Fiber-metal hybrid composite laminate and preparation method thereof

A technology of composite layer and metal base layer, applied in the direction of metal layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems that the thickness of the adhesive layer cannot be controlled and affects the performance of fiber-metal hybrid composite materials, etc., to achieve Avoid electrochemical corrosion problems, suitable for popularization and use, simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

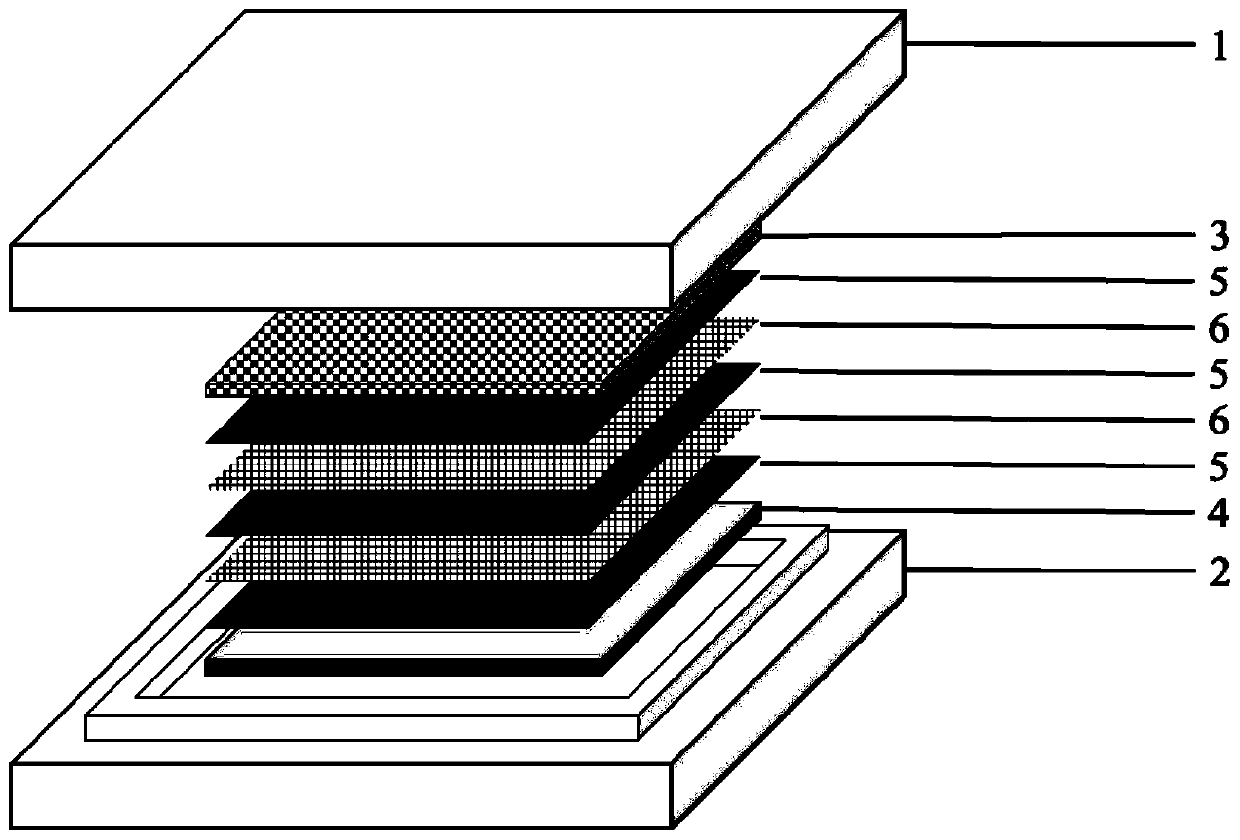

[0024] Such as figure 1 As shown, the fiber-metal hybrid composite laminate includes a layer of 1.5mm thick steel plate, a layer of carbon fiber composite material with a thickness of about 1.5mm, and an intermediate glue layer, and a certain number of layers of Nylon fiber mesh cloth is used as the base material of the adhesive layer. The laying sequence is steel plate-adhesive film-adhesive base material-adhesive film-adhesive base material-adhesive film-carbon fiber prepreg, and the adhesive layer base material and adhesive film are laid alternately to realize the control of the thickness of the adhesive layer. After the layer is laid, put it into the mold, and use the molding process to co-cure the adhesive film and the prepreg to obtain a carbon fiber-steel hybrid composite laminate with a certain thickness of the adhesive layer. Concrete preparation method is as follows:

[0025] a) Perform solvent scrubbing, degreasing, sandblasting and silanization on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com