A kind of detection method of moisture, vanadium pentoxide and carbon content in vanadium hexamine

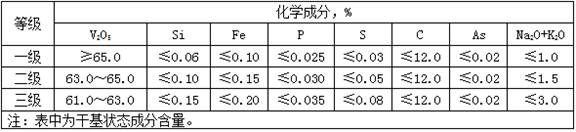

A vanadium pentoxide and detection method technology, applied in the detection of vanadium pentoxide and carbon content, and in the field of moisture in vanadium hexaamine, can solve the problem of inability to accurately measure component content, fail to meet production process, quality judgment, and business settlement and other problems, to achieve the effect of easy operation and accurate method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The detection method of moisture, vanadium pentoxide and carbon content in a kind of vanadium hexaamine of the present embodiment, described method comprises the following steps:

[0028] (1) Sample pretreatment and moisture determination: fully mix the hexaamine vanadium sample, weigh 30g sample, accurate to 0.0001g, put the sample in a weighing bottle, and put it into a nitrogen gas flow device In a drying oven at a constant temperature of 105±2°C, dry to constant weight, calculate the moisture content, and the moisture content is 17.79%.

[0029] (2) Determination of vanadium pentoxide content: weigh 0.2000g of dried hexaamine vanadium sample, add 20mL of hydrochloric acid (1+1) to dissolve the sample, then add 5mL of nitric acid (ρ1.42g / mL), add Sulfuric acid (1+1) 40mL, heat to dissolve, continue to heat until sulfuric acid fumes 1-2min, remove and cool, dilute to 100mL with water, then add ferrous ammonium sulfate solution (10%) 10mL, then add ammonium persulfate ...

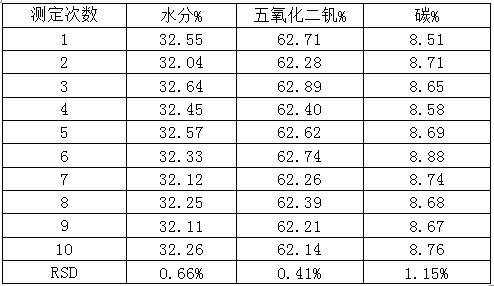

Embodiment 2

[0035] The detection method of moisture, vanadium pentoxide and carbon content in a kind of vanadium hexamine of the present embodiment, described method comprises the following steps:

[0036] (1) Sample pretreatment and moisture determination: fully mix the hexaamine vanadium sample, weigh 30g sample, accurate to 0.0001g, put the sample in a weighing bottle, and put it into a nitrogen gas flow device In a drying oven at a constant temperature of 105±2°C, dry to constant weight, calculate the moisture content, and the moisture content is 32.33%.

[0037] (2) Determination of vanadium pentoxide content: weigh 0.2000g of dried hexaamine vanadium sample, add 20mL of hydrochloric acid (1+1) to dissolve the sample, then add 5mL of nitric acid (ρ1.42g / mL), add Sulfuric acid (1+1) 40mL, heat to dissolve, continue to heat until sulfuric acid fumes 1-2min, remove and cool, dilute to 100mL with water, then add ferrous ammonium sulfate solution (10%) 10mL, then add ammonium persulfate s...

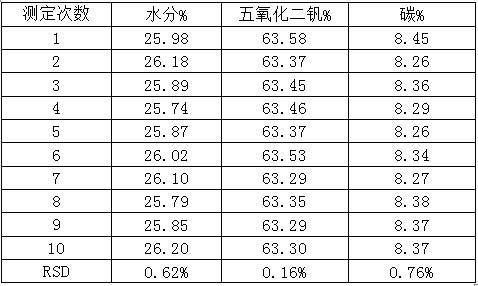

Embodiment 3

[0043] The detection method of moisture, vanadium pentoxide and carbon content in a kind of vanadium hexaamine of the present embodiment, described method comprises the following steps:

[0044] (1) Sample pretreatment and moisture determination: fully mix the hexaamine vanadium sample, weigh 30g sample, accurate to 0.0001g, put the sample in a weighing bottle, and put it into a nitrogen gas flow device In a drying oven at a constant temperature of 105±2°C, dry to constant weight, calculate the moisture content, and the moisture content is 20.33%.

[0045] (2) Determination of vanadium pentoxide content: weigh 0.2000g of dried hexaamine vanadium sample, add 20mL of hydrochloric acid (1+1) to dissolve the sample, then add 5mL of nitric acid (ρ1.42g / mL), add Sulfuric acid (1+1) 40mL, heat to dissolve, continue to heat until sulfuric acid fumes 1-2min, remove and cool, dilute to 100mL with water, then add ferrous ammonium sulfate solution (10%) 10mL, then add ammonium persulfate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com