Method for producing basic chrome sulphate with dichromiumtris (chromate) slag

A technology of chromium chromate slag and chromium sulfate, applied in the direction of chromium sulfate and the like, can solve the problems of low environmental protection benefit, high unit consumption, unfavorable energy saving and emission reduction, etc., and achieve the effect of saving resources, reducing unit consumption and solving environmental protection problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

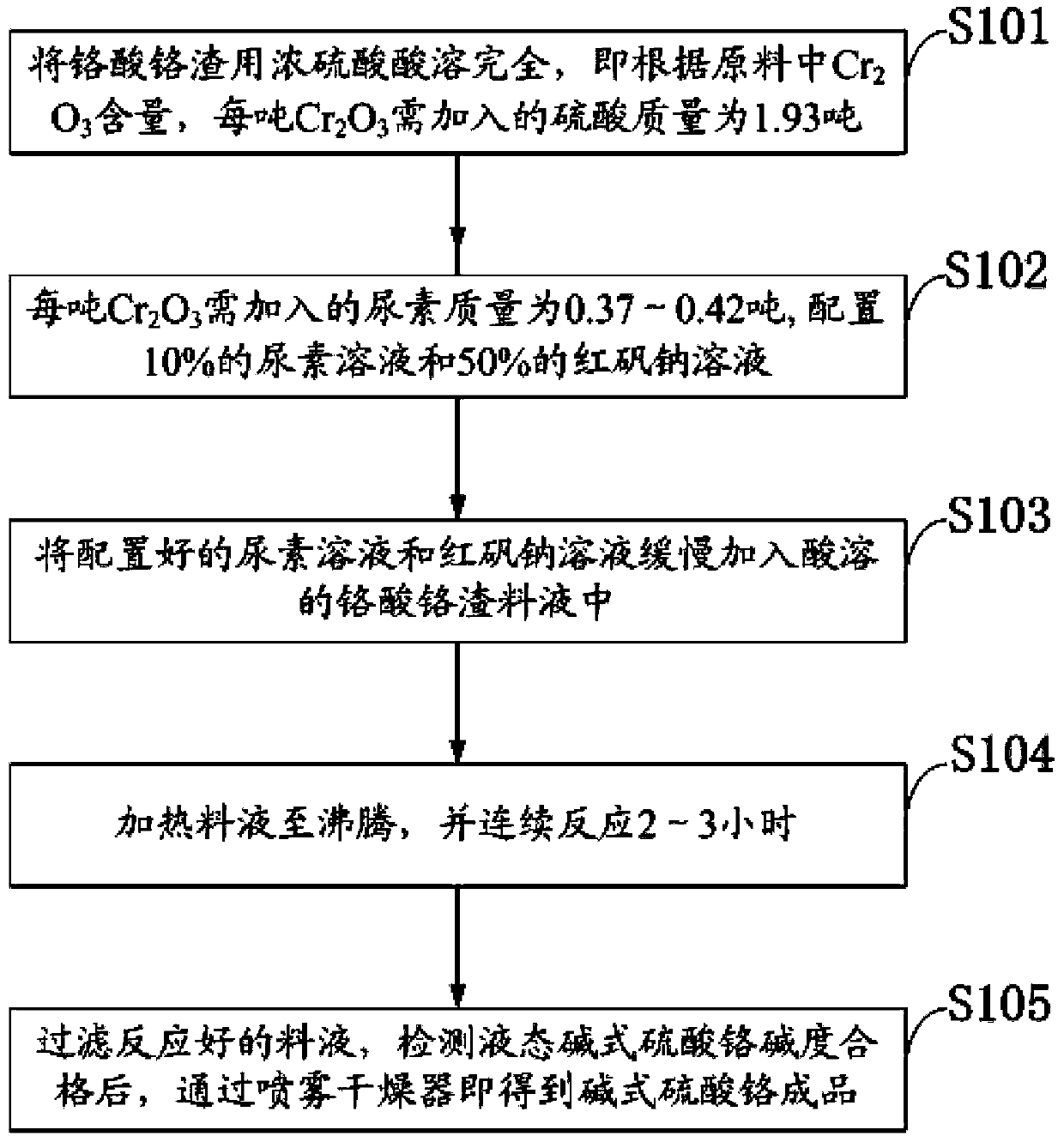

Method used

Image

Examples

Embodiment 1

[0062] In the first step, 500Kg of chromate slag (Cr 2 o 3 Content: 8.58%) with 610Kg industrial concentrated sulfuric acid (content 93.5%) acid-dissolved completely;

[0063] Second step, 110Kg urea is dissolved in 1100Kg water and is configured into urea solution, and 500Kg sodium rufium is dissolved in 1000Kg water and is configured into sodium rufium solution;

[0064] In the third step, slowly add the configured urea solution and the sodium red alum solution into the acid-soluble chromate slag feed liquid;

[0065] The 4th step, heating feed liquid to boiling, and continuous reaction 2 hours;

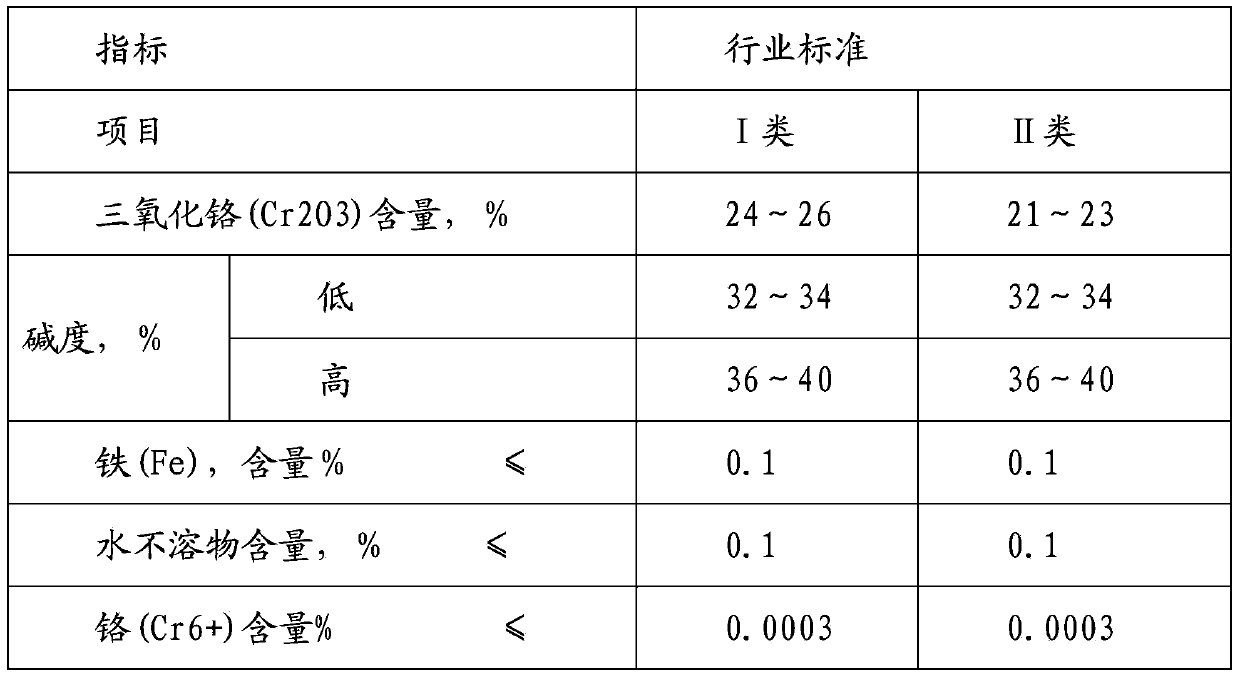

[0066] The fifth step is to filter the reacted feed liquid, and the filtrate is liquid basic chromium sulfate. After testing the basicity of the liquid basic chromium sulfate, the finished product of basic chromium sulfate is obtained through a spray dryer. The results of the full analysis of the finished product are as follows:

[0067] content

[0068] After inspect...

Embodiment 2

[0070] In the first step, 500Kg of chromate slag (Cr 2 o 3 Content: 8.58%) with 615Kg industrial concentrated sulfuric acid (content 93.5%) acid-dissolved completely;

[0071] Second step, 119Kg urea is dissolved in 1190Kg water and is configured into urea solution, and 500Kg red alum sodium is dissolved in 1000Kg water and is configured into red alum sodium solution;

[0072] In the third step, slowly add the configured urea solution and the sodium red alum solution into the acid-soluble chromate slag feed liquid;

[0073] The 4th step, heating feed liquid to boiling, and continuous reaction 2.5 hours;

[0074] The fifth step is to filter the reacted feed liquid, and the filtrate is liquid basic chromium sulfate. After testing the basicity of the liquid basic chromium sulfate, the finished product of basic chromium sulfate is obtained through a spray dryer. The results of the full analysis of the finished product are as follows:

[0075] content

[0076] After i...

Embodiment 3

[0078] In the first step, 500Kg of chromate slag (Cr 2 o 3 Content: 8.58%) with 620Kg industrial concentrated sulfuric acid (content 93.5%) acid-dissolved completely;

[0079] Second step, 125Kg urea is dissolved in 1250Kg water and is configured into urea solution, gets workshop sodium dichromate content and is 400L of red alum sodium acidification solution of 1250g / l, then adds 800Kg water and is diluted into red alum sodium solution;

[0080] In the third step, slowly add the configured urea solution and the sodium red alum solution into the acid-soluble chromate slag feed liquid;

[0081] The 4th step, heating feed liquid to boiling, and continuous reaction 3 hours;

[0082] The fifth step is to filter the reacted feed liquid, and the filtrate is liquid basic chromium sulfate. After testing the basicity of the liquid basic chromium sulfate, the finished product of basic chromium sulfate is obtained through a spray dryer.

[0083] The results of the full analysis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com