Waste incineration improved process

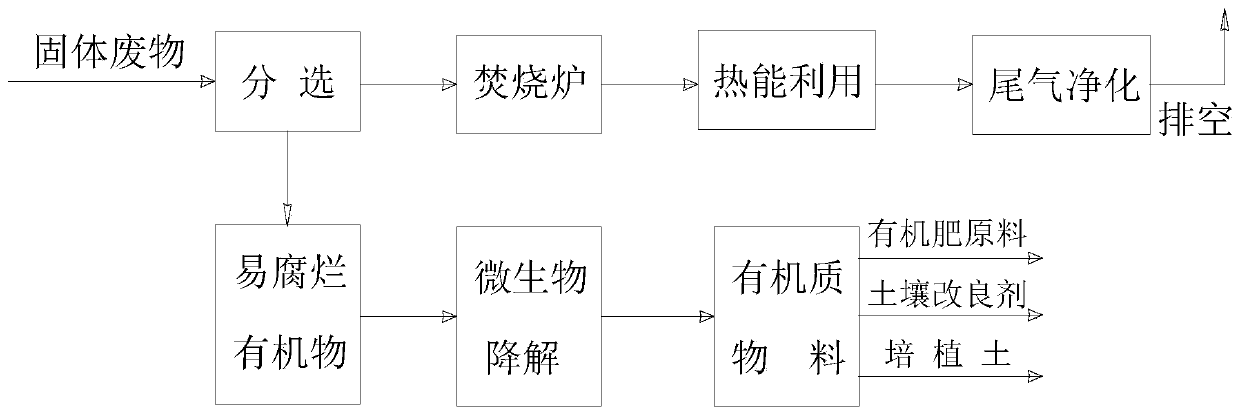

A waste incineration and process technology, applied in incinerators, combustion methods, chemical industries, etc., can solve the problems of increasing energy consumption, operating costs, and large exhaust emissions, and achieve efficiency improvements, environmental hazards, and treatment costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a waste incineration improvement process, and the specific operations are as follows:

[0038] In step 1, the garbage is sorted and processed to obtain perishable organic matter and combustible matter; the sorting and processing operation process is: send the material into the production line and go through bag breaking, air separation, bouncing separation, magnetic separation, primary screening, Electrostatic separation, secondary screening, and throwing for sorting operations;

[0039] Step 2, use the combustion material for incineration to generate electricity; the combustion material includes plastics, rubber products, bamboo products, wood products, cotton fabrics, paper, and fiber fabrics with high calorific value; the calorific value of the combustion material is at least higher than that of burning household waste The lower limit of calorific value is 3344kJ / kg;

[0040] In step 3, aerobic microorganisms are used to degrade peris...

Embodiment 2

[0042] The present embodiment provides a waste incineration improvement process, and the specific operations are as follows:

[0043] In step 1, the garbage is sorted and processed to obtain perishable organic matter and combustible matter; the sorting and processing operation process is: send the material into the production line and go through bag breaking, air separation, bouncing separation, magnetic separation, primary screening, Electrostatic separation, secondary screening, and throwing for sorting operations;

[0044] Step 2, use the combustion material for incineration to generate electricity; the combustion material includes plastics, rubber products, bamboo products, wood products, cotton fabrics, paper, and fiber fabrics with high calorific value; the calorific value of the combustion material is at least higher than that of burning household waste The lower limit of calorific value is 3344kJ / kg;

[0045] In step 3, aerobic microorganisms are used to degrade peris...

Embodiment 3

[0050] The present embodiment provides a comprehensive treatment process for perishable organics, and the specific operations are as follows:

[0051] In step 1, the garbage is sorted and processed to obtain perishable organic matter and combustible matter; the sorting and processing operation process is: send the material into the production line and go through bag breaking, air separation, bouncing separation, magnetic separation, primary screening, Electrostatic separation, secondary screening, and throwing for sorting operations;

[0052] Step 2, use the combustion material for incineration to generate electricity; the combustion material includes plastics, rubber products, bamboo products, wood products, cotton fabrics, paper, and fiber fabrics with high calorific value; the calorific value of the combustion material is at least higher than that of burning household waste The lower limit of calorific value is 3344kJ / kg;

[0053] In step 3, aerobic microorganisms are used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com