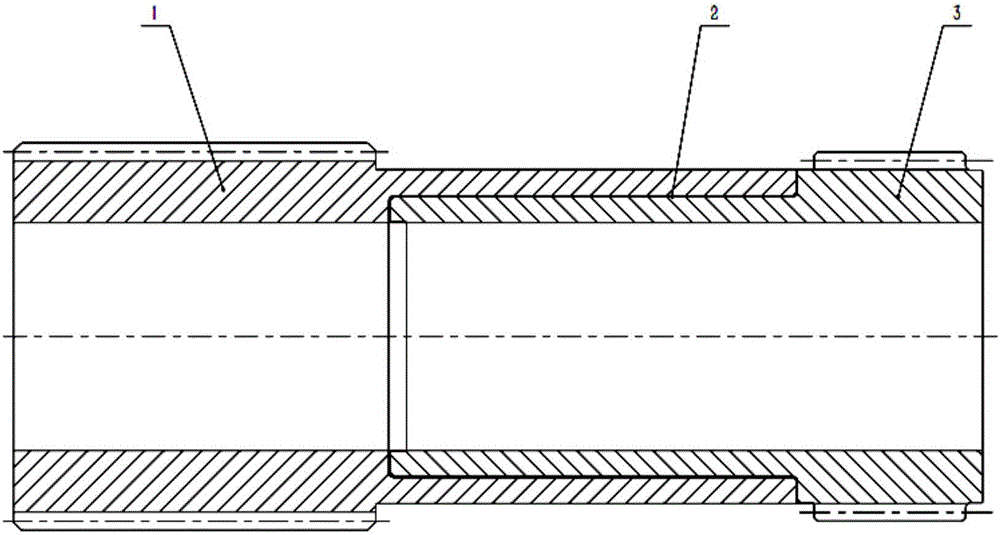

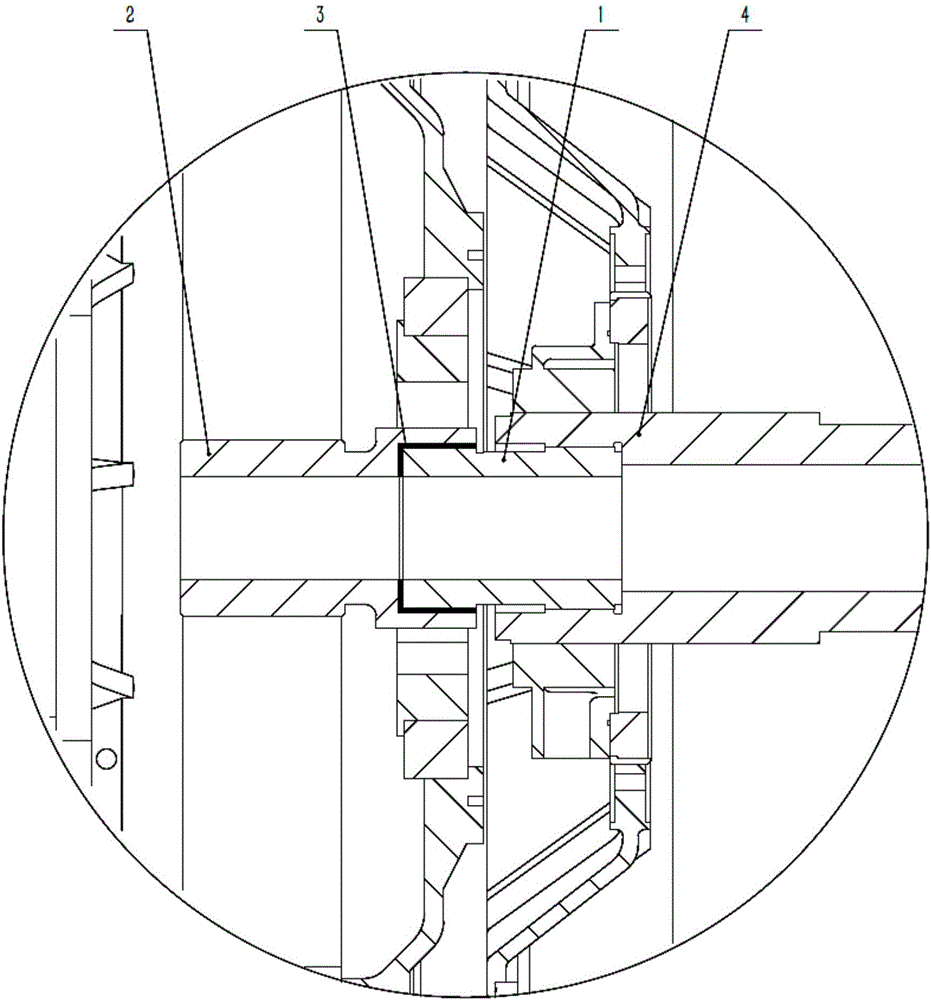

Insulating transmission shaft for connecting with motor and gear case

A gearbox and transmission shaft technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of regular replacement, pollution of engine room and unit, and inability to collect carbon powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

[0022] Wind energy is a green renewable energy source. Considering environmental protection, all countries in the world are committed to the development of wind resources. In recent years, the Chinese government has attached great importance to the development of wind power generators, and the localization of wind power generation equipment in China is constantly developing. With the strong support of relevant national ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com