Citric acid mother liquor treatment process

A treatment process, citric acid technology, applied in the direction of adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that easy carbides and other impurities cannot be removed, and mother liquor cannot be obtained Effectively deal with problems such as unacceptable by customers, to achieve the effect of reducing the amount of unqualified mother liquor, huge economic and environmental significance, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

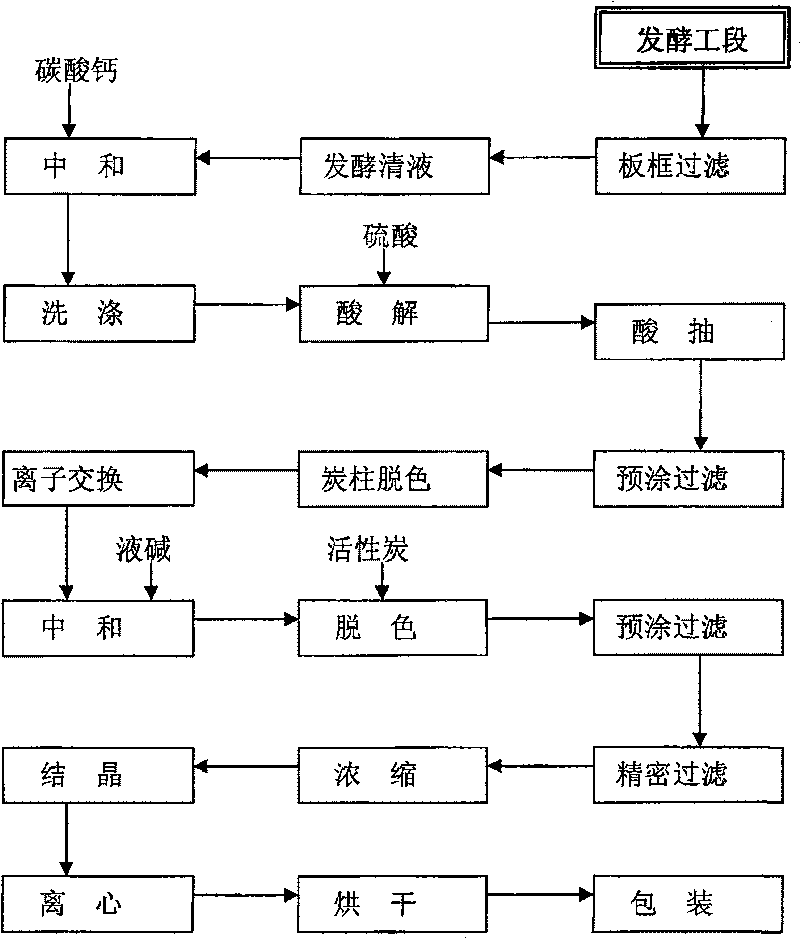

Method used

Image

Examples

Embodiment 1

[0019] Take the unqualified citric acid mother liquor and make it into a concentration of 800L of 40% (w / w). At room temperature, add powdered activated carbon as a coagulant in an amount of 1.5‰ of the volume of the citric acid mother liquor (that is, 1.2 kg), and start stirring for 2 minutes. Finally, add an acrylamide flocculant with a concentration of 1‰ (w / w) in an amount of 1.0% of the volume of the citric acid mother liquor (that is, 8 liters) as a degumming agent, mix and let stand for 2 hours before the mother liquor is separated. Take out the supernatant, process the precipitate with a centrifuge, and combine the supernatant with the supernatant taken out earlier, which is the mother liquor for citric acid purification.

[0020] Concentrate the purified mother liquor obtained above to 76% (w / w), put it into a crystallization pot for cooling and crystallization, and then centrifuge and dry to obtain the product.

Embodiment 2

[0022] Take unqualified citric acid mother liquor and make it into 50% (w / w) concentration of 700L, press 2.5kg / m at 30°C 3 Add perlite as a coagulant aid, start stirring, and after 5 minutes, the volume of the mother liquor is 45g / m 3 Chitosan was added as a degumming agent in an amount of 3 hours after mixing and the mother liquor was layered. Take out the supernatant, process the precipitate with a centrifuge, and combine the supernatant with the supernatant taken out earlier, which is the mother liquor for citric acid purification.

[0023] Concentrate the purified mother liquor obtained above to 80% (w / w), put it into a crystallization pot for cooling and crystallization, and then centrifuge and dry to obtain the product.

Embodiment 3

[0025] Get unqualified citric acid mother liquor to be mixed with the concentration 800L of 20% (w / w), press 4.5kg / m under room temperature 3 Add the coagulant diatomaceous earth in the amount of the added amount, start stirring, and after 2 minutes, the volume of the mother liquor is 5g / m 3 Add the mixture of commonly used acrylamide flocculant and chitosan with a weight fraction of 7:3 as a degumming agent, mix well and let it stand for 2 hours. Take out the supernatant, process the precipitate with a centrifuge, and combine the supernatant with the supernatant taken out earlier, which is the mother liquor for citric acid purification.

[0026] Concentrate the purified mother liquor obtained above to 76% (w / w), put it into a crystallization pot for cooling and crystallization, and then centrifuge and dry to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com