Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Achieve cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

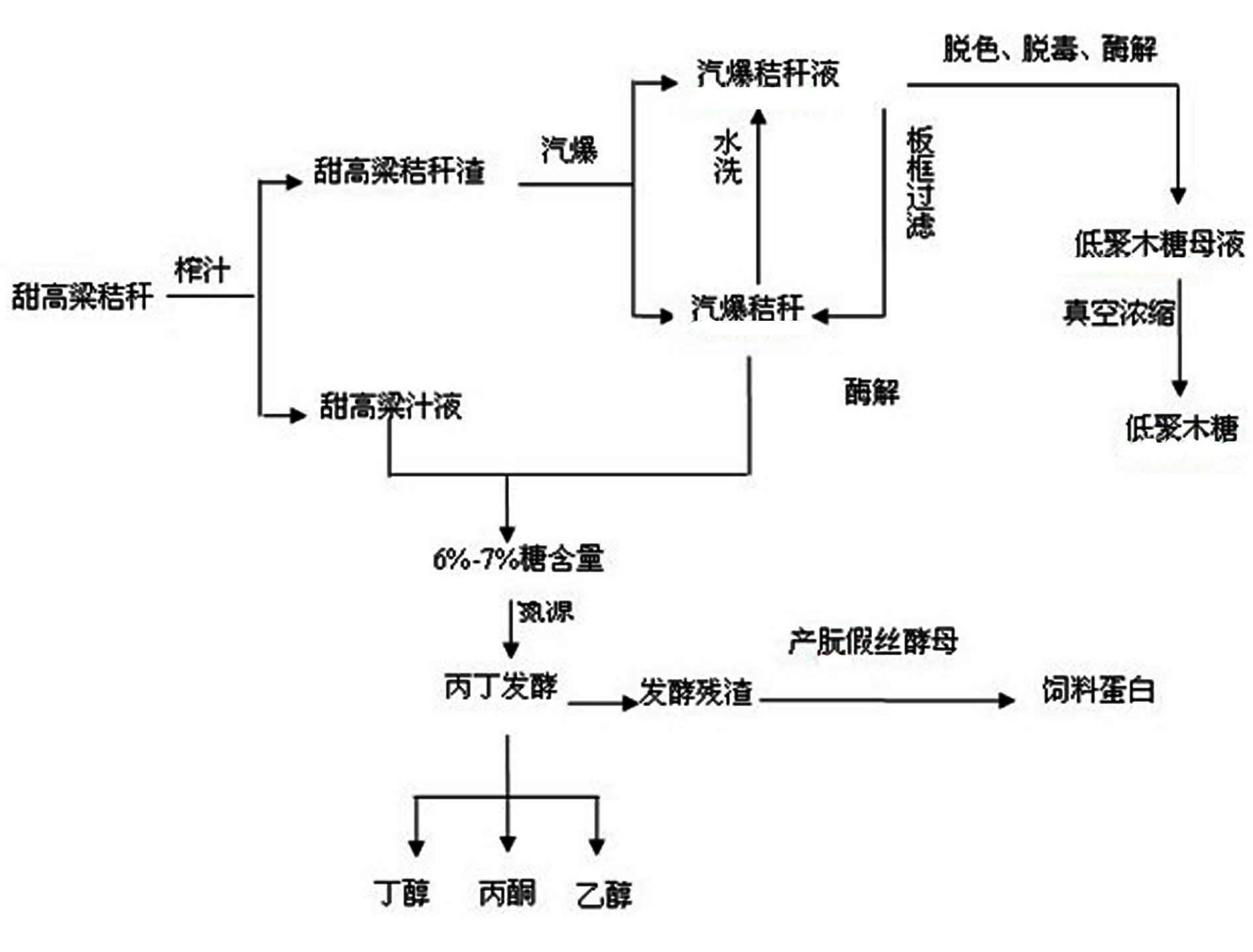

Comprehensive utilization method of sweet sorghum straw and juice thereof

ActiveCN102321679AImprove use valueTo achieve hierarchical utilizationBiofuelsMicroorganism based processesSweet sorghumDrug biotransformation

The invention discloses a comprehensive utilization method of sweet sorghum straw and juice thereof, which comprises the following steps: juicing sweet sorghum straw, separating the juice from straw residues, performing steam explosion of the sweet sorghum straw residues to obtain steam exploded straw and a steam exploded straw eluate; performing enzymatic hydrolysis of the steam exploded straw, mixing with the sweet sorghum juice, controlling the sugar content to be 6%-7%, adding a nitrogen source, performing acetone butanol fermentation to produce acetone, butanol and ethanol; inoculating bacteria into the fermentation residues to produce feed protein; performing decoloration, detoxification, and enzymatic hydrolysis of the steam exploded straw eluate to extract xylo-oligosaccharides. The invention realizes graded utilization of saccharides, cellulose and hemicellulose in sweet sorghum, can produce xylo-oligosaccharides, and can produce fermentation products such as acetone, butanol, ethanol, feed protein and the like through biotransformation. The invention realizes the comprehensive utilization of sweet sorghum straw resources, has no waste material or pollutant discharge during the production, realizes cleaner production, and has good social benefit and economic benefit.

Owner:江苏联海生物科技有限公司

Preparation method for glucosamine sulfate

ActiveCN104710483AAvoid damageMild reaction conditionsSugar derivativesSugar derivatives preparationOrganosolvPotassium

The invention relates to a preparation method for glucosamine sulfate. According to a technical scheme in the invention, the preparation method comprises the following steps: step 1, dispersing D-glucosamine hydrochloride in an alcoholic solvent; step 2, neutralizing D-glucosamine hydrochloride with alkali; step 3, adding sulfuric acid into a glucosamine solution drop by drop so as to form a salt; step 4, carrying out precipitation and separation; and step 5, carrying out refining by repeatedly washing a solid with a small amount of an organic solvent until no chloride ion is eluted and carrying out drying under reduced pressure, wherein the organic reagent is ethanol, propyl alcohol, acetone or the like with a concentration of 80 to 100%. With the technical scheme, glucosamine sulfate with low sodium or potassium content is obtained.

Owner:迪嘉药业集团股份有限公司

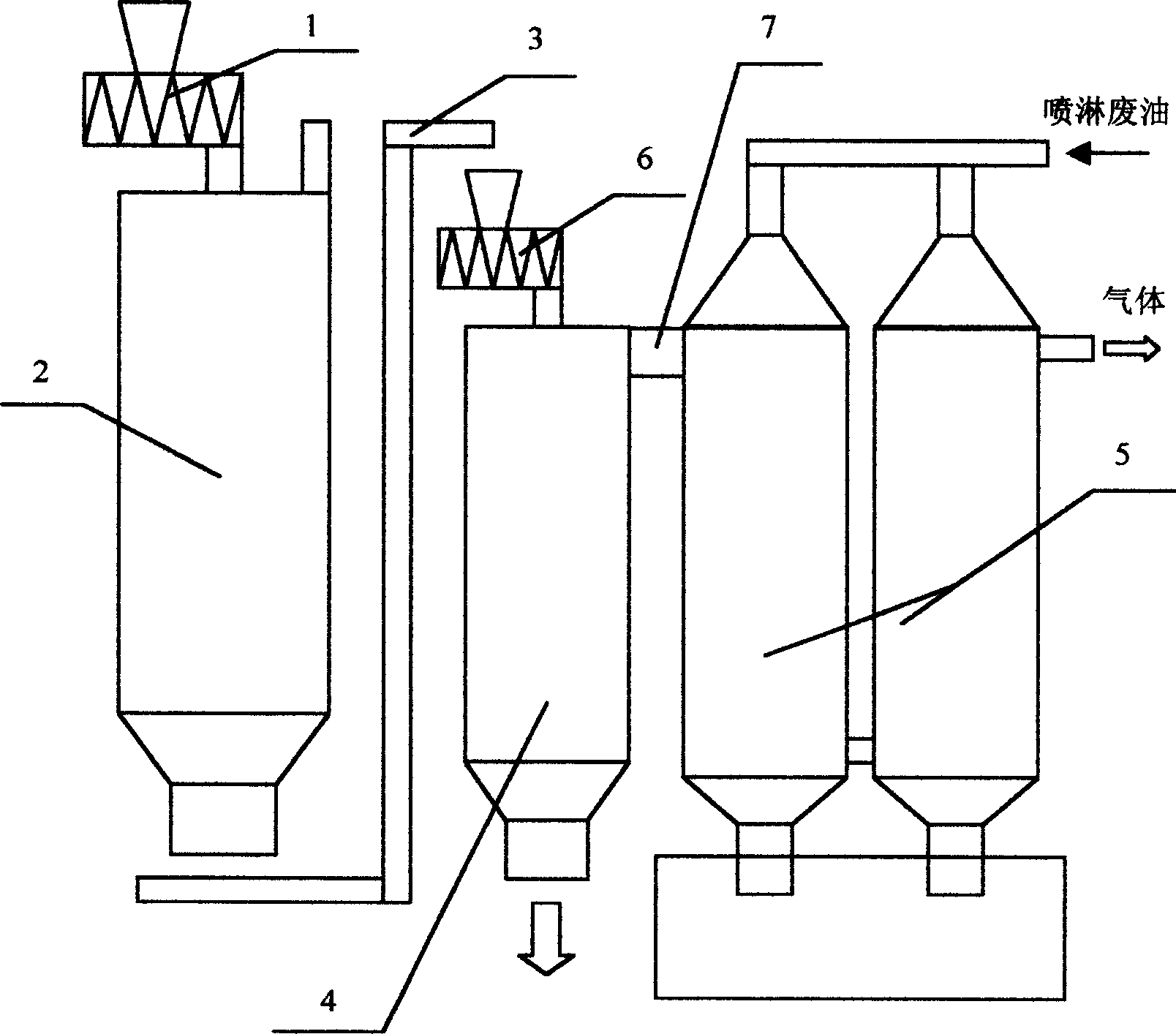

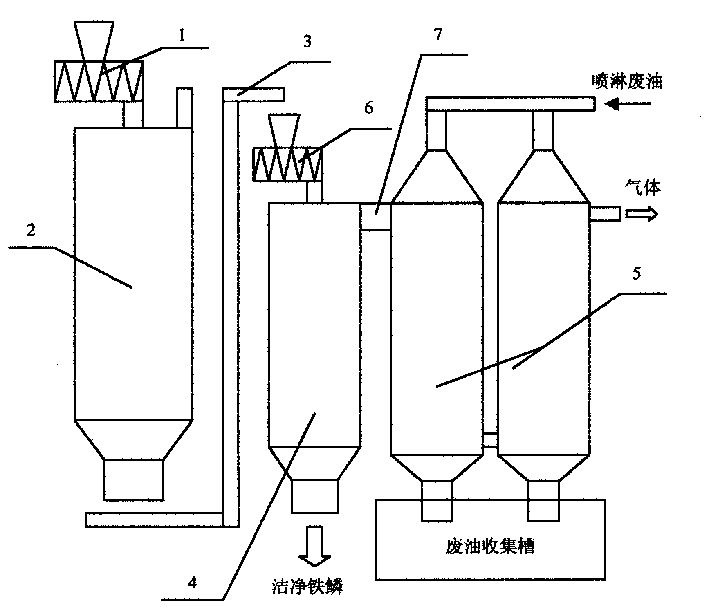

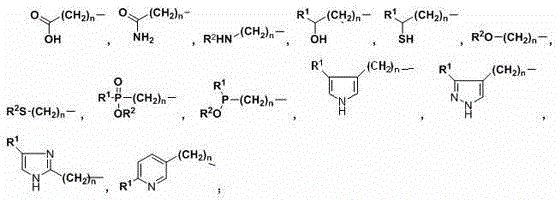

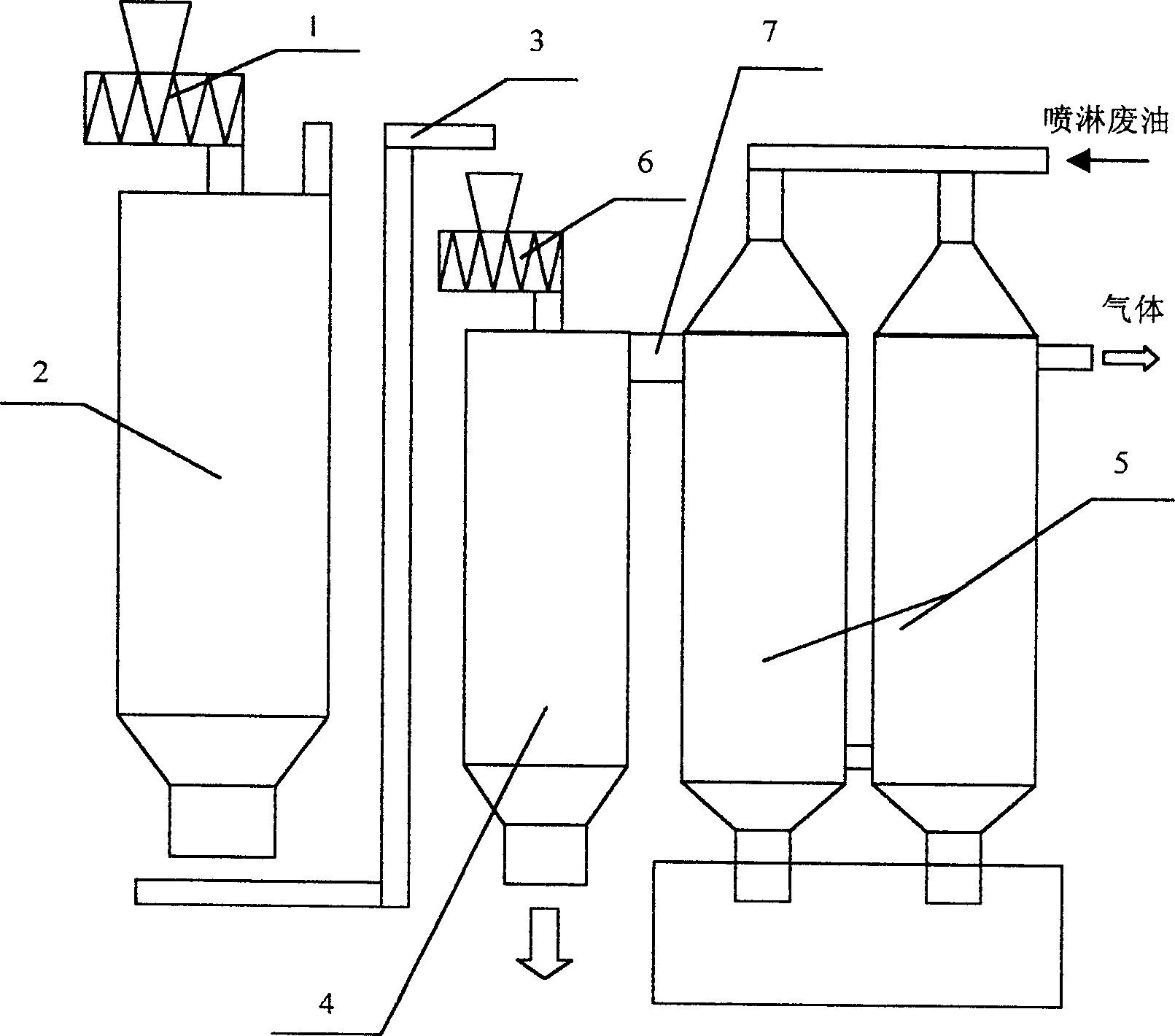

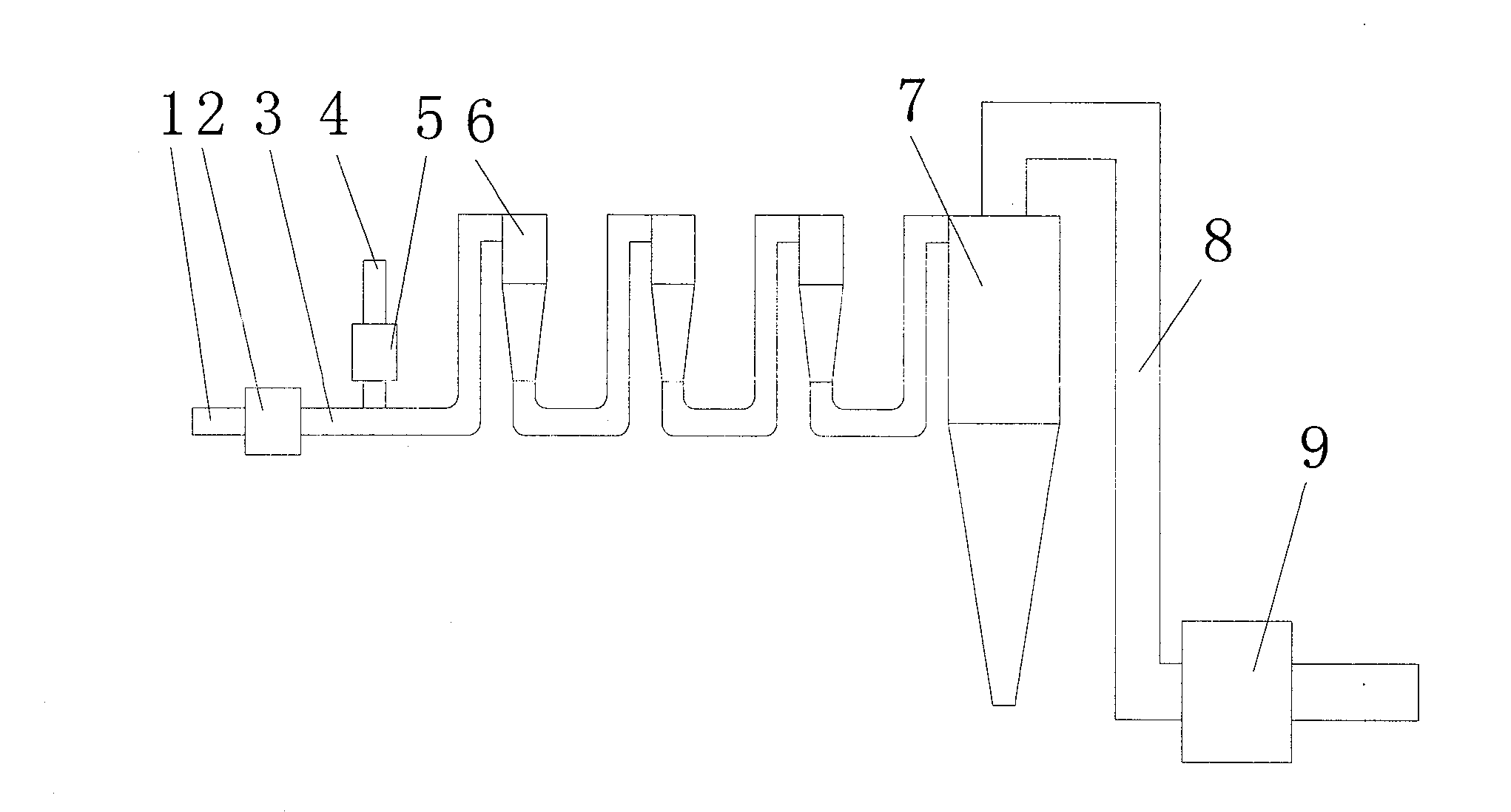

Method and equipment system for treating oil-containing iron scale for steel rolling

InactiveCN1579972AAvoid pollutionReduce churnSludge treatment by de-watering/drying/thickeningSolid waste disposalMetallurgySludge

The invention discloses an approach to recycle waste oil of steel rolling iron scale and its equipment system. It relates to processing technology and equipment of steel rolling sludge, especially the waster oil recycling approach and equipment system of steel rolling iron scale. Character of the invention is that firstly vaporize to remove moisture, then remove waste oil using low-temperature distillation, and finally, reach the target of cleaning iron scale and recycling waste oil of iron scale. The equipment is made up with desiccation dehydration system, microtherm deoiling system and waste oils recycling system. Merits of the invention are that it can avoid soot and water body pollutant, recycle waste oils and clean deoiling iron scale can be used as deep-processing materials.

Owner:SHOUGANG CORPORATION +1

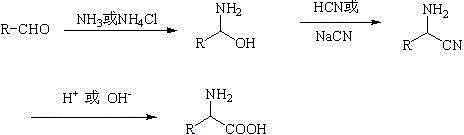

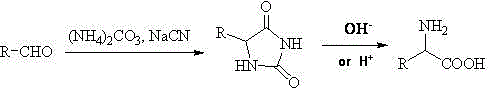

Synthesis and purification method for alpha-amino acid compound

ActiveCN104892521AHigh purityReduce solubilityOrganic compound preparationGroup 5/15 element organic compoundsSolubilityPurification methods

The invention relates to a synthesis and purification method for an alpha-amino acid compound. The synthesis and purification method is characterized by comprising the following steps: (1) adding substituted alpha-amino nitrile or a substituted hydantoin-based compound into alkali M(OH)x or metal oxide MxO, adding water or an alcohol and water mixed solvent, and heating for reaction to obtain alpha-amino acid salt; (2) adding ammonium carbonate or ammonium bicarbonate or introducing carbon dioxide into the solution in the step (1), separating to obtain filter liquor and precipitates MxHyCO3, performing reduced pressure concentration on the filter liquor, and recrystallizing in an alcohol solvent to obtain the alpha-amino acid compound (I). The synthesis and purification method for the alpha-amino acid compound is simple, the yield and purity of the obtained alpha-amino acid compound are high; furthermore, recycling utilization and cleaning production of materials can be realized; the synthesis and purification method is especially suitable for synthesis of the alpha-amino acid compound with high water solubility.

Owner:HEBEI VEYONG BIO CHEM

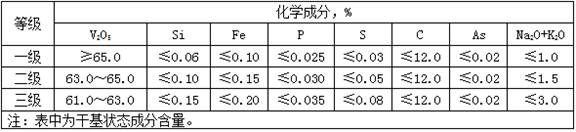

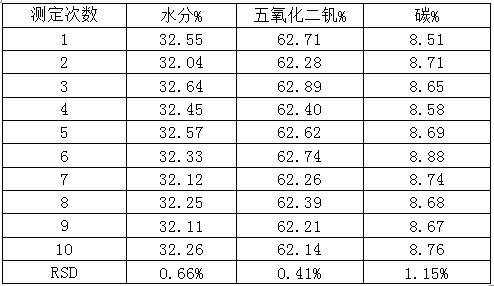

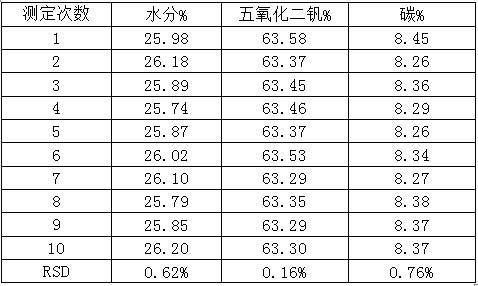

Method for detecting moisture content, vanadium pentoxide content and carbon content in hexamine vanadium

ActiveCN109596454AMeet the production processSatisfy production qualityWeighing by removing componentChemical analysis using titrationAmmonium ferrous sulfateSulfur

The invention discloses a method for detecting moisture content, vanadium pentoxide content and carbon content in hexamine vanadium. The method comprises the following steps: sample pretreatment withnitrogen protection, moisture determination, determination of vanadium pentoxide content with ammonium ferrous sulfate standard solution drop method, and determination of carbon content with an infrared carbon-sulfur analyzer. A drying method for moisture determination of a hexamine vanadium sample, a sample dissolving method for vanadium pentoxide determination, and an equivalent correction method for carbon determination are established, thereby realizing accurate detection of the moisture content, the vanadium pentoxide content and the carbon content in hexaamine vanadium. The method is easy to operate and can meet the requirements of production process, quality judgment and business settlement of hexamine vanadium.

Owner:HEBEI IRON AND STEEL

Method for producing artistic paperboard by taking commercial wood pulp as raw material

ActiveCN105332316AModerately absorbentMeet the requirements of printing performanceCoatings with pigmentsWater-repelling agents additionPaperboardPapermaking

The invention discloses a method for producing an artistic paperboard by taking a commercial wood pulp as a raw material. The method comprises preparing a mixed wood pulp, then preparing a paper pulp, successively adding an internal sizing agent, heavy calcium carbonate and polyacrylamide into the paper pulp, and finally performing calendaring and reeling for obtaining finished paper, so as to obtain raw paper of the artistic paperboard; and preparing a coating, smearing the raw paper with the coating, performing calendaring by a supercalender, and performing rewinding by a rewinder, so as to obtain the artistic paperboard finished product. The beneficial effects comprise that 1, after the raw paper produced from high-quality commercial wood pulp is subjected to coating and calendaring, the surface is fine, printing ink absorption property is moderate, and printing performance is good; 2, the production technological flow does not employ self-made pulp and whitening agents, pollution source is less, and environmental influence is extremely small; and 3, produced sewage is extremely less, and cleaning production and neutral environment-friendly papermaking are realized.

Owner:临朐玉龙造纸有限公司

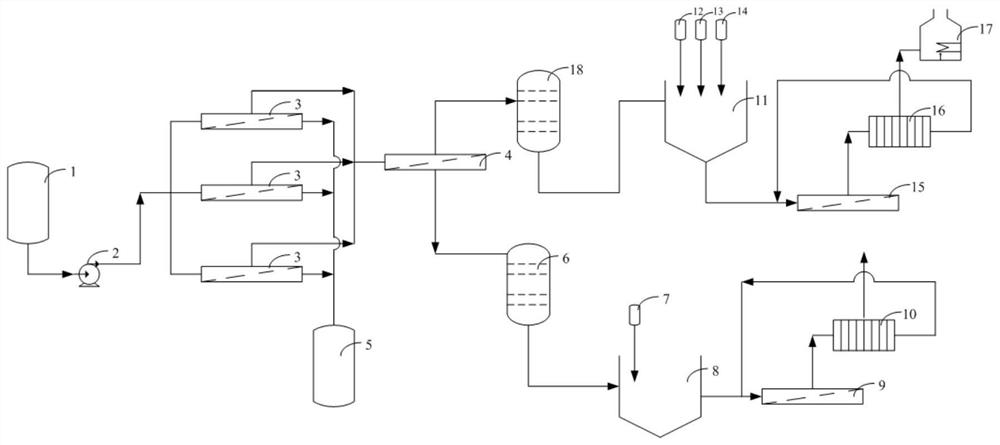

Method for concentrating and softening brine and device thereof

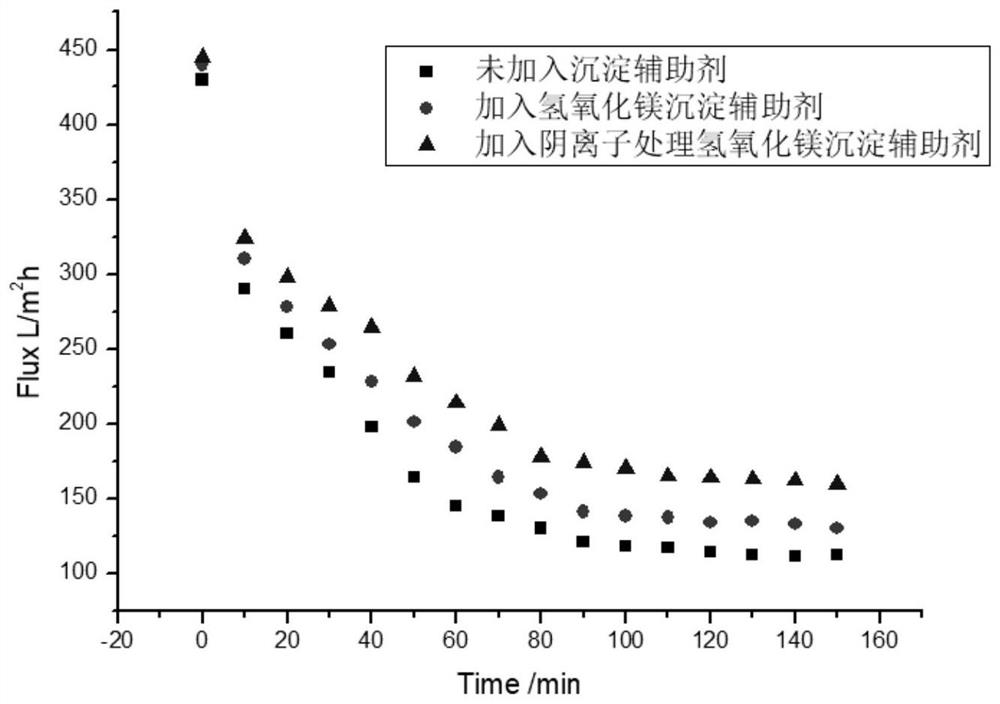

PendingCN111620458AAchieve cleaner productionHigh purityWater/sewage treatment by centrifugal separationWater contaminantsPhysical chemistryReverse osmosis

The invention discloses a method for concentrating and softening brine by integrating reverse osmosis and nanofiltration and a device thereof. A reverse osmosis membrane and a nanofiltration membraneare mainly integrated into a whole; concentrating the brine through a reverse osmosis membrane; the concentrated solution directly enters a nanofiltration membrane to be softened; the brine is integrally concentrated and softened on line; the reverse osmosis membrane and the nanofiltration membrane are integrated on the same device; according to the device, the nanofiltration membrane is directlydriven by the pressure of the reverse osmosis concentrated solution to achieve the separating, softening and filtering effects, the energy consumption, the occupied area and the investment cost of thewhole engineering system can be reduced, and the device has good engineering economy and generalization performance and is suitable for the field of brine refining, and brine comprises salt lake brine, underground brine and salt-making brine.

Owner:JIANGSU JIUWU HITECH

Mixed pulp compound papermaking pulp substrate as well as preparation method and application thereof

ActiveCN103866601AImprove uniformityImprove flatnessBiocideInorganic fibres/flakesHigh concentrationFluff pulp

The invention provides a mixed pulp compound papermaking pulp substrate as well as a preparation method and an application thereof. The mixed pulp compound papermaking pulp substrate is prepared from following raw materials in parts by weight: 70-80 parts of bamboo pulp, 5-15 parts of reed pulp, 5-15 pats of cane syrup, 2-8 parts of fluff pulp and 0-2 parts of fly ash. The preparation method comprises the following steps: pulping, preparing the pulp, carrying out high-concentration degritting, grinding the pulp, carrying out low-concentration degritting, carrying out pressure screening, slushing, compounding and making paper with the pulp, drying and the like. The raw materials of the mixed pulp compound papermaking pulp substrate are selected from perennial wild herbaceous plants, processing industrial wastes, and fire coal wastes of power planes and industrial boilers; a product is uniform in texture and smooth in surface; no pollutants are discharged in a preparation process; water for diluting, agitating and conveying can be cyclically utilized; the mixed pulp compound papermaking pulp substrate provided by the invention can be used for producing electric mats and cockroach killing pieces or can be used as an industrial filtering material.

Owner:苏州吉臣日用品有限公司

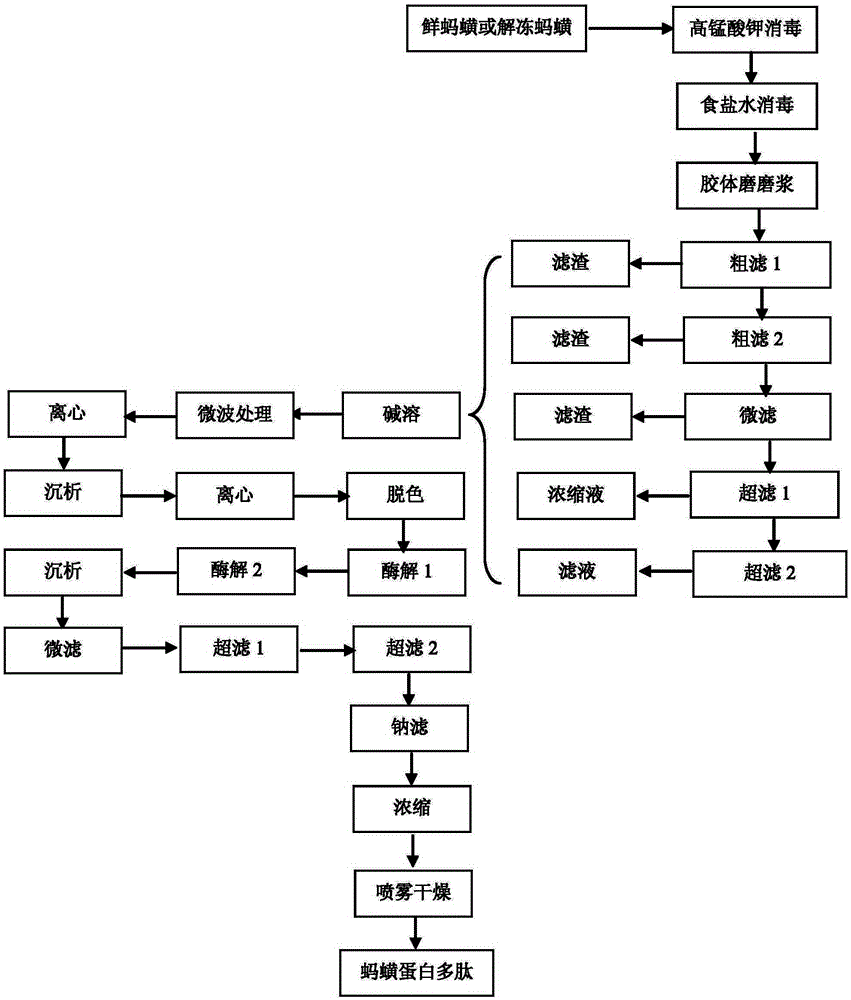

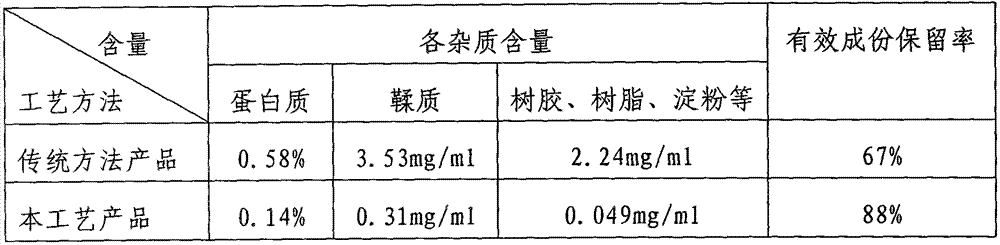

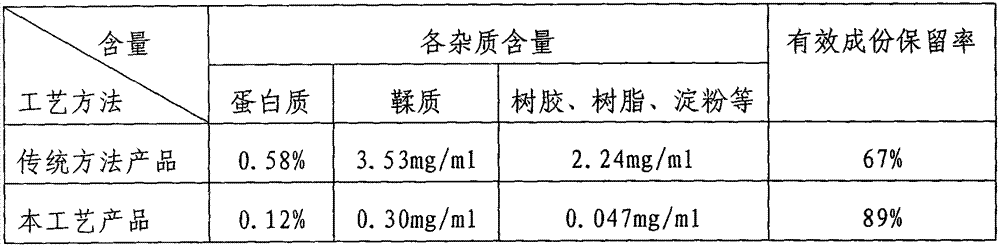

Method for extracting protein peptide from poecilobdella manillensis

ActiveCN105385739AImprove separation rateProtective activityPeptide preparation methodsFermentationChemistryEnzymatic hydrolysis

The invention belongs to the technical field of biological engineering, and specifically relates to a method for extracting protein peptide from poecilobdella manillensis. The method comprises the following steps: disinfection, grinding, coarse filtration, microfiltration, ultrafiltration, alkali dissolution, microwave treatment, centrifugation, precipitation, discoloring, enzymatic hydrolysis, precipitation, microfiltration, ultrafiltration, nano filtration, condensation, and spray drying. A physical method is used to replace a chemical method to separate acidic polypeptide so as to obtain a coarse product of acidic polypeptide; the coarse product can be used to produce Chinese patent medicine containing acidic polypeptide and purified acidic polypeptide, the separation rate is high, the activity can be well protected, no pollution is generated, and clean production is achieved.

Owner:深圳知本康业有限公司

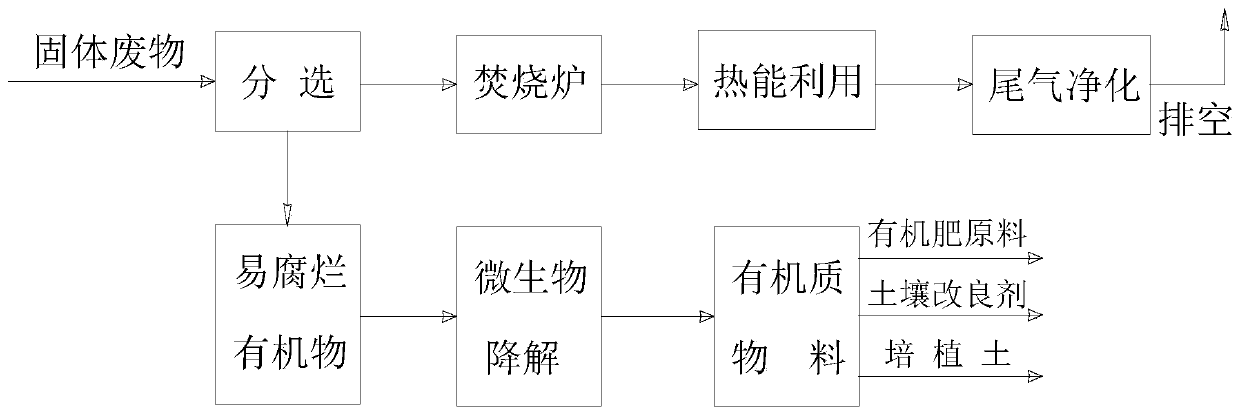

Waste incineration improved process

PendingCN109812814AFast heatingImprove efficiencyClimate change adaptationChemical industryAtmospheric pollutantsNatural gas

The invention discloses a waste incineration improved process comprising the following step 1 of performing sorting treatment to wastes, and obtaining perishable organic matters and comburents; the step 2 of putting the comburents into an incinerator for incineration power generation; and the step 3 of degrading the perishable organic matters by using aerobes, and converting the organic matters into organic materials. The problems that the heat value of materials added to a furnace is low, and combustion-supporting materials need to be added; and the operating cost is high and the overall benefit is poor are solved. According to the improved process, the overall heat value of remaining wastes after sorting can be improved greatly, and the wastes are conveyed into the furnace and burnt quickly; the combustion-supporting materials (coal, fuel, natural gas and the like) are not required; not only are energy sources saved, but also the operating cost is reduced; not only is the amount of the wastes added to the furnace reduced, but also the combustion-supporting materials are not required; the emission of waste gas is reduced greatly, and pollution to environment by atmospheric pollutants is reduced; the cost for waste gas purification and treatment is decreased; and the problems that the heat value of the materials added to the furnace is low and the combustion-supporting materials need to be added; and the operating cost is high and the overall benefit is poor are solved.

Owner:王英宾

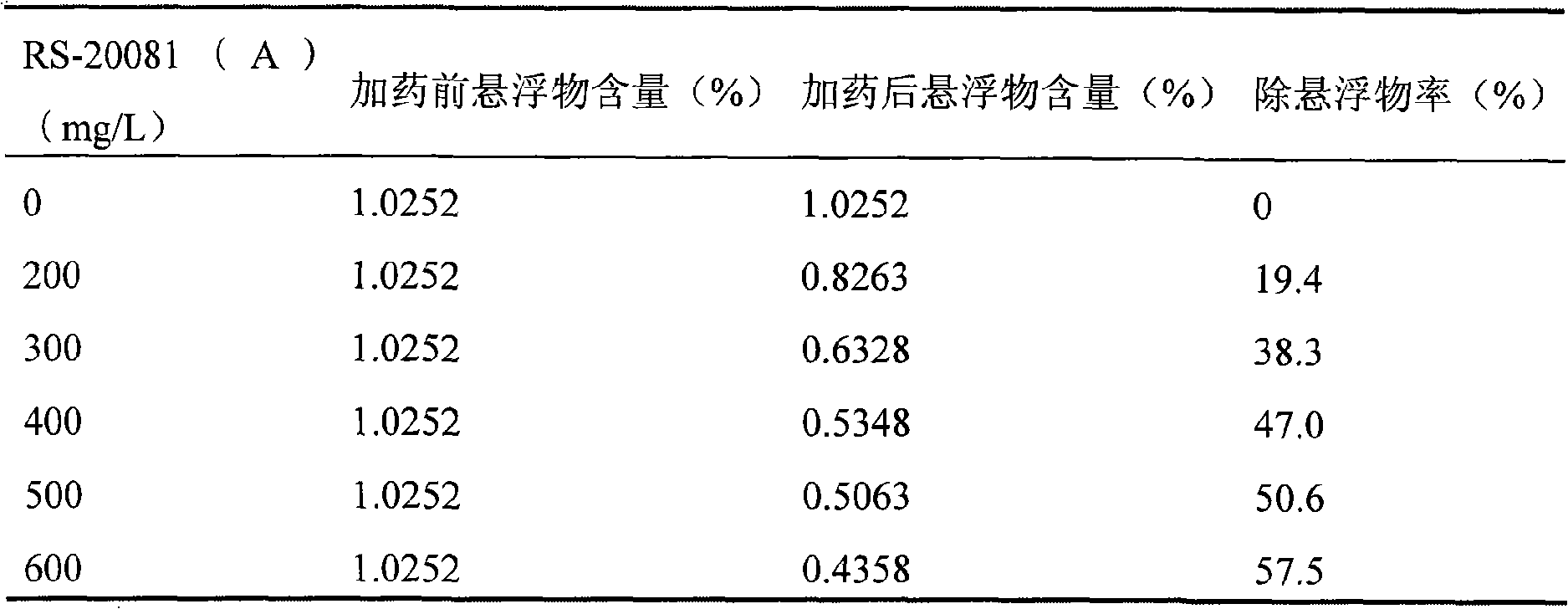

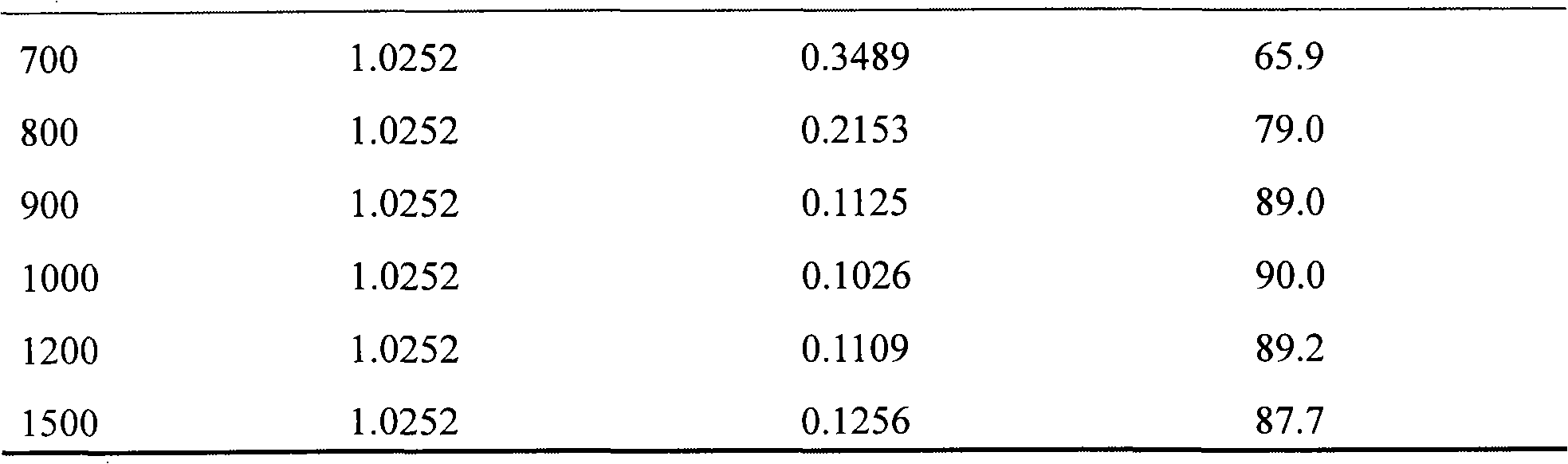

Water-soluble flocculant and preparation thereof

InactiveCN101289239AGood removal effectMeet processing needsWater/sewage treatment by flocculation/precipitationSewageWater soluble

The invention provides a flocculant used for terra alba sewage treatment in catalyst factory. The flocculant is obtained by the mechanical blending of sodium polyacrylate with the weight percentage of 50 percent to 55 percent and polyacrylamide with the weight percentage of 45 percent to 50 percent. The flocculant of the invention can remove suspended substances by over 90 percent during the treatment of sewage containing terra alba catalyst, which has better effect than the like products both at home and abroad (presently the other flocculant applied to the same device can only remove the suspended substances by about 70 percent); therefore, the flocculant of the invention can meet the requirements of the treatment of sewage containing terra alba catalyst, so as to meet the emission requirements.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

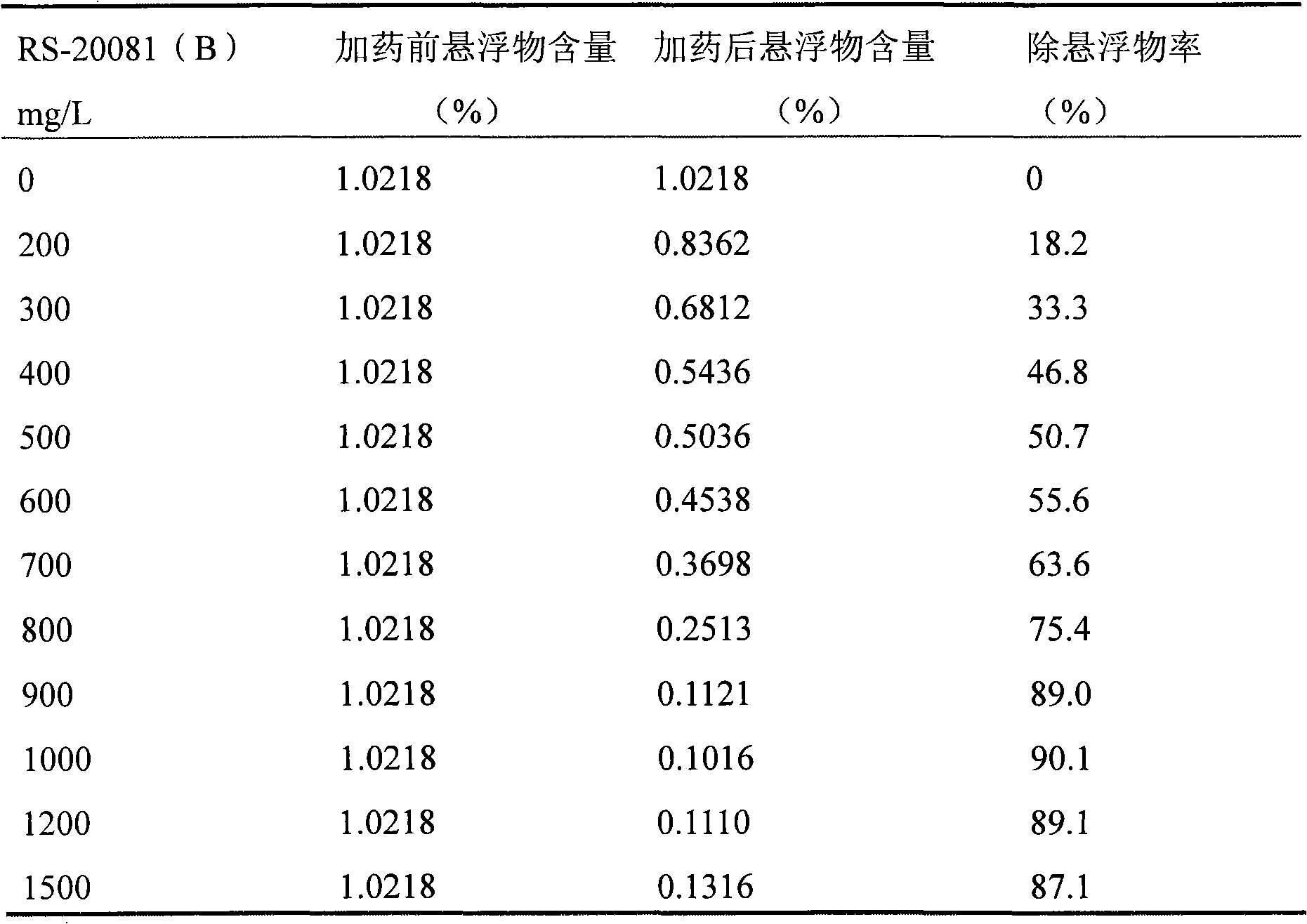

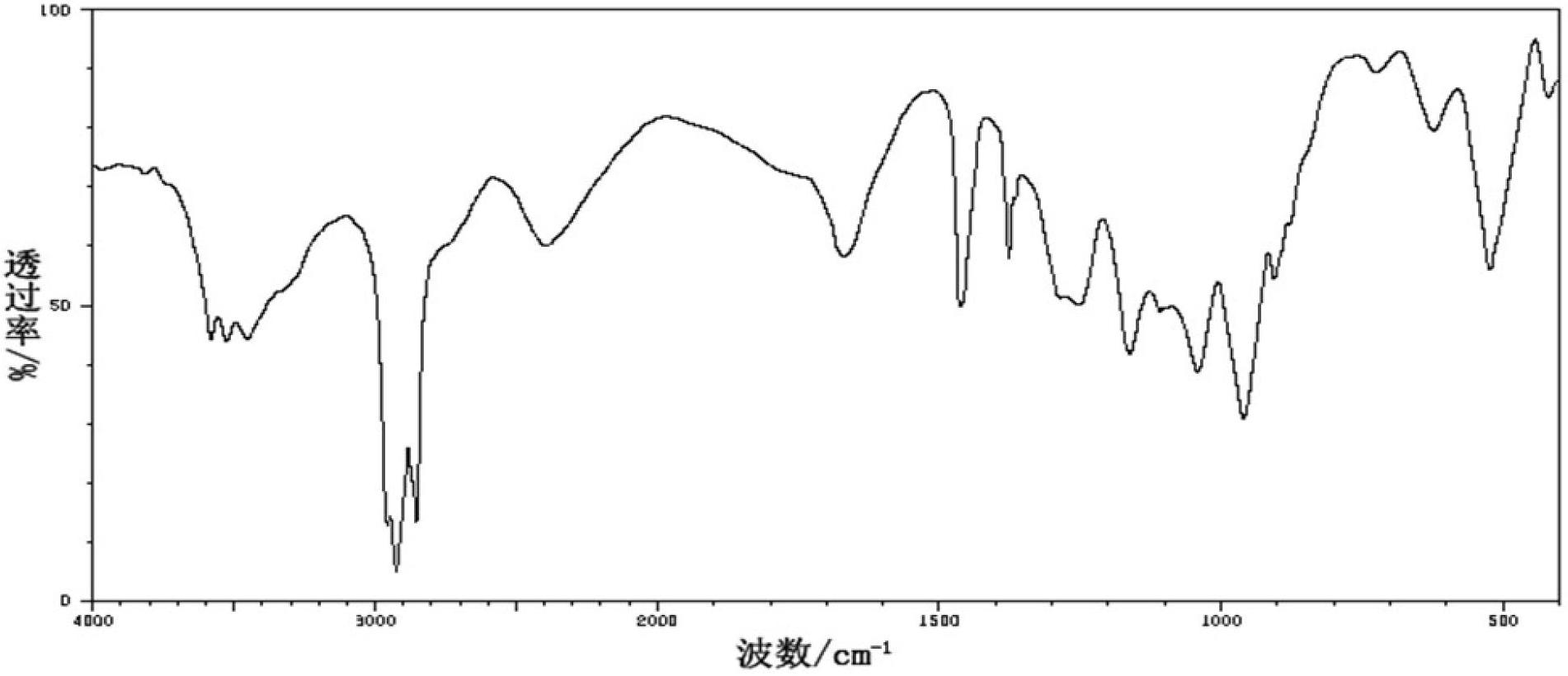

Technology for preparing salviae miltiorrhizae oral liquid with ceramic membrane

ActiveCN103494879ASolving Clarity IssuesEnsure clarityPlant ingredientsUltrafiltrationFiltration technique

A technology for preparing salviae miltiorrhizae oral liquid with a ceramic membrane is characterized by comprising the following steps of decoction, concentration, centrifugal filtration through a high-speed centrifuge, primary filtering by ceramic membrane with the hole diameter of 150000-180000 molecular weight, secondary filtering by ceramic membrane with the hole diameter of 80000-120000 molecular weight, ultrafiltration by ceramic membrane with the hole diameter of 20000-50000 molecular weight, nanofiltration concentration by ceramic membrane with the hole diameter of 300-450 nanometers, concentrating medicine liquid to the amount 2.5-3.5 times that of medicinal materials, final preparation and embedment sterilization. Heating processes in the whole technology course are reduced, ceramic membrane filtering with different molecular weights and refining under normal temperature are carried out, impurities are effectively removed, effective constituents are reserved to the maximum degree, an extracting technology is shortened, pollution is lowered, energy is saved, clean production is achieved, the technology accords with traditional Chinese medicine theoretical system, an ultrafiltration membrane filtering technology is used, degerming and pyrogen effect is good, and the clarity of medicine liquid is guaranteed and improved.

Owner:江苏恒沣药业有限公司

Method for recovering and utilizing titaniferous fine materials

InactiveCN109761271ALow costEfficient use ofChemical industryTitanium dioxideMaterials scienceEnergy conservation

The invention discloses a method for recovering and utilizing titaniferous fine materials. The method mainly comprises the steps of titaniferous fine material forming, formed material roasting, crushing grading and the like. The method has the beneficial effects that the operation of the method for recovering and utilizing the titaniferous fine material is simple; only the processes of forming, roasting, crushing and the like are performed; the investment cost is low; a great number of fine material grade materials can be effectively treated; the utilization value of fine material grade titanium slag or other fine material grade titaniferous substances can be obviously improved. The method provided by the invention has the advantages that in the whole realization process, the cost of the used production equipment is reduced; the byproduct coal gas of the titanium slag furnace can also be effectively used, and the effects of clean production and energy source saving is achieved.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Method for preparing propylene glycol monomethyl ether acetate (PMA) by continuous reaction and distillation

ActiveCN101838196AReduce the unit consumption of acetic acidReduce equipment corrosion rateOrganic compound preparationCarboxylic acid esters preparationDistillationFixed bed

The invention discloses a method for preparing propylene glycol monomethyl ether acetate (PMA) by continuous reaction and distillation. The method comprises the following steps of: mixing propylene glycol methyl ether and acetic acid serving as raw materials in a mol ratio of 1 to 1, and preheating the mixture; allowing the mixture to enter a fixed bed reactor for pre-reaction and then enter an esterification reactor for temperature raising and further reaction; performing rectification, condensing and phase-splitting on the gasified reaction crude product to obtain an oil phase and a water phase; refluxing a part of the upper-layer oil phase to an esterification tower top and the rest to a crude ester jar for preliminary treatment and then light components removal treatment; refluxing a part of the collected lower-layer water phase to the esterification tower top and allowing the balance to the recovery section for treatment, wherein the catalyst for the fixed bed reaction is sulfonyl strongly acidic ion-exchange resin; and the catalyst for the esterification reactor is one of sulfuric acid, methanesulfonic acid, p-toluenesulfonic acid and mixed catalyst A. The method realizes the continuous and pollution-free production of the PMA.

Owner:JINJIANG TAIXING CHEM IND CO LTD

Industrial production process for penis cervi protein oligopeptide

InactiveCN108179166ALow costOligopeptide contentPeptide preparation methodsFermentationPenisFreeze-drying

The invention provides an industrial production process for penis cervi protein oligopeptide. The industrial production process comprises the following specific steps: (1) raw material preparation, (2) soaking and softening, (3) trituration, (4) degreasing, (5) defibrination, (6) salting out, (7) filter pressing, (8) enzymolysis, (9) oligopeptide ultrafiltration, (11) nanofiltration, entrapment, concentration, desalination and impurity removal; (11) degerming, (12) encapsulation, (13) freeze drying and (14) bottle cap plug pressing and labeling. The industrial production process is simple andreasonable in design, natural resources are adequately utilized, and high value-added industrial and large-scale production can be realized. The penis cervi protein oligopeptide can taken eaten as a Chinese patent medicine and a functional health product additive, or can be directly taken and simultaneously can be directly used as a nutritional a cosmetic additive.

Owner:通化百泉保健食品有限公司

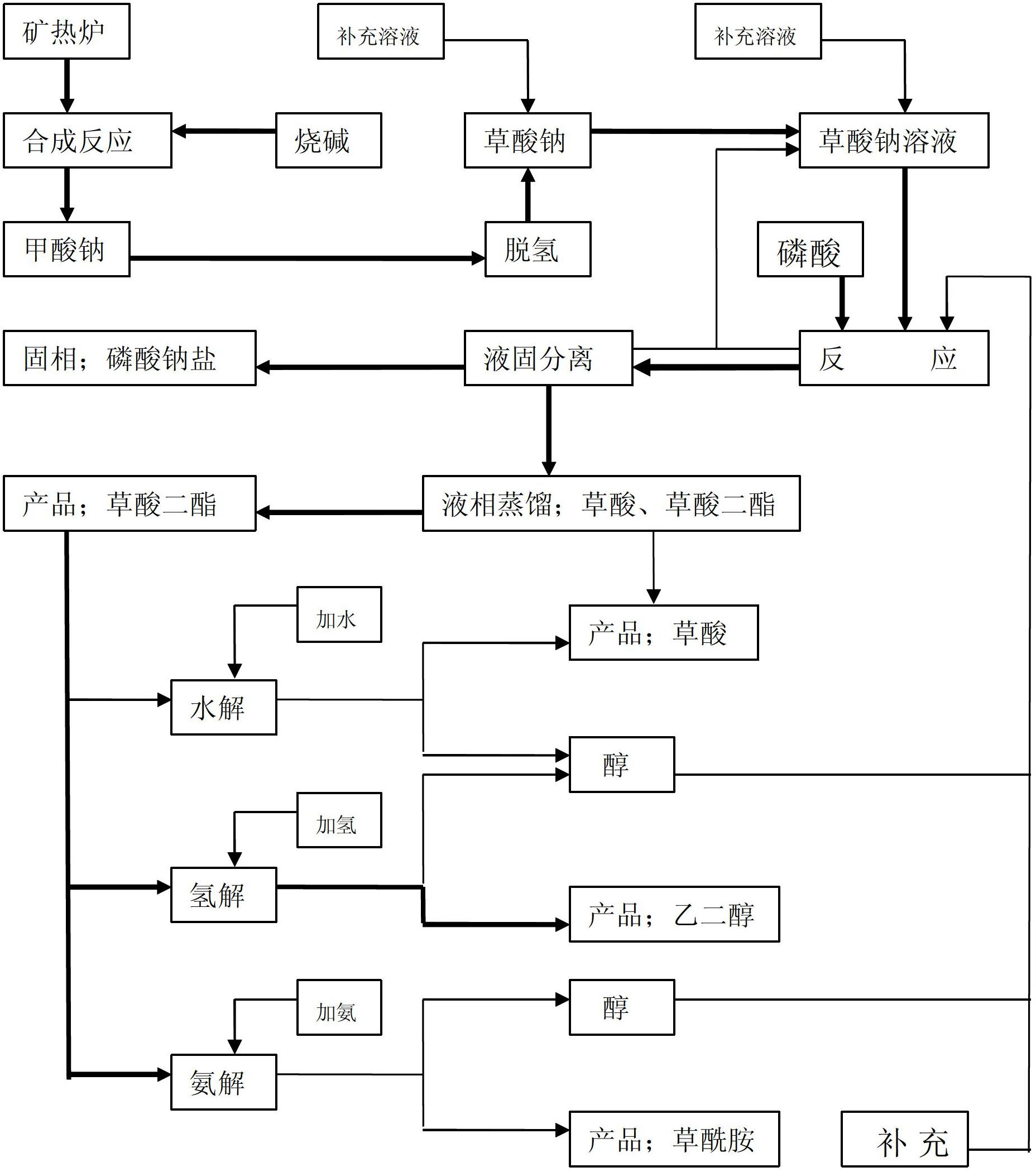

Chemical reaction system for producing oxalic acid diester and oxalic acid as main products by using sodium formate as raw materials

InactiveCN102659556ANo pollution to the environmentReduced compression energy consumptionPreparation from carboxylic acid saltsOrganic compound preparationChemical reactionDistillation

The invention discloses a chemical reaction system for producing oxalic acid diester and oxalic acid as main products by using sodium formate as raw materials. The chemical reaction system comprises a first reaction unit, a second reaction unit and a third reaction unit, wherein the sodium formate is subjected to dehydrogenation reaction to generate sodium oxalate in the first reaction unit; in the second reaction unit, the sodium oxalate is mixed with solvents, then, the oxalic acid is added, the reaction is carried out, and then, the solid and liquid separation is carried out, wherein the solid phase is phosphate, and the oxalic acid diester is rich in the liquid phase; and in the third reaction unit, the oxalic acid diester-rich liquid phase is subjected to distillation separation, then, the oxalic acid diester is respectively subjected to hydrolysis, hydrogenolysis and ammonolysis, and oxalic acid, alcohol, glycol and oxamide are obtained. The chemical reaction system disclosed by the invention has the advantages that the influence on environment is avoided, the environment problems of lead-containing sewage and other waste discharge do not exist, phosphates from sodium ions and with higher additional values are generated, the process separation becomes simple, the implementation is easy, and the production process reaches the requirements of clean production and energy saving environment-friendly type production process.

Owner:天津市碳一有机合成工程设计有限公司

Method for recycling phosphorous acid from dimethyl ester rectification residual liquid

InactiveCN106335886AReduce the discharge of three wastesHigh recovery rateWater contaminantsTreatment involving filtrationChemistryActivated carbon

The invention provides a method for recycling phosphorous acid from a dimethyl ester rectification residual liquid, wherein the method mainly includes the following steps: (1) heating the dimethyl phosphite rectification residual liquid, and decoloring with active carbon; (2) filtering the solution after decoloring in the step 1 while being hot, and collecting the filtrate; (3) dropping hydrochloric acid, controlling the dropping speed, the acidolysis temperature and the vacuum degree, and stirring fully until acidolysis is completed; (4) when no obvious gas is discharged after acid dropping, stopping acid dropping, after the acid dropping is stopped, if gas is still discharged, requiring to appropriately supplement hydrochloric acid, and allowing tail gas generated in the acidolysis process to be merged into a chloromethane recycling header pipeline; and (5) obtaining an aqueous solution having chloromethane gas removed, namely liquid phosphorous acid, concentrating and crystallizing the aqueous solution, and purifying to obtain solid phosphorous acid with the content of more than or equal to 98% or directly taking as an aqueous solution for use. The method achieves clean production, reduces three-waste emissions, improves the by-product recovery rate, and reduces the production cost.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Industrial production technology of deerskin protein oligopeptide

InactiveCN108484753AQuality assuranceImprove crushing effectConnective tissue peptidesPeptide preparation methodsSide effectFreeze-drying

The invention provides an industrial production technology of deerskin protein oligopeptide. The industrial production technology comprises the following specific steps: 1, preparing a raw material; 2, slicing; 3, soaking for thawing; 4, mincing; 5, defatting; 6, grinding into a slurry; 7, salting out; 8, performing pressure filtration; 9, enzymolyzing; 10, performing ultrafiltration to obtain oligopeptide; 11, concentrating through nanofiltration interception, desalting and removing impurities; 12, sterilizing; 13, filling; 14, performing freeze drying; 15, pressing a bottle stopper and labeling. By the industrial production technology, the technology is simple, the design is reasonable, a natural resource is fully utilized, and high-added value industrial and large-scale production can be achieved. Hydrolysis is performed by using food-grade protease, so that the safety is high no side effects are caused; the deerskin protein oligopeptide can be used as an additive of a proprietary Chinese medicine and a functional health-care product or directly taken and can be also used as a cosmetic additive.

Owner:通化百泉保健食品有限公司

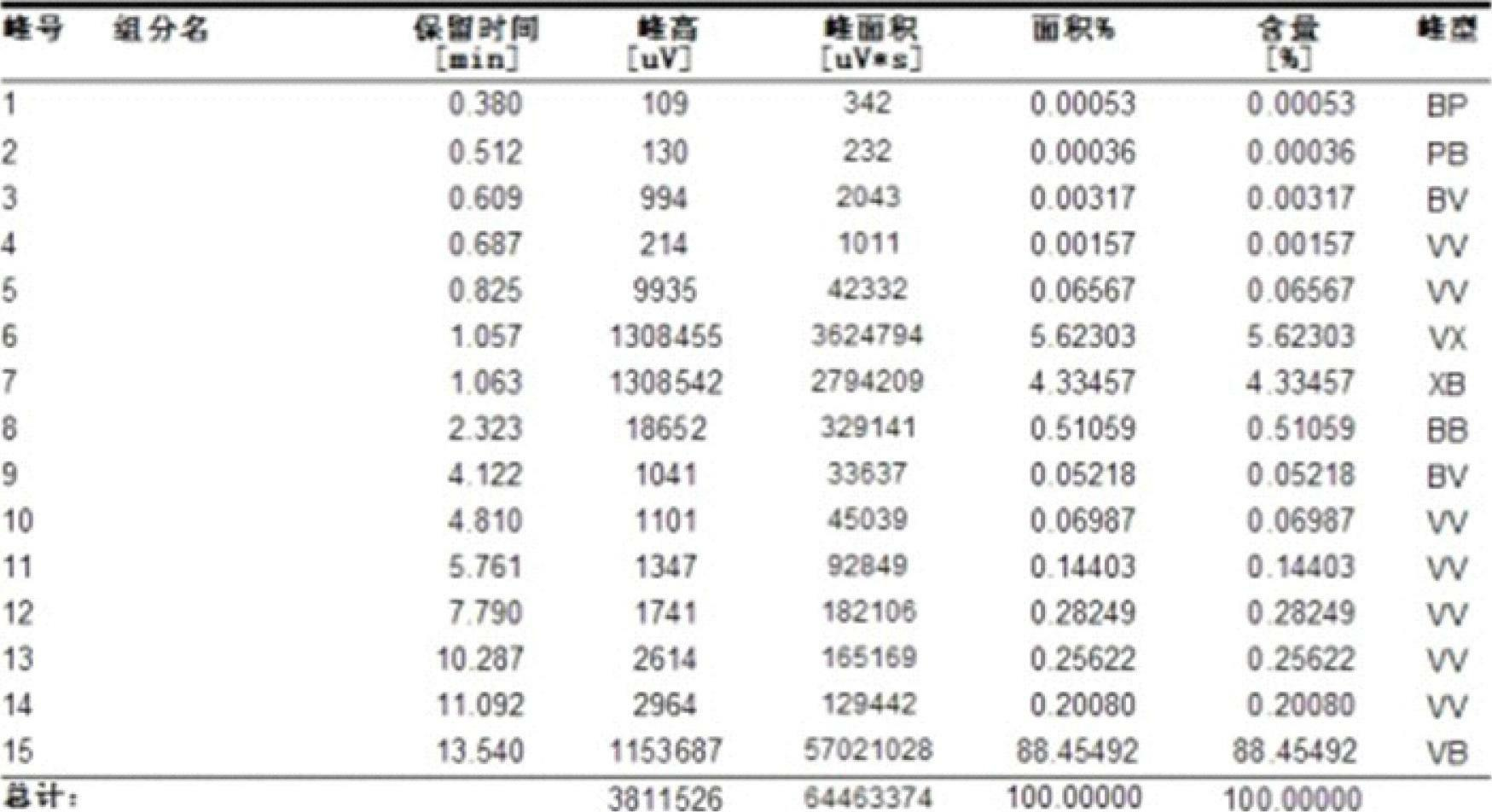

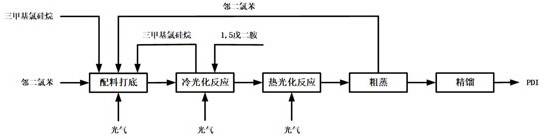

Method for preparing 1,5-pentamethylene diisocyanate

InactiveCN112457217AAvoid generatingHigh yieldCarbamic acid derivatives preparationOrganic compound preparationPtru catalystChemical reaction

The invention relates to a method for preparing 1,5-pentamethylene diisocyanate (PDI). The method comprises the following steps: taking o-dichlorobenzene as a solvent and trimethylchlorosilane as a catalyst, carrying out luminescence reaction on 1,5-pentanediamine and phosgene at 15-30 DEG C under normal pressure to generate diaminoformyl chloride; after the reaction is finished, heating the reaction materials to 110-120 DEG C, and evaporating out a small amount of solvent and all the catalyst for recycling; continuously introducing a certain amount of phosgene into the diaminoformyl chloride,heating to 150-170 DEG C, and carrying out thermal photo-chemical reaction until the material becomes clear and transparent; and after the photo-chemical reaction is finished, carrying out reduced pressure distillation to remove the solvent, and continuously carrying out reduced pressure distillation to obtain the 1,5-pentamethylene diisocyanate product. Trimethylchlorosilane is used as a catalyst, so that the generation of hydrochloride can be avoided, and the generation of polymerization byproducts caused by the secondary reaction of amine with acyl chloride and isocyanate generated in thelow-temperature photo-chemical reaction can also be avoided; the PDI product yield and the product quality in the photo-chemical reaction process are greatly improved.

Owner:甘肃银光聚银化工有限公司

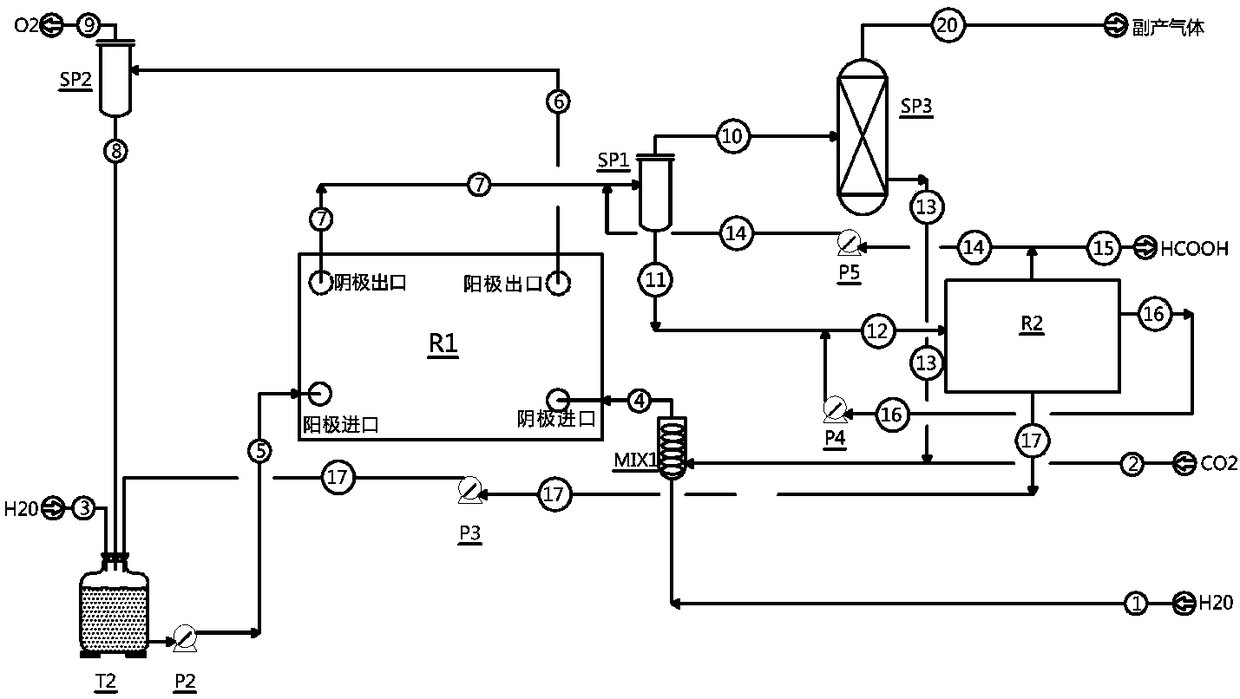

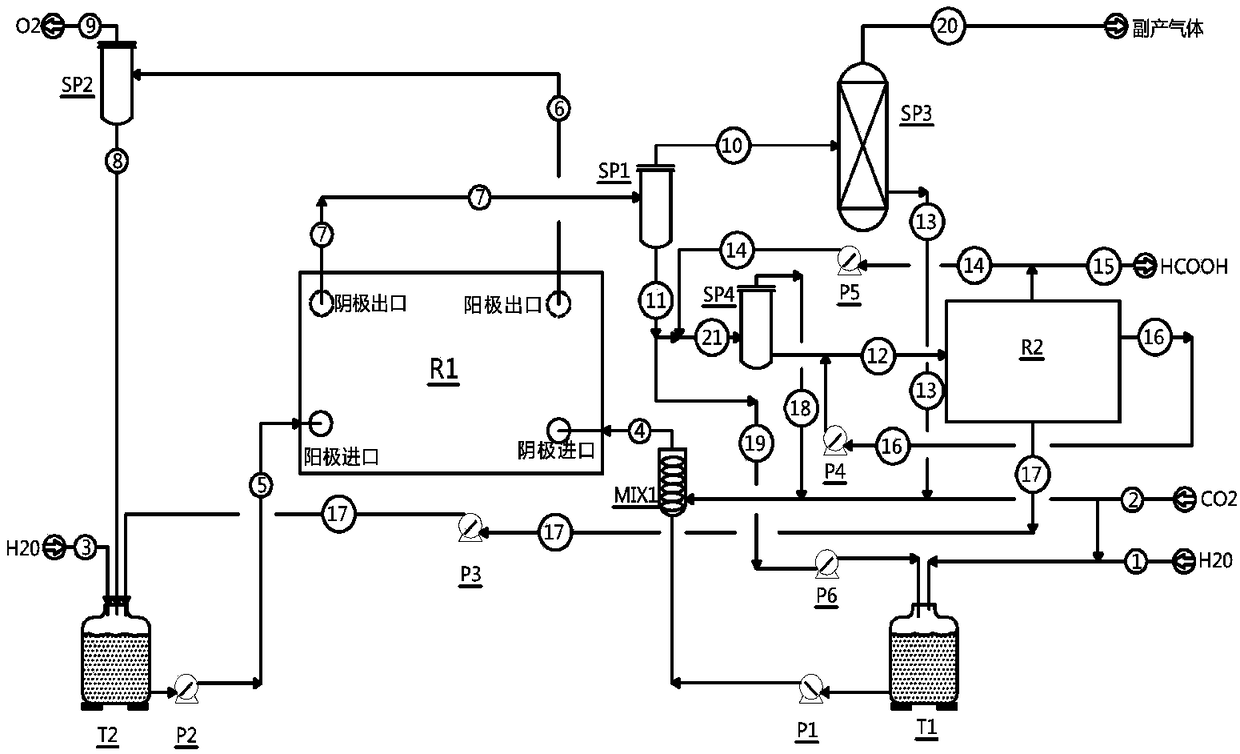

Formic acid preparation method

ActiveCN108385129AHigh purityWide range of concentrationElectrolysis componentsElectrolytic organic productionElectrochemical responseDicarbonate

The invention provides a formic acid preparation method. The formic acid preparation method comprises the steps that a bicarbonate solution or carbonate solution is mixed with carbon dioxide to be ledinto a cathode chamber of an electrochemical reactor, a strong base solution is led into an anode chamber of the electrochemical reactor, and an electrochemical reaction is carried out; a product ofthe cathode chamber is separated through a cathode gas-liquid separator, and carbon dioxide and formate are separated out; the formate generates formic acid and a strong base solution through a bipolar membrane electrodialysis reactor; and the separated-out carbon dioxide is circulated to the cathode chamber to be used, and the strong base solution generated by the bipolar membrane electrodialysisreactor is circulated to the anode chamber to be used. An acid-base reproducible and circulated closed loop route in the intermediate reaction process is constructed, other alkaline or salt matter does not need to be guided in successively during reaction, clean production is achieved, and the economic benefit is high. By means of the method, environment protection and carbon dioxide industrial large-scale recycling can be achieved.

Owner:BEIJING FUMEIJIA ENERGY TECH CO LTD

Industrial production process for wood frog body protein oligopeptide

InactiveCN108179167AIncrease profitPromote development and utilizationConnective tissue peptidesPeptide preparation methodsFood additiveFreeze-drying

The invention provides an industrial production process for wood frog body protein oligopeptide. The industrial production process comprises the following specific steps: (1) raw material preparation,(2) soaking and softening, (3) trituration, (4) degreasing, (5) defibrination, (6) decoloration, (7) salting out, (8) filter pressing, (9) enzymolysis, (10) oligopeptide ultrafiltration, (11) filterpressing, entrapment, concentration, desalination and impurity removal; (12) degerming, (13) encapsulation, (14) freeze drying and (15) bottle cap plug pressing and labeling. The industrial productionprocess is simple and reasonable in design, natural resources are adequately utilized, and industrial and large-scale production can be realized. By hydrolyzing by virtue of food grade protease, thesafety is high, and side effects are avoided; and the wood frog body protein oligopeptide can be directly eaten as a health product, a functional food additive or a nutritional food and simultaneouslycan be safely used as a cosmetic additive.

Owner:通化百泉保健食品有限公司

Method and equipment system for treating oil-containing iron scale for steel rolling

InactiveCN1270989CEfficient recyclingAvoid secondary pollutionSludge treatment by de-watering/drying/thickeningSolid waste disposalMetallurgySludge

The invention discloses an approach to recycle waste oil of steel rolling iron scale and its equipment system. It relates to processing technology and equipment of steel rolling sludge, especially the waster oil recycling approach and equipment system of steel rolling iron scale. Character of the invention is that firstly vaporize to remove moisture, then remove waste oil using low-temperature distillation, and finally, reach the target of cleaning iron scale and recycling waste oil of iron scale. The equipment is made up with desiccation dehydration system, microtherm deoiling system and waste oils recycling system. Merits of the invention are that it can avoid soot and water body pollutant, recycle waste oils and clean deoiling iron scale can be used as deep-processing materials.

Owner:SHOUGANG CORPORATION +1

Industrial production process for deer sinew protein oligopeptide

InactiveCN108396052ASolve UtilizationSolve the problem of low added valueConnective tissue peptidesPeptide preparation methodsNatural resourceSalting out

The invention provides an industrial production process for deer sinew protein oligopeptide. The industrial production process comprises the following specific steps: 1, preparing raw materials; 2, soaking and softening; 3, mincing; 4, degreasing; 5, grinding into thick liquid; 6, salting out; 7, filter-pressing; 8, performing enzymolysis; 9, ultra-filtering oligopeptide; 10, nano-filtering and intercepting, concentrating, de-salting and removing impurities; 11, degerming; 12, filling; 13, freeze-drying; and 14, pressing a bottle cap plug and labeling. The method is simple in process, is reasonable in design, sufficiently utilizes natural resources, and can realize industrial and large-scale production with a high additional value. The deer sinew protein oligopeptide can be directly takenas a Chinese patent medicine and an additive of a functional healthcare product, and also can be used as a cosmetic additive.

Owner:通化百泉保健食品有限公司

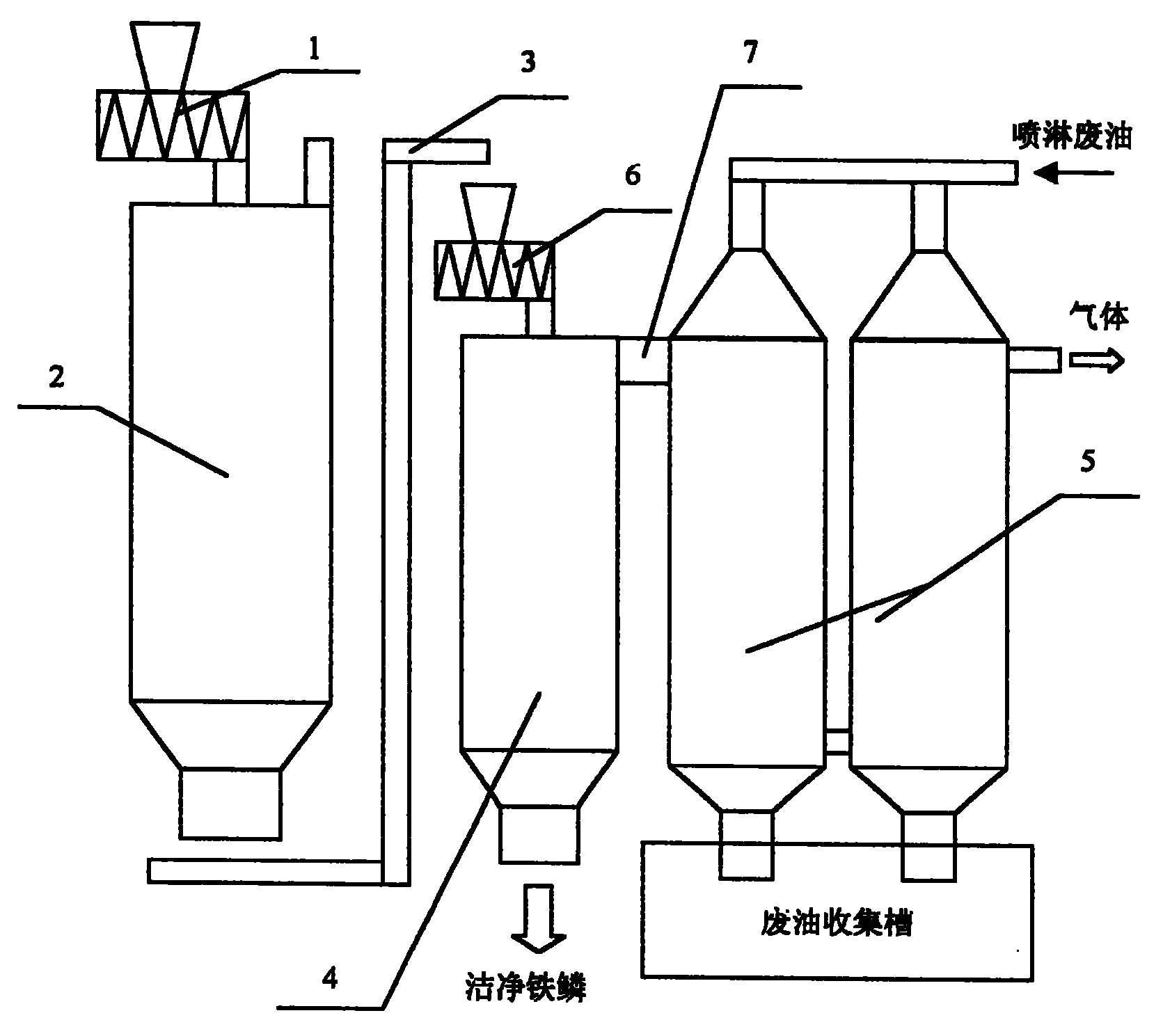

Method using glycerol and silicon tetrachloride to prepare epichlorohydrin and white carbon black

InactiveCN102584745AAchieve energy saving and emission reductionAchieve cleaner productionOrganic chemistrySilicaSilicone GelsPtru catalyst

The invention relates to a method using glycerol and silicon tetrachloride to prepare epichlorohydrin and white carbon black, which belongs to the technical field of chemical industrial preparation. The method comprises using biomass glycerol in grease processing byproducts and silicon tetrachloride in polysilicon industry byproducts, hydrolyzing the silicon tetrachloride in a non-proton solvent to obtain silica gel and byproduct hydrochloric acid (HCl), chloridizing the glycerol in the present of a catalyst by the byproduct HCl to achieve glycerol dichloride and byproduct water which is used for hydrolysis of the silicon tetrachloride. The silica gel is thermally treated to obtain the white carbon black, and the glycerol dichloride is saponified to obtain the epichlorohydrin. The white carbon black and the epichlorohydrin can be prepared on the situation without external sources of water and HCl, so that the purposes of saving energy, reducing emission, cleaning production and reducing product cost are achieved. The method uses the non-proton solvent as a reaction medium, thereby improving heat and mass transfer in a coupling reaction process, improving reaction selectivity, preventing generated silica gel from being adhered to equipment and pipelines to block the equipment and the pipelines and enabling reaction to stably run for a long time.

Owner:CHANGZHOU UNIV

A kind of preparation method of glucosamine sulfate

ActiveCN104710483BAvoid damageMild reaction conditionsSugar derivativesSugar derivatives preparationPotassiumSolvent

The invention relates to a preparation method for glucosamine sulfate. According to a technical scheme in the invention, the preparation method comprises the following steps: step 1, dispersing D-glucosamine hydrochloride in an alcoholic solvent; step 2, neutralizing D-glucosamine hydrochloride with alkali; step 3, adding sulfuric acid into a glucosamine solution drop by drop so as to form a salt; step 4, carrying out precipitation and separation; and step 5, carrying out refining by repeatedly washing a solid with a small amount of an organic solvent until no chloride ion is eluted and carrying out drying under reduced pressure, wherein the organic reagent is ethanol, propyl alcohol, acetone or the like with a concentration of 80 to 100%. With the technical scheme, glucosamine sulfate with low sodium or potassium content is obtained.

Owner:迪嘉药业集团股份有限公司

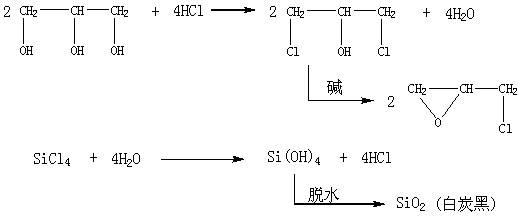

Citric acid mother liquor treatment process

InactiveCN101182079BReduce consumptionAvoid it happening againWater/sewage treatment by centrifugal separationWater/sewage treatment by ion-exchangeSimulated moving bedMoving bed

Owner:RIZHAO LUXIN JINHE BIOCHEM

Circulating high-temperature flue gas flowing-state non-blocking tubular bagasse drying system

InactiveCN104110954ABurn fullyIncrease temperatureDrying gas arrangementsCombustion technology mitigationCycloneHeat balance

A bagasse heating and drying system is composed of a high-temperature flue gas pipe inlet, a high-pressure fan, a flue gas pipe, a bagasse inlet, a discharging valve, cyclone-type fire extinguishers, a cyclone separator, a flue and a circulating high-pressure fan. The high-temperature flue gas pipe inlet is mounted in front of a high-temperature coal economizer, the high-temperature fan is connected with an incoming and outgoing pipe of the high-temperature flue gas pipe, and a bagasse inlet and the discharging valve are mounted above the high-temperature flue gas pipe. A small amount of high-temperature flue gas in front of the coal economizer is utilized to heat and dry bagasse, and the bagasse is enabled to reach high temperature before catching fire and enabled to be fully burnt in the process of burning, so that temperature of a hearth is increased, heat radiation is enhanced, and heat efficiency of a boiler is improved; the flue gas after being dried is drawn by the circulating high-pressure fan into the boiler to serve as disturbing air to be used so as to realize heat balance running of the boiler; balance ventilation is adopted, so that the drying system is enabled to run under a non-blocking state and enabled to realize clean production, energy conservation and emission reduction, and plays an important role in promoting economy development of cane sugar industry and improving enterprise benefit and social benefit.

Owner:覃天毕

- A method for preparing protein peptides from Phnom Penh Leech

ActiveCN105385739BImprove separation rateHigh activityPeptide preparation methodsFermentationFiltrationDissolution

The invention belongs to the technical field of biological engineering, and specifically relates to a method for extracting protein peptide from poecilobdella manillensis. The method comprises the following steps: disinfection, grinding, coarse filtration, microfiltration, ultrafiltration, alkali dissolution, microwave treatment, centrifugation, precipitation, discoloring, enzymatic hydrolysis, precipitation, microfiltration, ultrafiltration, nano filtration, condensation, and spray drying. A physical method is used to replace a chemical method to separate acidic polypeptide so as to obtain a coarse product of acidic polypeptide; the coarse product can be used to produce Chinese patent medicine containing acidic polypeptide and purified acidic polypeptide, the separation rate is high, the activity can be well protected, no pollution is generated, and clean production is achieved.

Owner:深圳知本康业有限公司

A kind of detection method of moisture, vanadium pentoxide and carbon content in vanadium hexamine

ActiveCN109596454BAchieve cleaner productionRealize cleaner productionWeighing by removing componentChemical analysis using titrationFerrous ammonium sulfateVanadium atom

Owner:HEBEI IRON AND STEEL

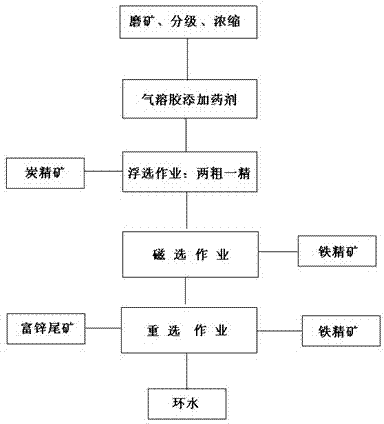

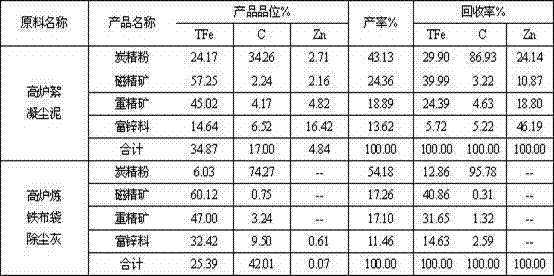

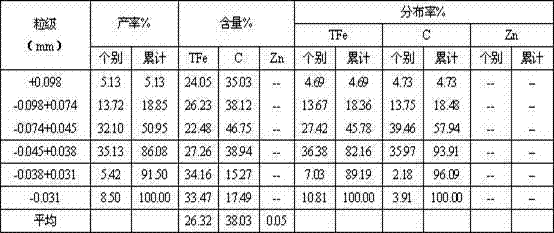

Method for recycling valuable elements from blast furnace flocculated dust

InactiveCN103551244BReduce lossesEliminate the effects of smeltingWet separationSludgeGravity separation

A method for recovering valuable elements from blast furnace flocculation dust and sludge, which adopts a combined process of flotation, magnetic separation and gravity separation to process low-grade blast furnace flocculation dust and sludge containing 2-8% zinc to recover valuable elements. element. The specific steps include: firstly grind the blast furnace bag ash, and then use a fine sieve for coarse classification, and then return to the classification operation after grinding the product on the coarse-grained sieve; machine; the graded under-screen products are mixed and then concentrated, and added with chemicals for flotation. The flotation is divided into two roughings and one beneficiation. Zinc raw material final tailings. The invention has the beneficial effects of simple process, low energy consumption and low production cost. The comprehensive recycling effect is good. The selected carbon concentrate can be used as coal injection for steel enterprises, the iron concentrate is directly returned to the pelletizing process, and the final tailings (zinc-rich material) are used for pyrometallurgy to extract zinc oxide.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com