Formic acid preparation method

A formic acid and carbonate technology, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of shortened life, decreased electrochemical reaction performance, and reduced product quality, etc., to achieve cost saving, wide application range, cleanliness The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The invention provides a kind of preparation method of formic acid, comprises the steps:

[0069] The bicarbonate solution or carbonate solution is mixed with carbon dioxide and passed into the cathode chamber of the electrochemical reactor, and the strong alkali solution is passed into the anode chamber of the electrochemical reactor to carry out the electrochemical reaction;

[0070] The product of the cathode chamber is separated through a cathode gas-liquid separator to separate carbon dioxide and formate;

[0071] The formate produces formic acid and strong alkali solution through a bipolar membrane electrodialysis reactor;

[0072] Wherein, the separated carbon dioxide is recycled to the cathode chamber for use, and the strong alkali solution produced by the bipolar membrane electrodialysis reactor is recycled to the anode chamber for use.

[0073] Specifically, the bicarbonate solution or the carbonate solution is used as a buffer solution during start-up, and t...

Embodiment 1

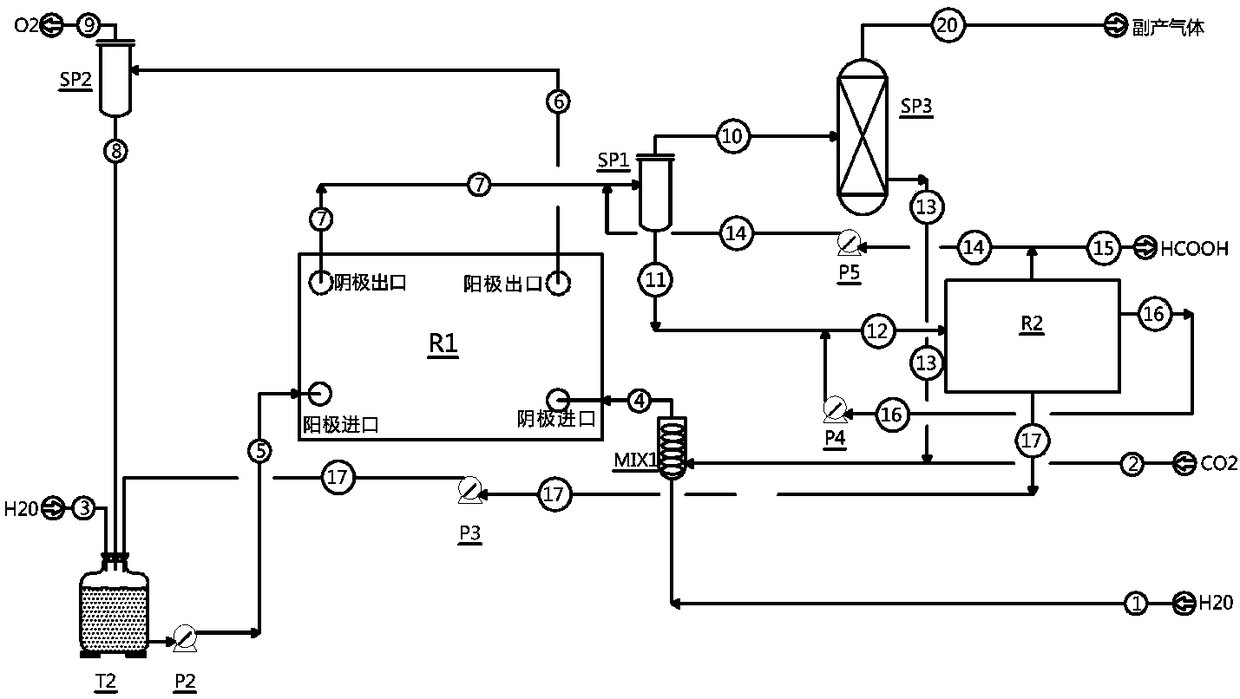

[0090] figure 1 It is a schematic diagram of a device for preparing formic acid in Example 1 of the present invention. Such as figure 1 As shown, the device includes: electrochemical reactor R1, bipolar membrane electrodialysis reactor R2, gas-liquid mixer MIX1, anode tank T2, anode pump P2, strong alkali circulation pump P3, formate solution circulation pump P4, Cathode gas-liquid separator SP1, anode gas-liquid separator SP2, adsorption-desorption device SP3, cathode tank supply and drainage pipeline 1, raw carbon dioxide pipeline 2, anode tank water supply pipeline 3, cathode feed pipeline 4, anode feed pipeline 5 , Anode discharge pipeline 6, cathode discharge pipeline 7, SP2 liquid circulation pipeline 8, oxygen product pipeline 9, SP1 gas outlet pipeline 10, SP1 liquid outlet pipeline 11, SP3 carbon dioxide circulation pipeline 13, formic acid product pipeline 15, formate Solution circulation pipeline 16, strong alkali solution circulation pipeline 17, SP4 carbon dioxi...

Embodiment 2

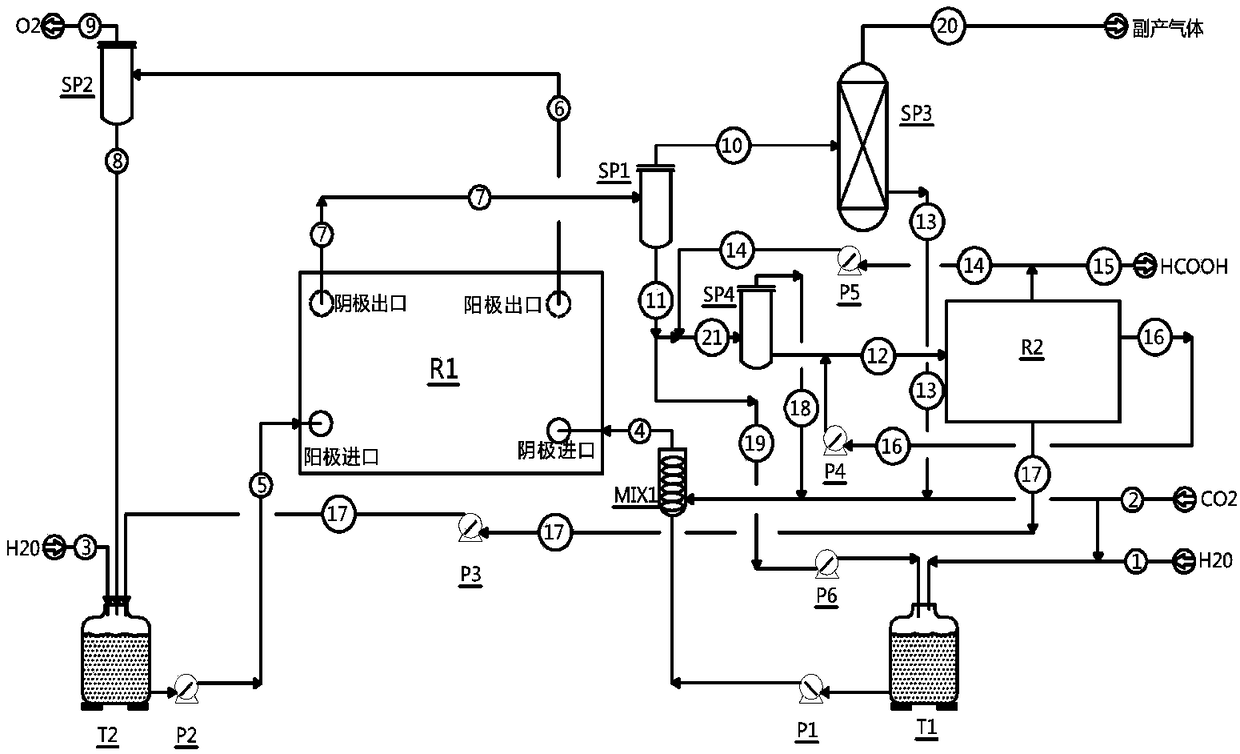

[0100] Formic acid prepared by the method of Example 1, its final product formic acid may be mixed with carbon dioxide gas. Such as figure 2 shown in figure 1 On the basis of the shown device, a formic acid circulation line 14 and a formic acid circulation pump P5 are added, and a part of the formic acid produced by the electrodialysis unit is circulated to the cathode outlet pipeline 7 of the electrochemical reactor, and the sodium bicarbonate in the cathode product is converted into sodium formate, releasing Carbon dioxide to improve the formate purity of the feed to the electrodialysis unit. Ultimately improve the quality of formic acid products. Through liquid chromatography analysis, the mass percentage concentration of the formic acid product prepared by the method is 8%-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com