Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Surface wrinkling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low gloss dry erasable surface

InactiveUS20050112324A1Excellent low gloss propertyMaintain good propertiesWriting boardsSynthetic resin layered productsRough surfacePolymer chemistry

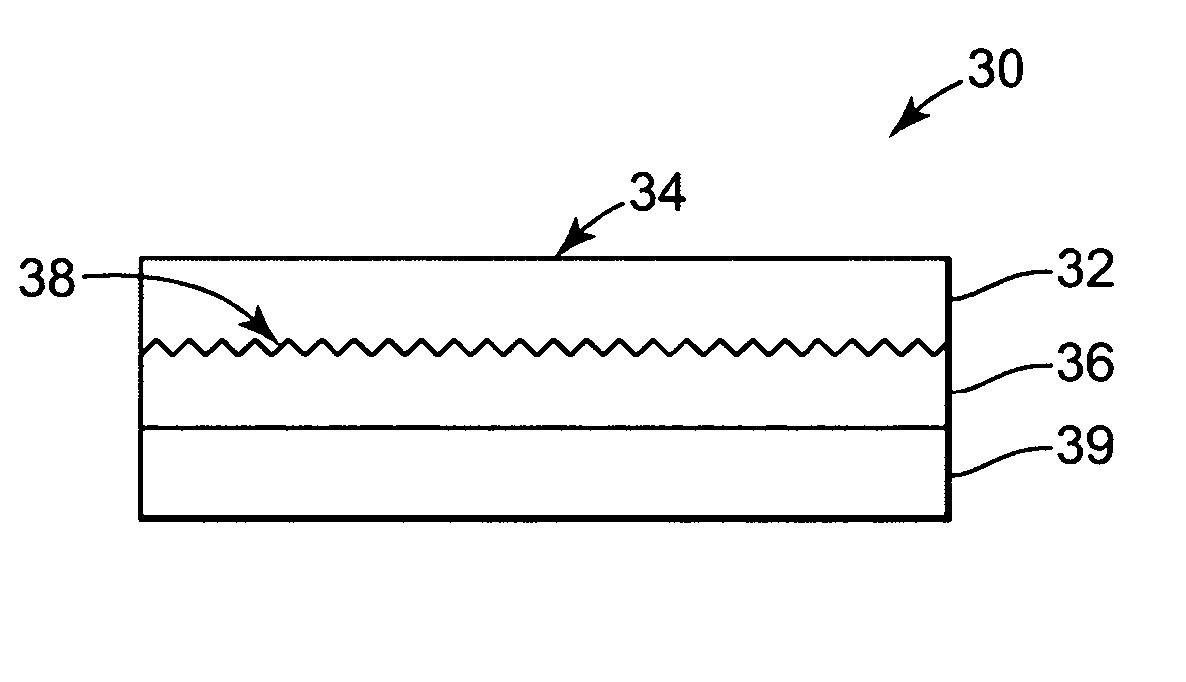

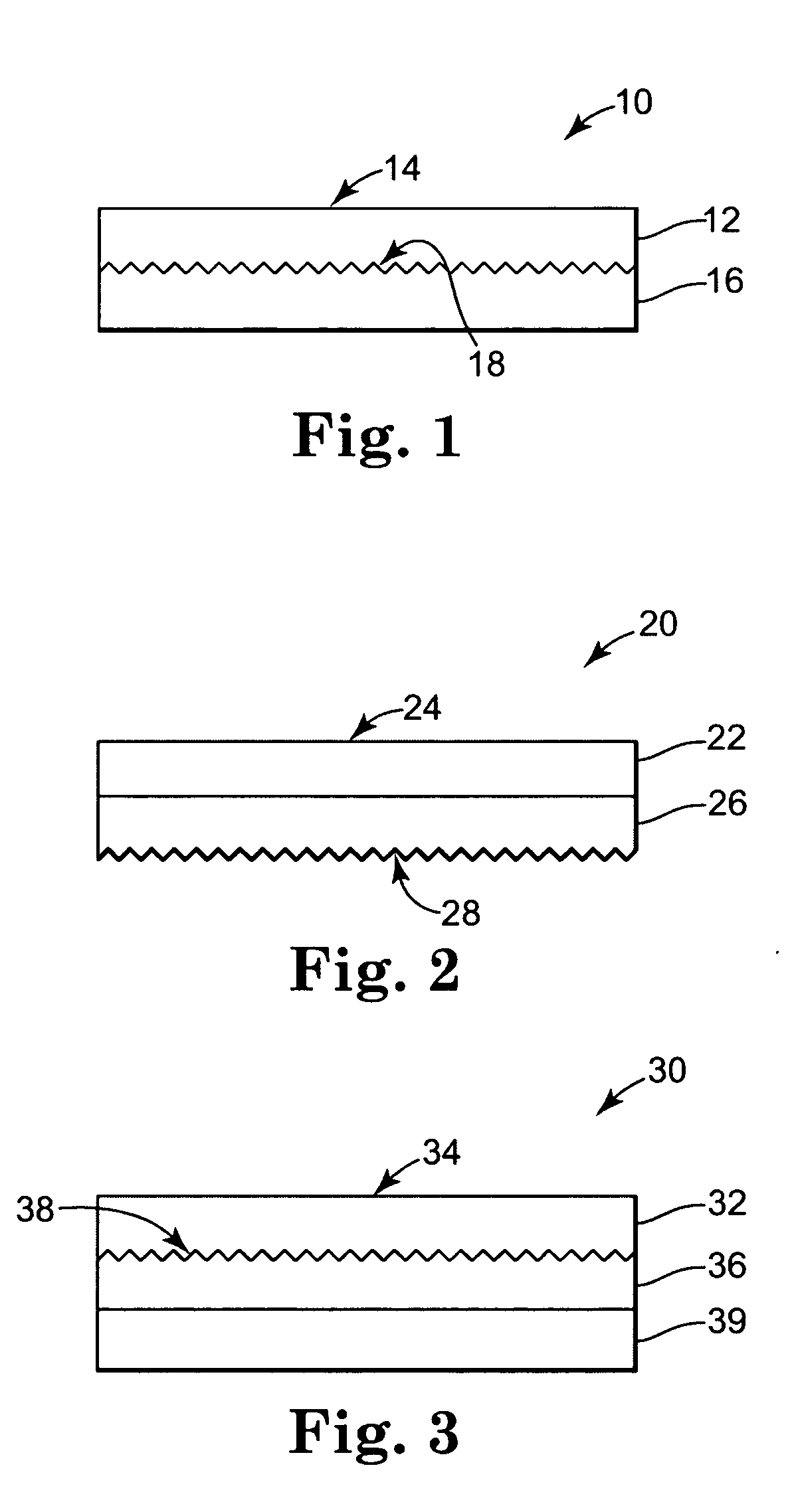

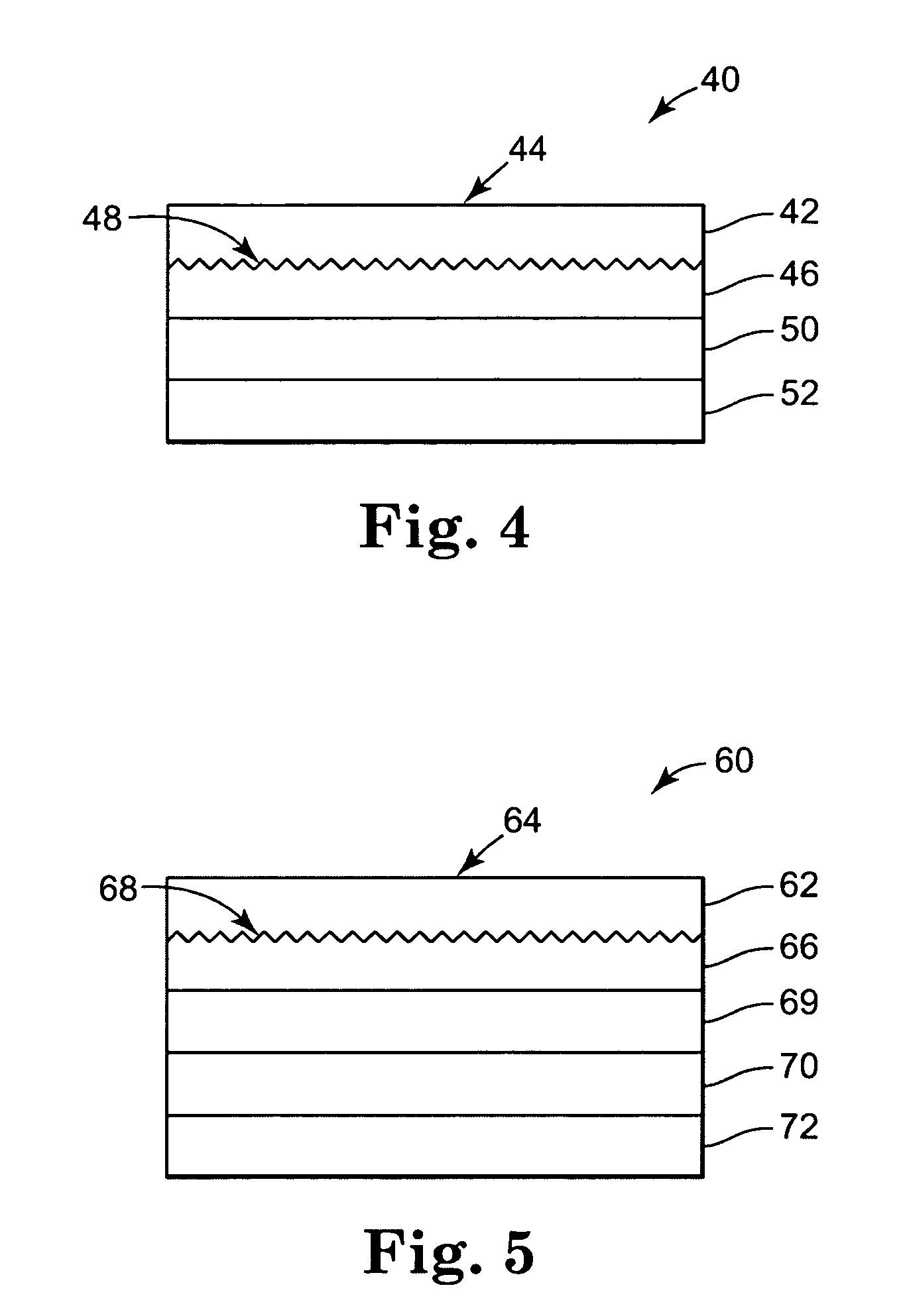

A low gloss dry-erasable multilayer composite comprises a first layer having a dry-erasable outer surface and a second layer having a microroughened surface. Preferably, the second layer is microroughened by cure-induced surface wrinkling. The first layer preferably comprises a polymer comprising at least one pendant fluoroalkoxyalkyl functionality. Methods of making low gloss dry erasable multilayer composites are also provided. New dry-erasable coating compositions comprising certain amine resin crosslinking agents are also provided.

Owner:OMNOA SOLUTIONS

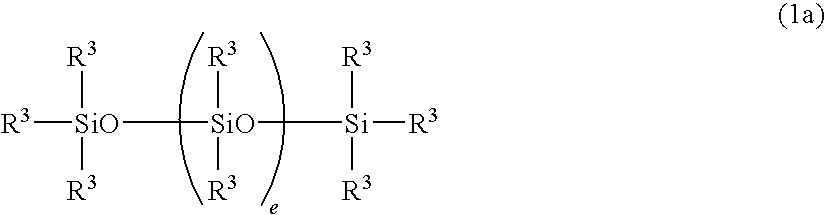

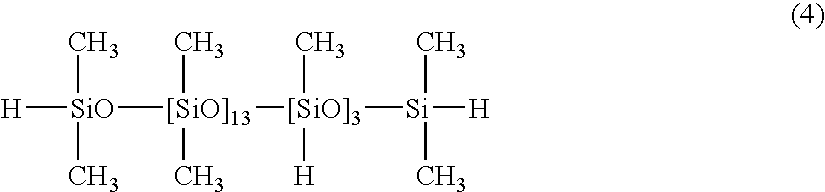

Curable organopolysiloxane composition

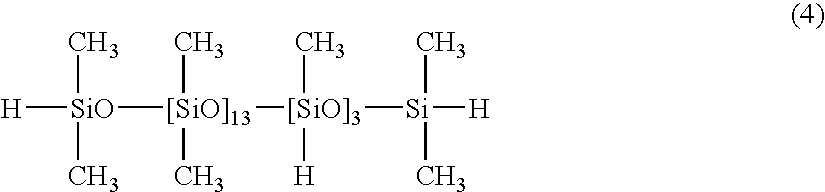

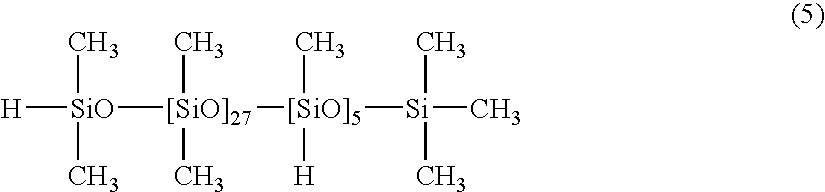

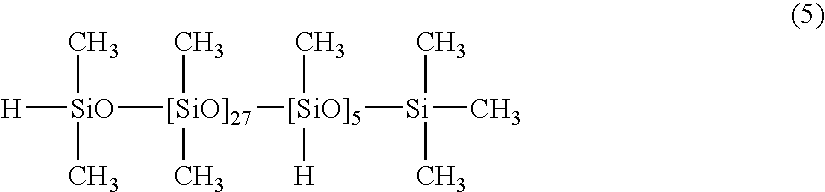

InactiveUS20050272893A1Improve featuresEasy to synthesizeSemiconductor/solid-state device detailsSolid-state devicesHydrogen atomHydrogen

A curable organopolysiloxane composition is provided, which includes (A) an organopolysiloxane containing at least one silicon atom-bonded alkenyl group within each molecule, (B) an organohydrogenpolysiloxane, which contains, within each molecule, at least one silicon atom-bonded hydrogen atom at a molecular chain terminal, and at least two silicon atom-bonded hydrogen atoms at non-terminal positions within the molecular chain, and which satisfies the formula shown below: 0<α / β0.25(wherein, a represents the number of silicon atom-bonded hydrogen atoms at non-terminal positions within the molecular chain, and β represents the total number of silicon atoms within the component (B)), in sufficient quantity to provide from 0.1 to 5 silicon atom-bonded hydrogen atoms per silicon atom-bonded alkenyl group within the component (A), and (C) a platinum-based catalyst. The composition can be cured even at low temperatures, generates a cured product that suffers no surface wrinkling, and displays excellent storage characteristics

Owner:SHIN ETSU CHEM IND CO LTD

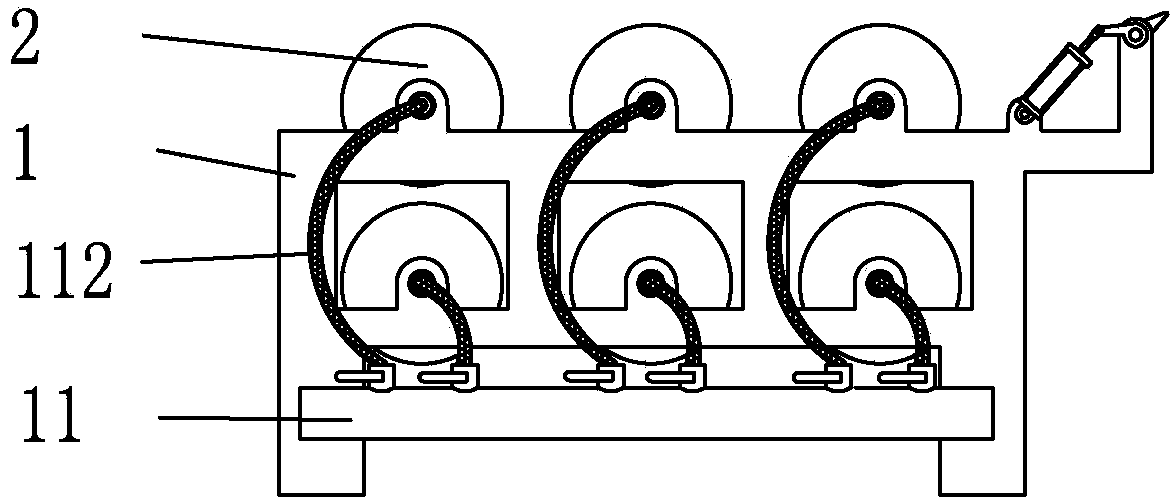

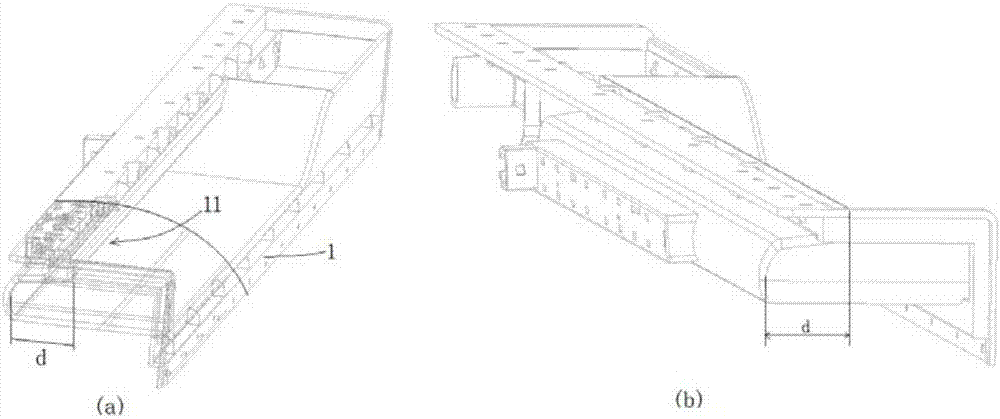

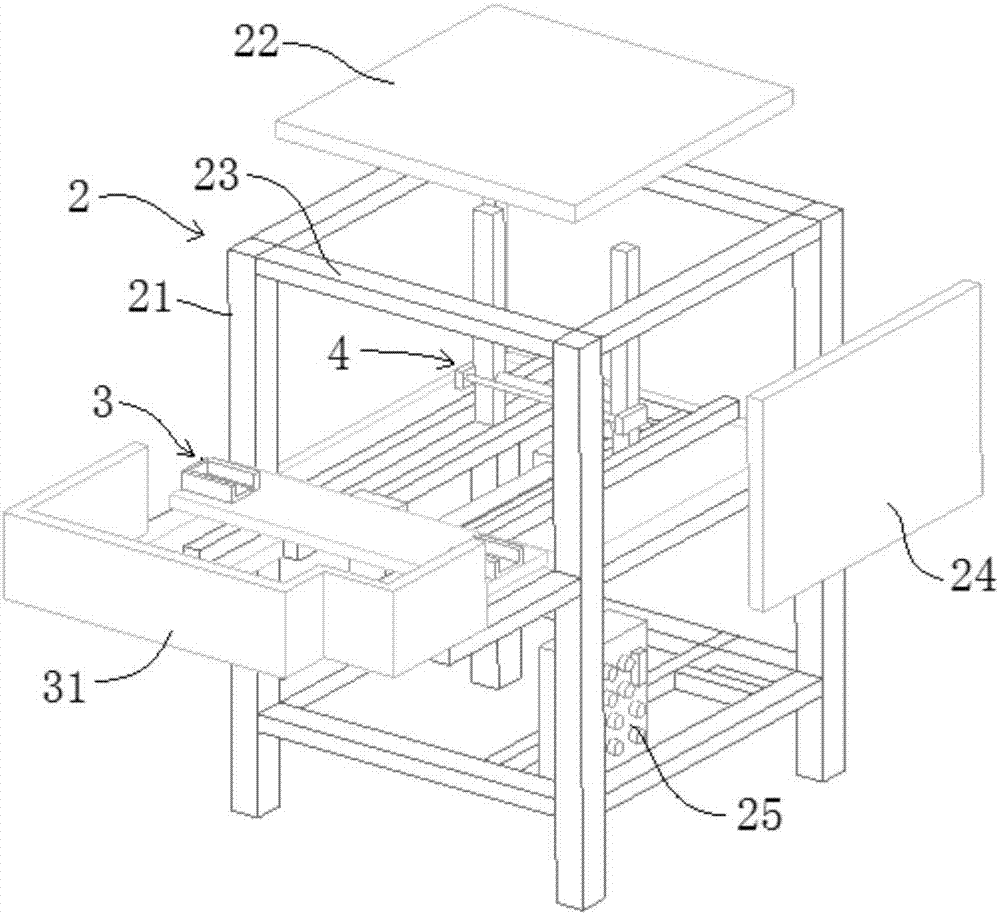

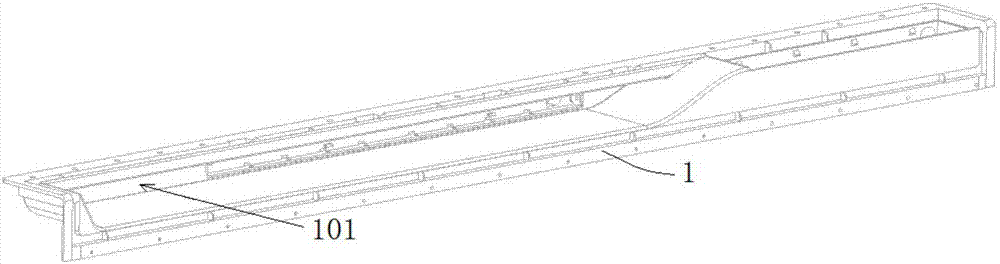

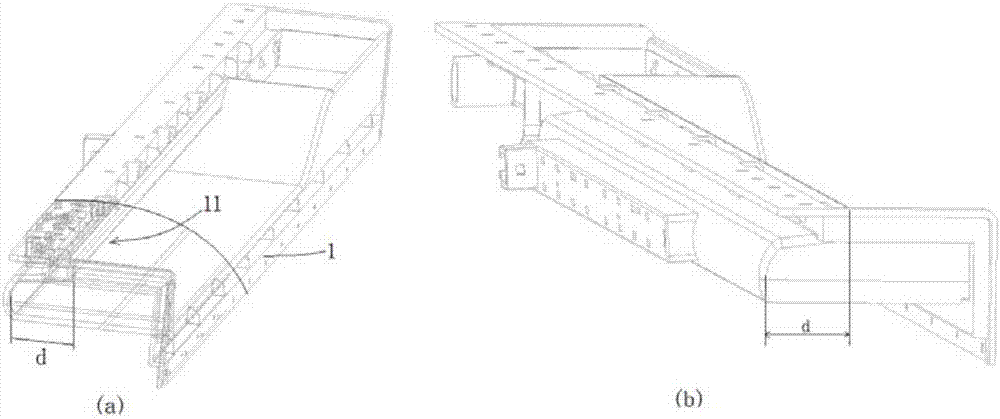

LED (light-emitting diode) chip carrier positioning and absorbing device

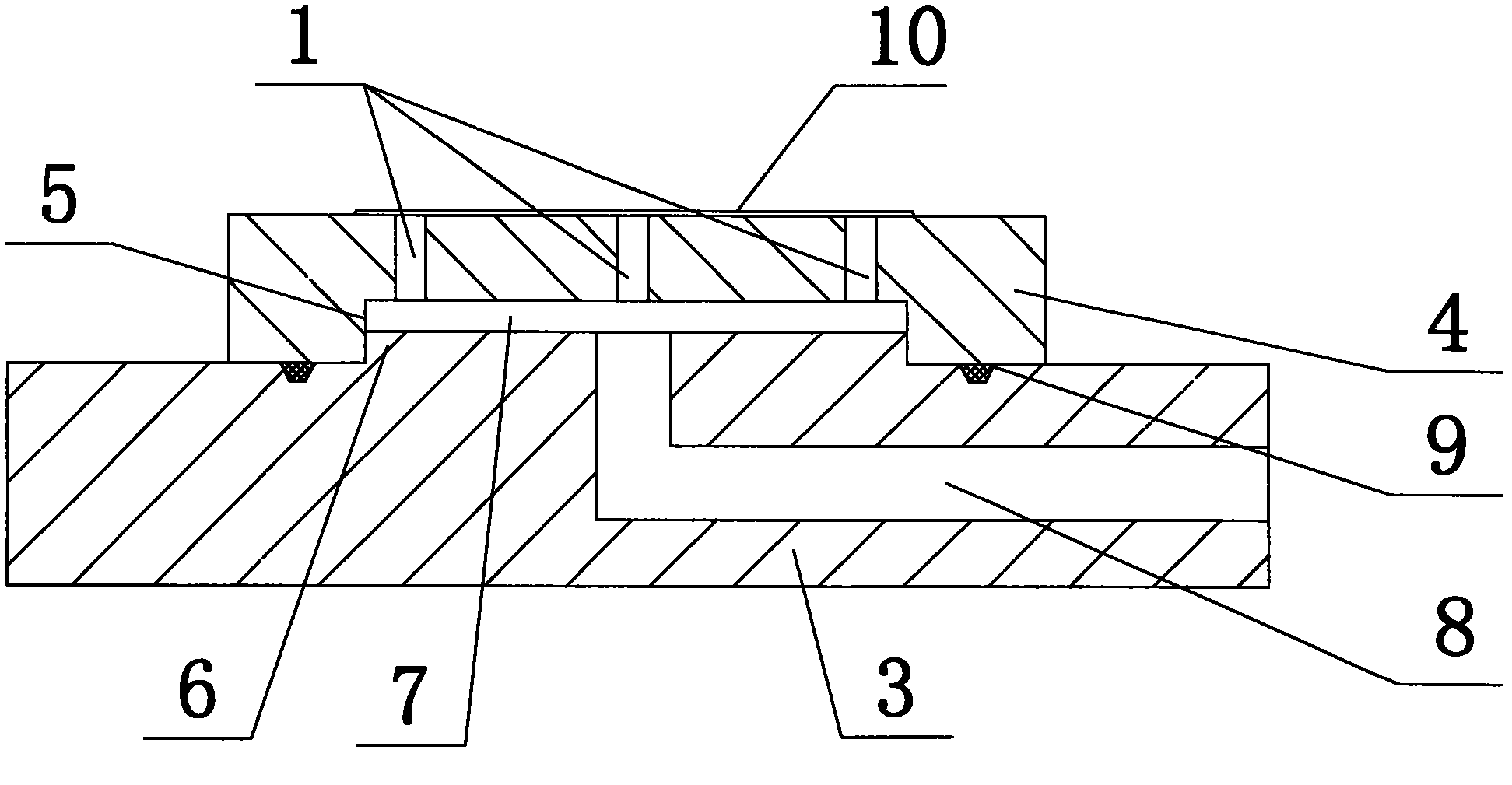

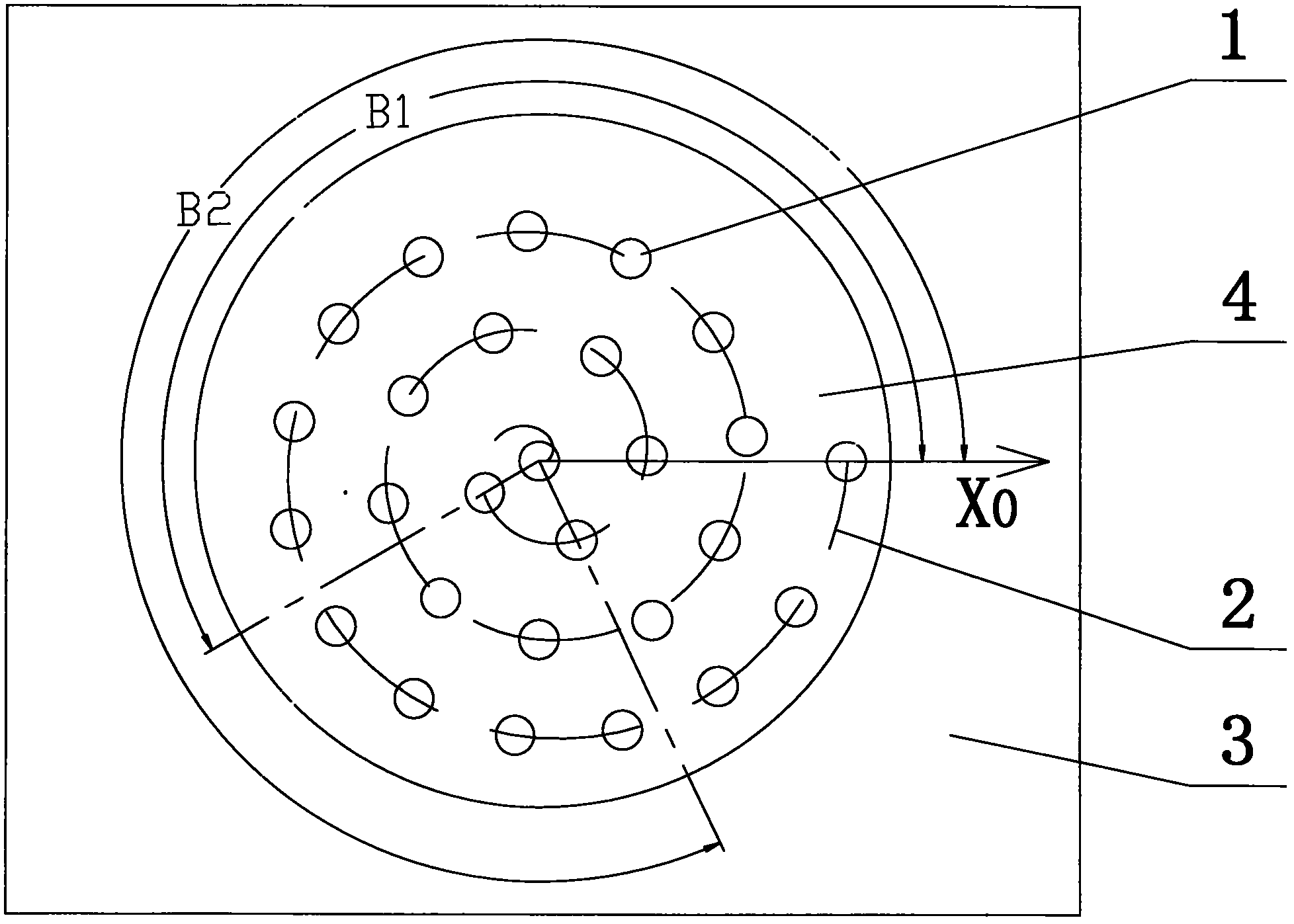

InactiveCN102637623AImprove accuracyAvoid surface wrinklingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSurface wrinklingEngineering

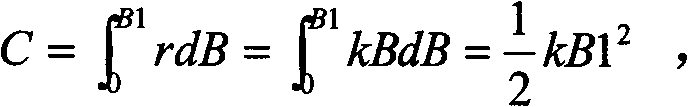

The invention relates to an LED (light-emitting diode) chip carrier positioning and absorbing device which comprises an absorbing platform with an absorbing plane; the absorbing plane is provided with a plurality of absorbing holes; an absorbing platform body is internally provided with an air pumping channel, the inlet end of the air pumping channel is communicated with each absorbing hole and the outlet end of the air pumping channel is connected with a vacuumizing device; each absorbing hole is sequentially distributed and arrayed by taking the spiral center of the Archimedes spiral line as a starting point along the extending direction of the Archimedes spiral line; the absorbing hole positioned at the spiral center of the Archimedes spiral line is a central hole, except for the central hole, an included angle of the connecting lines of the hole core of each absorbing hole and the spiral center of the Archimedes spiral line relative to a starting coordinate axis X0 meets the following relationship Bn=n<1 / 2> *B1. According to the invention, an LED chip carrier can be uniformly absorbed and positioned on the absorbing plane of the absorbing platform, the phenomenon of surface wrinkling generated when the LED chip carrier is absorbed is prevented, and the accuracy of the detection and positioning of an LED chip is improved.

Owner:PUTIAN UNIV

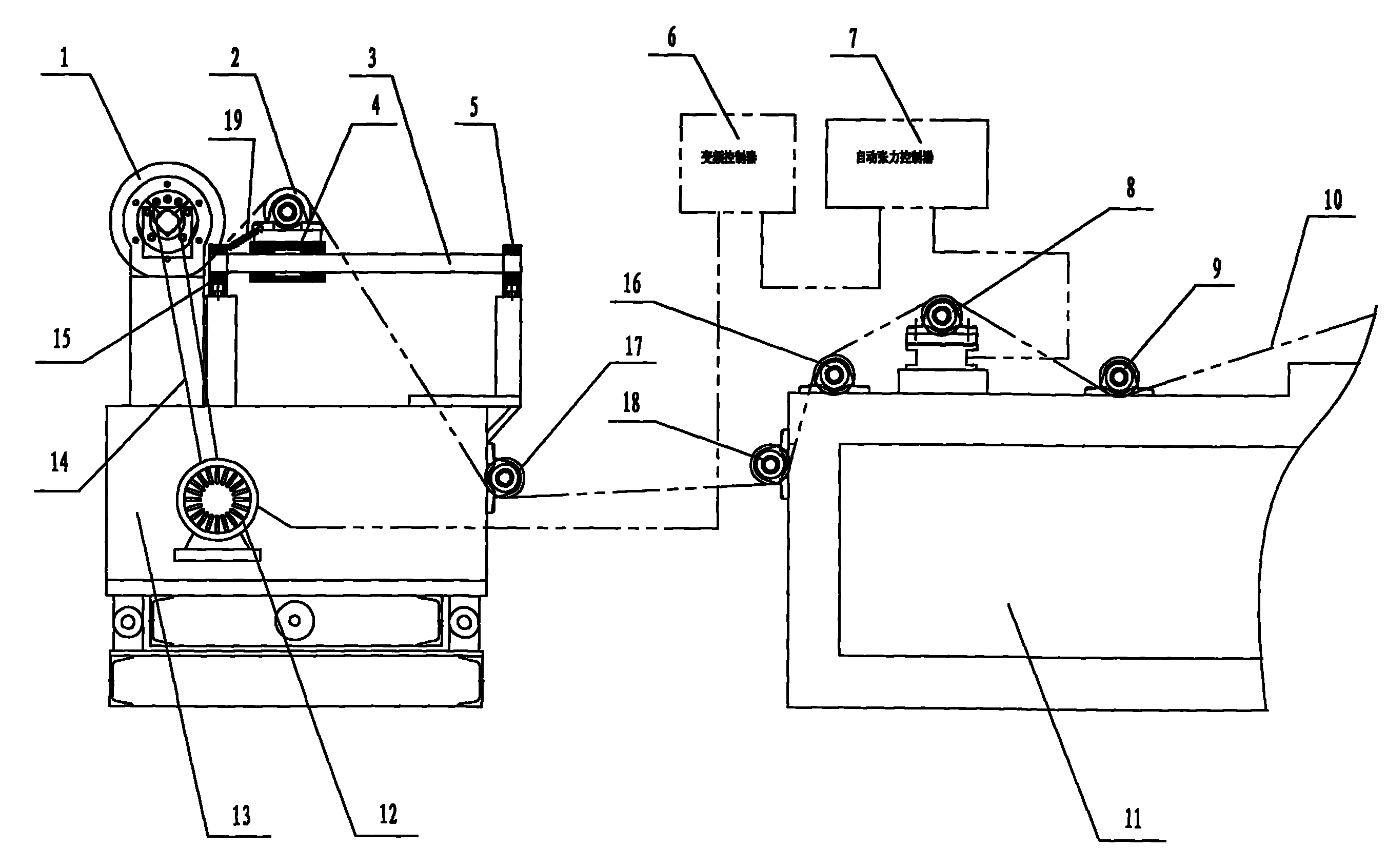

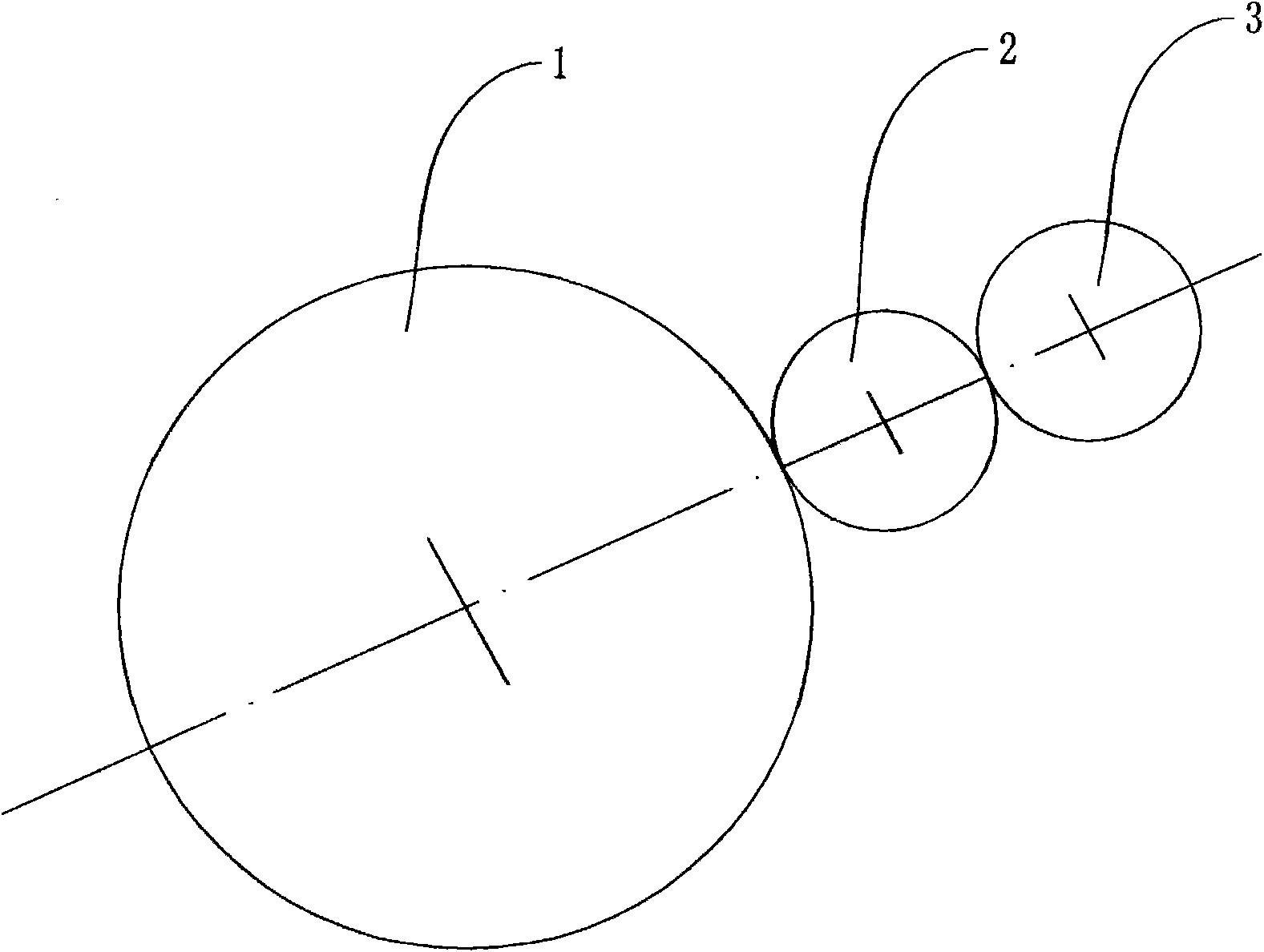

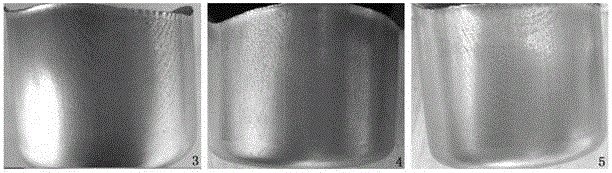

Rolling method for solving surface wrinkling problem of ferritic stainless steel

InactiveCN103506381AUniform grain sizeEliminate surface chromatic aberrationMetal rolling arrangementsSingle passMaterials science

The invention relates to a rolling method for solving the surface wrinkling problem of ferritic stainless steel. The rolling method comprises the following steps that firstly, a casting blank is formed through smelting and casting; secondly, hot rolling is conducted on the casting blank. The rolling method further comprises the following steps that thirdly, single-pass cold rolling is conducted; fourthly, intermediate annealing acid picking is conducted; fifthly, a plate band obtained after the annealing process in the fourth step is ground with number 240 sand rubber; sixthly, cold rolling is conducted; seventhly, final annealing acid picking is conducted. According to the rolling method, single-pass cold rolling, rough grinding conducted after intermediate annealing and cold rolling conducted through cold rolls with different roughness are adopted, and the rolling method can effectively solve the 2B surface wrinkling problem of the medium chromium pure ferritic stainless steel.

Owner:BAOSTEEL STAINLESS STEEL

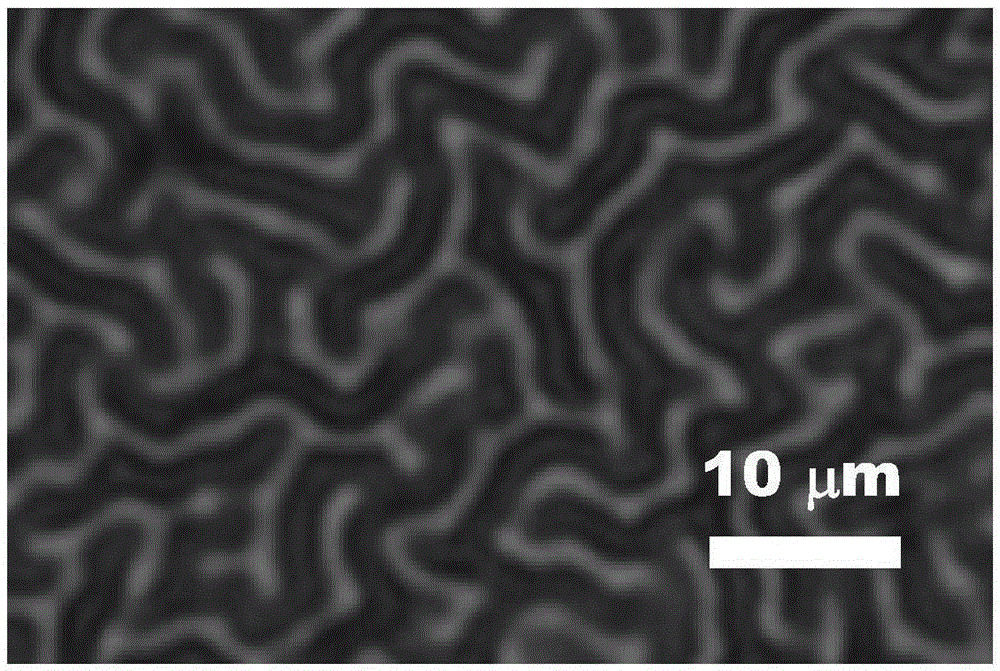

Method for constructing multistage ordered microstructure by combination of template imprinting and surface wrinkling

InactiveCN104476895ALow costHigh precisionLamination ancillary operationsSynthetic resin layered productsWrinkle skinWater baths

The invention provides a method for constructing a multistage ordered microstructure by combination of template imprinting and surface wrinkling, which comprises the following steps: carrying out spin coating on a clean glass substrate by using a polyethyleneimine water solution, drying, and continuing spin coating by using a polystyrene (PS) tetrahydrofuran solution; in a water bath environment, and transferring the PS film to a drawn polydimethylsiloxane (PDMS) substrate to form a PDMS / PS soft / hard composite system; covering a previously prepared wrinkle template on the sample, and forming a primary pattern on the PDMS / PS double-layer system in the cooling process; and retracting the prestressed PDMS to form a secondary wrinkle pattern on the PDMS / PS double-layer system. The intersection angle between the primary pattern obtained by template imprinting and the secondary pattern obtained by surface wrinkling is changed to control the anisotropy of the composite pattern. The method has the advantages of low cost, simple process and favorable repetitiveness, and implements the construction of the precise controllable multistage ordered microstructure on the PDMS substrate.

Owner:TIANJIN UNIV

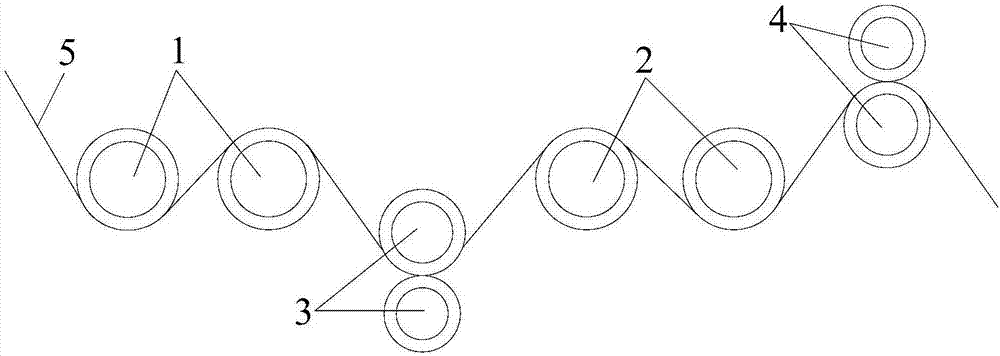

Rolling machine

The invention discloses a rolling machine, comprising a stand, a spreading roll, a rolling gas expanded shaft rotatably connected with the stand, a rolling motor connected with the stand to drive the rolling gas expanded shaft to rotate, and a transmission unit for conveying cloth. The transmission unit is arranged at one side of the machine frame, and the spreading roll is arranged at one side of the rolling gas expanded shaft. The spreading roll comprises a spreading roll support, guide rails, a left guide rail support and a right guide rail support, wherein the left and the right guide rail supports are both connected with the stand, the guide rails are connected between the left guide rail support and the right guide rail support, and the spreading roll is rotatably connected with the spreading roll support which is connected with the guide rails in a sliding mode. The invention has the advantage that the rolling machine can prevent the surface of cloth from crimping in the rolling process, thereby ensuring quality of cloth rolls after rolling.

Owner:NINGBO XIN XING LINGFENG FLOCKING & LEATHER MFG

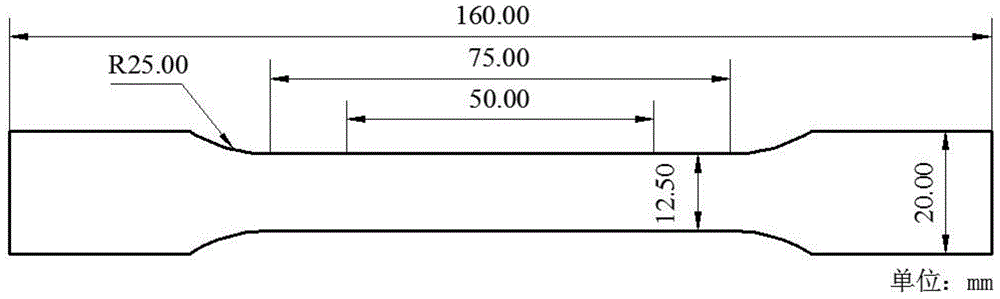

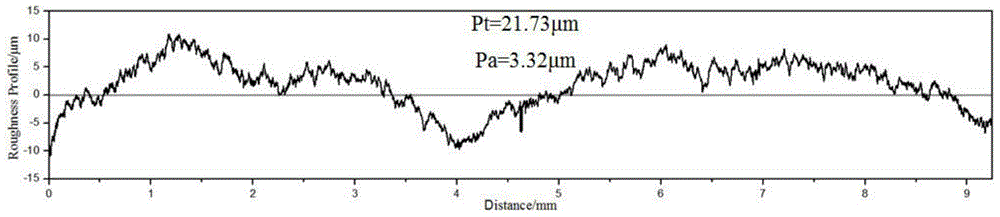

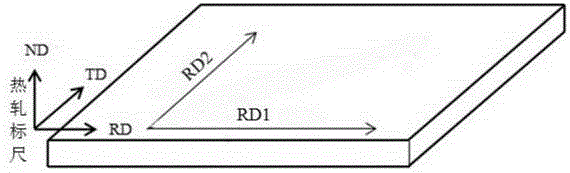

Rolling method for enhancing ferritic stainless steel surface wrinkling resistance

The invention relates to a rolling method for enhancing ferritic stainless steel surface wrinkling resistance. The rolling method comprises the steps of: 1) conducting hot rolling treatment on the casting blank; 2) conducting annealing pickling on the hot rolled steel sheet; 3) conducting cold rolling on the hot-rolled annealed and pickled steel sheet by an asynchronous rolling way, and controlling the total rolling reduction and cold rolling; and 4) conducting annealing treatment on the steel sheet obtained from asynchronous cold rolling by using a reasonable annealing process system. Through the above process, the surface roughness Pa and the maximum wrinkling height Pt of the steel sheet are improved substantially; and the method is quite effective in improving the surface wrinkling of medium-chromium series ultra-pure ferrite stainless steel, which is supplemented with Nb and Ti stabilizing elements and contains about 16% of Cr.

Owner:UNIV OF SCI & TECH BEIJING

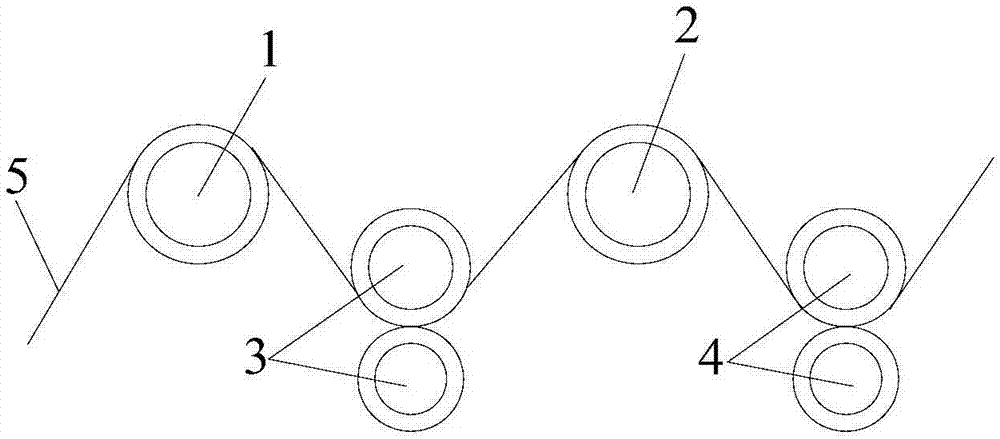

Method for improving cutting and winding effects of polyester film

InactiveCN102152985AImprove slitting and winding effectEasy dischargeArticle deliveryWebs handlingPolyesterLow speed

The invention discloses a method for improving cutting and winding effects of a polyester film. When in winding, a first compression roller is pressed on the surface of a polyester film roll, a second compression roller is pressed on the surface of the first compression roller, circle centers of cross sections of the polyester film roll, the first compression roller and the second compression roller are arranged on the same straight line, and the polyester film is wound under the winding tension of 150-200N / m and the winding speed of 300-450m per minute; by adopting a winding method of two compression rollers, the straightness of the compression roller pressed on the polyester film roll is high, which is beneficial to the exhaust of air in the winding process; large-tension winding and lower-speed winding are also beneficial to the exhaust of air in the winding process; the shore hardness of the polyester film roll wound by using the method is larger than 95 degrees; and by using the method, the cutting and winding effects of the polyester film are greatly improved and the problems of winding bottom wrinkling, middle wrinkling and surface wrinkling are solved.

Owner:WEIFANG FUWEI PLASTIC

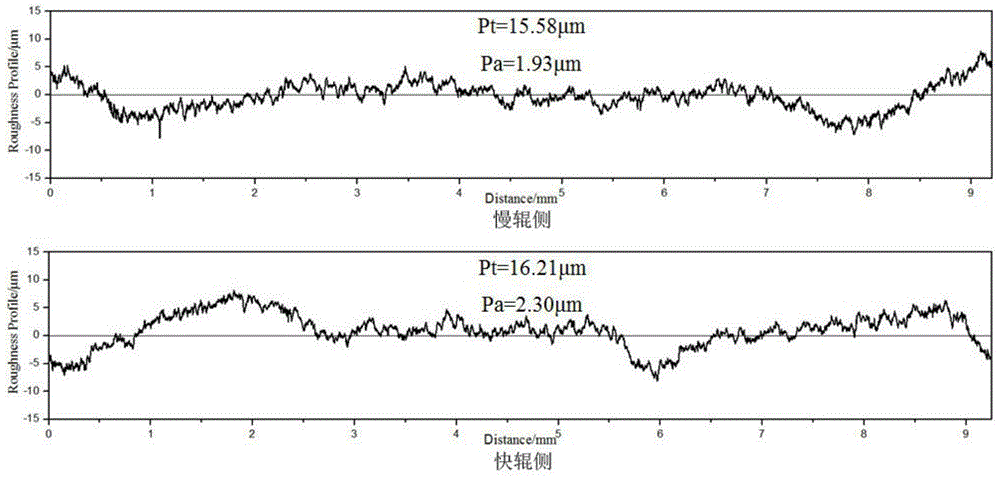

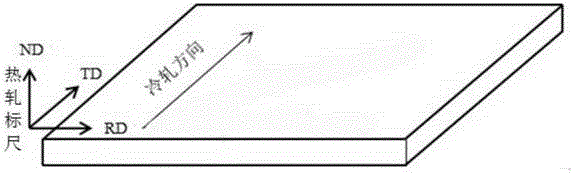

Transverse cold rolling method for improving surface wrinkling of ferritic stainless steel

The invention relates to a cold rolling method for improving surface wrinkling of ferritic stainless steel. The ferritic stainless steel is medium chrome ferritic stainless steel added with stabilizing elements Nb and Ti and containing about 16% of Cr and less than or equal to 0.02% of C and N. A manufacturing method for a stainless steel plate comprises the steps of 1) smelting and casting for forming a blank; 2) hot rolling annealing for the casting blank, and acid washing; 3) cold rolling and re-crystallization annealing. The method is characterized in that multiple times of rolling is performed in the cold rolling process by adopting the direction (namely the transverse direction of a hot-rolled annealed plate) perpendicular to the hot rolling direction on the rolled surface of the hot-rolled annealed plate as a cold rolling direction. The surface wrinkling morphology of a tensile test piece of the ferritic stainless steel cold-rolled annealed plate manufactured by adopting the method disclosed by the invention is obviously alleviated, and the surface of a deep drawn part of the cold-rolled annealed plate does not have wrinkles.

Owner:UNIV OF SCI & TECH BEIJING

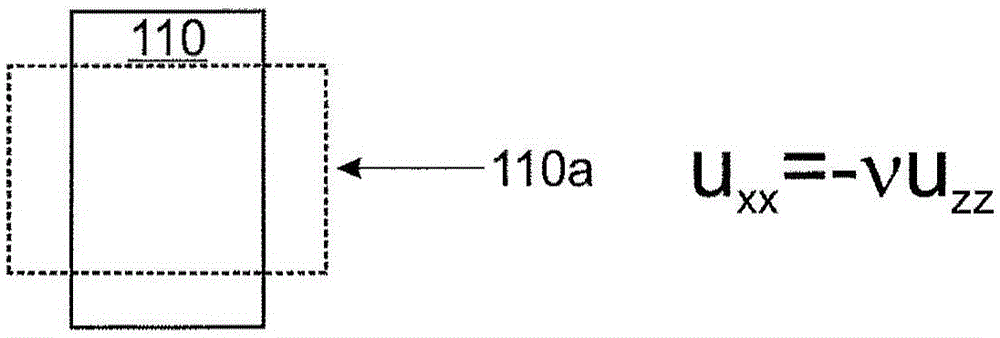

Haptic feedback and capacitive sensing in a transparent touch screen display

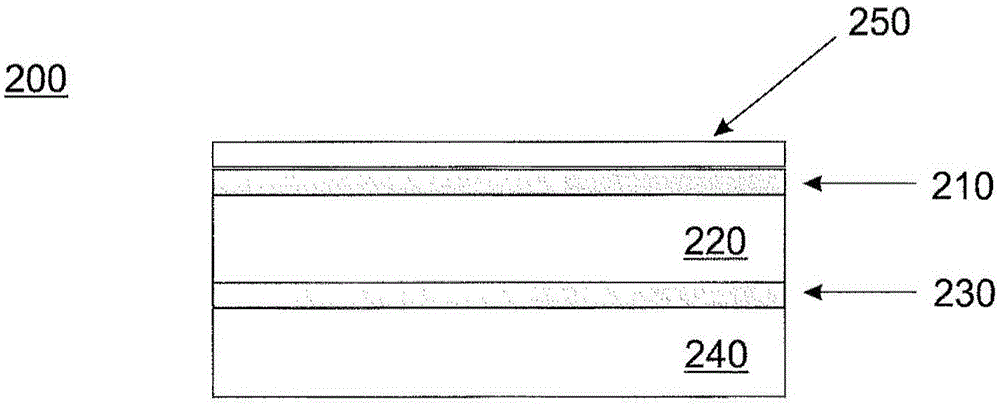

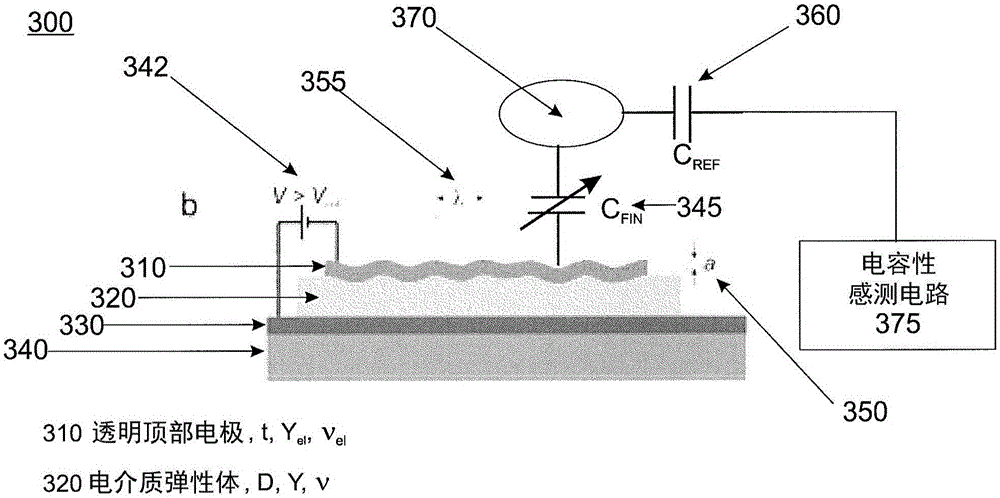

Consistent with an example embodiment, a user (touch screen) interface has haptic feedback. The user interface comprises, a substrate, a transparent bottom electrode on top of the substrate, a transparent wrinkling layer on top of the transparent bottom electrode, a transparent top electrode on top of the transparent wrinkling layer; and a transparent protective surface on top of the transparent top electrode. The transparent wrinkling layer changes from a smooth surface to a roughened surface upon application of a voltage between the top electrode and the bottom electrode; the voltage generates an electrostatic force mutually attracting the top and bottom electrodes to exert a compressive force upon the transparent wrinkling layer sufficient to generate a degree of surface wrinkling that is perceptible to the touch.

Owner:NXP BV

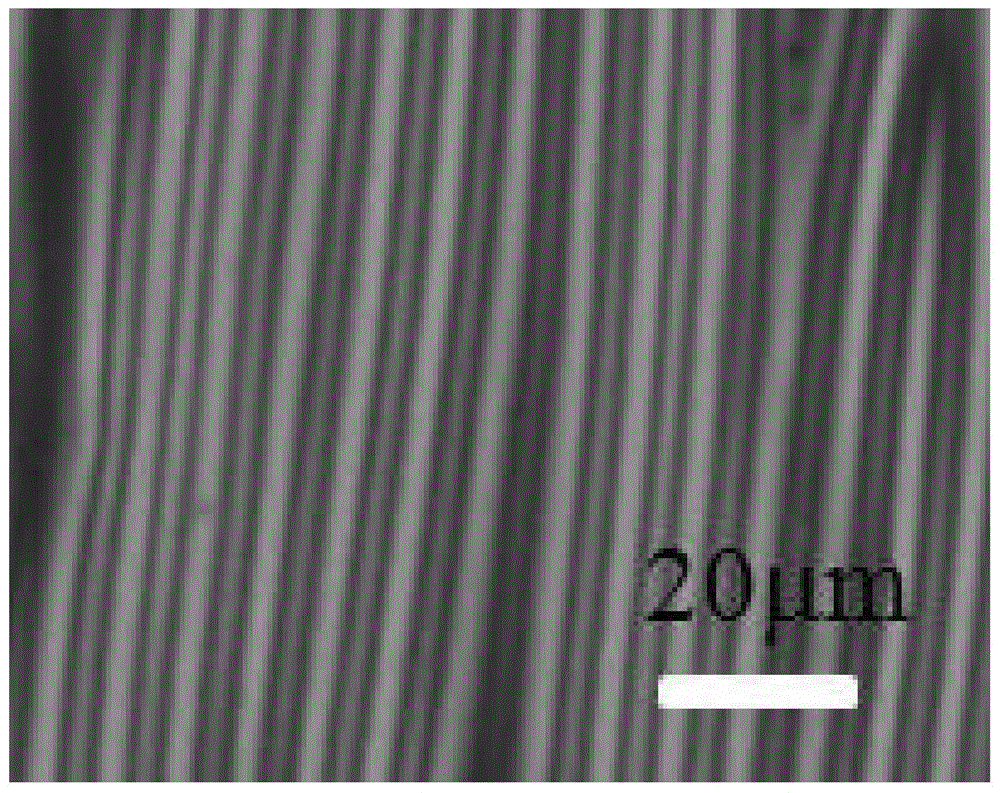

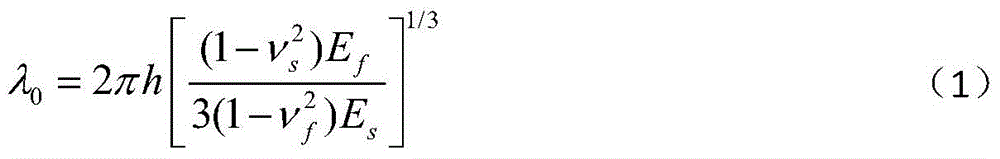

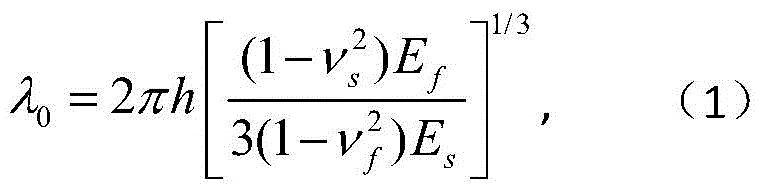

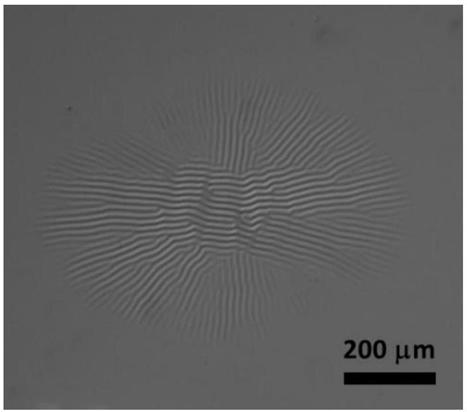

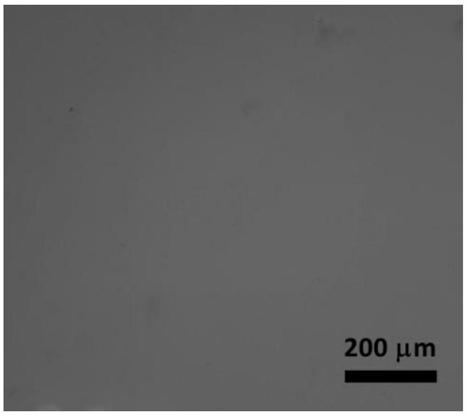

A method for measuring light softening of an azobenzene thin film through utilization of surface wrinkling

InactiveCN105699703AAccurate measurementAccurate calculationScanning probe microscopyWater bathsWrinkle skin

The invention discloses a method for measuring light softening of an azobenzene thin film through utilization of surface wrinkling. Through utilization of surface wrinkling technology, a light softening effect, i.e. photoinduced elastic modulus reduction, of the azobenzene thin film is simply and conveniently measured through utilization of the surface wrinkling technology. Firstly, a tetrahydrofuran solution of an azobenzene polymer (PAzo) is coated in a spinning mode on a clean glass substrate. In a water-bath environment, the PAzo thin film is transferred to a stretched polydimethylsiloxane (PDMS) substrate to form a PDMS / PAzo soft and hard composite system. Retraction of the stretched polydimethylsiloxane (PDMS) is conducted under an illumination effect. Through control of irradiation light intensity, formation of wrinkles of a PDMS / PAzo double layer system can be regulated and controlled. Through measurement of a wrinkle period and the thickness of the PAzo film, an elastic modulus of the PAzo thin film can be obtained through calculating. The method is simple to operate and good in repeatability, avoids usage of complex and expensive apparatuses and tedious and complex theoretical simulation, and has a broad application prospect in tests of azobenzene thin film light softening.

Owner:TIANJIN UNIV

Self-adhesive vacuum-plating electronic protective film

ActiveCN105567107AImprove mechanical propertiesSolve the warping problemNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolyester

The invention discloses a self-adhesive vacuum-plating electronic protective film which comprises a thermoplastic polyester elastomer, a polyolefin elastomer, PE (polyethylene) wax, high-density polyethylene, polyvinyl alcohol, nano silicon carbide, a tackifying resin, an antioxidant, a functional monomer and an antistatic agent. When in use, the self-adhesive vacuum-plating electronic protective film disclosed by the invention has the advantages of no surface wrinkling or deformation, stable adhesive force, favorable adhesiveness, favorable repeeling property, no residual adhesive phenomenon, favorable barrier property, favorable mechanical properties and lower dielectric constant, is an excellent vacuum-plating protective film material, and is nontoxic, environment-friendly, safe and practical.

Owner:广东顺德君盈包装科技股份有限公司

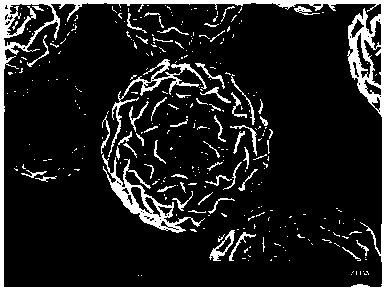

Preparation method of polymer particles with wrinkling surfaces

The invention relates to a preparation method of polymer particles with wrinkling surfaces. According to the preparation method, macromolecular poly(glycidyl methacrylate) with initiating activity andamphiphilicity is taken as a raw material, and without adding additional small molecular emulsifiers or initiators, a hydrophobic cross-linking monomer is initiated to polymerize, so that polymer particles having a surface wrinkling morphology are obtained. Compared with an existing preparation method for polymer particles with wrinkling surfaces, the method is simple in system and technology, simple for post-processing, high in universality, low in cost and suitable for industrial mass production. The prepared polymer particles have wide application prospects in the fields of optical devices, drug loading systems, self-cleaning coatings, cell adhesion, super-hydrophobic materials, electronic self-assembly templates and the like due to a relatively large surface area and morphological controllability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and device for film surface shaping

The invention discloses a method and device for film surface shaping. The method comprises the steps that a thin film is firstly heated and flattened, then the heated and flattened thin film is subjected to tension cutoff, cooling and sizing are carried out, and the thin film obtained after cooling and sizing is subjected to tension cutoff again. The device comprises at least one flattening and heating roller and at least one flattening and cooling roller. A press roller A used for cutting off tension is arranged between the flattening and heating rollers and the flattening and cooling rollers, and a press roller B used for cutting off tension is also arranged at the rear ends of the flattening and cooling rollers. According to the method and device, film surface defects with the collapse width being smaller than or equal to 200 mm can be effectively flattened, traces generated by film surface wrinkling and veining can be completely eliminated, and the flatness of the thin film can be obviously improved; the online operating speed of the thin film can reach up to 100 m / min or above, and the shaping efficiency is obviously improved; and in addition, a roller type structure is adopted, the structure is simple, operation is easy, and the shaping requirements of thin films of different breadths are easy to meet.

Owner:LIYANG YUEQUAN ELECTRIC ENERGY CO LTD

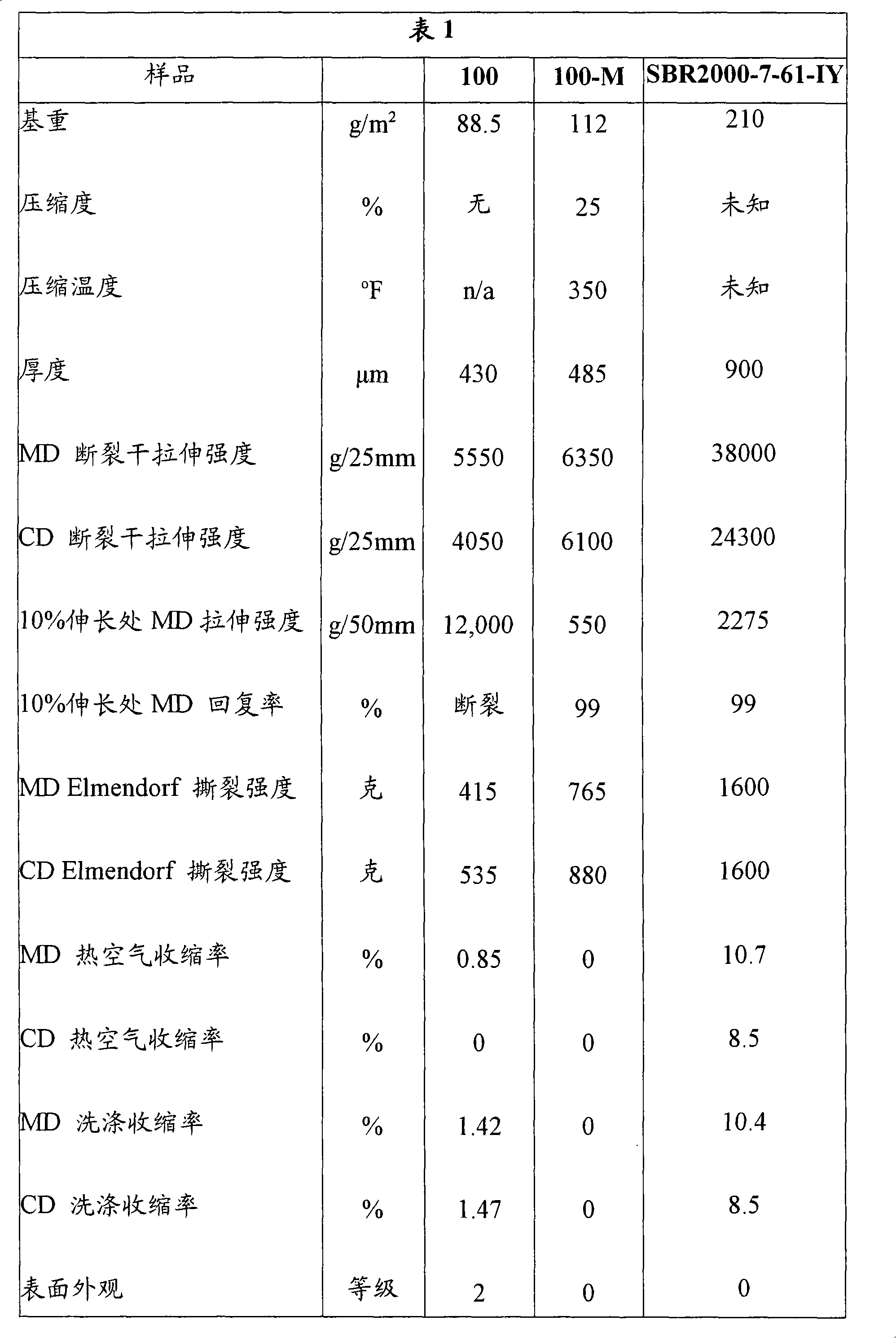

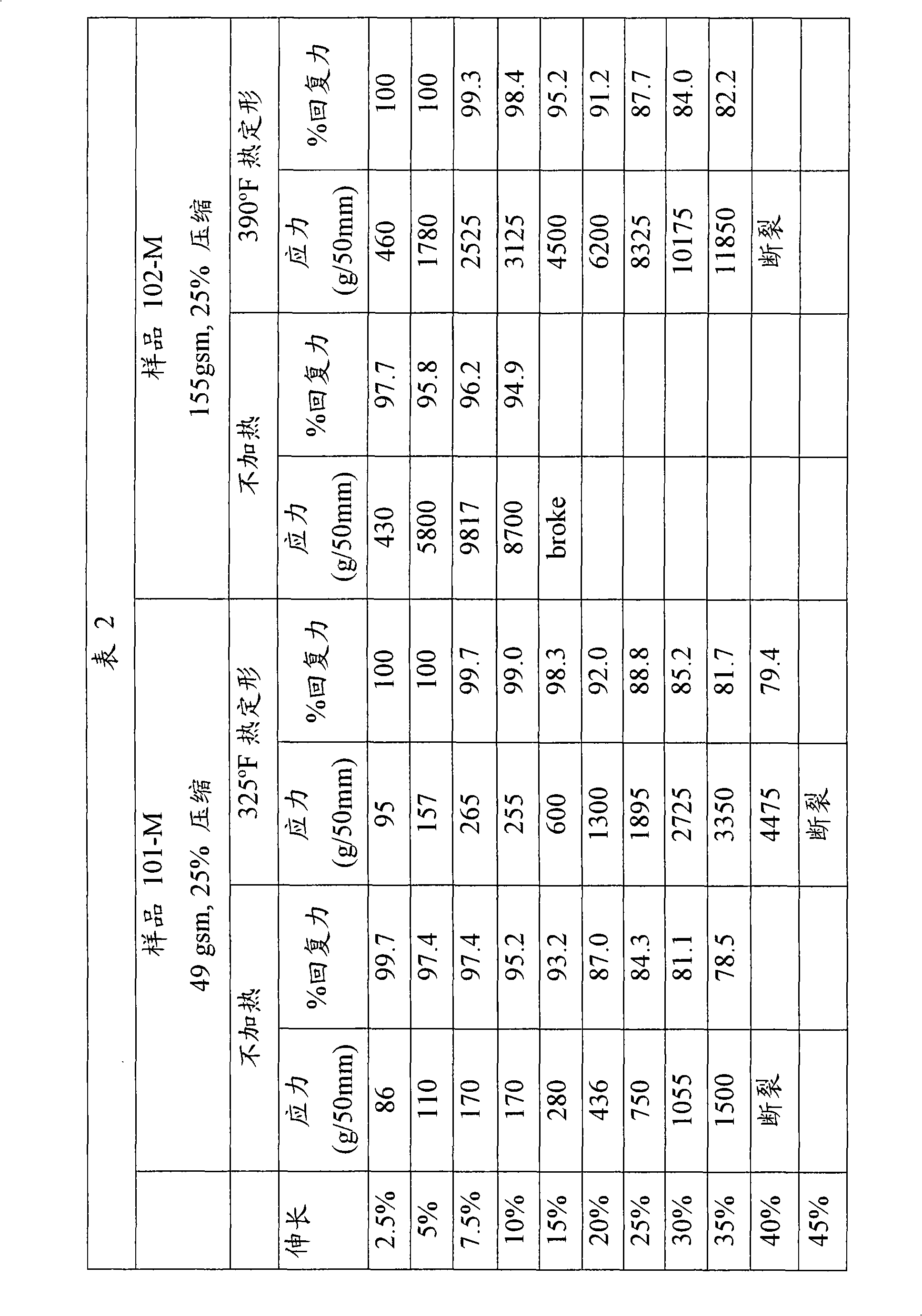

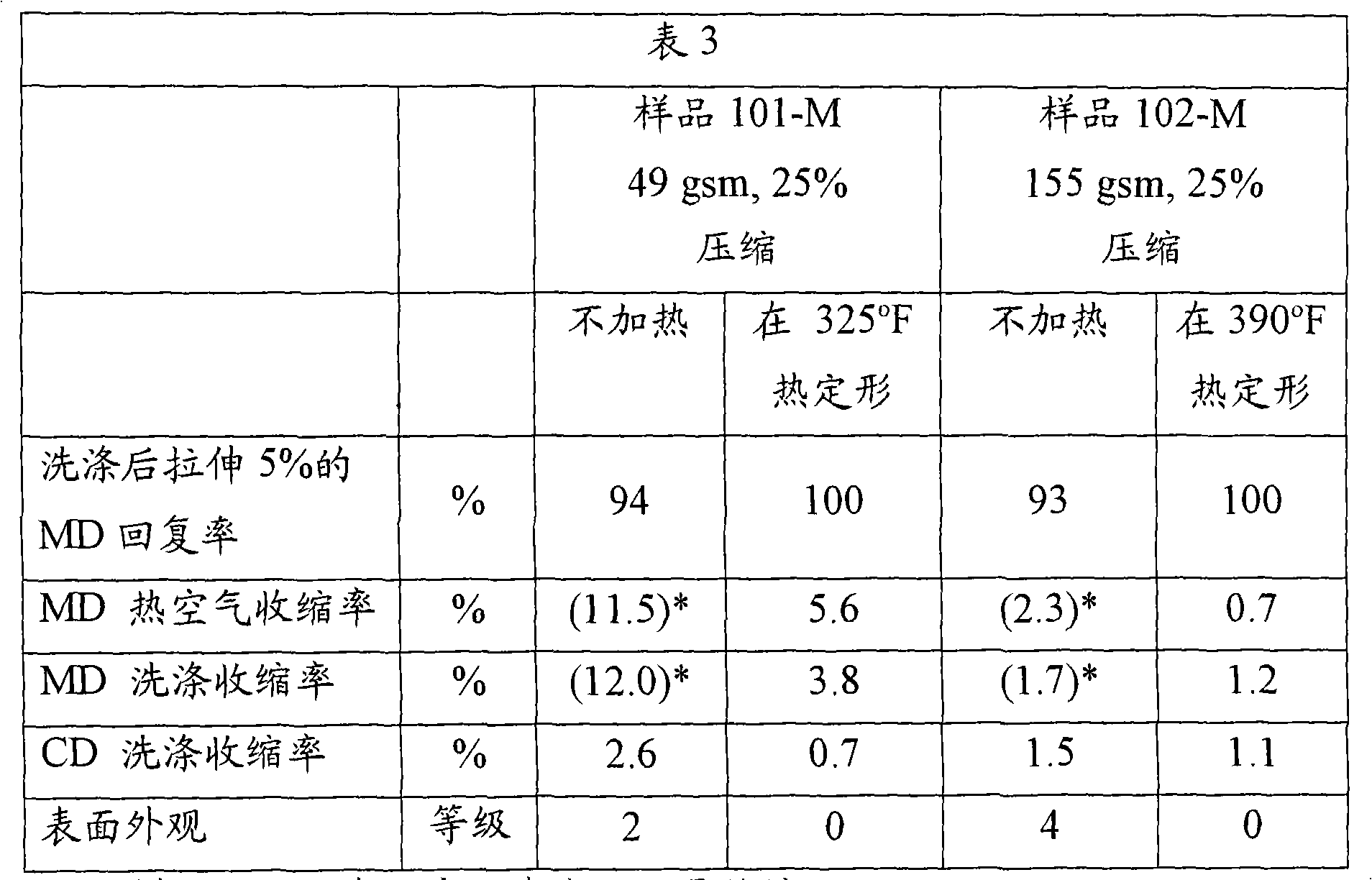

Highly Resilient, Dimensionally Recoverable Nonwoven Material

InactiveUS20080311343A1Low energy recoverable machine direction stretchImprove isotropic performancePattern makingLayered productsHeat settingWaste management

A microcreped wet laid nonwoven with recoverable stretch suitable for apparel applications such as waistbands and interlinings. The microcreping and heat setting improves dimensional stability after washing and drying cycles, minimizes shrinkage and substantially eliminates the surface wrinkling phenomenon, known in the industry as “alligatoring”, associated with wet laid and other apparel nonwovens.

Owner:A AHLSTROM CORP

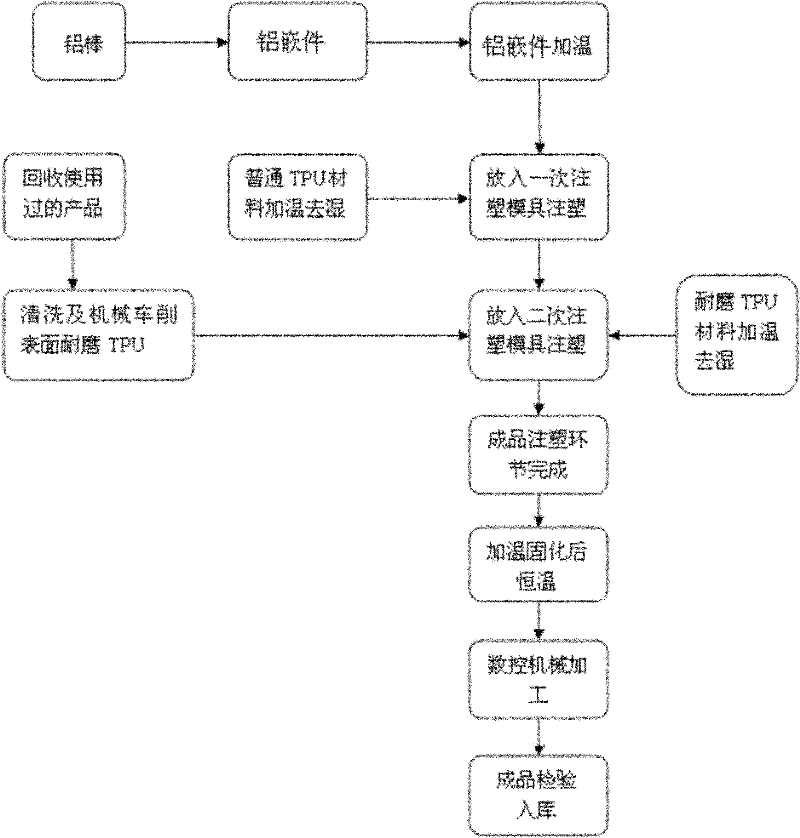

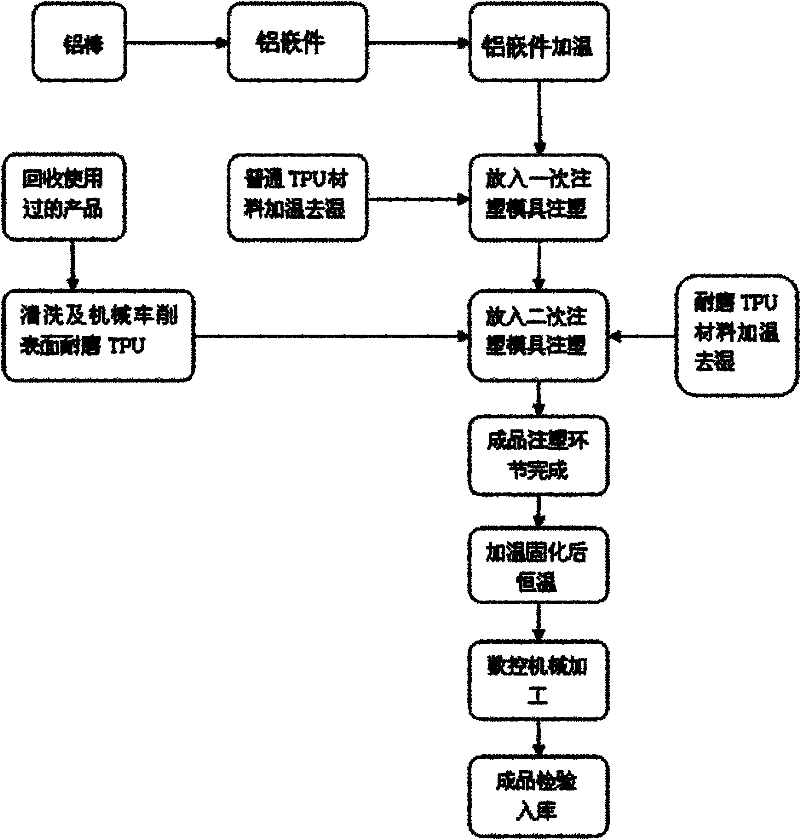

High-wear-resistant driving wheel processing process

The invention discloses a processing process of a high-wear-resistant driving wheel used in a crystalline silicon cutting machine. In the processing process, a two-time injection molding process is adopted, an inner layer is prepared from a common wear-resistant material and an outer layer is prepared from a high-wear-resistant material, thus on one hand, the product cost is lowered, and on the other hand, after the product is worn, the outer polyurethane layer is stripped off and injection-molding is carried out so as to finish a recycling reutilization process, therefore, the recycling cost is lowered, the reuse time of the high-wear-resistant driving wheel is high, the high-wear-resistant driving wheel can be recycled 10 times averagely, and an environmentally-friendly utilization effect is achieved. Before the first injection molding, heat treatment is carried out on an aluminum insert, thus the phenomenon of wrinkle and bubble existing on the injection-molded layer surface due to overlarge temperature difference between the aluminum insert and the injection-molded layer and the product yield is improved; and before mechanical processing, the secondary injection-molded product is subjected to heat insulation treatment, thus the problem of fluffing on the surface of the driving wheel in the use process is solved, materials are not stuck to the product surface during the mechanical processing of the product, and smoothness and cleanness of the mechanically processed product are guaranteed.

Owner:汤子仁

Method for adjusting and controlling surface wrinkling or wrinkle removing through oxidation-reduction environment

The invention discloses a method for adjusting and controlling surface wrinkling or wrinkle removing through the oxidation-reduction environment. The swelling state of a PANI film on the PDMS surface is adjusted and controlled through the oxidation-reduction environment, and then the surface topography of the PANI film is adjusted and controlled. The method includes the steps that a PDMS elastomer long-strip sample with the wrinkled PANI thin film on the surface is placed in a sodium borohydride solution, wrinkles on the surface disappear, the sample without the wrinkles is placed in a hydrogen peroxide solution, and the wrinkles on the surface appear again. The PDMS long-strip sample with the wrinkled PANI film on the surface is placed in a strong-oxidizing-property potassium peroxodisulfate solution, the wrinkles can also disappear, then the sample without the wrinkles is immersed in a hydrochloric acid solution, and the wrinkles can reappear. According to the method, reversible adjusting and controlling over the wrinkle topography are achieved through a simple operation mode and a novel oxidation-reduction means, a new way is developed for intelligent responsiveness surface preparing, adjusting and controlling, and a new idea is provided for functional-response-interface constructing.

Owner:TIANJIN UNIV

Curable organopolysiloxane composition

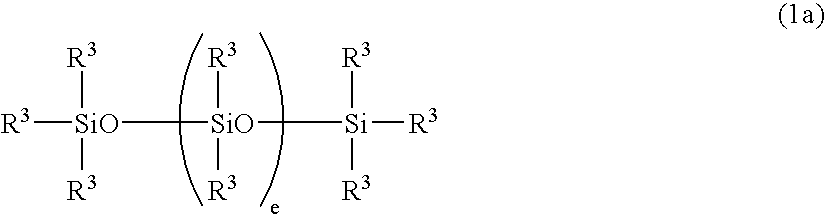

InactiveUS7741412B2No surface wrinklingImprove featuresSemiconductor/solid-state device detailsSolid-state devicesHydrogenHydrogen atom

A curable organopolysiloxane composition is provided, which includes (A) an organopolysiloxane containing at least one silicon atom-bonded alkenyl group within each molecule, (B) an organohydrogenpolysiloxane, which contains, within each molecule, at least one silicon atom-bonded hydrogen atom at a molecular chain terminal, and at least two silicon atom-bonded hydrogen atoms at non-terminal positions within the molecular chain, and which satisfies the formula shown below:0<α / β0.25(wherein, α represents the number of silicon atom-bonded hydrogen atoms at non-terminal positions within the molecular chain, and β represents the total number of silicon atoms within the component (B)), in sufficient quantity to provide from 0.1 to 5 silicon atom-bonded hydrogen atoms per silicon atom-bonded alkenyl group within the component (A), and (C) a platinum-based catalyst. The composition can be cured even at low temperatures, generates a cured product that suffers no surface wrinkling, and displays excellent storage characteristics.

Owner:SHIN ETSU CHEM IND CO LTD

Leather cooling device

InactiveCN103451321ASimultaneous cooling effectWon't wear outLeather manufacturingDomestic cooling apparatusEngineeringMechanical engineering

The invention discloses a leather cooling device which comprises a frame, wherein the frame is provided with at least one pair of rollers arranged side by side; each pair of rollers includes two rollers distributed in the vertical direction; the inside of each roller is hollow and is fully filled with cooling water; and leather is fed in from the left side and is attached to the outer wall of the roller in an S-shaped manner. Thus, both the upper surface and the lower surface of the fed leather can be in contact with the outer wall of the roller, so that both the two surfaces are cooled, thus avoiding the problem of uneven cooling and preventing surface wrinkling of the leather.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

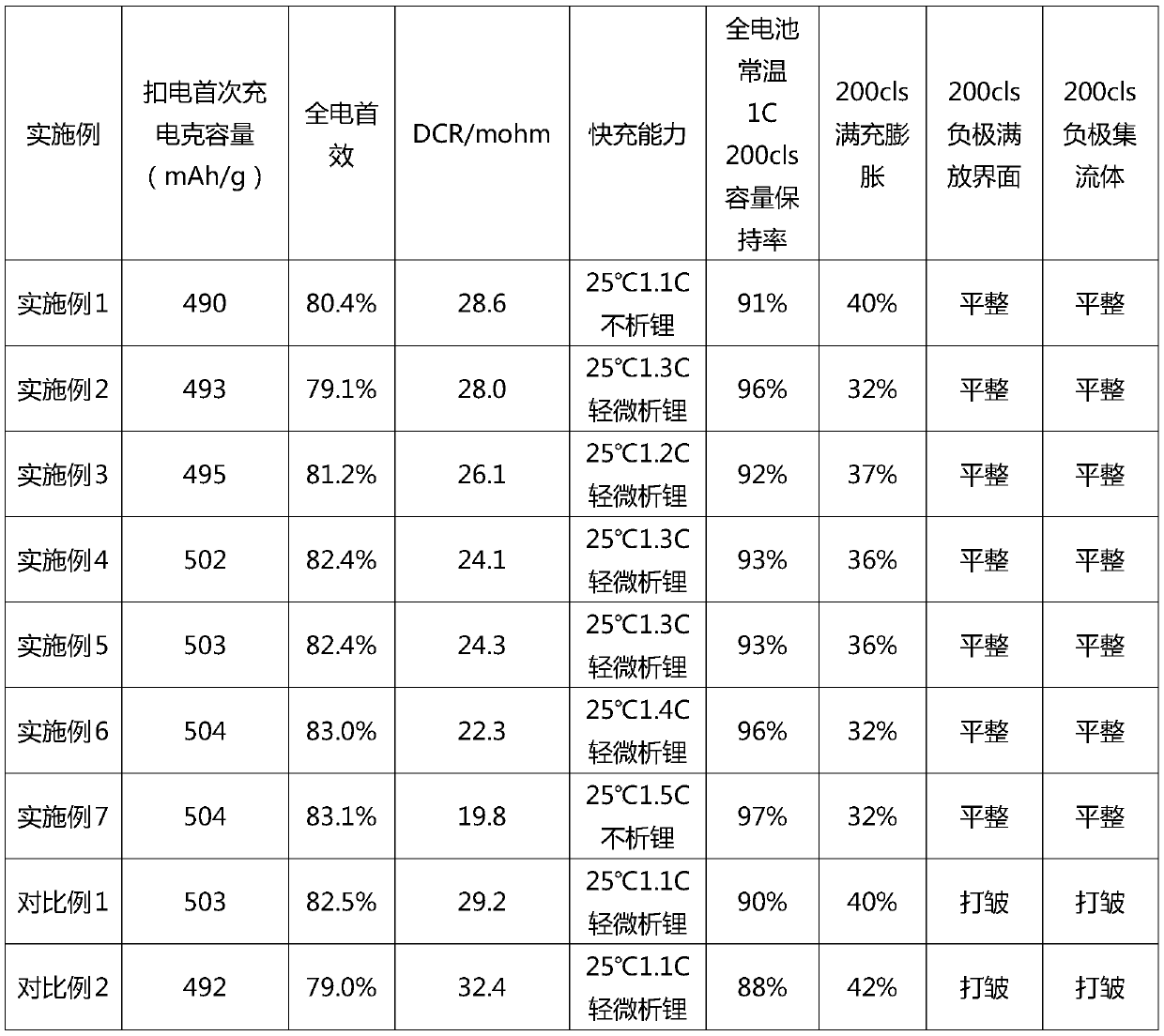

Negative electrode material, preparation method thereof and multilayer electrode

The invention relates to a negative electrode material, a preparation method thereof and a multilayer electrode. The negative electrode material is prepared from the following raw materials: SiOx, graphite, porous carbon and asphalt, and x is 0.1-2. The negative electrode material comprises SiOx, graphite, porous carbon and amorphous carbon, a low-expansion graphite layer and the porous carbon cover the surface of SiOx, the graphite layer can buffer volume expansion of SiOx, and meanwhile, the porous carbon has a certain pore volume, so that SiOx expansion is reduced, the electrode surface wrinkling phenomenon is overcome, the interface stability is improved, and the cycle life of the negative electrode is prolonged; and meanwhile, SiOx has relatively high gram volume, so that the energy density of the electrode can be improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

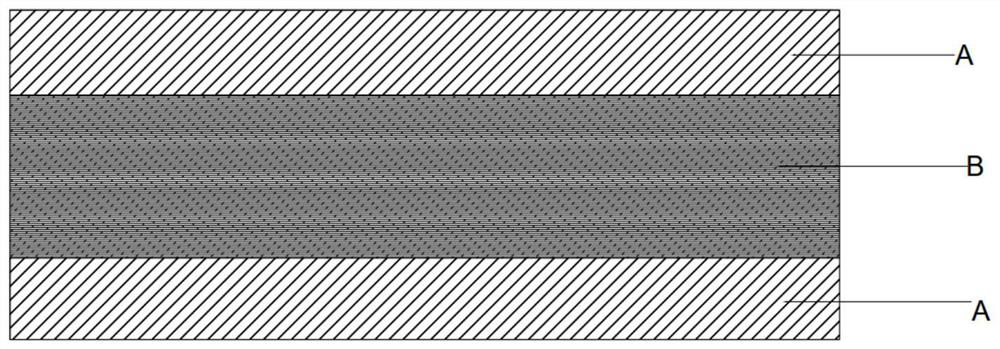

Flexible heat-shrinkable composite film formed by tape casting and preparation method of flexible heat-shrinkable composite film

PendingCN111976252AGuaranteed flexibilitySolve the phenomenon of poor shrinkage, etc.Flexible coversWrappersComposite filmButadiene Dioxide

The invention relates to a flexible heat-shrinkable composite film formed by a tape casting. The flexible heat-shrinkable composite film formed through tape casting is of an A / B / A three-layer composite structure, and the A layer is a surface layer and is mainly made of a mixture of PETG resin and an anti-blocking agent; and the layer B is a core layer and is mainly prepared from styrene-butadienesegmented copolymer (SBS) resin and maleic anhydride (MAH). The invention also provides a preparation method of the flexible heat-shrinkable composite film formed by tape casting. The heat-shrinkablecomposite film prepared by the method has the characteristics of wide shrinkage range, good flexibility, excellent printing performance and the like, and the phenomena of local pattern deformation, poor circular arc shrinkage and the like in the label sleeving process caused by high rigidity of a PETG film are avoided; and besides, the phenomena of film surface wrinkling and film layer separationcaused by inconsistent shrinkage of surface layer and core layer materials of a common composite film are avoided. The heat-shrinkable composite film prepared by the method has a wide market application space.

Owner:河南银金达新材料股份有限公司

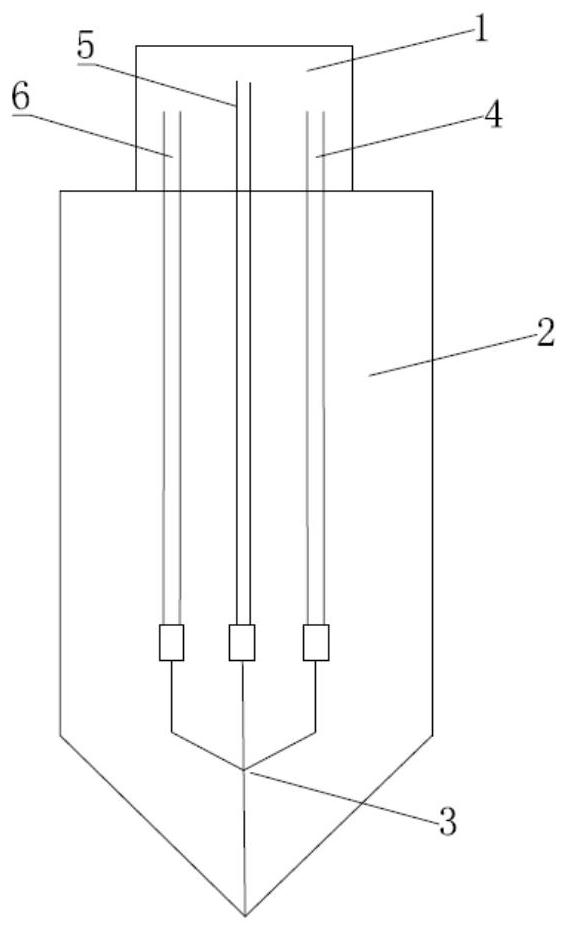

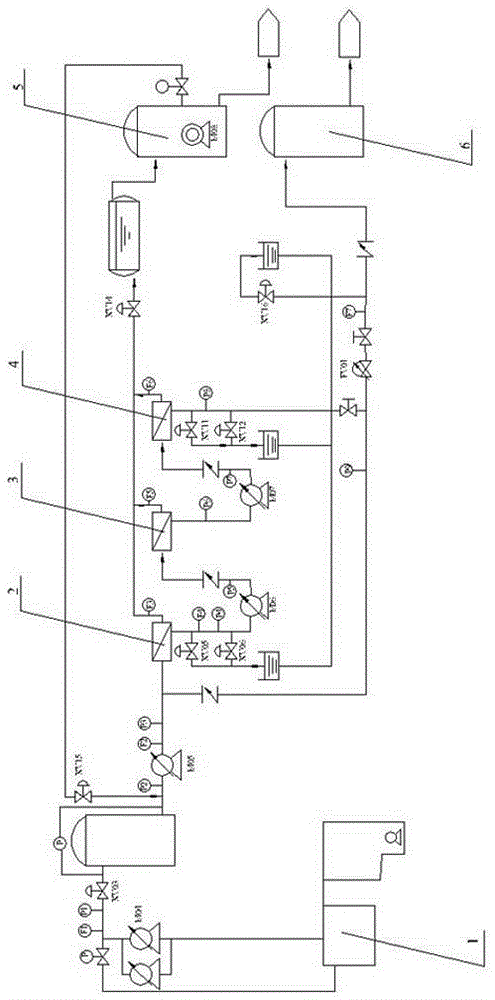

Reverse-flow-free nanofiltration apparatus or reverse osmosis apparatus and shutdown method thereof

ActiveCN105523609AExtended service lifeGuaranteed desalination effectWater treatment parameter controlMembranesDesalinationReverse osmosis

The present invention discloses a reverse-flow-free nanofiltration apparatus or a reverse-flow-free reverse osmosis apparatus, and in particular relates to a shutdown reverse-flow-free nanofiltration apparatus or a shutdown reverse-flow-free reverse osmosis apparatus. The shutdown reverse-flow-free nanofiltration apparatus or the shutdown reverse-flow-free reverse osmosis apparatus includes an adjusting tank and a filter film unit which is connected with the adjusting tank, the filter film unit is provided with a water inlet and two water outlets, the two water outlets are respectively connected with a production water tank and a concentration water tank, the concentration water tank and the production water tank are respectively provided with water discharge ports, the production water tank is provided with two water discharge ports, and one of the water discharge ports is connected with the water inlet of the filter film unit. When in shutdown work, water in the production water tank is led into the water inlet of the filter film unit by a pipe to replace water in the adjusting tank for sustained input, the phenomenon of reverse flow, which is caused by internal high osmotic pressure due to sudden shutdown of a high-pressure pump, of production water of a film to a concentration water side can be effectively avoided, filtrationfilm surface wrinkling and damage can be avoided, filtrationfilm desalination performance and system stability can be ensured, and the service life of the reverse-flow-free nanofiltration apparatus or the reverse-flow-free reverse osmosis apparatus can be prolonged.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Preparation method of full-light-control azobenzene thin film surface reversible wrinkle microstructure

The invention discloses a preparation method of a full-light-control azobenzene thin film surface reversible wrinkle microstructure. The method comprises the steps of mixing a PDMS prepolymer and a cross-linking agent according to the mass ratio being 10:1, fully stirring to form a uniform prepolymer, degassing the prepolymer in a vacuum pump, casting into watch glass, heating for 4h at 70 DEG C,and carrying out cross-linking and curing to obtain a PDMS elastomer; carrying out oxygen plasma surface active treatment on the PDMS elastomer, then spin-coating a tetrahydrofuran solution with PDO3with the mass fraction being 2 percent by weight, degassing in the vacuum pump, removing a residual organic solvent, and obtaining a PDMS / PDO3 soft-hard composite system; then irradiating through high-light-intensity visible light, and obtaining an azobenzene thin film with the surface wrinkling; then irradiating through low-light-intensity visible light, and gradually disappearing wrinkles so asto obtain an azobenzene thin film with the smooth surface; repetitively wrinkling / eliminating wrinkles for 10 to 20 times circularly. The method provided by the invention is clean and efficient, and the use of expensive instruments and the complicated operation step are avoided.

Owner:TIANJIN UNIV

Highly resilient, dimensionally recoverable nonwoven material

InactiveCN101258276AMechanical paper treatmentSynthetic cellulose/non-cellulose material pulp/paperEngineeringHeat setting

The present invention provides a microcreped wet laid nonwoven with recoverable stretch suitable for apparel applications such as waistbands and interlinings. The microcreping and heat setting improves dimensional stability after washing and drying cycles, minimizes shrinkage and substantially eliminates the surface wrinkling phenomenon, known in the industry as ''alligatoring'', associated with wet laid and other apparel nonwovens.

Owner:AHLSTROM MUNKSJO OYJ

Anti-wrinkling cold rolling method for 443 ultra-pure ferritic stainless steel

PendingCN114082782AIncreasing the thicknessEliminate and Improve Rolling Wrinkle DefectsTemperature control deviceMetal rolling arrangementsSS - Stainless steelSurface wrinkling

The invention provides an anti-wrinkling cold rolling method for 443 ultra-pure ferritic stainless steel. The method comprises the following steps of molding molten iron into a plate blank, rolling the plate blank into an NO1 plate, pickling and annealing the NO1 plate, rolling the NO1 plate into a cold-rolled hard steel coil by adopting a low pressure reduction rate and fewer passes, and finally slitting and packaging the steel coil. Compared with an existing 443 stainless steel rolling method, the anti-wrinkling cold rolling method has the effects that the rolling reduction rate is low, the total deformation amount is small, the surface wrinkling phenomenon of the plate is effectively reduced, and meanwhile the production efficiency is effectively improved due to the fact that the rolling reduction rate is low and the number of passes is small.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

UV curing device for groove body printing

The invention discloses an UV curing device for groove body printing, and belongs to the technical field of UV curing. The UV curing device for groove body printing comprises a support mechanism, an illumination curing mechanism and a location feeding mechanism, wherein the support mechanism is used for supporting and sealing the illumination curing mechanism; a lamp tube support is arranged in the illumination curing mechanism, an UV lamp tube is connected with the lamp tube support through a transversal connection plate, and the UV lamp tube is transversally suspended; and the location feeding mechanism is used for locating and placing a workpiece provided with a groove, and feeding the workpiece into a sealed space of the support mechanism through driving a cylinder body, and the UV lamp tube is enabled to stretch into the groove. According to the UV curing device for groove body printing, the suspended UV lamp tube stretches into the groove, and the inner surface of the groove is cured through illumination, so that the phenomenon of wrinkles on the inner surface of the groove is avoided, and a good use effect is achieved.

Owner:马鞍山甬兴模塑有限公司

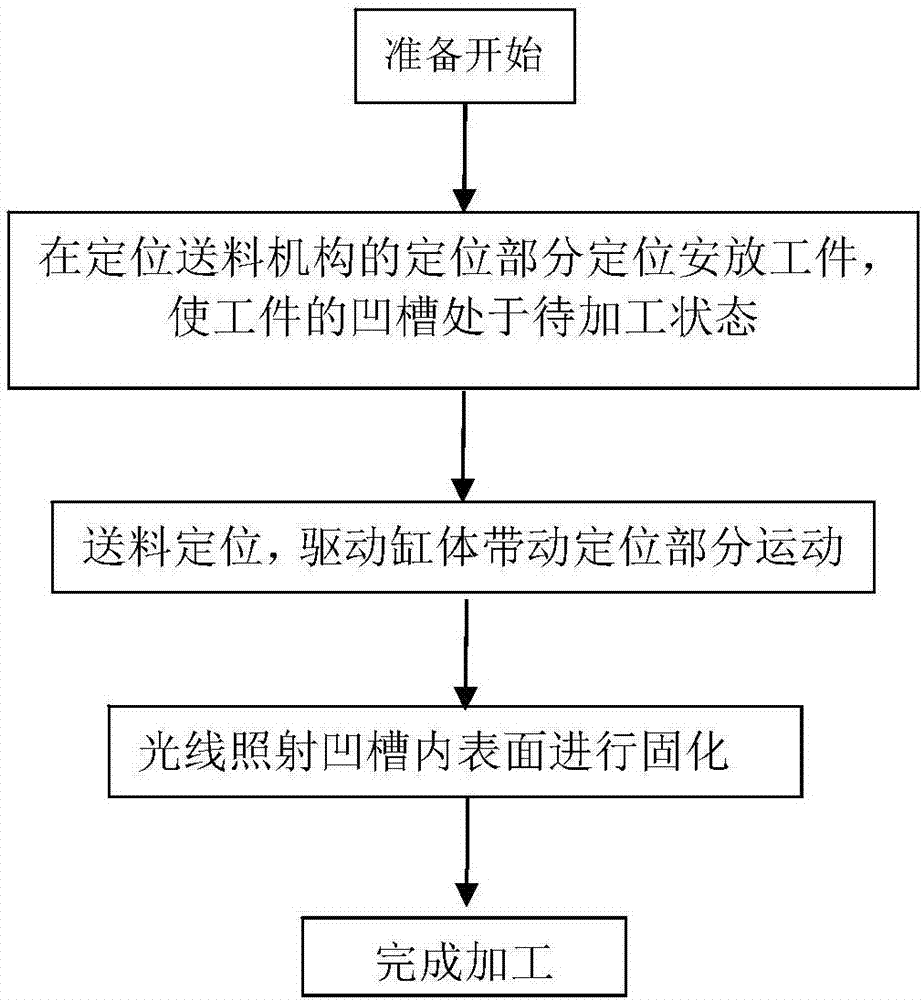

UV solidifying method for inner surface of groove body of printed workpiece

The invention discloses a UV solidifying method for the inner surface of a groove body of a printed workpiece and belongs to the technical field of UV solidifying. The UV solidifying method adopts a UV solidifying device for solidifying. According to the solidifying machining process, firstly the workpiece is positioned; the workpiece is positioned and placed on a positioning part of a positioning feeding mechanism, and feeding positioning is executed; a system switch is started, a driving cylinder body in a movement part of the positioning feeding mechanism drives the positioning part to move, and a UV lamp tube in an illuminating solidifying mechanism is inserted into a groove; the UV lamp tube works in the groove, and light rays illuminate the inner surface of the groove to conduct solidifying; and finally the driving cylinder body enables the positioning part to move out of an enclosed space formed by a supporting mechanism to return to an original station, and machining is completed. According to the UV solidifying method for the inner surface of the groove body of the printed workpiece, the UV lamp tube suspending in air is adopted to extend into the groove, the inner surface of the groove is illuminated and solidified, the phenomenon that the inner surface of the groove wrinkles is avoided, and a good using effect is achieved.

Owner:马鞍山甬兴模塑有限公司

Fluorescent glue capable of improving light spots and packaging process emplopying fluorescent glue

The invention belongs to the technical field of LED packaging, and discloses fluorescent glue for improving light spots. The fluorescent glue is characterized in that the fluorescent glue contains thefollowing components in parts by weight: 15-40 parts of fluorescent powder; 1-5 parts of diffusion powder; and 55-84 parts of glue, wherein the fluorescent powder is one of silicon-based nitride, europium-doped nitrogen oxide, aluminate and Ga-YAG or more. The invention also discloses a packaging process adopting the fluorescent glue. The invention aims to provide fluorescent glue capable of improving light spots and the packaging process employing the fluorescent glue. Through the improvement of the fluorescent glue, the settling speed of the fluorescent powder is reduced, and the fluorescent powder is effectively and uniformly diffused, so that the refraction route of emergent light is changed, the required color is maximized, the output of other miscellaneous colors is reduced, the surface wrinkling phenomenon of the glue is improved, and the refraction of the light is increased to improve light spots.

Owner:广东晶锐半导体有限公司

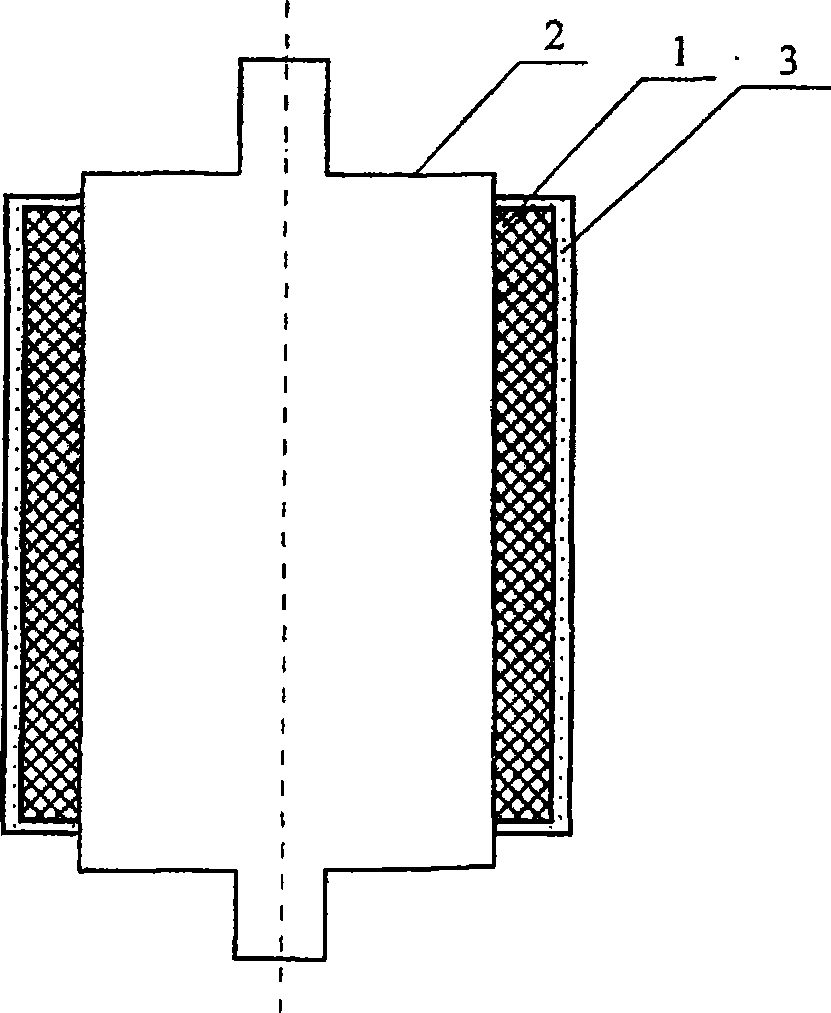

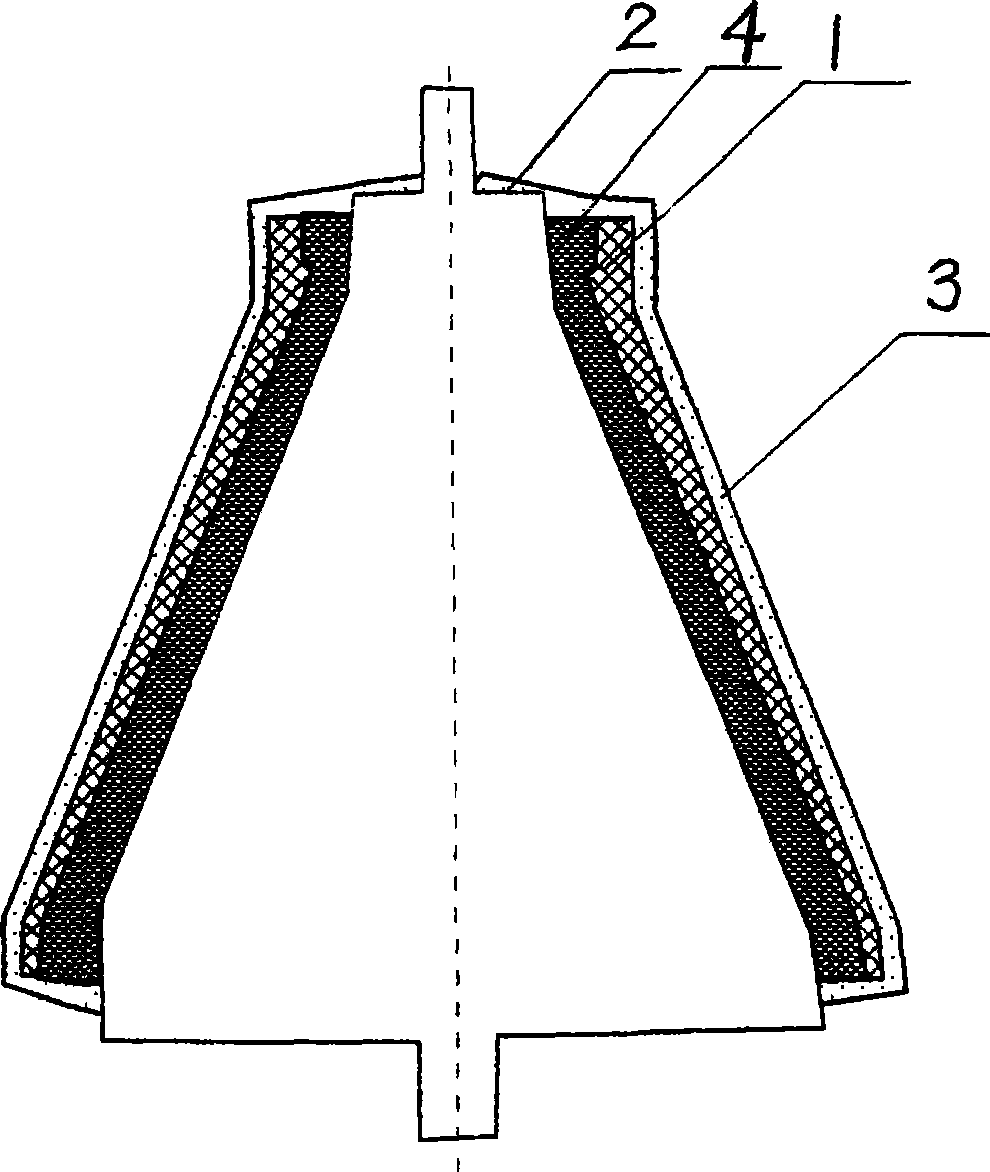

Method for solidifying cloth band winding phenoic composite material product

ActiveCN100496936COvercome timeOvercoming large investment in equipmentResin-Based CompositeConductor Coil

The present invention discloses a fast solidification method of parts made of phenolic aldehyde composite materials; the performed parts made of phenolic aldehyde composite materials by glass fiber / epoxy preimpregnated galloon is wound and the performed parts is solidified by an oven; and at last the compact products made of phenolic aldehyde composite materials are obtained. The present invention overcomes the defect that the solidification time of hydraulic kettle and air pressure kettle used at present is long; the equipment investment is large and the product cost is high; the present invention boasts of short process cycle and low cost; at the same time, the present invention solves the problem that the surface of the solidified product is crinkly after being solidified by the hydraulic kettle and air pressure kettle; the circumferential extension strength is promoted and net-shape product can be produced; the roughcast batch can be reduced and vacuum bags do not need to be manufactured; in this way, the present invention saves raw materials; the manufacturing of pressure layer adopts a fiber numerically controlled winder for winding which can meet the requirements of pressure layer molding of thin walls of different complicated shapes and parts made of different phenolic resin-based composite materials.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

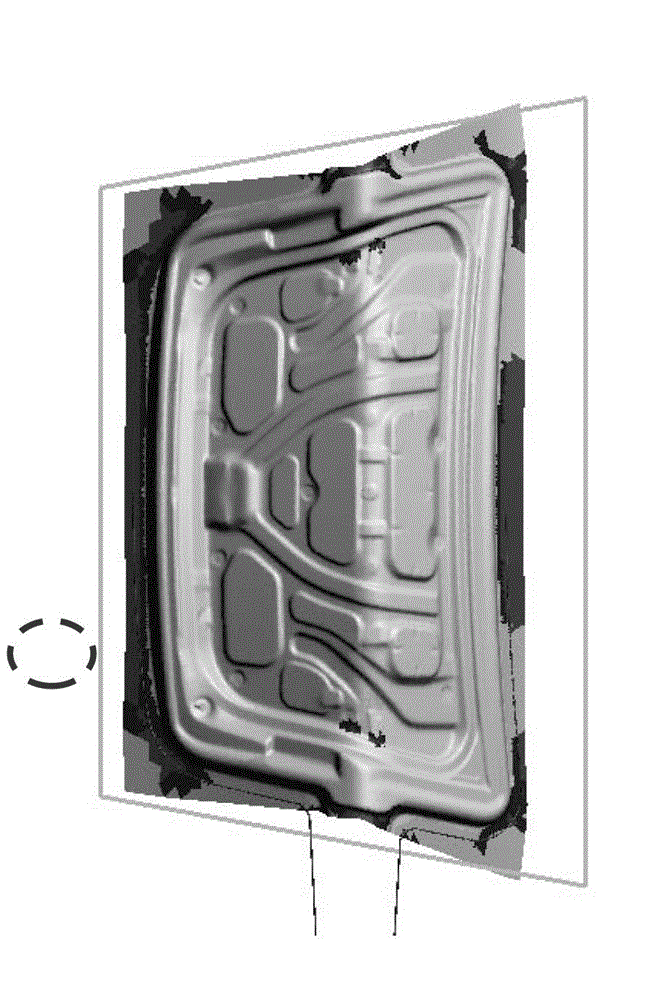

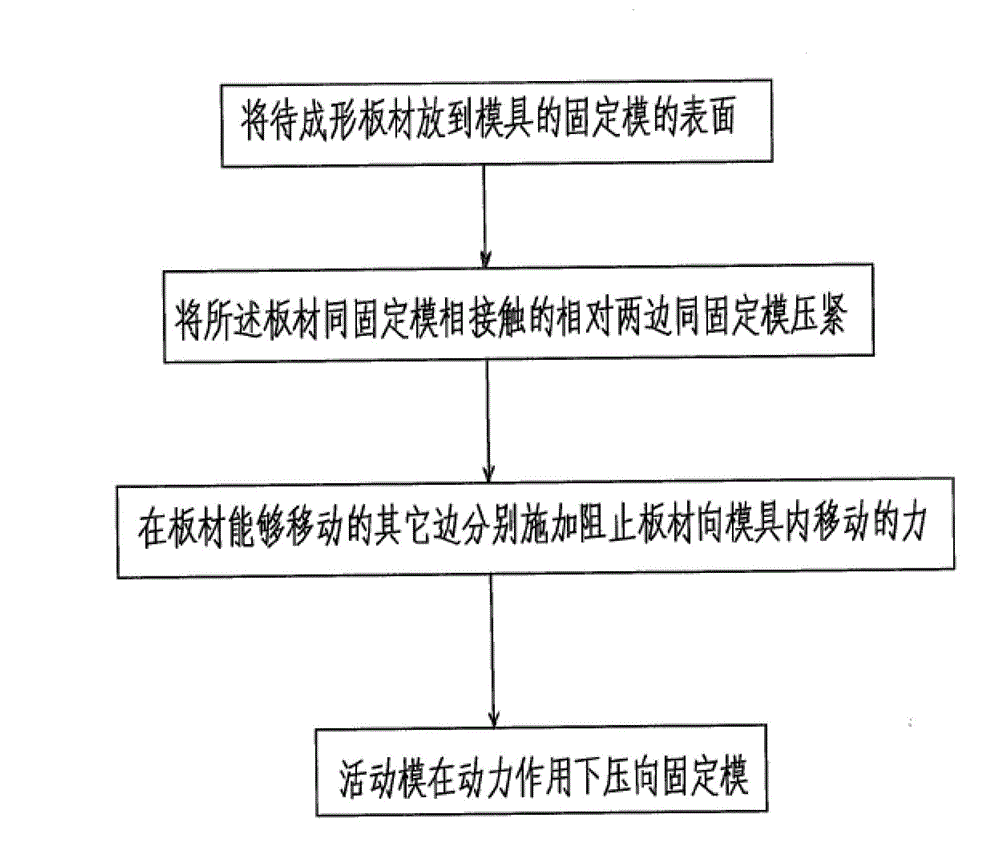

Method for forming tail door inner plate die surface

The invention relates to a die surface for controlling surface wrinkling when an automobile panel tail door inner plate is drawn to form. Specifically, the corresponding technological complement of an easy wrinkling position is made to form a 'residual part' characteristic; the corresponding technological complement of the easy wrinkling position adopts 'semi-opening' drawing; and a novel parting line mode is adopted, a panel veneer is reversely tensioned to control the panel veneer moving. The die surface well controls the wrinkling degree, the blank size is reduced, and the material utilization rate is greatly improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com