Method for preparing super active carbon by taking biomass power plant ash as raw material

A technology of biomass power plant ash and activated carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of insufficient utilization of active ingredients and pollution of the environment, and achieve the effect of optimizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

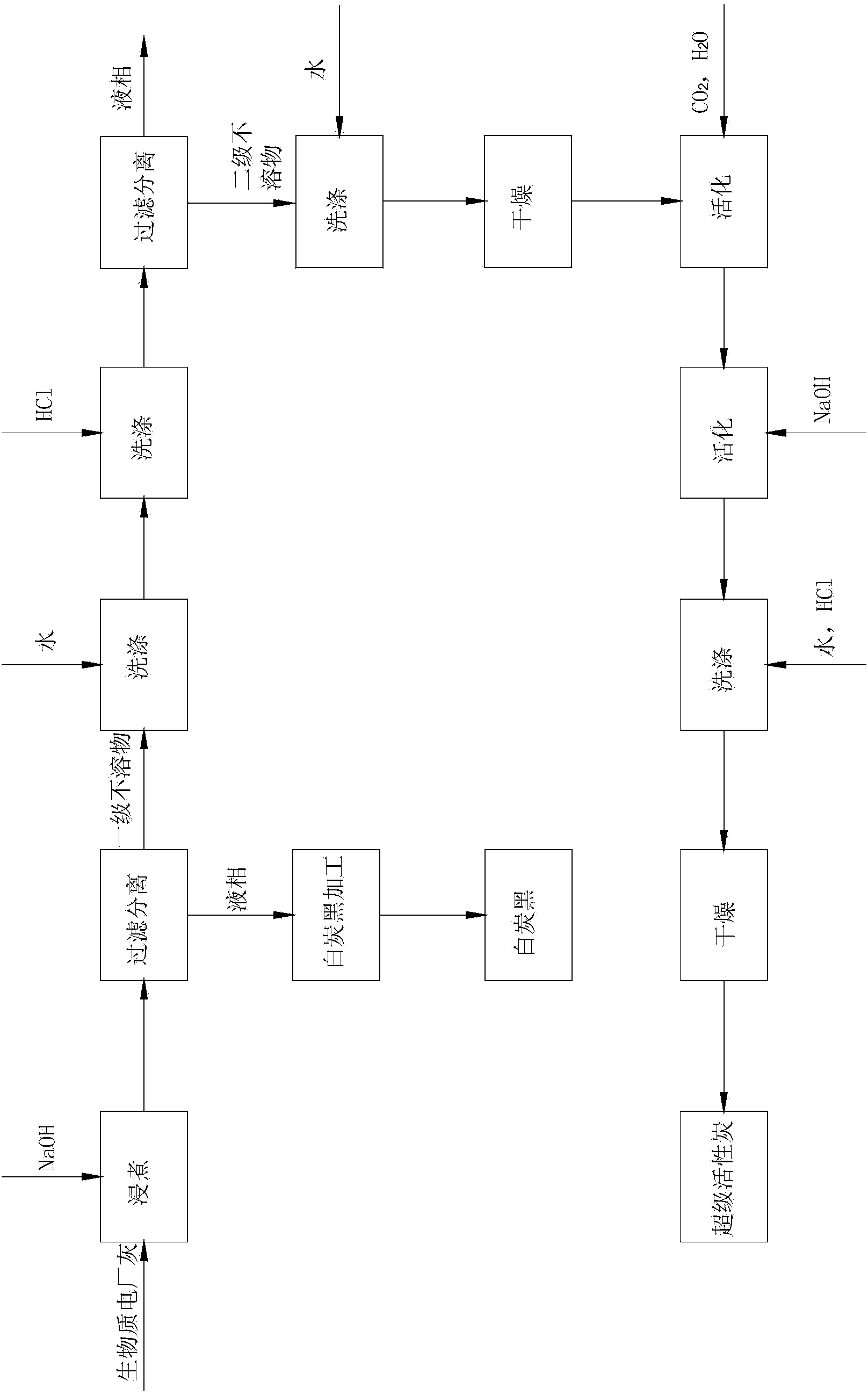

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing super activated carbon with biomass power plant ash as raw material, comprising the following steps:

[0039] 1) Add biomass power plant ash with a particle size of 20-50 μm into a NaOH solution with a mass percentage of 25-35%, and soak for 1.5-2.5 hours at a temperature of 85-90°C to make it fully react, filter and separate Obtain sodium silicate solution and primary insoluble matter; The obtained sodium silicate solution enters the operation of producing white carbon black to obtain white carbon black, wherein, the mass percent of each component in the biomass power plant ash is: SiO 2 : 55~75%; CaO: 8~15%; K 2 O: 3~9%; carbon residue: 4~8%; the balance is Fe 2 o 3 , MgO, P 2 o 5 and unavoidable impurities;

[0040] 2) Wash the primary insoluble matter obtained in step 1) in water for 2 to 3 times, then place it in hydrochloric acid solution, under the condition of controlling the pH to 1 to 3, carry out airtight stirring for 4 to 7 hours,...

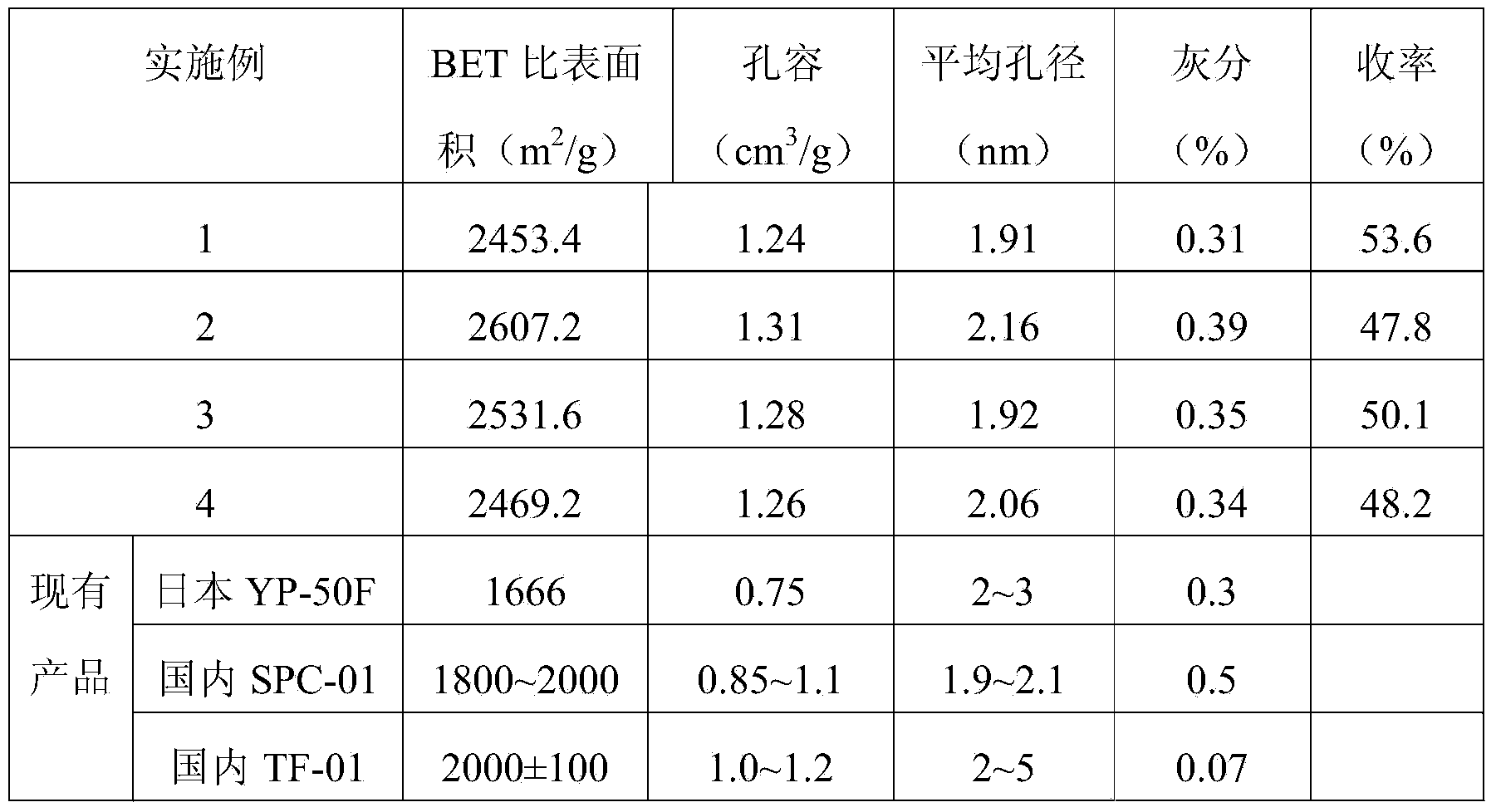

Embodiment 2

[0046] A method for preparing super activated carbon with biomass power plant ash as raw material, comprising the following steps:

[0047] Prepare charcoal residue with embodiment 1 method, difference is:

[0048] 1) Place the obtained carbon residue in water vapor and CO at a temperature of 800°C 2 Activated in a mixed gas environment to obtain an intermediate product of activated carbon, wherein water vapor and CO in the mixed gas 2 The volume ratio is 2:1, the flow rate of the mixed gas is 100ml / min, and the activation time is 2h;

[0049] 2) Mix the activated carbon intermediate product obtained in step 2) with NaOH, and activate it for 2 hours after heating up from room temperature to 800 °C at a heating rate of 4 °C / min in a nitrogen environment; the activated carbon intermediate product is obtained with The weight ratio of NaOH is 1:4,

[0050] 3) Wash the activated product obtained in step 5) with water for 2 times, then wash with 20% hydrochloric acid for 1 to 4 t...

Embodiment 3

[0053] A method for preparing super activated carbon with biomass power plant ash as raw material, comprising the following steps:

[0054] Prepare charcoal residue with embodiment 1 method,

[0055] 1) Put the obtained carbon residue in water vapor and CO at a temperature of 600°C 2 Activated in a mixed gas environment to obtain an intermediate product of activated carbon, wherein water vapor and CO in the mixed gas 2 The volume ratio is 3:1, the flow rate of the mixed gas is 400ml / min, and the activation time is 2h;

[0056] 2) Mix the activated carbon intermediate product obtained in step 2) with NaOH, and activate it for 1 hour after heating from room temperature to 900 °C at a heating rate of 5 °C / min in a nitrogen environment; the activated carbon intermediate product is obtained with The weight ratio of NaOH is 1:5,

[0057] 3) Wash the activated product obtained in step 5) with water for 2 times, then wash with 22% hydrochloric acid for 1 to 4 times, then wash with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com