Fluorescent glue capable of improving light spots and packaging process emplopying fluorescent glue

A packaging process and fluorescent glue technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of unstable sedimentation process, low viscosity of fluorescent glue, etc. The basic effect of light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

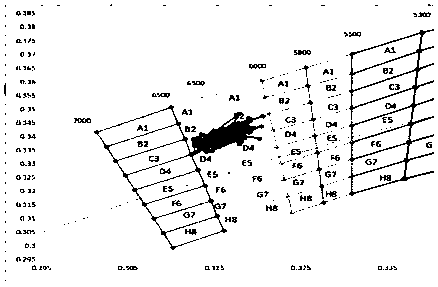

Image

Examples

Embodiment 1

[0027] Embodiment 1: A fluorescent glue for improving light spots, specifically including the following components:

[0028] 15 parts of silicon-based nitride;

[0029] 1 part of spherical micropowder of silicone resin;

[0030] 84 parts of silicone resin;

[0031] The particle size of the silicon-based nitride is 9um, the viscosity of the silicone resin is 4000pcs, and the refractive index is 1.54;

[0032] The preparation process of adopting described fluorescent glue is as follows:

[0033] (1) Put the silicon-based nitride, silicone resin spherical micropowder, and silicone resin into the machine and stir in four stages and vacuumize to prepare fluorescent glue;

[0034] The first stage: the stirring time is 30 seconds, the revolution speed is 600RPM, the rotation speed is 600RPM, and the vacuum value is 1.00KPa;

[0035] The second stage: the stirring time is 100 seconds, the revolution speed is 600RPM, the rotation speed is 400RPM, and the vacuum value is 1.00KPa;

...

Embodiment 2

[0042] Embodiment 2: A fluorescent glue for improving light spots, specifically including the following components:

[0043] 22 parts of europium-doped oxynitride;

[0044] 4 parts of spherical micropowder of silicone resin;

[0045] 76 parts of silicone resin;

[0046] The particle size of the europium-doped oxynitride is 11um, the viscosity of the silicone resin is 4500pcs, and the refractive index is 1.54;

[0047] The preparation process of adopting described fluorescent glue is as follows:

[0048] (1) Put the europium-doped nitrogen oxide, silicone resin spherical micropowder, and silicone resin into the machine and stir in four stages and vacuumize to prepare fluorescent glue;

[0049] The first stage: the stirring time is 30 seconds, the revolution speed is 600RPM, the rotation speed is 600RPM, and the vacuum value is 1.00KPa;

[0050] The second stage: the stirring time is 100 seconds, the revolution speed is 600RPM, the rotation speed is 400RPM, and the vacuum va...

Embodiment 3

[0057] Embodiment 3: A fluorescent glue for improving light spots, specifically including the following components:

[0058] 29 parts of aluminate;

[0059] 3 parts of spherical micropowder of silicone resin;

[0060] 69 parts of silicone resin;

[0061] The particle size of the aluminate is 13um, the viscosity of the silicone resin is 5000pcs, and the refractive index is 1.54;

[0062] The preparation process of adopting described fluorescent glue is as follows:

[0063] (1) Put the aluminate, silicone resin spherical micropowder, and silicone resin into the machine and stir in four stages and vacuumize to prepare fluorescent glue;

[0064] The first stage: the stirring time is 30 seconds, the revolution speed is 600RPM, the rotation speed is 600RPM, and the vacuum value is 1.00KPa;

[0065] The second stage: the stirring time is 100 seconds, the revolution speed is 600RPM, the rotation speed is 400RPM, and the vacuum value is 1.00KPa;

[0066] The third stage: the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com