Method for solidifying cloth band winding phenoic composite material product

A curing method and composite material technology, which is applied in the curing field of tape-wound phenolic composite material products, can solve the problems of long curing process time, large equipment investment, high production cost, etc., and achieve saving raw material consumption, reducing feeding amount, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

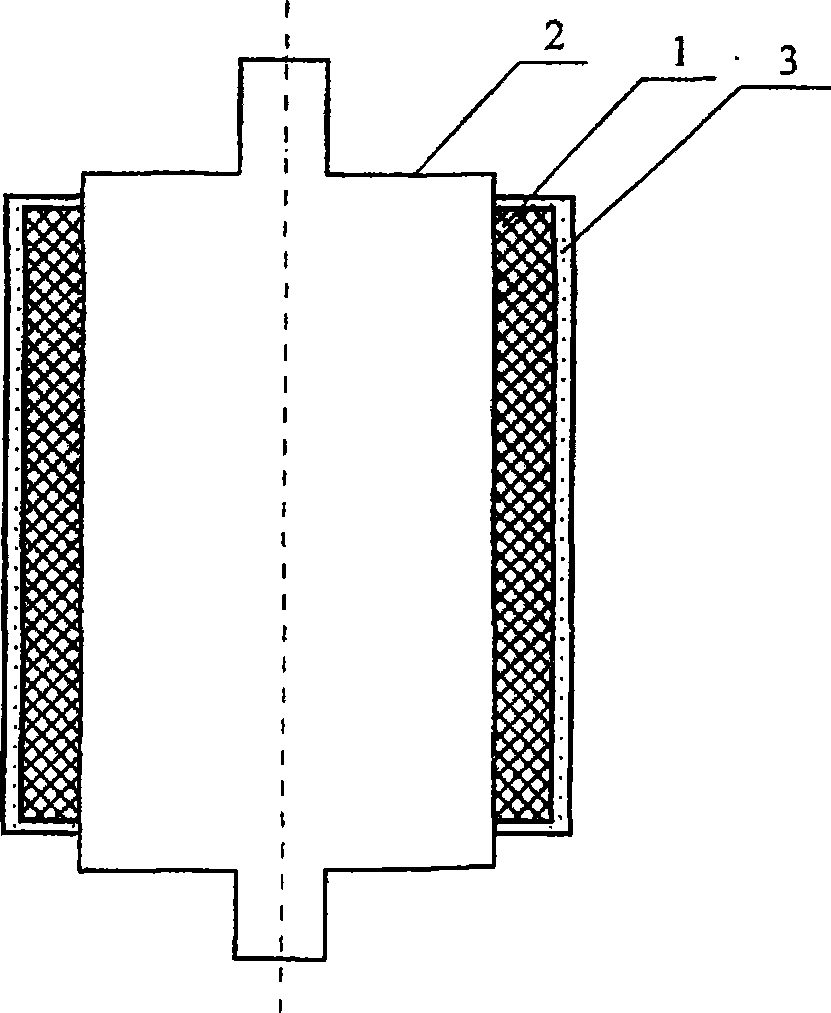

[0022] Such as figure 1 As shown, for the carbon / boron phenolic composite material combustion chamber blank 1 produced by cloth tape winding, the following curing method can be used: the combustion chamber blank 1 is placed on the lightweight mandrel 2, and then installed on the numerical control winding machine, the winding package Cover with perforated film, and then wrap a layer with glass fiber / epoxy E51 resin prepreg tape as pressure layer 3; then place it in an oven in a curing furnace and heat it up to 80°C for 3 hours; then continue to heat up to 175°C Solidify for 5 hours; take out the furnace after cooling down to remove the pressurized layer, and obtain a carbon / phenolic combustion chamber with a density of 1.42g / cm 3 .

Embodiment 2

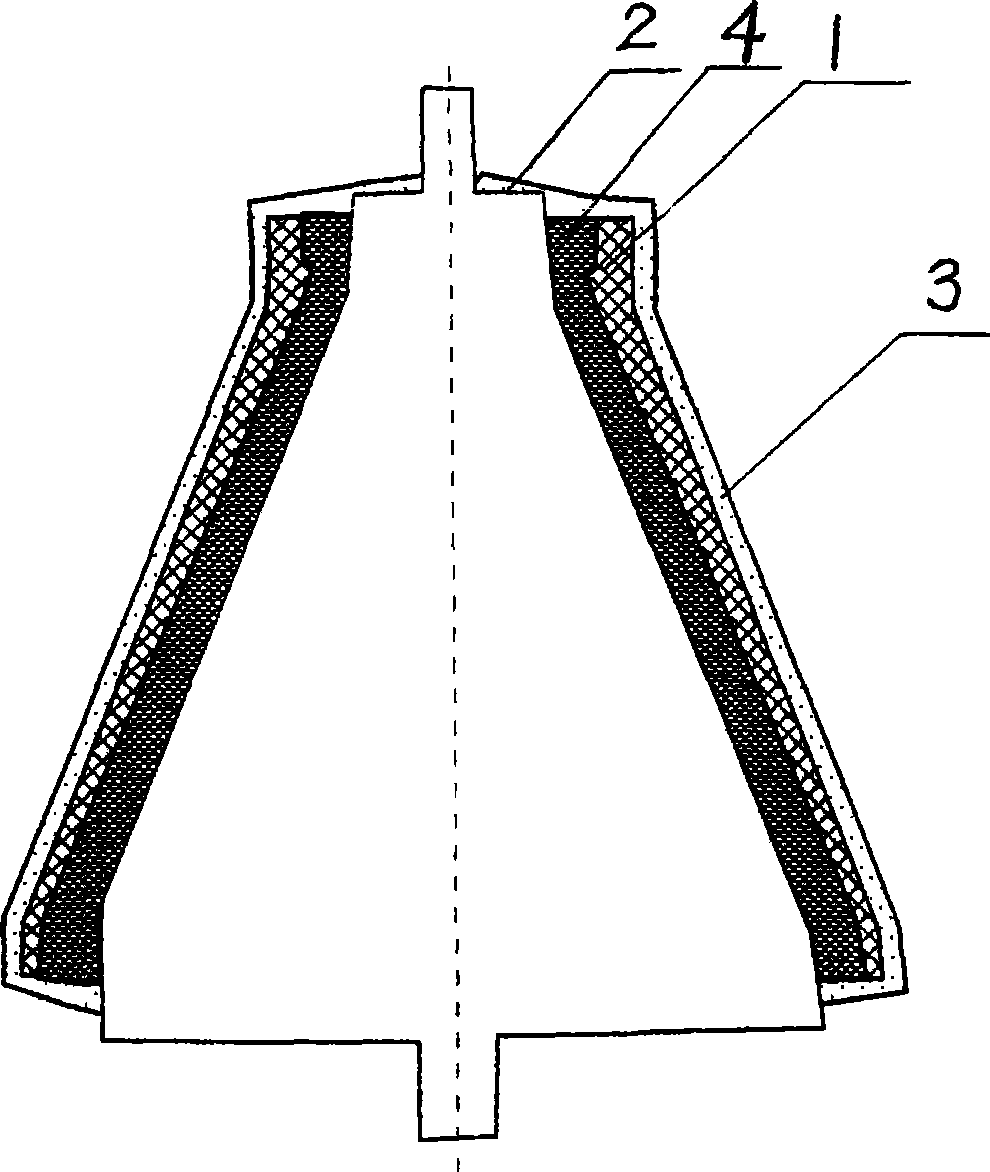

[0024] Such as figure 2 As shown, the following curing method can be used for the blank 1 of the tape-wound high silicon oxide / barium phenolic back wall insulation layer of the C / C expansion section 4: put the blank 1 on the lightweight mandrel 2, and then install it on the CNC winding machine , wound and coated with a perforated film, and then wrapped with a glass fiber / epoxy E51 resin prepreg tape as a pressure layer 3; then placed in an oven in a curing furnace to heat up to 80 ° C for 3 hours; then continue to heat up Cured at 155°C for 4 hours; after cooling down, it was removed from the furnace to remove the pressurized layer to obtain a high-silica / barium phenolic back wall insulation layer with a density of 1.67g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com