Wax printing process of pattern shell fabric and equipment for wax printing process

A fabric and pattern technology, applied in the batik process of patterned fabrics, can solve the problems of insufficient wax patterns, high labor intensity, and lower work efficiency, and achieve fine wax patterns, reduce labor intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The batik process of a kind of pattern fabric of the present invention comprises the following steps: first prepare anti-dyeing agent, described anti-dyeing agent quality composition is: the paraffin of 80-90%, the starch of 5-10%, the starch of 15-20% Rosin, first heat and melt the rosin, then add paraffin wax and starch in turn to fully stir to form the anti-dyeing agent, and at the same time pretreat the fabric first, the pretreatment is to bleach the fabric with straw ash, then clean it, dry it and put it on One side of the fabric is coated with a paste, the paste is a mixture of soybean starch and quicklime, and then the fabric coated with the paste is dried, and after drying, the dried paste is smoothed. Finally, paint patterns or patterns on the fabric that has not been coated with the sticky side. After the pattern or pattern is painted, apply a dye resist on the pattern or pattern painted. During the coating process, the temperature of the resist At 40-50°C, pa...

Embodiment 2

[0023] Compared with Embodiment 1, the difference between this implementation and the first implementation is that the fabric is dyed after the anti-dyeing agent is coated, and the dyeing adopts a smearing method. Lay it on the film, the film is easy to curl, use a scraper to evenly paint the dye on the side coated with the anti-dye agent, and adjust the number of times of brushing according to the depth of the color to complete Finally, roll up the film and the fabric and place it for 2 days, where the ambient temperature is 30-35°C.

[0024] After dyeing, the fabric is dewaxed, and the dewaxing temperature is 90-100°C. After the dewaxing, the fabric can be rinsed twice with hot water and alkali, and finally, the fabric is ironed.

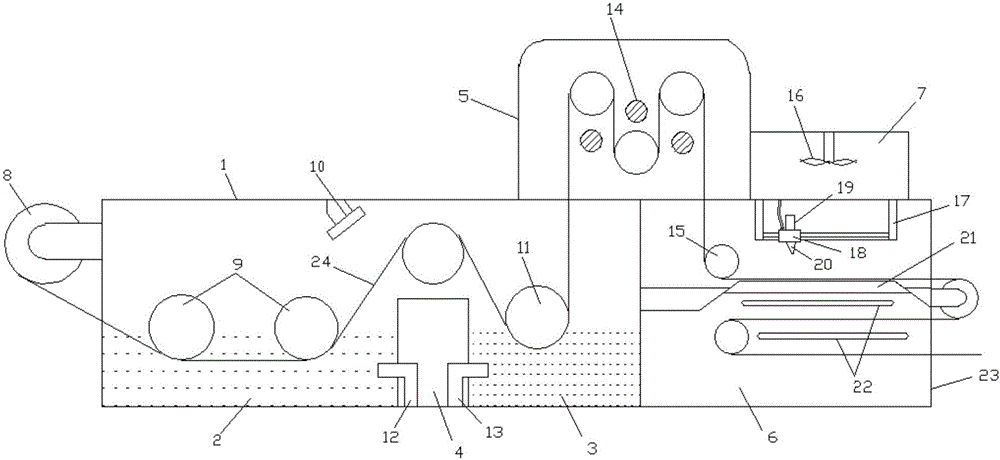

[0025] A kind of equipment that is used for the batik craft of above-mentioned pattern fabric, comprises front frame 1 and rear frame 23, and described front frame 1 is provided with front guide roller 8, above the front frame 1 and rear frame 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com