Bearing ring grinding tool and method

A bearing ring and grinding technology, which is applied in the field of bearing manufacturing, can solve problems such as unstable part processing quality, long tooling adjustment time, and process parameters that cannot be solidified, so as to improve product processing efficiency, improve grinding quality, and save tooling The effect of adjusting the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

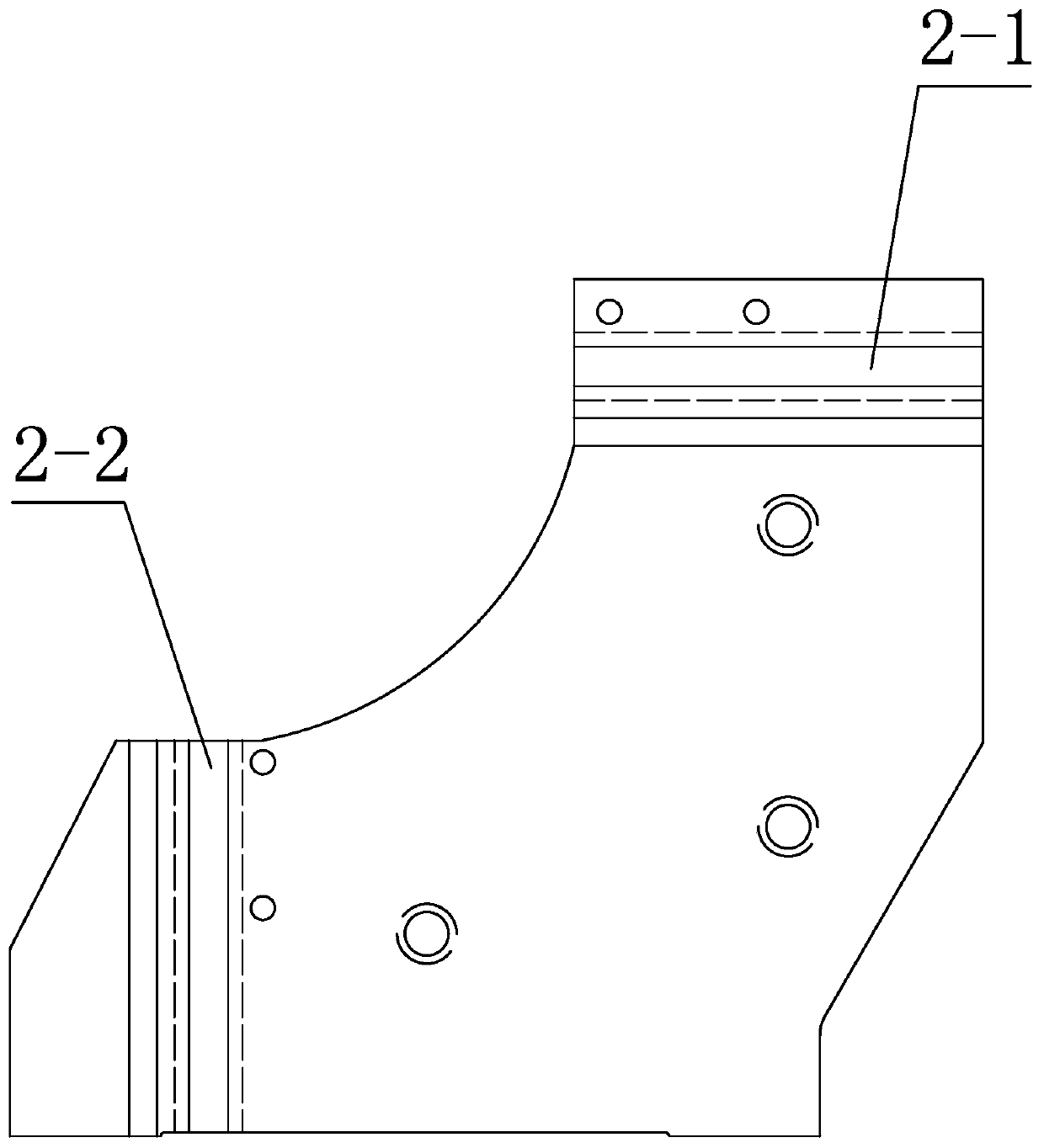

[0043] Specific implementation mode one: combine Figure 1 to Figure 6Describe this embodiment, a bearing ring grinding tool of this embodiment, which includes a positioning reference scale panel 1, a fulcrum seat 2, an adjustment knob 3, an axle 4, a horizontal fulcrum 5, a vertical fulcrum 6, and a main positioning pin 7 and auxiliary positioning pin 8, a dial is provided on the end face of the positioning reference scale panel 1, and the positioning reference scale panel 1 in the center of the dial is provided with a first assembly hole matched with the adjustment knob 3, and the fulcrum seat 2 passes through the main The positioning pin 7 and the auxiliary positioning pin 8 are fixed on the positioning reference scale panel 1, and the adjustment knob 3 includes a first cylinder 3-1, a second cylinder 3-2 and a pointer 3-3, and the second cylinder 3-2 is eccentrically arranged on the second cylinder 3-2. On the end face of a cylinder 3-1, the pointer 3-3 is set on the outer...

specific Embodiment approach 2

[0047] Specific implementation mode two: combination Figure 8 to Figure 11 , Figure 13 to Figure 15 Describe this embodiment, the structure of horizontal fulcrum 5 of this embodiment and vertical fulcrum 6 is identical, and horizontal fulcrum 5 comprises horizontal fulcrum rod 5-1, horizontal rotary shaft 5-3, horizontal fulcrum head 5-4 and two horizontal shafts. The retaining ring 5-5, the upper end surface of the horizontal fulcrum rod 5-1 is provided with a positioning groove 5-1-1 along the vertical direction, and the two side walls of the positioning groove 5-1-1 are provided with a horizontal axis of rotation 5 along the horizontal direction. -3 matched first shaft hole 5-1-2, the lower part of the horizontal support head 5-4 is inserted in the positioning groove 5-1-1, and the horizontal support head 5-4 is provided with a horizontal return along the horizontal direction. The second shaft hole 5-4-3 matched with the rotating shaft 5-3, the horizontal fulcrum head 5-...

specific Embodiment approach 3

[0048] Specific implementation mode three: combination Figure 8 to Figure 13 To illustrate this embodiment, the horizontal fulcrum 5 of this embodiment also includes a hexagon socket head cap screw 5-2, and the bottom surface of the positioning groove 5-1-1 is also provided with a locking groove 5-1-3 along the vertical direction, and the lock The two side walls of the tight groove 5-1-3 are provided with the first threaded hole 5-1-4 matched with the hexagon socket head screw 5-2 along the horizontal direction, and the horizontal support head 5-4 passes through the hexagon socket head screw 5-2 is fixedly connected with horizontal fulcrum rod 5-1. Set in this way, when the horizontal fulcrum 5 slides to the outer circle of the opposite axle 4 along the horizontal fulcrum slot 2-1, after the horizontal fulcrum 5 is in close contact with the opposite axle 4, screw the hexagon socket head cap screw 5-2 on the first thread In the hole 5-1-4, the horizontal fulcrum head 5-4 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com