Preparation method of super capacitor electrode

A technology for supercapacitors and electrodes, which is applied in the field of preparation of electrodes for supercapacitors, can solve the problems of poor cycle life of supercapacitor monomers, low bonding strength of active materials, poor electrode uniformity, etc., and achieves high specific volume and high peeling strength. , Improve the effect of electrode specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

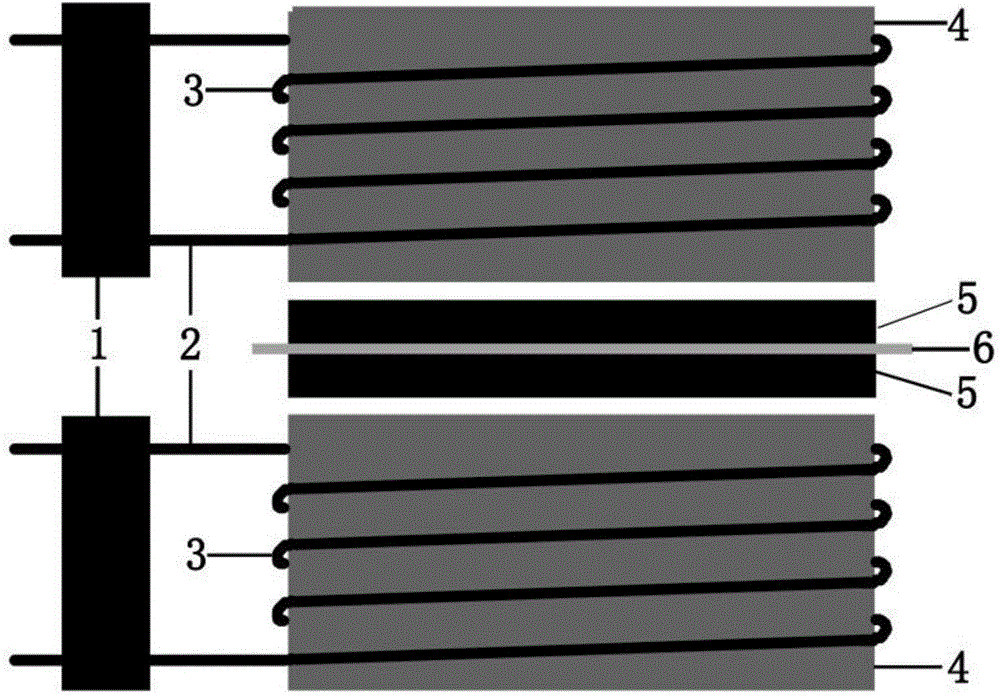

Image

Examples

Embodiment 1

[0035] After 880 grams of activated carbon and 50 grams of conductive carbon black were dry mixed with a planetary mixer, 1500 grams of solid content was added to be 2% sodium carboxymethyl cellulose aqueous solution and continued to stir for 2 hours; Ethylene emulsion and continue to stir, add 760 grams of water to adjust the viscosity of the slurry to 3820cp; use a transfer coater to evenly coat the resulting slurry on a 20μm corroded aluminum foil, with a thickness of 100μm on one side, and use a high-frequency electromagnetic induction device Heat the corroded aluminum foil at an induction frequency of 350kHz to dry the electrode, and the drying time is 30 seconds.

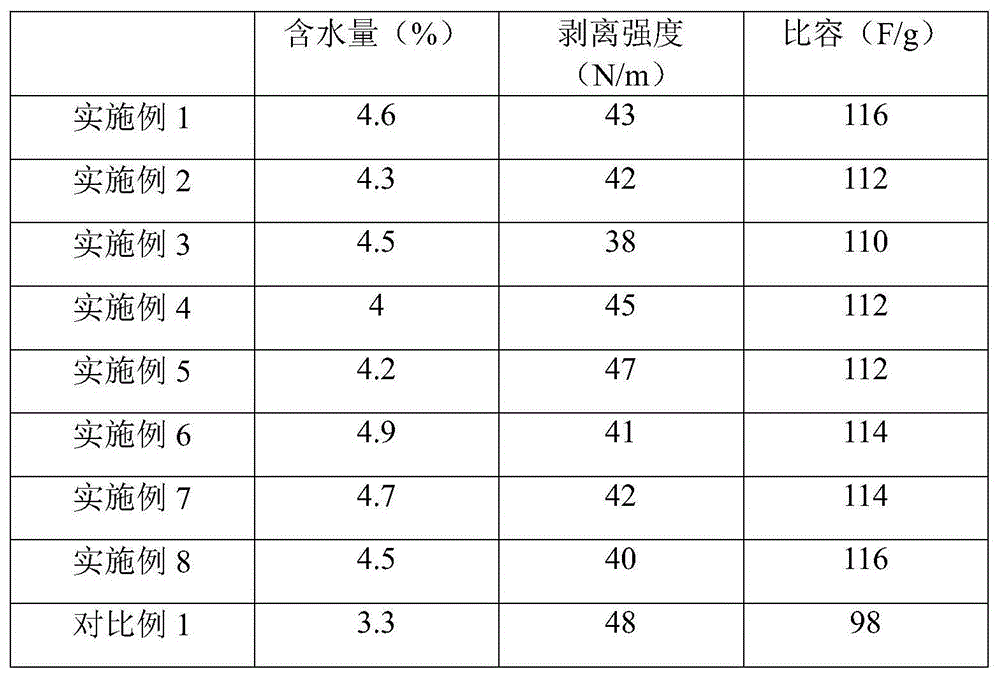

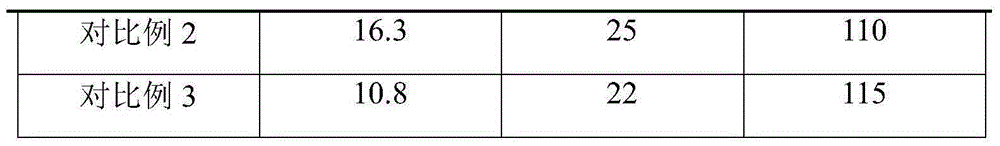

[0036] After the obtained electrode was rolled with a linear pressure of 4kN / cm, the water content of the pole piece was tested with an infrared moisture tester. Select some of the electrodes and use a cutter to cut the obtained electrodes into specifications of 10cm in length and 2cm in width, and use 3M doub...

Embodiment 2

[0038] After 900 grams of graphene and 30 grams of carbon nanotubes were dry-mixed uniformly with a vacuum kneader, 1500 grams of solid content was added to be 2% poly-N-vinylacetamide aqueous solution and continued to stir for 2 hours; 1 gram of styrene-butadiene rubber emulsion and continue to stir, add 600 grams of water to adjust the viscosity of the slurry to 2800cp; use a pull-type coater to evenly coat the gained slurry on a 20 μm corroded aluminum foil, with a single-side coating thickness of 120μm, use a high-frequency electromagnetic induction device to heat the corroded aluminum foil at an induction frequency of 300kHz to dry the electrode, and the drying time is 1min.

[0039] Test items and methods are the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0041] After dry mixing 860 grams of activated carbon fibers and 70 grams of conductive carbon black with a banbury mixer, add 1500 grams of N-methylpyrrolidone and continue to stir for 2 hours; add 80 grams of polyacrylate to the resulting mixture and continue to stir, add 520 grams of N-methylpyrrolidone adjust the viscosity of the slurry to 2530cp; the resulting slurry is evenly coated on a 20 μm corroded aluminum foil with an extrusion coater, and the corroded aluminum foil is heated with a high-frequency electromagnetic induction device at an induction frequency of 200kHz to Dry the electrode, the coating thickness on one side is 160 μm, and the drying time is 3 minutes.

[0042] Test items and methods are the same as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com