Magnesium alloy vehicle wheel surface treatment method and magnesium alloy vehicle wheel

A surface treatment and magnesium alloy technology, which is used in the processing and manufacturing of magnesium alloy wheels, the field of thermal deformation after spraying aluminum on the surface of magnesium alloy wheels, which can solve the problem of coating peeling, difficulty in meeting the requirements of wheel use, and low bonding force between aluminum coating and magnesium substrate. and other problems, to improve the bonding force, solve the problem of electrochemical corrosion, and have no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation will be described in detail below in conjunction with the accompanying drawings (this embodiment is a further description of the present invention, rather than any limitation to the present invention).

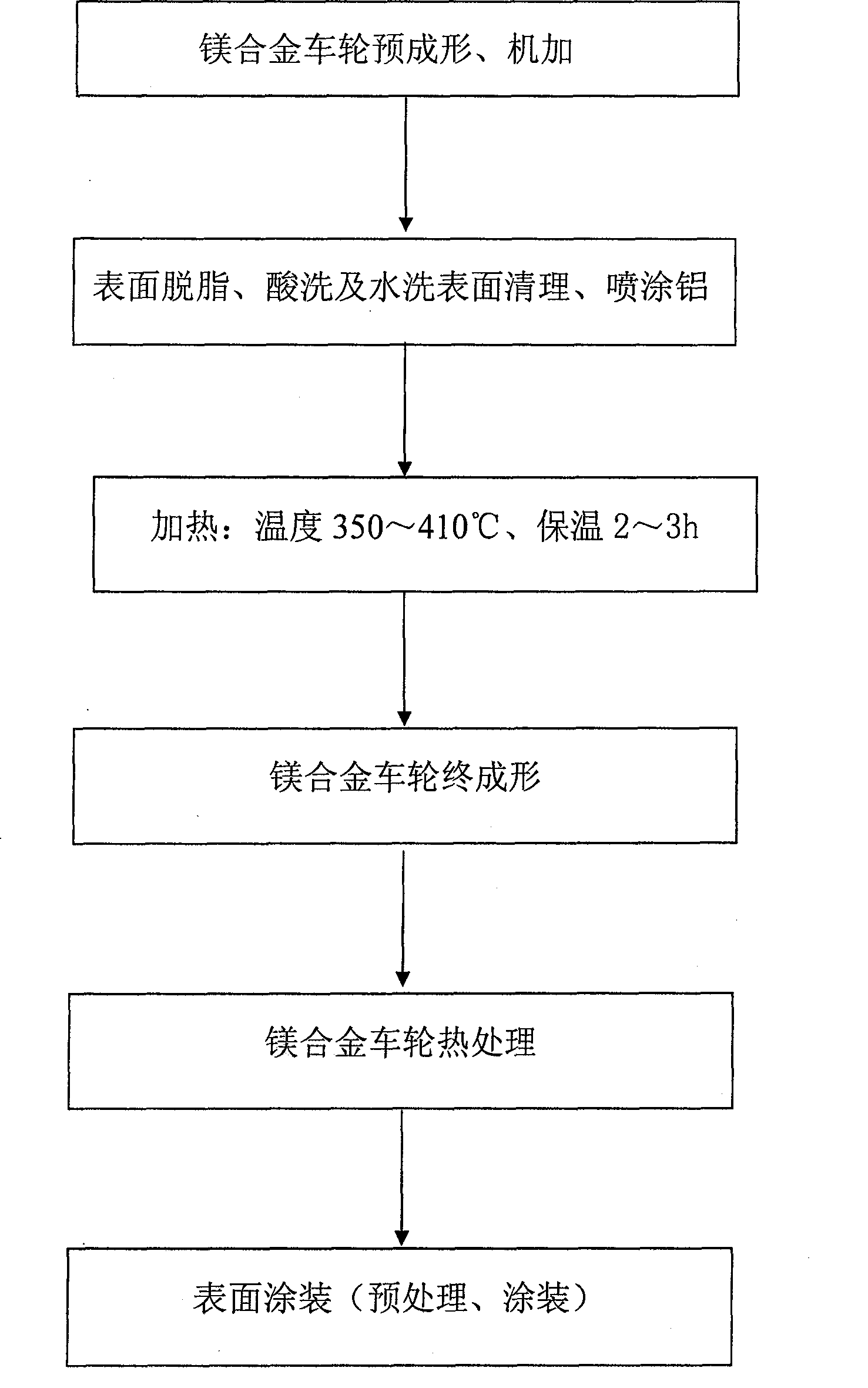

[0019] Such as figure 1 Shown, the process flow chart of magnesium alloy wheel surface treatment method of the present invention. A surface treatment method for a magnesium alloy wheel includes preforming, machining, aluminum spraying on the surface, heating and diffusion, final forming, heat treatment, and surface coating. The method of the invention can be used to make a magnesium alloy wheel with a layer of aluminum or aluminum alloy on the surface.

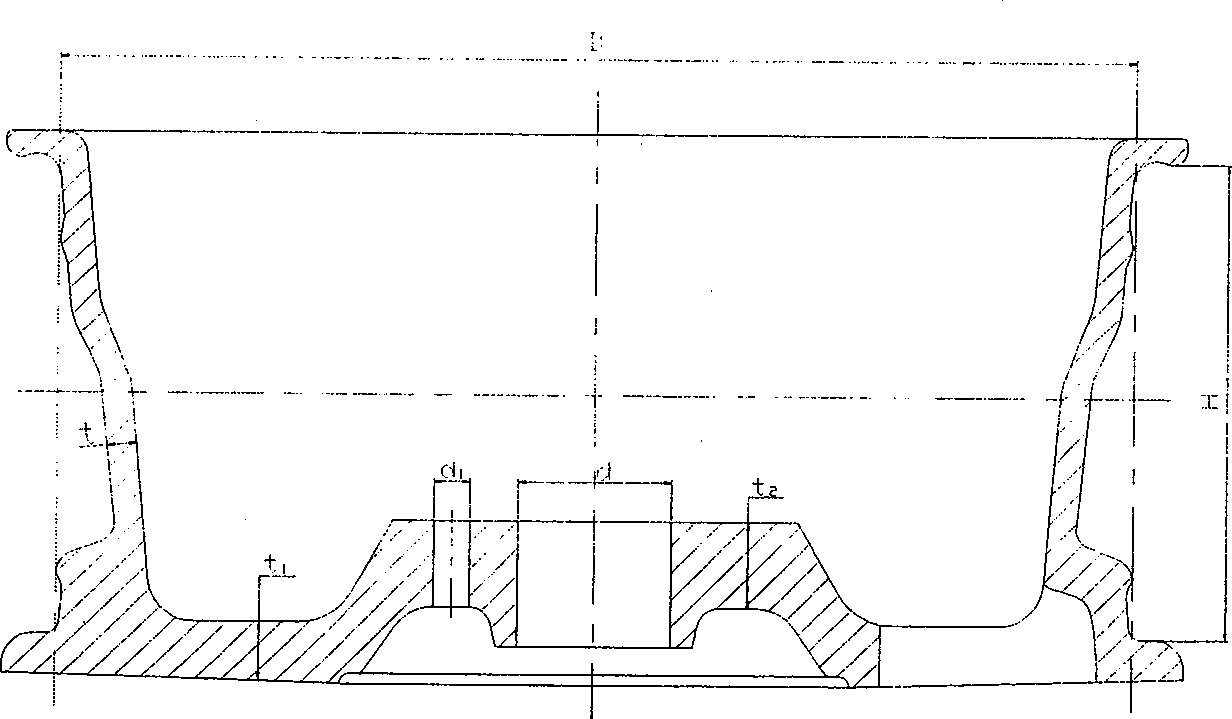

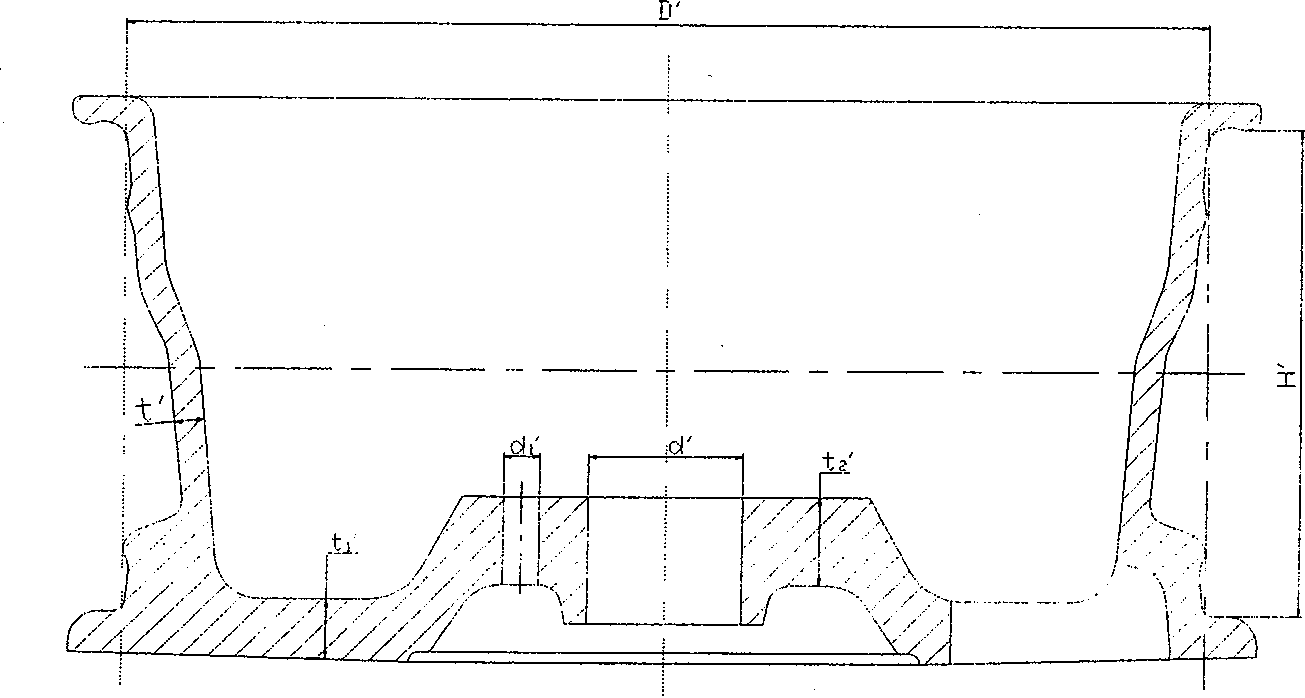

[0020] In the preforming process, the wheel blank is prepared by plastic deformation, and the wheel semi-finished product is obtained after machining, leaving a suitable amount of deformation for the final forming; the preforming is determined according to the specification and shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com