High voltage and ultrahigh voltage flexible direct current transmission optical fiber composite extrusion insulation power cable

A flexible DC power transmission and optical fiber composite technology, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, cables, etc., can solve the problems of easy pollution of graphite particles, environmental pollution of production workshops, and difficult cleaning of asphalt. Achieve the effects of overcoming electric field distortion or even breakdown, preventing electrical tree aging, and overcoming electrochemical corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

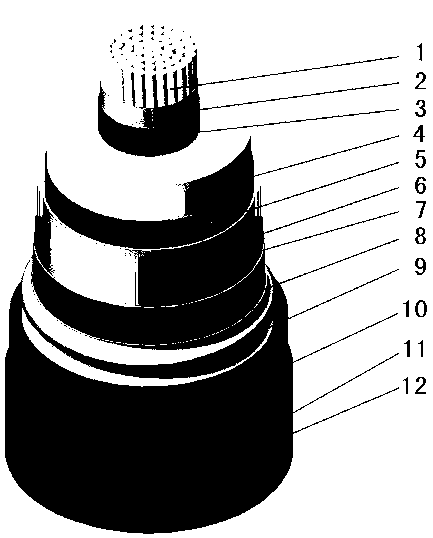

[0020] This embodiment is a rated voltage ±320 kV flexible direct current transmission optical fiber compound extruded insulated power cable.

[0021] (1) Water-blocking conductor 1, made of pure aluminum, with a cross-sectional area of 1400 mm 2 , using a stranded circular compact conductor structure or a split conductor structure, and the gap between the conductors is filled with water-blocking materials;

[0022] (2) Semi-conductive Tetoron wrapping tape 2, thickness 0.18 mm;

[0023] (3) Semi-conductive inner shield 3 with a thickness of 1.5 mm;

[0024] (4) The extruded insulating layer 4 is an ultra-clean PE cross-linked material added with a space charge inhibitor. The working temperature is 90°C, the dielectric constant is 2.3, the DC breakdown field strength is greater than 45 kV / mm, and the insulating layer thickness (22~ 24) mm; the mixture of ultra-clean PE cross-linking material and space charge inhibitor is made by melt mixing method;

[0025] (5) Semi-condu...

Embodiment 2

[0034] This embodiment is a rated voltage ±200 kV flexible direct current transmission optical fiber compound extruded insulated power cable.

[0035] (1) Water-blocking conductor 1, made of aluminum alloy or copper for cable conductors, with a cross-sectional area of 1000 mm 2 , using a twisted circular compact conductor structure, the gap between the conductors is filled with water-blocking materials;

[0036] (2) Semi-conductive Tetoron wrapping tape 2, thickness 0.18 mm;

[0037] (3) Semi-conductive inner shield 3 with a thickness of 1.5 mm;

[0038](4) The extruded insulating layer 4 is an ultra-clean PE crosslinking material added with a space charge inhibitor, the working temperature is 90°C, the dielectric constant is 2.3, the DC breakdown field strength is greater than 45 kV / mm, and the insulating layer thickness (12~ 14) mm; the mixture of ultra-clean PE crosslinking material and space charge inhibitor is made by melt mixing method;

[0039] (5) Semi-conductive ...

Embodiment 3

[0048] This embodiment is a rated voltage ±160 kV flexible direct current transmission optical fiber compound extruded insulated power cable.

[0049] (1) Water-blocking conductor 1, made of copper, with a cross-sectional area of 500 mm 2 , using a twisted circular compact conductor structure, the gap between the conductors is filled with water-blocking materials;

[0050] (2) Semi-conductive nylon wrapping tape 2, thickness 0.1 mm;

[0051] (3) Semi-conductive inner shield 3, thickness (1.2-1.5) mm;

[0052] (4) The extruded insulating layer 4 is an ultra-clean PE crosslinking material added with a space charge inhibitor, the working temperature is 90°C, the dielectric constant is 2.3, the DC breakdown field strength is greater than 45 kV / mm, and the insulating layer thickness (11~ 13) mm; the mixture of ultra-clean PE crosslinking material and space charge inhibitor is made by melt mixing method;

[0053] (5) Semi-conductive outer shield 5, thickness 1 mm;

[0054] (6)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com