Method for characterizing material corrosion resistance in high-throughput manner by using micro-channel electrochemical system

A corrosion resistance and electrochemical technology, which is applied in the field of corrosion resistance detection of metal materials and high-throughput characterization of corrosion resistance of metal materials, can solve the problem of reducing the correct rate of corrosion resistance screening results, not effectively avoiding galvanic corrosion, The preparation of wire bundle electrodes is cumbersome and other problems, so as to avoid the problem of galvanic corrosion, shorten the test time, and reduce the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

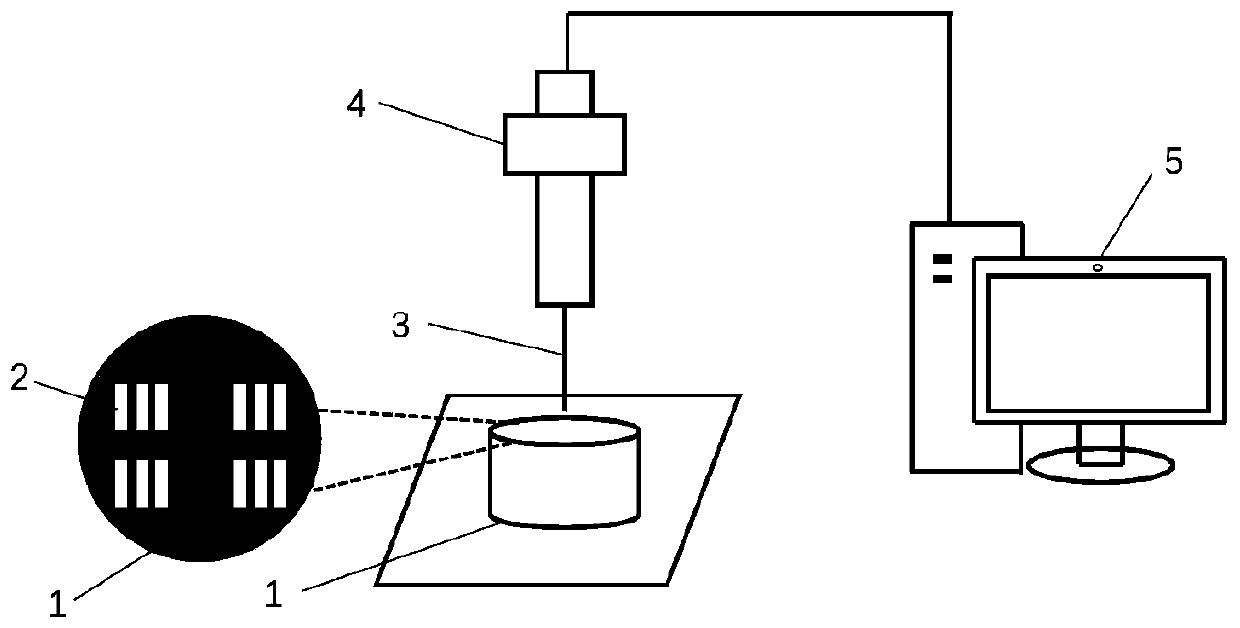

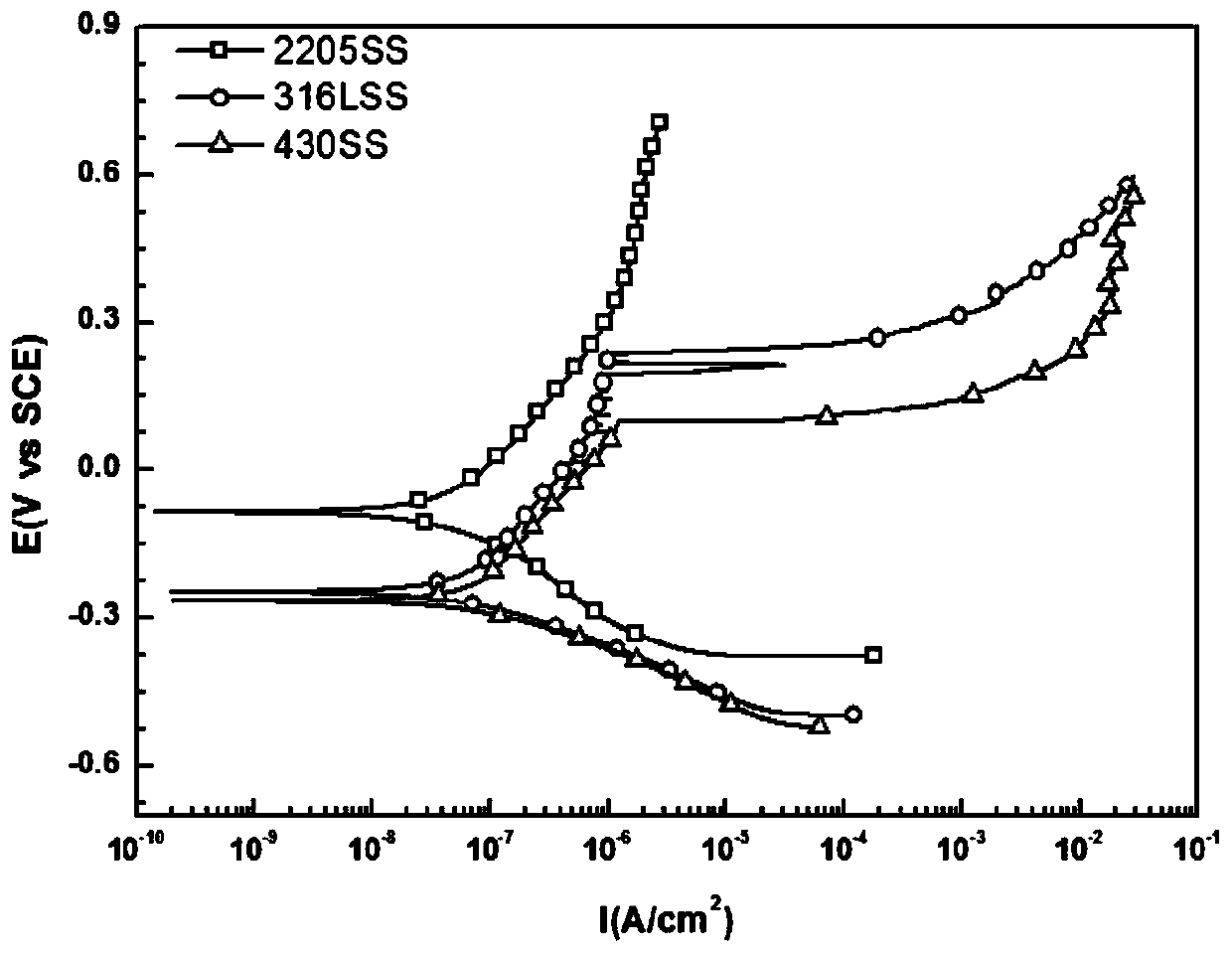

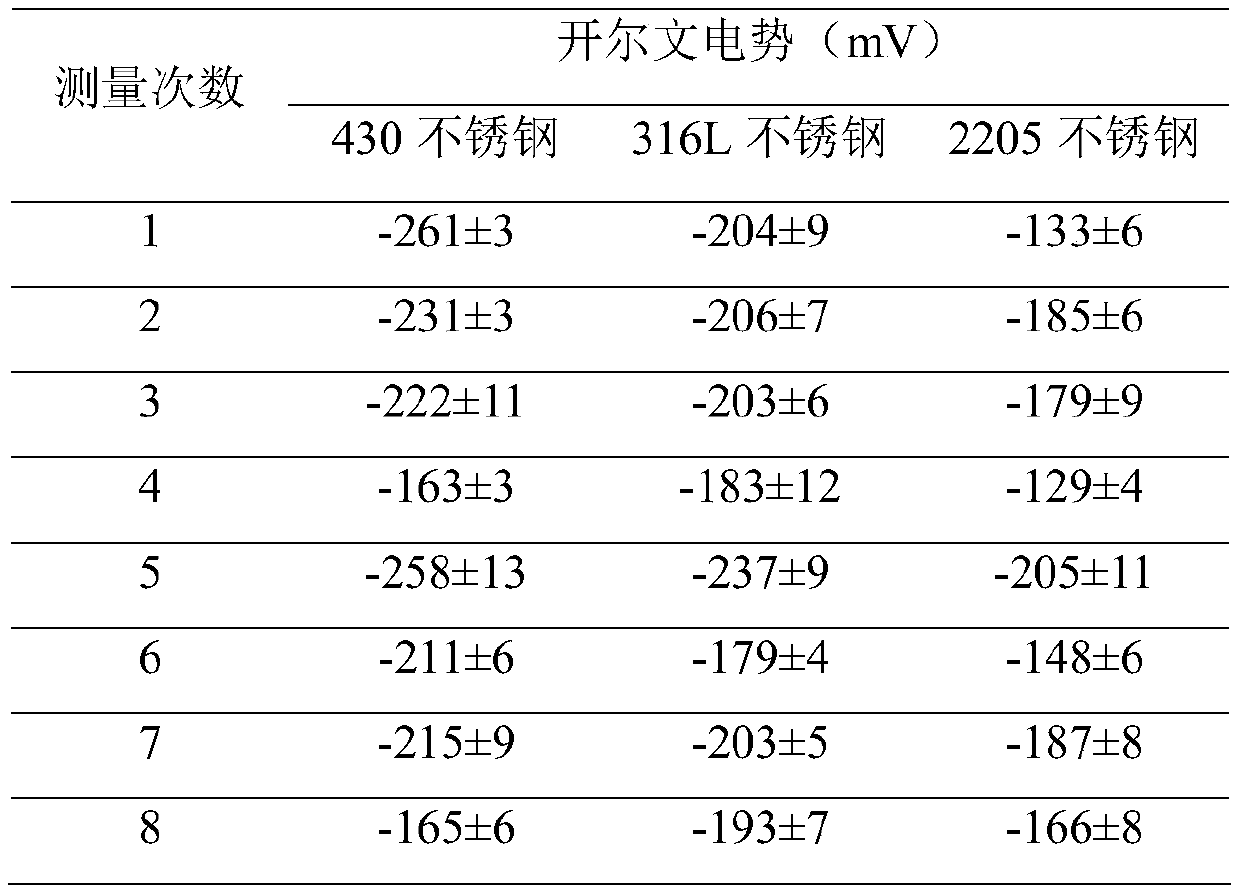

[0026] In this example, see figure 1 , the schematic diagram of the characterization device used is shown in figure 1 As shown, the device mainly includes SKP data acquisition device 5, SKP three-dimensional mobile platform 4, SKP probe 3 and coupled integrated electrode 1, wherein the coupled integrated electrode 1 arranges a variety of different metal samples 2 according to requirements In the micro-area mold, taking three stainless steel samples of 430, 316L, and 2205 as examples, using the high-throughput method of micro-area electrochemical system to characterize the corrosion resistance of materials, by preparing metal material samples with composition gradients, each metal material The samples are packaged together to form an integrated electrode. The working end faces of each metal material sample are placed on the same horizontal plane, and coupled with the micro-area electrochemical SKP module for high-throughput parallel testing. By comparing the potential of each m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com