Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Avoid Galvanic Corrosion Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy vehicle wheel surface treatment method and magnesium alloy vehicle wheel

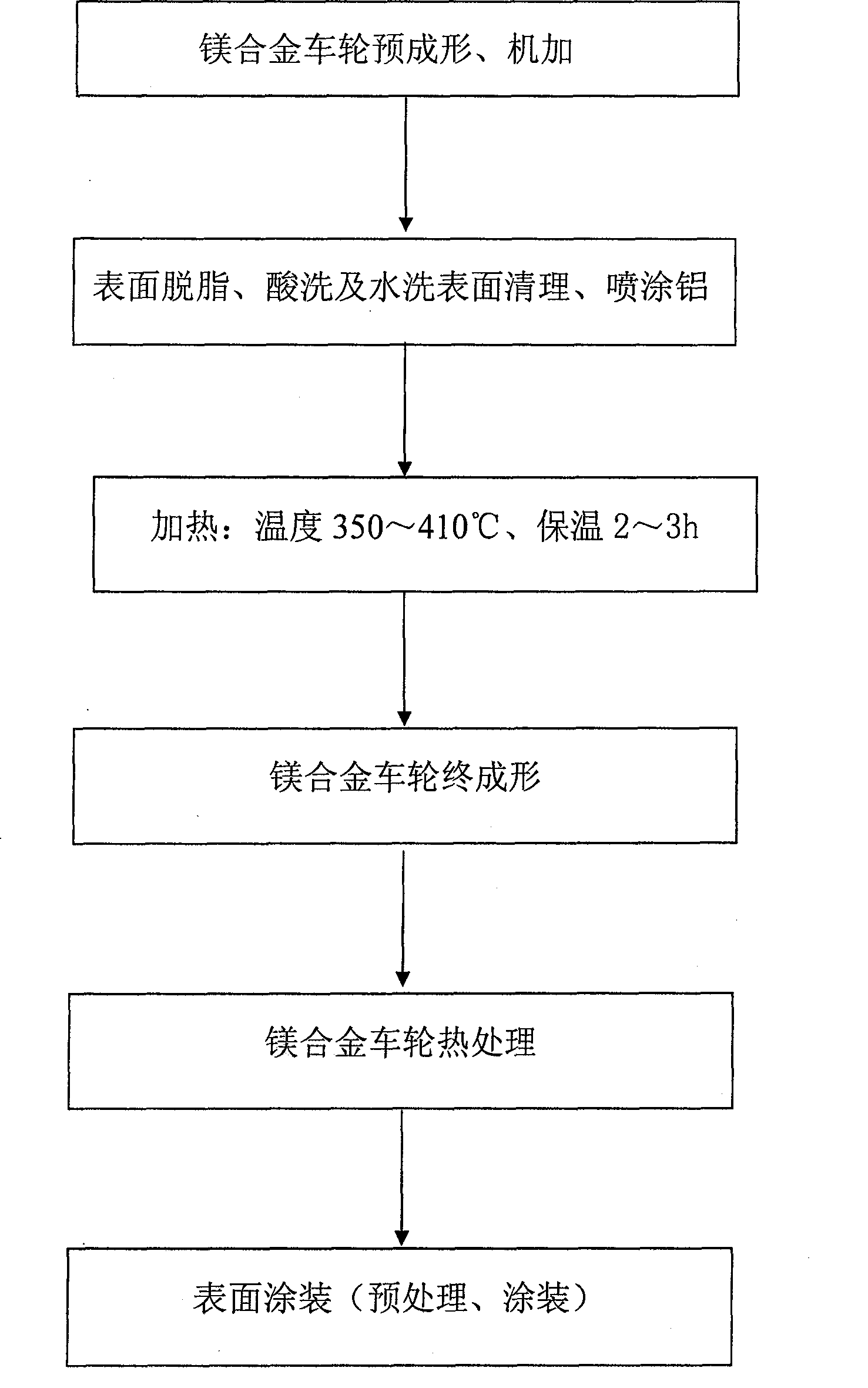

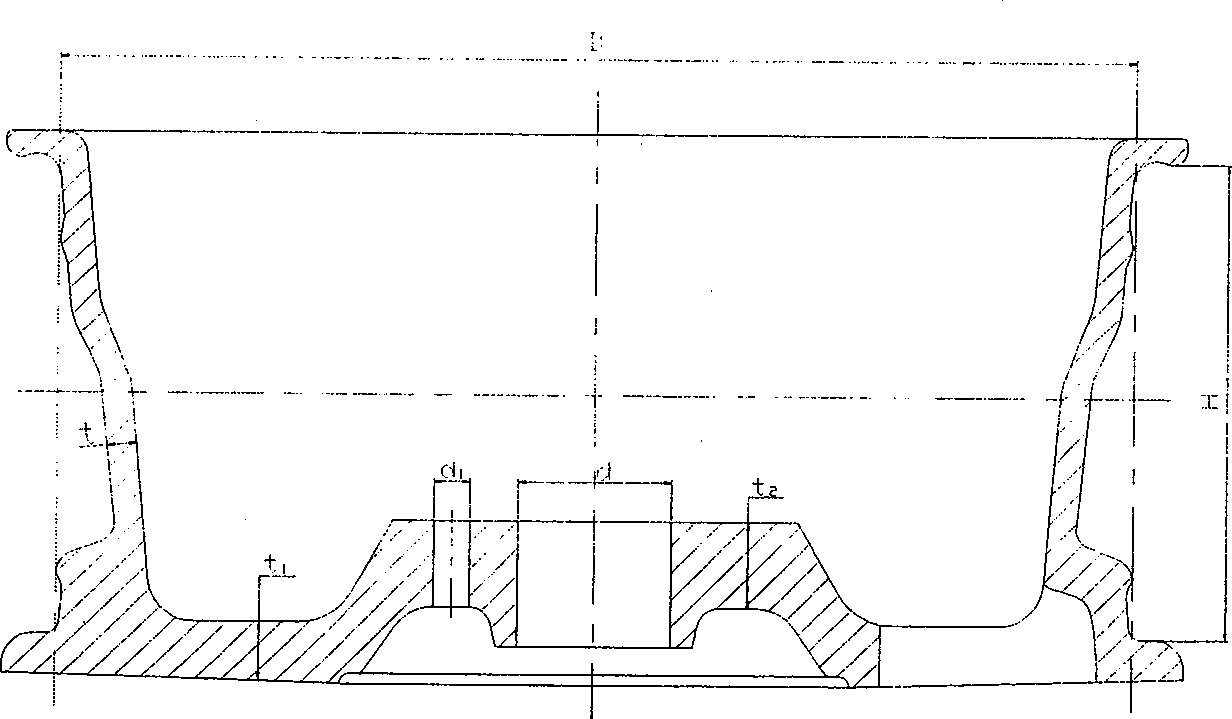

InactiveCN101392380AImprove corrosion resistanceSolving Galvanic Corrosion ProblemsMolten spray coatingSurface finishingWork in process

The invention pertains to a surface treatment method of magnesium alloy wheels. The surface treatment method is characterized by the inclusion of preliminary shaping, machining, aluminium coating on the surface, heating and diffusion, final shaping, heat treatment and surface coating treatment, wherein, the preliminary shaping and the machining can provide a semi-product of a magnesium alloy wheel with a deflection left for the final shaping; after the aluminium coating on the surface and the heating and diffusion, a finished product of the magnesium alloy wheel can be obtained through the final shaping. Heating action during the procedure of the heating and diffusion and mechanical action during the procedure of deformation improve the bonding force of an aluminium coating and a magnesium alloy substrate as well as corrosion resistance of the magnesium alloy wheel, solve the problem of electrochemical corrosion of a bonding part and the problem that a coating with a common treatment method is liable to fall off, and do not reduce mechanical performance of materials of the magnesium alloy substrate with low production cost and no environmental pollution.

Owner:ZHONGBEI UNIV

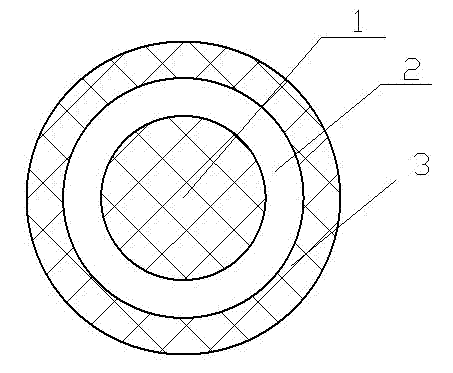

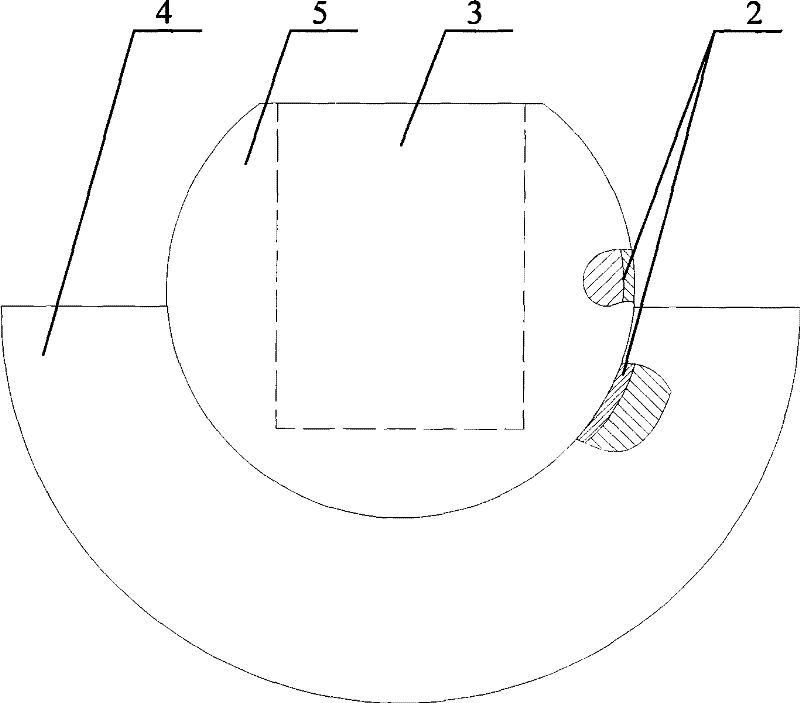

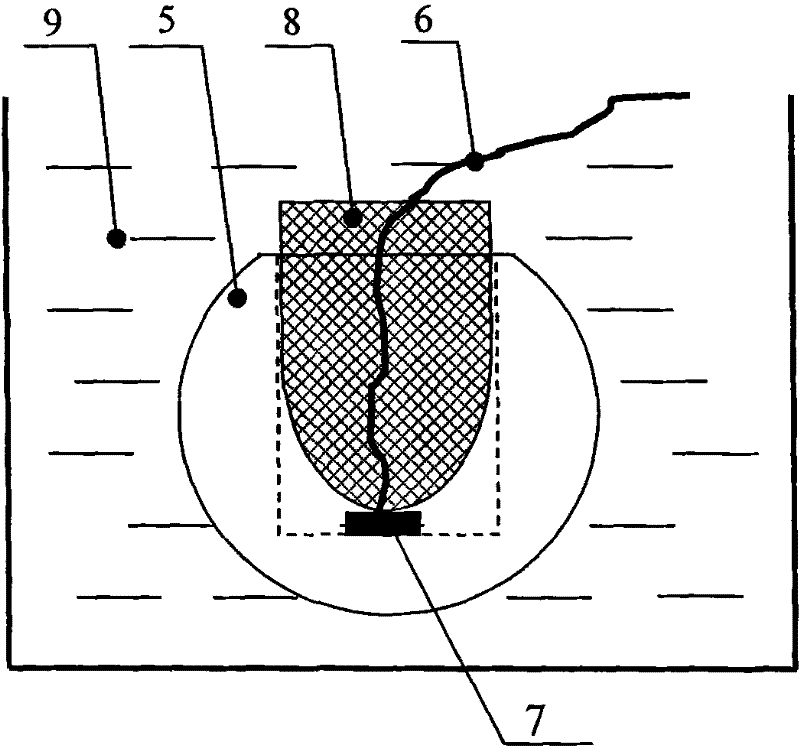

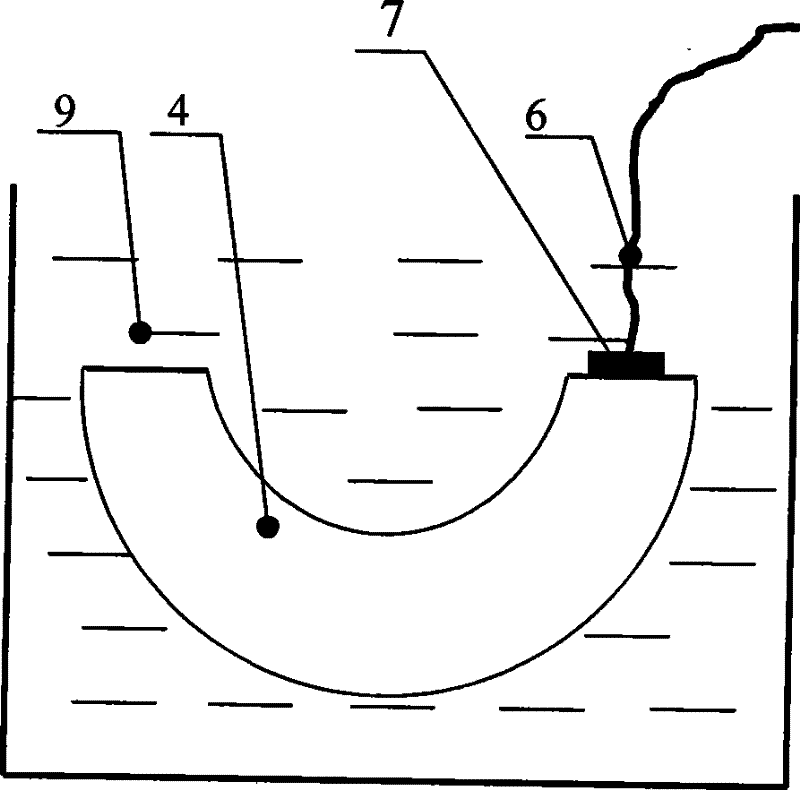

Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

ActiveCN101718297AImprove wear resistanceAccelerated corrosionBearing componentsSliding contact bearingsWater basedCarrying capacity

The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid, which comprises a bearing sleeve, wherein a flange is arranged at one end of the bearing sleeve, and external threads are arranged at the other end of the bearing sleeve; a ceramic shaft sleeve is assembled at the outer layer of the bearing sleeve; a ceramic shaft bushing which comprises a special liquid cavity and a liquid hole structure is arranged outside the ceramic shaft sleeve; a shaft bushing sleeve with the special liquid cavity and the liquid hole structure is assembled at the outer layer of the ceramic shaft bushing; and the bearing of the invention also comprises a bearing end cover, wherein a ceramic ring is assembled at the inner end of the bearing end cover, and internal threads matched with the external threads of the bearing sleeve are arranged on the inner ring of the bearing end cover. The bearing of the invention can improve the wear resistance and the corrosion resistance, can operate in the poor water condition where sandy solid particles are contained, can be lubricated by the water-based lubricating liquid formed by adding other additives into water or water-based liquid; at the same time, the bearing has larger carrying capacity and rigidity, and can ensure a safe and stable operating state, thereby greatly prolonging the operation life.

Owner:TIANJIN UNIV

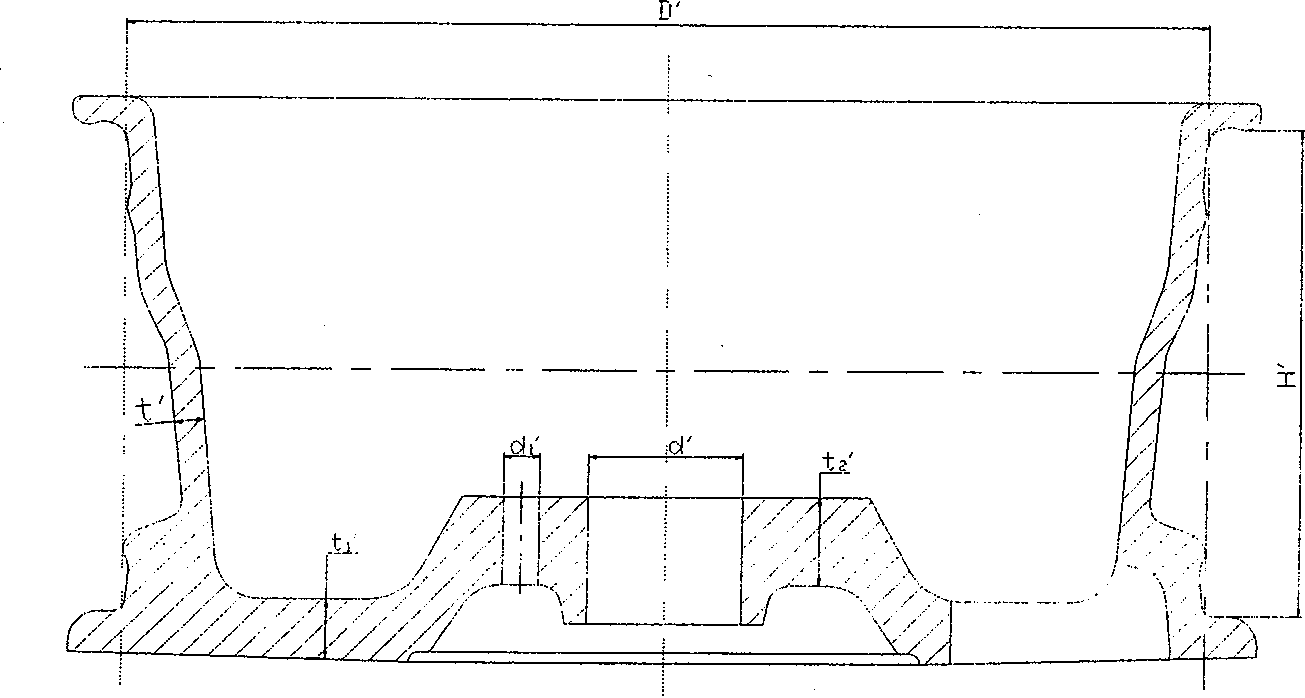

Low-alloyed degradable miniature inner fixed assembly, magnesium alloy preparation method and magnesium alloy material

PendingCN108236495ALow content of alloying elementsLow impurity contentFastenersBone platesMagnesium alloySmelting

The invention discloses a low-alloyed degradable miniature inner fixed assembly, a magnesium alloy preparation method and a magnesium alloy material. The low-alloyed magnesium alloy material which ismicro in impurity content and low in degrading rate is obtained by means of the preparation methods of smelting, solution heat treatment and the like. Different strength and plasticity are matched bymeans of adjusting and rolling and post-rolling annealing process of the magnesium alloy material, so as to prepare medical implant miniature inner fixed assemblies which have different demands on strength and plasticity.

Owner:西安卓恰新材料科技有限公司

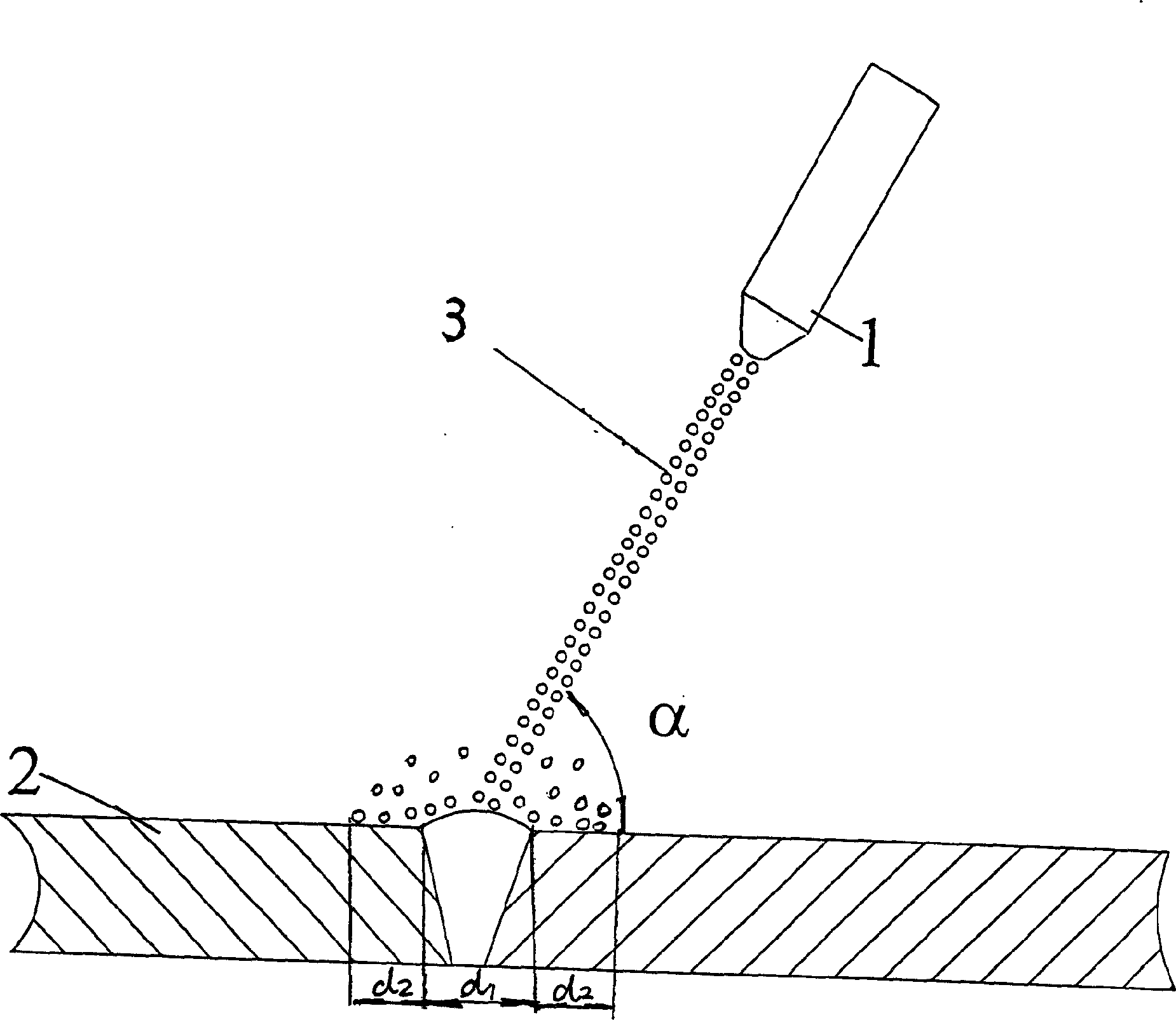

Glass cloudburst treatment art for improving anti-stress corrosion performance of welding joint of stainless steel

ActiveCN1757484AImprove stress corrosion resistanceStress Corrosion Resistant StrengtheningAnti stressCloudburst

A glass grit blasting technology for increasing the stress corrosion resistance of the welded seam between stainless steels includes such steps as cleaning the surface of the welded seam, blasting the glass grits onto the welded seam by a blasting gun driven by compressed air and with an inclination by 70-100 deg.C, cleaning the surface of welded workpiece, and detecting the residual stress by X-ray diffractometer.

Owner:NANJING UNIV OF TECH

Bipolar plate for flow batteries

ActiveCN103474673AAvoid Galvanic CorrosionExtended service lifeCell electrodesEngineeringElectrochemical corrosion

The invention relates to a bipolar plate for flow batteries, belonging to the field of flow batteries. The bipolar plate is divided into an electrode zone and a non-electrode zone, wherein the electrode zone is a zone where the flow battery bipolar plate contacts the adjacent electrodes on the two sides, and the rest is the non-electrode zone; the non-electrode zone is divided into a flow channel zone and a non-flow channel zone; the flow channel zone is a zone where the non-electrode zone contacts flow-channel-bearing frames of the adjacent electrode frames on the two sides, and the rest of non-electrode zone is the non-flow channel zone; and the flow channel zone is an anti-corrosion insulation zone. The flow channel zone of the bipolar plate is the anti-corrosion insulation zone, and the bipolar plate flow channel zone in contact with the flow channel zone of the electrode frame is set as the anti-corrosion insulation zone so as to achieve the goal of preventing electrochemical corrosion, thereby prolonging the service life of the bipolar plate and ensuring the stable operation of the flow battery.

Owner:DALIAN RONGKE POWER

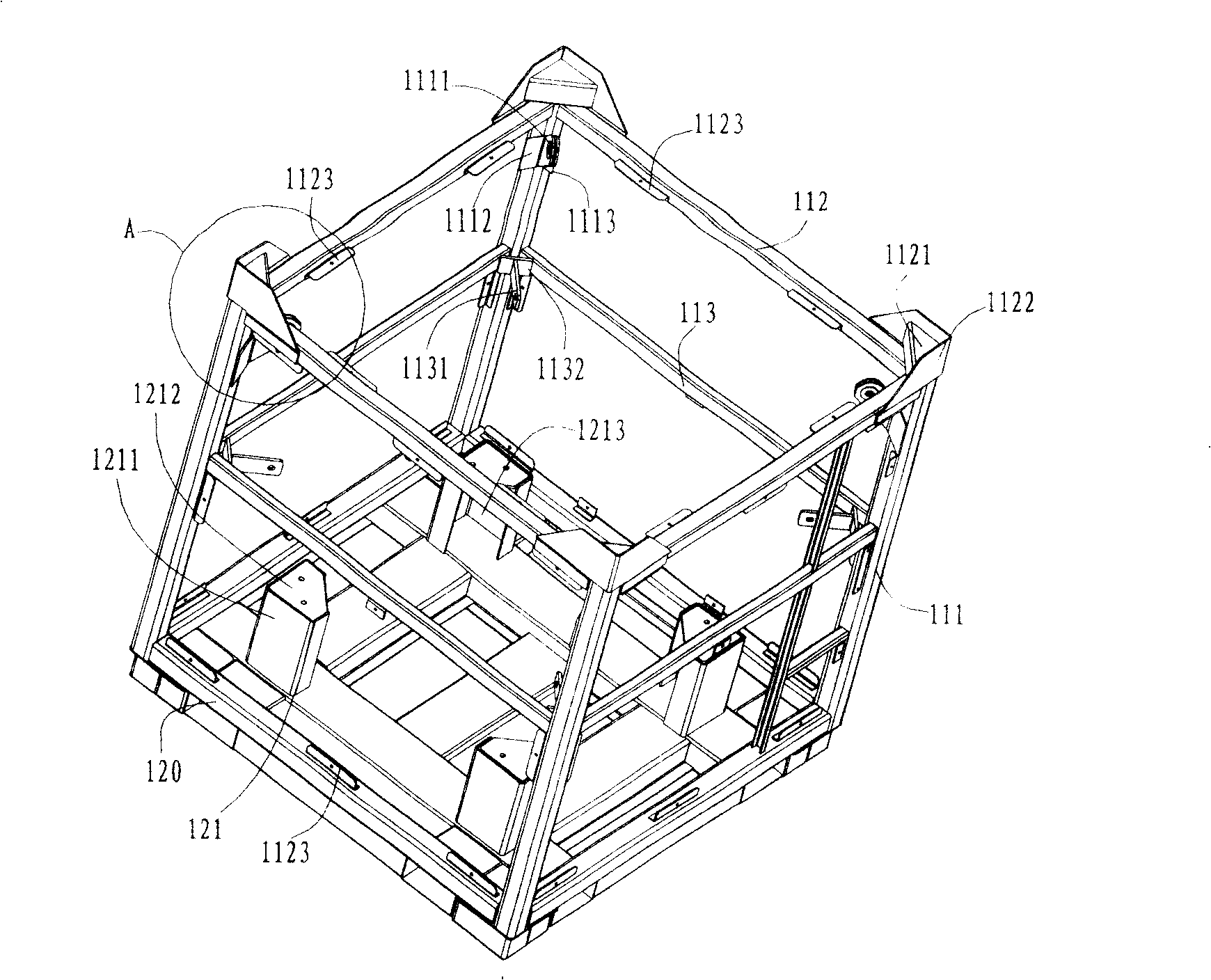

Detachable can-type pallet case

InactiveCN101254844AReduce manufacturing costAvoid Galvanic Corrosion ProblemsLarge containersMetallic materialsLateral shear

The invention discloses a removable tank pallet, comprising a frame and a cylinder body, wherein the frame and the cylinder body are made of different materials and removably connected together, and a non-metal material is respectively cushioned between the landing legs of the cylinder body and the landing legs of the frame and among connecting plates of four corners, so as to insulate the cylinder body from the frame, and prevent electro-chemical corrosion. In addition, the inventive tank pallet is provided with an embedded type lifting lug structure, which has better lateral shearing stress resistant ability and can prevent the lifting rope from interfering with the lifting lug when hoisting or lowing down. The inventive tank pallet is also provided with an underframe structure with four-way yoke, so that the inventive tank pallet has higher overall mechanical properties and shock resistant ability and can better adapt to harsh application environment.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

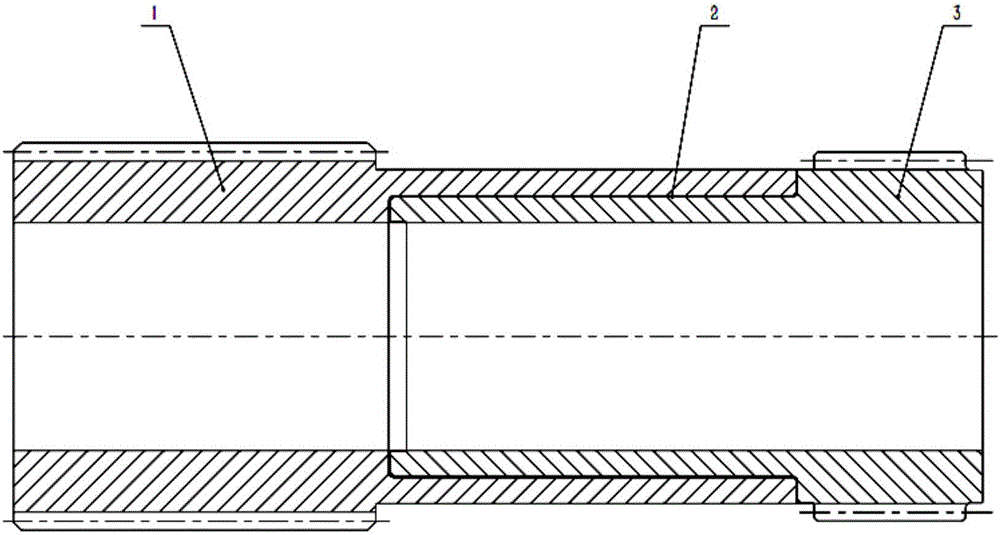

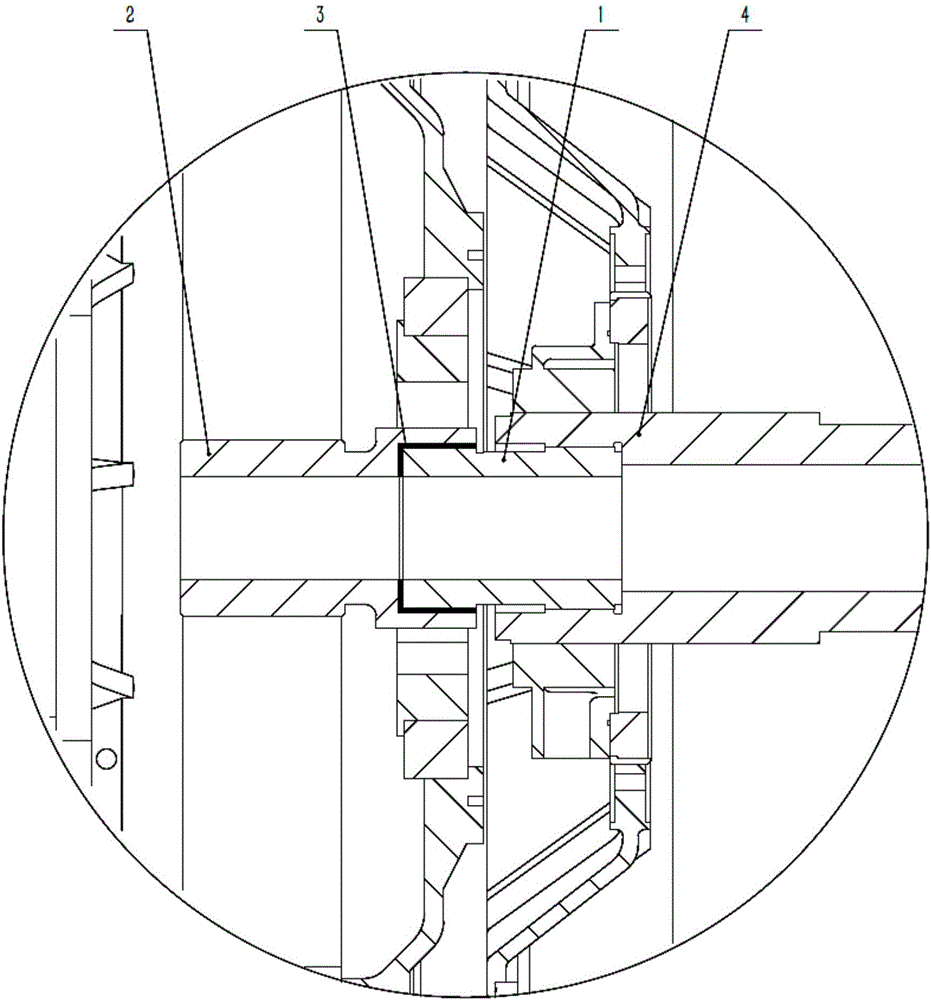

High-potential metal seawater pipeline penetration piece with composite structure

InactiveCN102758971AAvoid Galvanic Corrosion ProblemsThere is no problem of weakening effect after damageFlanged jointsVessel partsHigh potentialSeawater

The invention belongs to the technical field of ship engineering and provides a high-potential metal seawater pipeline penetration piece with a composite structure. The high-potential metal seawater pipeline penetration piece comprises an inner pipe, a flange and a sleeve, wherein the inner pipe and the flange are made of high-potential metal and the sleeve is made of low-potential metal; the inner pipe and the sleeve are concentric pipelines, wherein the inner diameter of the sleeve is larger than the outer diameter of the inner pipe, the sleeve is shorter than the inner pipe, and the sleeve is connected with a low-potential metal ship structure plate; and two ends of the inner pipe are fixedly connected with the concentric flange, and the flange is connected with a high-potential metal pipeline. The high-potential metal seawater pipeline penetration piece is simple in structure and convenient to use, can structurally ensure that a high-conductivity medium can be in simultaneously contact with the high-potential metal and the low-potential metal and thoroughly solves the electrochemical corrosion problem.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Carbon fiber composite core wire and production method

The invention discloses a carbon fiber composite core wire and a production method. The wire comprises an inner wire core and an aluminium alloy conductor, the aluminium alloy conductor is hinged around the inner wire core, the inner wire core is composed of multiple strands of carbon fiber reinforced composite cores and at least one layer of glass fiber strip protection coating which are obliquely twisted and bonded into a whole, each carbon fiber reinforced composite core is composed of high temperature epoxy resin, a curing agent, accelerant and carbon fibers in the ratio of 100:120:2:80, and the carbon fibers are polyacrylonitrile-based carbon fibers. The carbon fibers pass through a yarn guiding mechanism, a tension mechanism, a quantitative coupling agent sprayer, a vacuum injection preimpregnation device and a drying drum to obtain composite carbon fibers, and the composite carbon fibers pass through a winding machine and are subjected to infiltration and gluing prior to being fed to a strander to produce the wire according to a conventional method. The wire is high in conductivity, large in current-carrying capacity, large in strength, lightweight, resistant to corrosion and long in service life.

Owner:STATE GRID CORP OF CHINA +2

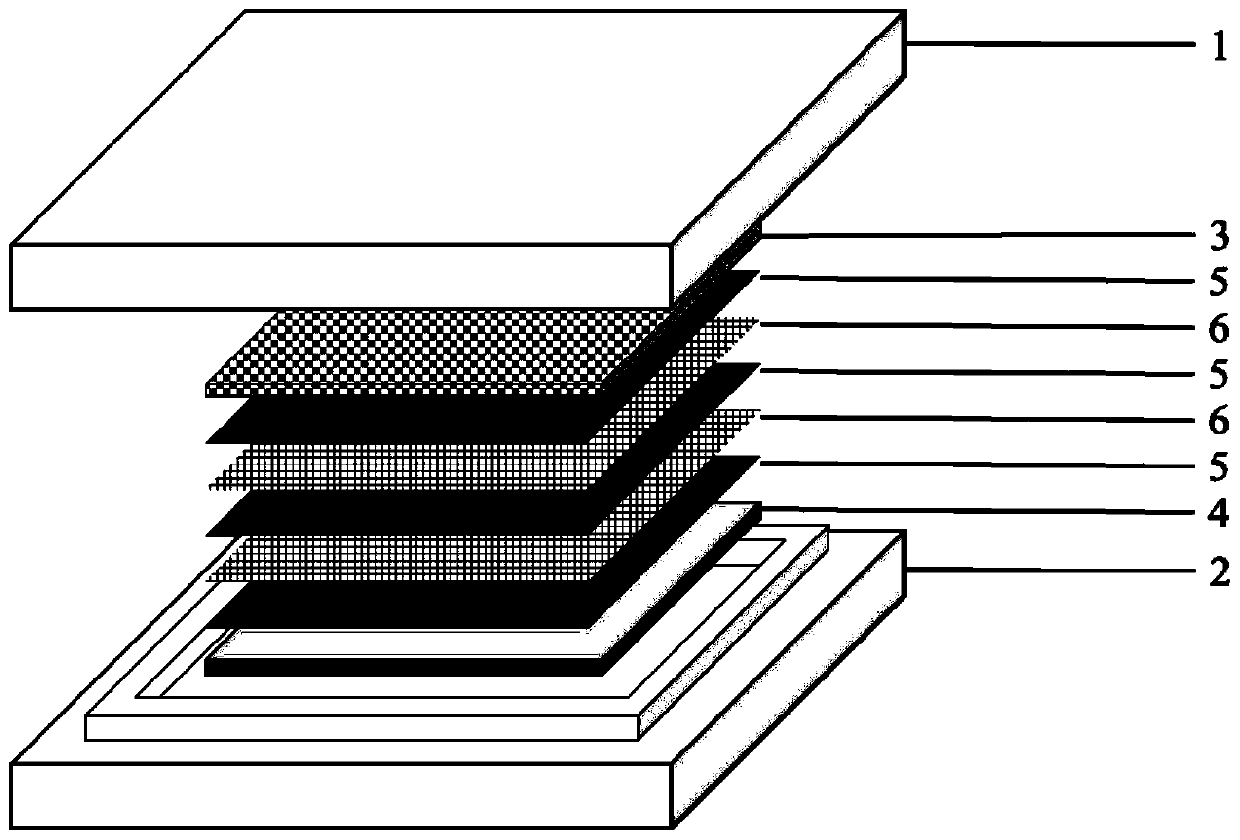

Fiber-metal hybrid composite laminate and preparation method thereof

InactiveCN111231456AAvoid Galvanic Corrosion ProblemsIncrease productivityLamination ancillary operationsSynthetic resin layered productsCompression moldingPolymer science

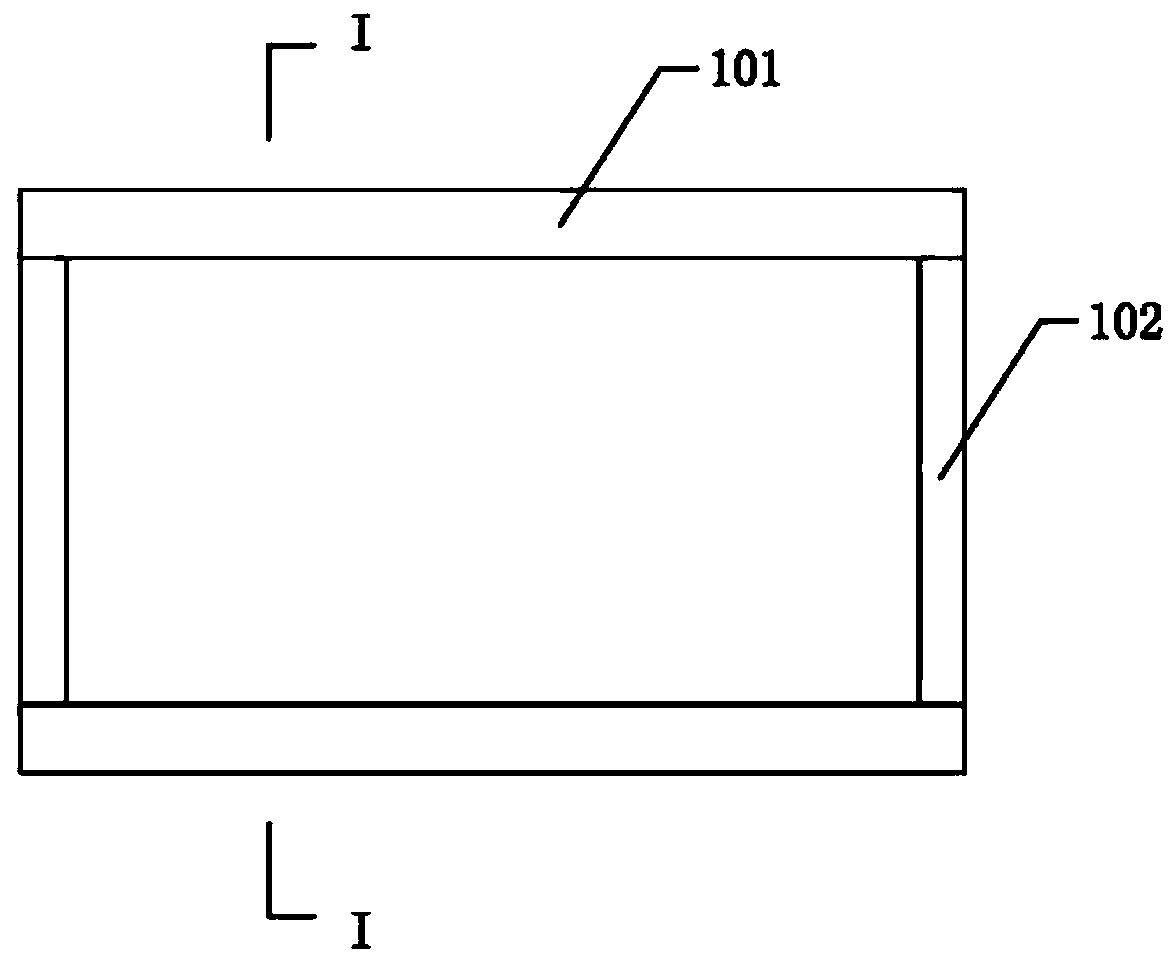

The invention discloses a fiber-metal hybrid composite laminate. The fiber-metal hybrid composite laminate comprises a metal base layer, a resin-based composite material layer and an adhesive layer located between the metal base layer and the resin-based composite material layer, wherein the adhesive layer is mainly composed of M layers of adhesive layer base materials and N layers of adhesive films, M and N are integers, N is larger than or equal to 1, N is larger than M, and M is larger than or equal to 0; the fiber-metal hybrid composite laminate can be used in the field of automobile materials, can be co-cured and formed in the compression molding process, and is high in production efficiency; the thickness of the adhesive layer of the fiber-metal hybrid laminate can be controlled by controlling the number of layers of added fiber gridding cloth and the adhesive film, so that the performance of the fiber-metal hybrid composite material is optimized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-strength fly ash brick and preparation method thereof

InactiveCN113698166AImprove mechanical propertiesGood dispersionGroup 5/15 element organic compoundsFiberDigestion Treatment

The invention discloses a high-strength fly ash brick and a preparation method thereof, and belongs to the technical field of building material preparation, the preparation method of the fly ash brick comprises the following steps: 1, mixing and stirring fly ash, gypsum, calcium carbonate, calcium chloride and potassium sulfate to obtain a mixture; mixing and stirring the mixture with a reinforcing agent, cement and zeolite in parts by weight, and adding water in the stirring process to obtain a mixed material; and 2, carrying out digestion treatment on the mixed material; carrying out compression molding treatment to obtain a green body, transferring the obtained green body into a still kettle, and curing for 12 hours to obtain the high-strength fly ash brick. The reinforcing agent in raw materials of the fly ash brick takes brucite fiber as a matrix, the surface of the brucite fiber is coated with a layer of polyphosphoric acid, the polyphosphoric acid and a flame-retardant component are combined in an ionic bond or coordination form, the flame-retardant component is introduced into the surface of the brucite fiber to form a polyphosphamide coating layer, the mechanical property is improved by adding the reinforcing agent, and the flame retardant property is improved.

Owner:涡阳县晟丰新型建材有限公司

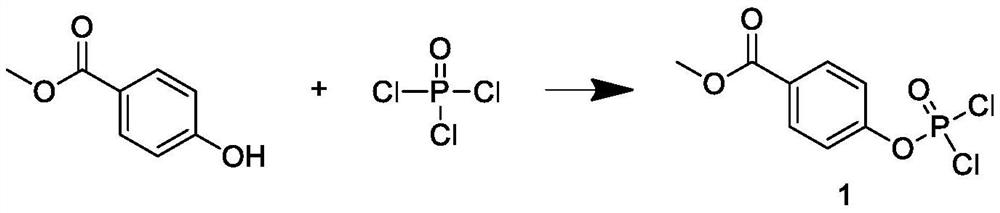

Dissimilar metal connector anticorrosive lubricating coating for metal composite structures

PendingCN110684424ASolving Galvanic CorrosionMaintain long-term lubricating propertiesAnti-corrosive paintsPaint stripperPolyamide

The invention relates to a dissimilar metal connector anticorrosive lubricating coating for metal composite structures. The coating comprises the following material components in parts by weight: 2000-4000 parts of molybdenum disulfide, 0-180 parts of strontium chromate, 2000-6000 parts of heat-resistant phenolic resin, 4000-5000 parts of ethylene glycol ethyl ether acetate, 0-200 parts of polytetrafluoroethylene, 30-50 parts of bentonite, 100-150 parts of a polyamide wax liquid modifier aid and 10-30 parts of a leveling aid. The dissimilar metal connector anticorrosive lubricating coating forthe metal composite structures, which is provided by the invention, is applicable to anticorrosive treatment on surfaces of dissimilar metal connectors for metal composite structures such as an aluminum alloy and a titanium alloy, and has high temperature resistance, paint remover resistance and self-lubricating properties.

Owner:沈阳市航达科技有限责任公司

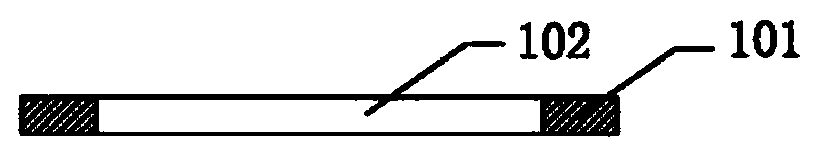

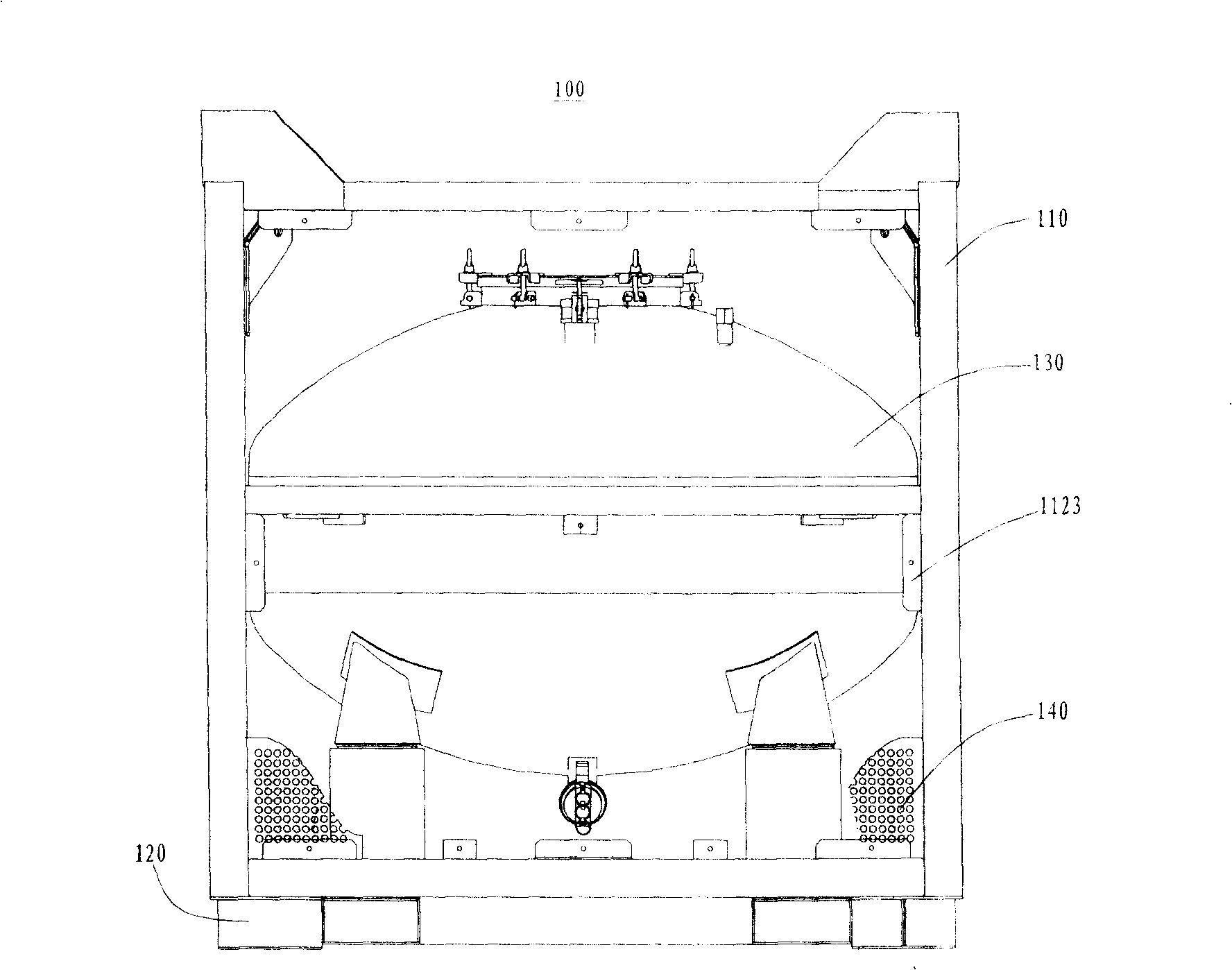

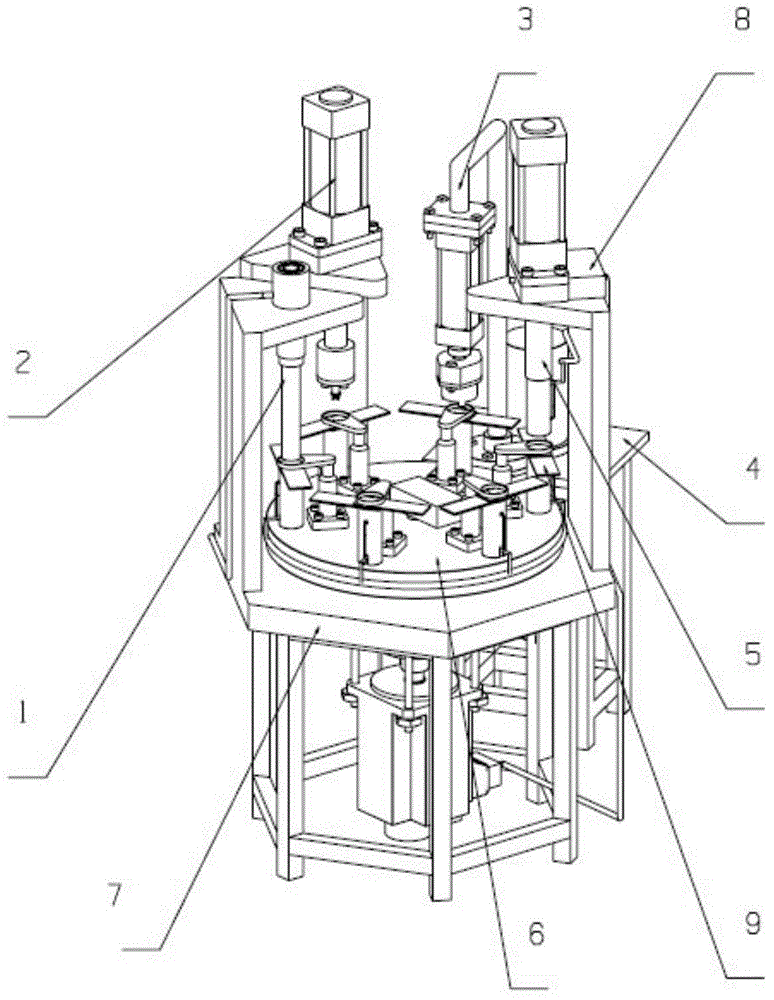

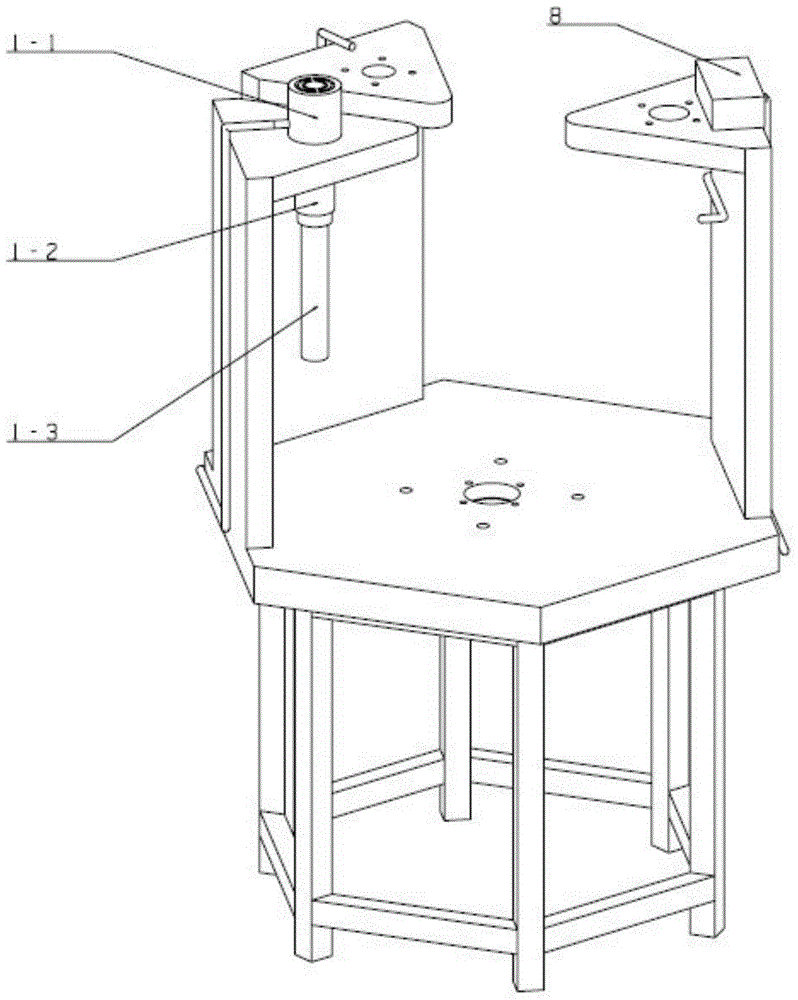

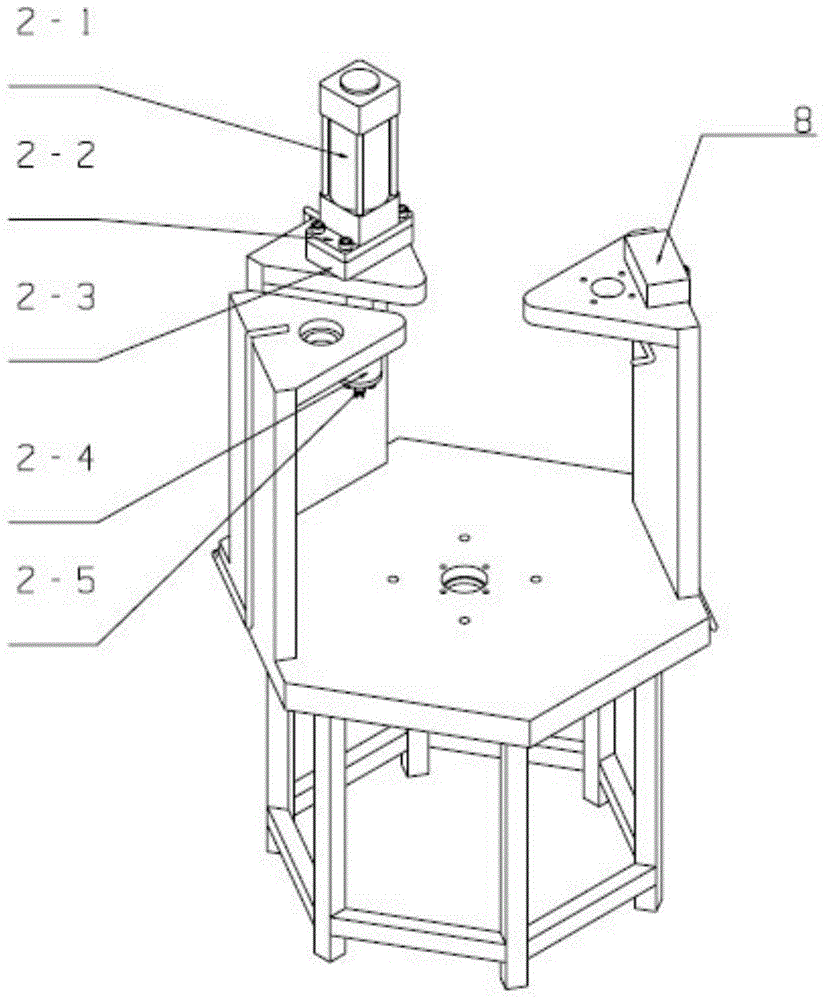

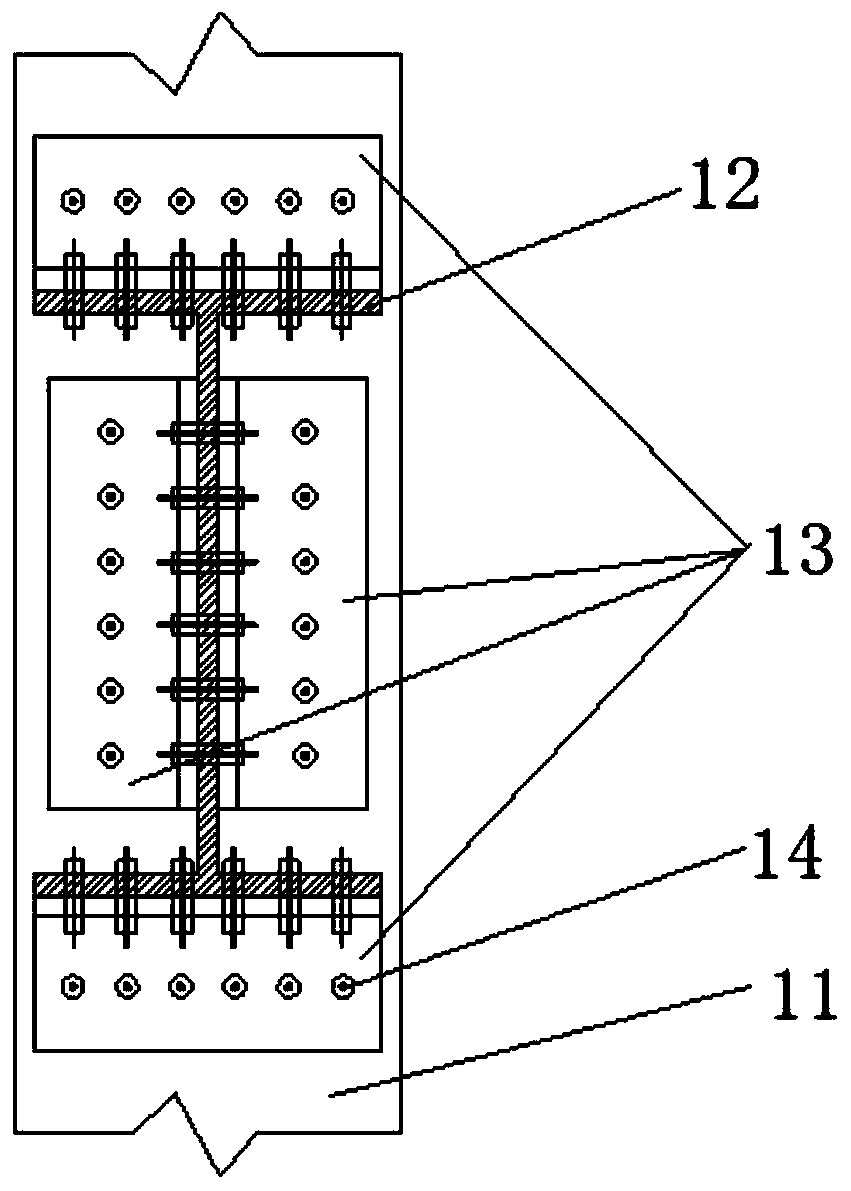

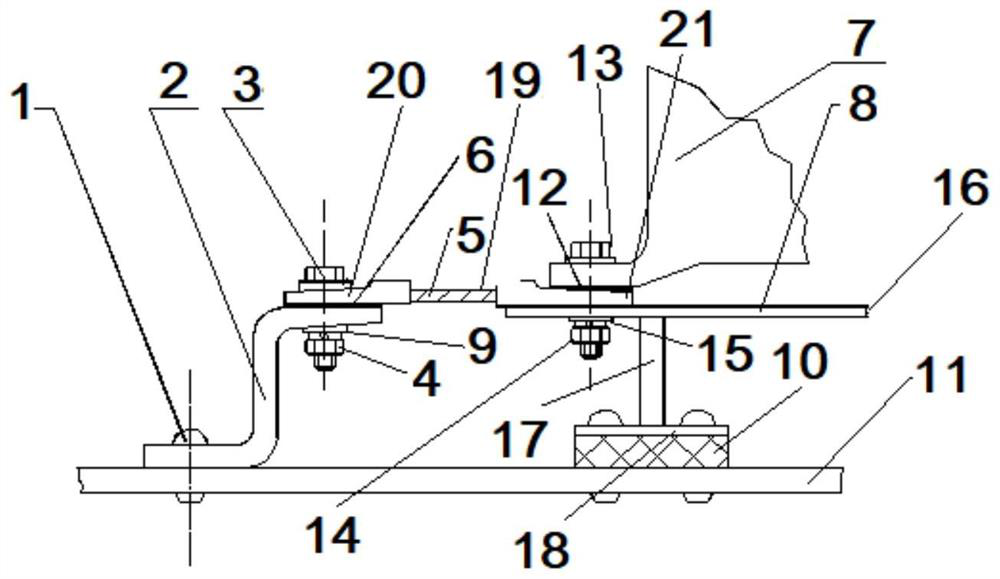

Hot-pressing jointing device for braided fiber reinforced composite plate

The invention discloses a hot-pressing jointing device for a braided fiber reinforced composite plate. The hot-pressing jointing device comprises a rivet supply system, wherein the rivet supply system is matched and connected with an automatic rivet mounting system; a hot air heating system, a plate perforating system, the automatic rivet mounting system, a riveting system and a servo turntable system are arranged on a support frame; a jointing plate is arranged on the servo turntable system through a pneumatic clamping device connected to the servo turntable system; and along with the rotation of the servo turntable system, a joint is formed by sequentially heating a connected part by the hot air heating system, perforating the connected part by the plate perforating system, mounting a rivet by the automatic rivet mounting system and hot-pressing riveting by the riveting system. By using the hot-pressing jointing device, fiber damage caused in the jointing process of the braided fiber reinforced composite plate is reduced, meanwhile, automatic production is realized, and the jointing cost is reduced.

Owner:XI AN JIAOTONG UNIV +1

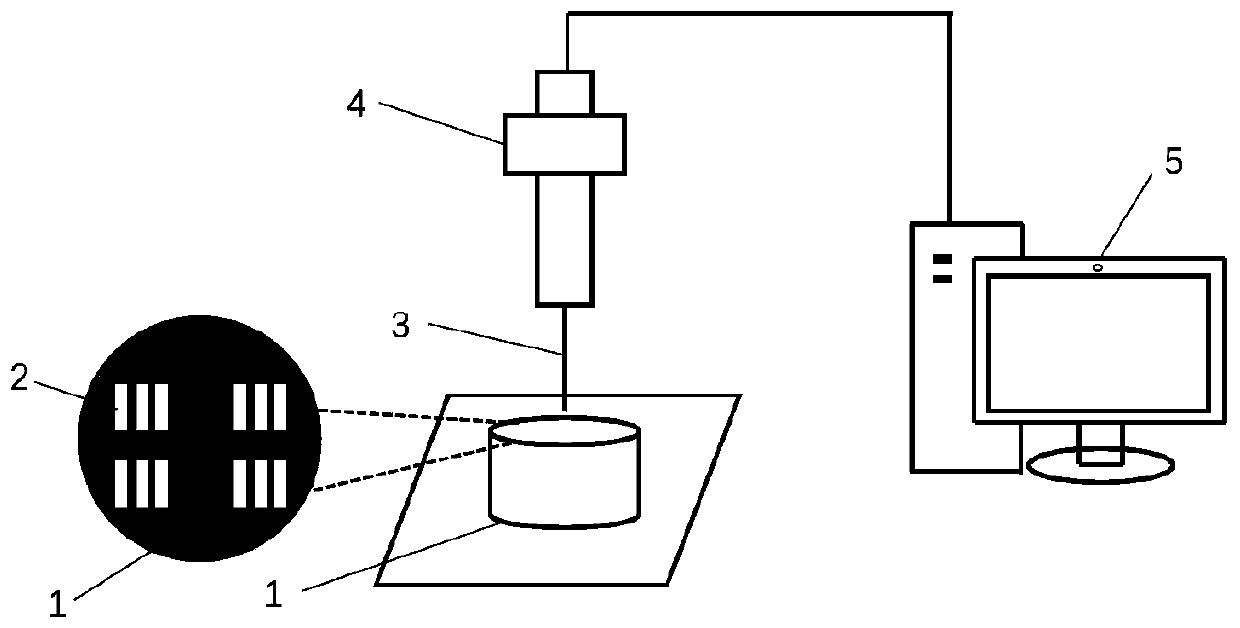

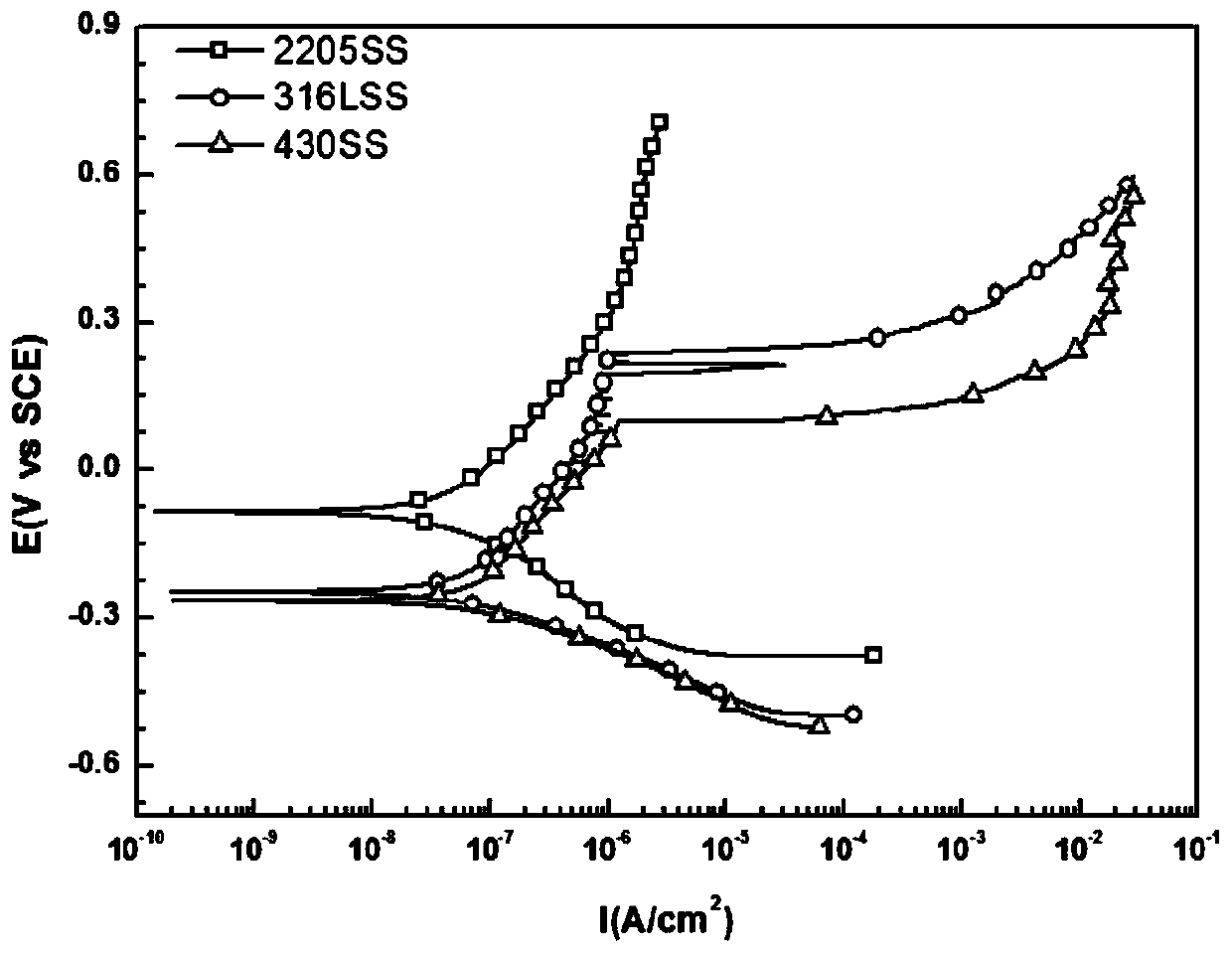

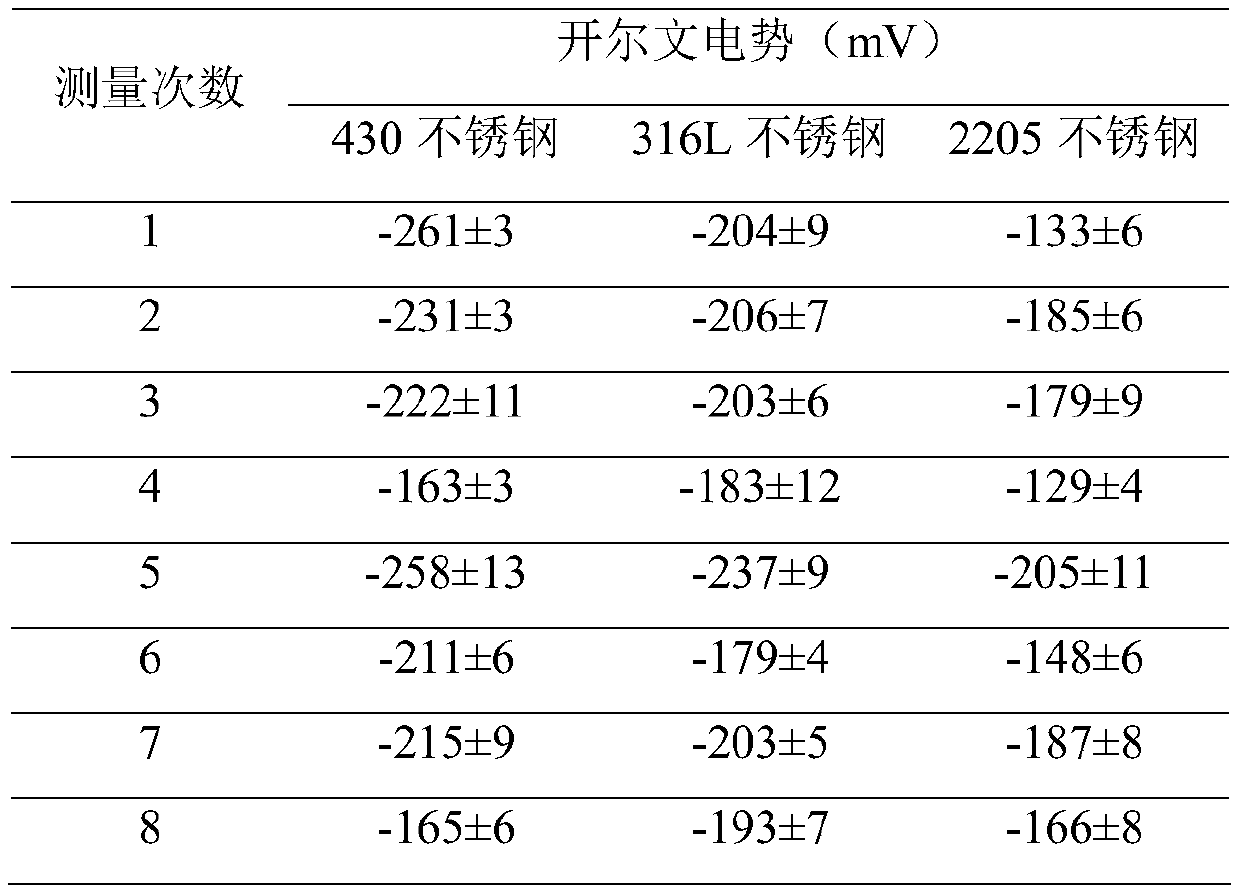

Method for characterizing material corrosion resistance in high-throughput manner by using micro-channel electrochemical system

ActiveCN110132830AShorten test timeImprove accuracyWeather/light/corrosion resistanceNon destructiveCoupling

The present invention discloses a method for characterizing the material corrosion resistance in a high-throughput manner by using a micro-channel electrochemical system. The method is characterized in that: a plurality of to-be-measured samples are uniformly arranged in the micro-area mounting mold to be solidified into an integrated electrode, scanning Kelvin probes are used to measure the Kelvin potential of each sample, and high-throughput in-situ non-destructive detection is performed to achieve rapid screening of corrosion resistance of different material samples, so that the problem ofgalvanic corrosion caused by the difference of composition of the tow electrode during the screening process is effectively avoided, and the accuracy and efficiency of the screening result are improved, wherein the accuracy of the sample coupling test is greatly improved from 37.5% of the individual test to 75%. The method provided by the present invention has the following advantages that: 1, byperforming high-throughput parallel testing, the test time is greatly reduced; 2, the human error in the debugging process is reduced and the accuracy of the test result is improved; and 3, the galvanic corrosion problem of the tow electrode method is avoided, and the system error is effectively reduced. The method provided by the present invention has significant application value for screening of material corrosion resistance.

Owner:SHANGHAI UNIV

Carbon fiber composite core composition and method for preparing carbon fiber composite core

ActiveCN101698739BHigh strengthImprove conductivityInsulated cablesInsulated conductorsFiberCarbon composites

The invention relates to an electric lead, in particular to a carbon fiber composite core composition and a method for preparing a carbon fiber composite core. The composition comprises high-temperature epoxy resin, a curing agent, an accelerant and carbon fiber. The preparation method comprises the following steps that: the carbon fiber enters a coupling agent sprayer by a creel through a yarn-guide mechanism and a tension control mechanism; a tension controller adjusts the tension; a high-pressure spray head is arranged in the coupling agent sprayer to spray a foggy solvent; the fiber enters a vacuum injection pre-soaking device through the coupling agent sprayer to soak a high-temperature epoxy resin adhesive and then enters a heating molding mould to be cured and molded; the molding mould is divided into three areas for heating, and the three areas are a preheating area, a gelling area and a curing area respectively; the fiber is cured again by a drying cylinder after being cured; and the whole process is continuously driven by a hydraulic driving machine. Compared with the conventional lead, a carbon composite core lead has the advantages of light weight, high strength, low line loss, small sag, high temperature resistance, corrosion resistance, environmental friendliness and the like, and achieves the energy conservation, environmental protection and security of power transmission. The carbon fiber composite core composition and the method for preparing the carbon fiber composite core are widely applied to overhead power lines.

Owner:艾瑞科电力电子科技(江苏)有限公司

Automobile top cover aluminum alloy shell and processing process thereof

ActiveCN114029214AGood mechanical propertiesHigh aspect ratioElectrolytic inorganic material coatingAnti-corrosive paintsMachining processHigh conductivity

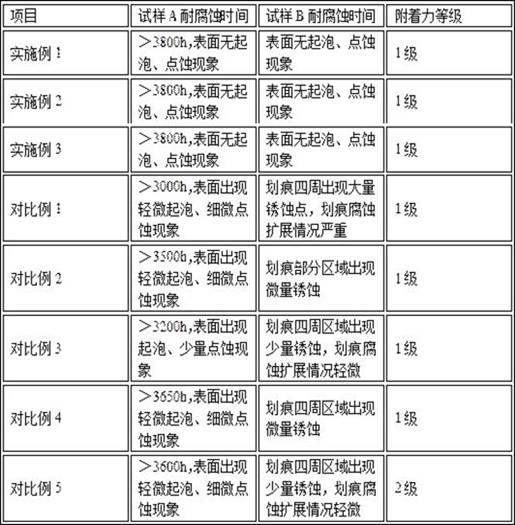

The present invention discloses an automobile top cover aluminum alloy shell and a processing technology thereof. Aiming at the problems that when the surface of an alloy is covered with graphene oxide, galvanic corrosion is easily caused by the high conductivity of the graphene oxide, and the corrosion to metal can be accelerated; according to a conventional solution, the graphene oxide is generally dispersed into an organic coating, then the organic coating is coated on the surface of an alloy to avoid the problem of galvanic corrosion, but during the actual operation, it is found that the problem of galvanic corrosion cannot be thoroughly avoided by only depending on the organic coating, so that the invention discloses the automobile top cover aluminum alloy shell and the processing process thereof. The automobile top cover aluminum alloy shell specifically and structurally comprises an aluminum alloy matrix, a transition layer, a middle layer and a corrosion-resistant coating. The prepared aluminum alloy shell has excellent corrosion resistance and is durable in corrosion resistance, when the corrosion-resistant coating on the outer surface is damaged, the aluminum alloy shell still can keep certain corrosion resistance, the corrosion resistance of the automobile shell can be effectively guaranteed, and higher practicability is achieved.

Owner:江苏瑞振压铸有限公司

Gallium electrolytic refining method

InactiveCN102011142AAvoid direct contactAvoid pollutionPhotography auxillary processesProcess efficiency improvementPlatinumElectrolysis

The invention discloses a gallium electrolytic refining method, which relates to a gallium electrolytic refining process, in particular to a method for improving electrode materials in a refining process. The method is characterized in that: in the electrolytic refining process, a metal gallium sheet is used in places of a foil sheet as a cathode; and a platinum wire serving as a cathode lead wire is provided with a clean FEP tube protective layer. In the method, when the measures are carried out, the electrochemical corrosion problem of the foil is solved, the cathode foil sheet is replaced completely, the foil content in the electrolytic product is reduced from 0.08 to 0.2ppm before improvement to 0.01 ppm which is lower than a detection limit of glow discharge mass spectrometry, the product quality is improved, and operation flow is simplified.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Device for high-depth-diameter-ratio micro-hole high-speed electrosparking

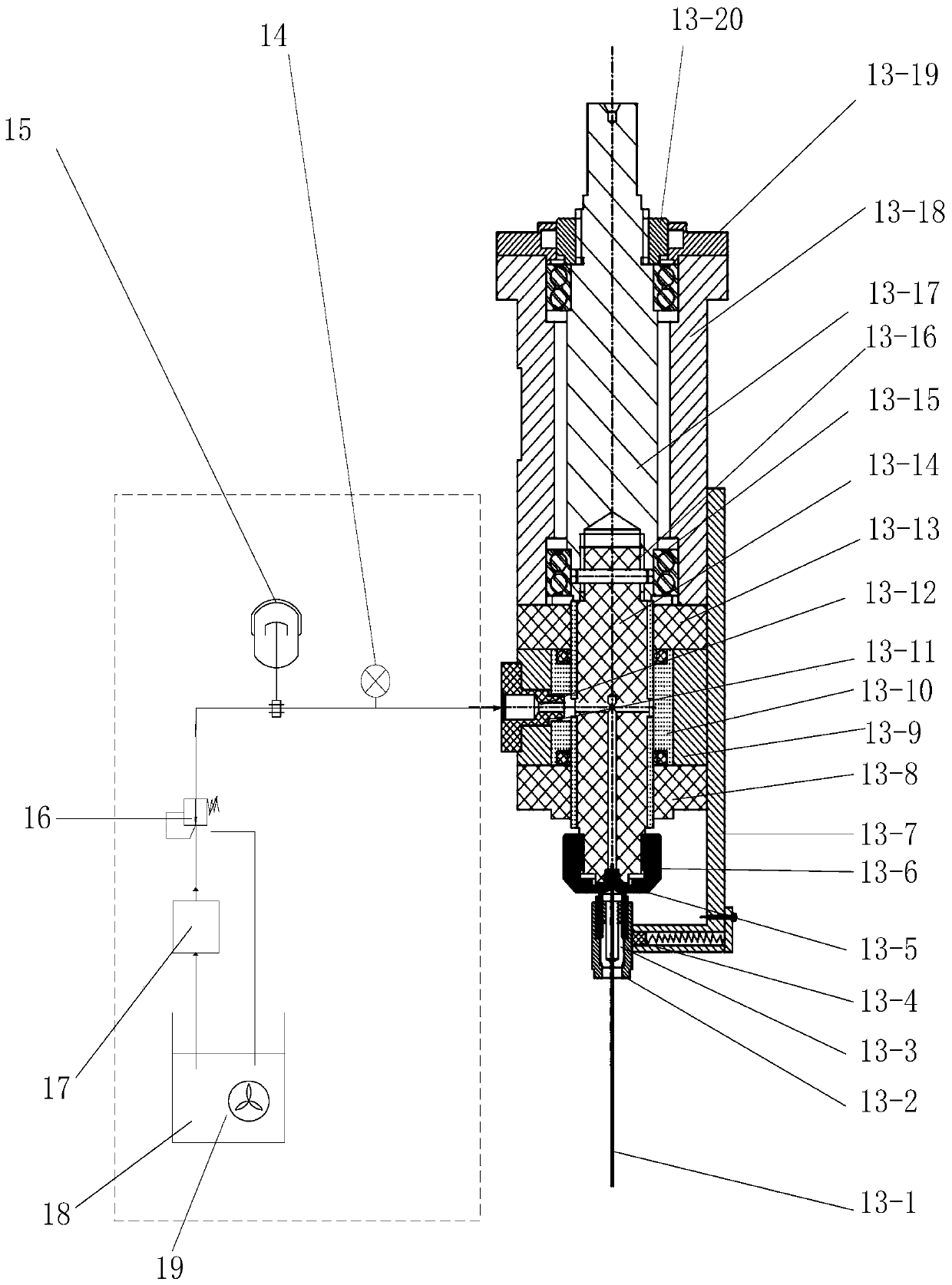

The invention provides a device for high-depth-diameter-ratio micro-hole high-speed electrosparking, and belongs to the field of machining and tools. Through the innovative design of a rotating spindle structure, ceramic and polytetrafluoroethylene materials are ingeniously applied, the problems of serious internal electrochemical corrosion of a spindle, high abrasion rate of a sealing piece and difficult replacement are solved, the rotating precision of the spindle is improved, and the service life of the spindle is prolonged.

Owner:DALIAN UNIV OF TECH

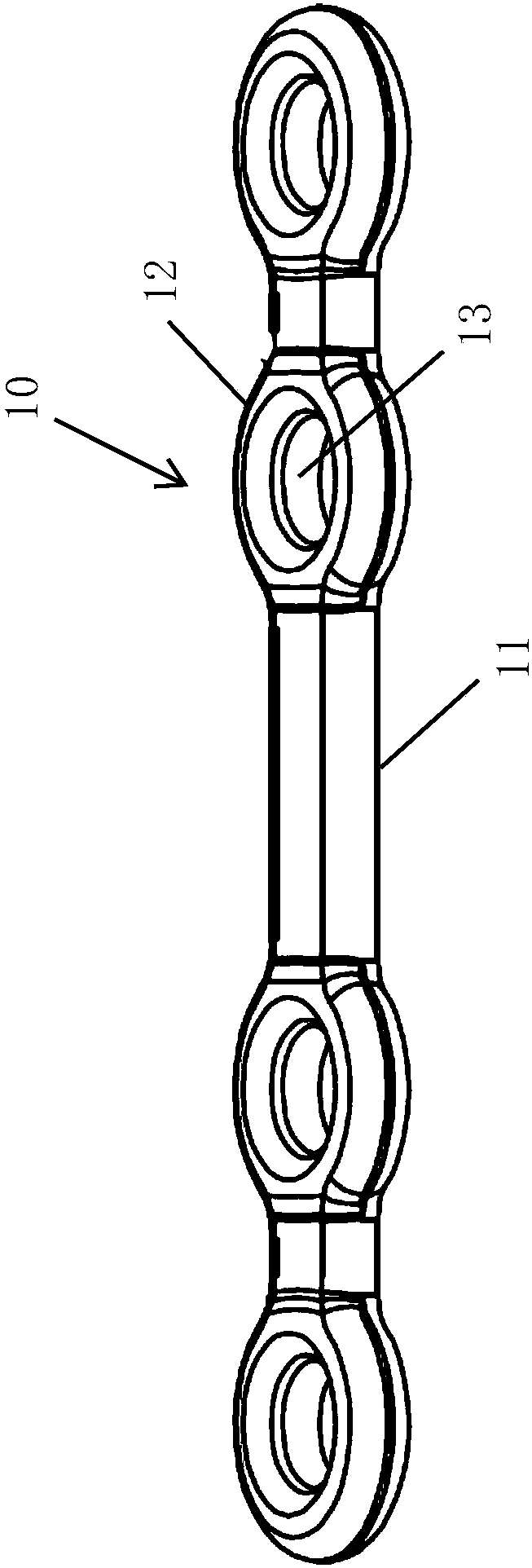

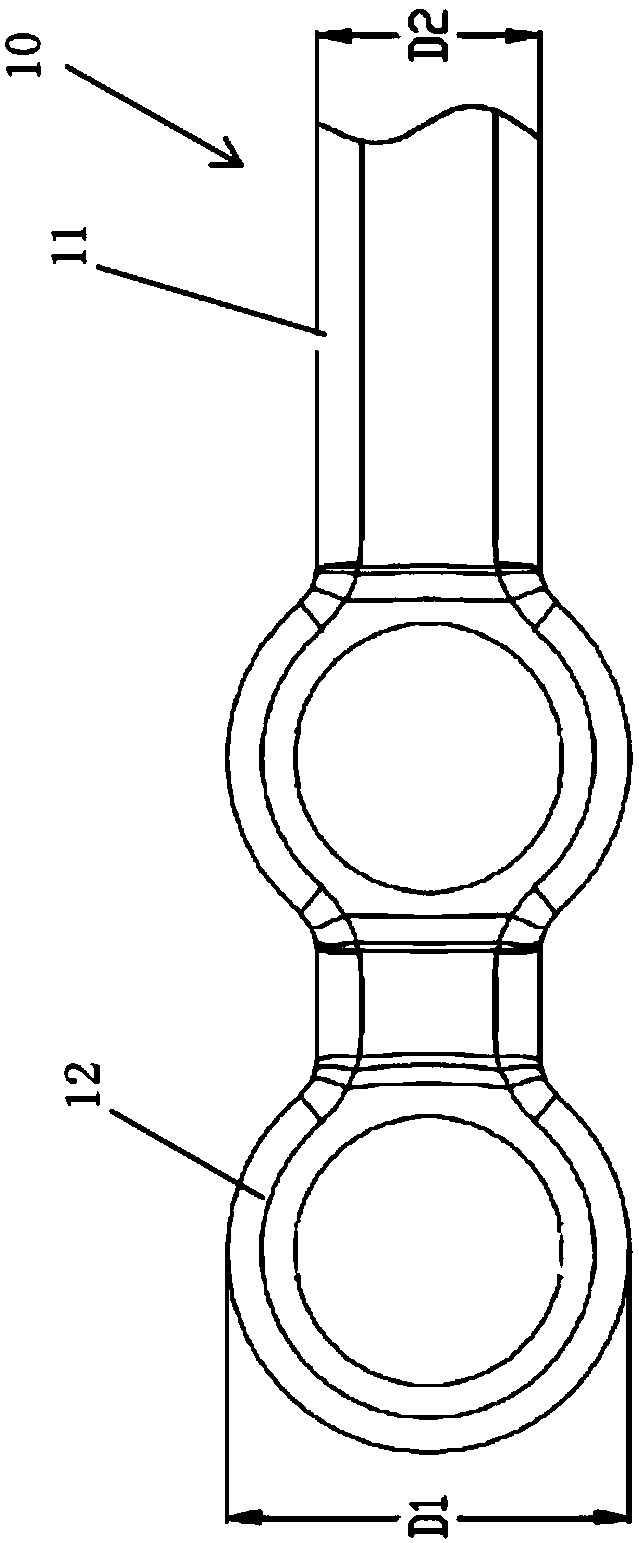

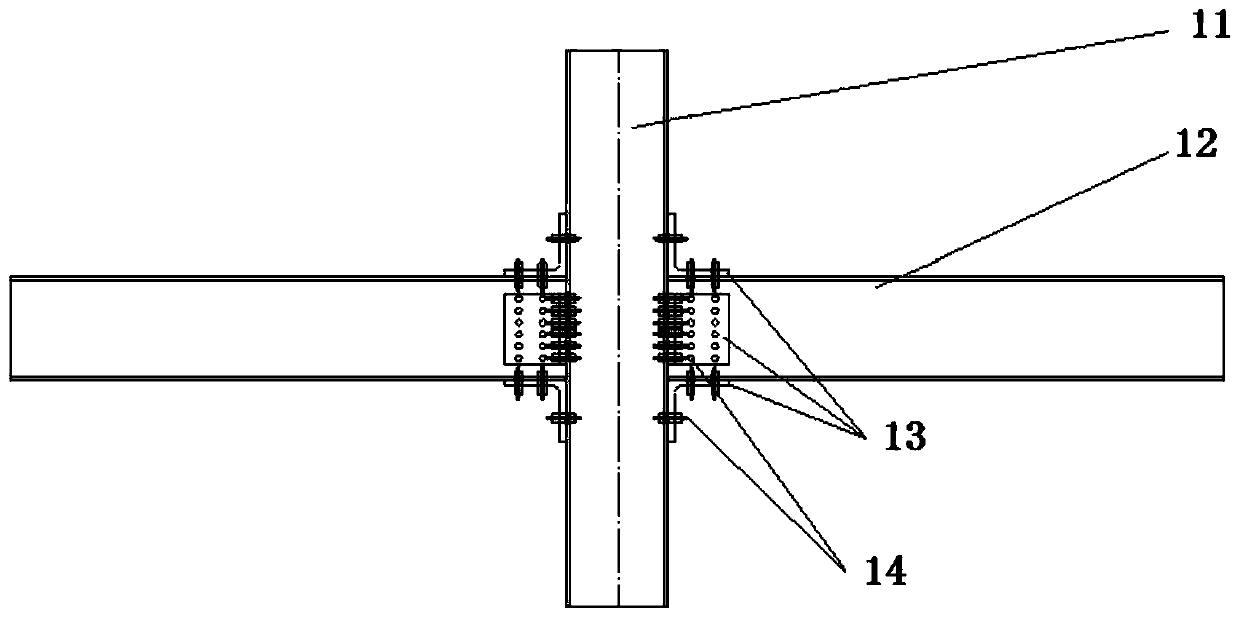

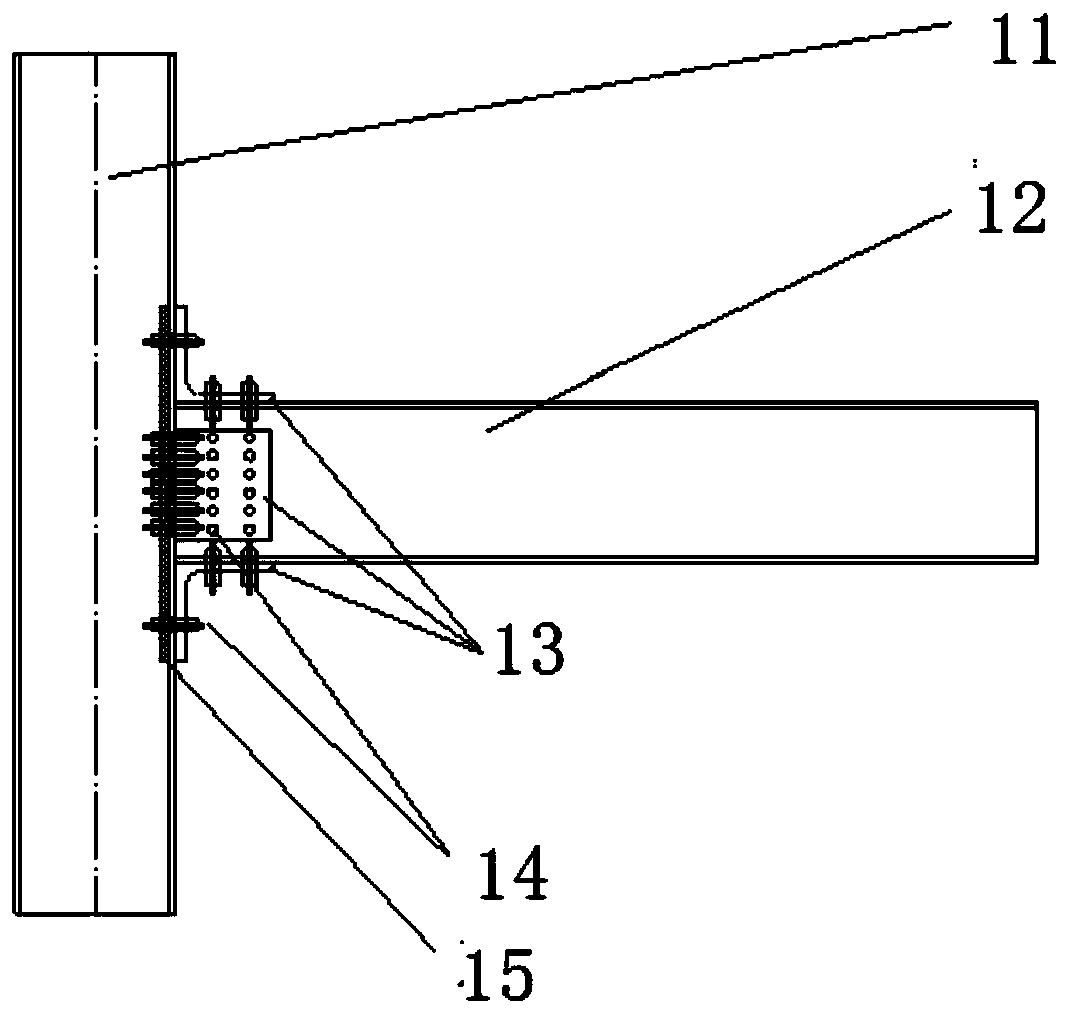

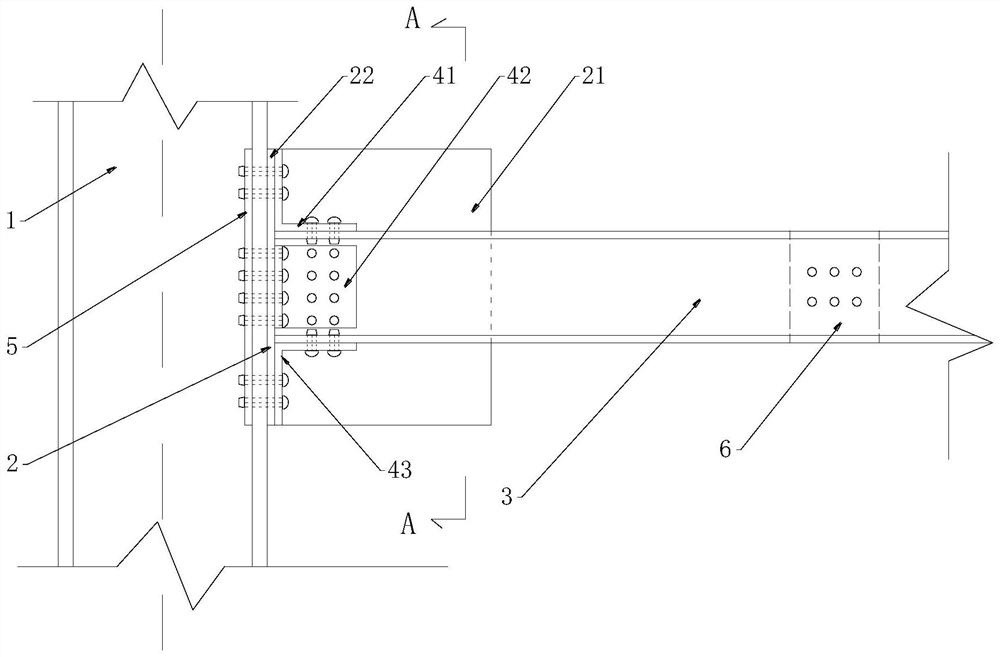

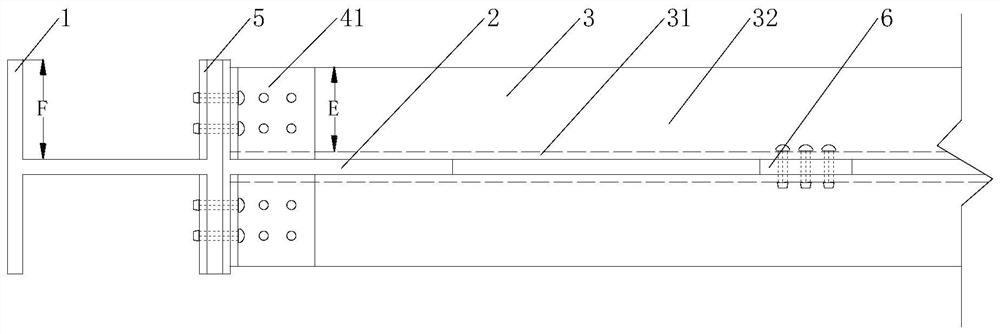

Aluminum alloy semi-rigid beam and column joint connected through ring groove rivets

ActiveCN110093981AOvercoming Strength Reduction ProblemsImprove mechanical propertiesRivetsRod connectionsButt jointAluminium alloy

The invention discloses an aluminum alloy semi-rigid beam and column joint connected through ring groove rivets. The aluminum alloy semi-rigid beam and column joint comprises an aluminum alloy I-shaped beam, an aluminum alloy column and the ring groove rivets; the end face of the aluminum alloy I-shaped beam is in butt joint with flanges of the aluminum alloy column, and the aluminum alloy I-shaped beam and the aluminum alloy column are connected through angular stainless steel connection pieces; and the four angular stainless steel connection pieces are arranged at the junction of the beam and the column in pairs, arranged on upper and lower flanges of the beam and the two sides of a beam web correspondingly, and connected with the column flanges correspondingly. The joint further has thevery high bearing capacity and initial rotation stiffness besides having excellent performance of common joints, for example, the joint can be quickly assembled on a construction site, and the strength reduction problem of welding joints and the problem of electrochemical corrosion of bolt connecting joints can be solved; the ring groove rivets, serving as novel connecting fasteners, can providehigh pre-tightening force, prevent loosening and resist vibration; and the novel joint can greatly improve mechanical performance of an aluminum alloy structure, increase the construction speed of thealuminum alloy structure, and help to solve the problem of excess capacity of electrolytic aluminum in China by being extensively used in engineering.

Owner:TSINGHUA UNIV

Insulating transmission shaft for connecting with motor and gear case

InactiveCN105811644AAvoid Galvanic Corrosion ProblemsClosely connectedMechanical energy handlingDrive shaftControl theory

The invention provides an insulating transmission shaft for connecting with a motor and a gear case, wherein the shaft comprises: an A shaft of which a first end is connected with a motor main shaft; a B shaft of which a first end is connected with the gear case; a second end of the A shaft and a second end of the B shaft are connected; and an insulating layer covers the second end of the A shaft and / or the second end of the B shaft. The insulating layer between the second end of the A shaft and the second end of the B shaft solves an electro-corrosion problem on tooth surface and a bearing of the gear case caused by shaft current which is generated on the motor side in an integrated motor and gear case structure and passes through a transmission shaft, the damage from the shaft current to the integration is prevented, the service life of the integration can be greatly prolonged, and the reliability of the integration is improved.

Owner:NANJING HIGH DRIVE ELECTROMECHANICAL AUTOMATION EQUIP CO LTD

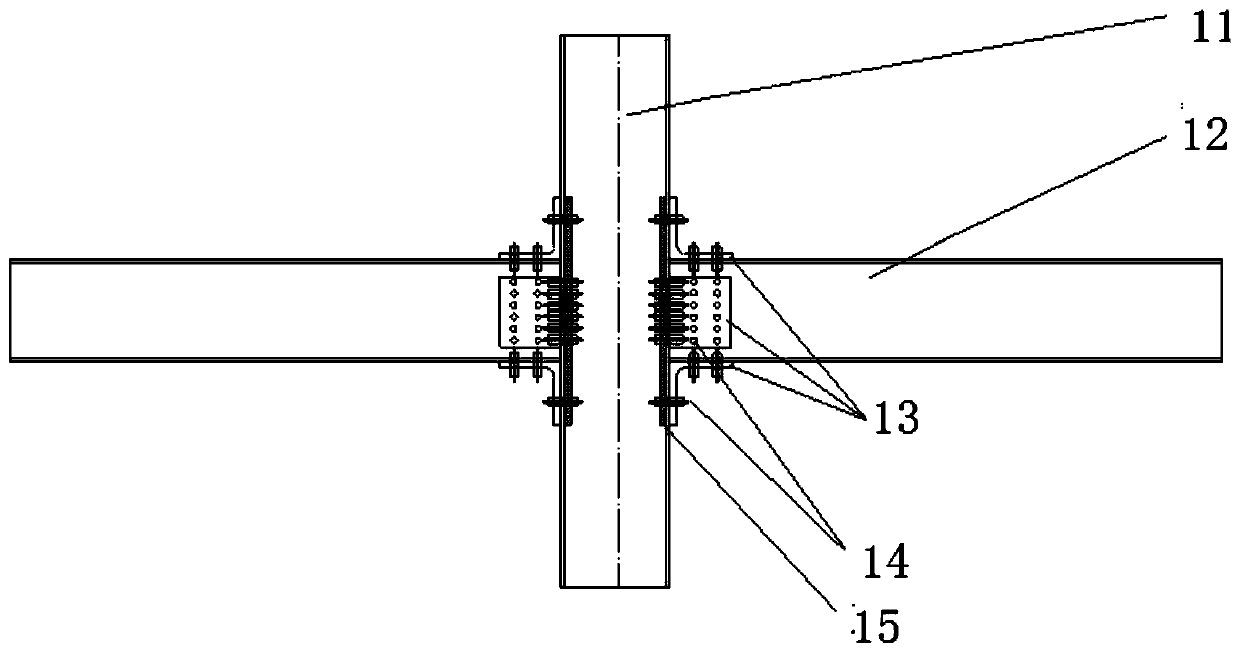

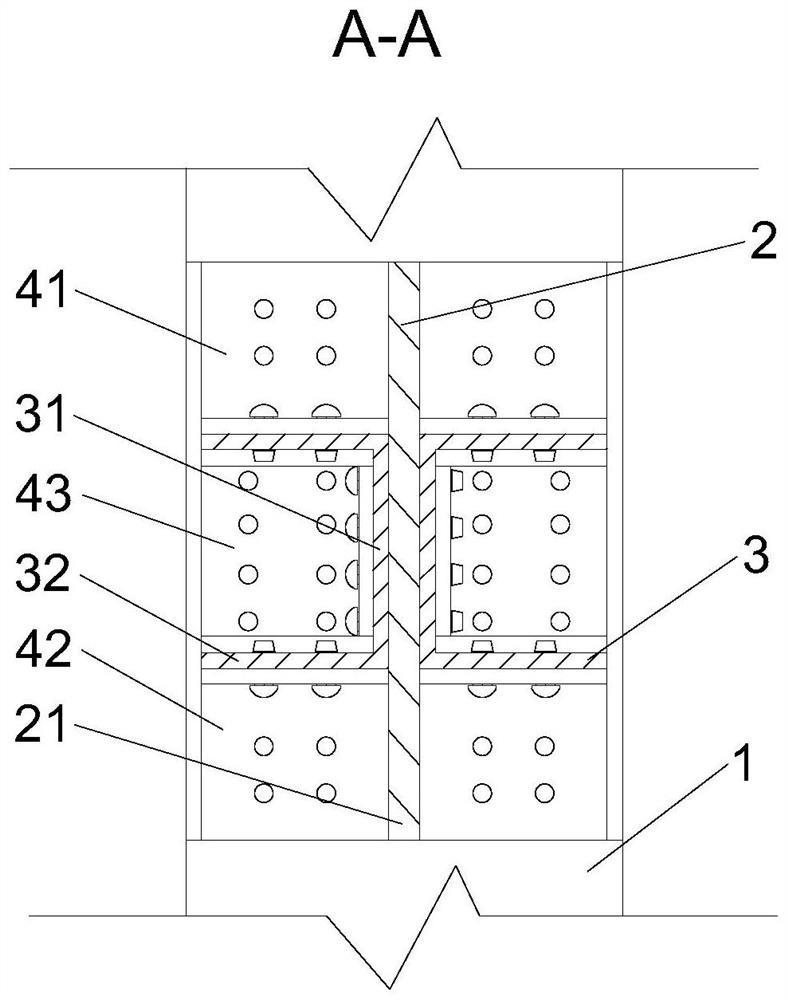

Base plate reinforced type ring-grooved rivet connection aluminum alloy beam-column joint

ActiveCN110106974AImprove carrying capacityHigh initial rotational stiffnessBuilding constructionsCarrying capacityAluminium alloy

The invention relates to a base plate reinforced type ring-grooved rivet connection aluminum alloy beam-column joint. The base plate reinforced type ring-grooved rivet connection aluminum alloy beam-column joint comprises an aluminum alloy I-shaped beam, an aluminum alloy column, four angled stainless steel connecting parts, ring-grooved rivets and reinforced base plates, the four angled stainlesssteel connecting parts are arranged at the junction of the beam and the column in pairs, arranged at an upper flange and a lower flange of the beam and the two sides of a beam web plate correspondingly and all connected with column flanges, and the base plates are symmetrically arranged on the inner sides of the column flanges. The joint has the excellent performance which is owned by an ordinarybeam-column joint, for example, the joint can be quickly assembled on a construction site, the strength reduction problem of a welding joint can be solved, and the problem of electrochemical corrosion of bolt connection joints is solved, in addition, the joint has the quite high carrying capacity and the quite high initial rotation stiffness; the ring-grooved rivets serve as novel connection fasteners, can provide high pretightening force, and resist loosening and resist vibration; and through the novel joint, the mechanical performance of an aluminum alloy structure can be greatly improved,and the construction speed of the aluminum alloy structure is increased.

Owner:TSINGHUA UNIV

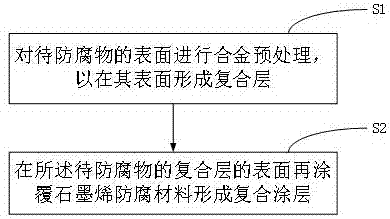

Trail traffic buckle accessory alloy pretreatment and graphene material compound corrosion resistance technology

InactiveCN107418345ASolving Galvanic Corrosion ProblemsImprove comprehensive anti-corrosion abilitySolid state diffusion coatingAnti-corrosive paintsCorrosion resistantPre treatment

The invention relates to a trail traffic buckle accessory alloy pretreatment and graphene material compound corrosion resistance technology which comprises the following steps: S1, performing alloy pretreatment on the surface of a to-be-corrosion resistant object to form a compound layer on the surface thereof; and S2, then coating the surface of the compound layer of the to-be-corrosion resistant object with a graphene corrosion-resistant material to form a compound coating. The compound corrosion resistance technology comprises the S1 of obtaining the compound layer (an alloy co-diffusing layer). The alloy co-diffusing layer can be combined with a metal matrix firmly, so that the electrochemical corrosion problem can be solved. Meanwhile, the problem of collision in a construction process is solved without affecting the hardness of metal. The alloy co-diffusing layer can be combined with the graphene corrosion-resistant coating well, so that the comprehensive corrosion-resistant ability of a product is improved. By combining the two, corrosion-resistance and collision resistance of the product can be solved at the same time.

Owner:戴鹏 +1

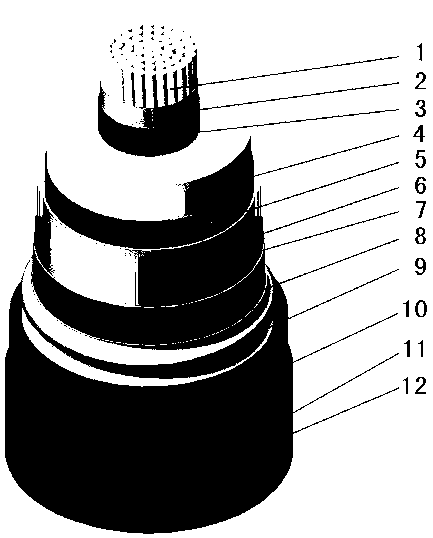

High voltage and ultrahigh voltage flexible direct current transmission optical fiber composite extrusion insulation power cable

ActiveCN103123826AReduce weightLow costPower cables with screens/conductive layersInsulation layerElectrical conductor

The invention discloses a high voltage and ultrahigh voltage flexible direct current transmission optical fiber composite extrusion insulation power cable. A water-resistant conductor is arranged at the center of the cable. A semiconductive wrapping belt, an extrusion inner shielding layer, an extrusion insulation layer, an extrusion outer shielding layer, a first buffer water-resistant layer, a second buffer water-resistant layer, a metal sleeve, a non-metal extrusion outer sheath and an extrusion conductive layer are sequentially wrapped outside the water-resistant conductor. Optical fibers are placed between the buffer water-resistant layers. The insulation layer is made of ultra-clean materials containing a space charge inhibitor, the largest allowable working temperature is 90 DEG C, and the shortcoming of electric field distortion even breakdown caused by space charge accumulation of a traditional cable insulation material is overcome. A copper sleeve is adopted to avoid use of asphalt in corrosion resistance. The power cable achieves the effects of being clean and environment in production and installation, overcomes the electrochemical corrosion shortcomings and prevents environment pollution caused by the fact that a graphite conductive layer is coated on the surface of a traditional cable outer sheath to serve as an experiment electrode by extruding a conductive layer on the outer sheath to serve as the experiment electrode.

Owner:STATE GRID ELECTRIC POWER RES INST +1

Method for producing titanium alloy artificial hip joint with abrasion-proof ceramic coat

InactiveCN101347358BImprove wear resistanceAvoid Galvanic Corrosion ProblemsJoint implantsHip jointsArtificial hip jointsWear resistant

The invention relates to a manufacturing method of a titanium alloy artificial hip joint provided with a wear-resistant ceramic coat, which relates to the titanium alloy artificial hip joint and the manufacturing method thereof. The invention solves the problems existing in the existing caput femoris provided with a film of thin film thickness, low bonding strength of the film and a matrix, poor mechanical bearing strength and bad wear resistance and durable stability. The wear-resistant ceramic coat is coated on the spherical surface of the titanium alloy caput femoris and the surface of a titanium alloy articulation coax cup. A cylindrical slot that has fit connection with a femur handle is arranged on the upper end surface of the titanium alloy caput femoris. The method of the invention is that the joint is polished, shielded, installed and blocked; then the joint is processed by spark intensifying electrochemical oxidation to produce the wear-resistant ceramic coat; the joint is taken out, cleaned and dried; and finally, the surface of the joint is processed by polishing treatment. The artificial hip joint of the invention has the advantages of thick caput femoris film, strong bonding strength of the film and the matrix, good mechanical bearing strength and sound wear resistance and durable stability, etc. And the manufacturing method of the invention has simple process flows.

Owner:HARBIN INST OF TECH

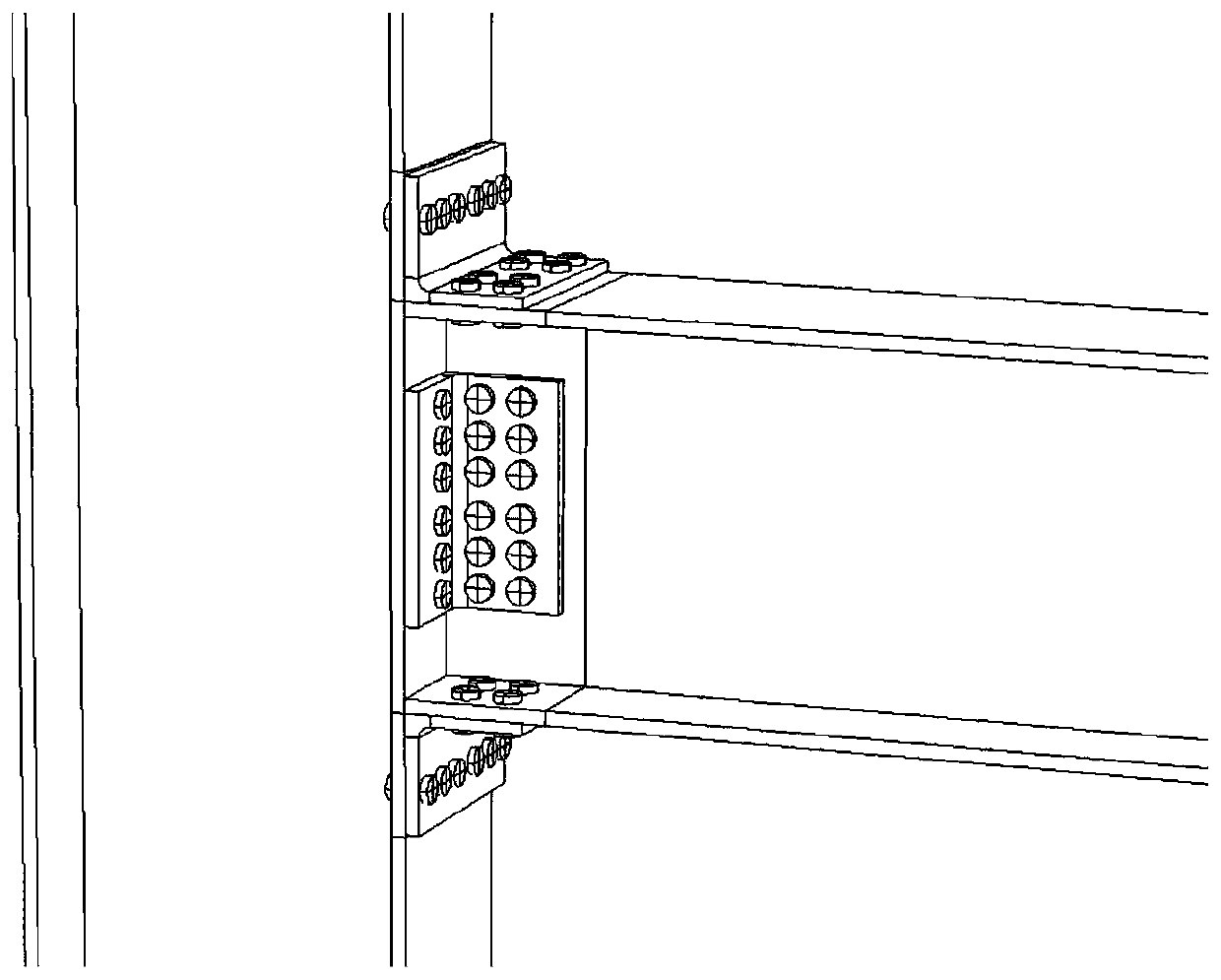

Novel assembly type aluminum alloy anti-seismic frame structure

ActiveCN113502918AImprove bearing capacityGood ductilityProtective buildings/sheltersBuilding reinforcementsEarthquake resistantEngineering

The invention discloses a novel assembly type aluminum alloy anti-seismic frame structure. Each stainless steel T-shaped connecting plate is composed of a connecting plate flange and a connecting plate web integrally and fixedly connected to the middle of the flange, and two rectangular I-shaped column base plates are arranged on the inner side of the aluminum alloy I-shaped column flange; the connecting plate webs in the pair of stainless steel T-shaped connecting plates which are oppositely arranged are oppositely arranged and are connected through two aluminum alloy groove-shaped beams; at least one rectangular groove-shaped beam base plate is mounted between the two aluminum alloy groove-shaped beams; and the upper portion of each connecting plate flange is connected with a groove-shaped beam flange above the corresponding aluminum alloy groove-shaped beam through an upper stainless steel angle connecting piece, the middle of the connecting plate flange is connected with a groove-shaped beam web through a middle stainless steel angle connecting piece, and the lower portion of the connecting plate flange is connected with a lower groove-shaped beam flange through a lower stainless steel angle connecting piece. The stainless steel T-shaped connecting plates can effectively gather the beams, the columns and the supports at one position, and the integrity of the frame structure is improved.

Owner:上海通正铝结构建设科技有限公司 +1

Insulation installation grounding device for ship electrical equipment

PendingCN113839231AReduce failureImprove the safety of useCoupling protective earth/shielding arrangementsConnection contact member materialElectrical conductorMarine engineering

The invention provides an insulation installation grounding device for ship electrical equipment, which is applied to the technical field of ships. A steel bracket (8) is arranged on an insulation gasket (10) of the insulation installation grounding device for the ship electrical equipment, one end of a grounding conductor (5) is connected with an aluminum grounding bracket (2), and the other end of the grounding conductor (5) is connected with the steel bracket (8); the grounding conductor (5) is connected with the equipment bottom foot (7) at the same time, the tinfoil layer I (6) is clamped between the grounding conductor (5) and the aluminum grounding support (2), and the tinfoil layer II (12) is clamped between the grounding conductor (5) and the equipment bottom foot (7). The insulation installation grounding device for the ship electrical equipment is simple in structure and low in cost, and the grounding requirement of the electrical equipment is met, the problem of electrochemical corrosion between dissimilar metal materials when electrical equipment is installed on an aluminum structure can be effectively solved, electrical equipment faults are effectively reduced, and the use safety and the service life of ship electrical equipment are improved.

Owner:WUHU SHIPYARD CO LTD

Hot tinning process of ultrafine copper wire

The invention discloses a hot tinning process of an ultrafine copper wire, and belongs to the field of tinned copper wires. The process comprises the following steps: taking a copper wire for paying off, then placing the copper wire into an annealing tube for annealing, drying the copper wire after annealing, placing the copper wire into tin liquid for tinning, and taking up the copper wire after cooling to prepare the ultrafine copper wire. Before annealing, the surface of the copper wire is continuously coated with ethanol during paying off; at least three temperature sections are arranged in the annealing tube for annealing, and the temperature of the copper wire out of the annealing tube is controlled to be 40 DEG C or below. According to the hot tinning process, the internal stress of the copper wire can be fully released by adopting multi-section temperature annealing, so that the surface stress of the copper wire is reduced, subsequent processing is facilitated, and the quality of the tinned copper wire is improved.

Owner:JIANGXI FUHONG METAL CO LTD

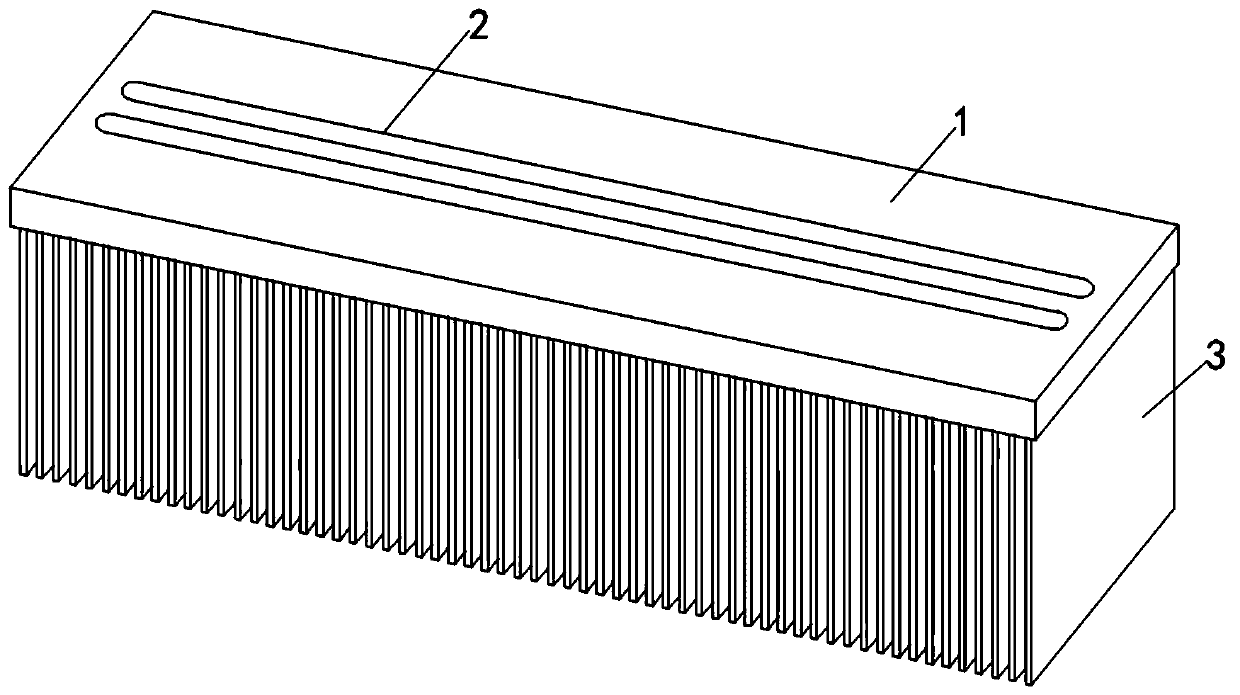

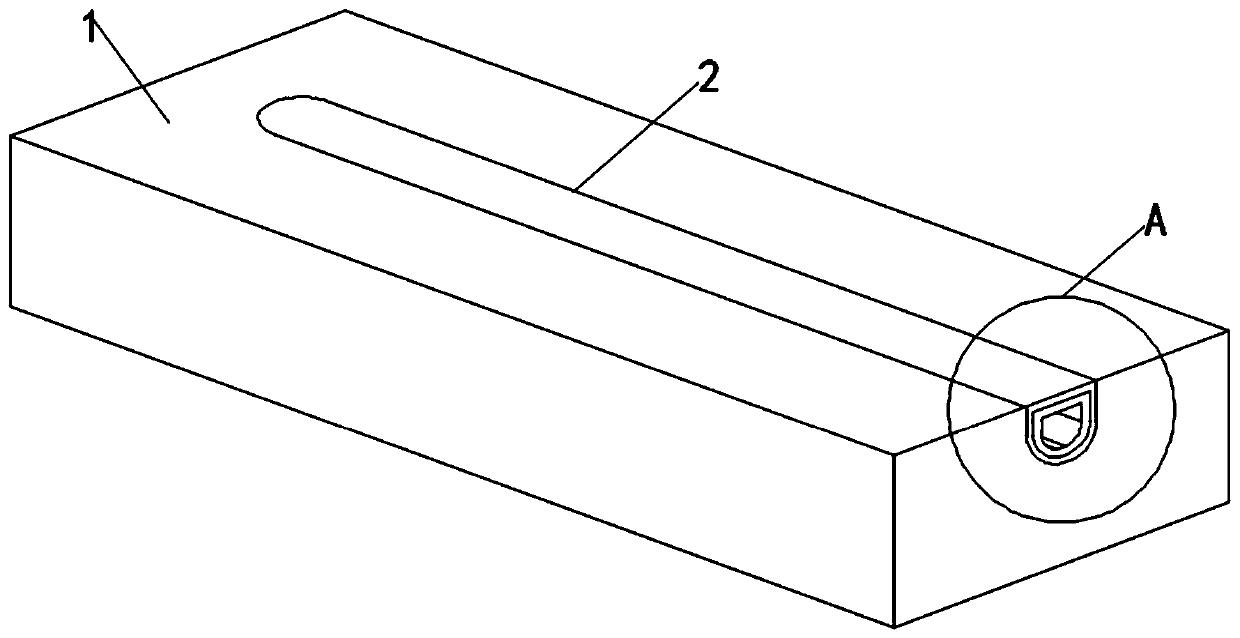

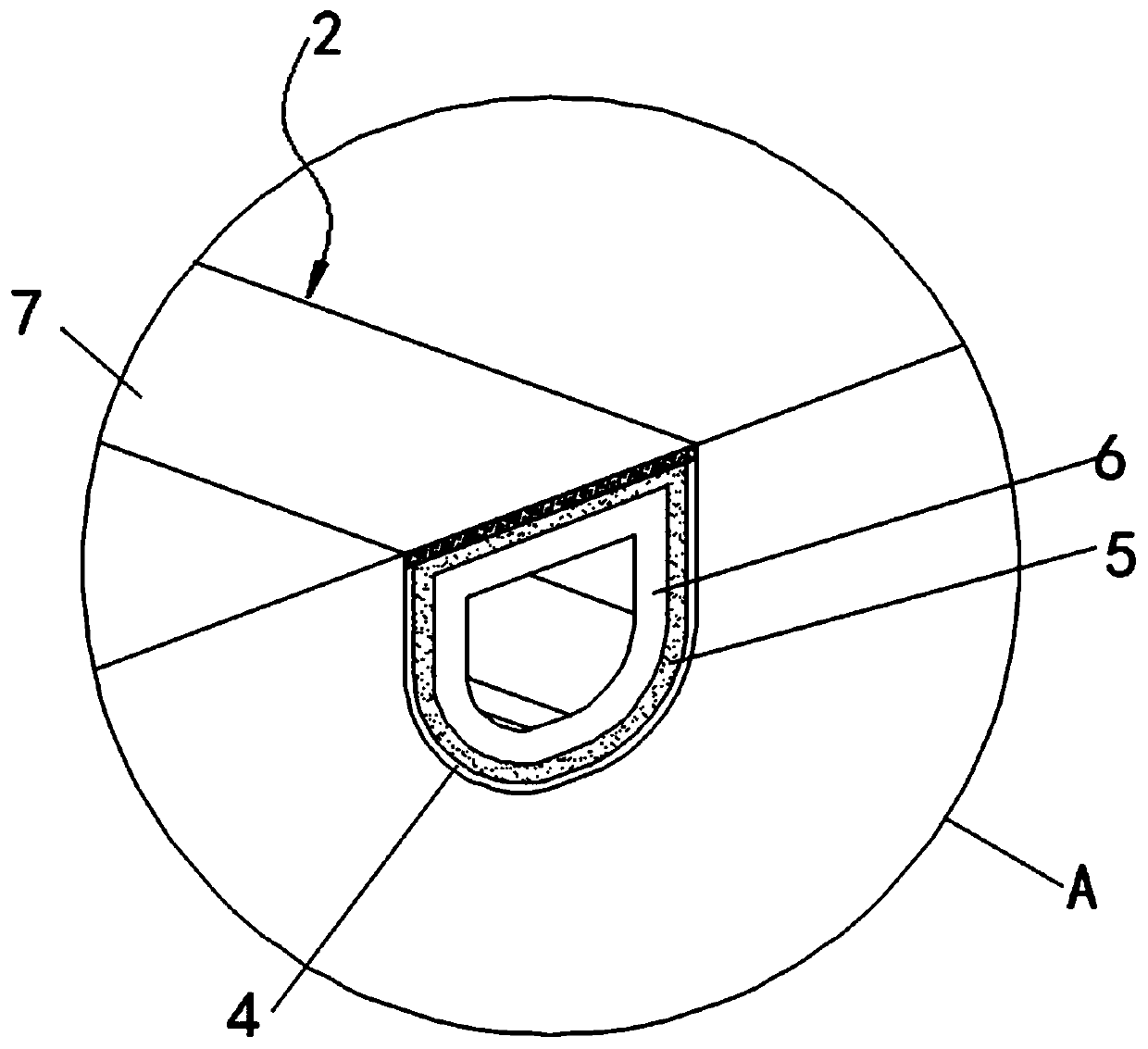

Anti-electrochemical corrosion radiator heat pipe embedding structure

PendingCN111442671AAvoid formingAvoid Galvanic Corrosion ProblemsCorrosion preventionIndirect heat exchangersSolderingElectrolyte

The invention discloses an anti-electrochemical corrosion radiator heat pipe embedding structure, and relates to the technical field of heat pipe radiators. The anti-electrochemical corrosion radiatorheat pipe embedding structure comprises a radiator aluminum substrate, a groove is formed in the upper surface of the radiator aluminum substrate, a radiating fin plate is fixedly connected to the lower surface of the radiator aluminum substrate, a welding aid coating is arranged on the inner wall of the groove, a heat pipe is arranged in the groove in an embedded mode, a heat pipe sintered wickis arranged in the heat pipe in an embedded mode, a soldering layer is arranged on the upper surface of the heat pipe, and the peripheral side walls of the soldering layer are in close fit with the welding aid coating correspondingly. According to the anti-electrochemical corrosion radiator heat pipe embedding structure, the soldering layer and the welding aid coating are arranged, the heat pipe is welded and buried by soldering by means of partial surface treatment, thus the seamless soldering layer is formed on the upper surface of the heat pipe, meanwhile the soldering layer and the weldingaid coating are welded seamlessly, so that the outer surface of the pipe wall of the heat pipe is protected by the soldering layer to isolate air, so as to avoid the formation of an electrolyte, andthe purpose of solving the problem of electrochemical corrosion is achieved.

Owner:江苏海鋆自动化技术有限公司

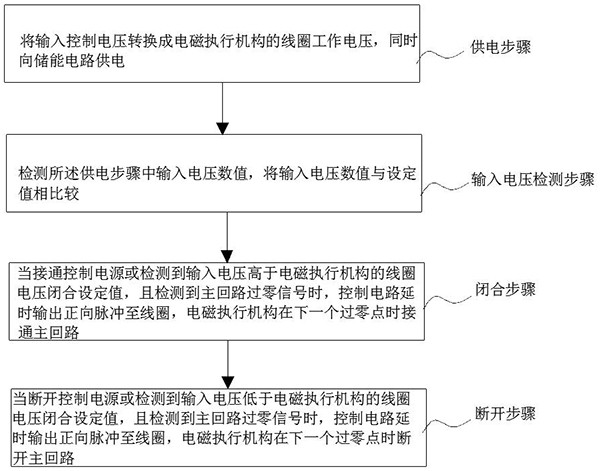

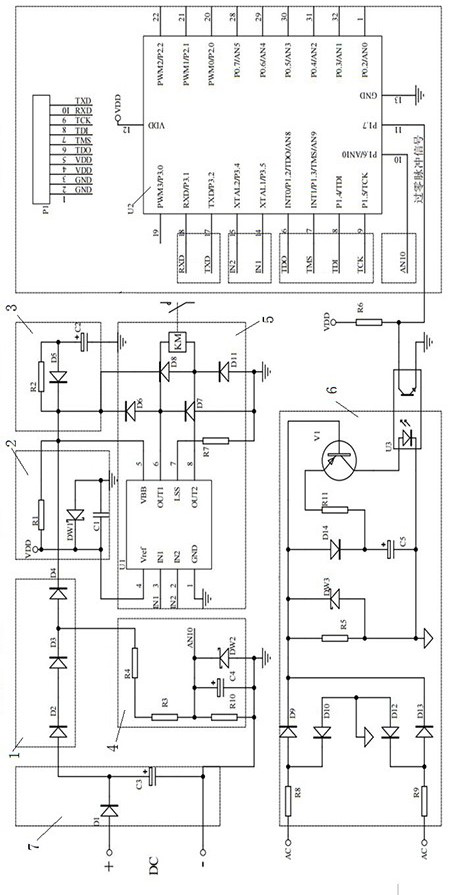

Control method of arc-free breaking alternating current circuit

ActiveCN114415580AEasy to useSolve electrocorrosionProgramme controlComputer controlPower controlInput control

The invention discloses a control method of an arc-free breaking alternating current circuit, which belongs to the technical field of power control, and comprises the following steps: a power supply step: converting an input control voltage into a coil working voltage of an electromagnetic actuating mechanism, and supplying power to an energy storage circuit at the same time; an input voltage detection step: detecting an input voltage value in the power supply step, and comparing an input control voltage value with a set value; in the closing step, the control circuit outputs a forward pulse to the coil in a delayed mode, and the electromagnetic executing mechanism switches on the main loop at the next zero crossing point; in the disconnection step, the electromagnetic executing mechanism disconnects the main loop at the next zero crossing point; the problem that electric arcs are generated in the on-off switching process of the alternating-current load is solved, high efficiency and energy conservation are achieved, the time of closing and opening the circuit of the electromagnetic executing mechanism is controlled in a time-delay mode through software, time-delay on-off control is conducted on the contact in a time-sharing mode so that a real current zero crossing point can be found, and the problem of electric corrosion of the contact in the load switching process is effectively solved.

Owner:NANJING QUANNING ELECTRIC +1

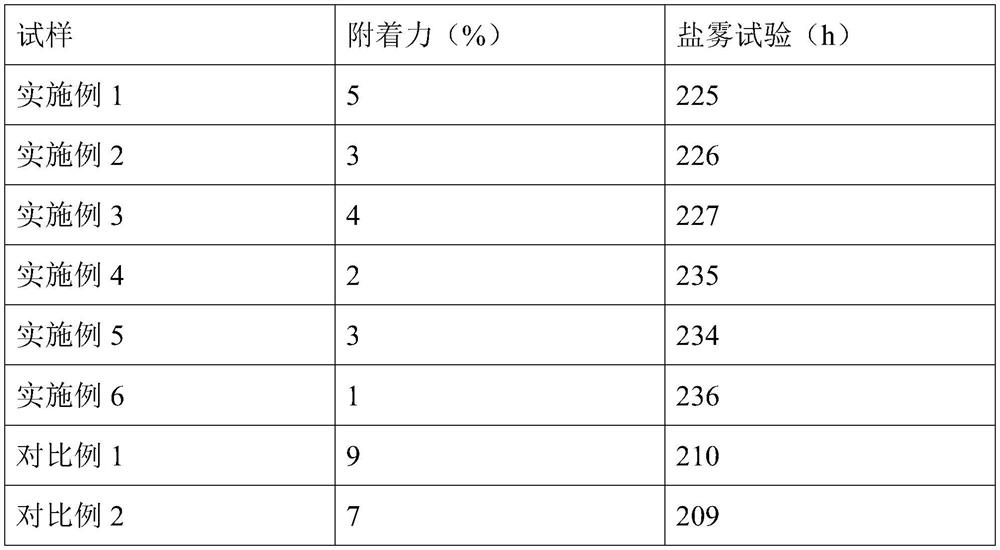

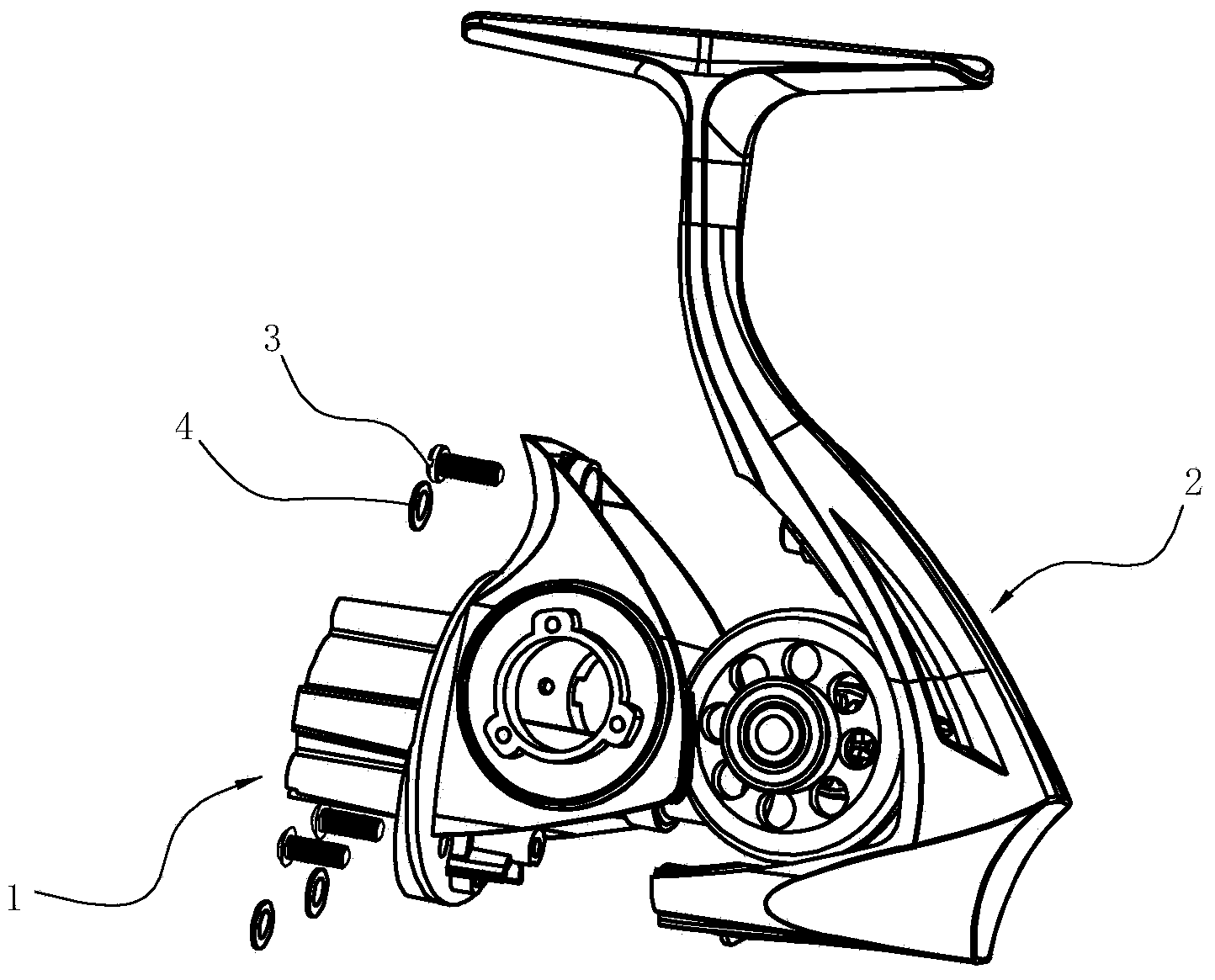

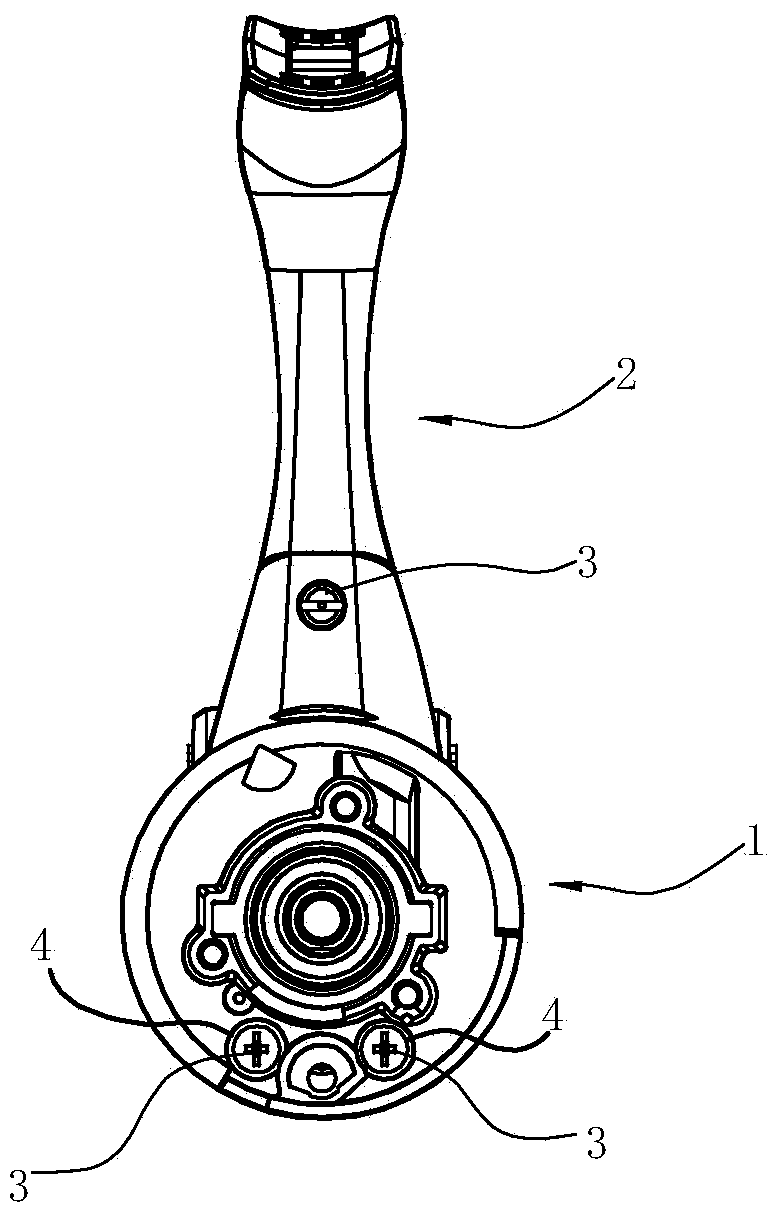

Fishing reel surface corrosion resistance process

ActiveCN103710716AImprove corrosion resistanceReduce pollutionElectrophoretic coatingsElectrophoresisEngineering

The invention relates to a fishing reel surface corrosion resistance process. A fishing reel comprises a main body and a main cover, wherein the main body is connected with the main cover via screws to form a main structure of the fishing reel. The process is characterized by comprising the following steps: (1) carrying out surface treatment by shot blasting, (2) carrying out immersion cleaning, (3) spraying, (4) washing, (5) activating; (6) cleaning up acid on the surface of the main structure of the fishing reel with purified water, (7) phosphating, (8) washing, (9) carrying out electrophoresis, (10) washing and (11) drying. Compared with the prior art, the fishing reel surface corrosion resistance process has the beneficial effects that after the fishing reel undergoes 168-hour neutral and acid salt spray tests, the surface of the fishing reel does not have obvious changes and does not fall off in scribing tests after the tests, thus greatly improving the corrosion resistance of the fishing reel; the fishing reel has beautiful appearance, high production efficiency and low labor intensity and is slight in environmental pollution in the treating process.

Owner:NINGBO HAIBO GRP CO LTD

Epoxy floor coating and preparation method thereof

The invention provides an epoxy floor coating, which comprises the following raw materials in parts by weight: 100 parts of a bisphenol A epoxy resin solution, 10-15 parts of a graphene microchip, 2-6parts of zinc powder, 0.5-1 part of polyamide wax slurry, 3-8 parts of n-butanol, 25-60 parts of xylene, 0.08-0.2 part of dibutyl phthalate and 0.1-0.2 part of polydimethylsiloxane. The graphene of the epoxy floor coating is uniformly dispersed and highly dispersed, so that the mechanical property of the graphene is brought into play, the impact resistance of the epoxy floor coating is effectively improved, the problem of electrical corrosion of the graphene is avoided, and the service life of the floor coating layer is effectively prolonged.

Owner:江苏道蓬科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com