Apparatus and method for dyeing waterless precursor using vacuum transfer, and precursor manufactured according to dyeing method

A technology of dyeing device and dyeing method, which is applied in the direction of transfer printing, textiles and papermaking, transfer local treatment, etc., can solve the problems of impact, economic decline, large amount of pollutant waste water, etc., and achieve easy and rapid dyeing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described in this specification and the configurations shown in the drawings are only a preferred example of the disclosed invention, and various modifications may exist that can replace the embodiments and drawings of the present application at the time of filing this application. .

[0034] Hereinafter, the apparatus and method for anhydrous raw yarn dyeing by vacuum transfer according to the present invention and the raw yarn produced by the dyeing method will be described in detail according to the embodiments described later with reference to the accompanying drawings.

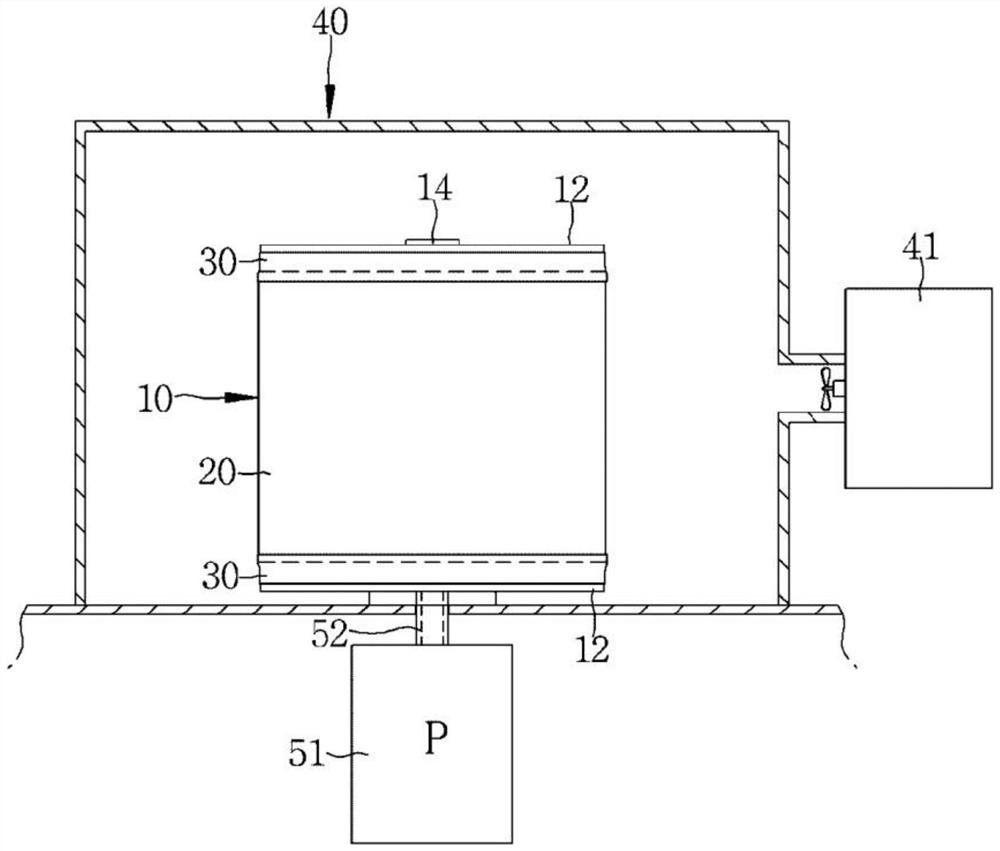

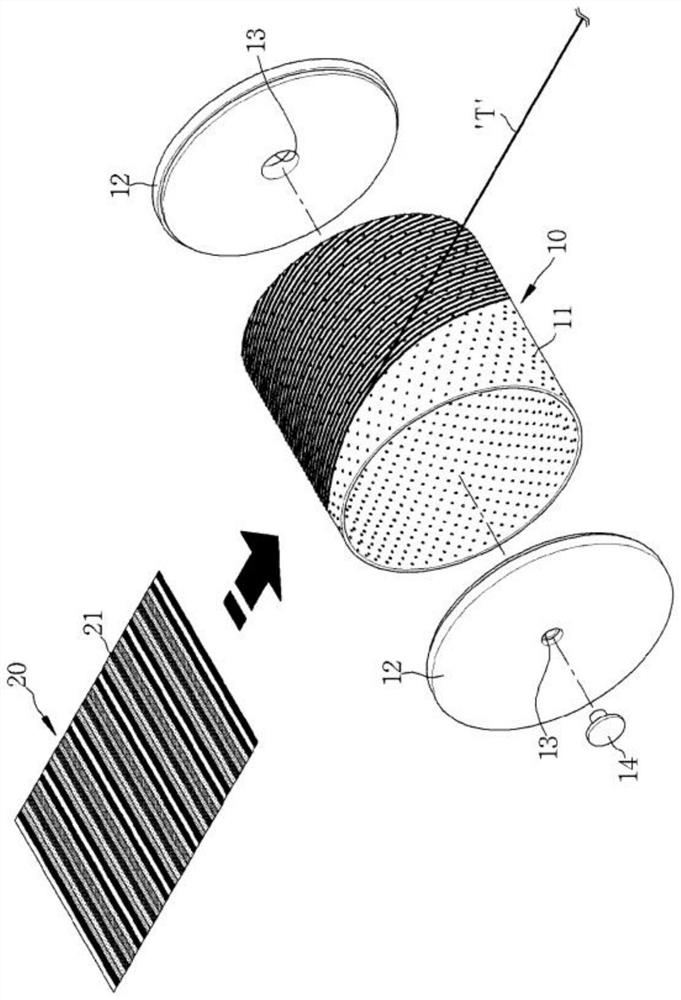

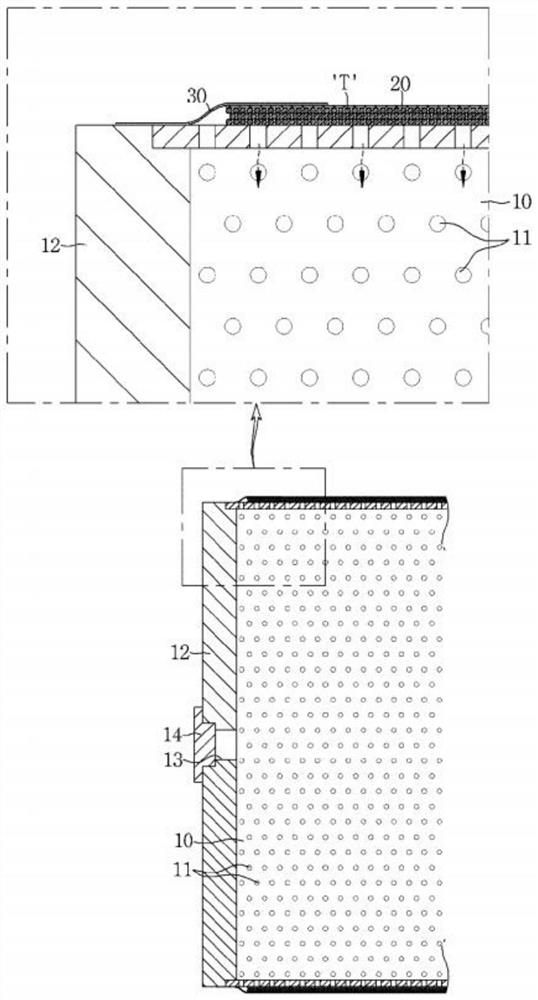

[0035] refer to Figure 1 to Figure 5 , according to an embodiment of the present invention, the anhydrous raw silk dyeing device includes: a hollow barrel 10, which is formed with a plurality of small holes 11 in a through form, and the raw silk T to be dyed is wound on the outside; a transfer film 20 , which covers the outside of the raw yarn T wound on the barrel 10, and is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com