Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Avoid risk of cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid end

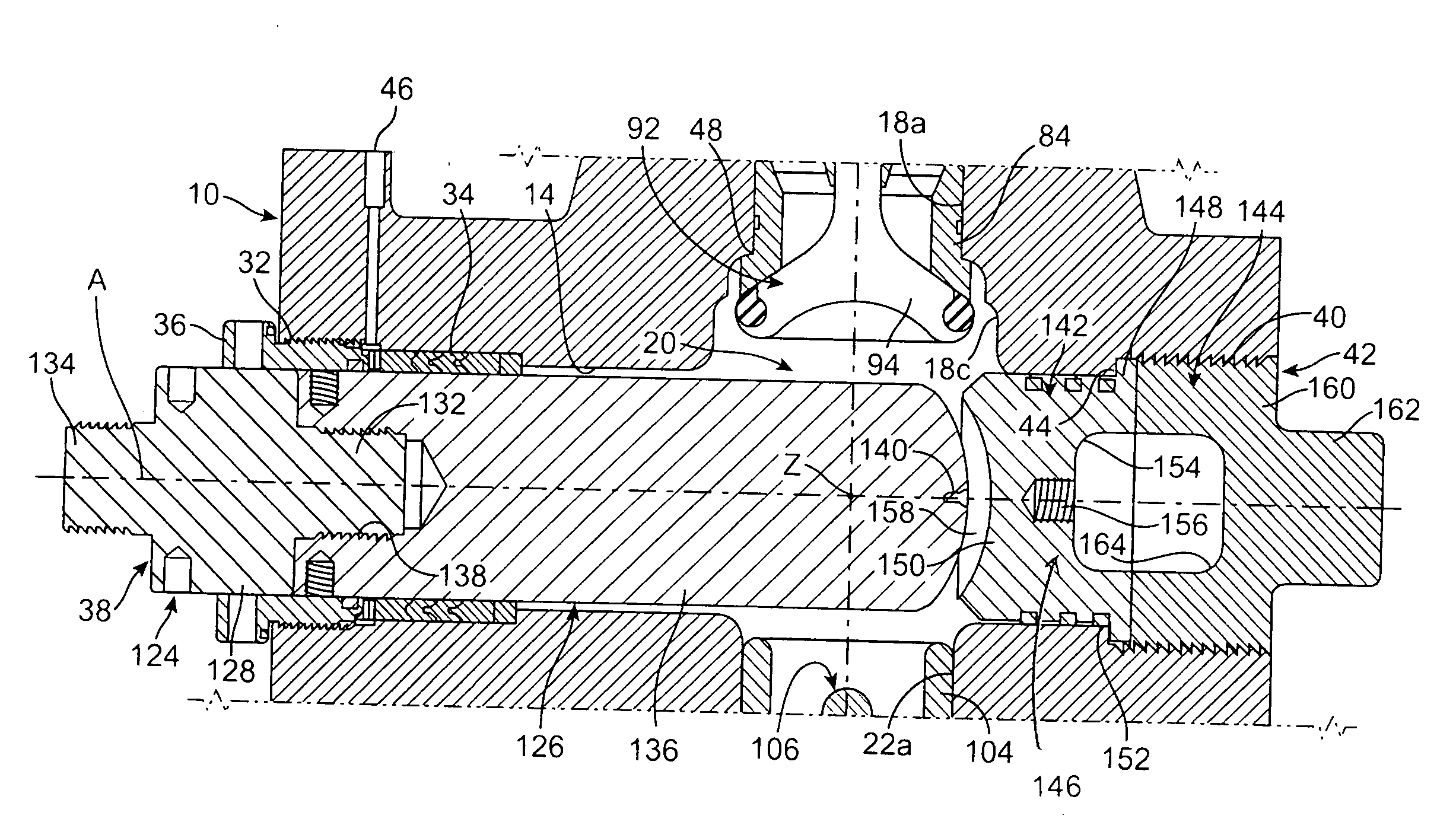

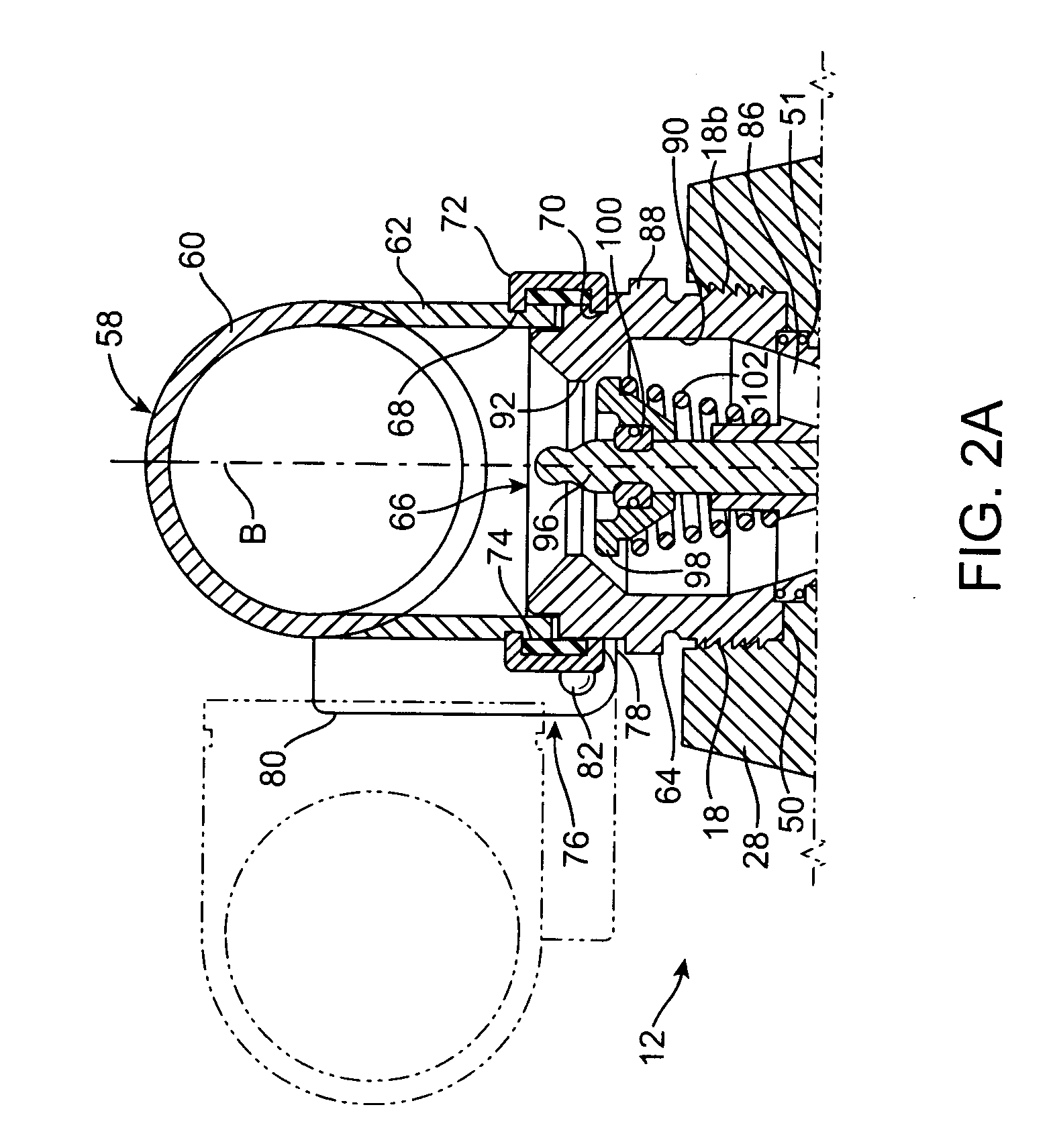

InactiveUS20110189040A1Reduce manufacturing costEasy to usePositive displacement pump componentsPositive-displacement liquid enginesPump chamberEngineering

A fluid end for a high-pressure pump including a metallic block having a front, back, top, bottom, and opposed sides. The block has a horizontal, plunger passage extending from the front to the back thereof. A horizontal, outlet passage extends from one of the opposed sides of the block to the other with the outlet passage being positioned beneath, and at right angles to, the plunger passage. A suction passage extends vertically downward from the top of the block and intersects the plunger passage to define a pumping chamber at the point of intersection. A discharge passage extends vertically downward from the pumping chamber to the bottom of the block. The discharge passage is located adjacent to the outlet passage. A connector passage extends from the discharge passage to the outlet passage so as to place the discharge passage and outlet passage in fluid communication. A reciprocating plunger assembly is located the end of the plunger passage adjacent the back of the block. A plug is located in the end of the plunger passage adjacent the front of the block. A suction valve is located in the suction passage. A discharge valve is located in the discharge passage. A fluid supply manifold is pivotally secured to the top of the block and is in fluid communication with the suction passage.

Owner:J MAC TOOL

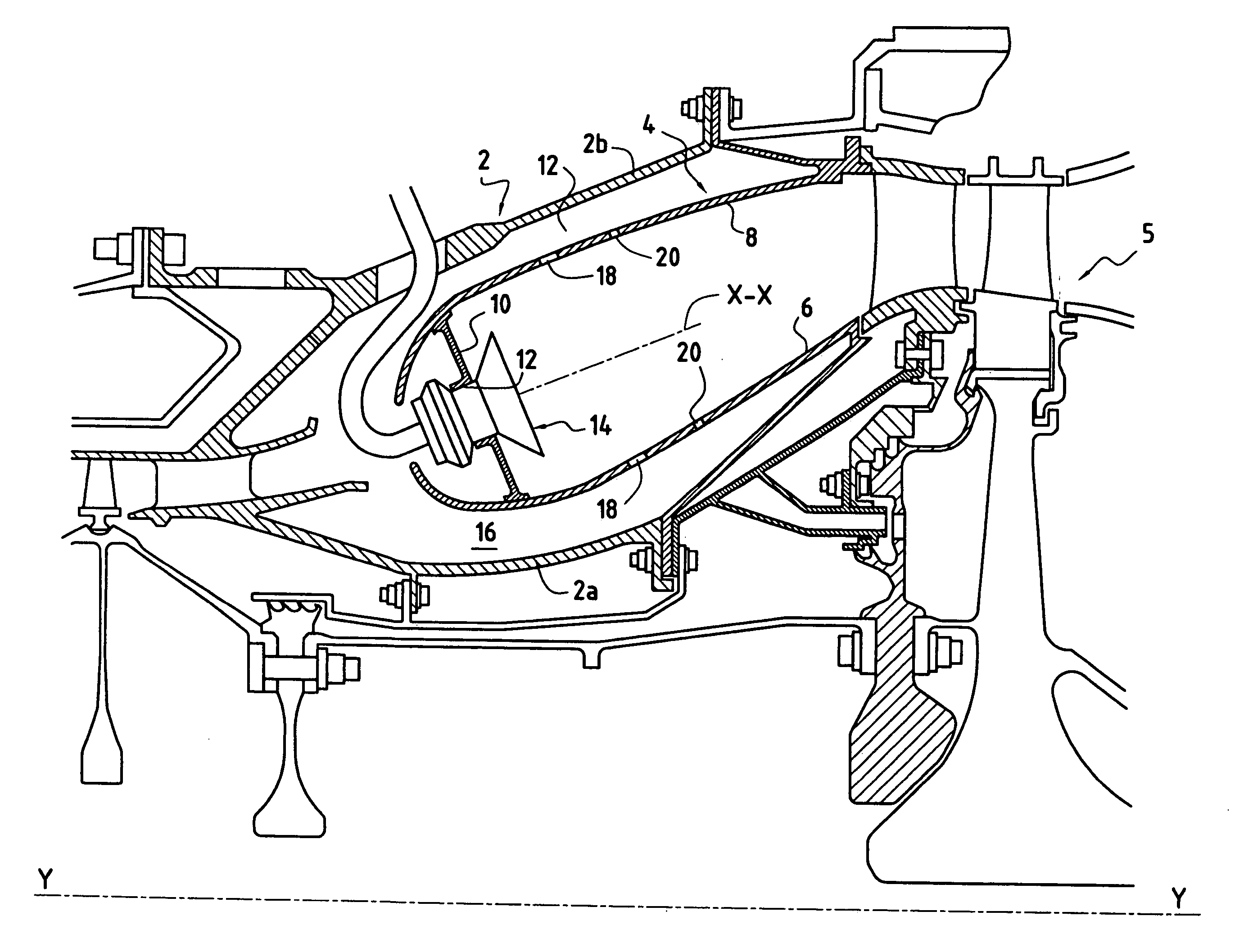

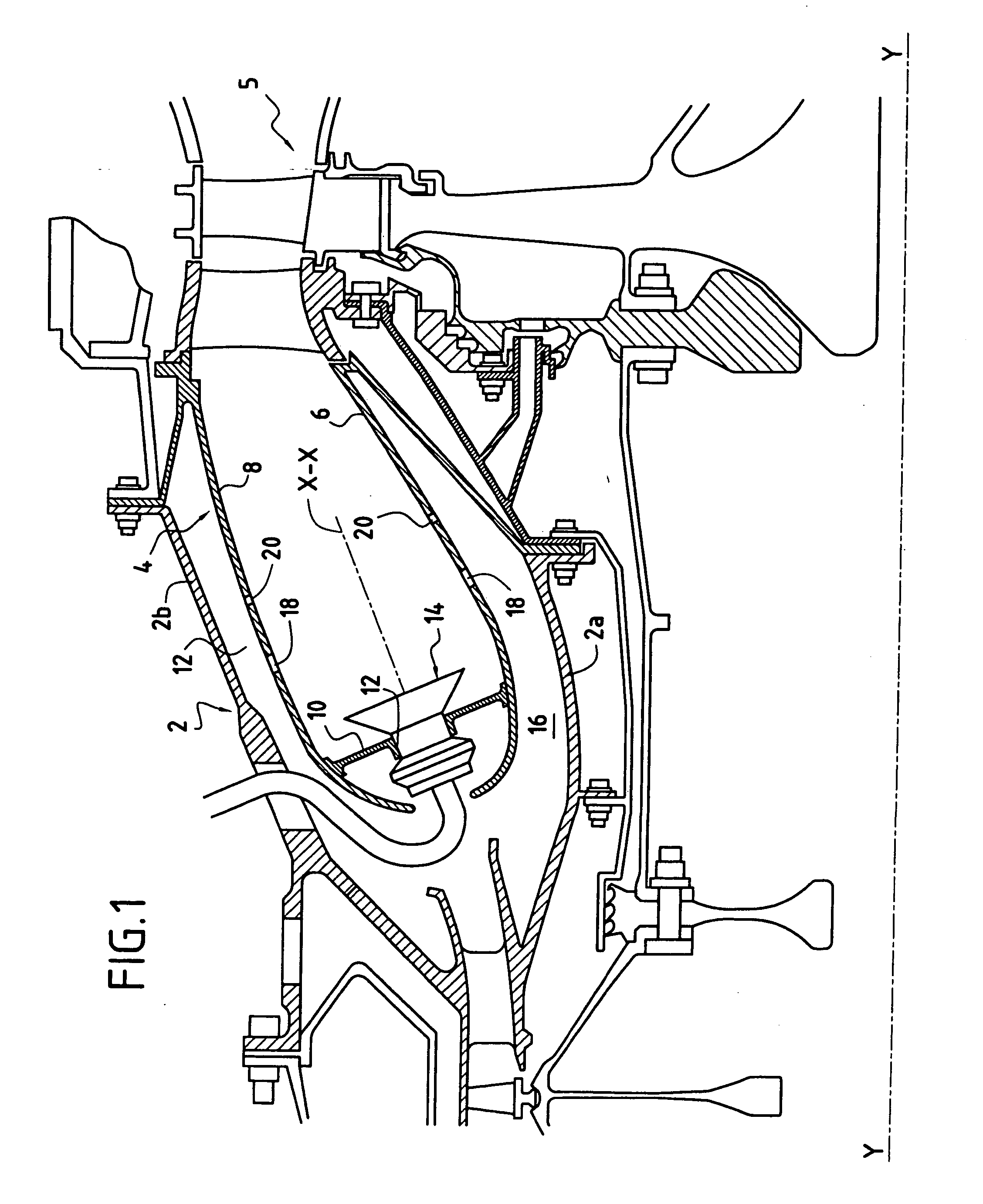

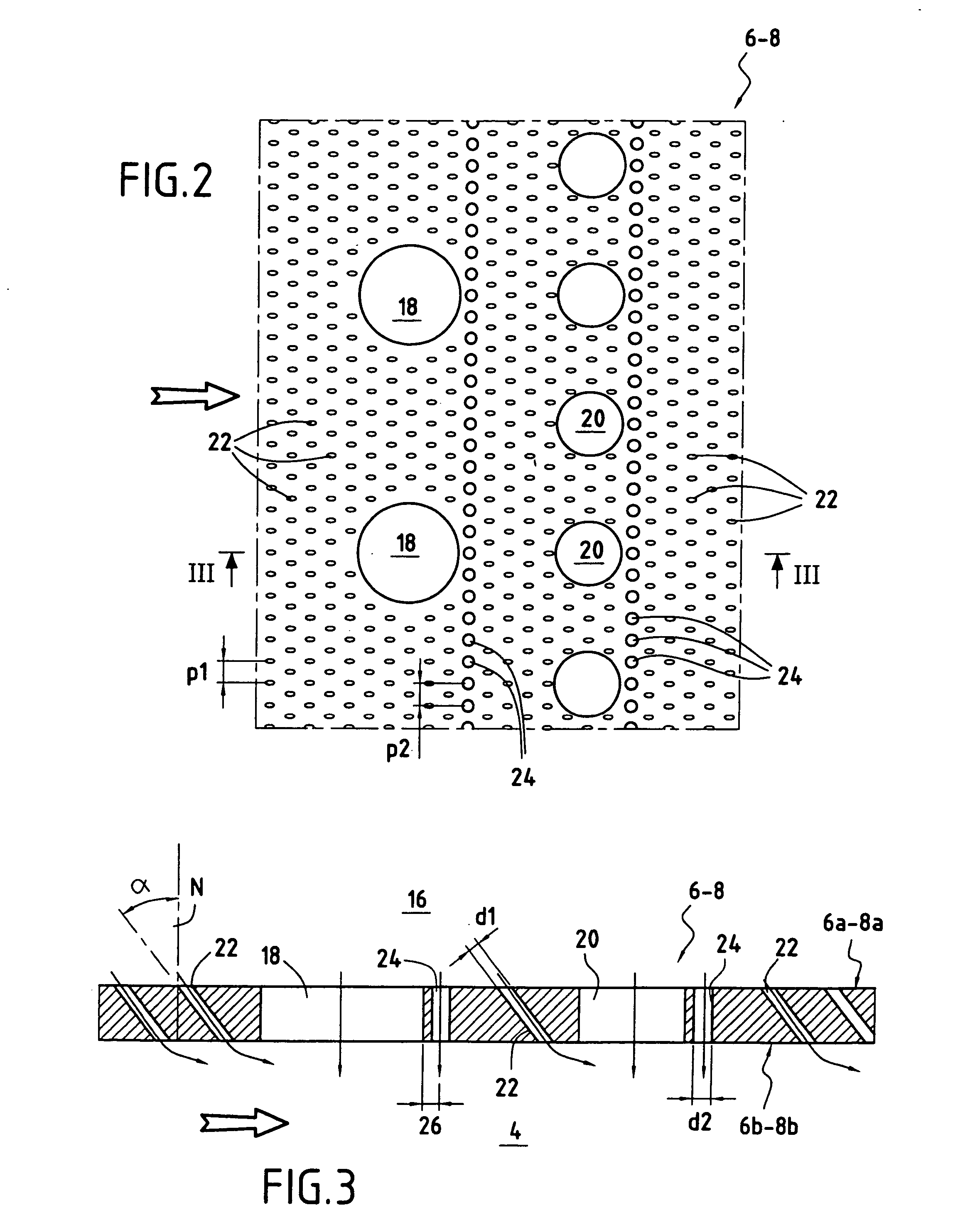

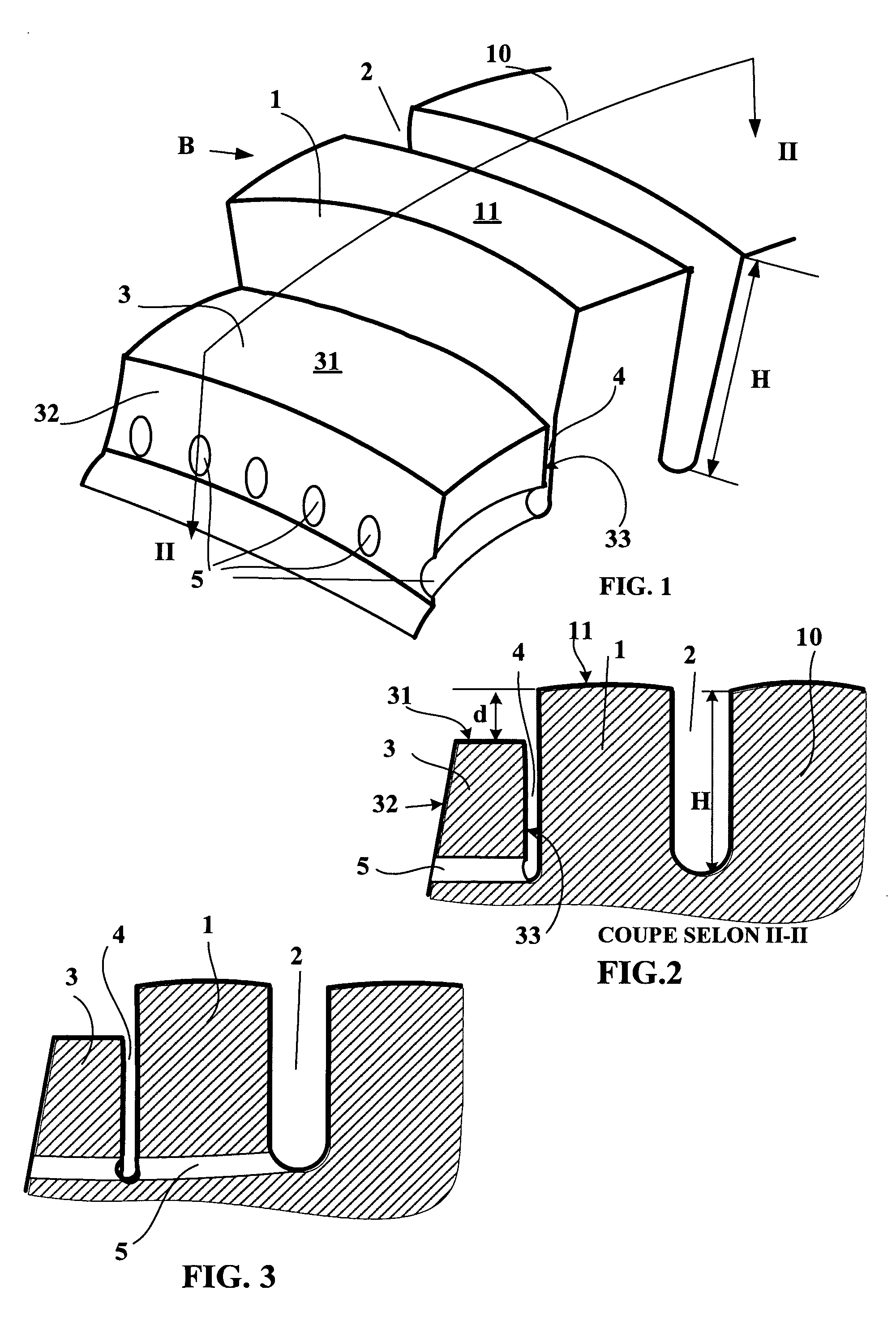

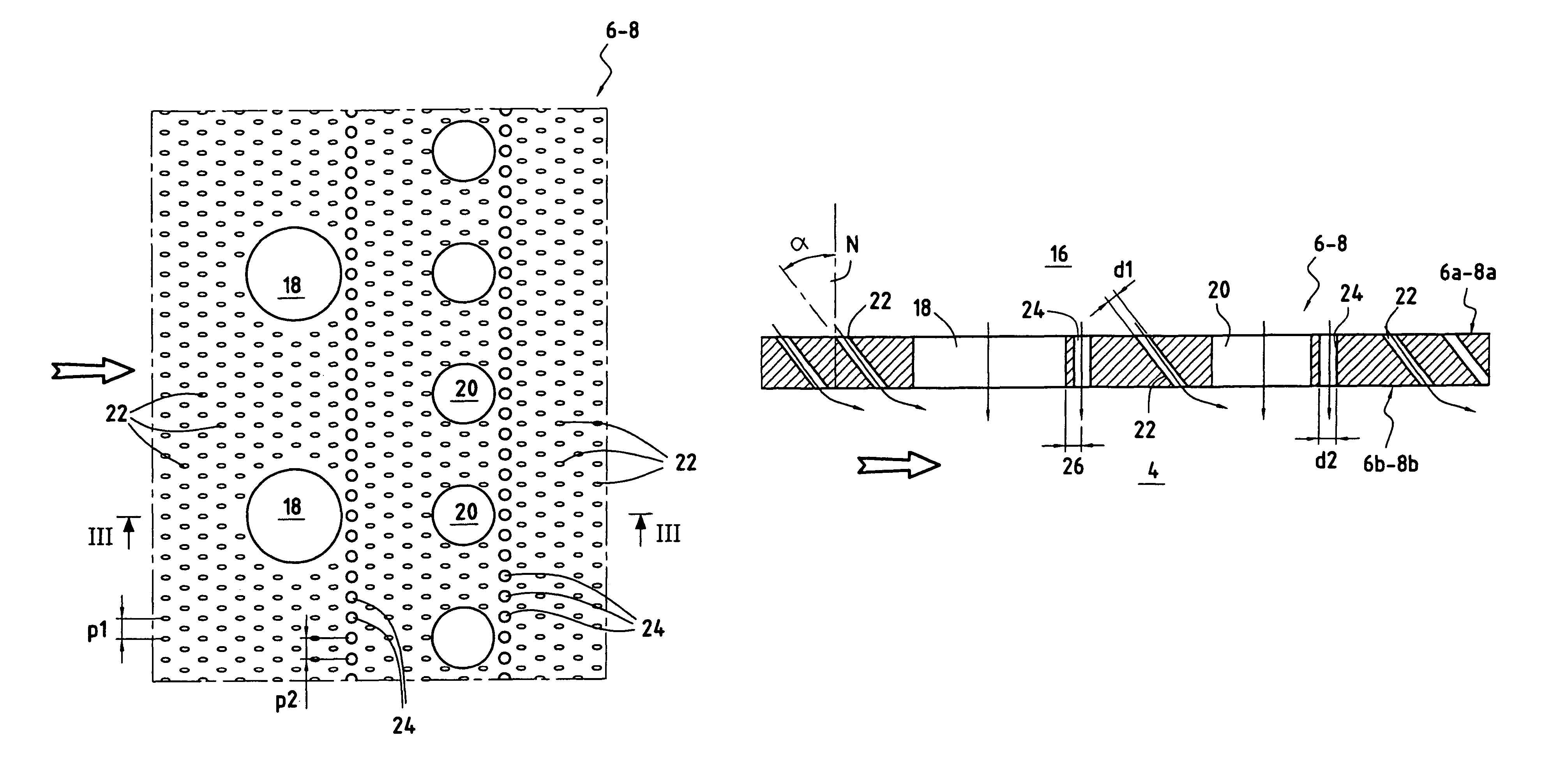

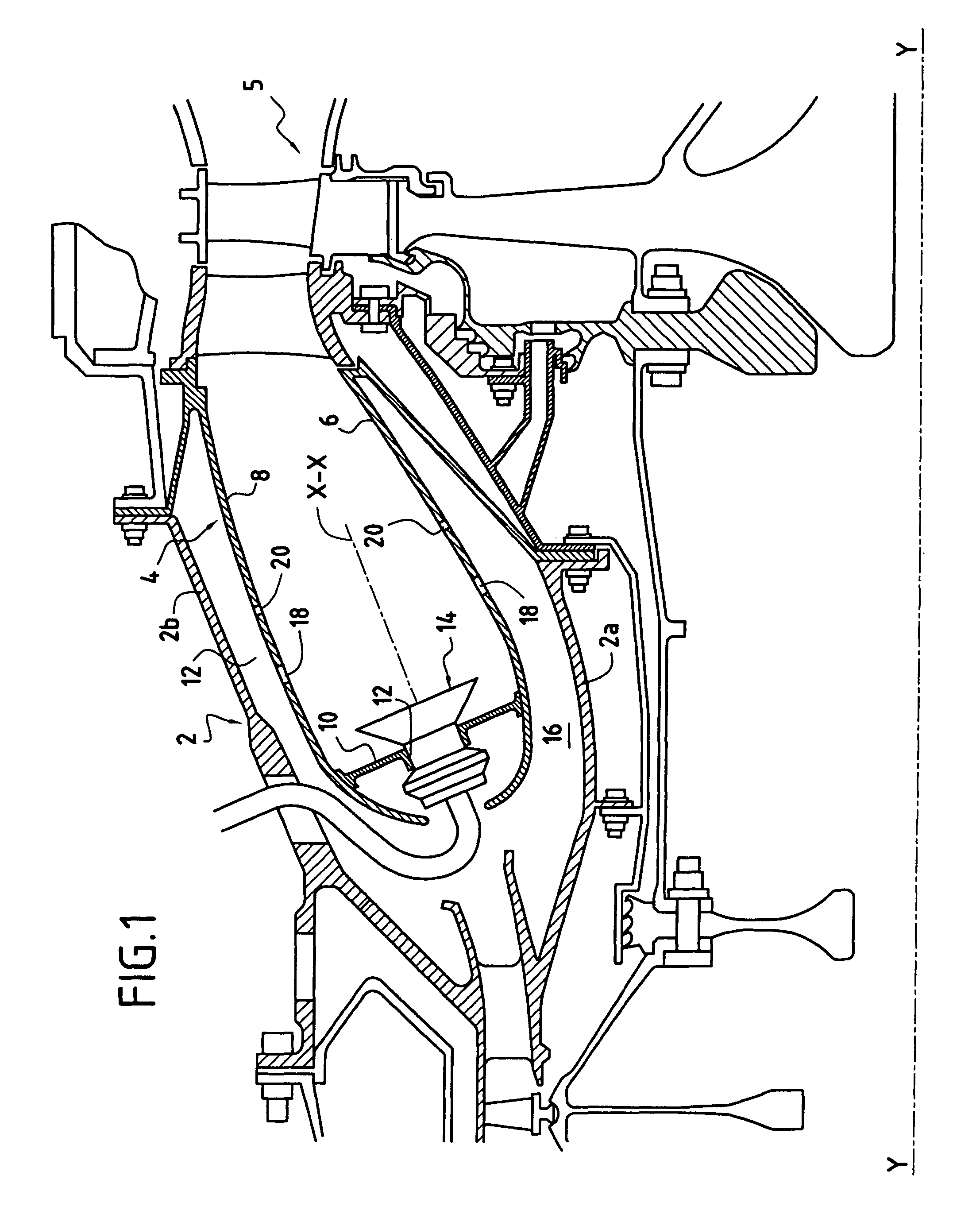

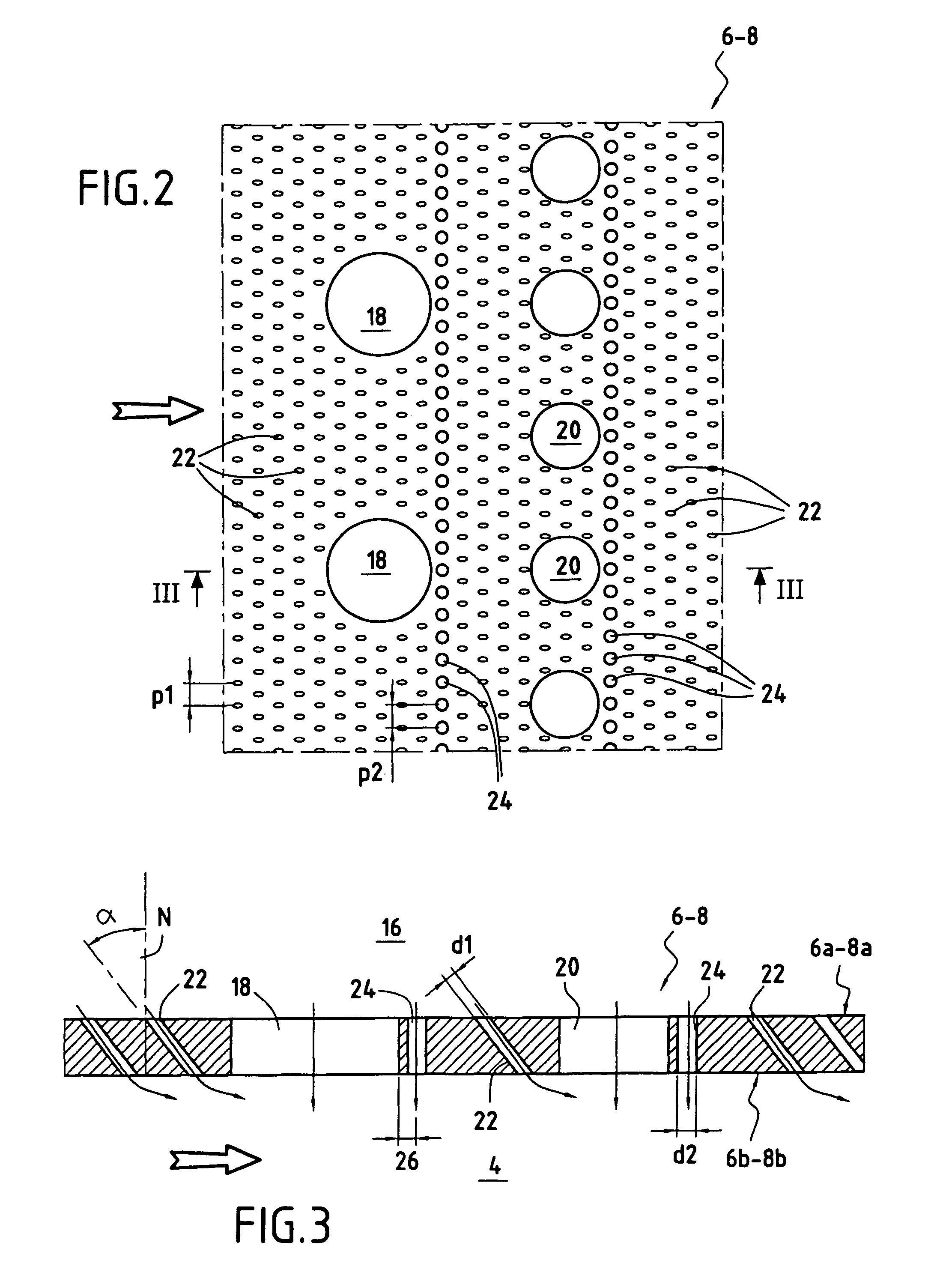

Performance of a combustion chamber by multiple wall perforations

ActiveUS20070084219A1Mitigate such drawbackAvoid risk of crackingContinuous combustion chamberGas turbine plantsCold sideCombustion chamber

An annular wall for the combustion chamber of a turbomachine has a cold side and a hot side, said wall being provided with a plurality of primary holes and a plurality of dilution holes distributed in circumferential rows, together with a plurality of cooling orifices that are distributed in a plurality of circumferential rows that are spaced apart axially from one another, the number of cooling orifices being identical in each row thereof, and the wall further including bores disposed immediately downstream from the primary holes and from the dilution holes and distributed in circumferential rows, the bores in any one row presenting a substantially identical diameter, being spaced apart at a pitch that is constant, and presenting intrinsic characteristics that are different from the intrinsic characteristics of the cooling orifices of the adjacent rows.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

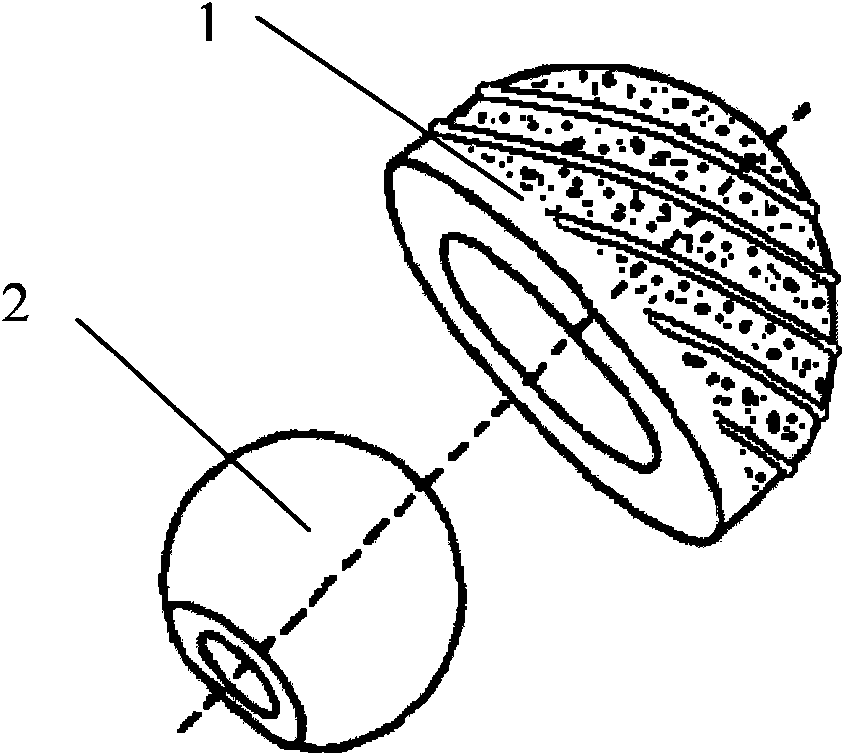

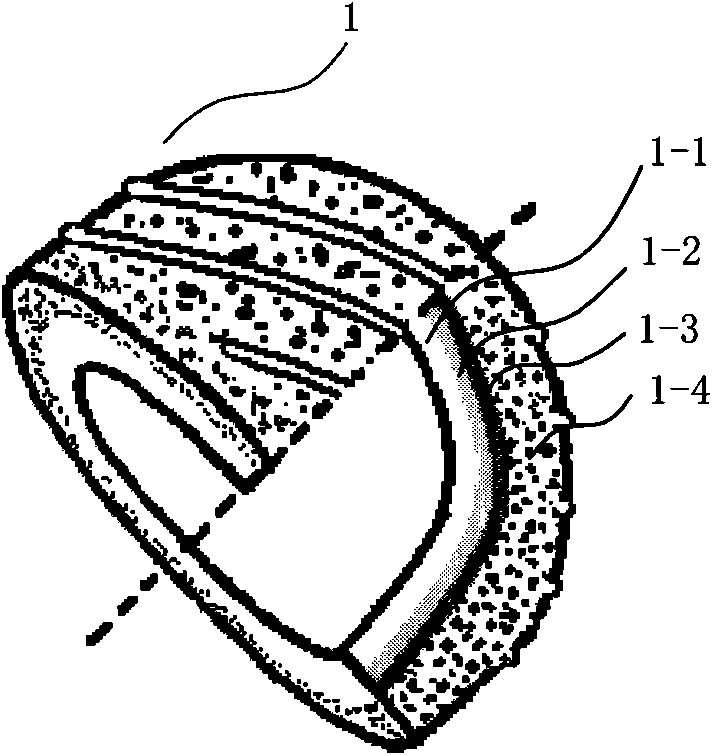

Artificial hip joint consisting of multilayer shell core composite structural components

The invention discloses an artificial hip joint consisting of multilayer shell core composite structural components. The artificial hip joint comprises an artificial acetabulum and an artificial thigh bone. The artificial hip joint is characterized in that: the artificial acetabulum has a multilayer shell core composite structure and consists of a ceramic acetabulum lining, a transition layer, a porous metal, a porous alloy or a porous toughened ceramic acetabulum shell; the artificial thigh bone has a multilayer shell core composite structure and consists of a ceramic spherical shell layer, a transition layer and a toughened ceramic inner core. The ceramic acetabulum lining and the spherical shell layer of the artificial thigh bone have high hardness, corrosion resistance and abrasion resistance; the artificial acetabulum shell layer and the inner core of the thigh bone have high toughness and impact resistance; and the transition layers are made of gradient composite materials between the materials for the shell layer and the inner core layer, and have the functions of increasing the bonding strength between the shell layer and the inner core layer, reducing the interface stressbetween the shell layer and the inner core layer and the like. The artificial hip joint has the characteristics of long service life, high reliability, high performance and the like.

Owner:SUZHOU DINGAN ELECTRONICS TECH

Heat treatment deformation control method of thin-wall saddle-shaped aluminum alloy casting

The invention discloses a heat treatment deformation control method of a thin-wall saddle-shaped aluminum alloy casting. The heat treatment deformation control method is suitable for large thin-wall casting aluminum alloy parts. According to the characteristics of the casting, a blocking disc and a clamp are arranged on the casting before heating, one end with a thicker wall is put into a furnace by a vertical placement way; thermal stress during heating can be reduced by heating in stages; in a solid melting stage, deformation during quenching can be reduced by adjustable tooling shape maintainance; in an aging stage a pretightening force is continued to be applied for maintainance of a tooling constraining force. The advantages of the heat treatment deformation control method are that: the heat treatment deformation control method uses an adjustable tooling shape maintainance method in heating, solid melting and aging stages to solve the heat treatment deformation control problem of the thin-wall casting aluminum alloy and avoid the problems of repeated deformation calibration and difficulties in shape, position and size control after solid melting. By application of the pretightening force before heating and after solid melting according to deformation rules, the purpose of precise deformation control can be achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

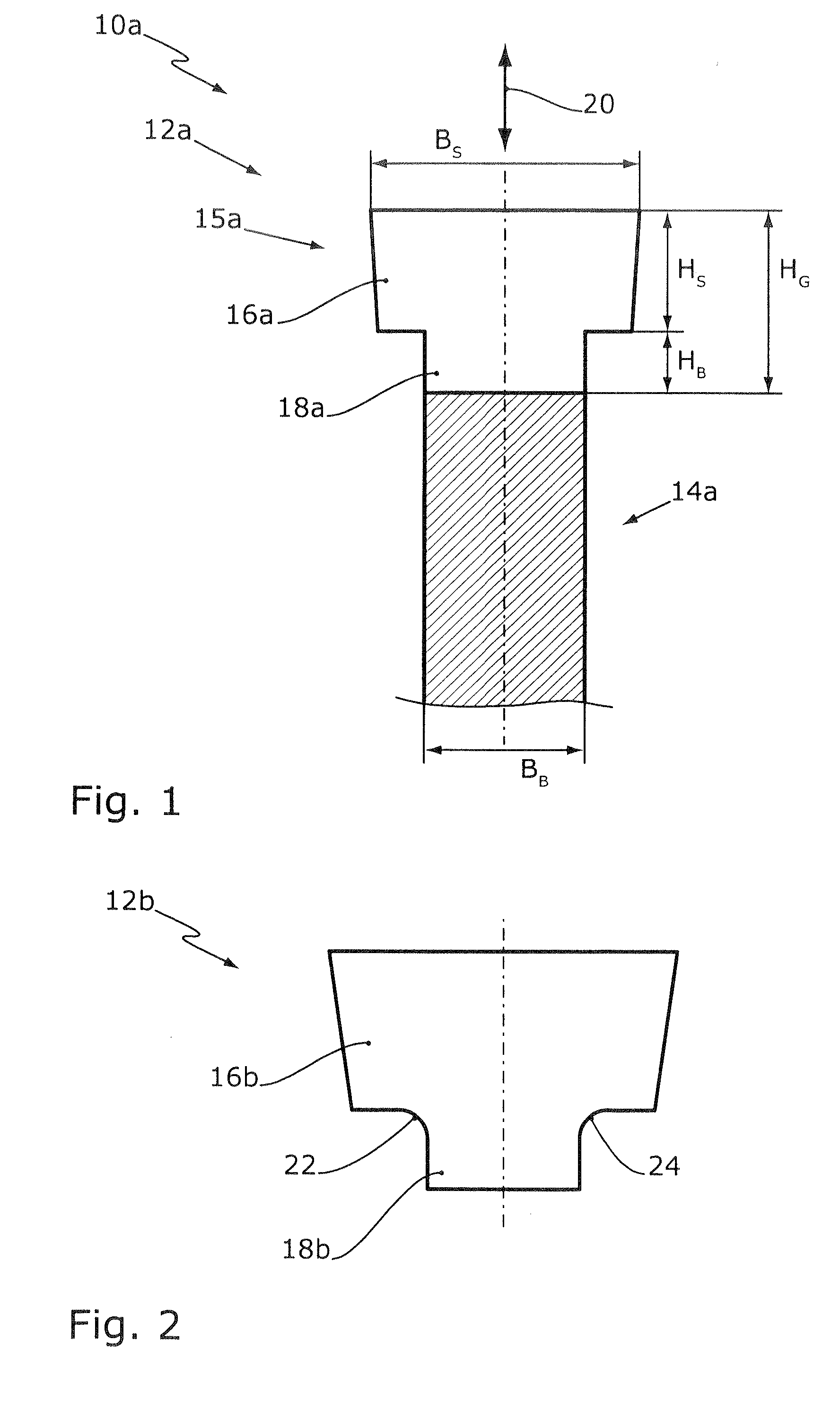

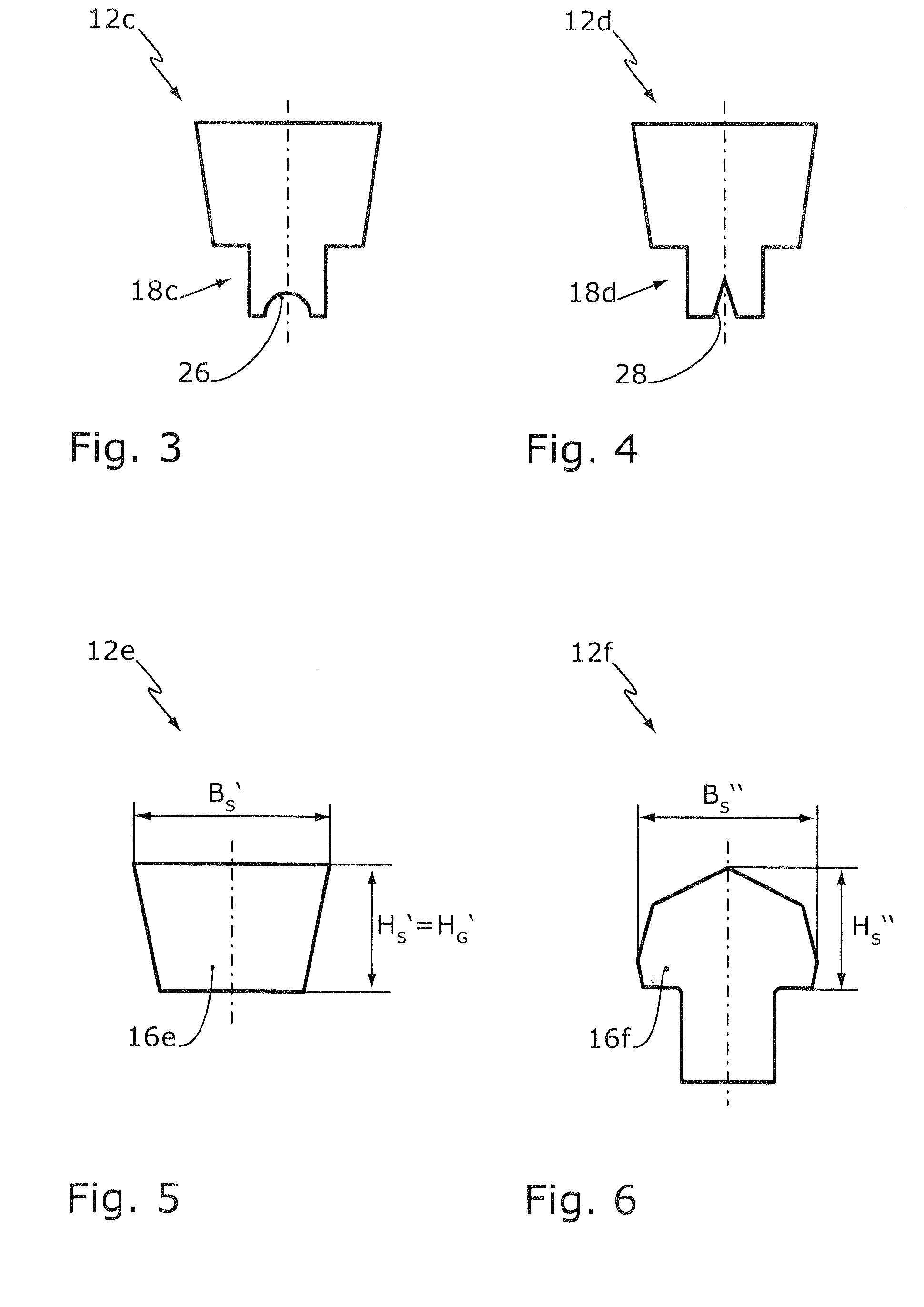

Tread comprising a ventilated device for countering irregular wear

InactiveUS20060090827A1Lower Level RequirementsWithstanding impactTyre tread bands/patternsNon-skid devicesEngineeringTread

A tread (B) provided with a tread pattern formed of a plurality of elements in relief (1, 10) which are defined by grooves and / or incisions (2), this tread pattern comprising on each of its edges, that is to say axially furthest to the outside of the tread, an edge rib (1) of circumferential orientation defined axially to the inside by a groove (2) of the same general orientation and of depth H, this tread furthermore comprising, axially to the outside of each edge rib (1), a rib (3) offset relative to the outer contact surface (11) of the neighboring edge rib (1) by a distance d other than zero, this offset rib (3) being separated from the edge rib (1) by a groove (4) of a depth identical or close to the depth H of the groove (2) defining the edge rib (1), wherein the tread comprises, on either side where a sacrificed rib (3) is formed, a plurality of channels (5) opening on to the lateral faces of the tread, these channels (5) being extended in the tread until they open into the groove (4) between the offset rib (3) and the neighboring edge rib (1).

Owner:MICHELIN RECH & TECH SA

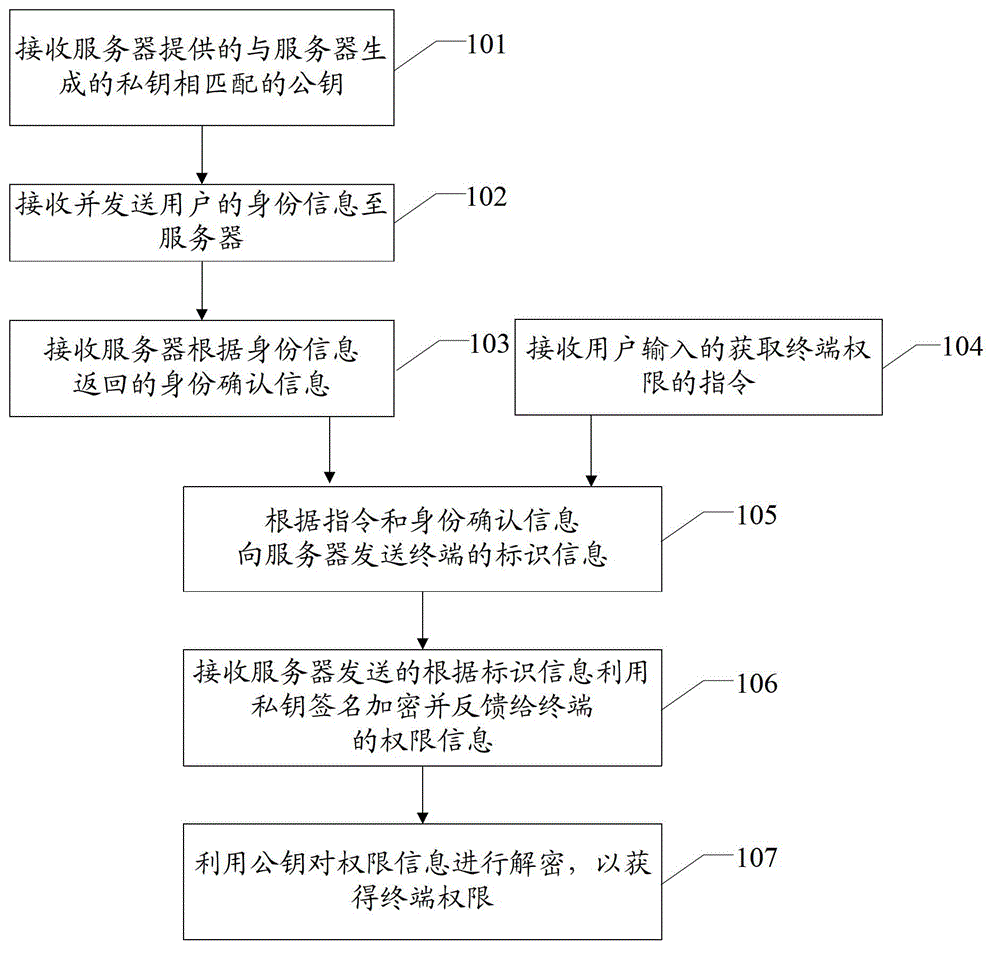

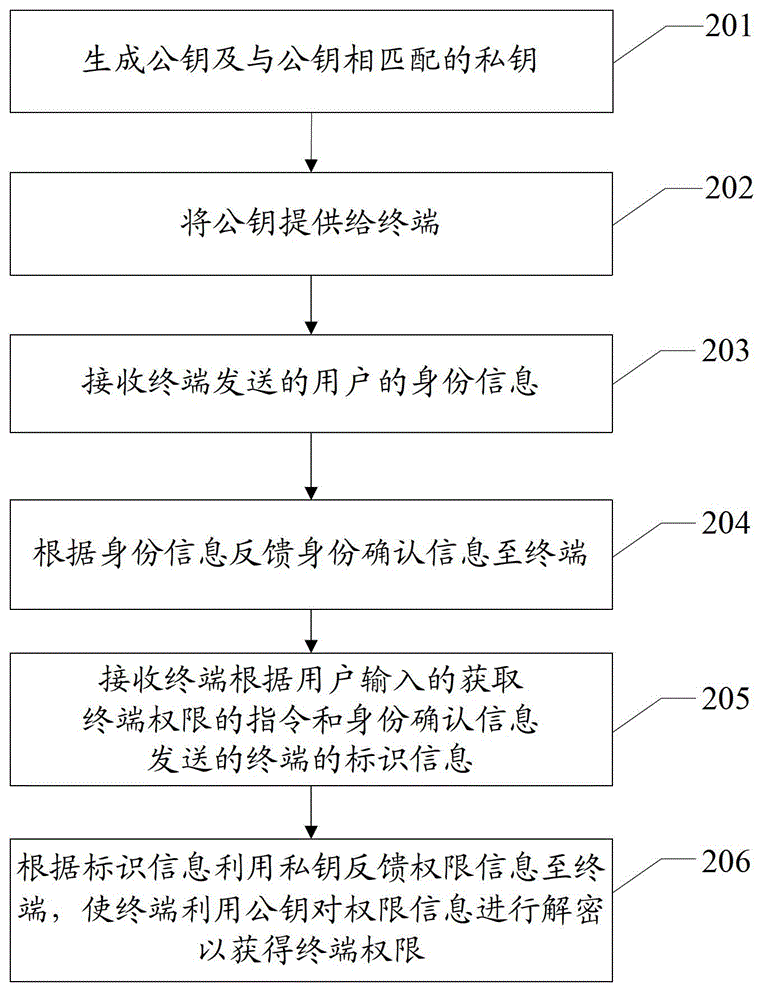

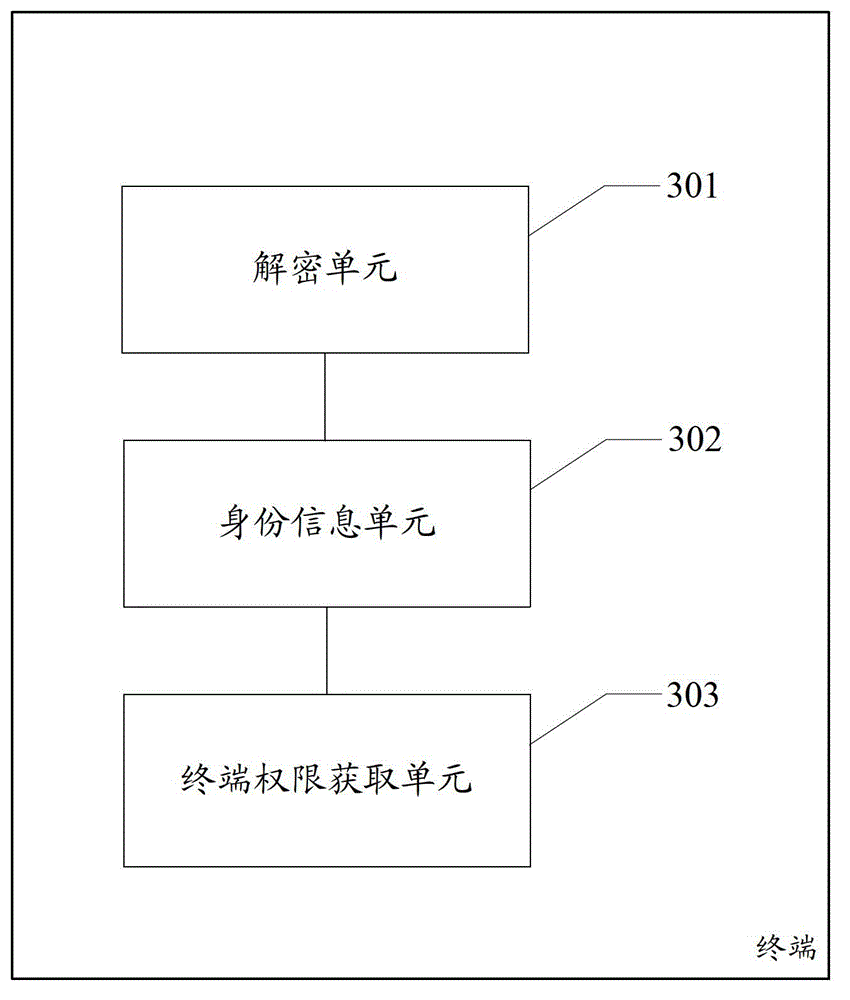

Method, terminal and server for obtaining terminal authorization

The embodiment of the invention relates to the technical field of communication, and discloses a method, a terminal and a server for obtaining the terminal authorization. The method comprises the following steps of receiving a public key, which is matched with a private key generated by a server and is provided by the server; receiving and sending the identity information of a user to the server; receiving identity confirming information fed from the server; receiving a command which is input by a user for obtaining the terminal authorization; according to the command and the identity confirming information, sending terminal identification information to the server; receiving the authorization information which is sent by the server and fed to the terminal by the private key according to the identification information; and deciphering the authorization information by the public key to obtain the terminal authorization. When the embodiment of the invention is implemented, the method for obtaining the authorization can be simplified, and the key breaking risk is effectively avoided, thereby being safer and more reliable.

Owner:MEIZU TECH CO LTD

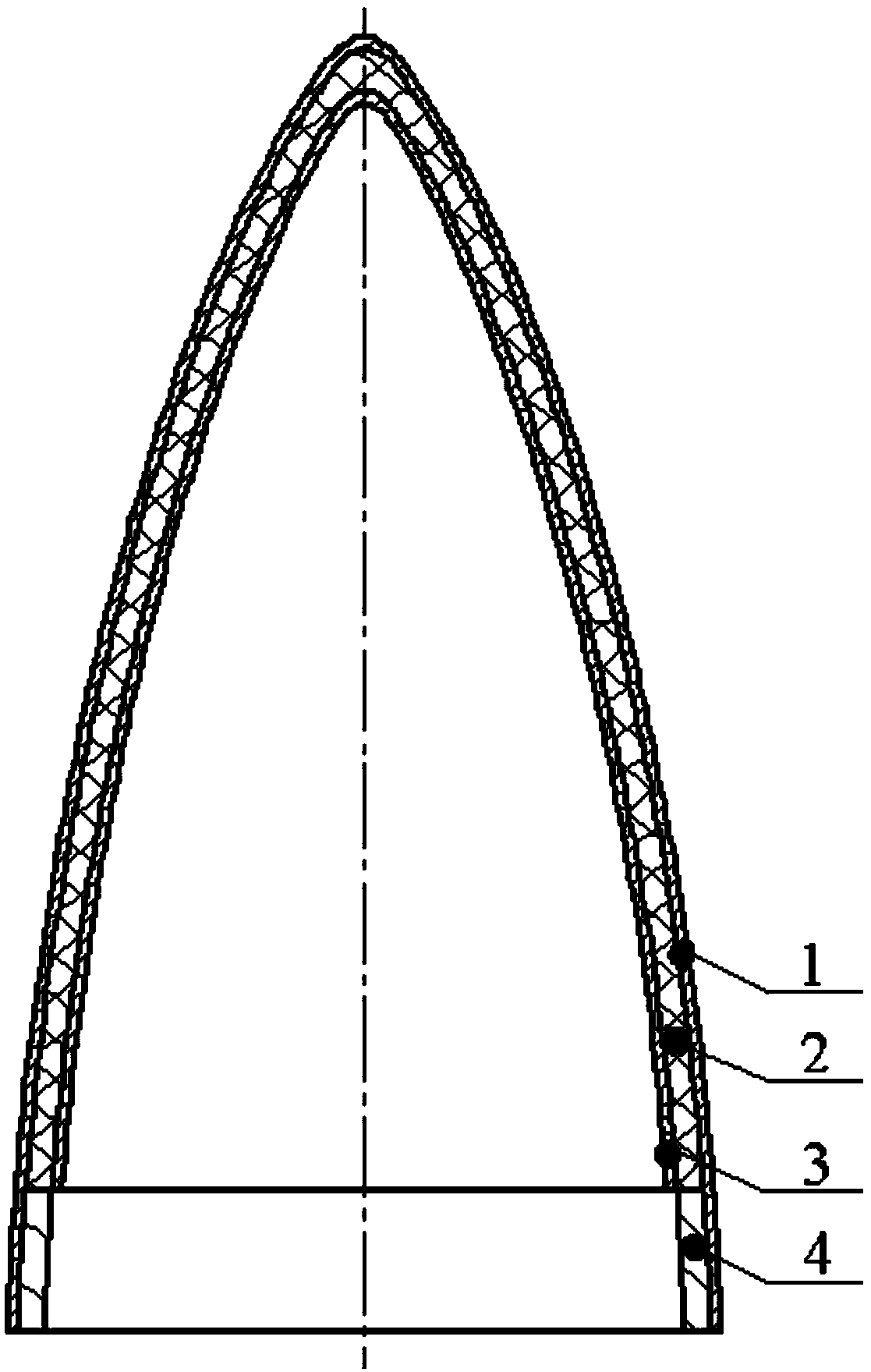

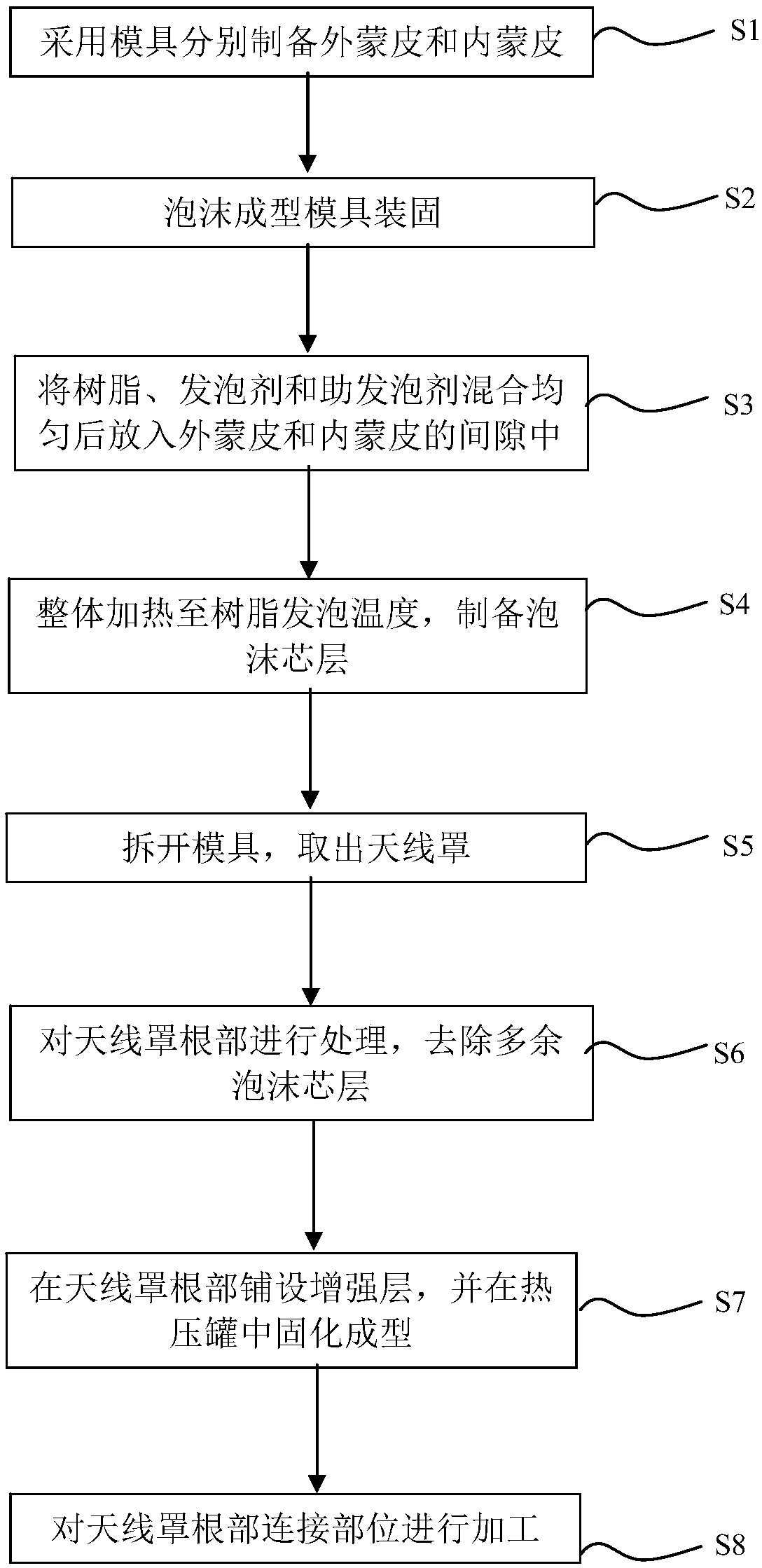

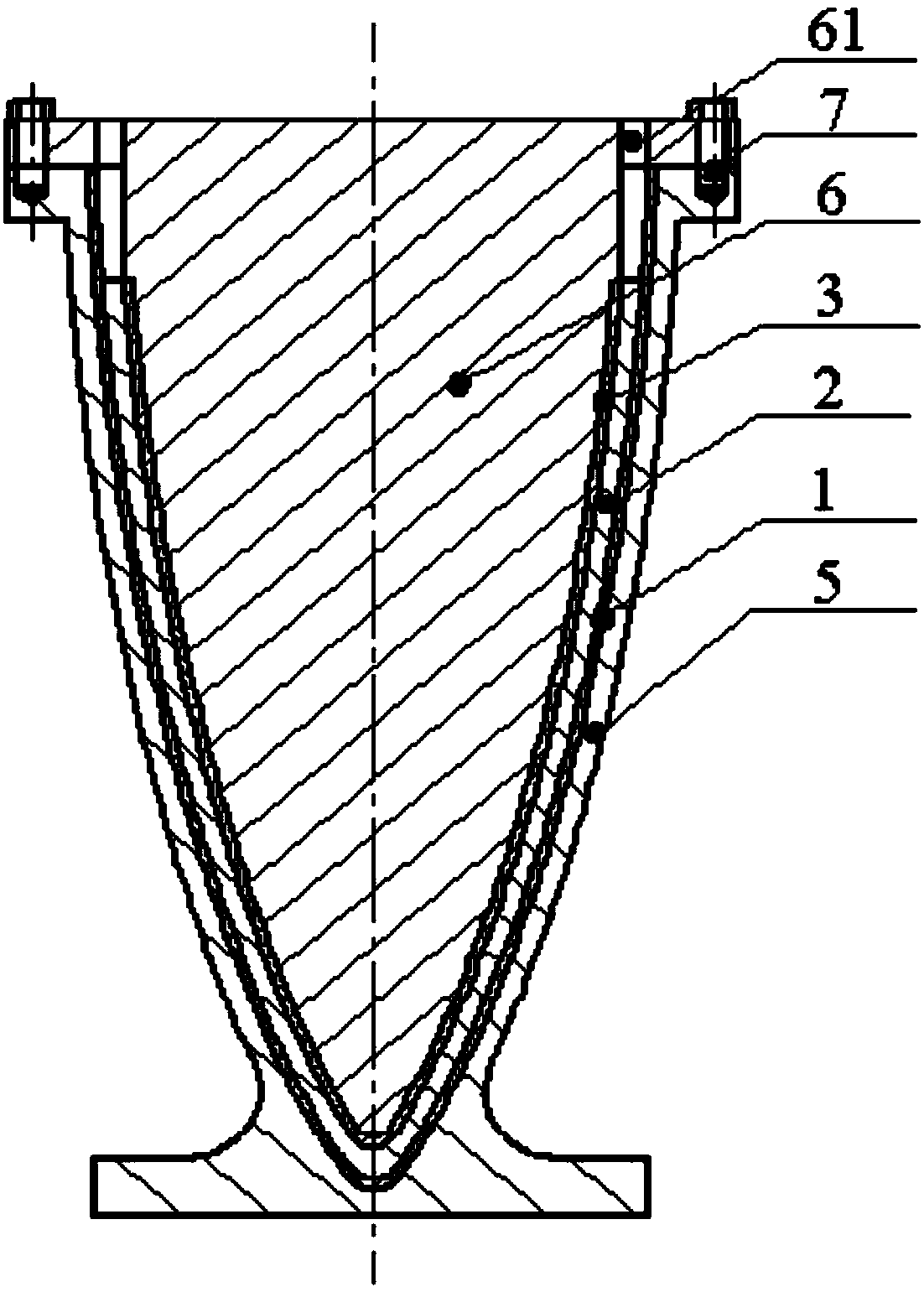

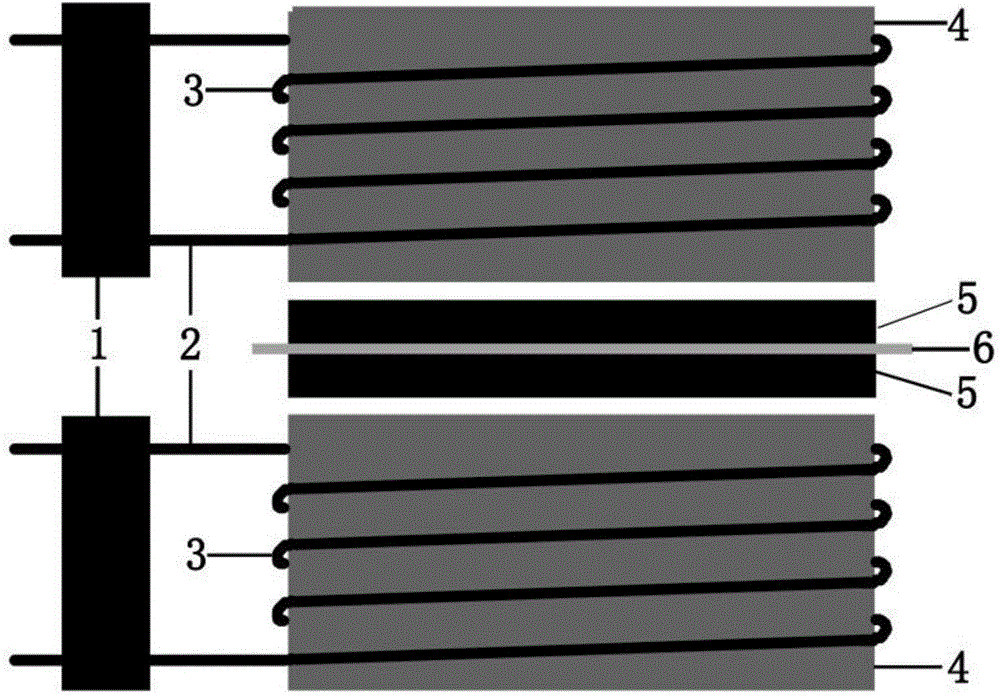

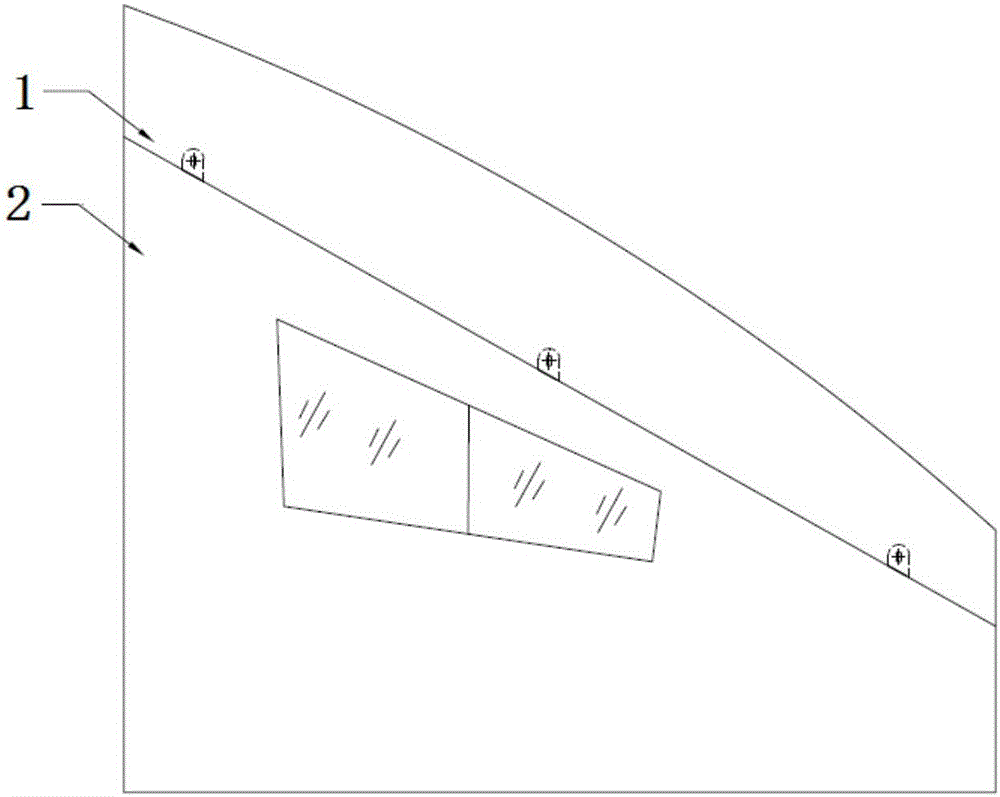

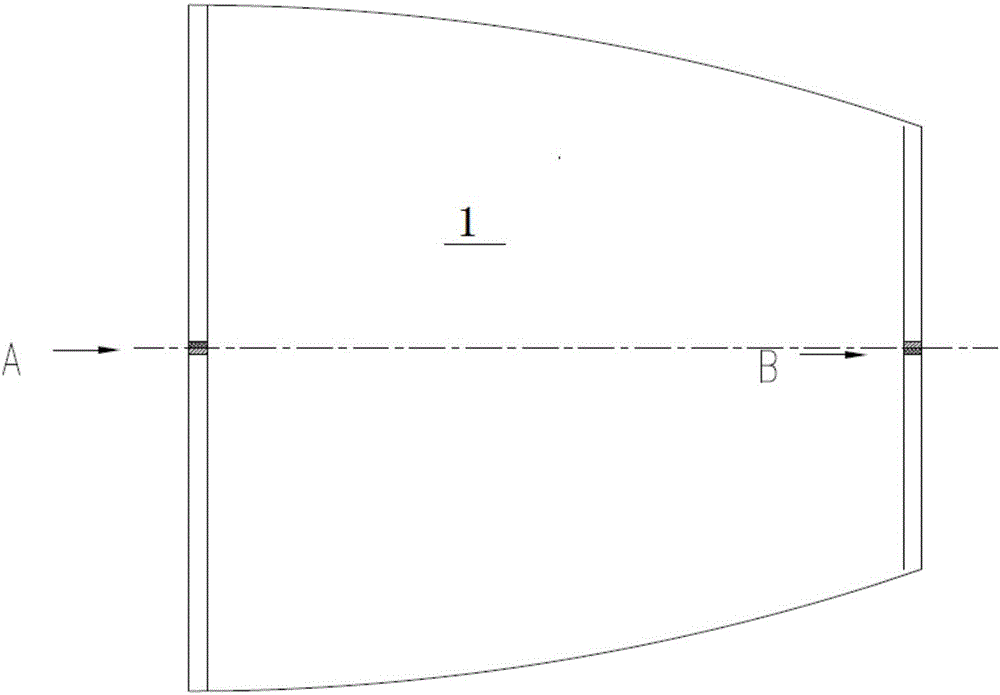

High-temperature-resistant foam A-interlayer composite antenna cover and preparation method thereof

ActiveCN109638445AGuaranteed preparation accuracyEasy to implementRadiating element housingsTemperature resistanceEngineering

The invention discloses a high-temperature-resistant foam A-interlayer composite antenna cover and a preparation method thereof, and relates to the technical field of resin-based composite structure forming processes. The high-temperature-resistant foam A-interlayer composite antenna cover is constituted by an outer skin, a foam core layer, an inner skin and a reinforcing layer, and the outer skin, the inner skin and the reinforcing layer are made of fiber-reinforced resin-based composites, and the foam core layer is made of high-temperature-resistant resin foam; after being prepared and formed, the outer skin and the inner skin serve as moulds, the foam core layer is overall formed, the preparation precision of the interlayer antenna cover is ensured, and the influences of gaps between the skins and the core layer on the strength and performance of the antenna cover are avoided; and for meeting the high-bearing requirement for the root of the antenna cover, a thickening layer is laidon the root, the structural strength of the root of the antenna cover is improved, and meanwhile, connecting and assembling of the antenna cover are facilitated. According to the high-temperature-resistant foam A-interlayer composite antenna cover, the high-precision preparation problem of the high-temperature-resistant foam A-interlayer composite antenna cover is solved, the working demands of the interlayer antenna cover for high-temperature resistance and high strength are met, and realizing is convenient.

Owner:SHANGHAI RADIO EQUIP RES INST

H13 steel vacuum time-control quenching heat treatment technique

InactiveCN101121954AAvoid risk of crackingImprove impact toughnessHeat treatment process controlQuenching agentsSalt waterTime control

The invention discloses a time-controlled sudden cooling vacuum heat treatment process for H13 steel, which includes heating and heat preserving, quenching and tempering; the quenching media for quenching after heating and heat preserving is salt water containing 5 to 10 percent NaC1, and the quenching treatment lasts for 1 to 5 minutes. The invention adopts a special time-controlled sudden cooling process, which not only prevents the danger of cracking during quenching of the salt water, but also greatly improves the quenching quality, so as to effectively improve the impact toughness of the H13 steel after tempering, and thus greatly extends the service life of the mould.

Owner:上海市机械制造工艺研究所有限公司

Performance of a combustion chamber by multiple wall perforations

ActiveUS7748222B2Mitigate such drawbackAvoid risk of crackingContinuous combustion chamberGas turbine plantsCold sideCombustion chamber

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

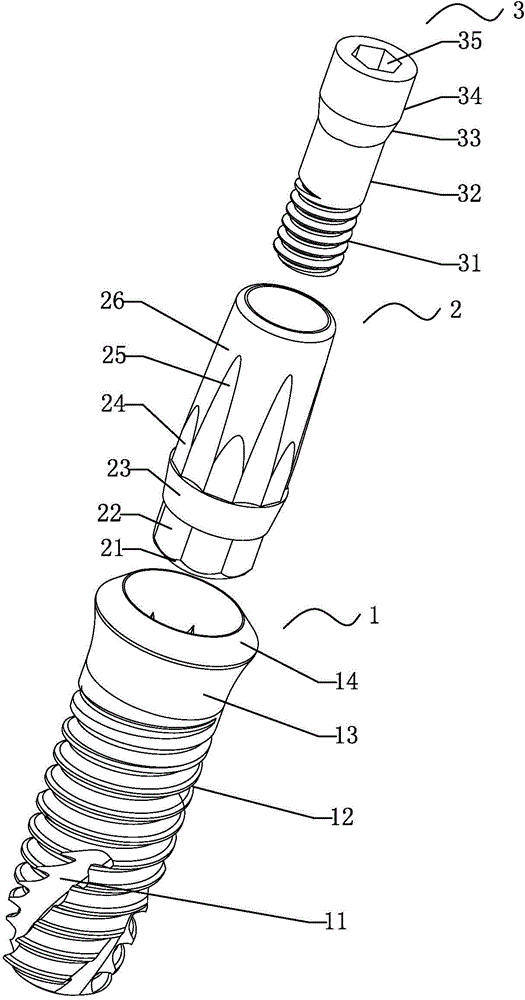

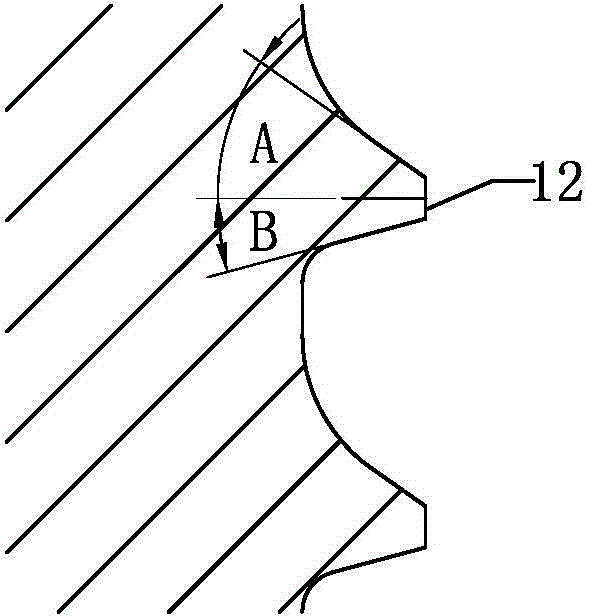

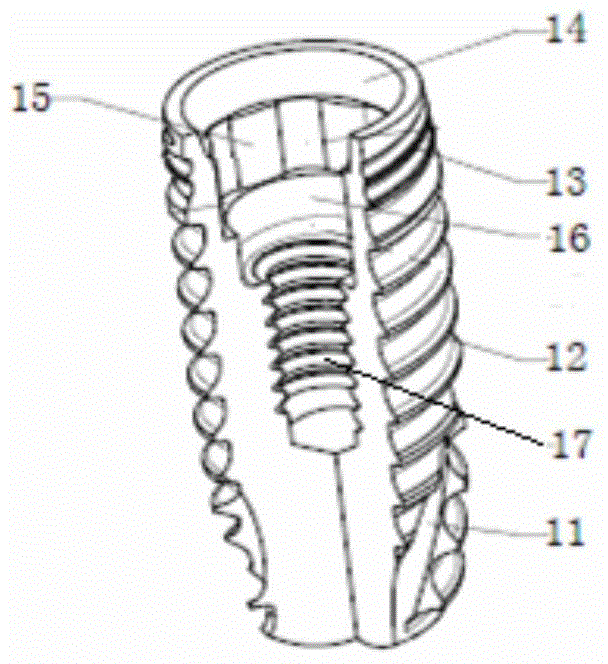

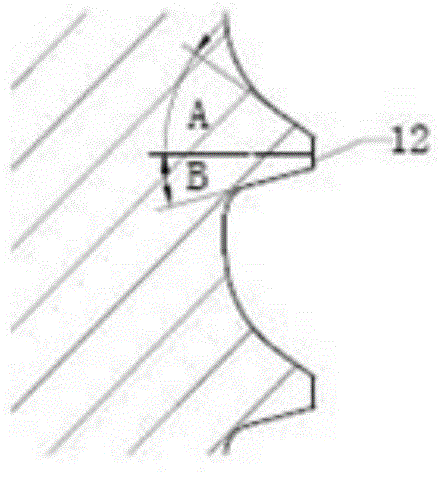

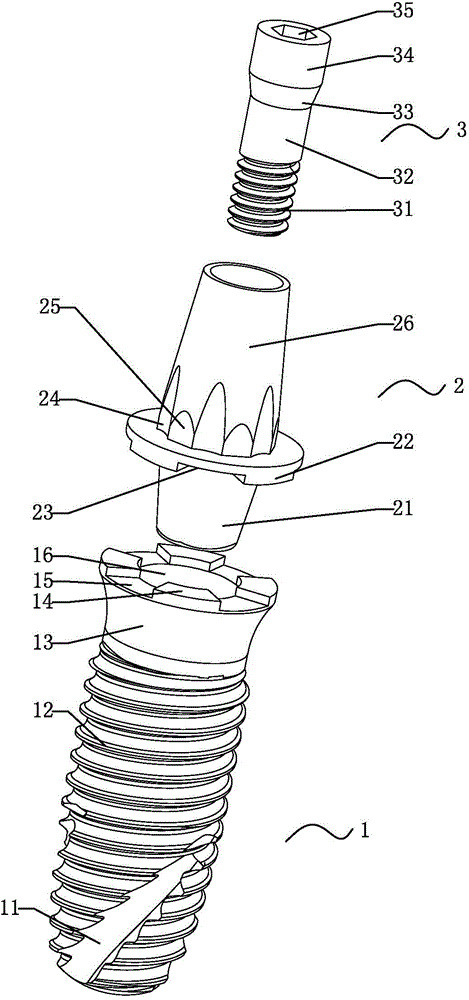

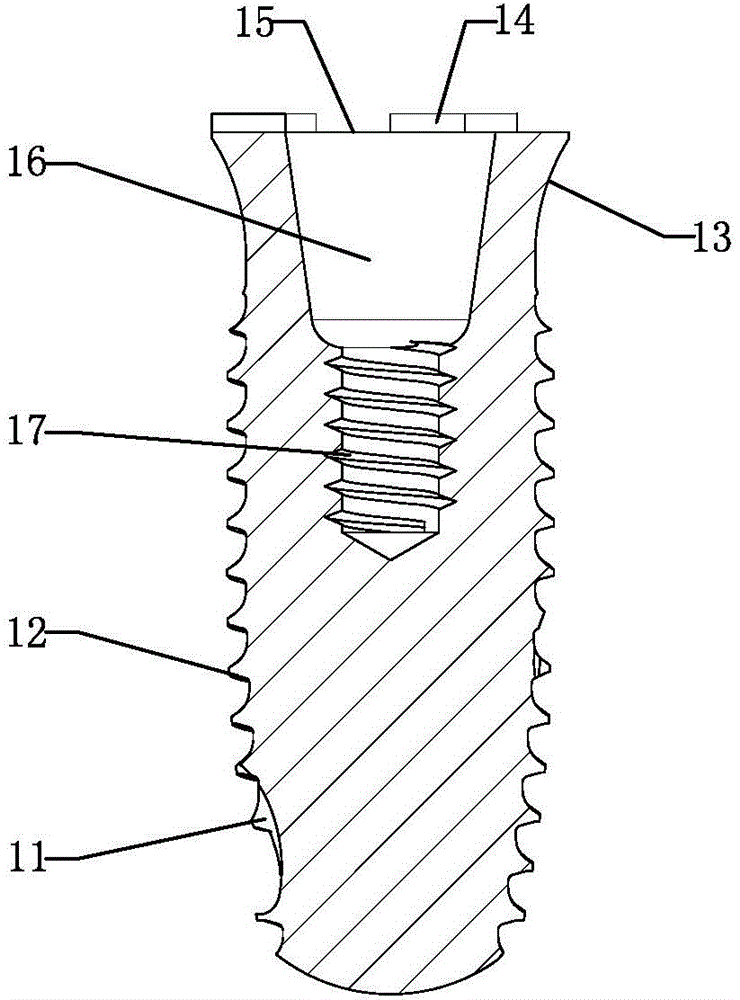

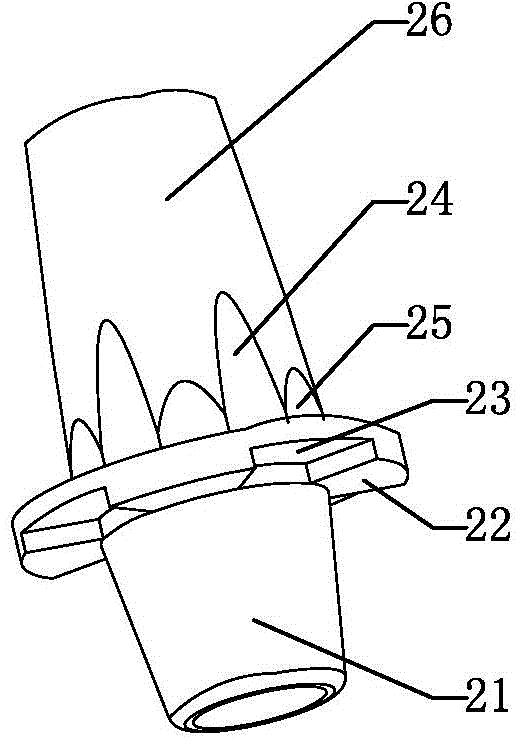

Easily-removing implant device and screwing-out tool thereof

InactiveCN103550003AReduce the risk of absorbingAvoid secondary surgeryDental implantsNeck partsImplanted device

The invention discloses an easily-removing implant device and a screwing-out tool thereof. The easily-removing implant device comprises an implant, a base station and a central bolt; the easily-removing implant device is characterized in that the implant comprises a gum-penetrating neck part and a head part, wherein a thread is formed on the outer surface of the head part, at least two spiral self-tapping grooves are also formed in the outer surface of the head part, a connecting hole coaxial with the implant is formed in the implant, the connecting hole comprises a tapered hole, an anti-rotation hole, an implant taking-out section and a blind threaded hole, which are sequentially connected coaxially, the base station comprises a dental crown connecting section and an implant connecting section, the implant connecting section comprises a conical table and an anti-rotation column, a stepped hole matched with the central bolt is formed in the base station, and the central bolt penetrates through the stepped hole to be connected with the blind threaded hole, so that the base station and the implant are fixed integrally. According to the easily-removing implant device, the implant taking-out section with a reverse thread is additionally arranged in the implant, the problem that a part of the implant, which is remained in dentale due to fracture of the implant, is difficult to take out is solved, and the easily-removing implant device has the advantages of simple structure, strong practicability, and the like.

Owner:DALIAN SANSHENG SCI & TECH DEV

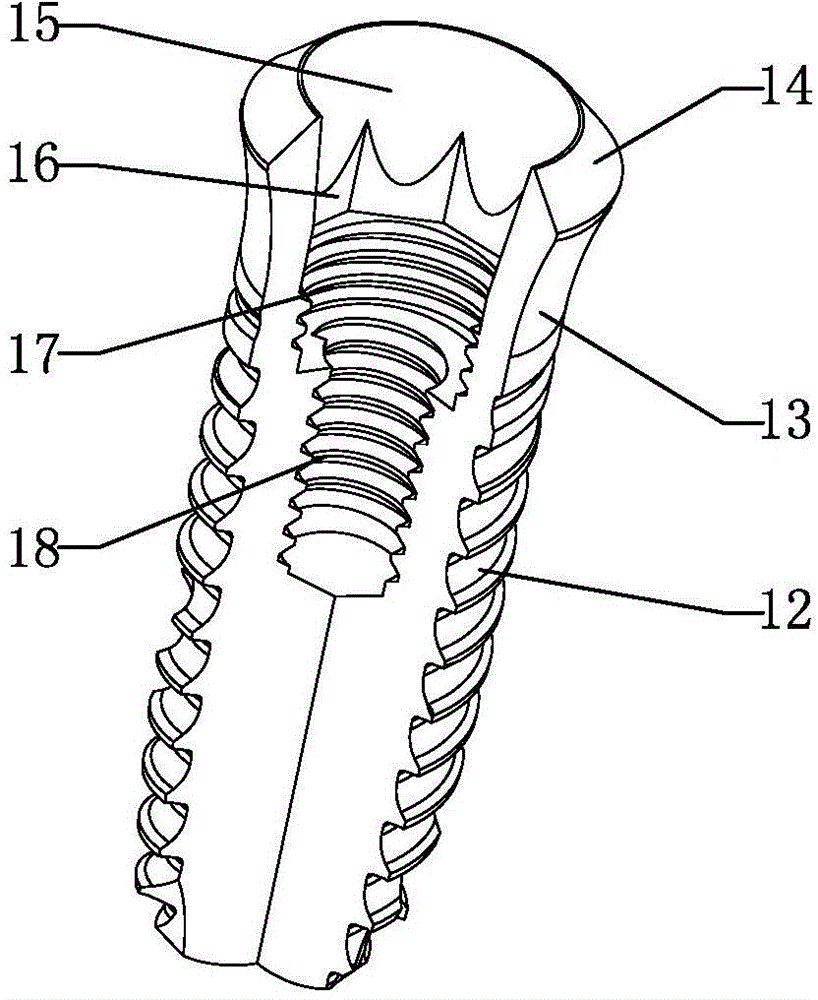

Artificial dental implant, artificial dental implanting system and implanting method

The invention provides an artificial dental implant, an artificial dental implanting system and an implanting method. A screwed thread is formed in the outer surface of an artificial dental implant, wherein a neck part and a head part are respectively arranged at two ends of the implant; a spiral tapping slot is formed in the outer surface of the head part, the spiral direction of the spiral tapping slot is the same as that of the screwed thread, and the spiral lead angle of the spiral tapping slot is different from that of the screwed thread. When the artificial dental implant is implanted, the cutting force and extrusion force of the implant to the bone tissues at the implanted position are reasonable, and the bone is effectively protected from injury; the artificial dental implant can accommodate bone chips generated in the tapping process, and the bone healing time can be shortened; the artificial dental implant is effectively prevented from rotating or loosing, and the service life of artificial tooth can be prolonged.

Owner:DALIAN SANSHENG SCI & TECH DEV

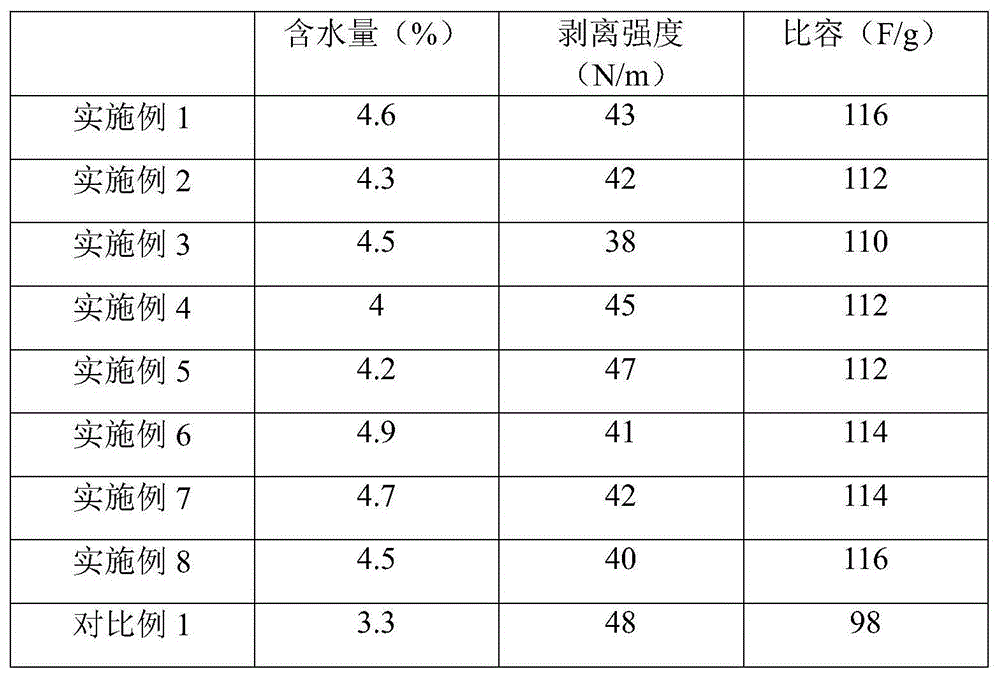

Preparation method of super capacitor electrode

ActiveCN104934235AIncrease specific volumeImprove mixing uniformityHybrid/EDL manufactureSupercapacitorSlurry

The present invention relates to a preparation method of a super capacitor electrode. A coating method is used to prepare the electrode, and comprises the steps of firstly stirring an active material, a conductive agent, a dispersing agent and an olefin polymer which can be in fibration under a high temperature in a solvent into a uniform slurry, then coating the slurry on a current collector evenly, and heating the current collector in an electromagnetic induction heating manner to dry the electrode and make the olefin polymer molecules as a binder in fibration, thereby bonding the active material and the conductive agent on the current collector firmly. By the technical scheme of the present invention, the problems that the super capacitor electrode is poor in uniformity and low in specific volume, the adhesive forces of the active material and the conductive agent on the current collector are small, the cycle life of an assembled super capacitor monomer is poor, etc., can be solved effectively.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

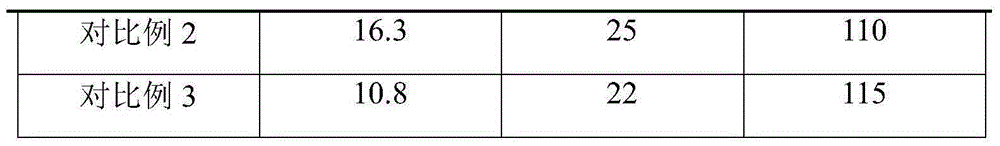

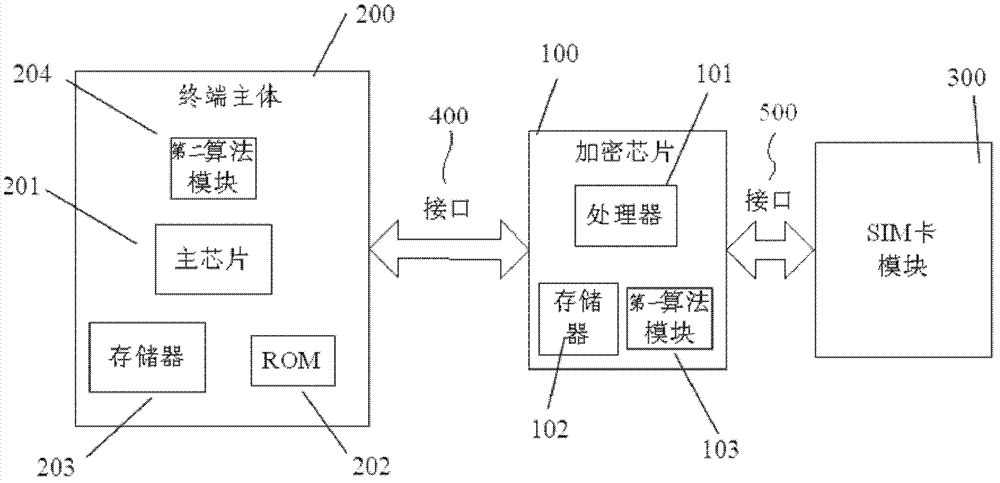

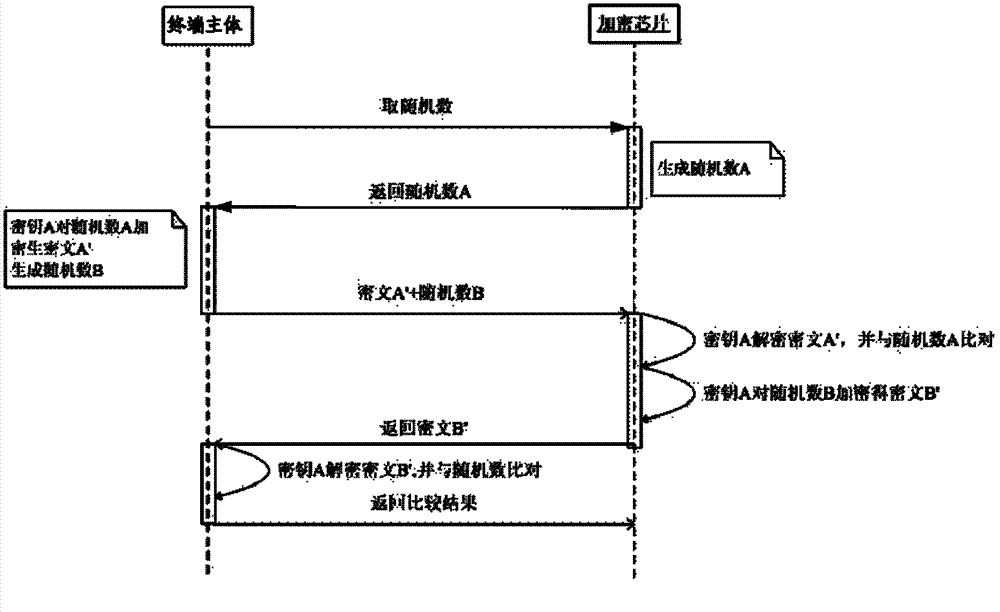

Communication terminal locking method and communication terminal

InactiveCN103200562AAvoid risk of crackingImprove reliabilitySecurity arrangementComputer moduleComputer terminal

The invention discloses a method and a device for communication terminal locking, and relates to the field of communication. On the basis of a traditional encryption chip network locking mode, starting-up authentication processes / modules of a terminal main body and an encryption chip of a communication terminal are added, therefore breaking risks of an encryption chip forced removing mode are avoided, reliability is high, protection in the aspect of software and others can be utilized, and locking application of terminal card locking and the like can be achieved.

Owner:NATIONZ TECH INC

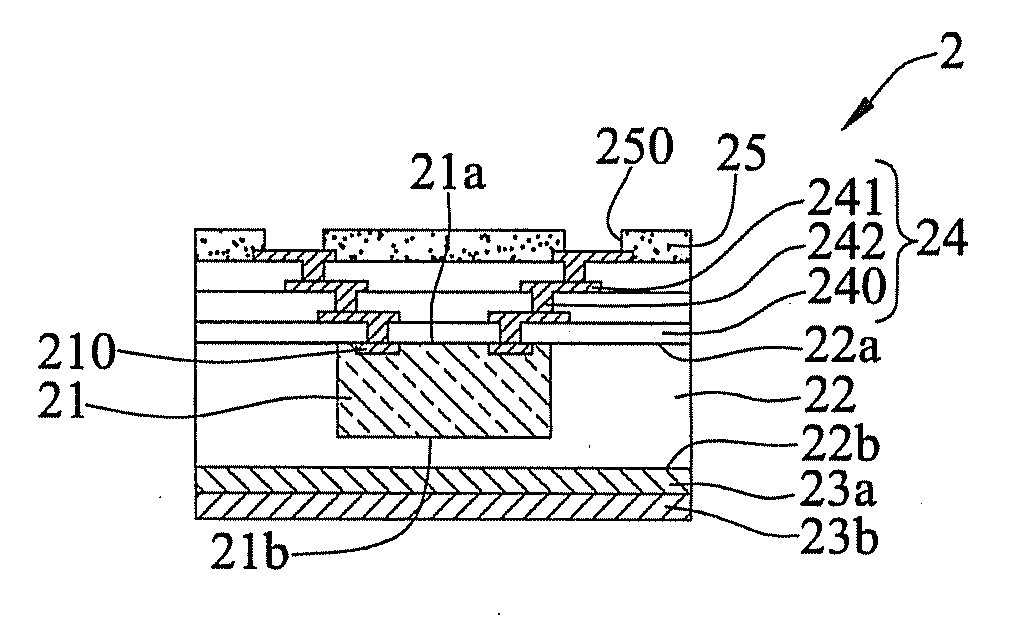

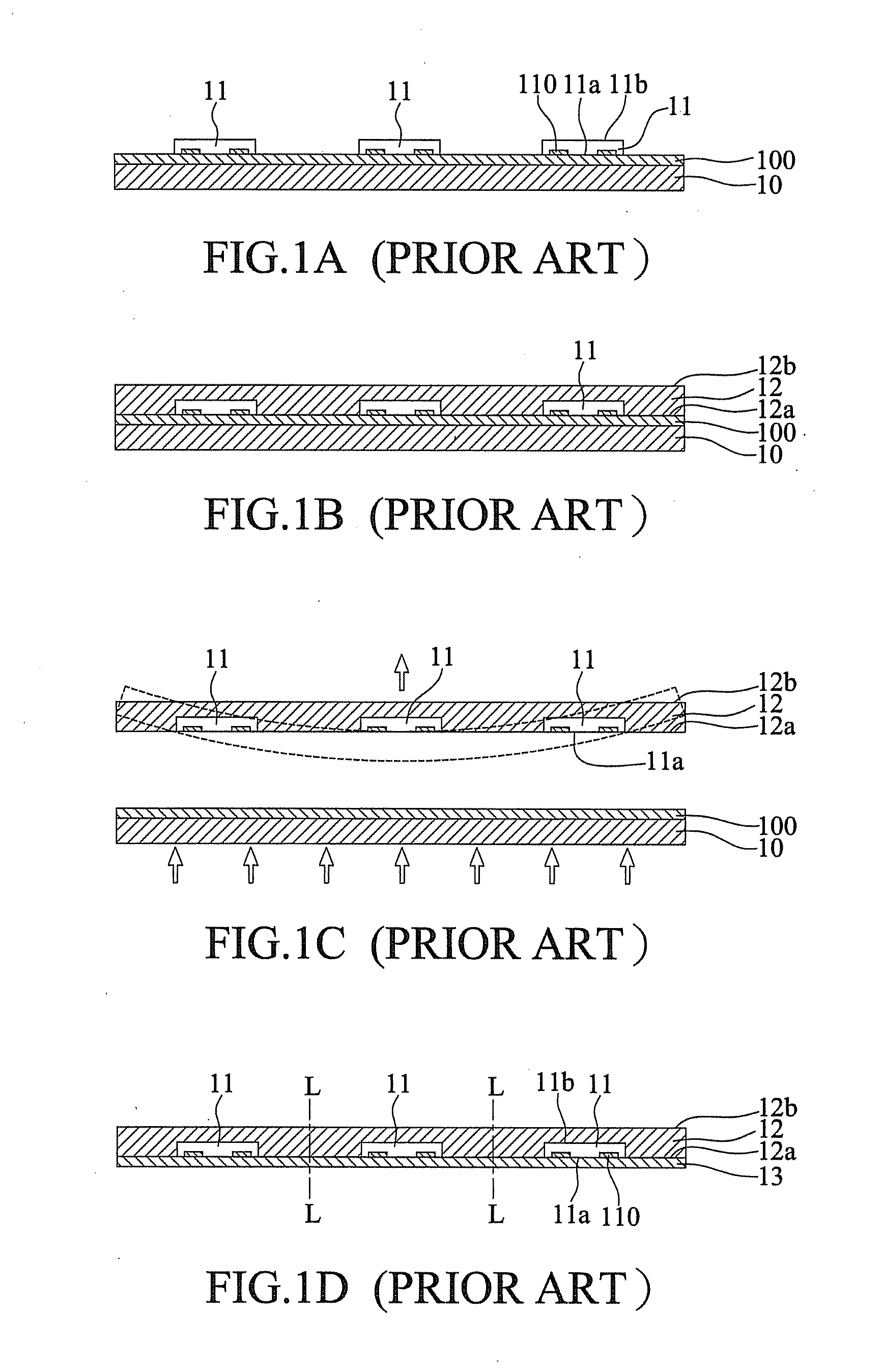

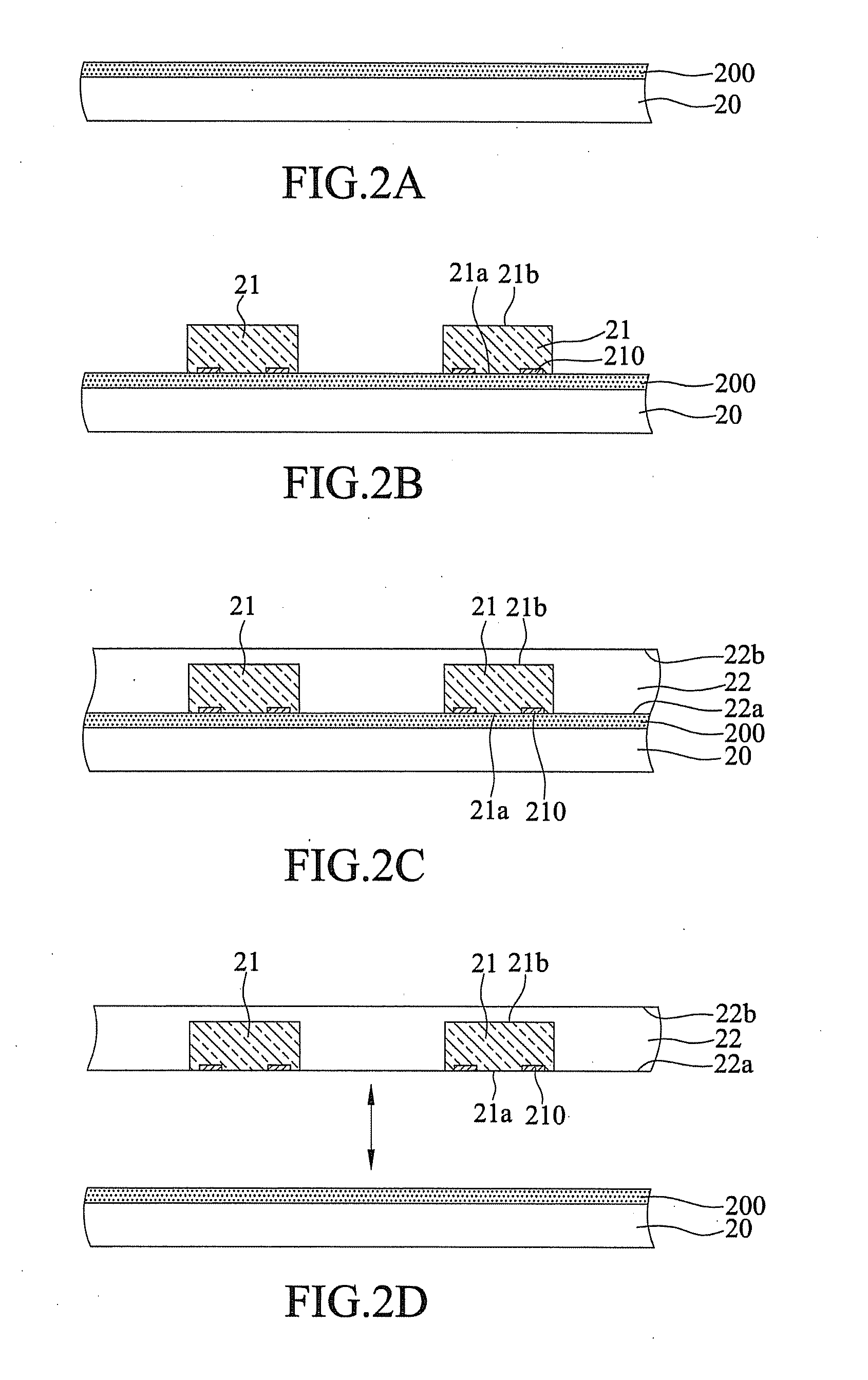

Semiconductor package and fabrication method thereof

ActiveUS20120161301A1Avoid warpingImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSealant

A semiconductor package includes: a chip having an active surface with a plurality of electrode pads and an inactive surface opposite to the active surface; an encapsulant encapsulating the chip and having opposite first and second surfaces, the first surface being flush with the active surface of the chip; and first and second metal layers formed on the second surface of the encapsulant, thereby providing a rigid support to the overall structure to prevent warpage and facilitating heat dissipation of the overall structure.

Owner:SILICONWARE PRECISION IND CO LTD

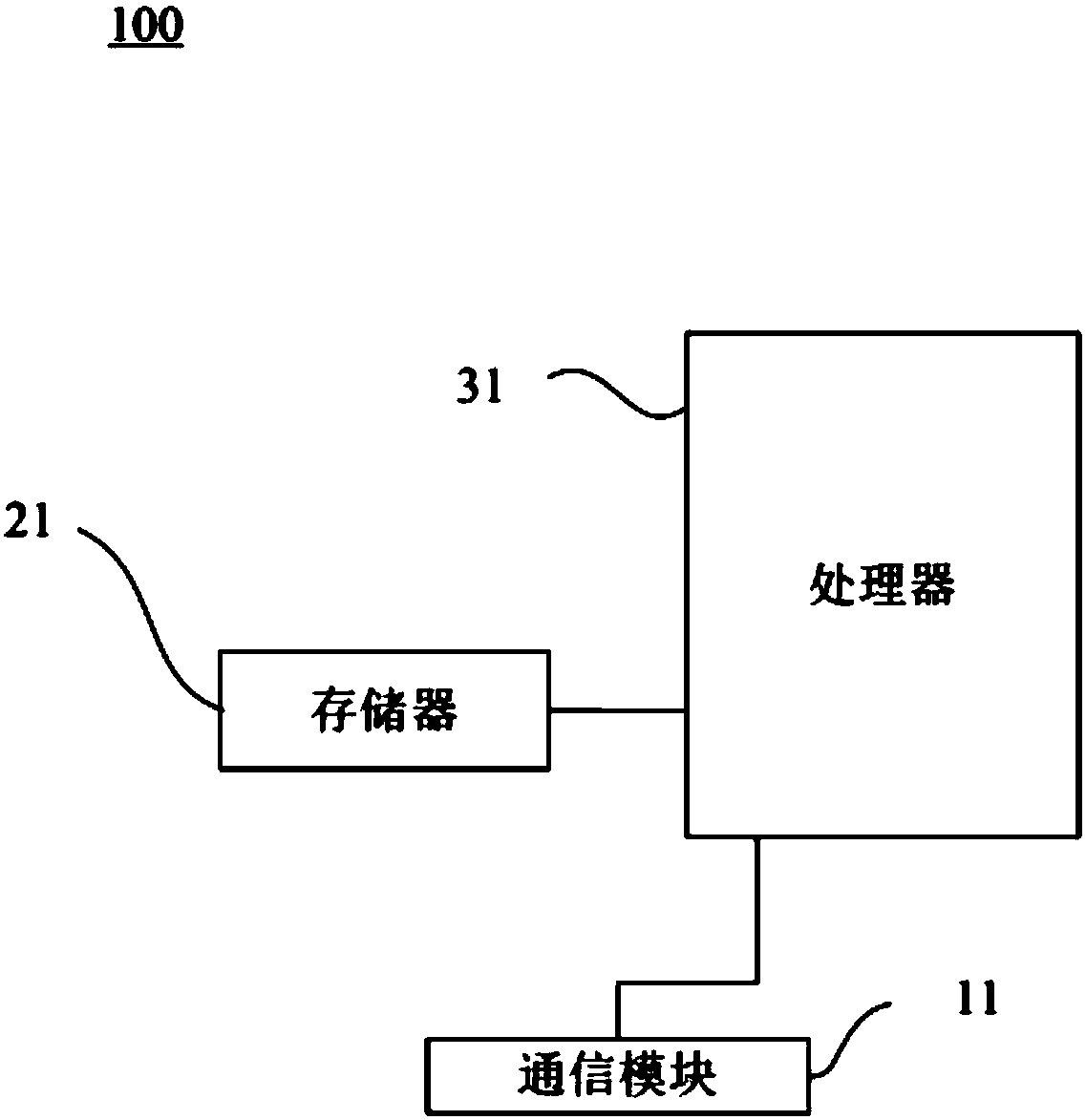

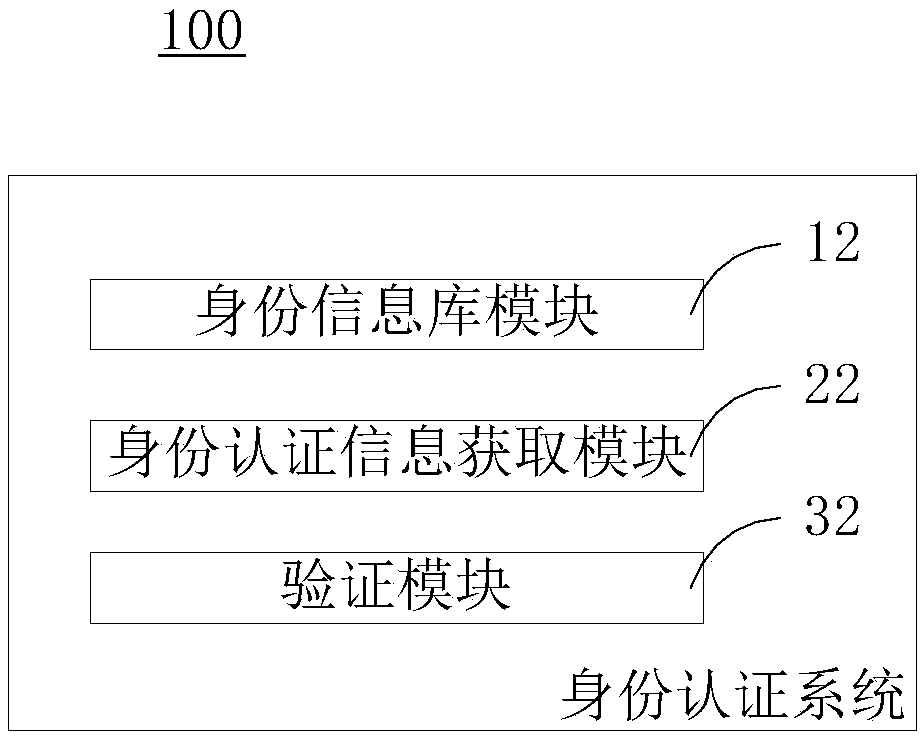

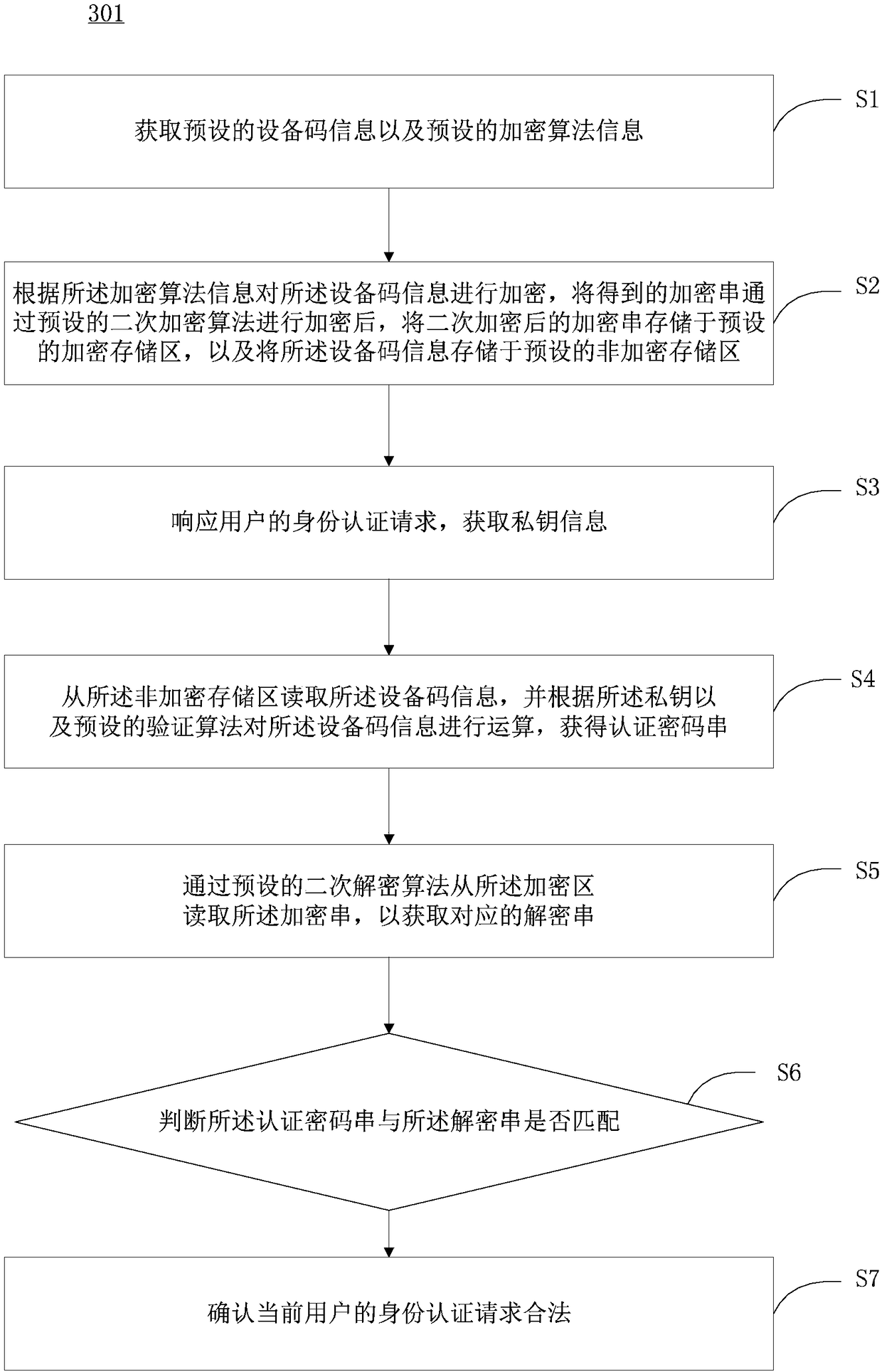

Identity authentication method and system and computer readable storage medium

ActiveCN108965222AEnsure safetyAvoid risk of crackingUser identity/authority verificationPasswordAuthentication system

The present invention discloses an identity authentication method. The method comprises the steps of: performing encryption of device code information according to encryption algorithm information, storing encryption strings after secondary encryption into a preset encryption storage area, and storing the device code information to a preset non-encryption storage area; when identity authenticationis performed, performing operation of the device code information according private keys to obtain authentication password strings; reading the encryption strings to obtain corresponding decryption stings; determining whether the authentication password strings are matched with the decryption strings or not; and performing verification of the validity of an identity authentication request of a current user. The identity authentication method does not depend on a server, and fully hides the identity information so as to effectively avoid the risk of crack based on the identity information files and achieve separation of three portions of hardware, encryption strings and the identity authentication program. The present invention further provides an identity authentication system and a computer readable storage medium.

Owner:PUHUA YUNCHUANG TECH (BEIJING) CO LTD

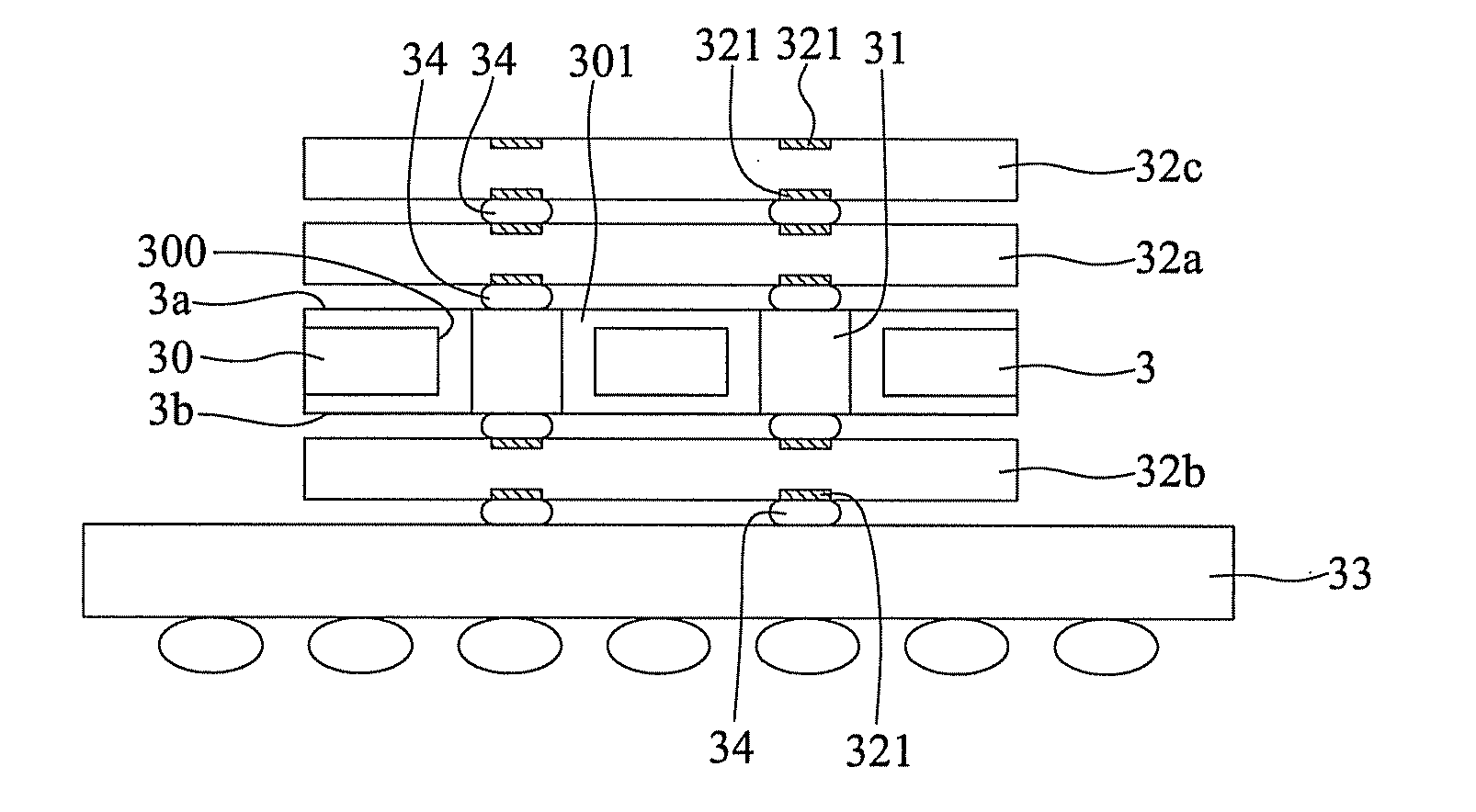

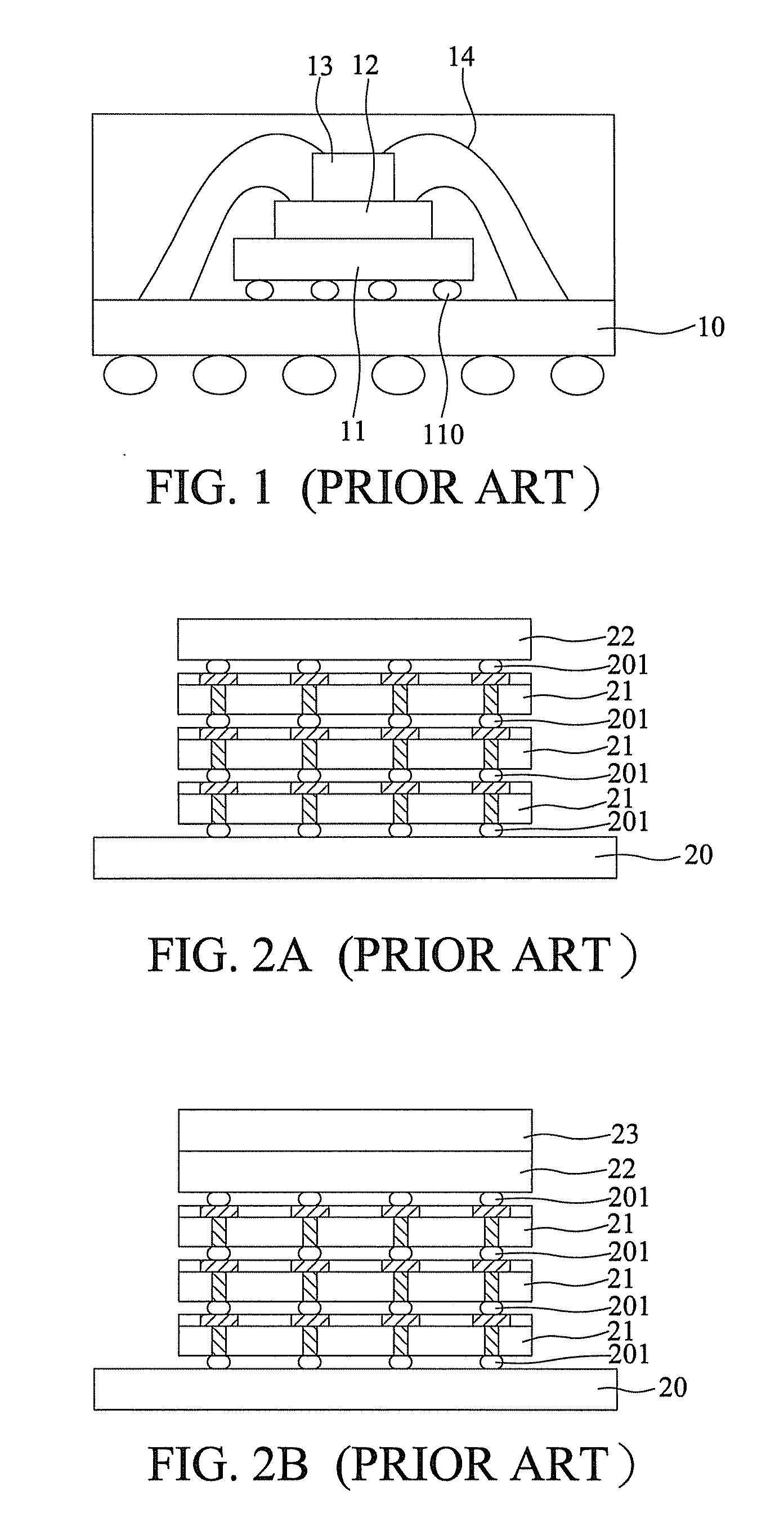

Multi-chip stack package structure and fabrication method thereof

InactiveUS20120168936A1Avoid risk of crackingImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A multi-chip stack package structure includes: an inner-layer heat sink having a first surface and a second surface opposing one another and having a plurality of conductive vias penetrating the first surface and the second surface; a first chip disposed on the first surface of the inner-layer heat sink; and a second chip disposed on the second surface of the inner-layer heat sink. Thereby, a heat-dissipating path is provided within inner-layers of the multi-chip stack package structure, and the rigidity of the overall structure is enhanced.

Owner:SILICONWARE PRECISION IND CO LTD

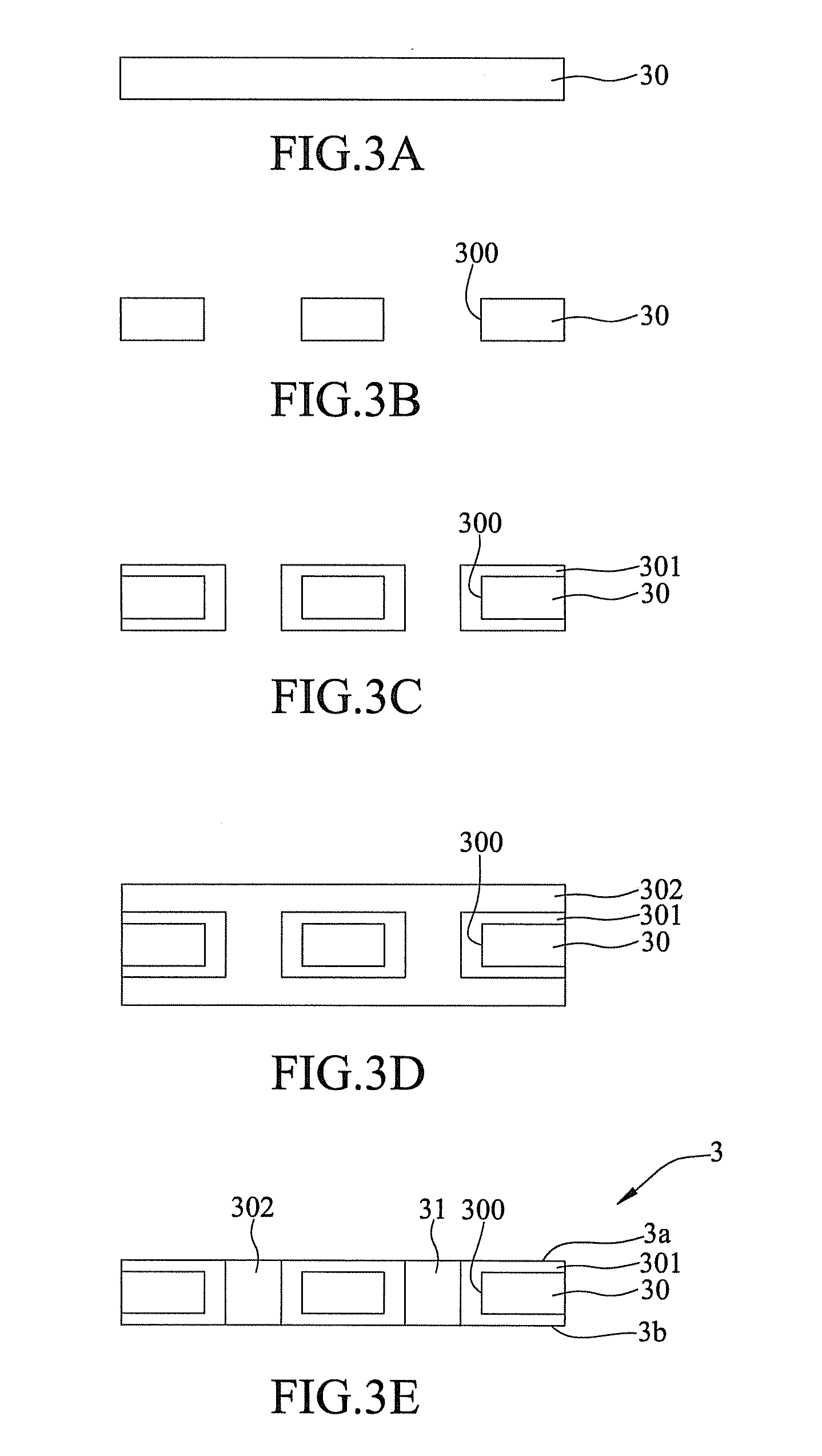

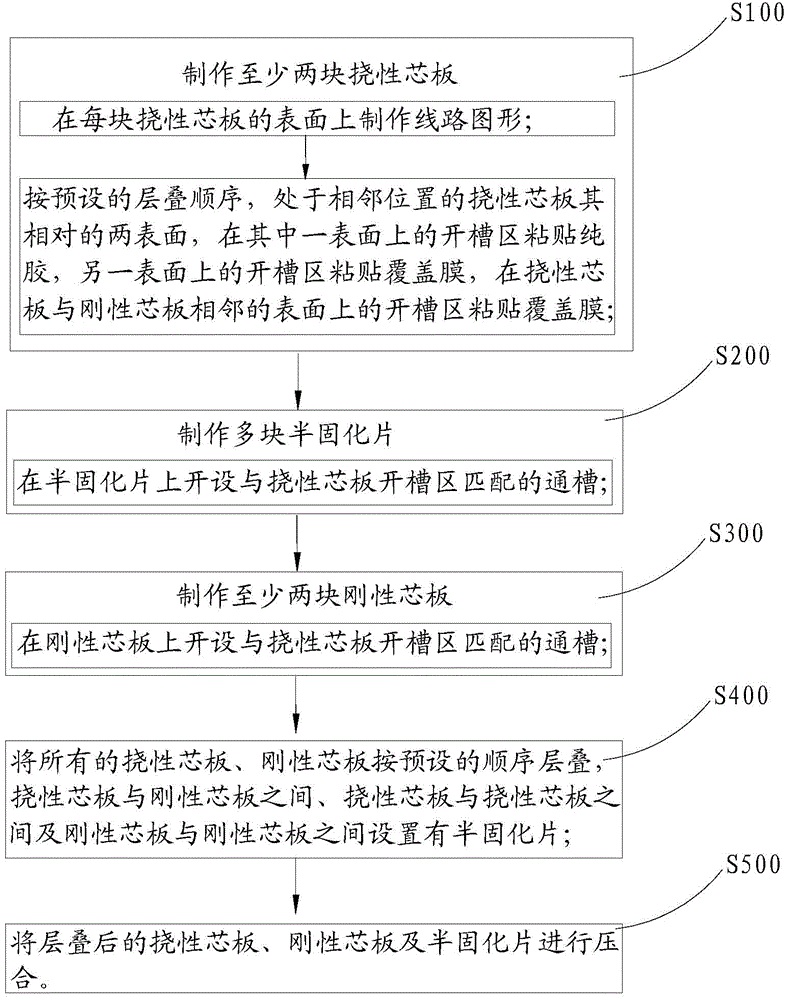

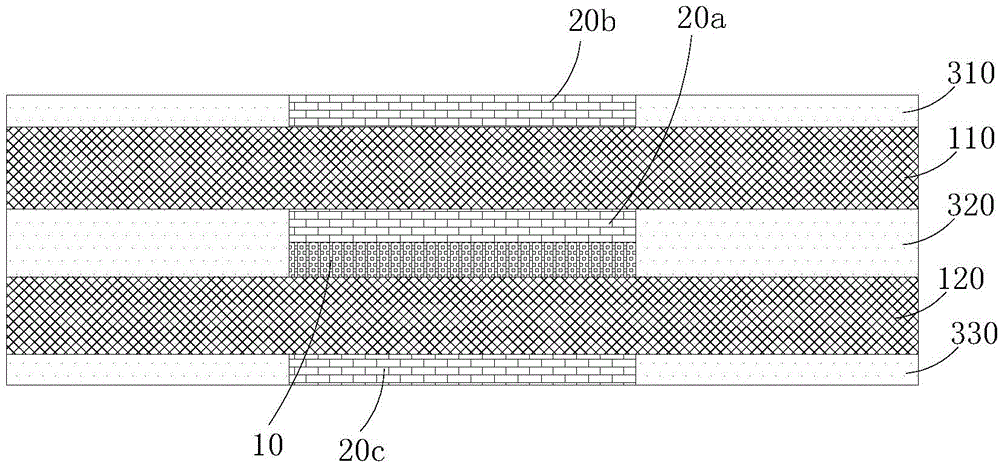

Non-laminated rigid-flexible printed circuit board and manufacturing method thereof

ActiveCN104394643AGuaranteed reliabilityGuaranteed dimensional stabilityProcessing steps orderMultilayer circuit manufactureRigid corePrinted circuit board

The invention provides a non-laminated rigid-flexible printed circuit board and a manufacturing method thereof. The manufacturing method of the non-laminated rigid-flex printed circuit board comprises the steps of: manufacturing at least two flexible core boards; manufacturing a circuit pattern on the surface of each flexible core board; sticking pure glue at the slotting zone on one of two opposite surfaces of the adjacent flexible core boards arranged according to the preset stack-up sequence, sticking a cover film at the slotting zone on the other surface and sticking the cover films at the slotting zones on the adjacent surfaces of the flexible core boards and the rigid core boards; arranging grooves, matching with the slotting zones of the flexible core boards, on the rigid core boards and the prepregs; stacking up and pressing all flexible core boards, rigid core boards and prepregs according to the preset sequence. According to the non-laminated rigid-flexible printed circuit board and the manufacturing method thereof, the cracking risk of holes can be effectively avoided, the heat-resisting reliability and size stability of the non-laminating rigid-flexible printed circuit board can be guaranteed and the impedance design requirement of the rigid-flexible print circuit board can be guaranteed.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

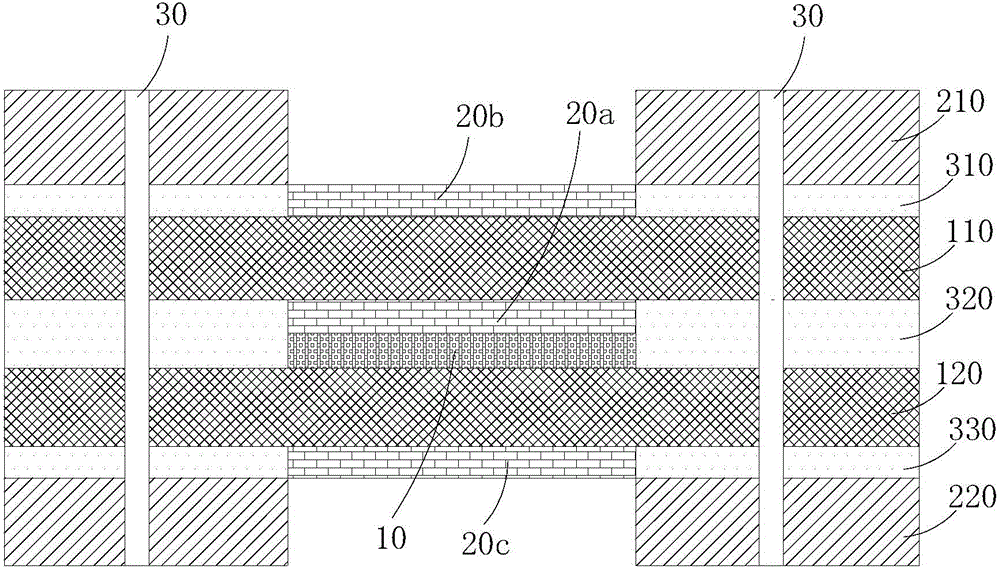

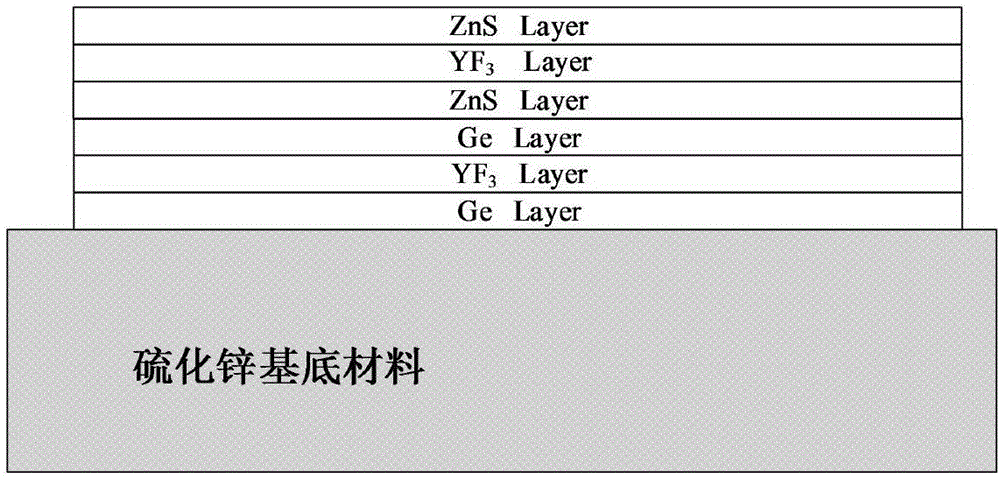

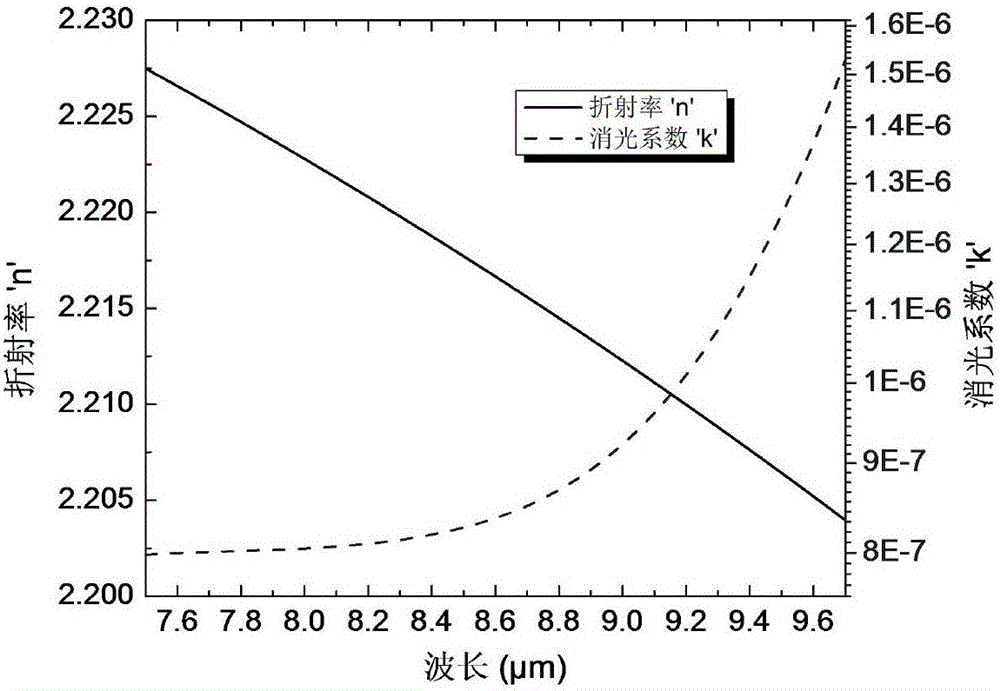

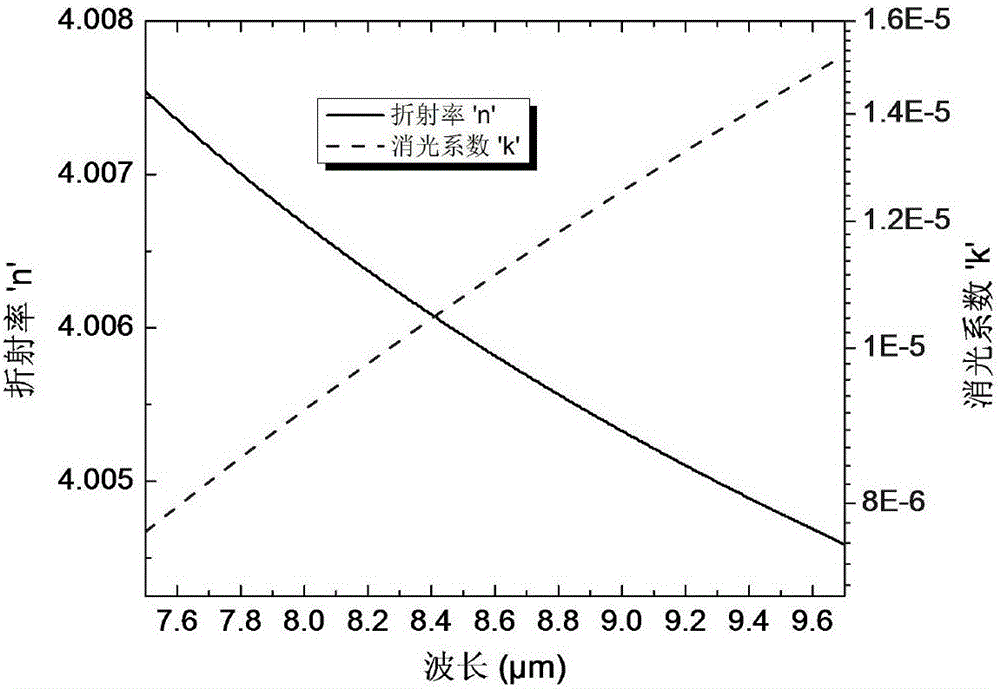

Ultralow residual reflectance ZnS substrate long wave antireflection film

ActiveCN106443841AAvoid cracking and falling offHigh application valueOptical elementsPhysicsWave band

The invention discloses an ultralow residual reflectance ZnS substrate long wave antireflection film. The antireflection film is characterized by being combined with three kinds of film material including germanium, zinc sulfide and yttrium fluoride, and the total physical thickness of the antireflection film is controlled within 2 micrometer. There are two layers of the yttrium fluoride film with high stress; the thickness of a larger yttrium fluoride film layer is less than 0.4 micrometer. By coating the antireflection film, the maximum residual reflectance of ZnS substrate at wave band of 7.5-9.7 micrometer can be lowered to below 0.5%, the average reflectance is lowered to below 0.1%. The antireflection film is applicable to all kinds of antireflection treatment for surface of zinc sulfide substrate and can be prepared by various sedimentation methods of thermal evaporation.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Preparation method for metal-doped modified turbine blade laser cladding surface coating layer

PendingCN109778184AHigh strengthHigh hardnessMetallic material coating processesStructure analysisStructural stability

The invention discloses a preparation method for a metal-doped modified turbine blade laser cladding surface coating layer. The preparation method comprises the following steps of performing cleaningpretreatment on a 17-4PH stainless steel blade matrix material; doping Mo powder into 17-4PH powder, performing full and uniform mixing in a ball mill, performing heating and drying in a drying furnace, and taking the dried powder as laser cladding composite powder for standby; under the argon condition, adopting a laser cladding process to enable the laser cladding composite powder to clad on thepretreated 17-4PH stainless steel blade matrix; and performing microscopic structure analysis and performance detection on a coating layer. The coating layer is high in hardness, excellent in corrosion resistance and good in structural stability; and through metallurgical bonding with the matrix, the coating layer is reasonable in cost and can better meet the service requirements of turbine powermechanical engineering.

Owner:XIAN UNVERSITY OF ARTS & SCI

Prefabricated bottom plate of laminated slab, laminated slab, and preparation method of laminated slab

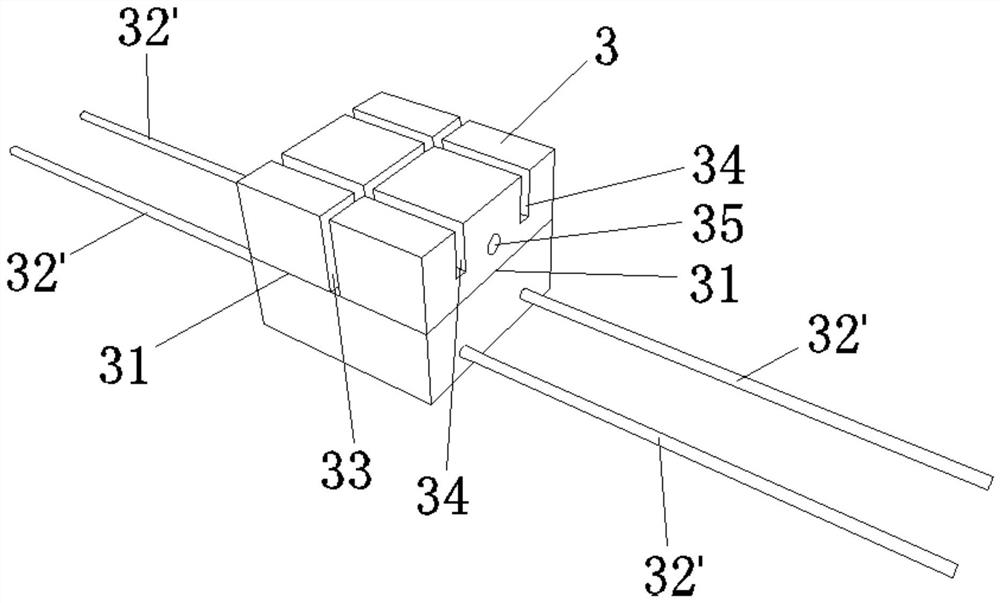

ActiveCN112012386AEasy to disassembleConvenient positioning and bindingFloorsCeramic shaping apparatusEngineeringRebar

The invention discloses a prefabricated bottom plate of a laminated slab, the laminated slab, and a preparation method of the laminated slab, and belongs to the field of prefabricated buildings. The prefabricated bottom plate of the laminated slab comprises connecting part groups, a first composite steel bar layer, and a concrete bottom plate. Each of connecting parts comprises a connecting blockand positioning steel bars horizontally penetrating through the lower part of the connecting block; the upper part of each of the connecting blocks is provided with a downwards concave connecting groove and penetrated plug pin holes vertical to the connecting groove; and the connecting grooves are used for inserting webs, with inserted holes, of profile steel parts. The first composite steel bar layer comprises an upper steel bar layer and a lower steel bar layer; the positioning steel bars of the connecting parts and the lower steel bar layer are located on the same plane; the connecting blocks penetrate through meshes of the first composite steel bar layer; and the plug pin holes are located above the concrete bottom plate. Due to the design of the connecting grooves and the plug pin holes in the upper side of the prefabricated bottom plate, the profile steel parts can be detached, hoisting and stacking are convenient, and the positioning steel bars of the prefabricated bottom platecan also prevent the risk that the multifunctional concrete block connecting parts are pulled out of the prefabricated bottom plate in the lifting and hoisting process.

Owner:上海凯汇建筑设计有限公司

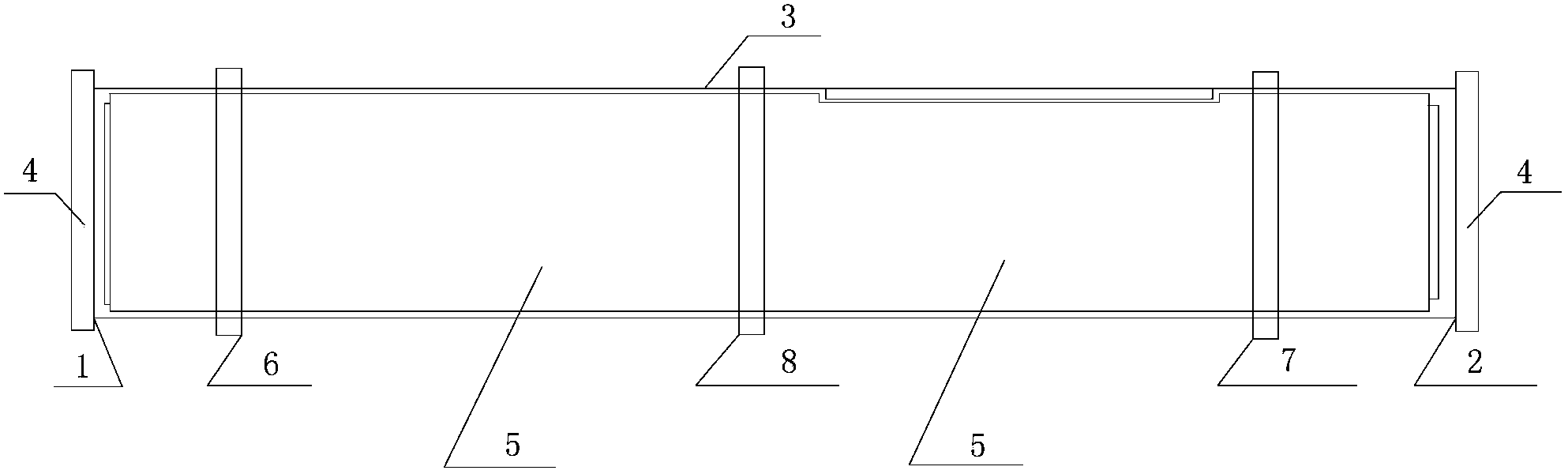

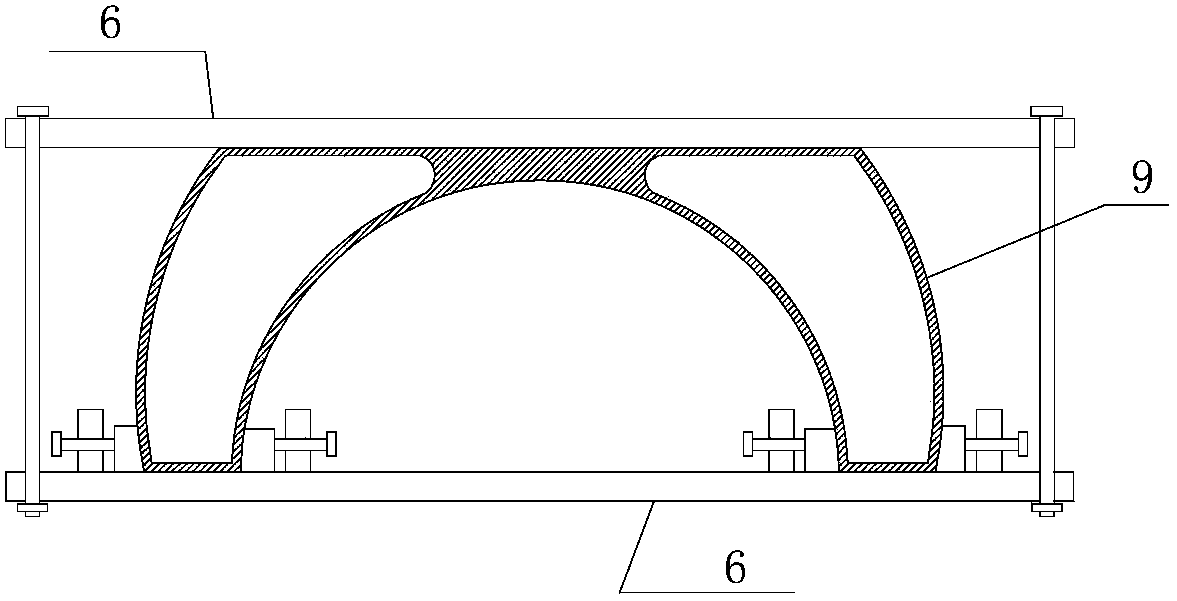

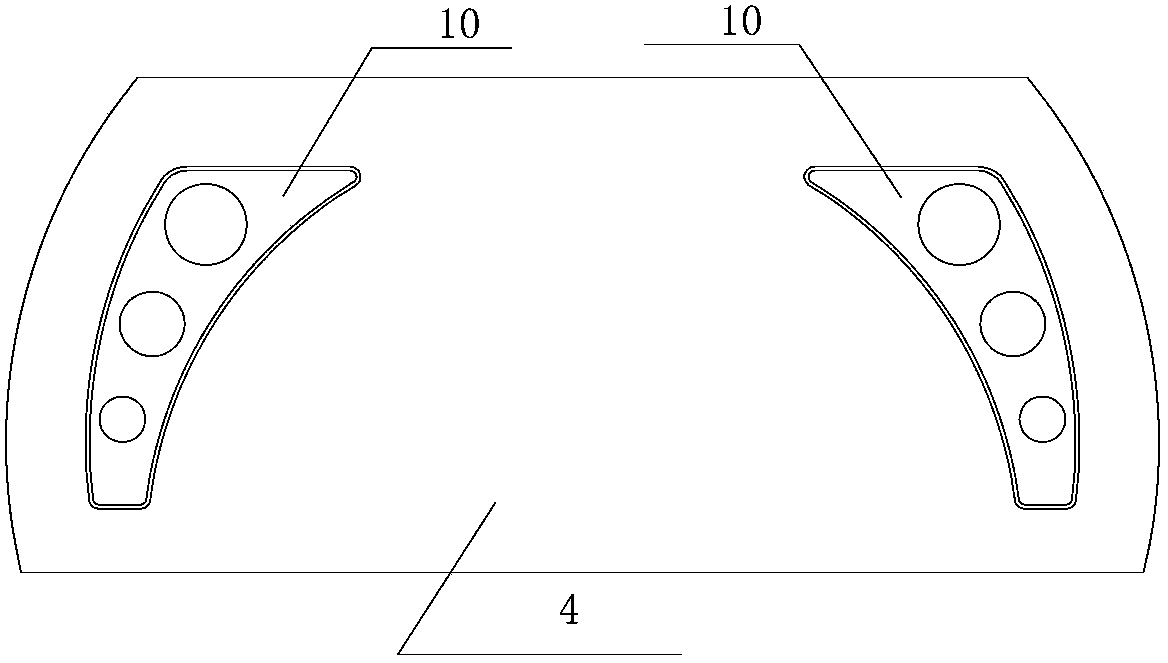

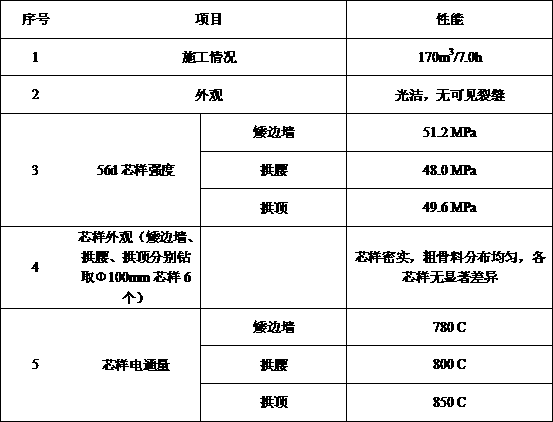

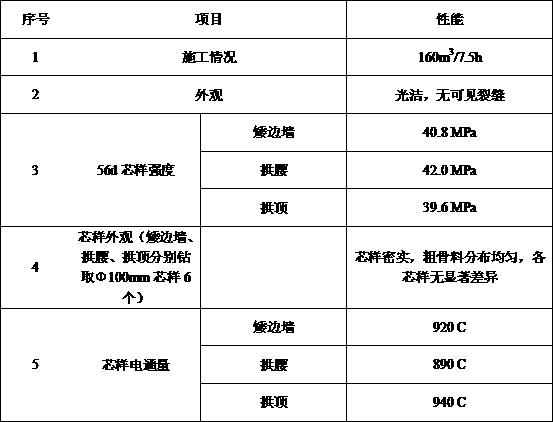

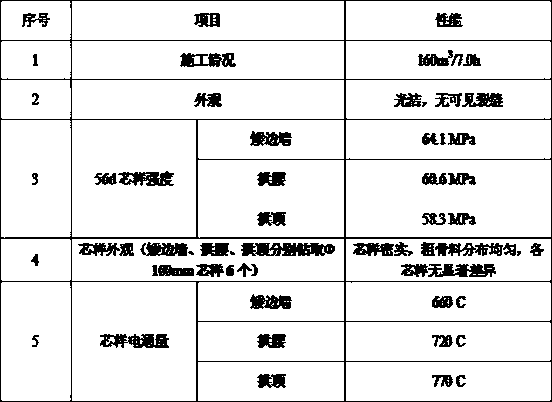

Self-filling concrete for railway tunnel lining

The invention belongs to the field of building materials, and particularly relates to self-filling concrete for railway tunnel lining, wherein the self-filling concrete is prepared by stirring a gelling component, an anti-cracking component, a viscosity adjusting component, a hydration temperature rise inhibiting component, an anti-corrosion component, an anti-freezing component, a water reducingcomponent, aggregate and water in a forced stirrer according to a certain ratio. According to the invention, the concrete has the performance characteristics of excellent self-filling property, gap trafficability, dynamic stability, high robustness, cracking resistance and the like under the action of micro-vibration, is suitable for railway tunnel lining structures, and is also suitable for the fields of highway tunnels, water conservancy tunnels, underground engineering and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

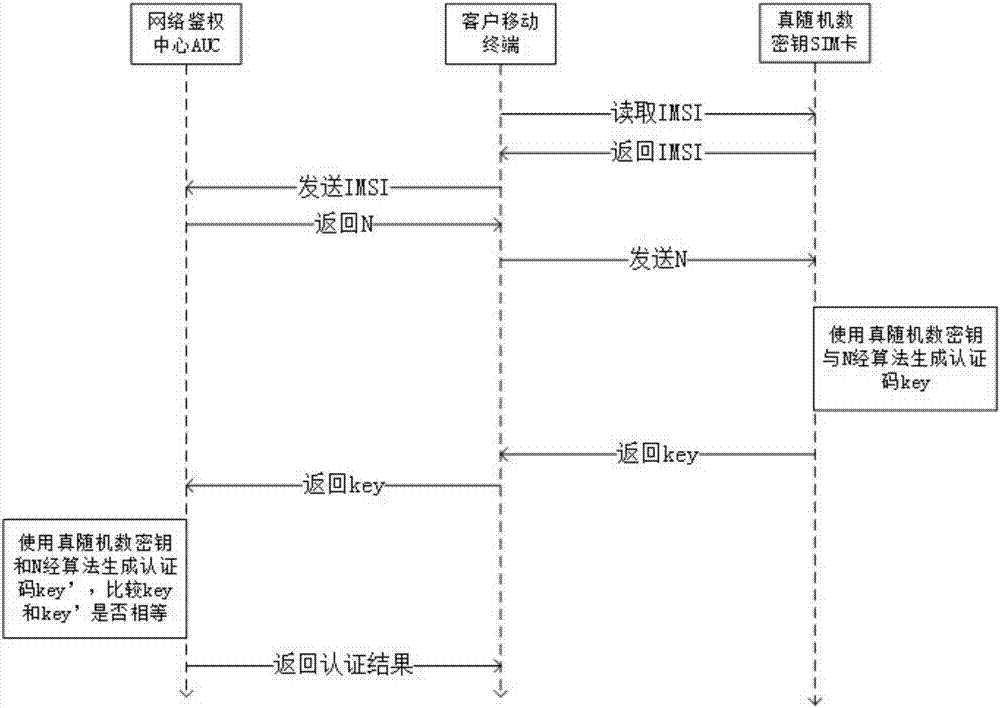

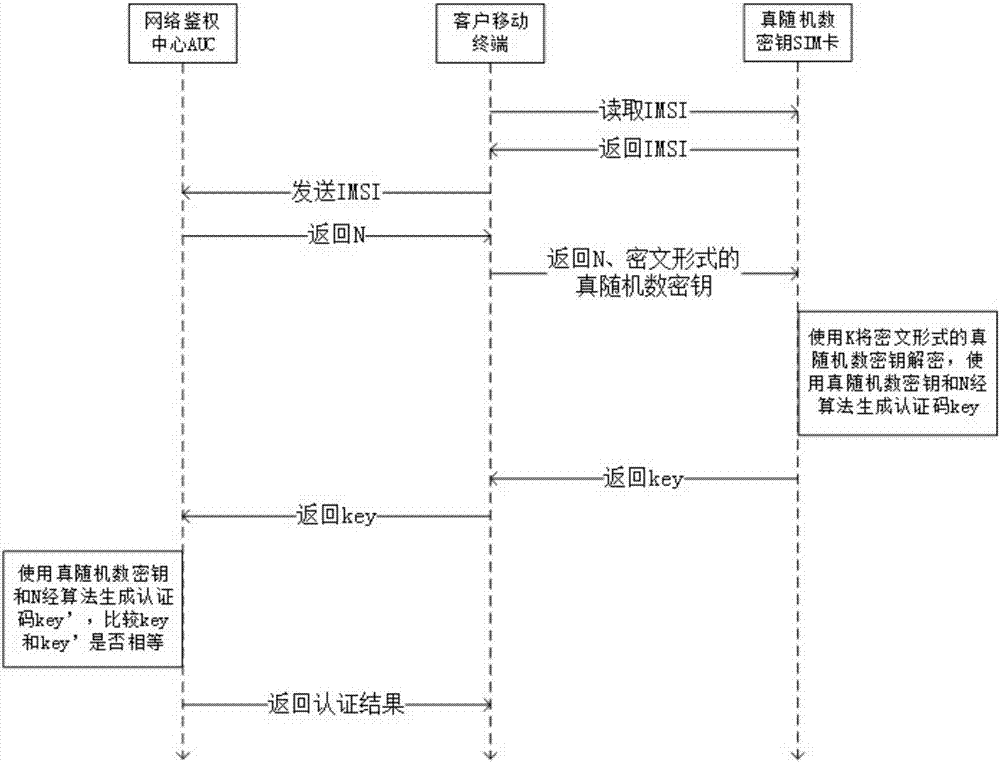

Improved SIM card and mobile communication identification method and system

ActiveCN107333263APrevent the risk of being crackedImprove securityKey distribution for secure communicationSecurity arrangementMobile communication networkRandom number generation

The invention discloses an improved SIM card, and a mobile communication identification method and system. The mobile communication identification method based on the improved SIM card, which is disclosed by the invention, is implemented between a mobile communication network and the SIM card mounted in a mobile terminal, and comprises the steps that: one of the mobile communication network and the SIM card utilizes a first authentication key and a random number from an opposite side to generate a first authentication response, and sends the first authentication response to the opposite side; and the opposite side generates a second authentication response by the random number and a second authentication key, and the first authentication response is compared with the second authentication response to carry out identification, wherein the first authentication key and the second authentication key are corresponding true random number keys and are distributed between the mobile communication network and the SIM card in advance. In the invention, an authentication code used when the mobile terminal logs in the mobile communication network every time is generated by the true random number keys shared by the SIM card and the mobile communication network, so that the risk that a Ki key in a conventional SIM card is cracked is effectively prevented.

Owner:ZHEJIANG SHENZHOU QUANTUM NETWORK TECH CO LTD

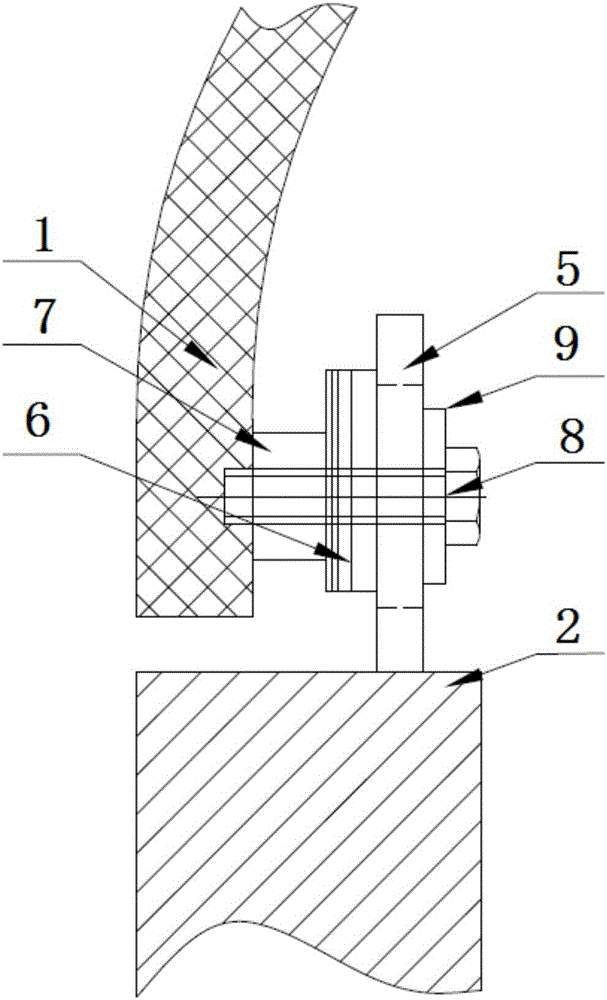

Mounting structure and mounting method for driver cab bow cap

ActiveCN106314460ASimple structureImprove positioning reliabilityRailway transportAxle-box lubricationFastenerMarine engineering

The invention discloses a mounting structure and a mounting method for a driver cab bow cap. The mounting structure for the driver cab bow cap comprises a centre positioning structure and a side positioning structure which are arranged between the bow cap and a vehicle body; the centre positioning structure comprises a bow cap positioning element and a vehicle body positioning element; the vehicle body positioning element and the bow cap positioning element are matched in the transverse direction of a driver cab for positioning; the side positioning structure comprises a plurality of positioning holes which are formed in a bow cap mounting surface and a plurality of positioning plates which are fixed to the side wall of the vehicle body; the positioning plates are fixedly connected with the positioning holes in the bow cap mounting surface through fasteners; adjusting elements are arranged between the positioning plates and the positioning holes in the bow cap mounting surface. According to the mounting structure and the mounting method for the driver cab bow cap, the problem that the bow cap is difficult to position when the bow cap is mounted, and the problems that molded lines of the bow cap and the vehicle body with a metal structure cannot be aligned because of the deformation of the bow cap and the vehicle body with the metal structure, the mounting time is long, a rubber layer cracks and the like are solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Anti-rotation implant device

The invention discloses an anti-rotation implant device which comprises an implant, an abutment and a central bolt. The anti-rotation implant device is characterized in that the implant comprises a gum penetrating neck and a head; a thread is arranged on the outer surface of the head; at least two helical self-tapping grooves are formed in the outer surface of the head; connecting holes are formed in the implant and are a positioning hole and a threaded blind hole which are coaxially connected in sequence; at least two positioning embossments are arranged on the upper end surface of the implant body; the abutment comprises a dental crown connecting section and an implant connecting section; an annular positioning table is arranged between the dental crown connecting section and the implant connecting section; positioning grooves matched with the positioning embossments are formed in the annular positioning table; a ladder hole matched with the central bolt is formed in the abutment; the central bolt penetrates through the ladder hole to be connected with the threaded blind hole so as to fix the abutment to the implant. According to the anti-rotation implant device, the positioning embossments on the upper end surface of the implant are matched with the annular positioning table on the abutment, so that a relatively large rotary torque can be born, connection is relatively firm, and the service life is prolonged.

Owner:DALIAN SANSHENG SCI & TECH DEV

Reducing type communtator manufacturing method

ActiveCN103001090AReduce processing costsThe process steps are simpleRotary current collectorCommutators manufactureThermal treatmentEngineering

The invention relates to a reducing type communtator manufacturing method. Compared with the prior art, the reducing type communtator manufacturing method adopts a support with an inner circular hole, a member used for fixing the outer circumference surface of a cylinder is formed on the inner wall of the support, the member is fittingly fixed with the portion, where a groove is arranged, of the cylinder to form a composite part, the composite part is integrally placed into a die for injection molding, and finally, a finished reducing type communtator is obtained. By removing adjacent reversing pieces of the support to realize insulation instead of milling grooves among the reversing pieces by subsequent procedures, and technical process is simplified. Further, a small pretension force is required to press the integral composite part into a die cavity, and risk of cracks during thermal treatment of plastics can be prevented by removing the support after die forming.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

Plastic anti-cracking coating process for domestic appliance

InactiveCN102974515AGood lookingGood decorative effectPretreated surfacesSpecial surfacesAcrylonitrile butadiene styreneHome appliance

The invention discloses a plastic anti-cracking coating process for a domestic appliance. The plastic anti-cracking coating process for the domestic appliance is characterized in that water-based plastic coating of various colors replaces solvent type plastic coating to be used for plastic coating of the domestic appliance, the water-based plastic coating is enabled to be correctly used for the plastic coating of the domestic appliance, not only is the quality problem of cracking occurring in poly carbonate (PC), polymethyl methacrylate (PMMA), acrylonitrile butadiene styrene (ABS)+PMMA and other plastic coating solved, but also the needs of decorative appearance of plastic of the domestic appliance are met.

Owner:GUANGZHOU QINGTIAN INDAL +1

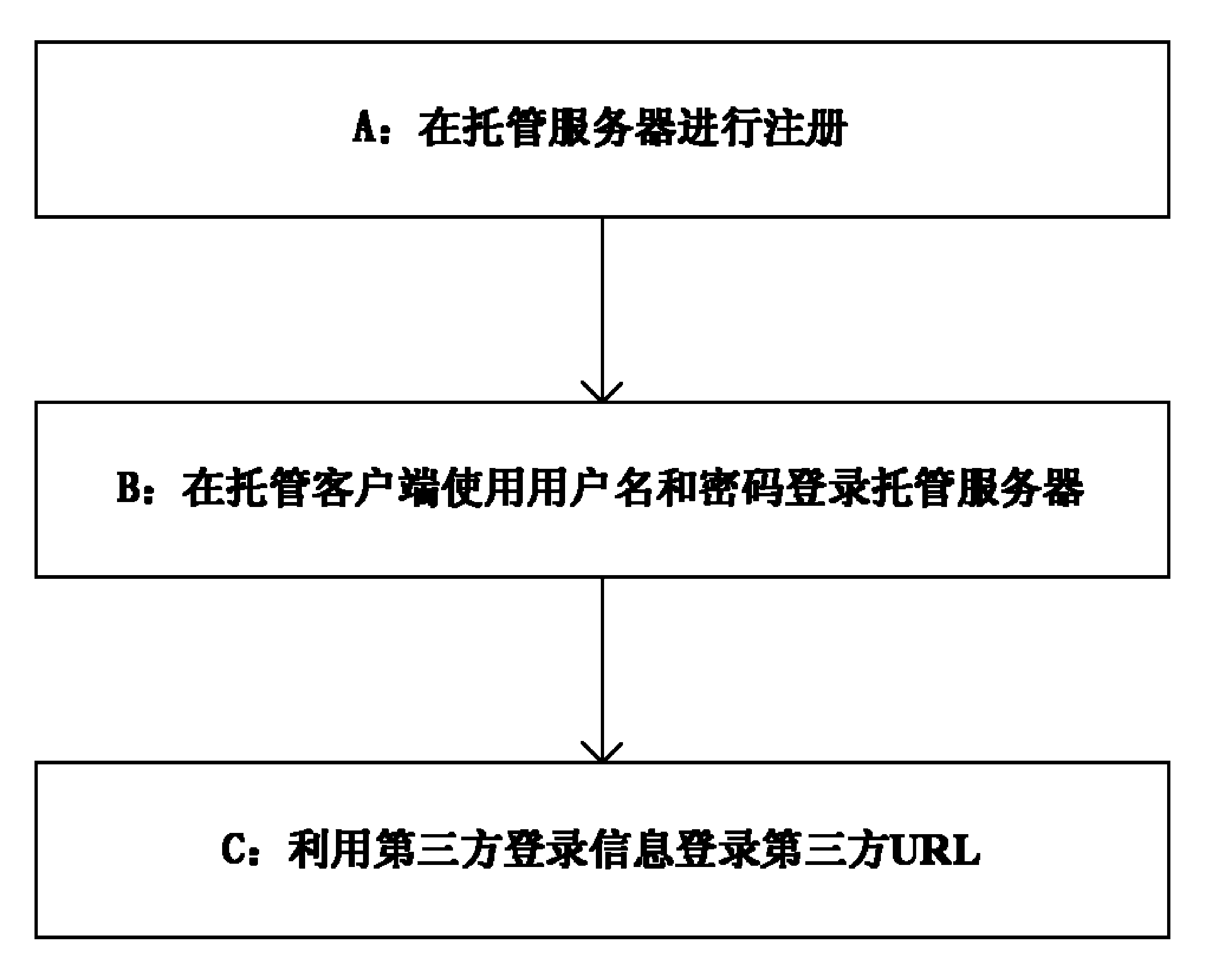

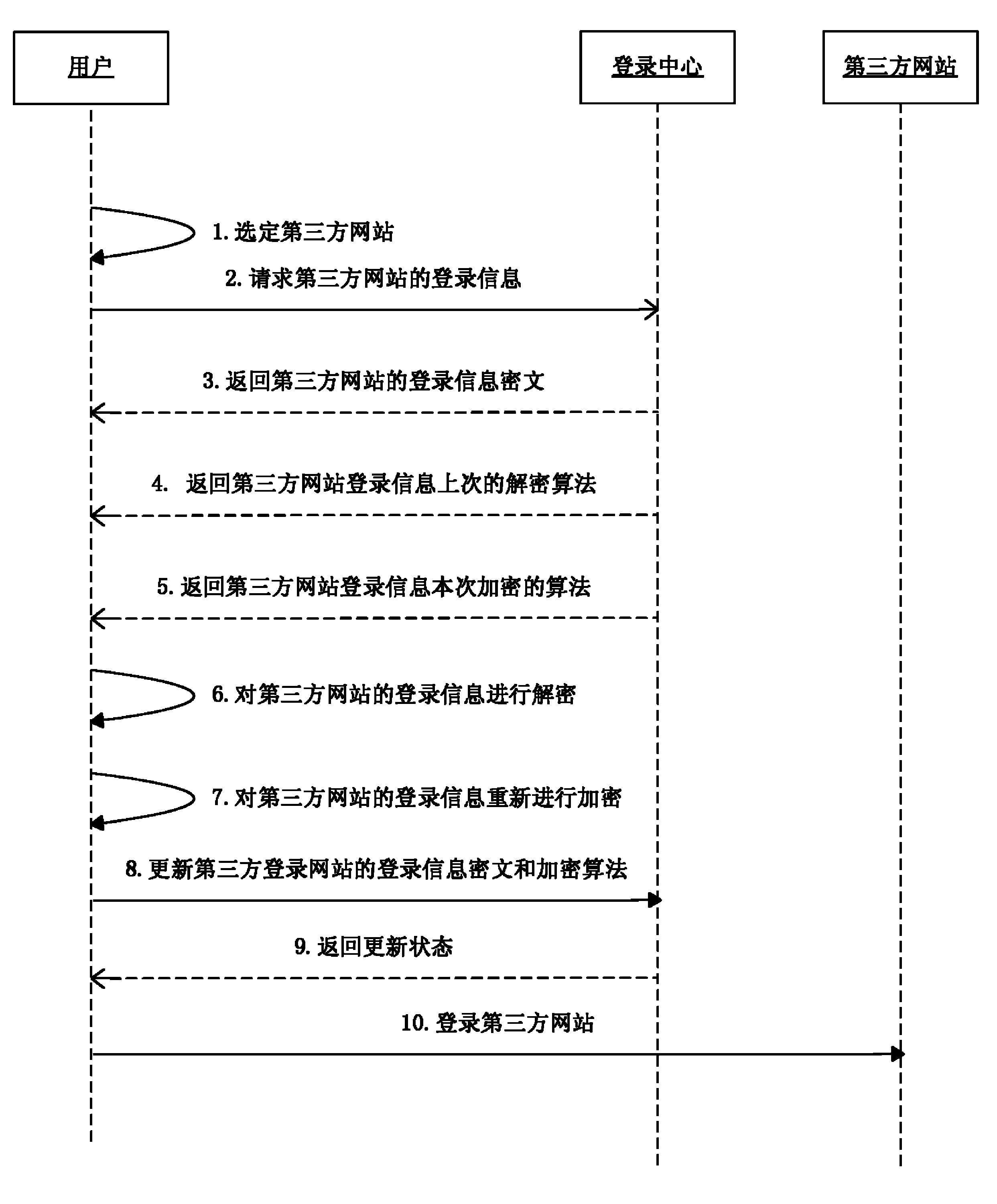

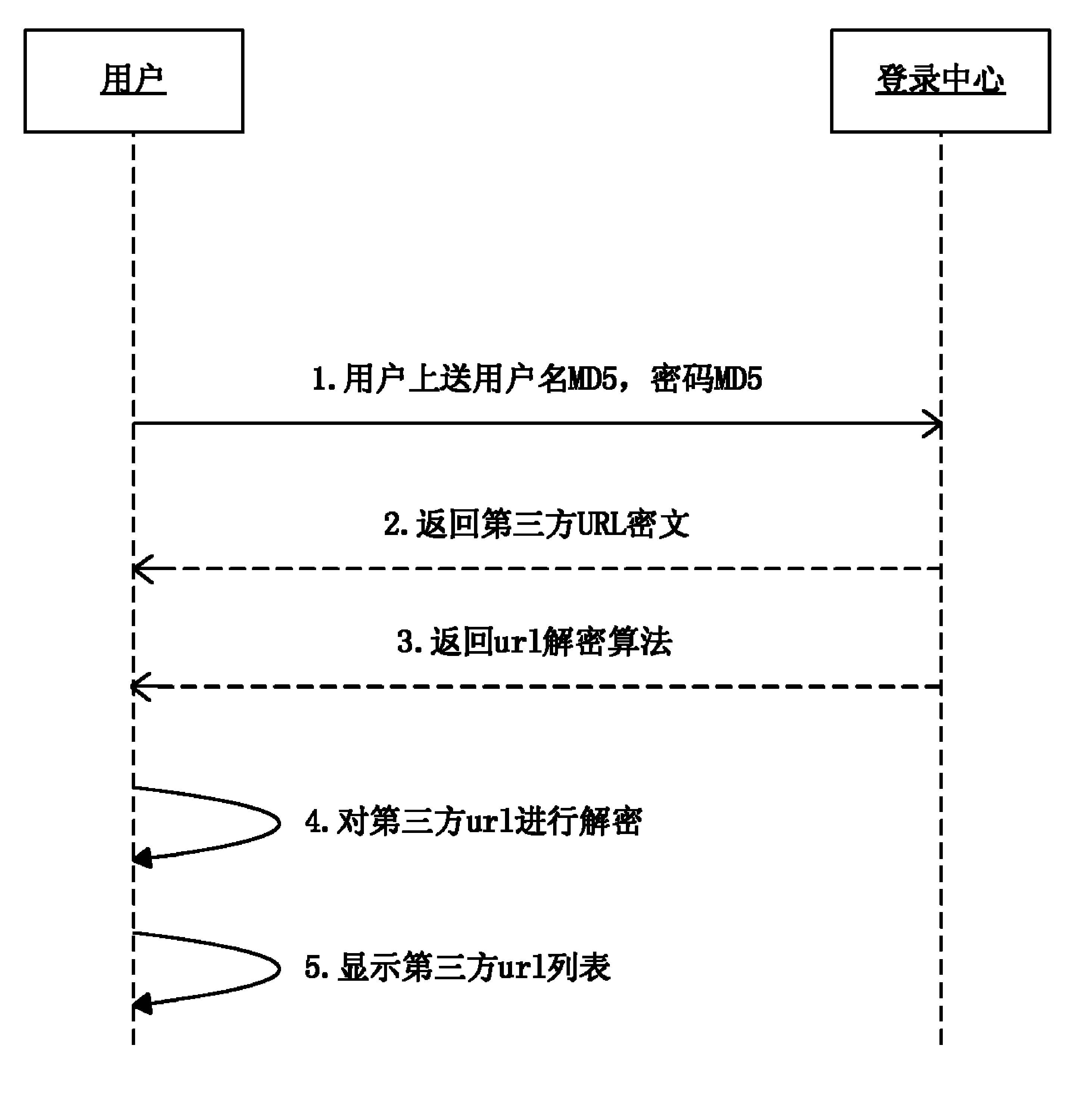

Third-party login information hosting method and system

The invention discloses a third-party login information hosting method and system. The third-party login information hosting method comprises the following steps that firstly, registration is conducted on a hosting server, wherein a user name and a password for the hosting server are generated through a hosting client side; secondly, a user logs in to the hosting server on the hosting client side through the user name and the password, wherein the hosting server returns third-party URL ciphertext to the hosting client side after the login succeeds; thirdly, third-party login information is used for logging in to a third-party URL, wherein third-party login information ciphertext and a decipherment algorithm of the third-party login information are acquired from the hosting server through the third-party URL ciphertext, the third-party login information ciphertext is deciphered through the decipherment algorithm of the third-party login information to obtain the third-party login information, and therefore the third-party URL is logged in.

Owner:CHINA UNIONPAY

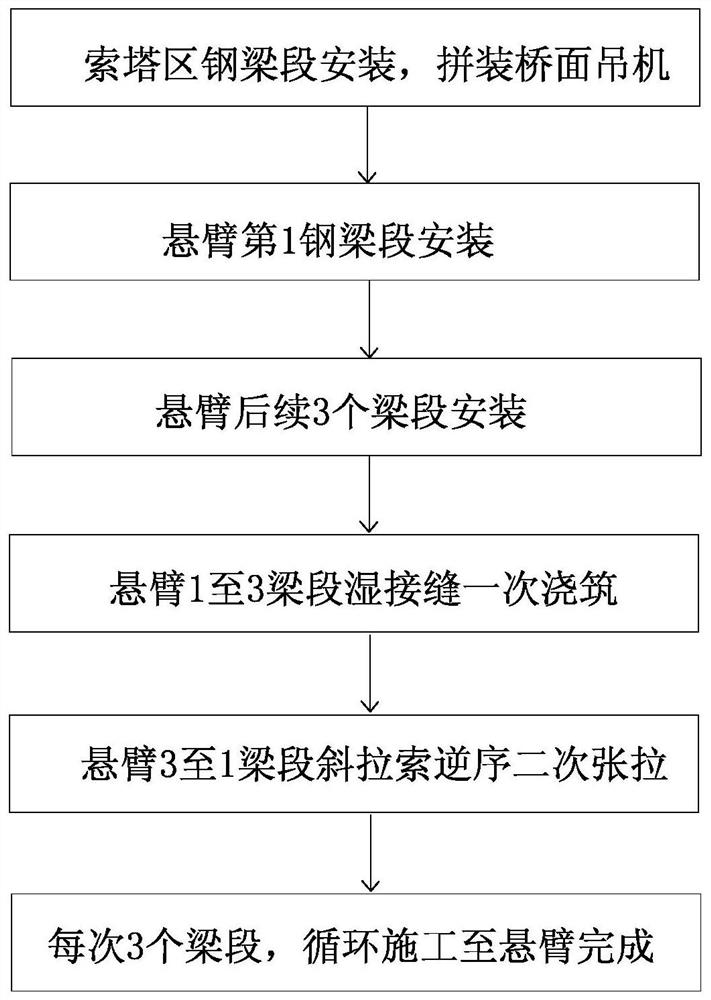

Rapid circulation construction method for upper structure of superposed beam cable-stayed bridge

ActiveCN111764283ALower requirementReduce interferenceCable-stayed bridgeBridge erection/assemblyCantilevered beamArchitectural engineering

The invention provides a rapid circulation construction method for an upper structure of a superposed beam cable-stayed bridge. The construction method comprises the following steps: firstly, continuously hoisting front four steel beam sections of a main beam cantilever, mounting a bridge deck on each beam section during connection, moving a bridge deck crane forwards to the forefront beam section, pouring wet joints of bridge decks of the other three beam sections at one time, and secondarily tensioning stay cables for a reverse sequence of the three beam sections; and then carrying out threebeam section construction every time according to the method till that all the cantilever beam sections are installed. Compared with an existing section-by-section installation method, by using the method of the invention, a construction progress can be improved; and compared with an existing method that wet joints of all beam sections are poured at the same time and the stay cables are tensionedin sequence, by using the method of the invention, a cracking risk of bridge decks and the wet joints can be avoided, cost is saved, and construction quality is guaranteed.

Owner:ROAD & BRIDGE INT +2

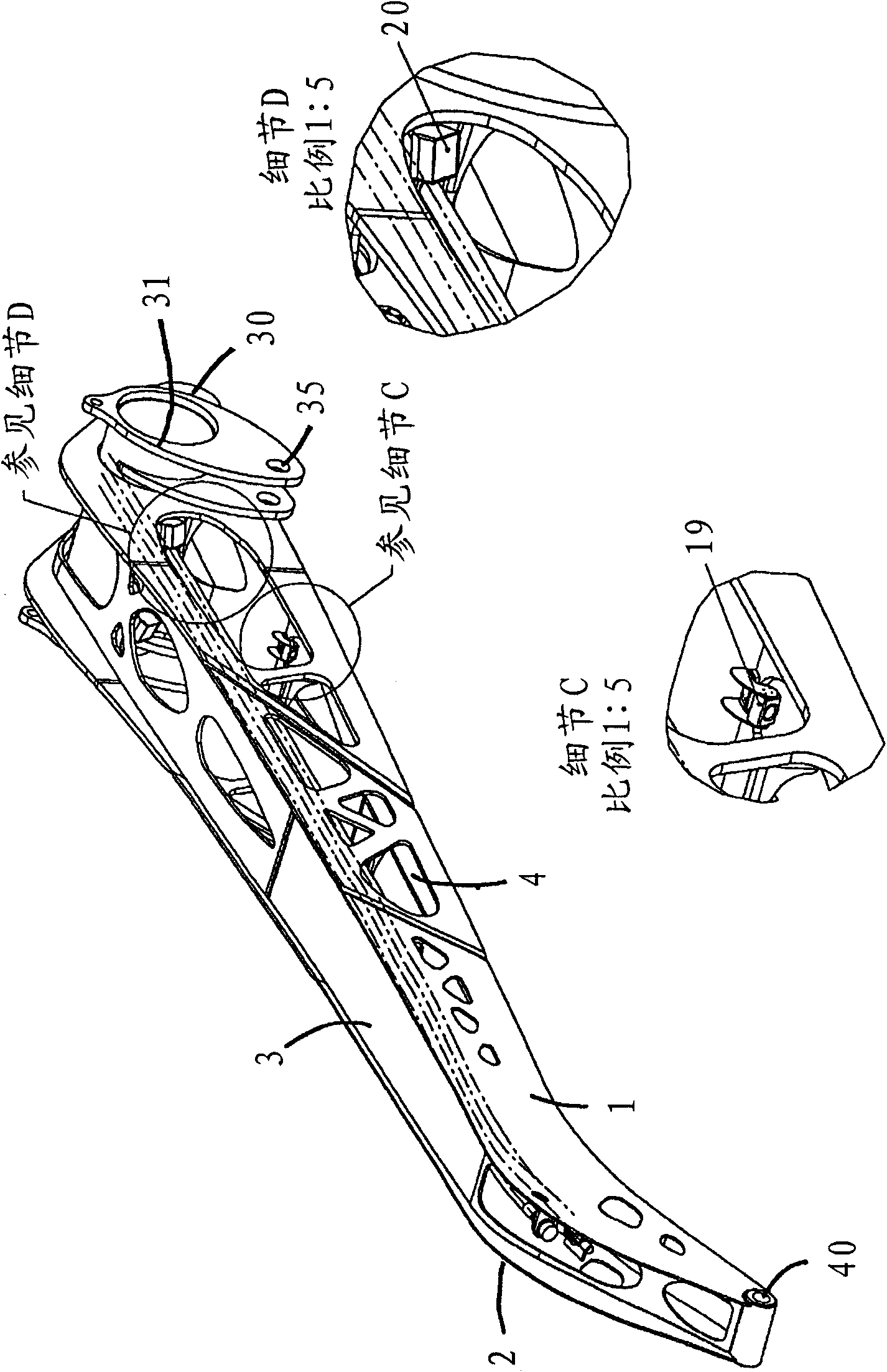

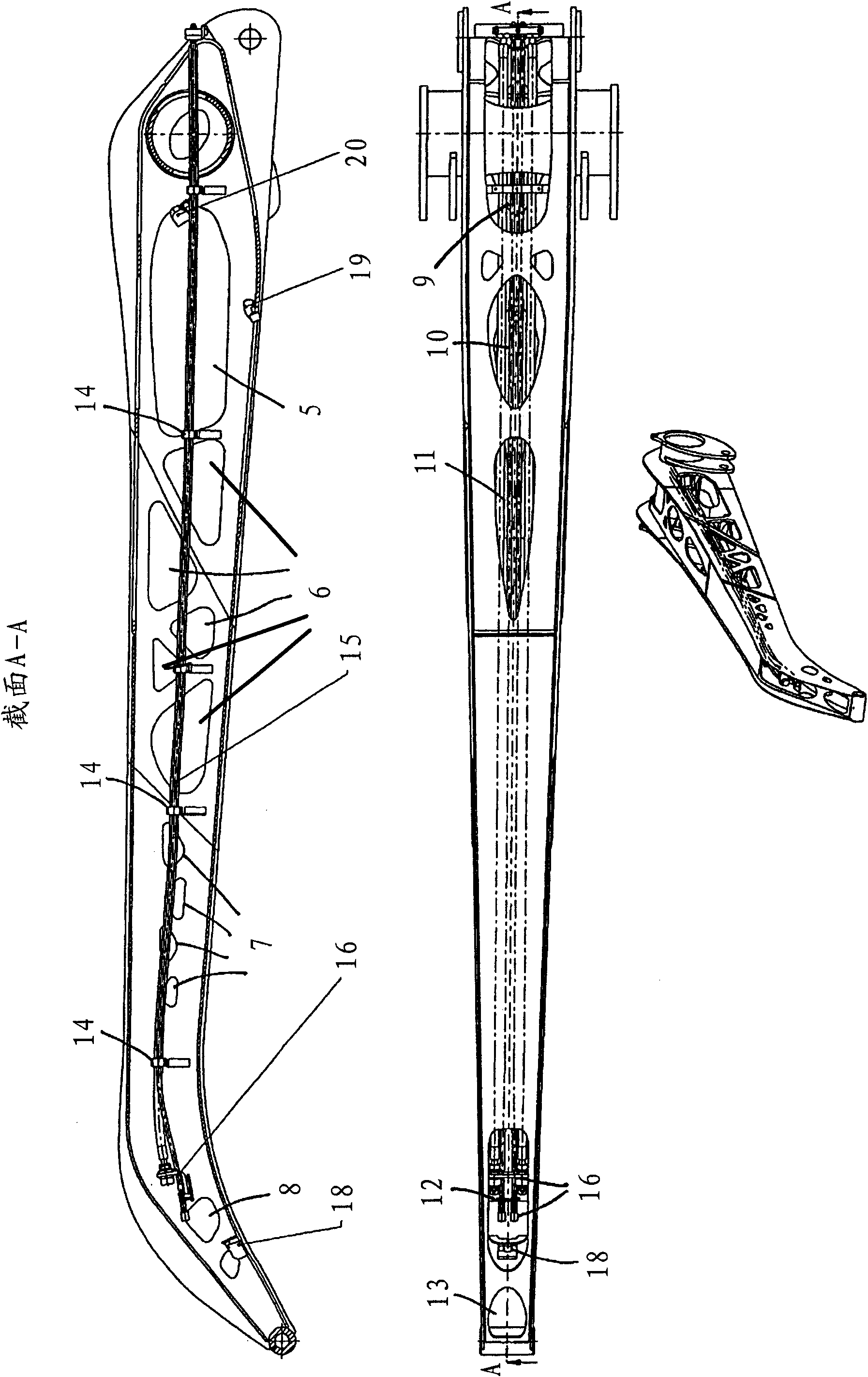

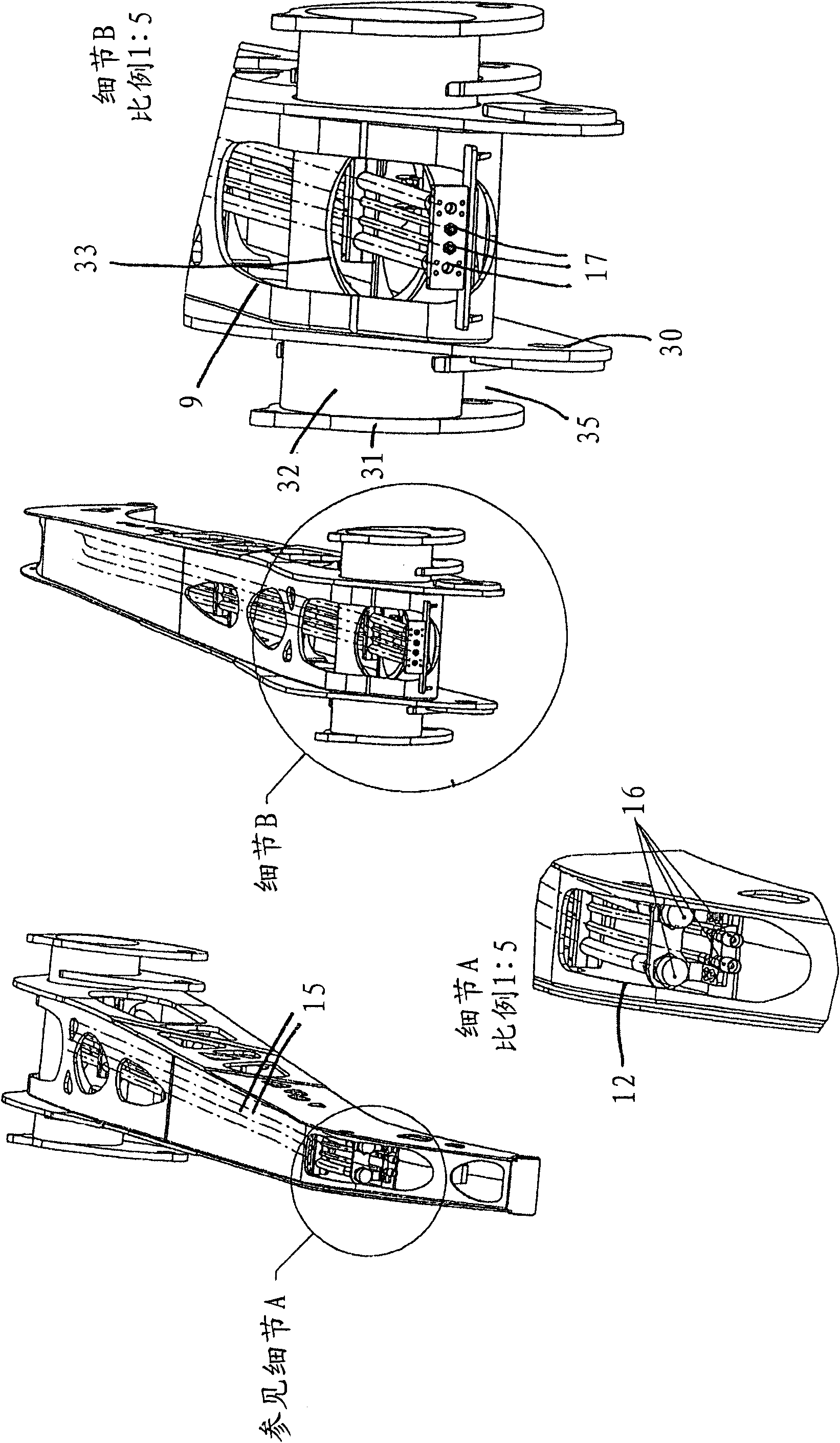

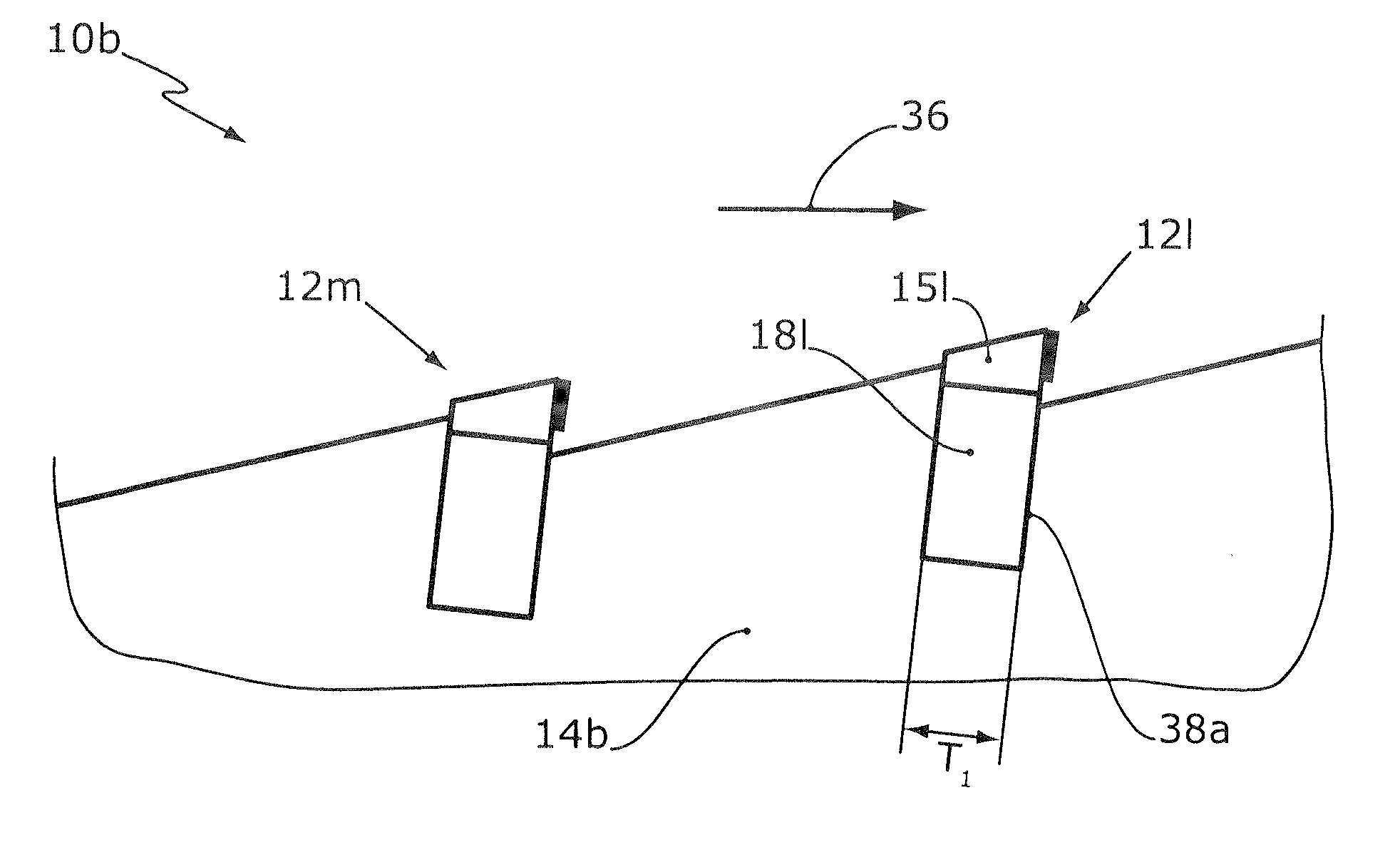

Excavator boom

This invention relates to a box section made of an upper and lower plate and side plates. The upper and lower plates and the side plates thus form a weldment. According to the invention, provision is made for the interior of the box section to be accessible from the outside through multiple cutouts that are arranged in the longitudinal direction of the excavator boom in the side plates and / or in the upper and / or lower plates.

Owner:LEIBHERR HYDRAULIKBAGGER GMBH

Saw blade having a small saw tooth

InactiveUS20140377021A1Avoid the notch effectAvoid risk of crackingMetal sawing devicesMilling cuttersEngineeringMechanical engineering

A saw tooth for a saw blade that is attached in a longitudinal direction thereof on the saw blade body to extend away, at least in part, from the saw blade body. The saw tooth is formed with a cutting-face part having a cutting face, a height of which extends in the longitudinal direction and a width of which extends perpendicularly to the longitudinal direction. The width of the cutting face is greater than a height of the cutting face.

Owner:AKE KNEBEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com