Thickened oil thermal production channel blocking nano-composite gel

A heavy oil thermal recovery and nano-composite technology, which is applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of reducing crude oil production, and achieve the effects of ensuring heavy oil production, good stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

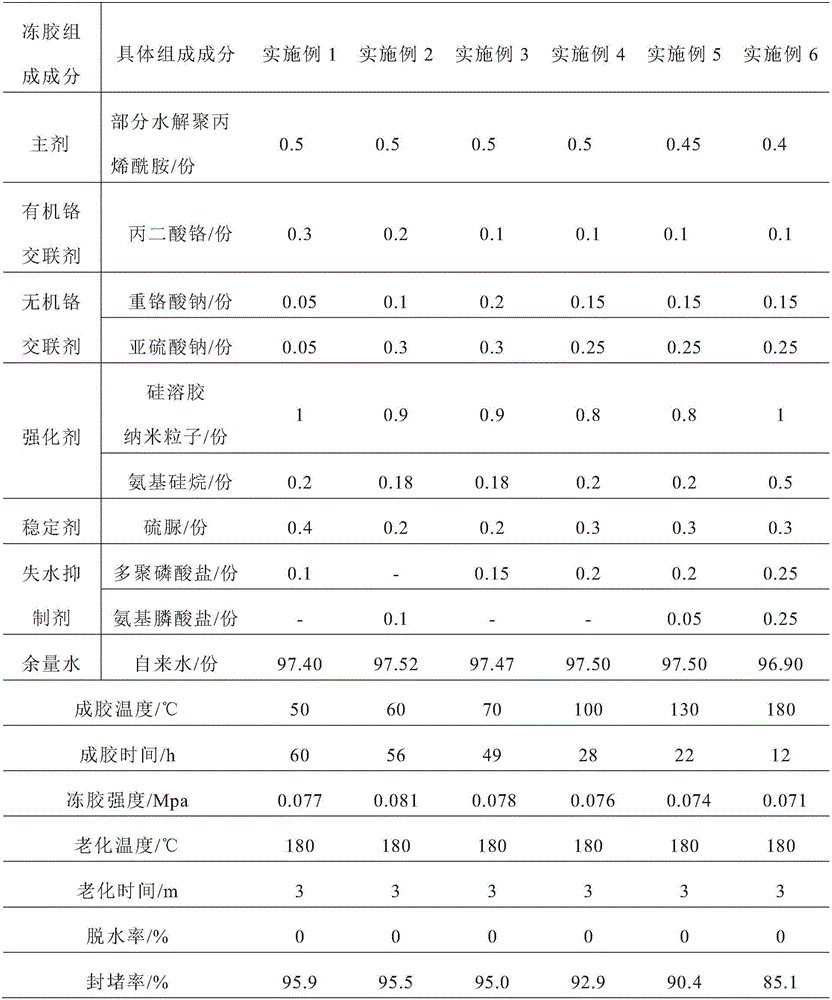

Embodiment 1

[0036] Add 0.05 part of sodium dichromate, 0.05 part of sodium sulfite, 0.3 part of chromium malonate, 1 part of silica sol nanoparticles, 0.2 part of aminosilane, 0.4 part of thiourea, and 0.1 part of polyphosphate into 47.9 parts of tap water, and stir well , make it fully dissolved, and then mix 50 parts of partially hydrolyzed polyacrylamide with a mass concentration of 1% prepared by tap water with the above solution, and stir evenly to obtain the gelling solution of the present invention. The gelling time of the gelling solution is 60 hours at 50° C., and the obtained jelly strength (measured by the vacuum breakthrough method) is 0.077 MPa, and there is no dehydration phenomenon after aging at 180° C. for 3 months.

[0037] Taking the above-mentioned nano-composite jelly for thermal recovery sealing of heavy oil as the research object, physical simulation experiments are conducted to illustrate the sealing ability of the thermal recovery sealing jelly for steam. The sand...

Embodiment 2

[0039] Add 0.1 part of sodium dichromate, 0.3 part of sodium sulfite, 0.2 part of chromium malonate, 0.9 part of silica sol nanoparticles, 0.18 part of aminosilane, 0.2 part of thiourea, and 0.1 part of aminophosphonate into 48.02 parts of tap water, and stir well , make it fully dissolved, and then mix 50 parts of partially hydrolyzed polyacrylamide with a mass concentration of 1% prepared by tap water with the above solution, and stir evenly to obtain the gelling solution of the present invention. The gelling time of the gelling liquid was 56 hours at 60° C., the strength of the obtained jelly was 0.081 MPa, and there was no dehydration phenomenon after aging at 180° C. for 3 months.

[0040] Taking the above-mentioned nano-composite jelly for thermal recovery sealing of heavy oil as the research object, physical simulation experiments are conducted to illustrate the sealing ability of the thermal recovery sealing jelly for steam. The sand filling pipe used in this test has ...

Embodiment 3

[0042] Add 0.2 part of sodium dichromate, 0.3 part of sodium sulfite, 0.1 part of chromium malonate, 0.9 part of silica sol nanoparticles, 0.18 part of aminosilane, 0.2 part of thiourea, and 0.15 part of polyphosphate into 47.97 parts of tap water, and stir well , make it fully dissolved, and then mix 50 parts of partially hydrolyzed polyacrylamide with a mass concentration of 1% prepared by tap water with the above solution, and stir evenly to obtain the gelling solution of the present invention. The gelling time of the gelling solution was 49 hours at 70° C., and the strength of the obtained jelly was 0.078 MPa. There was no dehydration phenomenon after aging at 180° C. for 3 months.

[0043] Taking the above-mentioned nano-composite jelly for thermal recovery sealing of heavy oil as the research object, physical simulation experiments are conducted to illustrate the sealing ability of the thermal recovery sealing jelly for steam. The sand filling pipe used in this test has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com