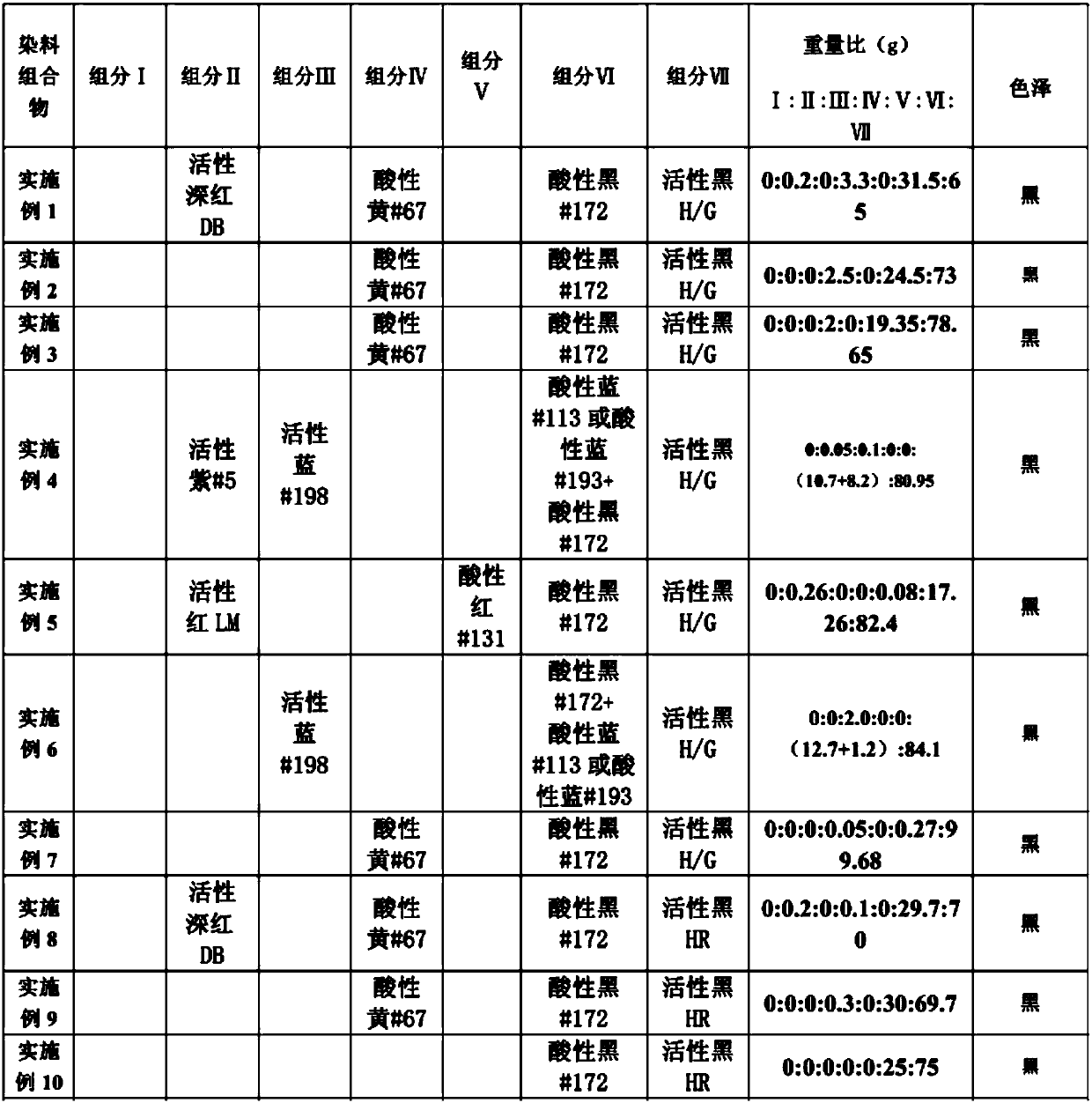

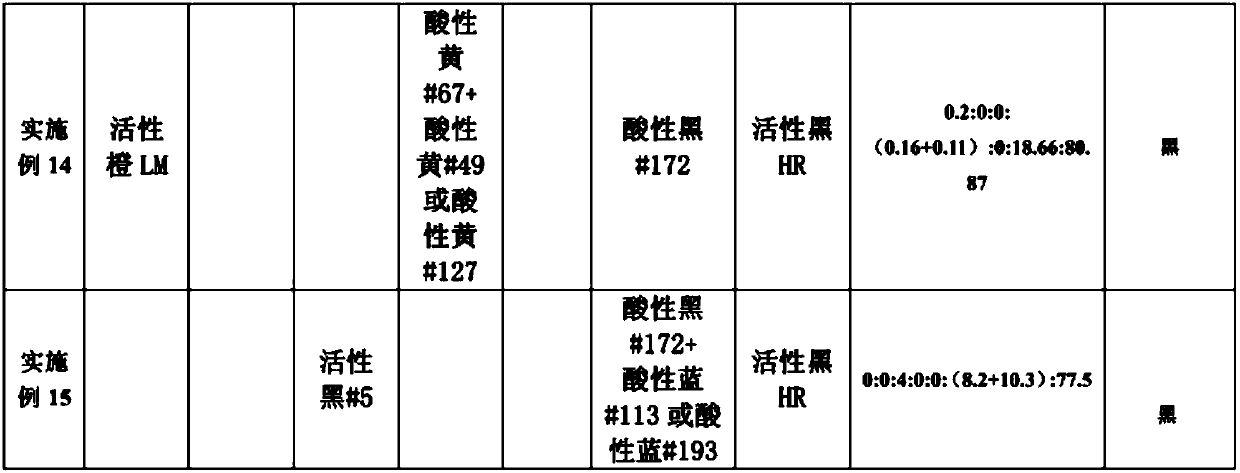

Reactive dye and acid dye composition and application thereof

A technology of reactive dyes and acid dyes, applied to dyes and their application fields, can solve the problems of difficult to achieve dyeing color yield, hue, low labor productivity, dyeing color yield, and hue balance defects will be exposed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 16

[0036] This embodiment is a composition of a reactive dye and an acid dye of the present invention applied to the cheese dyeing process of viscose / brocade 89 / 11,32s doubling yarn, the following is the operation process:

[0037] Firstly, put the bobbin yarn into each dyed bobbin and place it in the bobbin dyeing vat, then fill in the water, and correct the water level (water volume) to the specified bath ratio range (usually yarn weight: water weight = 1) when the pump is stopped. : 6), then run to drain after pretreatment such as degreasing or scouring, and set the automatically controlled dyeing process curve computer program while entering water to wash and cool the package to wait for dyeing, and enter the dyeing program.

[0038] Dyeing process:

[0039] Step 1: After entering the water to reach the water level required by the liquor ratio (reserve a part of clean water for the use of auxiliary agents in the subsequent process) to run, correct the head (pump force) and co...

Embodiment 17

[0049] The present embodiment is that the composition of a kind of reactive dyestuff of the present invention and acid dyestuff is applied to the dyeing process of sticky / brocade 70 / 30,40s Roman cloth, and the following is the operation process:

[0050] First, the dyeing vat is filled with water and then the cloth is fed, and the water level (water volume) is corrected to be within the specified liquor ratio range (usually cloth weight: water weight = 1:7) when the pump is stopped, and then it is run for pretreatment such as degreasing, and then While washing the cloth and waiting for dyeing, set the computer program of the automatically controlled dyeing process curve and enter the dyeing program.

[0051] Dyeing process:

[0052] The first step: After entering the water to the required water level of the bath ratio (reserve a part of clean water for the use of chemical additives in the subsequent process), run, and control the water temperature at 40°C.

[0053] Step 2: Re...

Embodiment 18

[0062] The present embodiment is that the composition of a kind of reactive dyestuff and acid dyestuff of the present invention is applied to the dyeing process of sticky / brocade 30 / 70,42s brocade wrapped sticky Roman cloth, and the following is the operation process:

[0063] First, the dyeing vat is filled with water and then the cloth is fed, and the water level (water volume) is corrected to be within the specified liquor ratio range (usually cloth weight: water weight = 1:7) when the pump is stopped, and then it is run for pretreatment such as degreasing, and then While washing the cloth and waiting for dyeing, set the automatically controlled computer dyeing process curve program and enter the dyeing program.

[0064] Dyeing process:

[0065] The first step: After entering the water to the required water level of the bath ratio (reserve a part of clean water for the use of chemical additives in the subsequent process), run, and control the water temperature at 40°C.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com