Technology for preparing salviae miltiorrhizae oral liquid with ceramic membrane

A preparation process and ceramic membrane technology, which is applied in the field of preparation of Danshen oral liquid, can solve the problems of incomplete removal of tannins, increased pollution, difficulty in adapting to modernization, etc., to solve the problem of clarity, reduce filtration resistance, and retain active ingredients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

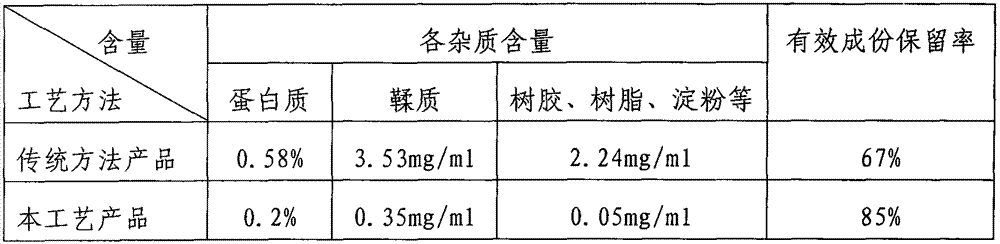

Embodiment 1

[0031] Example 1: Take 1000g of Salvia miltiorrhiza, add water and decoct three times, the amount of water added is 10 times, 8 times and 6 times respectively, decocting for 2 hours for the first time, decocting for 1.5 hours for the second time, and decocting for the third time After 1.5 hours, the decoction was combined, filtered, concentrated to 6 times the amount of medicinal materials, and centrifuged at a high speed (18,000 rpm). The centrifugate was pre-filtered with a ceramic membrane with a molecular weight of 150,000. The residue was discarded, and the filtrate was collected for later use. The primary filtrate was filtered again with a ceramic membrane with a molecular weight of 120,000, the residue was discarded, and the filtrate was collected for later use. The fine filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight of 50,000, and the ultrafiltrate is concentrated with a nanofiltration membrane. The specification of the nanofiltration...

Embodiment 2

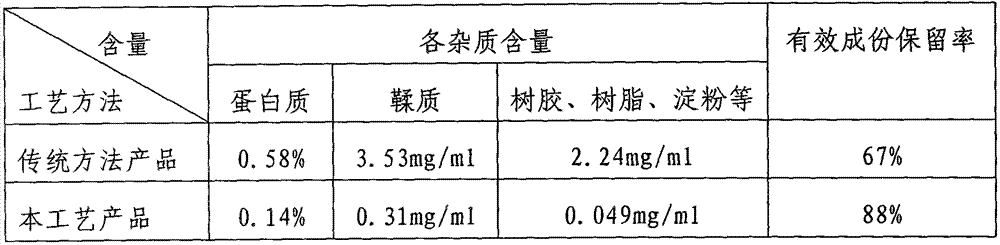

[0034] Example 2: Take 1000g of Salvia miltiorrhiza, add water and decoct three times, the amount of water added is 10 times, 8 times and 6 times respectively, decocting for 2 hours for the first time, decocting for 1.5 hours for the second time, and decocting for the third time After 1.5 hours, the decoction was combined, filtered, concentrated to 6 times the amount of medicinal materials, and centrifuged at a high speed (17,000 rpm). The centrifuged liquid was pre-filtered with a ceramic membrane with a molecular weight of 160,000. The residue was discarded, and the filtrate was collected for later use. The primary filtrate was filtered again with a ceramic membrane with a molecular weight of 100,000, the residue was discarded, and the filtrate was collected for later use. The fine filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight of 30,000, and the ultrafiltrate is concentrated with a nanofiltration membrane. The specification of the nanofilt...

Embodiment 3

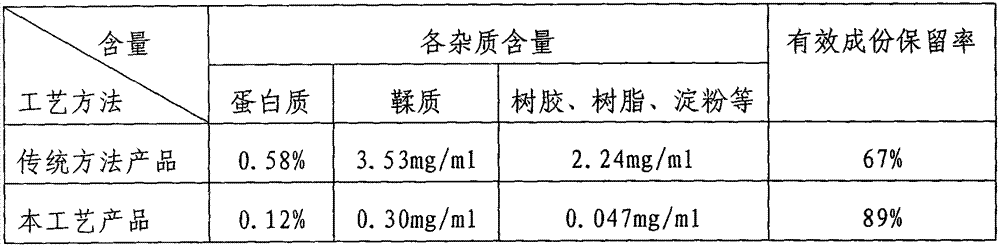

[0038] Example 3: Take 1000g of Salvia miltiorrhiza, add water and decoct three times, the amount of water added is 10 times, 8 times and 6 times respectively, decocting for 2 hours for the first time, decocting for 1.5 hours for the second time, and decocting for the third time After 1.5 hours, the decoction was combined, filtered, concentrated to 6 times the amount of medicinal materials, and centrifuged at a high speed (15,000 rpm). The centrifugal liquid was pre-filtered with a ceramic membrane with a molecular weight of 180,000. The residue was discarded, and the filtrate was collected for later use. The primary filtrate was filtered again with a ceramic membrane with a molecular weight of 80,000, the residue was discarded, and the filtrate was collected for later use. The fine filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight of 30,000, and the ultrafiltrate is concentrated with a nanofiltration membrane. The specification of the nanofiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com