Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Sodium bichromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling traditional chromium residue

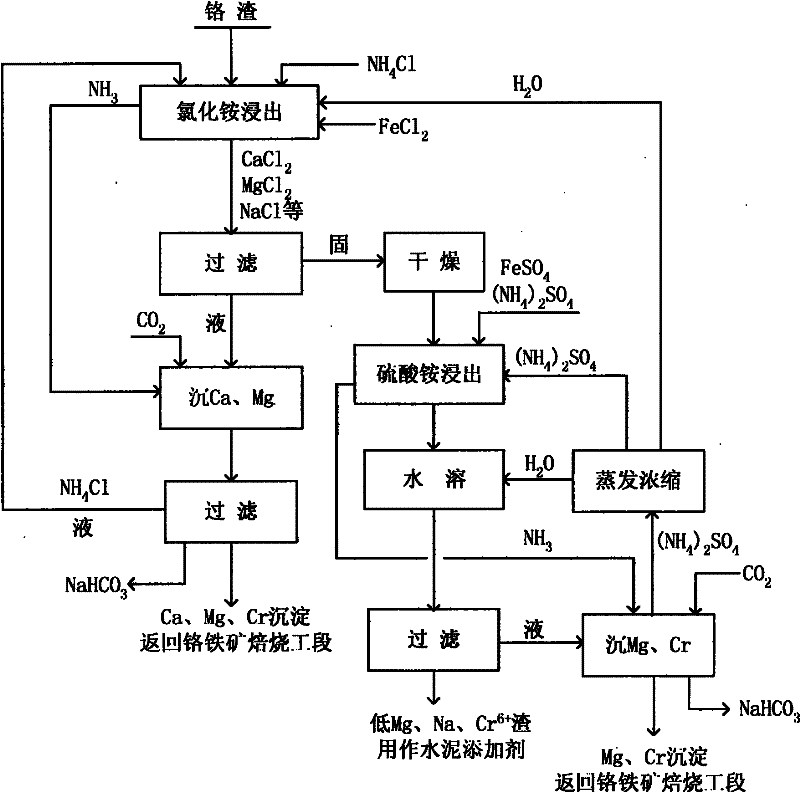

The invention relates to a method for recycling traditional chromium residue, in particular to a method for recycling the traditional chromium residue by replacing strong acid (hydrochloric acid or sulfuric acid) with an ammonium salt (ammonium chloride or ammonium sulfate) of the strong acid. In the method, chromium residue generated in the traditional calcium roasting production process for sodium bichromate is taken as a treatment object, ammonium salts (including ammonium chloride and ammonium sulfate) of the strong acid and reducing ferrous salts (including ferrous chloride and ferrous sulfate) are adopted to make calcium, magnesium, sodium, chromium and the like in the chromium residue form soluble chloride or sulfate, then the calcium, the magnesium and the chromium are precipitated by utilizing ammonia released by decomposing the ammonium salts and adding carbon dioxide, and are returned to the calcium roasting production process for the sodium bichromate to realize the circulation, ammonium chloride and ammonium sulfate regenerated by reacting with the chloride and the sulfate are recycled, and final slag is used as a raw material of cement after the treatment. In the method, the strong acid is not added, so the requirements on equipment materials are reduced; and the recycling of elements such as calcium, magnesium, chromium and the like greatly reduces the amount of the final slag, and greatly improves the utilization rate of traditional chromium residue raw materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

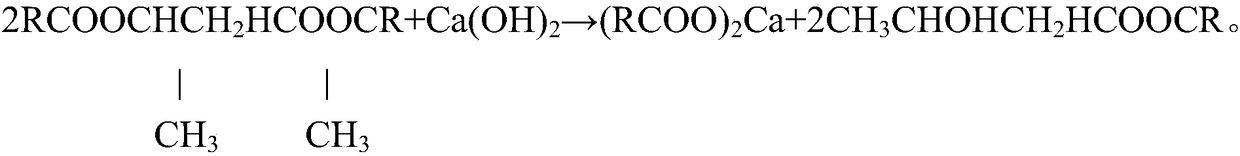

Rice bran calcium cerotate soap wax and preparation method thereof

ActiveCN108191602AHigh glossReduce manufacturing costOxygen-containing compound preparationOrganic compound preparationAcetic acidPolyol

The invention provides a preparation method of a rice bran calcium cerotate soap wax. The preparation method comprises the following steps: deoiling, soaking the deoiled but undecolorized rice bran wax into ethyl acetate, heating to melt, cooling, and cutting into slices for later use; oxidizing, heating the sliced rice bran wax and dilute sulphuric acid together to melt the rice bran wax, addinga sodium bichromate solution, constantly stirring and oxidizing, heating the oxidized rice bran wax into a liquid, then adding the dilute sulphuric acid, stirring, standing, layering, stirring while adding water, raising the temperature until the wax is completely melted, continuing to stir, standing and layering to obtain the rice bran wax cerotate; esterifying, heating and melting the rice branwax cerotate, raising the temperature, adding a polyhydric alcohol to have esterification reaction to obtain rice bran cerotate ester wax; saponifying, heating and melting the rice bran cerotate esterwax, and adding a calcium hydroxide solution to implement partial saponification to obtain the rice bran calcium cerotate soap wax. The invention further provides the rice bran calcium cerotate soapwax. The preparation method provided by the application is low in production cost, and the product is harder and has the performances of high temperature resistance and high gloss, and can substitutemouton wax soap.

Owner:重庆合才化工科技有限公司

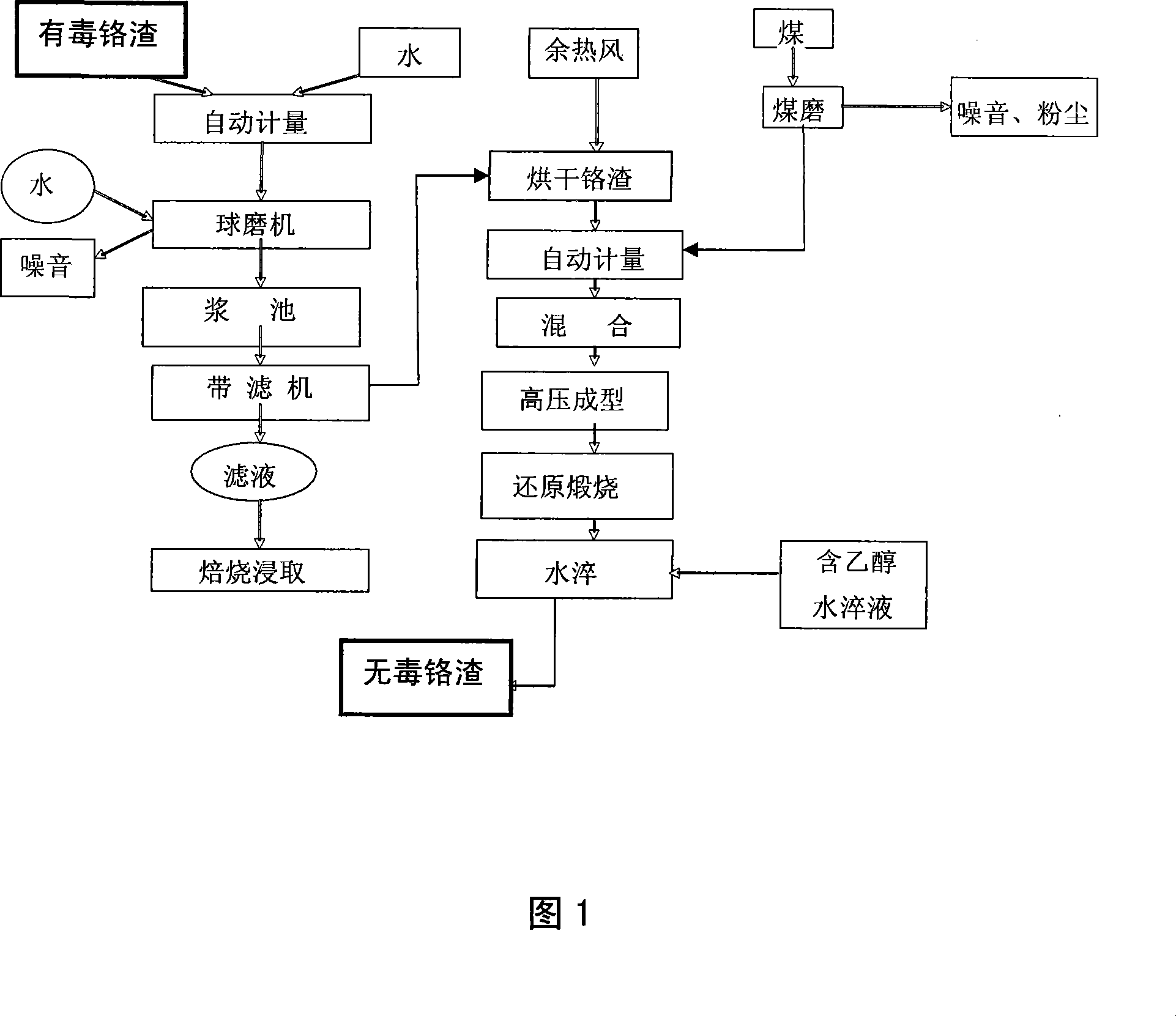

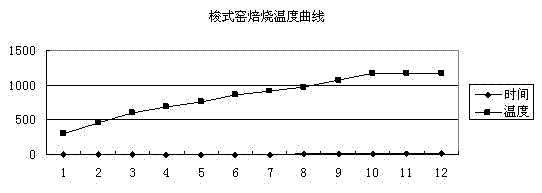

Method for using carbon monoxide to detoxicate chromium residue

The invention relates to a method by using carbon monoxide to detoxify chromium slag which belongs to the technical field in which hexavalent chromium ion Cr<6+> producing sodium bichromate chromium slag is reduced into trivalent chromium ion Cr<3+>. In order to ensure the mixture of chromium slag and coal to produce more CO in high temperature to reduce the hexavalent chromium ion Cr<6+> in the chromium slag into chromium ion Cr<3+>, the chromium slag and the coal are squeezed into chromium slag coal compact with density of 1.5*10<3> to 5.5*10<3>Kg / m<3>, and thickness of 5 to 50mm to calcinate, and ethanol solution is used for water quenching after calcinations. The method includes the following steps: grinding materials, drying, mixing chromium slag powder and coal powder to get a mixture with 91 percent to 98 percent of chromium slag powder and 2 percent to 9 percent of coal powder, squeezing the chromium slag and the coal into chromium slag coal compact, calcinating and water quenching by ethanol solution. The leaching solution of the chromium slag coal compact after being water quenched according to national standards has Cr<6+> with the content of 0.01 to 0.30mg / L, and is in accordance with the requirement of HJ / T301-2007 issued by national environmental protection headquarter.

Owner:SICHUAN YINHE CHEM

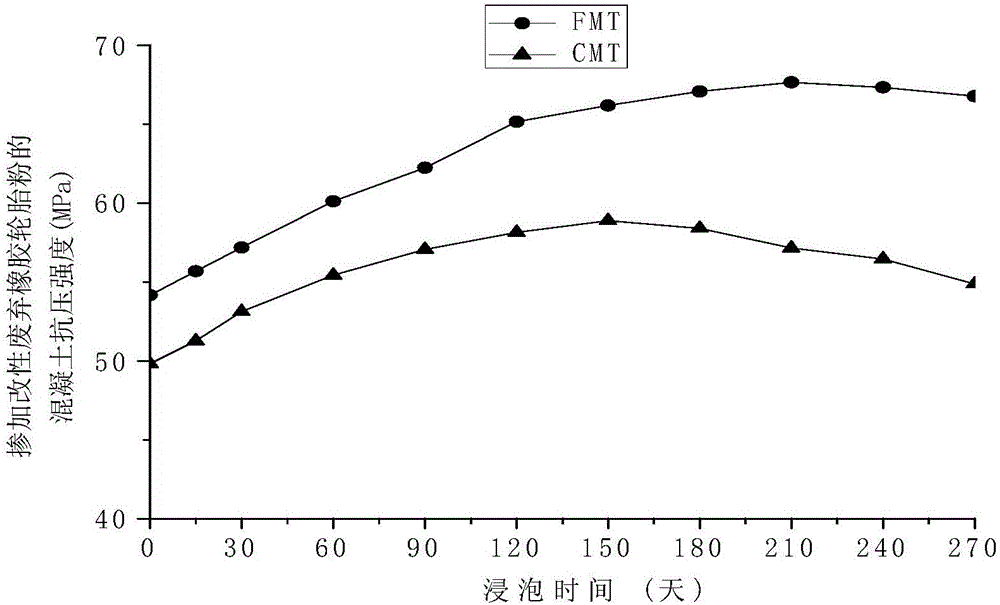

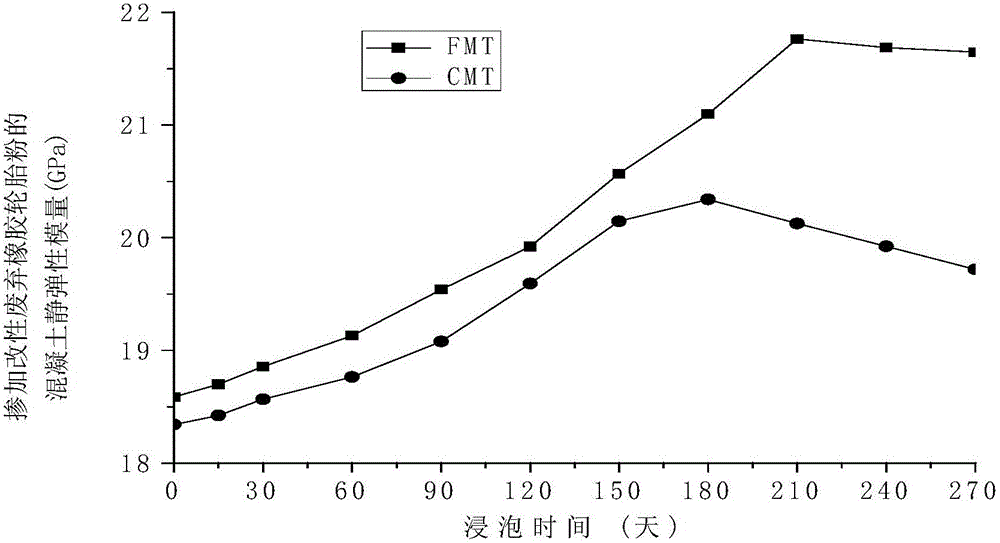

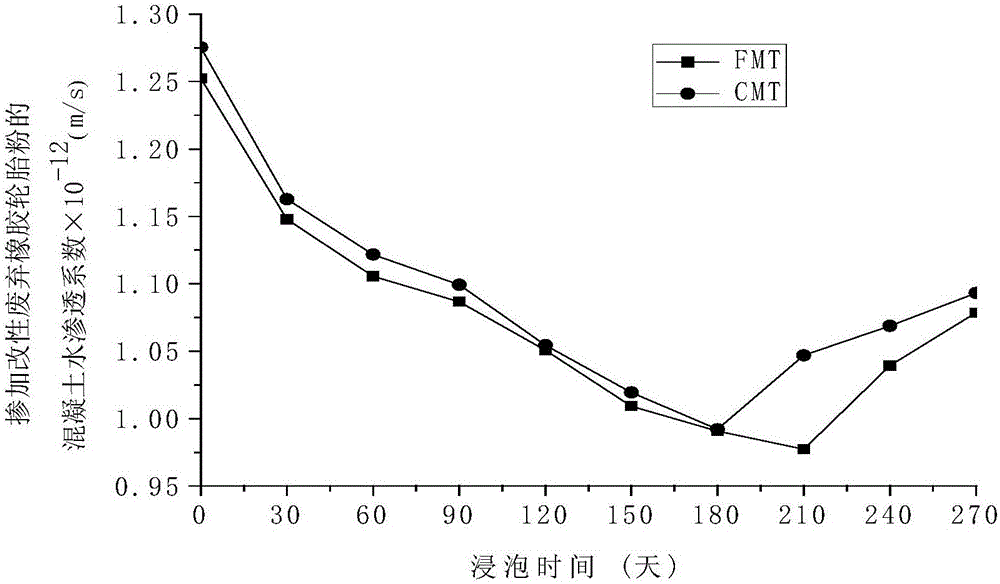

Preparation method of structural concrete capable of preventing erosion by sulfate mediums

ActiveCN105777003AImprove mechanical propertiesImprove compactnessSolid waste managementCeramic shaping apparatusSulfateCrushed stone

The invention discloses a preparation method of structural concrete capable of preventing erosion by sulfate mediums. The preparation method mainly comprises the following steps: crushing abandoned rubber tires into granules, screening the granules, and then grinding the screened granules so as to obtain abandoned rubber tire powder; performing surface chemical oxidation modification on the abandoned rubber tire powder with treatment fluid prepared from sodium bichromate, concentrated sulfuric acid and distilled water; stirring the abandoned rubber tire powder after the surface chemical oxidation modification, with cement, mineral admixture, broken stones, sand and water so as to obtain concrete mixed with abandoned rubber tire powder of surface chemical oxidation modification; finally performing conventional maintenance and CO2 gas maintenance. According to the preparation method, the technology is simple, the cost is reduced, through addition of the modified abandoned rubber tire powder and the CO2 gas maintenance, the capacity of the structural concrete resisting to the erosion of the sulfate mediums is improved, and the structural concrete has excellent mechanical properties.

Owner:HOHAI UNIV

Rice bran wax acid ester wax and preparation method thereof

InactiveCN108129302AStable structureHigh hardnessOrganic compound preparationCarboxylic acid esters preparationAcetic acidPolyol

The invention provides a preparation method of a rice bran wax acid ester wax. The method comprises the following steps of deoiling, soaking a deoiled and non-discolored rice bran wax through ethyl acetate, heating for melting, cooling, and slicing for standby use; oxidizing: heating the sliced rice bran wax and dilute sulphuric acid for melting the rice bran wax, then adding a sodium bichromate solution, and continuously stirring and oxidizing; heating the oxidized rice bran wax into a liquid, then feeding a dilute sulphuric acid for stirring, standing for layering, then adding water while stirring while heating until the wax is completely melted, then continuously stirring, and standing for layering to obtain a rice bran wax acid wax; preparing and melting: heating and melting the rice bran wax acid wax, then heating, and adding polyhydric alcohols and the rice bran wax acid wax for carrying out esterification reaction to obtain the rice bran wax acid ester wax. The invention also provides the rice bran wax acid ester wax. The rice bran wax is oxidized through the sodium bichromate so as to generate the rice bran wax acid wax, the rice bran wax acid wax is esterified with the polyhydric alcohols to generate the rice bran wax acid ester wax with a longer chain, and the rice bran wax acid ester wax is low in production cost, high in product hardness and glossiness, and capableof effectively replacing a montan E wax.

Owner:重庆合才化工科技有限公司

Light rice bran cerotic acid wax and preparation method thereof

PendingCN108048222AEffective oxidation removalGood emulsifying effectFatty substance recovery/refiningFatty substance recoveryAcetic acidEthyl ester

The invention provides a preparation method of light rice bran cerotic acid wax. The method includes the following steps of deoiling, oxidation and acid pickling and water scrubbing. During deoiling,deoiled rice bran wax to be discolored is soaked in ethyl acetate, heated for melting and then cooled and sliced for use. During oxidation, the sliced rice bran wax and dilute sulphuric acid are heated to enable the rice bran wax to be melted, then the rice bran wax is added into a sodium bichromate solution and then constantly stirred, the color of the rice bran wax turns light from brown, and natural cooling and standing are conducted to make the wax delaminated from a chromium slurry solution. During acid pickling and water scrubbing, the oxidized rice bran wax is heated into a liquid thenput into dilute sulphuric acid and stirred, standing is carried out to make the wax delaminated from a water scrubbing liquid, then the mixture is added with water, stirred and heated at the same timetill the wax is totally melted, stirring continues to be conducted, standing is carried out to make the wax delaminated from the water scrubbing liquid, and the oxidized rice bran wax at the upper layer is sliced and packed after being cooled. The invention further provides the light rice bran cerotic acid wax. According to the method, the rice bran wax is oxidized by sodium bichromate to generate the rice bran cerotic acid wax which is light in color, odorless and hard in texture, micromolecular materials are effectively removed, the emulsibility and the luster are obviously improved, and deep processing is facilitated.

Owner:重庆合才化工科技有限公司

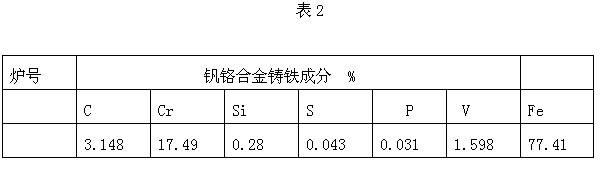

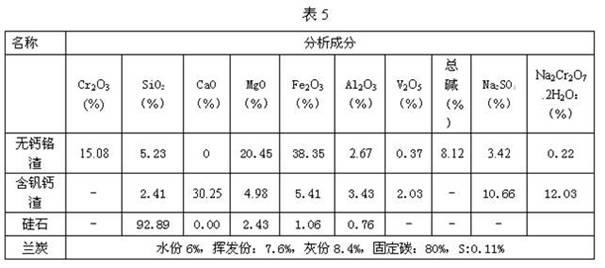

Method for smelting chromium-containing cast iron by using vanadium-containing calcium slag

ActiveCN102251114ASmelting completeSmelting and smelting reduction is completeElectric arc furnaceSlag

The invention aims to provide a method for smelting chromium-containing cast iron by using vanadium-containing calcium slag for solving the problems of high melting point and difficult slag iron separation in the conventional smelting of chromium-containing cast iron by calcium-free vanadium slag and the problems of hexavalent chromium pollution to vanadium-containing calcium slag and utilization of vanadium-containing resources. The method has the characteristics that: the vanadium-containing calcium slag discharged from a process for preparing sodium bichromate by calcium-free roasting is used as an additive and is uniformly mixed with calcium-free chromium slag, silica and a carbon reducer; the mixture is granulated, dried, and smelting in an arc furnace; and thus, vanadium and chromium alloy cast iron is obtained. In the invention, the alkalinity of the furnace slag is kept between 1.4 and 1.8, the melting point of the smelted furnace slag can be reduced to 1,450 to 1,600 DEG C, the weight ratio of the furnace slag to molten iron is (3.7-4.5):1, reduction is performed completely in the melting and smelting of calcium-free chromium slag, the slag and iron separation is complete, the phenomenon that furnace slag is mixed in finished vanadium and chromium alloy cast iron is eliminated, and the quality of the vanadium and chromium alloy cast iron is improved.

Owner:GANSU JINSHI CHEM

Preparation process of slow cross-linking agent for acrylic amide gel

The invention provides a method of preparing sustained cross-linking agent for polypropylene acylamide gel, using sodium bichromate, oil of vitriol, sodium sulfite, humic acid, acetic acid, citric acid, 40% NaOH solution and water as raw materials, charging cooling water in a vitreous enamel reaction kettle, adding water in 50%-5% in the kettle, starting a blender, adding in sodium bichromate in 10%-18%, then slowly adding in oil of vitriol in 10%-18%, blending and reacting for 1 hour, slowly adding in humic acid in 3%-6% to react for 0.5 hour, adding in sodium sulfite in 2%-5%, dissolving and then adding in citric acid in 5%-10% and acetic acid in 10%-18%, blending uniformly and then slowly adding in 40% NaOH solution in 10%-20%, blending uniformly and making it at once.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Biomass fuel based on sepiolite powder combustion improver and preparation method thereof

InactiveCN105238484ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsSludgeCopper oxide

The invention discloses a biomass fuel based on a sepiolite powder combustion improver and a preparation method thereof. The biomass fuel based on the sepiolite powder combustion improver comprises the following components by dry weight: 50-65 parts of sawdust, 20-35 parts of straw, 25-35 parts of returned sludge, 5-15 parts of attapulgite clay, 1-10 parts of a fluxing agent, and 5-15 parts of the combustion improver. The combustion improver, comprises, by weight, 40-60 parts of sepiolite powder, 10-20 parts of activated carbon, 5-10 parts of magnesium oxide, 4-8 parts of lanthanum nitrate, 2-7 parts of potassium perborate, 8-15 parts of fluorite, 2-7 parts of sodium bichromate, 1-6 parts of acetone, 4-8 parts of copper oxide, 5-10 parts of magnesium oxide, and 5-10 parts of calcium permanganate. The biomass fuel provided by the has a combustion temperature up to 1410-1520DEG C, combustion efficiency increased by about 30% than ordinary biomass fuels, a calorific value up to 5100-5200 kcal / kg, combustion tail gas in line with the relevant provisions of the state, a sulfur removal rate up to 94.3%, and a nitrate removal rate up to 94.8%.

Owner:杨阳

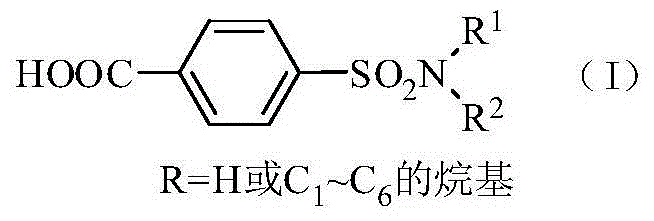

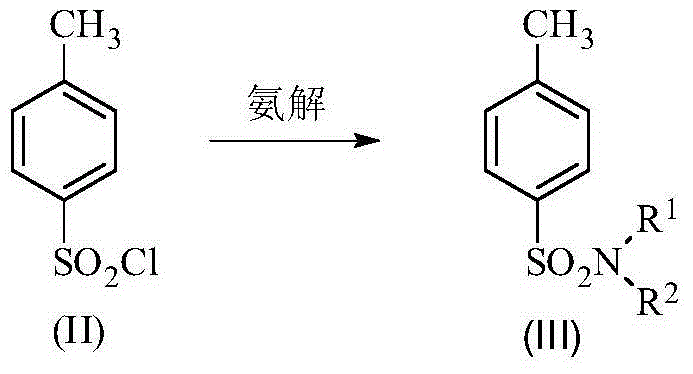

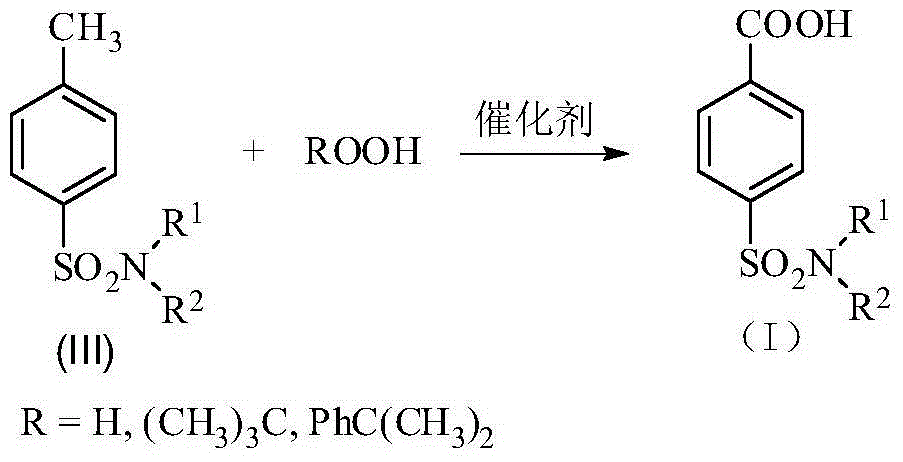

Method for synthesis of p-carboxybenzene sulfonamide through catalytic oxidation

ActiveCN104447434ANo pollution in the processUser-friendlySulfonic acid amide preparationHeteropoly acidCatalytic oxidation

The invention relates to a method for synthesis of p-carboxybenzene sulfonamide through catalytic oxidation, belonging to a method for preparing p-carboxybenzene sulfonamide. According to the method, p-carboxybenzene sulfonamide is prepared by two-step reaction by taking p-toluenesulfonyl chloride as raw material. The method comprises the following steps: firstly performing ammonolysis on p-toluenesulfonyl chloride to obtain p-toluenesulfonamide, oxidizing p-toluenesulfonamide to obtain a product, namely p-carboxybenzene sulfonamide by taking a hydroperoxide as an oxidant to replace traditional strong oxidants, namely sodium bichromate, potassium permanganate and the like under the catalytic action of a metal oxide and heteropoly acid in mild conditions in a water phase, wherein the yield is 81.83-87.88%, the purity of the product detected by analysis of an Agilent 1200 type high performance liquid chromatographic instrument is 92.54-95.47% and the selectivity of p-carboxybenzene sulfonamide can achieve 100%. According to the method, the catalysts and the oxidant are non-toxic and environment-friendly, a byproduct is water or alcohol which is environment-friendly, the reaction conditions are mild, the post-treatment is simple, the catalysts can be recycled, and the cost is saved, so that the method is an ideal green synthesis method of p-carboxybenzene sulfonamide.

Owner:CHINA UNIV OF MINING & TECH

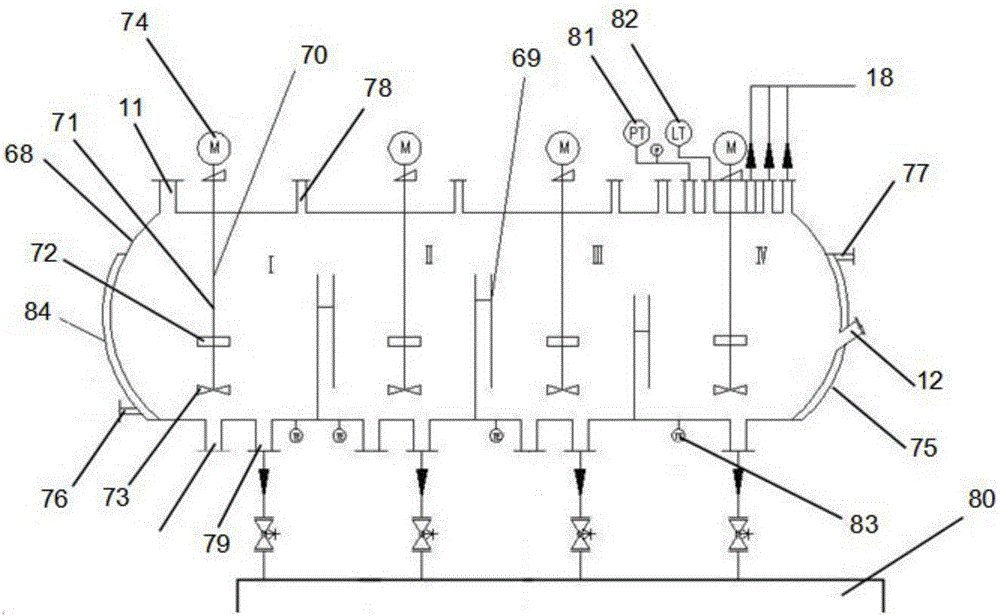

Sodium bichromate concentration and crystallization equipment and technology

ActiveCN103446776AReduce energy costsLow running costSolution crystallizationChromates/bichromatesPhysical chemistryProcess engineering

The invention discloses sodium bichromate concentration and crystallization equipment and a technology. The sodium bichromate concentration and crystallization equipment comprises a compression evaporation device, a two-effect evaporation device and a crystallization separation device. The technology comprises the steps of recompression evaporation of steam, first-effect evaporation of concentrated liquor, second-effect evaporation of concentrated liquor, crystallization separation of sodium bichromate and the like. The structure of the equipment disclosed by the invention is simplified; a steam recompression evaporation part makes use of a recycling function of the equipment, and extra steam is not needed; a two-effect evaporation part makes use of a steam spraying pump, so that the energy consumption and the operation cost are further reduced. According to the technology disclosed by the invention, through segment type evaporation compression and crystallization, the energy consumption and the cost of a sodium bichromate treatment process are reduced by cyclic pressurization of the equipment.

Owner:深圳市捷晶科技股份有限公司

Method for electrochemical synthesis of chromic anhydride from sodium chromate

The invention belongs to the fields of chromium chemical industry and production of chromium salts, more particularly relates to a method for electrochemical synthesis of chromic anhydride from sodium chromate. The method takes a sodium chromate solution as raw material, carries out secondary electrochemical synthesis reaction in a dual-chamber electrochemical synthesis reactor containing an anode chamber and a cathode chamber and carries out the electrochemical synthesis of a sodium bichromate solution in a primary electrochemical synthesis reactor, a cathode solution and an anode solution after the primary electrolysis are controllably transferred to the cathode chamber and the anode chamber of the secondary electrochemical synthesis reactor for carrying out the electrochemical synthesis reaction after dilution or concentration, the cathode chamber generates a sodium hydroxide solution and the anode chamber generates a chromic acid solution. Concentration, crystallization, separation, washing and drying are executed to the chromic acid solution obtained by an anode to prepare a chromic anhydride product (CrO3). The method has the advantages of short process flow, mild reaction conditions, good product quality, no side reactions, no pollution, strong operability, easy industrialization and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

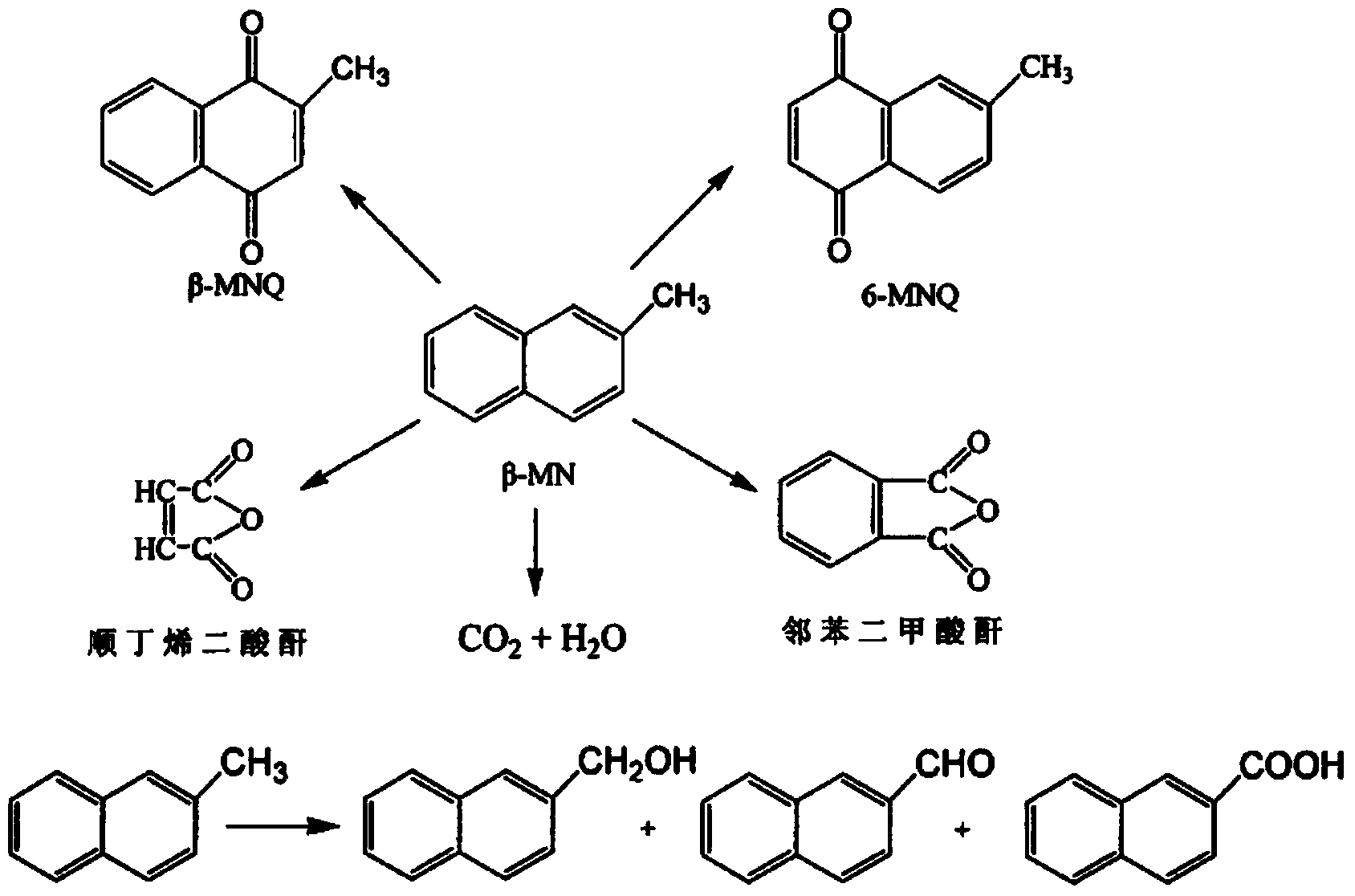

Method for promoting beta-menadione production through ultrasonic waves

ActiveCN103483174AReduce dosageLow reaction temperatureQuinone preparation by oxidationUltrasound - actionMenadione

The invention discloses a method for promoting beta-menadione production through ultrasonic waves. The method includes the steps that oxidation liquid is prepared from sodium bichromate and sulfuric acid, the oxidization liquid is slowly added into mixed mediums containing beta-methyl naphthalene, phase transfer catalysts and water to undergo reaction, and the ultrasonic waves act on the reaction system in the reacting process. Due to the fact that the ultrasonic waves have the promotion effect on the reaction, the temperature of the reaction system can be greatly lowered, side reactions are reduced, the product yield is improved, and the using amount of the oxidization liquid can be greatly reduced.

Owner:SICHUAN YINHE CHEM

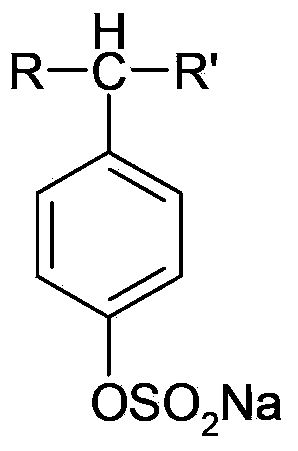

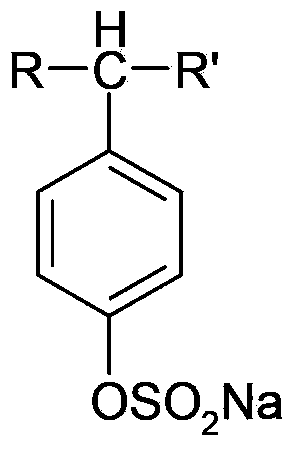

Oil well deep composite blocking profile control agent and application thereof

ActiveCN103421475ANot easy to flowPlay a sealing roleDrilling compositionSealing/packingSulfonateSodium Thiosulfate Pentahydrate

The invention relates to an oil well deep composite blocking profile control agent and the application thereof. The composite blocking profile control agent comprises the following components: gel blocking agent solution, particle blocking agent, authigene air source and surface active agent, wherein in the gel blocking agent solution, the weight ratio of the partially hydrolyzed polyacrylamide, the sodium bichromate and the sodium thiosulfate pentahydrate is 1:0.025:0.35, a water solution with the total weight concentration of 0.5-1% is prepared from the partially hydrolyzed polyacrylamide, sodium bichromate and sodium thiosulfate pentahydrate, and hydrochloric acid capable of adjusting the pH of the gel blocking agent solution to 3.5-4.5 is contained; the particle blocking agent comprises phenolic resin and phenolic resin, wherein the weight ratio of the phenolic resin and the phenolic resin is 1:0.06; the authigene air source is CO(NH2) 2; the surface active agent is alkylaryl sulfonate; the weight ratio of the gel blocking agent solution, the particle blocking agent, the authigene air source and the surface active agent is 60:6:2:1. According to the composite blocking profile control agent disclosed by the invention, deep blocking and profile control at the oil layer of an oil well is realized through the Jamin Effect of foam generated in the deep part of stratum and the physical blocking function of a solid phase blocking agent.

Owner:PETROCHINA CO LTD

Method utilizing chromium-containing sodium bisulfate to produce chromium oxide green

InactiveCN106395904AEnvironmentally friendlyEnergy savingChromium oxides/hydratesChromium(III) hydroxideSodium bisulfate

The invention discloses a method utilizing chromium-containing sodium bisulfate to produce chromium oxide green. The method comprises the following steps: directly reducing chromium-containing sodium bisulfate, which is discharged in chromic anhydride production (sulfuric acid method), by a reducing agent, adjusting the pH value of the solution to a neutral range, press-filtering the solution by a filter presser, washing the obtained chromium hydroxide filter cakes, and burning the chromium hydroxide filter cakes to obtain a chromium oxide green product. The conventional technology that chromium-containing sodium bisulfate is recovered and applied to the neutralization and acidification of a chromium salt production system is replaced, the production procedure of the provided method is short, the method is simple; moreover, the wastes namely chromium-containing sodium bisulfate are effectively consumed; the environment pollution is reduced, at the same time, the production of commercial sodium bichromate and the production of commercial chromic anhydride in the chromium salt production system can be effectively balanced; the harmful impurity enrichment caused by recovery of sodium bisulfate is relieved, and thus the quality of sodium bichromate and chromic anhydride is guaranteed. The production technology is environment-friendly, energy-saving, and efficient.

Owner:GANSU JINSHI CHEM

Method for continuously neutralizing and decontaminating sodium chromate alkali solution

ActiveCN102642870AQuality improvementCoarse sediment particlesChromates/bichromatesWastewaterAqueous solution

The invention relates to a method for continuously neutralizing and decontaminating a sodium chromate alkali solution. The method comprises the following step of: adding a neutral aqueous solution containing sodium chromate and an optional crystal seed which are used as bottom materials in a neutralization reactor for realizing neutralization and decontamination based on carbon dioxide as a neutralizing agent or chromium-containing acidic wastewater which is produced in the process of producing sodium bichromate from sodium chromate, a pre-acidification solution, an acidification solution, a sodium bichromate mother liquid, a sodium dichromate aqueous solution and inorganic acid, or any mixture of the former neutralizing agents. Through the control over the concentration, temperature, pH value and stirring speed of a reaction liquid, precipitate obtained by the method is large in particle and rapid in sedimentation speed; aluminum mud is good in filtering property and is easy to wash; and the content of hexavalent chromium in the aluminum mud in greatly reduced, thereby reducing the discharge amount of the aluminum mud. In addition, the neutralization reactor the upper part of which is provided with an overflowing port is adopted for neutralization reaction, so that the automation and continuty of the neutralization and decontamination process of the sodium chromate alkali solution are realized.

Owner:SICHUAN YINHE CHEM

Inflaming retarding, corrosion protecting, anti-mildew agent for materials of bamboo and wood

A flame-retarding, antiseptic and antimildew agent for bamboo or wood material contains ammonium hydrogen phosphate and the mixture of two or more of chlorothalonil, triadimefon, boric acid, borax, copper sulfate, santobrite, sodium bichromate, sodium fluoride, and zinc chloride.

Owner:ZHEJIANG FORESTRY UNIVERSITY

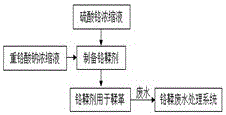

Novel method for chrome tanning wastewater treatment and chrome recycling

InactiveCN106630008AReduce processing costsProtection lossWater contaminantsWaste water treatment from animal processingFiberIon exchange

A novel method for chrome tanning wastewater treatment and chrome recycling comprises two parts of chrome tanning wastewater treatment and chrome recycling, wherein chrome tanning wastewater treatment is implemented as follows: the chrome tanning wastewater is subjected to homogenization and quantification in a collection tank and then pumped by a pump into a pretreatment system for removal of fur residues, leather chips, protein, dyes and other impurities; the chrome tanning wastewater after impurity removal enters an ionic exchange fiber system for exchange and adsorption, and effluent with total chrome and hexavalent chrome up to the standard is recycled as washing water for the leather tanning procedure or enters a follow-up treatment system for up-to-standard discharge; ionic exchange fibers are regenerated with a regeneration solution after being adsorbed and saturated, and the regenerated ionic exchange fibers are used for circularly treating the chrome tanning wastewater. Recycling of chrome is implemented as follows: a chrome sulphate solution obtained through regeneration and a sodium bichromate concentrated solution are taken as raw materials for preparation of a chrome tanning agent, namely, basic chrome sulphate; the prepared chrome tanning agent is used for leather tanning, so that chrome in the chrome tanning wastewater is effectively recycled. By means of the process, chrome in the chrome tanning wastewater is effectively recycled while stable and up-to-standard discharge of total chrome and hexavalent chrome is guaranteed. The process adopts a simple route, is low in energy consumption and high in chrome recycling rate, causes no secondary pollution and has good economic and social benefits.

Owner:SHENZHEN QIANHAI ZHONGSHENG ENVIRONMENTAL PROTECTION TECH

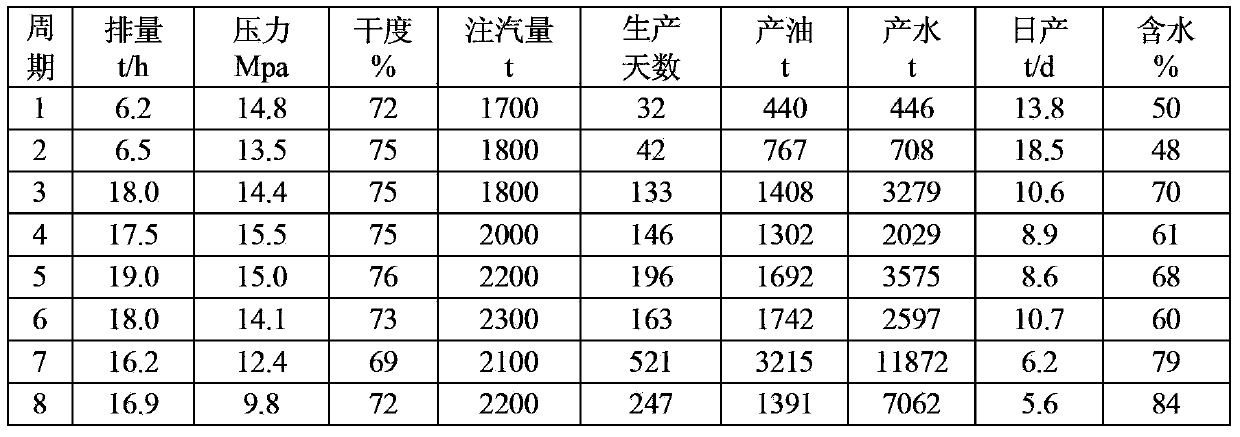

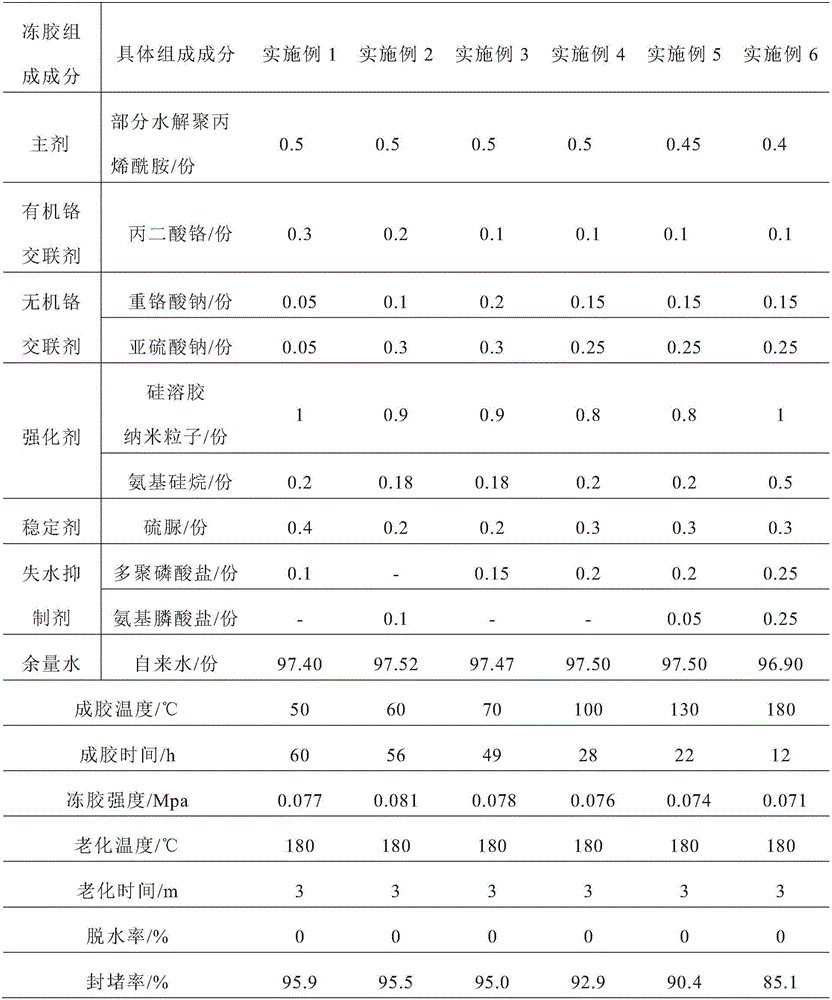

Thickened oil thermal production channel blocking nano-composite gel

ActiveCN106590559AGel forming time is controllableWide temperature range availableDrilling compositionCross-linkSulfite salt

The invention provides thickened oil thermal production channel blocking nano-composite gel. The gel comprises, by weight, 0.4-0.5 part of a main agent, 0.1-0.3 part of an organic chromium cross-linking agent, 0.1-0.5 part of an inorganic chromium cross-linking agent, 1-1.5 parts of a reinforcer, 0.2-0.4 part of a stabilizer, 0.1-0.5 part of a dehydration inhibitor and the balance water, wherein the sum of the weight parts of the components is 100. The main agent refers to partially hydrolyzed polyacrylamide. The organic chromium cross-linking agent refers to malonic acid chromium. The inorganic chromium cross-linking agent is sodium bichromate, and the ratio of the sodium bichromate to sodium sulfite is 1:1-3. The reinforcer is silica soil nano particles, and the ratio of the silica soil nano particles to amino silane is 2-5:1. The stabilizer is thiourea. The dehydration inhibitor is one or a combination of polyphosphates and phosphoro-amidate. The ratio of the polyphosphates to the phosphoro-amidate is 1-4:1 during combination. According to the thickened oil thermal production channel blocking nano-composite gel provided by the invention, the gel forming temperature can be selected to be 50-180 DEG C, the gel forming time is adjustable within the range of 12-60h, gel strength is high, viscoelasticity is good, temperature resistance water-holding power is high, no dehydration phenomenon happens after ageing for 3 months under the temperature condition of 180 DEG C, and steam channeling caused in the thickened oil thermal production process can be blocked selectively.

Owner:YANGTZE UNIVERSITY

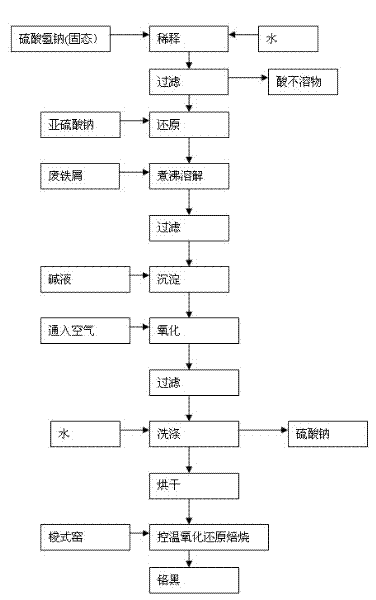

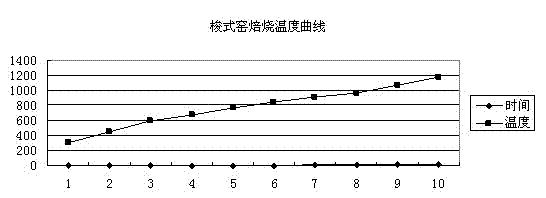

Method of producing eriochrome black with sodium bisulfate, byproduct of chromic trioxide

The invention discloses a method of producing eriochrome black with sodium bisulfate, a byproduct of chromic trioxide, and the method has the advantages of low cost and a simple process. The method is as follows: sodium bisulfate, the byproduct of chromic trioxide, and waste scrap iron are used as raw materials; solid sodium bisulfate is diluted with water and dissolved with stirring, sodium hydrosulphite is added into a sodium bisulfate solution which has been filtered and contains sodium bichromate for a reduction reaction, then waste scrap iron is added and dissolved through heating, and filtration is carried out to remove residues; the pH value of obtained filtrate is adjusted by a sodium hydroxide solution, air is blown in for stirring an obtained mixture, the mixture is then subjected to filtration and separation, obtained deposition is dried after rinsing and is then roasted at a high temperature so as to obtain an eriochrome black pigment with good dispersibility and powerful tinting strength. The beneficial effects of the invention are as follows: (1) raw materials used in the method are mainly the solid byproduct of sodium bisulfate generated in production of chromic trioxide and waste scrap iron, which enables environmental protection and energy saving to be realized, industrial waste materials to be effectively utilized and low cost to be achieved; (2) process flow is simple, the raw materials are easily available, and the method is applicable to industrial production.

Owner:GANSU JINSHI CHEM

Preparation of chromium anhydride

InactiveCN1424258AReduce solubilityPrevent precipitationChromium oxides/hydratesCooking & bakingSodium bichromate

A process for preparing chromic acid anhydride includes such steps as proportionally mixing concentrated sulfuric acid with solution of sodium bichromate, reacting white stirring for 2-3 hr, vacuum evaporating at 105-125 deg.C to educe out crystal of chromic acid anhydride, centrifugal dewatering at 80-95 deg.C, washing with the solution of chromic acid anhydride at 85-95 deg.C, and baking at 100-105 deg.C for 2-3 hr.

Owner:JINAN YUXING CHEM

Method for preparing multiple metallic ion leather tanning agents

InactiveCN101314796AEffectively form self-closed recyclingGood compatibilityTanning treatmentRecycling and recovery technologiesChromium CompoundsSodium bichromate

The invention discloses a method for preparing a plurality of metal ion leather tanning agents by utilizing chromium-containing and collagen solid wastes. Materials belonging to leather originally such as leather meal, leather bits and pieces, waste leather are used as raw materials for preparing chemical material which can be processed into leather; the chemical material is used in leather tanning and then is applied back to the leather; the chemical material has the best compatibility with the leather and can effectively form the self-closed recycle of materials. Namely, the chromium-containing and collagen solid wastes are used as a reducing agent instead of glucose, sulfur dioxide, etc., and ferrous sulfate is used as a supplementary reducing agent, so as to deoxidize sodium bichromate to prepare the leather tanning agents; chromium compounds in the solid wastes again become part of the metal ions which are used for preparing the tanning agents; collagen hydrolysate or oxidation products become filling materials in the tanning agents; the supplementary reducing agent becomes another metal ion in the tanning agents after being oxidized; the leather tanning agents containing a plurality of metal ions are prepared through the bridge link between sodium citrate and sodium tartrate.

Owner:JIAXING UNIV

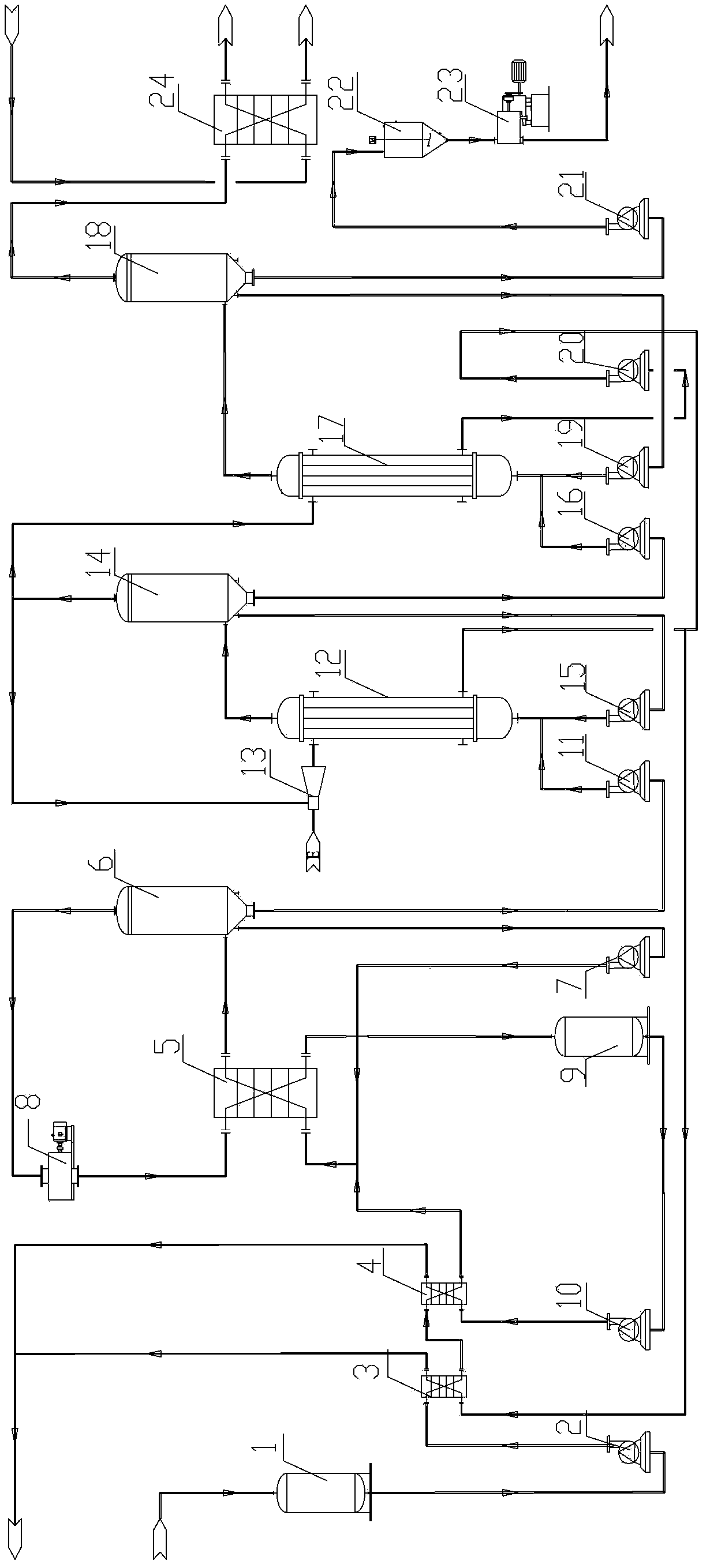

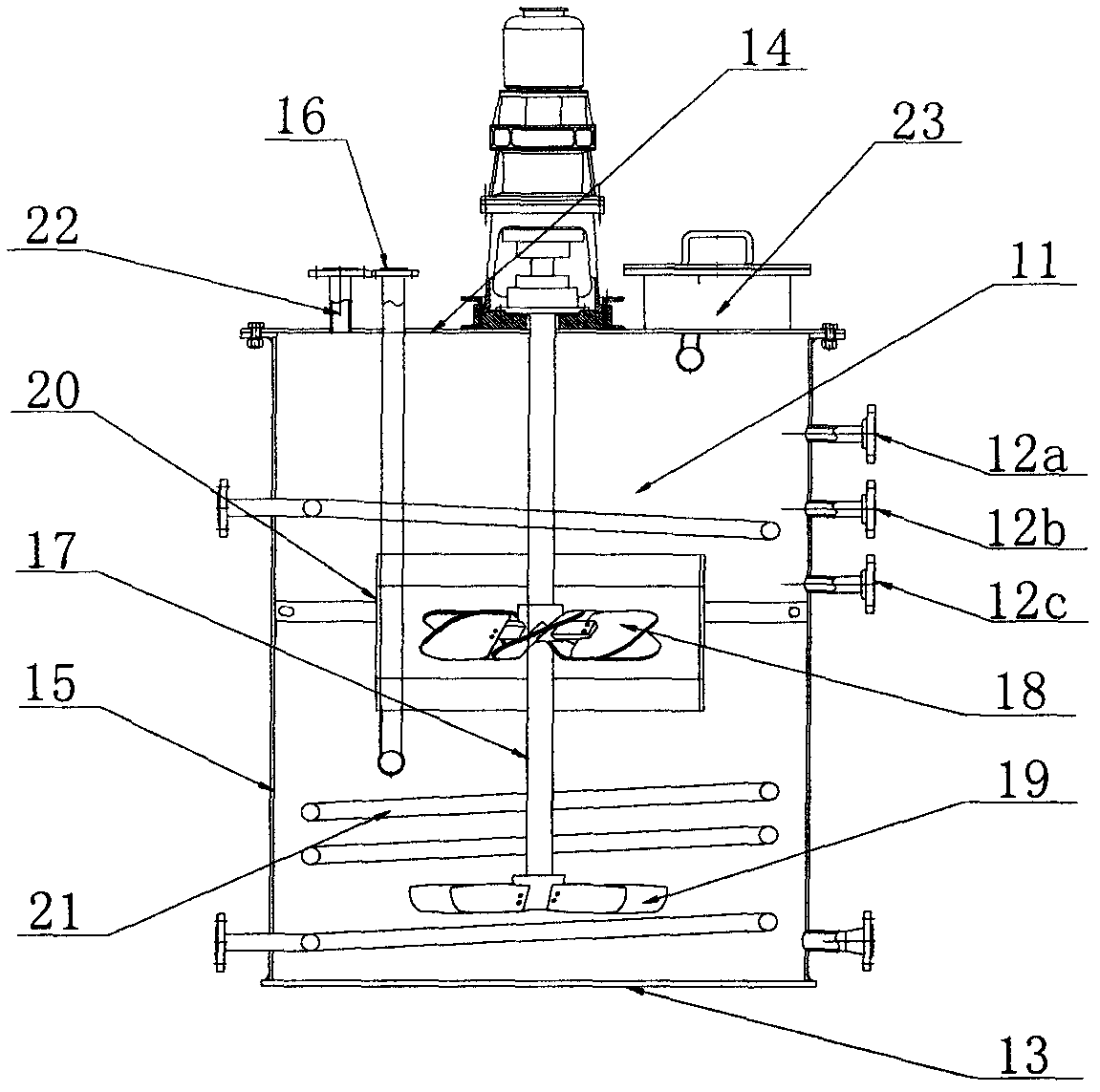

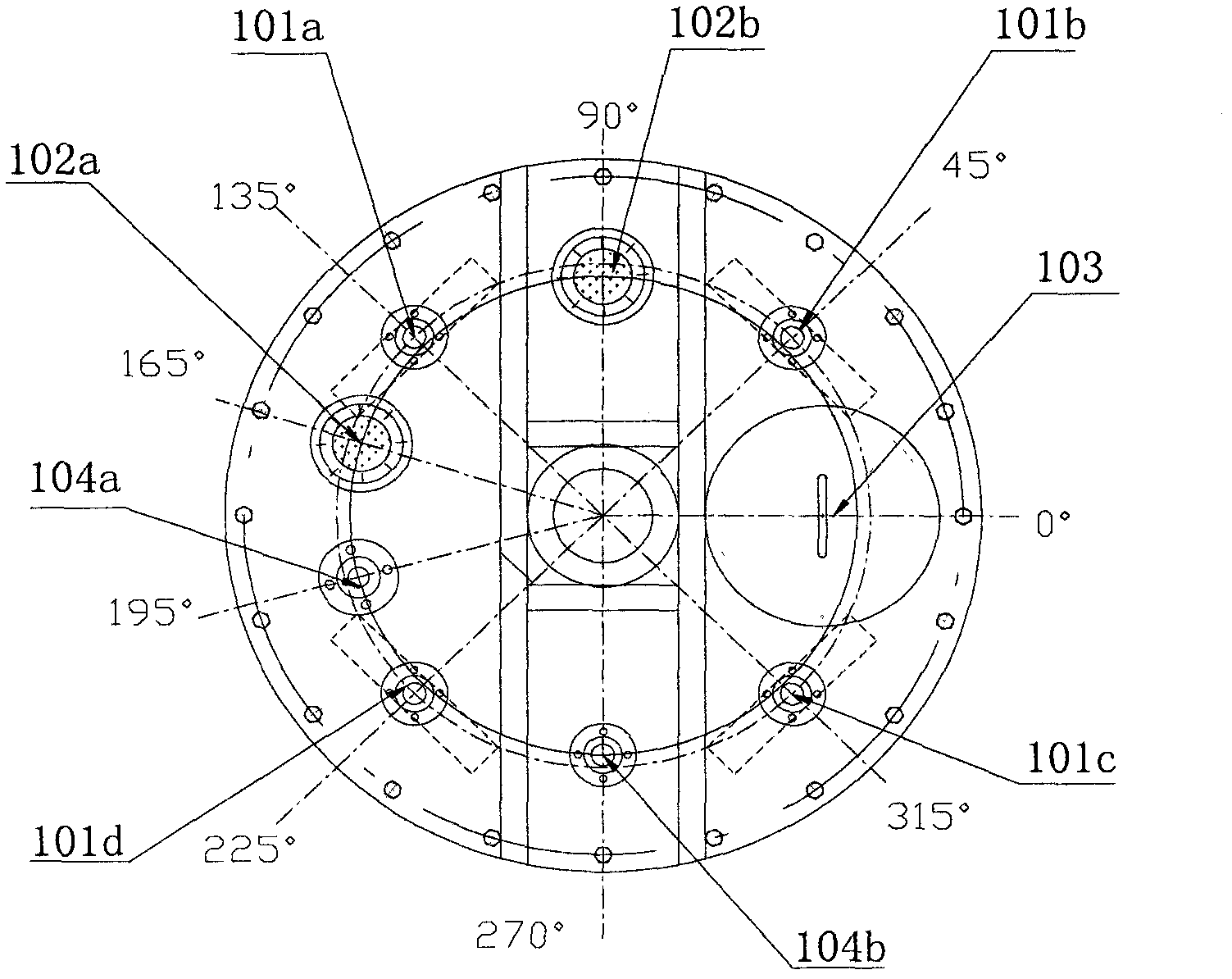

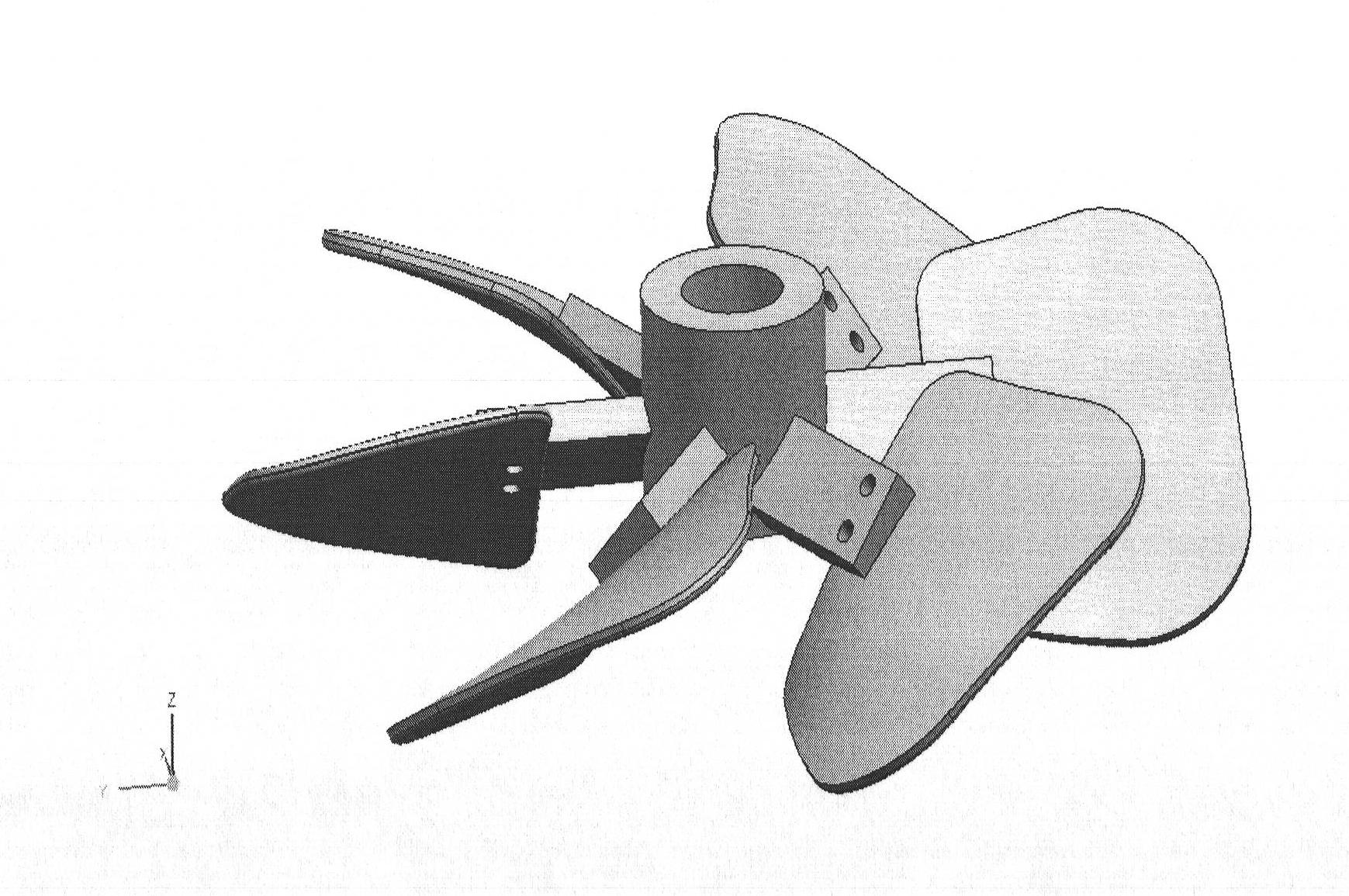

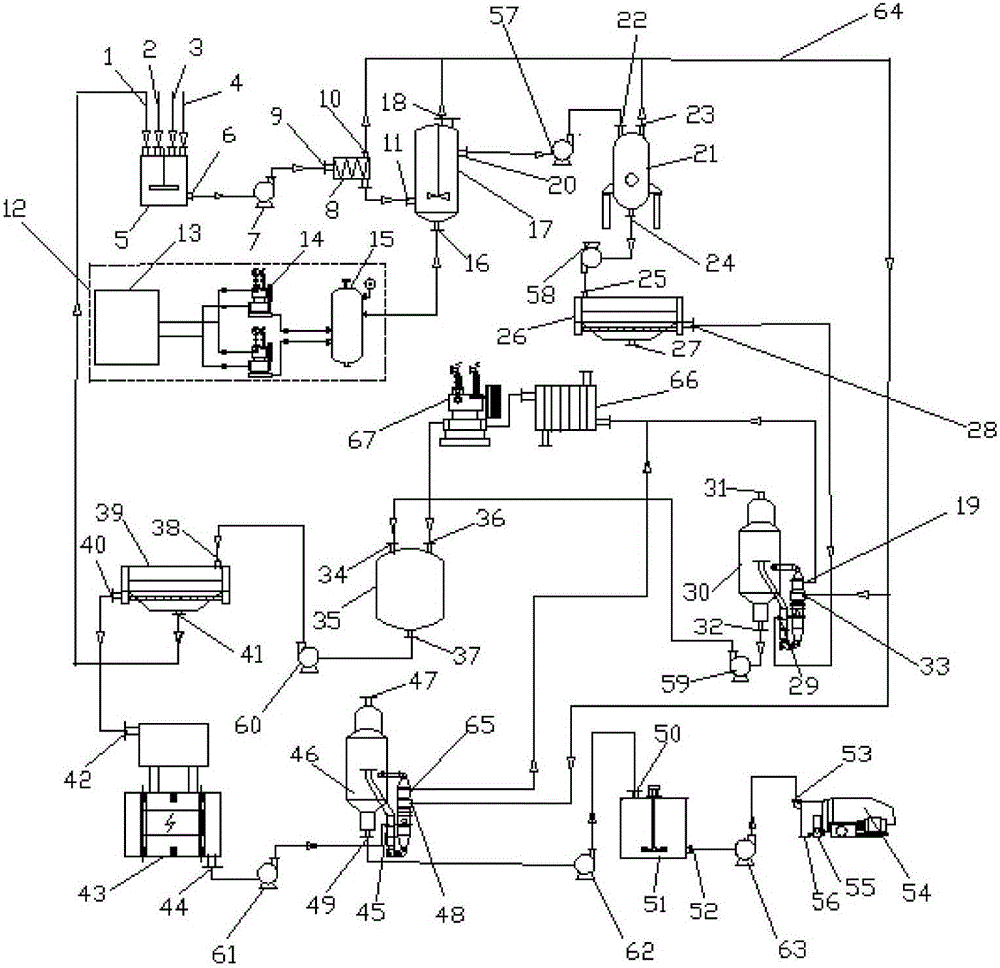

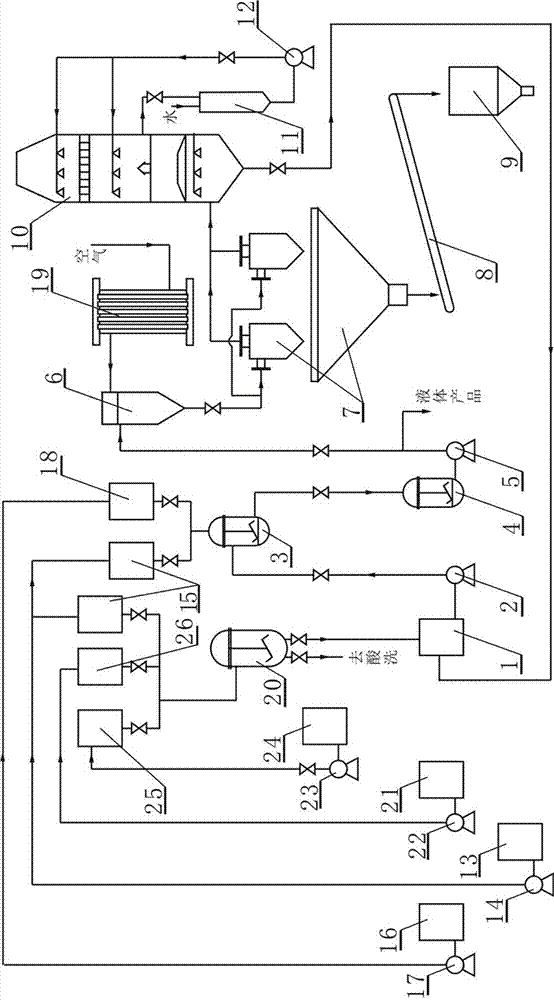

Efficient self-recycling system for continuously preparing sodium bichromate by wet method

ActiveCN105129852ACleaner production achievedFully enclosedChemical industryChromates/bichromatesSodium bicarbonateThermal energy

The invention discloses an efficient self-recycling system for continuously preparing sodium bichromate by a wet method. The system comprises a beating tank, an oxygen supply device, and a first delivery pump, a preheating device, a liquid-phase oxidation reaction device, a flash evaporation device, a first separation device, a first concentration device, a carbonization device, a second separation device, an electrolytic bath, a second concentration device, a cooling crystallization device and a centrifugation device, which are sequentially connected with the beating tank through a feed liquid delivery pipeline, wherein the oxygen supply device is used for introducing oxygen into the liquid-phase oxidation reaction device; CO2 generated by preheating decomposition, CO2 and steam, which are generated by oxidation, and steam generated by flash evaporation can be delivered to the concentration devices, the steam is used for feed liquid concentration, and CO2 is led into the carbonization device for carbonization reaction; chromium-containing sodium bicarbonate obtained by separation in the second separation device can be delivered to the beating tank as an ingredient. According to the system, the byproducts CO2 and steam are used for carbonization and feed liquid concentration and the product sodium bicarbonate is used as the ingredient, so that sodium, CO2 and heat are efficiently self-recycled, and energy waste is reduced.

Owner:SICHUAN YINHE CHEM

Ethylene propylene diene monomer outer sheath for self-limiting electric tracing band

The invention discloses an ethylene propylene diene monomer outer sheath for a self-limiting electric tracing band. The ethylene propylene diene monomer outer sheath is made of the following raw materials in parts by weight: 40-70 parts of ethylene propylene diene monomer, 16-28 parts of methyl phenyl vinyl silicone rubber, 15-32 parts of chloroprene rubber, 1-2.5 parts of sulfur, 4-4.5 parts of 2,5-dimethyl-2,5-di(butylperoxy)hexyne-3-hexine, 0.5-1.8 parts of isocyanuric acid triallyl ester, 0.5-1.5 parts of sodium bichromate, 60-85 parts of modified glass fiber, 10-20 parts of graphite powder, 5-15 parts of high abrasion furnace black, 10-20 parts of talc powder, 5-15 parts of kaolin, 10-20 parts of nanometer aluminum oxide, 1-2.5 parts of antioxidant AT-215, 1-3 parts of sodium lignin sulfonate, 1.2-1.8 parts of di-iso-decylphthalate, 1.2-1.8 parts of polyvinyl butyral, 1.2-1.8 parts of disproportionated rosin and 1.2-1.8 parts of zinc stearate. The ethylene propylene diene monomer outer sheath has high thermal conductivity, high hardness and superior abrasion resistance.

Owner:崇夕山

Concrete waterproof agent

The invention discloses a concrete waterproof agent. The concrete waterproof agent comprises the following chemical components in parts by weight: 0.2-0.8 part of calcium dodecyl benzene sulfonate, 10-30 parts of sulphoaluminate, 20-35 parts of sodium bichromate, 5-10 parts of zinc stearate, 0.25-0.4 part of hexadecyl triethoxysilane, 0.2-0.3 part of propyl triethoxy silane, 0.3-0.4 parts of polyvinylpyrrolidone, 0.2-0.3 part of polyoxyethylene fatty alcohol ester, 0.1-0.2 part of triolein, 0.2-0.8 part of polypropylene fiber and 25-40 parts of water. The concrete waterproof agent is high in penetration ability, good in hydrophobicity, low in corrosivity, waterproof and heat-insulating; through the adoption of the concrete waterproof agent, slope-making and leveling can be realized, and different functions of the concrete waterproof agent can be independently used according to requirements of different construction parts.

Owner:CHINA AERO POLYTECH ESTAB

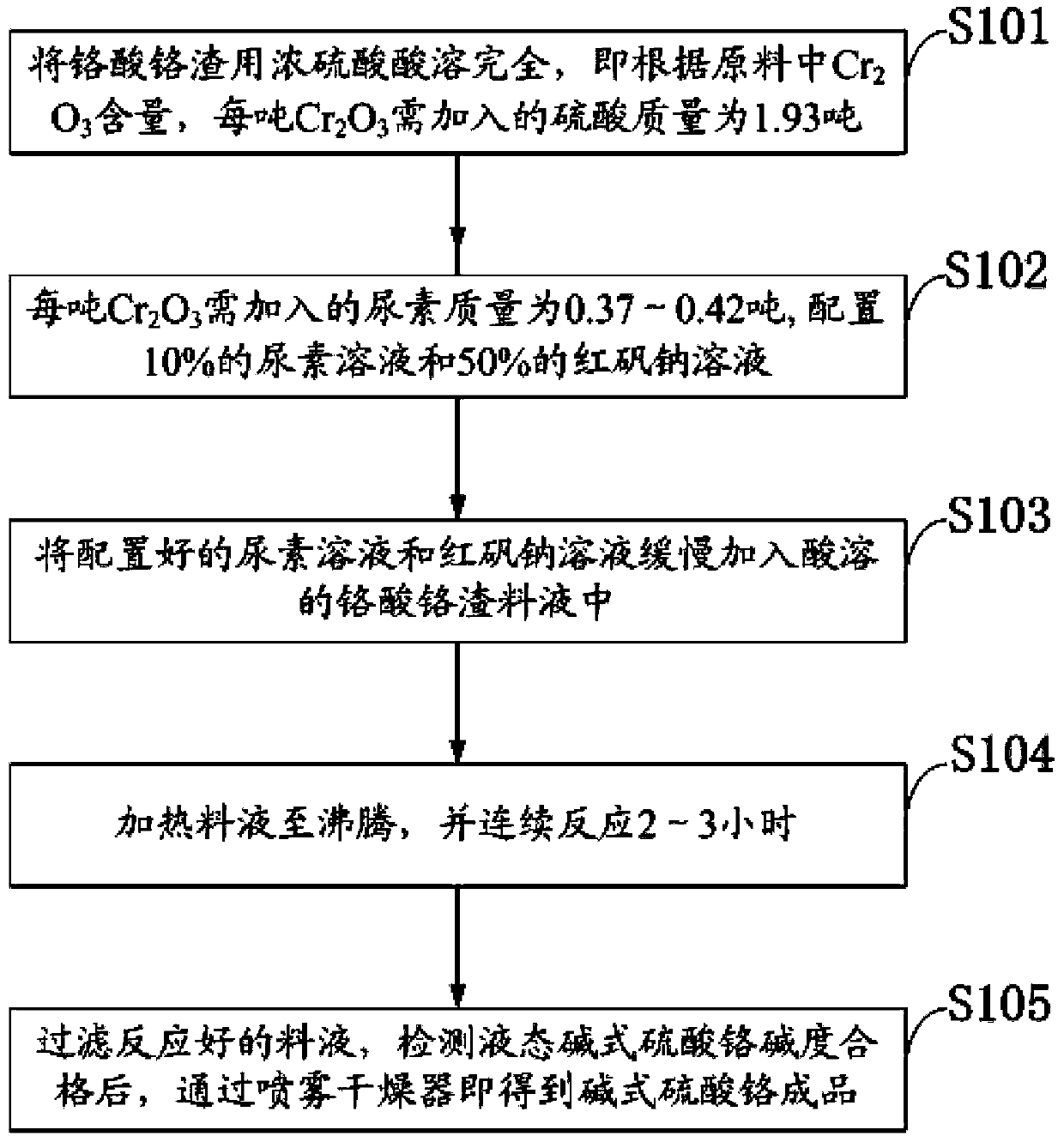

Method for producing basic chrome sulphate with dichromiumtris (chromate) slag

ActiveCN103466708AReduce unit consumptionReduced environmental benefitsChromium sulfatesAlkalinitySlag

The invention discloses a method for producing basic chrome sulphate with dichromiumtris (chromate) slag. The method for producing basic chrome sulphate with the dichromiumtris (chromate) slag comprises the following steps of completely dissolving the dichromiumtris (chromate) slag with concentrated sulfuric acid, that is, adding 1.93t sulfuric acid per ton of Cr2O3 according to a Cr2O3 content in a raw material, adding 0.37-0.42t urea per ton of Cr2O3 to prepare a 10% urea solution and a 50% sodium bichromate solution, slowly adding the prepared urea solution and the sodium bichromate solution into acid soluble dichromiumtris (chromate) slag slurry, heating the slurry to be boiled, performing continuous reaction for 2-3h, filtering the reacted slurry, and after alkalinity of liquid basic chrome sulphate is detected to be qualified, obtaining a basic chrome sulphate finish product through a spray dryer. The method takes the waste dichromiumtris (chromate) slag as a raw material, is environment-friendly, saves resources, reduces unit consumption, produces obvious economic benefits, and provides an energy-saving, environment-friendly and synergetic novel production technology.

Owner:GANSU JINSHI CHEM

Method and device for producing chromium tanning agent by using oxidized waste liquid obtained from S wax production

ActiveCN103642951AStrong transposition effectImprove waterproof performanceTanning treatmentChromium sulfatesLiquid wasteChromium trioxide

The invention discloses a method and device for producing a chromium tanning agent by using oxidized waste liquid obtained from S wax production. The method comprises the steps of carrying out acidification and two-stage oxidation on raw materials, namely lignite wax, sodium bichromate, chromic anhydride (chromium trioxide, CrO3) and sulfuric acid, so as to obtain the oxidized waste liquid; treating the oxidized waste liquid by using glucose serving as a reducing agent in a manner that glucose cooperates with sodium bichromate, so as to obtain a chromium tanning solution; drying and dewatering the chromium tanning solution, thereby obtaining the chromium tanning agent. The device comprises an oxidized waste liquid storage tank, an oxidized liquid reduction device, a chromium tanning agent recovery device, a high-position liquid supplying device and a supporting liquid distribution device. According to the method, the chromium tanning agent (alkaline chromic sulfate-chromium powder tanning agent) is prepared through reducing the chromium-containing oxidized waste liquid, formed during the production of S wax from lignite wax, by using glucose which cooperates with sodium bichromate, and tanned leather is plump, soft and elastic. According to the method and the device, the process is simple and energy-saving, the consumption of sulfuric acid and glucose is low, and the device is easy to implement, so that the large-scale, continuous and automated production can be realized.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Insect prevention pesticide

InactiveCN106342918ABroad insecticidal spectrumEasy to useBiocideAnimal repellantsWaxSodium stearate

The invention discloses insect prevention pesticide. The insect prevention pesticide comprises, by weight, 2-4 parts of 1-decanol, 3-5 parts of folium artemisiae argyi, 4-6 parts of melia azedarach leaves, 5-7 parts of sodium stearate, 3-5 parts of sodium bichromate, 4-6 parts of efficient cyfluthrin, 5-7 parts of bismerthiazol, 4-6 parts of tridemorph and 20-30 parts of agastache rugosus qi-guiding water. The insect prevention pesticide is non-toxic, safe in use, obvious in insect prevention effect on wax apples, harmless to human being, cattle, fruit and branches in spraying, wide in raw material, easy in production and low in cost.

Owner:青岛悦邦农种业有限公司

Cleaning agent

InactiveCN102994268ARaw materials are easy to getLow priceAnionic-cationic-non-ionic surface-active compoundsGlycerolPotassium hydroxide

A cleaning agent is formed by mixing the following standby raw materials by weight percent: 50-80 of disodium of 1-hydroxy ethylidene-1, 1-diphosphonic acid, 17-26 of bentonite, 2-5 of lauric acid, 1-3 of fatty alcohol-polyoxyethylene ether, 2-6 of sodium glycollate, 4-7 of coconut fatty acid diethanol amide, 1-3 of sodium oxalate, 3-5 of sodium gluconate, 4-9 of potassium hydroxide, 25-30 of magnesium stearate or zinc stearate, 15-20 of glycerol, 2-6 of sodium bichromate, 1-10 of ethylene glycol and 35-40 of water. The cleaning agent is prepared from easily obtained raw materials, is low in price and has a good cleaning effect.

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

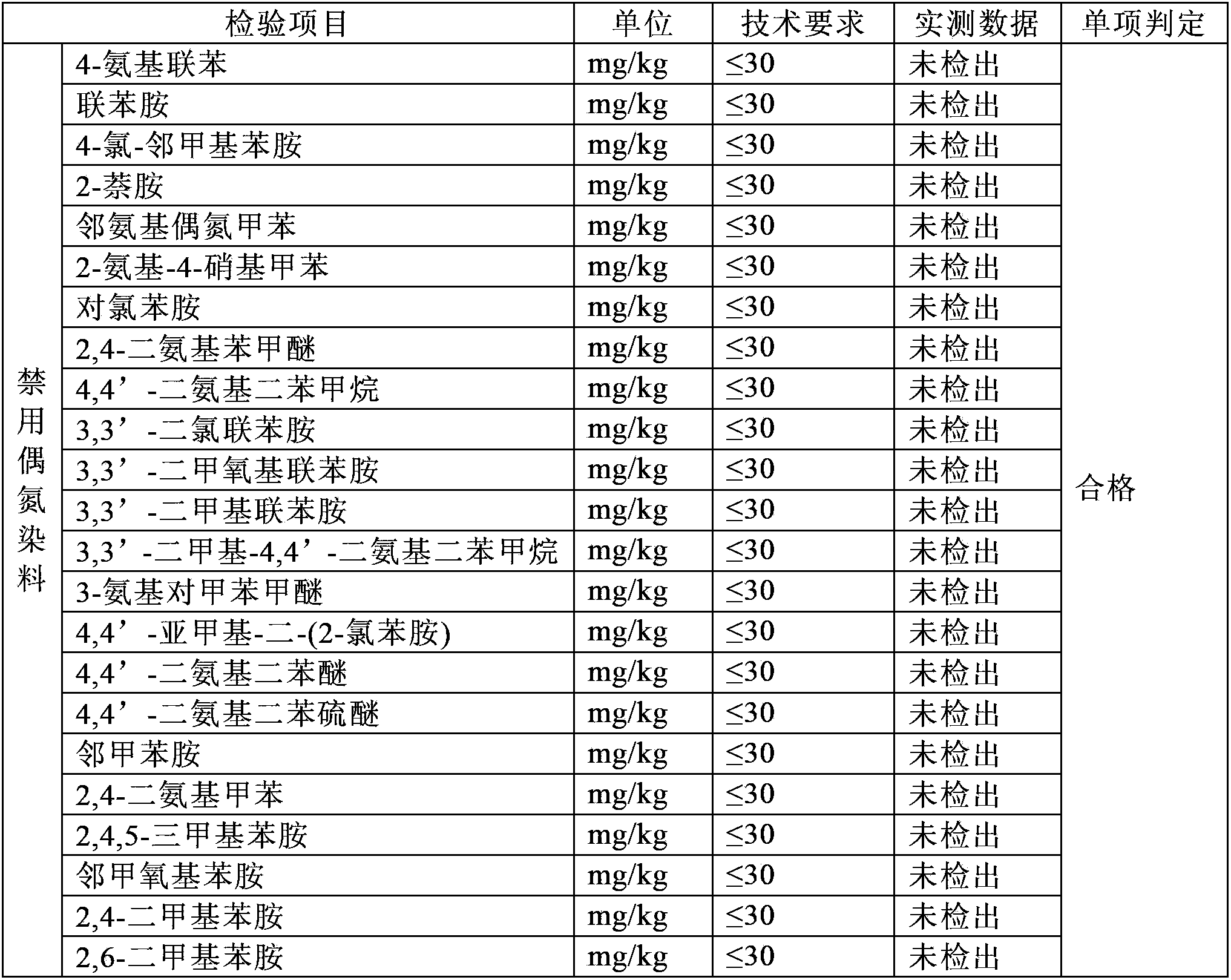

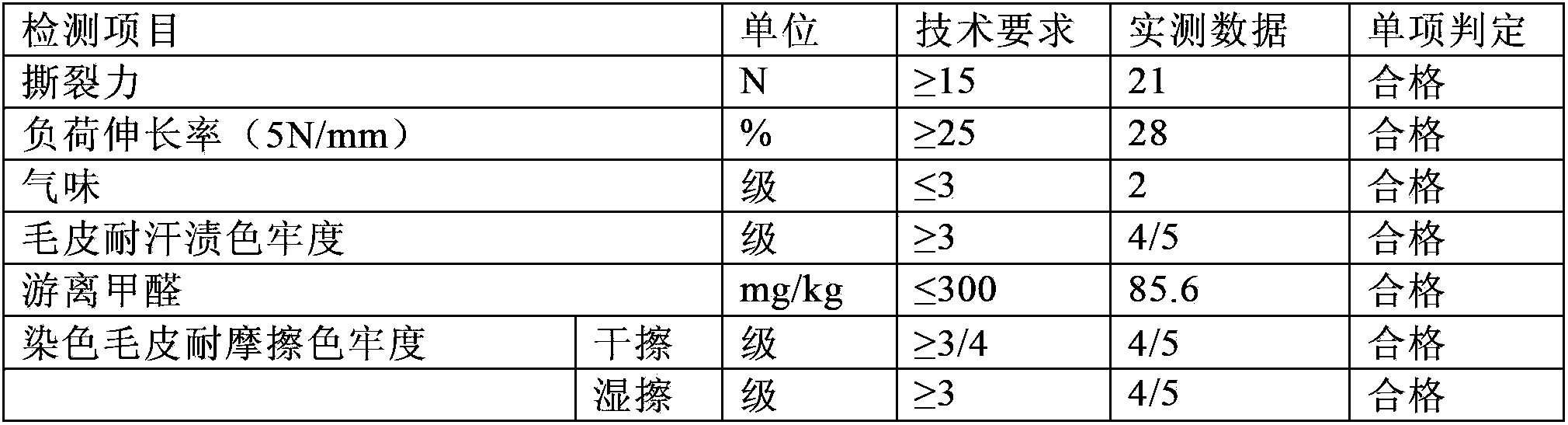

Recycling method of fur oxidation dyeing chrome mordant dye liquor

The invention discloses a recycling method of fur oxidation dyeing chrome mordant dye liquor, which comprises the following steps: preparing new mordant dye liquor, adding fur and performing mordant dyeing; performing microfiltration treatment on fur chrome mordant dyeing waste liquid by use of filter cloth to remove impurities; and supplementing sodium bichromate or potassium bichromate, industrial salt and a penetrant, so that the chrome mordant dye liquor can be recycled repeatedly, and the pollution of bichromate is remarkably alleviated. According to statistics, by the method disclosed by the invention, the recycling frequency of the chrome mordant dye liquor can exceed 100 times, the bichromate is saved by 20%-40%, the industrial salt is saved by 50%-75%, the penetrant is saved by over 90%, and water is saved by over 70%, thereby greatly reducing the production cost and remarkably alleviating environmental pollution.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com