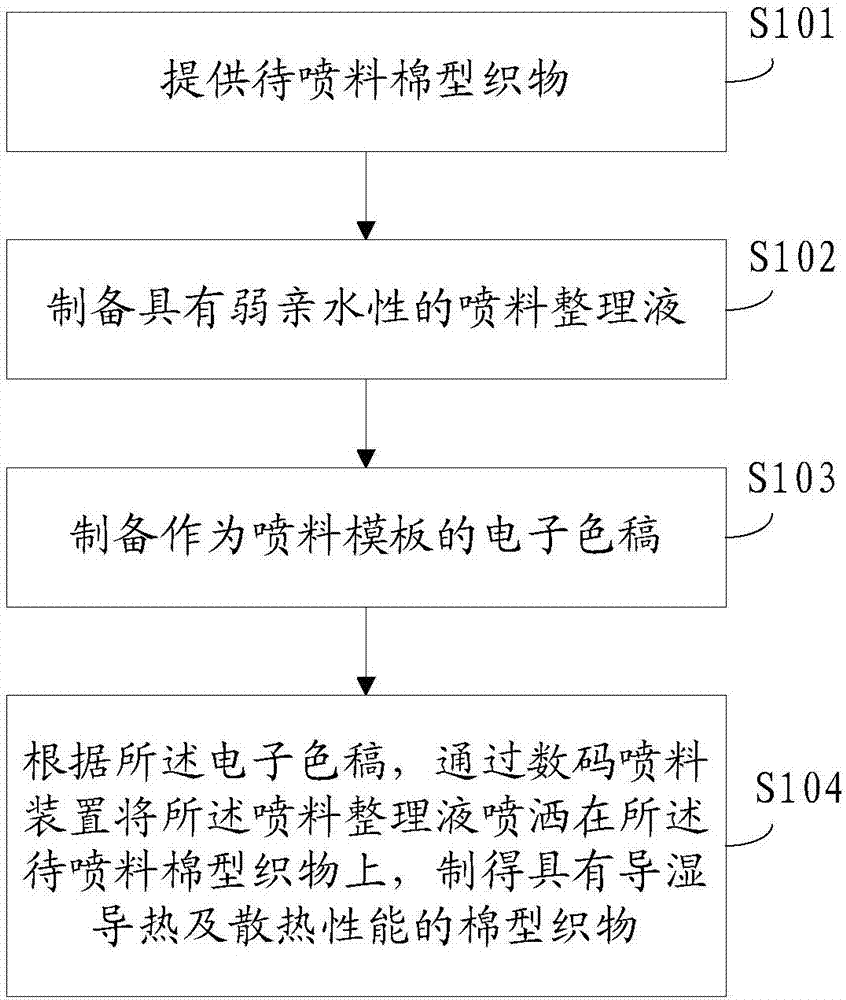

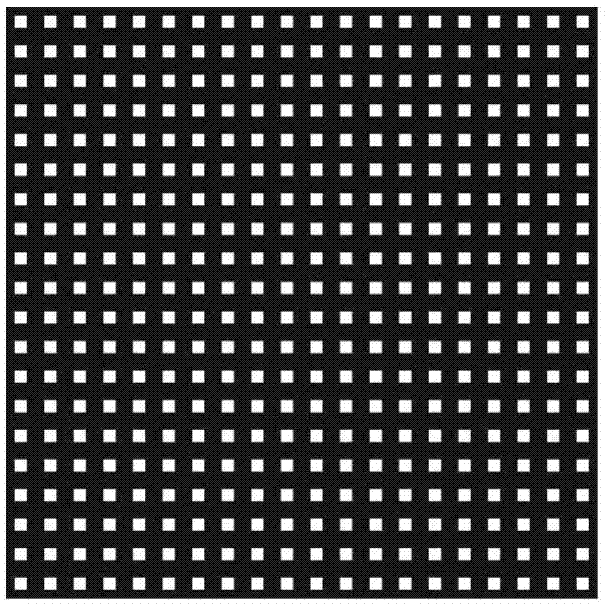

Preparation method of cotton textile, fabric, garment and finishing liquor

InactiveCN107385732AVariable styleEasy to operateBiochemical fibre treatmentLiquid/gas/vapor removalAgricultural engineeringControllability

The invention discloses a preparation method of a cotton textile. The preparation method comprises the steps that a cotton textile to be sprayed with is provided; a spray finishing liquid with weak hydrophilicity is prepared; an electronic color proof serving as a spraying template is prepared; according to the electronic color proof, the spray finishing liquid is sprayed on the cotton textile to be sprayed with through a digital spraying device, and the cotton textile with moisture conduction and heat conduction performance and heat dissipation performance is prepared. According to the preparation method of the cotton textile, the electronic color proof and the spray finishing liquid are prepared in advance, and the spray finishing liquid is sprayed on the surface of the cotton textile according to the electronic color proof, so that the prepared cotton textile has good moisture conduction and heat conduction performance and heat dissipation performance, the whole process is easy to operate, the area sprayed with the spray finishing liquid can be changed along with change of the electronic color proof, and the controllability is high.

Owner:ANTA CHINA

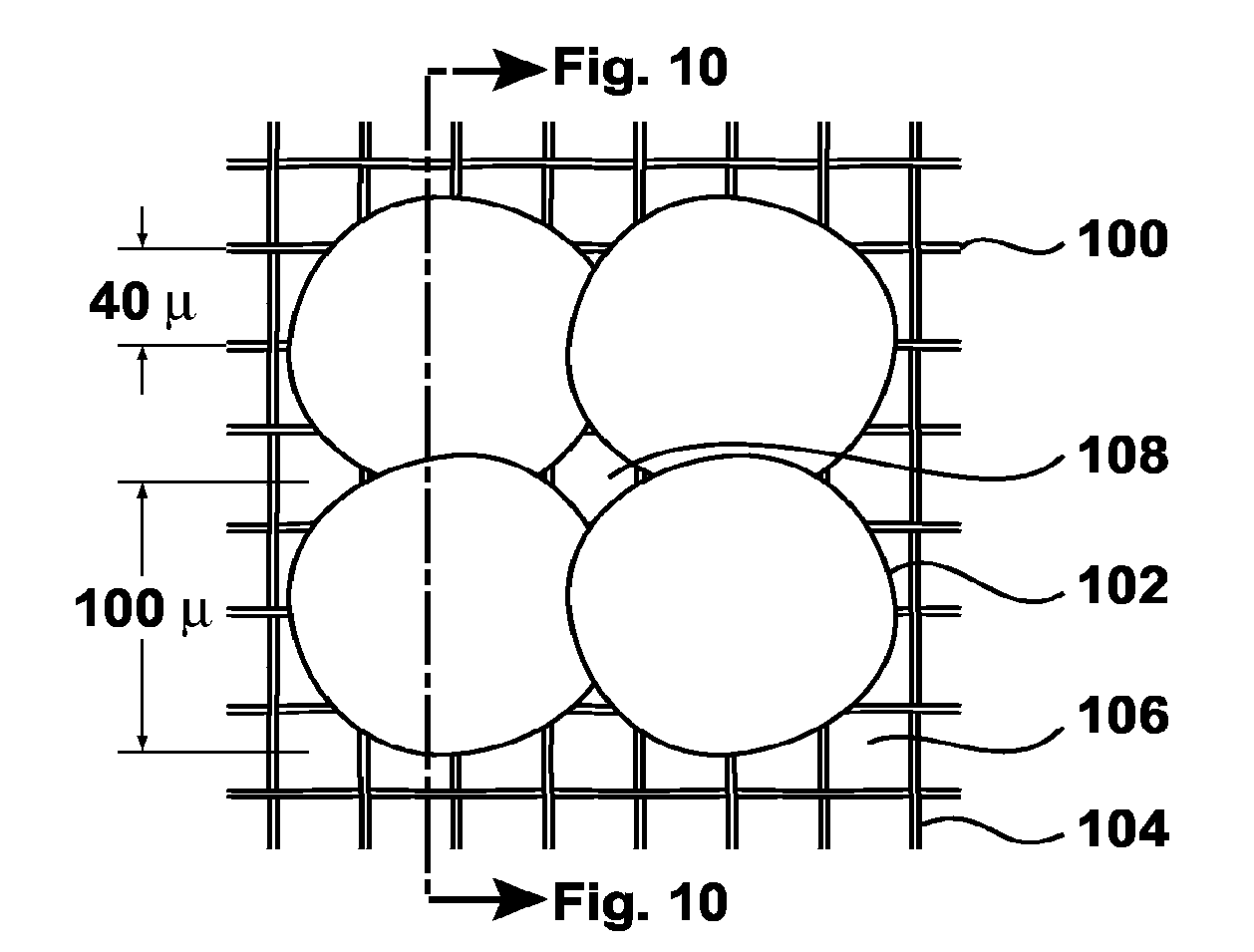

Flat Sheet for Receiving a Printed Pattern, Process for Producing Same, and Use Thereof

InactiveUS20070234533A1Reduce thicknessIncrease the areaPattern makingLayered productsColored whiteEngineering

In a sheet with openings which is designed to receive a printed pattern on one of its surfaces, a fabric woven from crossed threads, more particularly synthetic filaments, has different coloring on each surface with the printed pattern on the lighter surface. More particularly the woven fabric is a monofilament or multifilament synthetic woven fabric which either is made of black threads or is dyed black and is colored white on one surface. The threads are crimped at the same level and the lighter surface has a high degree of whiteness.

Owner:SEFAR AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com