Transfer tie-dyeing method and nylon-cotton lace fabric prepared by same

A technology of cotton and transfer medium, applied in the field of textile dyeing and finishing, can solve the problems of fabric area uncertainty, degree of tightness, poor color reproducibility, etc., achieve rich expression forms and technological means, improve dye utilization rate, color The effect of small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The sample of embodiment 1 brocade cotton edge lace fabric imitates color

[0046] The present embodiment is the sample color dithering before the large-scale production of brocade cotton edge lace fabric dyeing, and the dyestuff that adopts is reactive dyestuff. First, make a small sample according to the conventional dip-dyeing method, and then prepare the mass ratio concentration of the dye and auxiliaries according to the concentration ratio of the dip-dyeing formula, and make a transfer tie-dye sample to adjust the color depth.

[0047] In this embodiment, a grass-green color sample is used as an example, but it is not intended to limit the protection scope of the present invention.

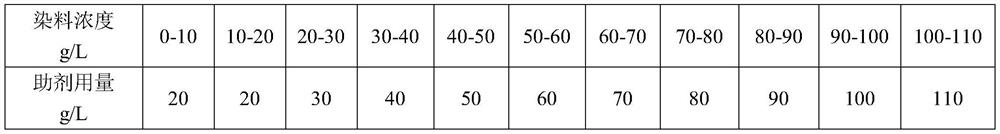

[0048] (1) Prepare the exhaust dyeing formula according to the standard color reference sample required by the customer. The formula and process conditions of dip-dyeing are shown in Table 1.

[0049] Table 1 Formula and dip-dyeing process condition table of grass green dip-dye samp...

Embodiment 2

[0060] Embodiment 2 The transfer tie-dyeing of brocade cotton edge lace fabric

[0061] The present embodiment provides the transfer tie-dyeing method of brocade cotton border lace fabric, and it comprises the following steps:

[0062] Pretreatment (bleaching→drying→cloth inspection→rolling)→gray fabric to be dyed→transfer medium preparation→transfer tie-dyeing→post-processing (stacking→drying→washing→soaping→dehydration→spreading→finished product setting).

[0063] (1) Gray cloth preparation: prepare the gray cloth to be dyed, which is a pretreated nylon cotton edge gray cloth, and its raw material composition includes 30% nylon and 70% cotton. Pretreatment includes bleaching, drying, cloth inspection and rolling.

[0064] (2) Transfer medium preparation: choose polyester air layer cloth (length 80cm, width 20cm, thickness 3mm) as the transfer medium, and bundle the polyester air layer cloth into a preset pattern to obtain a well-knotted transfer medium .

[0065] (3) Tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com