Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Basic chromium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

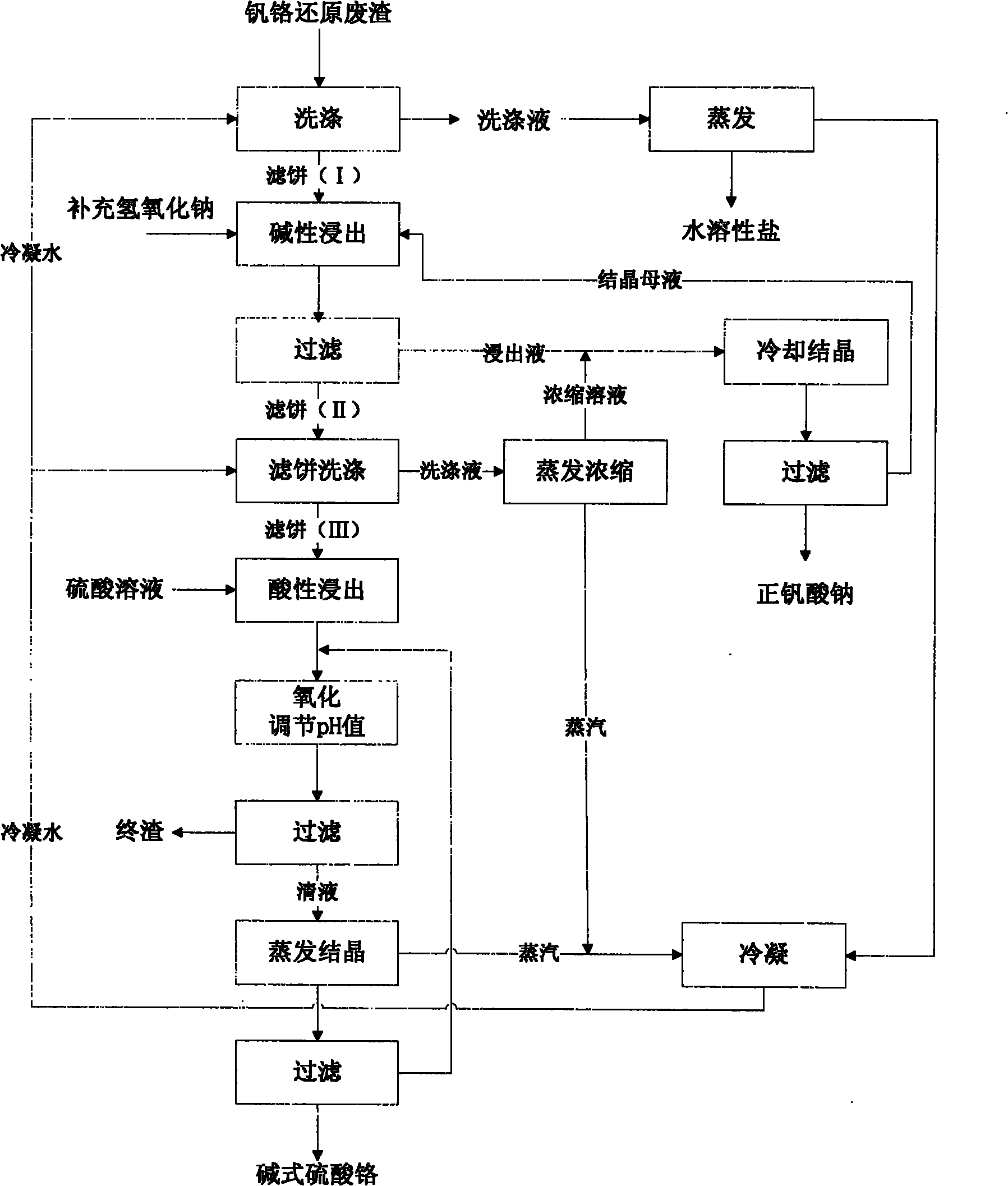

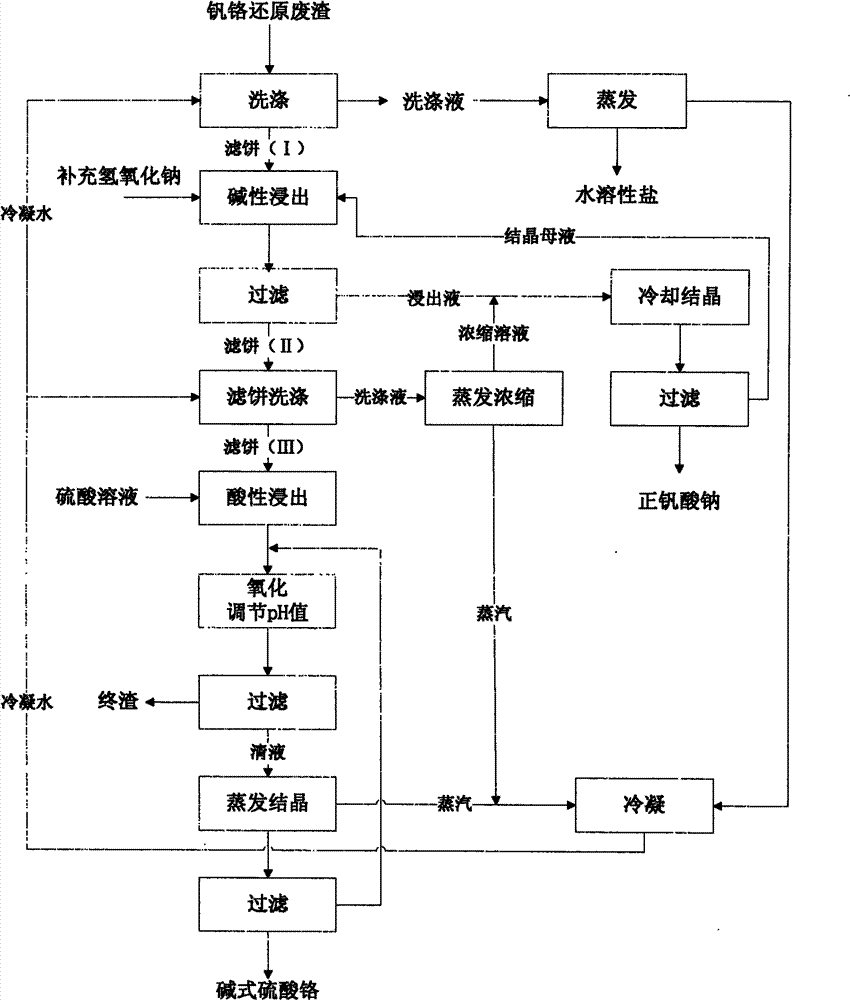

Method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue

ActiveCN102329964ASimple processEase of industrial productionProcess efficiency improvementWater solubleSodium orthovanadate

The invention relates to a method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue. The method comprises the following main steps of: after removing water-soluble salts through slurrying and washing, extracting vanadium from the rest vanadium-chromium reduced waste residue by oxidizing in an alkaline solution; meanwhile, realizing the vanadium-chromium separation; cooling and crystallizing a leaching solution to obtain obtaining a sodium orthovanadate product; carrying out acid leaching on the vanadium-chromium reduced waste residue subjected to vanadium extraction; and preparing a basic chromium sulfate product after removing impurities, evaporating and crystallizing. According to the invention, the purity of the sodium orthovanadate product prepared by the method is higher than 93%, the content of Cr2O3 in the basic chromium sulfate can reach 24%, the content of Fe is lower than 0.1%, and the requirements on the basic chromium sulfate I type product in the HG / T 2678-2007 are met.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

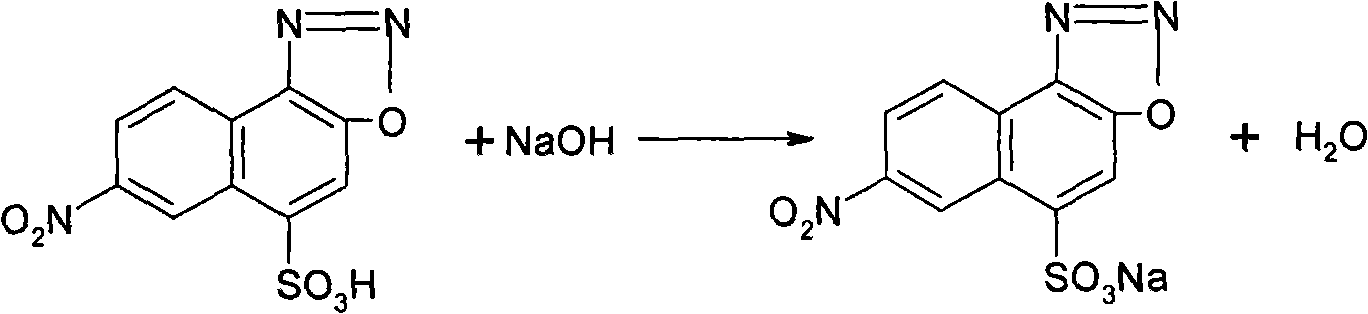

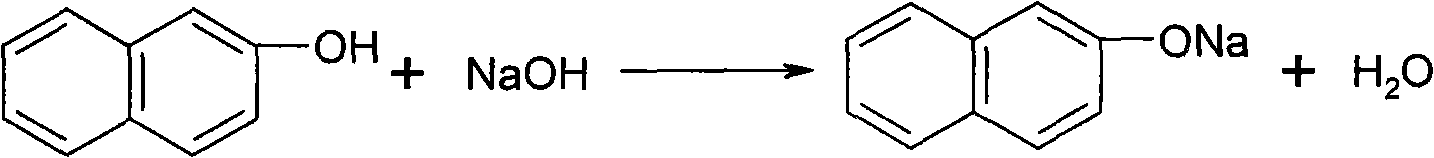

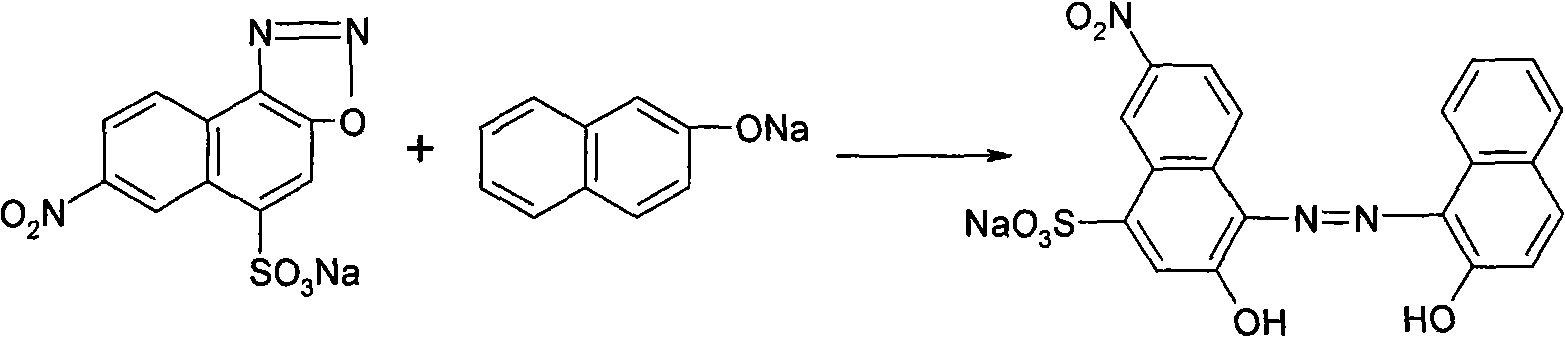

Method for preparing acid black 172

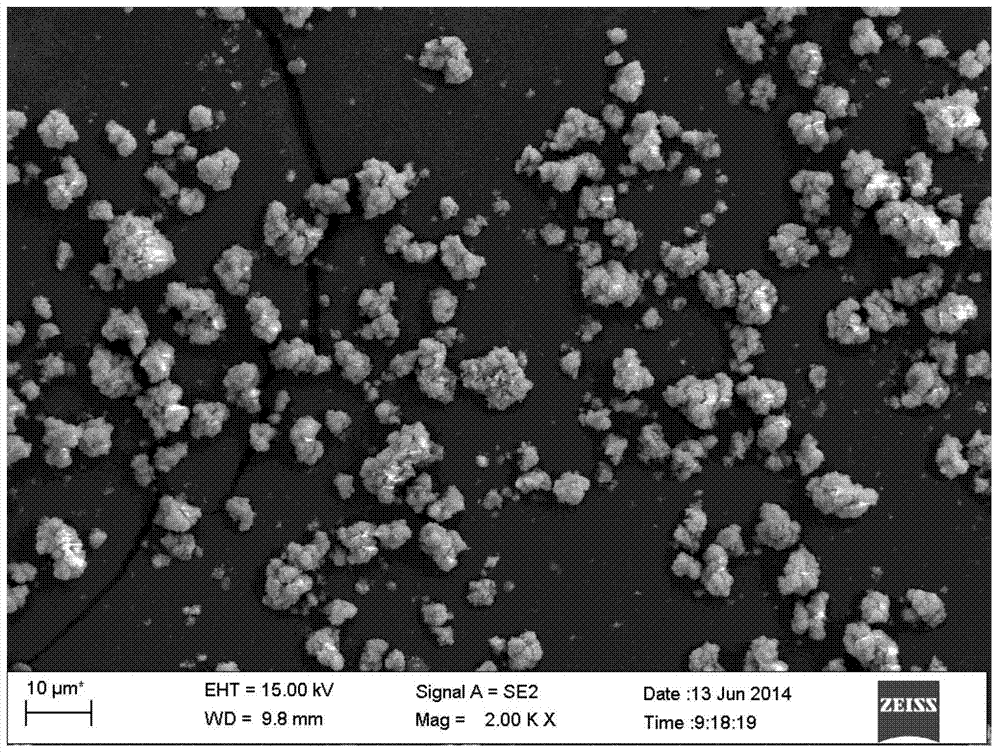

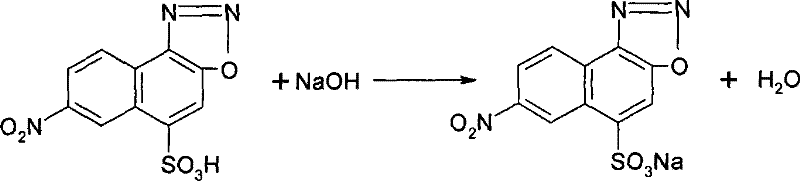

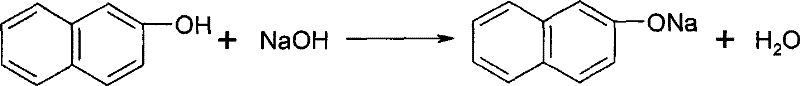

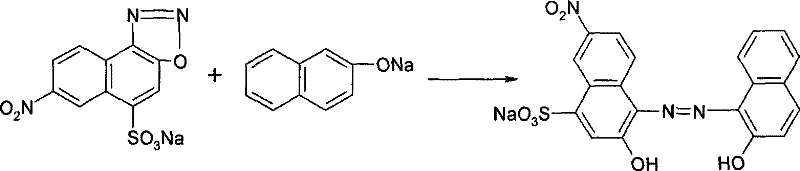

InactiveCN101538414AReduce viscosityIncrease concentrationDyeing processComplex metal azo dyesSodium bicarbonateDissolution

The invention relates to a method for preparing acid black 172. The method comprises the following steps that: (1) 6-nitro-1 and 2-diazoxynaphthalene-4-sulfonic acid are put into a dissolution tank, added with water for dissolution, added with a sodium hydroxide solution and stirred. (2) 2-naphthol is put into the dissolution tank, added with water for dissolution, added with the sodium hydroxide solution, stirred, heated, added with a dispersant and aliphatic diol or ether and stirred again; (3) a prepared 2-naphthol solution is rapidly put into and coupled with a solution with 6-nitro-1 and 2-diazoxynaphthalene-4-sulfonic acid so as to obtain coupled liquid; and (4) the coupled liquid is added with formic acid, ammonium bicarbonate or sodium bicarbonate and basic chromium sulfate, heated to be between 100 and 102 DEG C, thermally insulated and stirred so as to obtain an acid black 172 serous finished product. The method for preparing acid black 172 has the advantages of simple production process, scientific reasonable control on reaction conditions, short production cycle of produces, high yield, good quality, friction resistance, obviously raised fastness of resisting rinse and sunshine, obviously reduced side reaction and impurities, low production cost, high production efficiency and better environment-friendly property.

Owner:TIANJIN SANHUAN CHEM

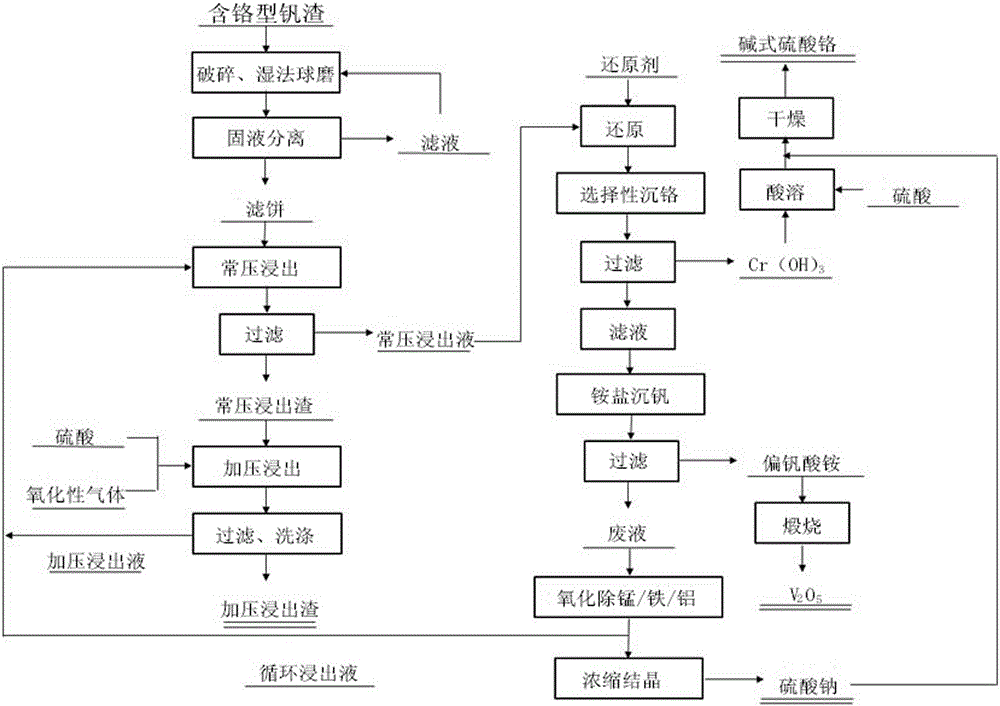

Method for carrying out two-stage countercurrent leaching on chromium-containing vanadium slag and extracting vanadium and chromium in separating manner

ActiveCN105695760AReduce consumptionImprove resource utilizationProcess efficiency improvementSlagResource utilization

The invention belongs to the technical field of wet metallurgy, and particularly relates to a method for carrying out two-stage countercurrent leaching on chromium-containing vanadium slag and extracting vanadium and chromium in a separating manner. The method comprises the following steps: carrying out atmospheric pressure leaching on the chromium-containing vanadium slag at first; leaching under pressure and selectively carrying out chromium depositing; then preparing basic chromium sulfate and V2O5; after removing manganese, iron, aluminum and impurities from waste liquid generated in the process by oxidation, carrying out evaporative crystallization on part of an obtained solution to obtain sodium sulfate; and returning the other part of the obtained solution as a circulating leaching liquid to the atmospheric pressure leaching procedure. A step-by-step extracting path of extracting chromium at first and then extracting vanadium is adopted, in the chromium extracting process, the vanadium is hardly extracted, vanadium and chromium separation rate is greater than 99%, finally, vanadium and chromium resource utilization rate is increased, the leaching rate of the vanadium is greater than 95%, and the leaching rate of the chromium is greater than 92%.

Owner:NORTHEASTERN UNIV

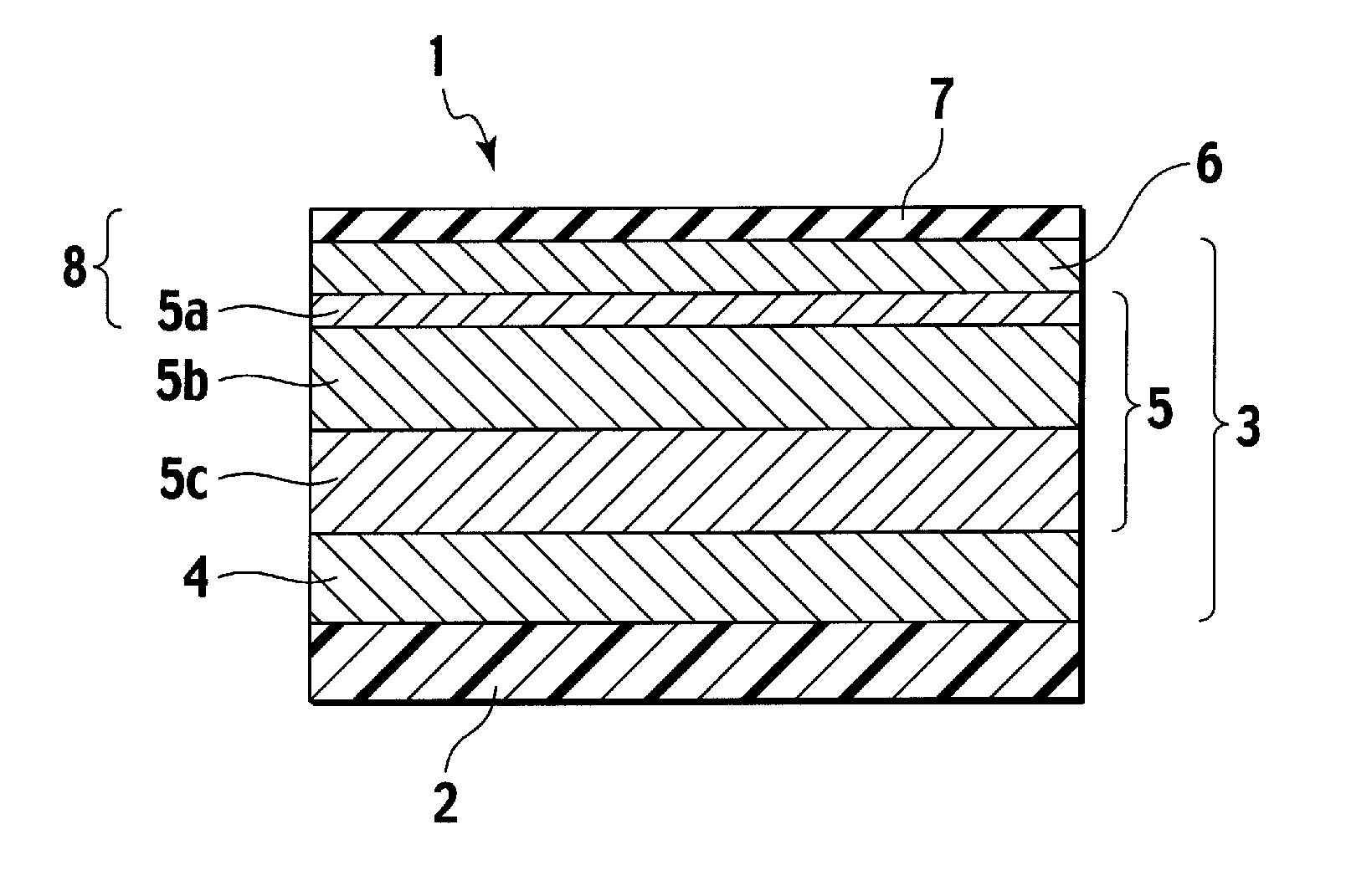

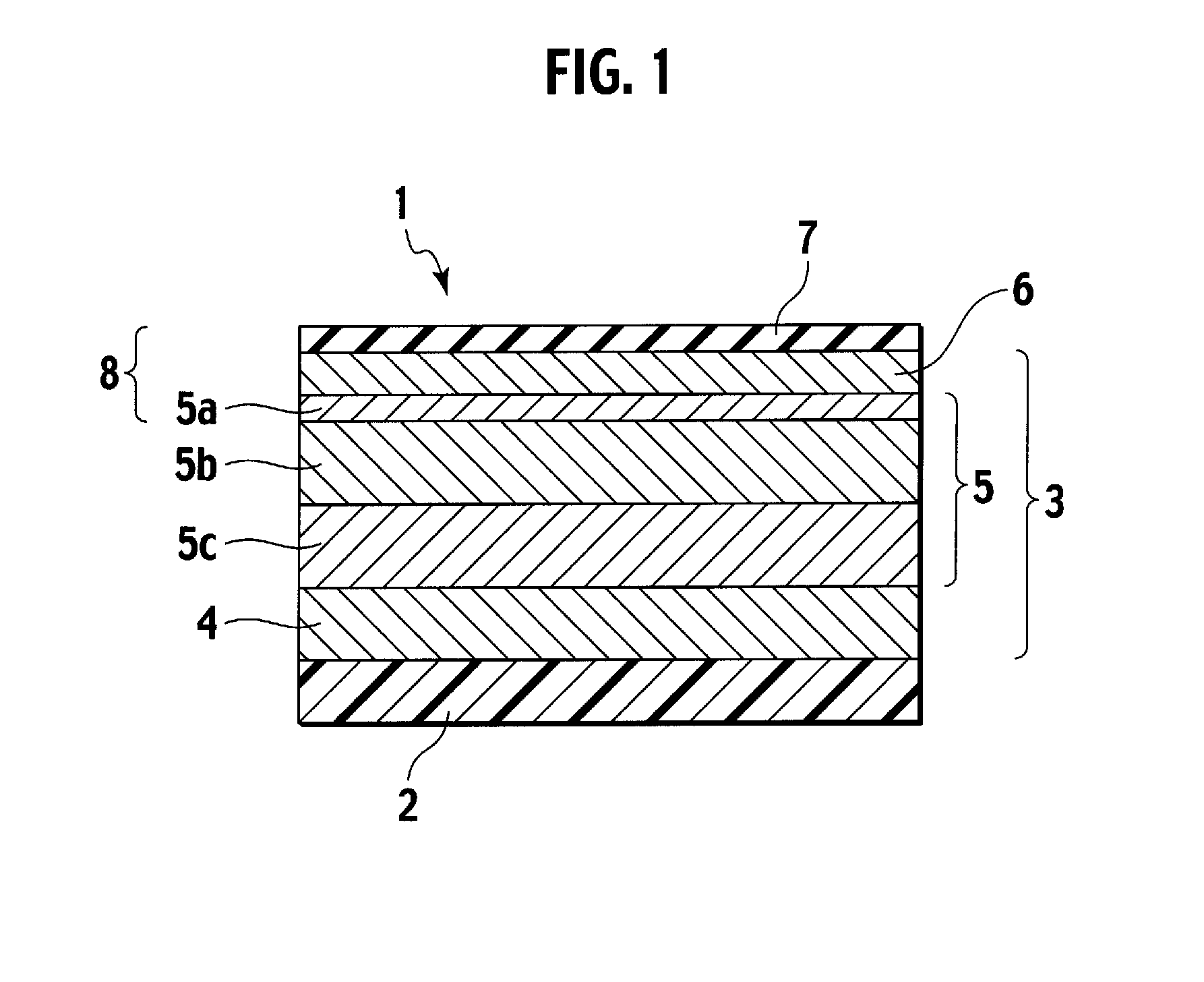

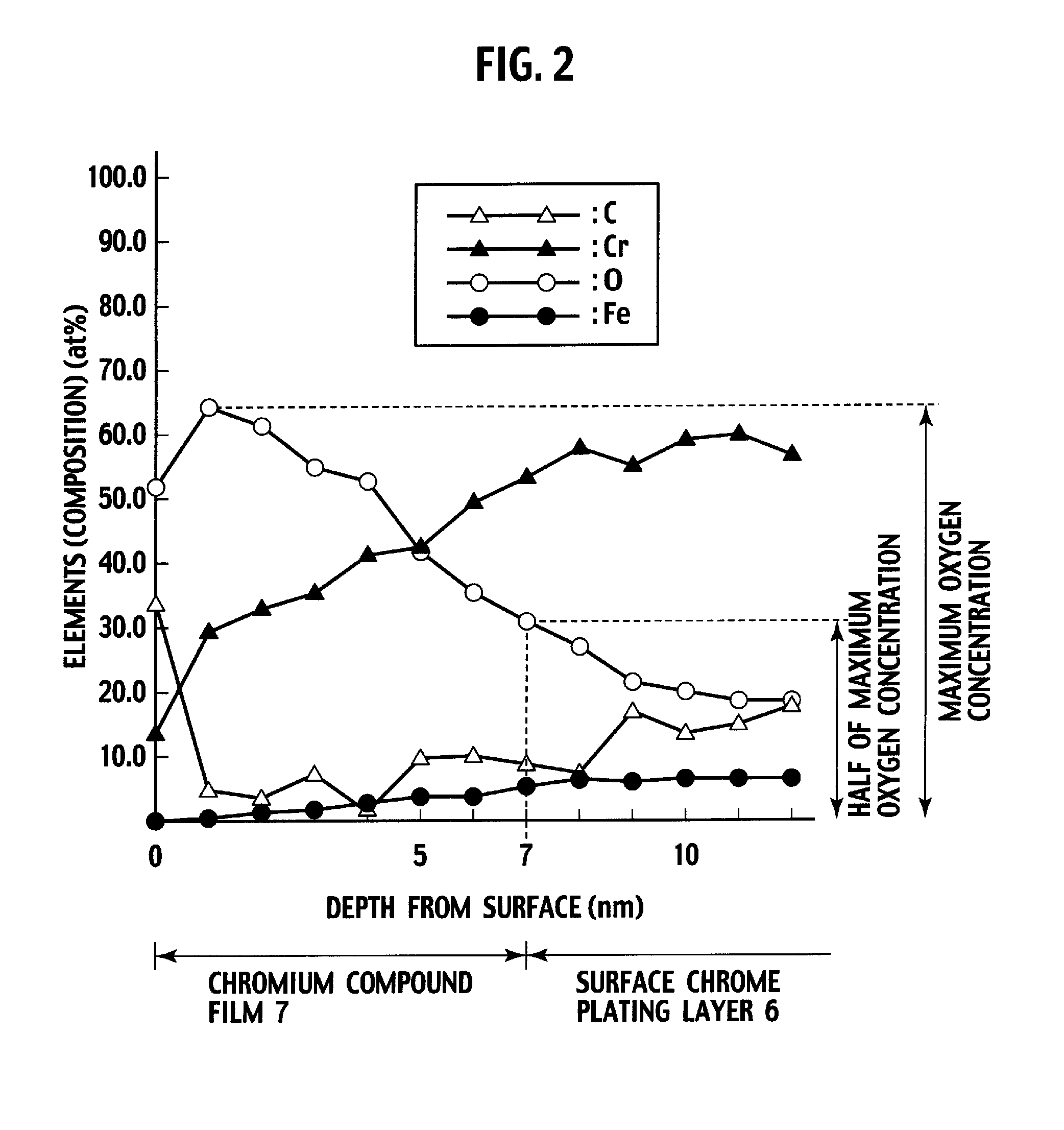

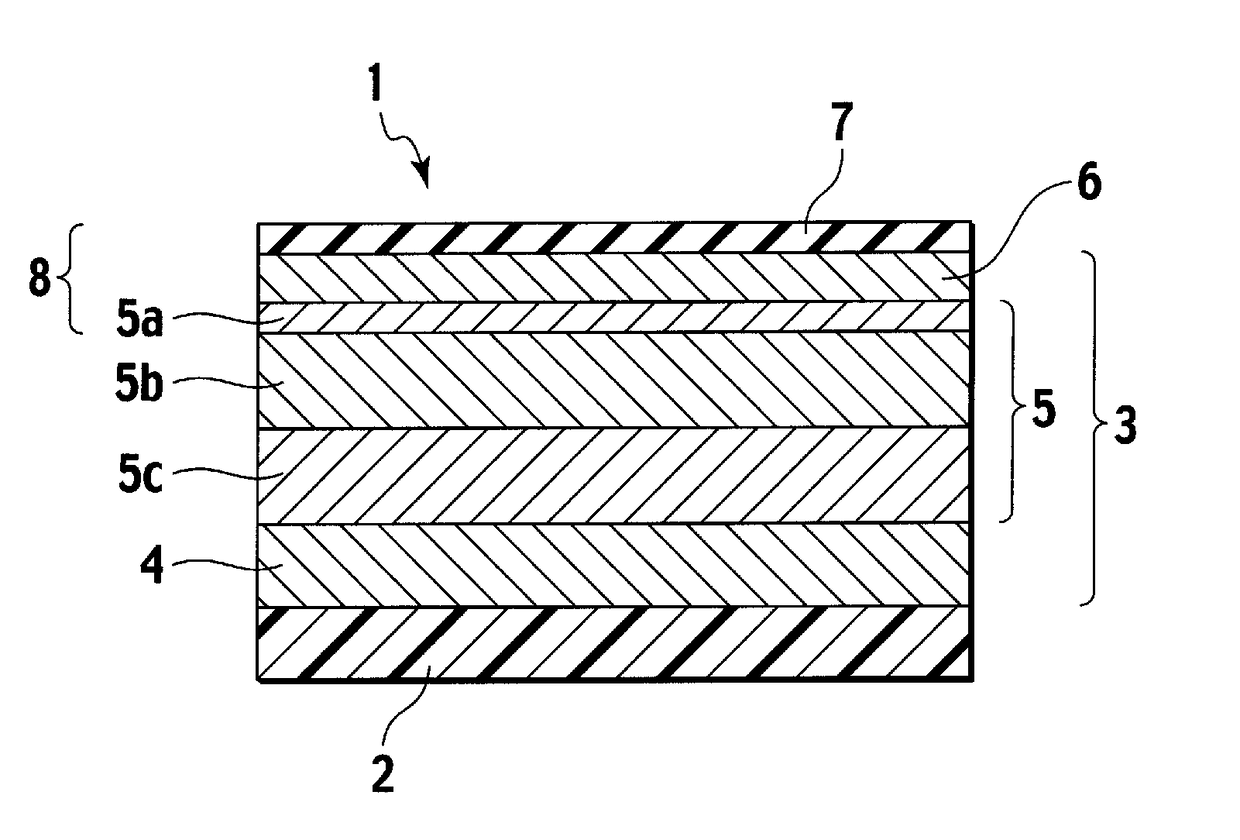

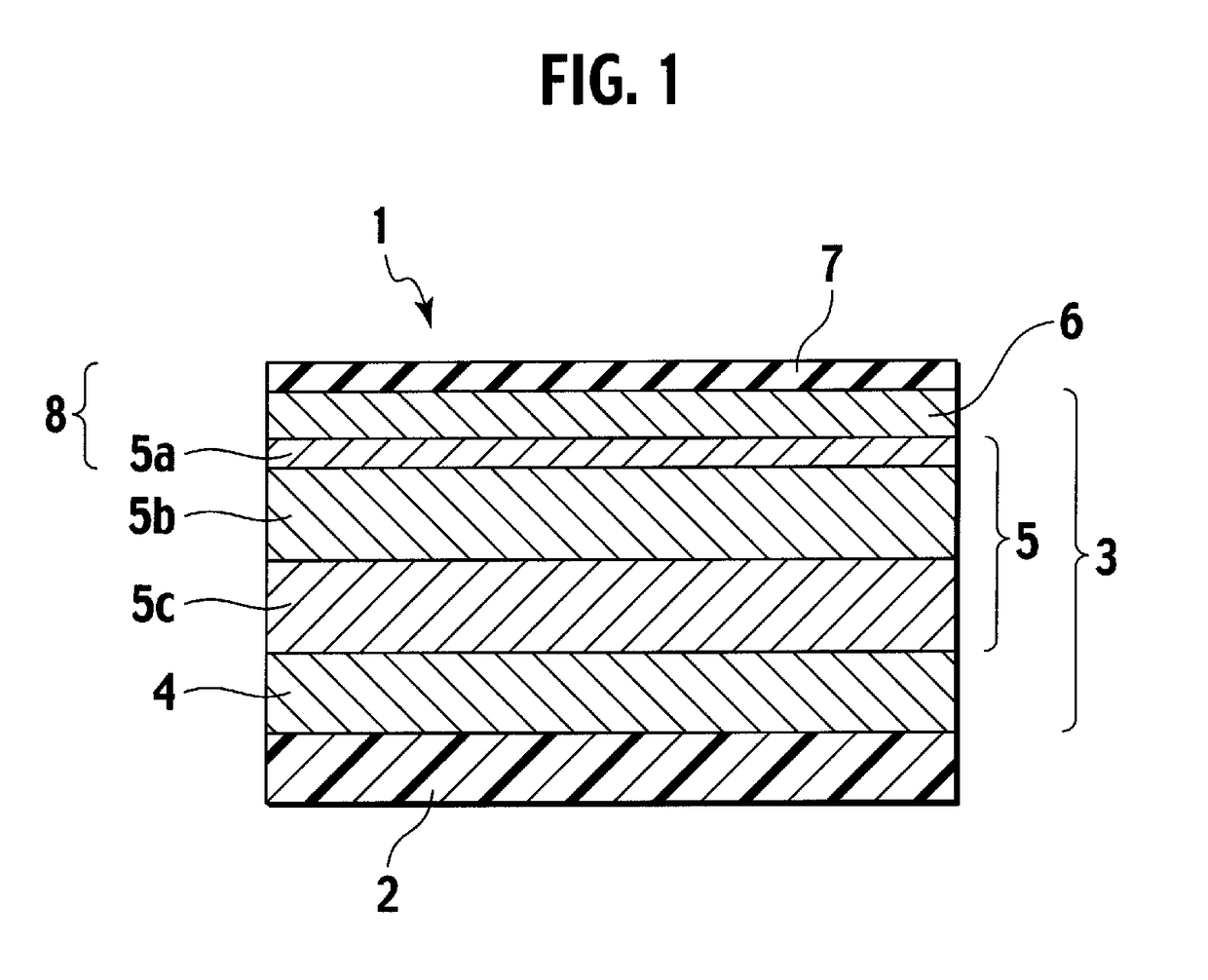

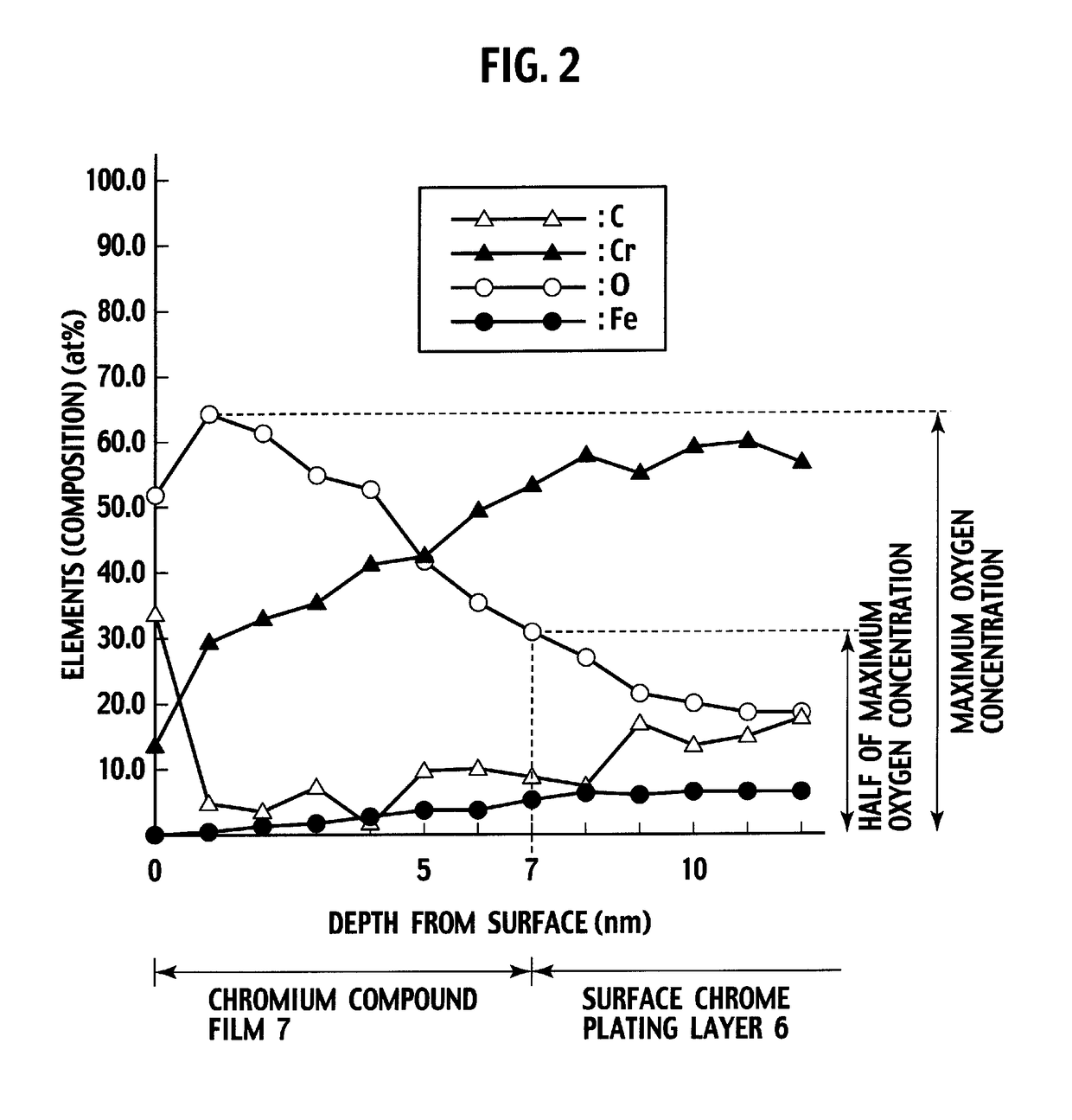

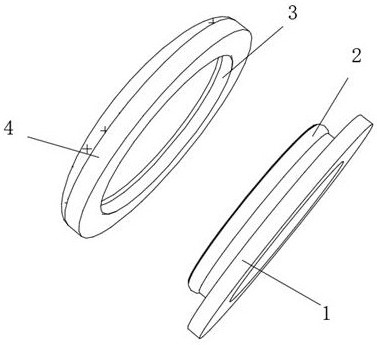

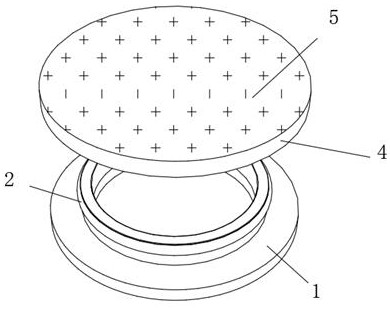

Chrome-plated part and manufacturing method of the same

ActiveUS20140284218A1Improve corrosion resistanceChromatisationThin material handlingChromium CompoundsMicrometer

An nickel plating layer (5a) intended for corrosion current distribution is formed over a body (2), and a 0.05 to 2.5 micrometers thick surface chrome plating layer (6) made of trivalent chromium is formed on the surface thereof using basic chromium sulfate as a source of metal. Further on the same, a not less than 7 nm thick chromium compound film (7) is formed by cathode acidic electrolytic chromatin. The corrosion distribution nickel plating layer (5a) has a function of forming a microporous structure, a microcrack structure, or the both of the same in the surface chrome plating layer (6).

Owner:NISSAN MOTOR CO LTD +1

Method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue

ActiveCN102329964BSimple processEase of industrial productionProcess efficiency improvementWater solubleSodium orthovanadate

The invention relates to a method for separating and recovering vanadium and chromium from vanadium-chromium reduced waste residue. The method comprises the following main steps of: after removing water-soluble salts through slurrying and washing, extracting vanadium from the rest vanadium-chromium reduced waste residue by oxidizing in an alkaline solution; meanwhile, realizing the vanadium-chromium separation; cooling and crystallizing a leaching solution to obtain obtaining a sodium orthovanadate product; carrying out acid leaching on the vanadium-chromium reduced waste residue subjected to vanadium extraction; and preparing a basic chromium sulfate product after removing impurities, evaporating and crystallizing. According to the invention, the purity of the sodium orthovanadate product prepared by the method is higher than 93%, the content of Cr2O3 in the basic chromium sulfate can reach 24%, the content of Fe is lower than 0.1%, and the requirements on the basic chromium sulfate I type product in the HG / T 2678-2007 are met.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Method for preparing basic chromium sulfate tanning liquor by using tanning chromium sludge

ActiveCN102965455AReduce dosageImprove tannabilitySludge treatmentTanning treatmentChemical reactionSludge

The invention discloses a method for preparing basic chromium sulfate tanning liquor by using tanning chromium sludge, and solves problems in existing method for preparing tanning liquor by using tanning chromium sludge, such as violent reaction, high operation risk coefficient, incomplete organic compound hydrolysis, poor infiltration of the obtained tanning liquor and complex preparation process and steps. The method comprises the following steps: (1) homogenization; (2) leaching; (3) filter pressing; (4) pressure reduction; and (5) cooling and depressurization. The invention has beneficial effects of mild chemical reaction, easily controlled reaction, capability of completely reducing hexavalent chromium to trivalent chromium, low production cost, no introduction of new impurity, simple processing steps, high purity of the finally obtained chrome tanning liquor, high reduction rate of hexavalent chromium, small consumption amount of ethanol or industrial alcohol, deep hydrolysis of organic small molecules, further enhancement of purity and tanning property of the finally obtained tanning liquor.

Owner:ZHEJIANG TELI RECYCLING RESOURCES

Method for preparing basic chromium sulfate-chrome tanning agent by using lignite wax as reducing agent

InactiveCN103613134AImprove performanceReduced neutral salt contentTanning treatmentChromium sulfatesWaxReaction temperature

The invention discloses a method for preparing a basic chromium sulfate-chrome tanning agent by using lignite wax as a reducing agent. The method comprises the processes of primary oxidation, secondary oxidation and oxidation liquid modulation, wherein the primary oxidation comprises the steps of acidizing the lignite wax for 1 hour and then stirring and oxidizing for 4-6 hours; the secondary oxidation comprises the steps of acidizing the primary oxidation liquid for 20-40 minutes and then stirring and oxidizing for 2-3 hours; the method further comprises the steps of adding the primary oxidation liquid and the secondary oxidation liquid into a reaction kettle, determining the adding amount of an oxidizing agent and a reducing agent, adding the oxidizing agent and the reducing agent into the reaction kettle sequentially and slowly, strictly controlling the reaction temperature at 105-115 DEG C, stirring and oxidizing for 1-2 hours, standing, ageing, spray-drying and forming to obtain the basic chromium sulfate-chrome tanning agent. Compared with the pure sugar reducing agent, the neutral salt content of the basic chromium sulfate-chrome tanning agent is reduced by above 30 percent, the chrome absorption quantity of leather is enhanced, and the plumpness and humidity-resistant and heat-resistant stability of the leather are improved. The basic chromium sulfate-chrome tanning agent comprises organic micromolecular acid with a good masking effect, particularly sulfonated phthalic acid, so that the leather is plump and soft, and has elasticity, natural brightness and wax feel.

Owner:南通金庆美术图案设计有限公司

Fur tanning process without salt and acid

InactiveCN101948938AReduce usageReduce generationTanning treatmentPre-tanning chemical treatmentRoom temperatureAluminum ammonium sulfate

The invention relates to a fur tanning process without salt and acid, which comprises the following steps: soaking: adding a penetrating agent to the water at normal temperature; re-soaking: adding the penetrating agent, a degreasing agent and a bactericide to the water at normal temperature, and removing residual meat on the fur after soaking; softening: the water temperature is 30-35 DEG C and the water contains neutral enzyme; and tanning: adding modified glutaraldehyde to the water at normal temperature, then adding aluminum ammonium sulfate after soaking, after a period of time, adding basic chromium sulfate, and then carrying out regular wet finishing and dry finishing after soaking. In the tanning process, the consumption of neutral salt is greatly reduced, the production cost is reduced, the generation of tanning waste water is reduced, the cost of treating the waste water is reduced, and the environment is protected. In addition, the process omits a general pickling procedure, greatly shortens the tanning time, improves the production efficiency and does not affect the quality of the tanned fur.

Owner:桐乡市鑫诺皮草有限公司

Method for preparing basic chromium sulfate from chromium-contained wastewater

The invention discloses a method for preparing basic chromium sulfate from chromium-contained wastewater. The method includes: adding excessive oxidizing agent into the chromium-contained wastewater to heat the chromium-contained wastewater up, adding alkaline liquor to adjust the pH (potential of hydrogen) value to be alkaline, filtering to remove heavy metal sediments in the chromium-contained wastewater, adding sulfuric acid into obtained filter liquor to adjust the pH value to be acidic, and adding oxalic acid till a chromium sulfate solution is obtained; adding alkaline liquor into the chromium sulfate solution with stirring so as to react to obtain syrup type viscous liquid, cooling to crystallize, centrifuging to obtain liquid basic chromium sulfate, and subjecting the liquid basicchromium sulfate to concentrating, washing, drying, smashing and screening to obtain solid basic chromium sulfate. According to the method, minute amount of heavy metal ions is removed by extracting principal components in the chromium-contained wastewater, and suitable conditions are furtherly chosen to prepare the basic chromium sulfate finally. The method for preparing the basic chromium sulfate from the chromium-contained wastewater is simple in technology, low in cost and high in product yield, and is not only capable of providing a new technical solution for recovery of the chromium-contained wastewater, but also is capable of preparing the basic chromium sulfate which is stable in state, high in purity and less in impurities.

Owner:XINGJIA BIO ENG CO LTD

Process for preparing basic chromium sulfate by using waste chromium material

ActiveCN102432067AReasonable optimizationAvoid pollutionSolid waste disposalChromium compoundsLiquid wasteFiltration

The invention relates to a process for treatment of heavy metal and recovery of an inorganic salt and especially to a process for preparing basic chromium sulfate by using a waste chromium material. In the process, a waste chromium liquid storage tank, an acidifying device, a reduction device, a reaction vessel, a condensation kettle, a press filtration device, a spray drying device and a gas purifying device are utilized; the process comprises the following steps: collecting electroplating and other chromium-containing waste liquid and waste residue, adding the collected waste liquid and waste residue into an acidifying reaction vessel, optimizing a formula for reagents, removing other impurity components except chromium components through addition and reaction of the reagents and press filtration, carrying out further dehydration by adjusting the condensation kettle for further reaction and preparing the product of basic chromium sulfate by using a centrifugal spray drier. The process provided in the invention is optimized, reasonable, simple and easy, makes the most of natural resources and natural conditions, has the advantages of low production cost, small investment and high yield and enables the problem of waste chromium pollution to be effectively overcome and the waste chromium material to be processed into inorganic chemical products, thereby producing remarkable environmental and economic benefits.

Owner:无锡金品环境技术有限公司

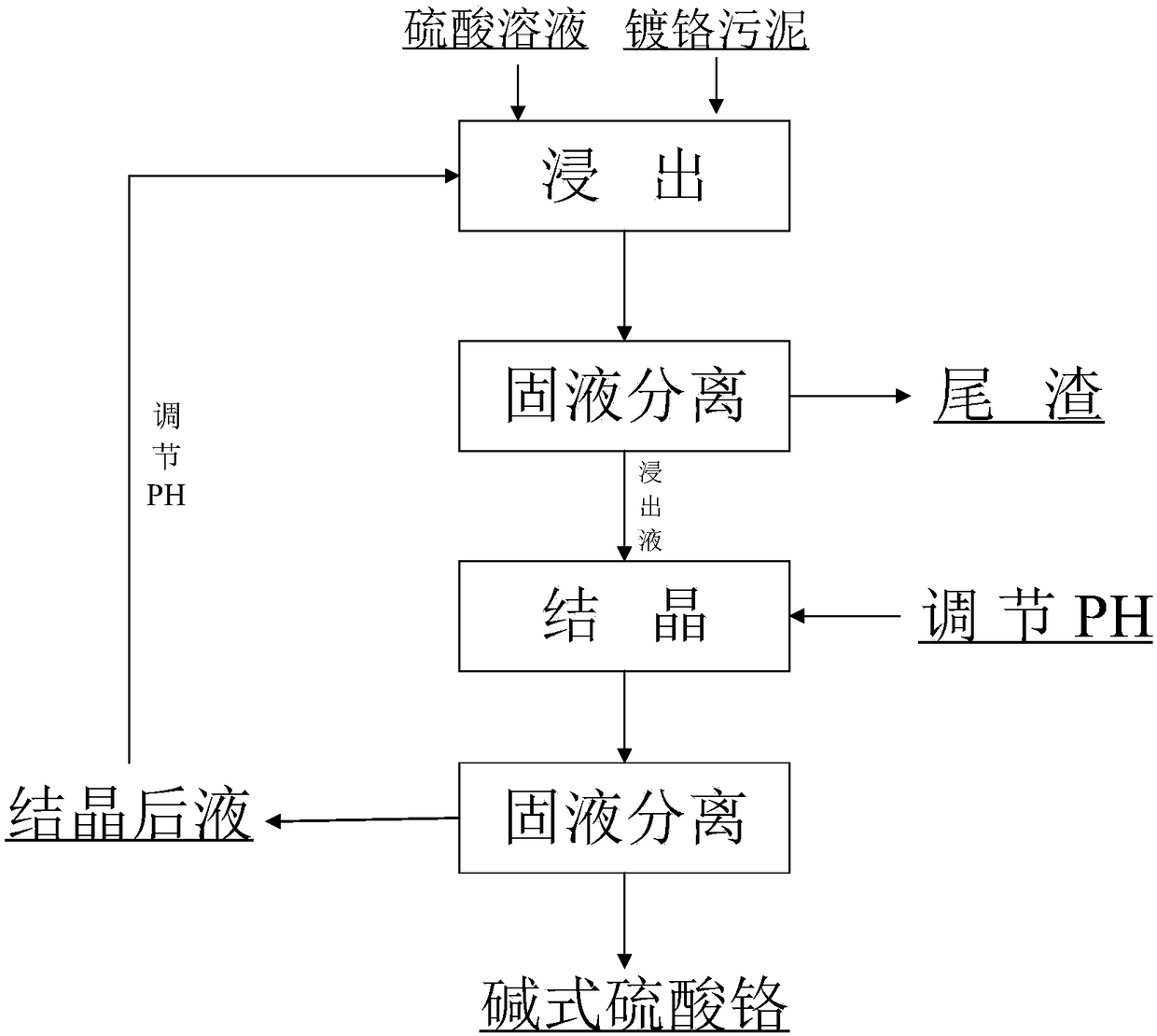

Method for preparing basic chromium sulfate from chromium plating sludge

InactiveCN108190956ARealize resource reuseNo emissionsChromium sulfatesPregnant leach solutionSludge

The invention relates to a method for preparing basic chromium sulfate from chromium plating sludge. The method is characterized in that the chromium plating sludge and a sulfuric acid solution are mixed; heating is performed for leaching; after the leaching is completed, solid-liquid separation is performed to obtain chromium-containing leaching liquid and tailings; the pH of the obtained chromium-containing leaching liquid is regulated; the solid-liquid separation is performed to obtain basic chromium sulfate and crystallized liquid. The sulfuric acid solution is used for performing leachingtreatment on the chromium plating sludge, so that the chromium leaching rate is greater than 90 percent; through subsequent operation, the basic chromium sulfate product is obtained; the mass percentage of dichromium trioxide in the basic chromium sulfate is 20 to 25 percent; the resource reutilization of chromium elements in the chromium plating sludge is realized. The technological process is simple; the energy consumption is low; no waste water is discharged out in the whole production process; good economic benefits and wide application prospects are realized.

Owner:HEBEI IRON AND STEEL

A method for preparing basic chromium sulfate by utilizing the raffinate obtained from the production of menadione

ActiveCN104386752BQuality improvementIncrease productivityChromium sulfatesReaction rateRates reactions

The invention discloses a method for preparing chromium sulfate basic by utilizing residual liquor obtained during menadione production. The method comprises the following steps: uniformly mixing the concentrated residual liquor with industrial sugar according to a certain molar ratio, and reacting in a pressure reactor for 0.5-4 hours at the temperature of 100 to 300 DEG C under the pressure of 0 to 4MPa; completely reducing a small amount of unreacted hexavalent chromium in the feed liquid into trivalent chromium by using a reducing agent after the reaction is ended; regulating the basicity of the feed liquid by using an alkaline solution, filtering, performing spray drying on the filtrate, thus obtaining the chromium sulfate basic product. According to the method disclosed by the invention, a pressure-conditioned curing reaction is adopted, residual organic matters in the menadione residual liquor can be effectively removed, and the quality of chromium powder is improved. The method disclosed by the invention is simple in process, high in reaction rate, low in energy consumption, clean and environment-friendly.

Owner:SICHUAN YINHE CHEM

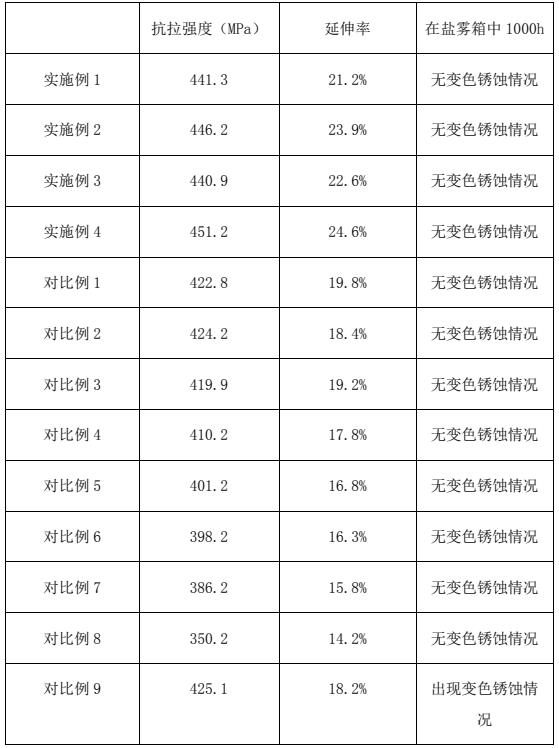

Cast aluminum alloy for automobile metal casting and processing technology of cast aluminum alloy

ActiveCN114107757AImprove performanceImproved eutectic silicon morphologyMachining processBasic chromium sulfate

According to the cast aluminum alloy for the automobile metal casting and the machining technology of the cast aluminum alloy, the comprehensive performance of the cast aluminum alloy is improved by limiting the element composition and content in the aluminum alloy and matching with the optimal design of the machining technology; the aluminum alloy is defined as follows: Zn + Cu < = 2Mg, Er + Sr + Y + Yb < = 0.7%, and the mass ratio of Mn to Fe is 1.1-1.3. The tensile strength of the aluminum alloy is greatly improved through the synergistic effect of Er, Sr, Y and Yb elements; according to the process, second-phase particles are distributed more uniformly and dispersed through high-temperature intermittent ultrasonic treatment, and intra-crystalline segregation is eliminated through homogenizing annealing; the annealed aluminum alloy is subjected to solid solution two-stage aging treatment to eliminate lattice distortion; after the formed aluminum alloy is subjected to arc oxidation, the hole sealing liquid obtained by compounding the potassium fluozirconate, the basic chromium sulfate, the acetic acid and the tartaric acid is used for hole sealing, and compared with existing hole sealing through boiling water, the hole sealing time is short, the hole sealing temperature is low, and the corrosion resistance of the aluminum alloy is effectively improved under low energy consumption.

Owner:江苏瑞振压铸有限公司

Chrome-plated part and manufacturing method of the same

ActiveUS9650722B2Improve corrosion resistanceChromatisationThin material handlingChromium CompoundsMicrometer

Owner:NISSAN MOTOR CO LTD +1

Method of preparing basic chromium sulfate tanning agent from chromite sulfuric acid leachate

Owner:NORTHEASTERN UNIV

Method for preparing acid black 172

InactiveCN101538414BReduce viscosityIncrease concentrationDyeing processComplex metal azo dyesSodium bicarbonateSlurry

The invention relates to a method for preparing acid black 172. The method comprises the following steps that: (1) 6-nitro-1 and 2-diazoxynaphthalene-4-sulfonic acid are put into a dissolution tank, added with water for dissolution, added with a sodium hydroxide solution and stirred. (2) 2-naphthol is put into the dissolution tank, added with water for dissolution, added with the sodium hydroxide solution, stirred, heated, added with a dispersant and aliphatic diol or ether and stirred again; (3) a prepared 2-naphthol solution is rapidly put into and coupled with a solution with 6-nitro-1 and2-diazoxynaphthalene-4-sulfonic acid so as to obtain coupled liquid; and (4) the coupled liquid is added with formic acid, ammonium bicarbonate or sodium bicarbonate and basic chromium sulfate, heated to be between 100 and 102 DEG C, thermally insulated and stirred so as to obtain an acid black 172 serous finished product. The method for preparing acid black 172 has the advantages of simple production process, scientific reasonable control on reaction conditions, short production cycle of produces, high yield, good quality, friction resistance, obviously raised fastness of resisting rinse and sunshine, obviously reduced side reaction and impurities, low production cost, high production efficiency and better environment-friendly property.

Owner:TIANJIN SANHUAN CHEM

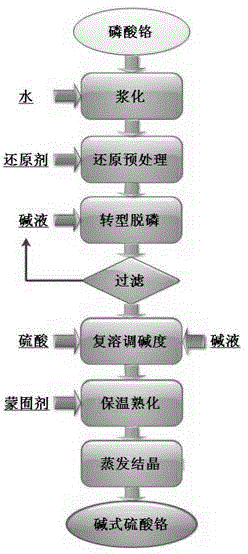

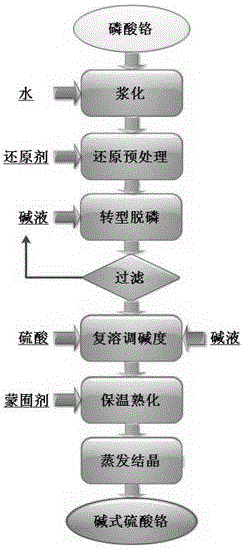

Method for preparation of basic chromium sulfate from chromium phosphate

ActiveCN104609473ABroaden sources of raw materialsNo secondary pollutionChromium sulfatesSludgeResource utilization

The invention discloses a method for preparation of basic chromium sulfate from chromium phosphate, relates to a method for preparation of the basic chromium sulfate from chromium-containing material chromium phosphate, particularly relates to a method for extraction and separation of chromium in mixed electroplating sludge and phosphorus chromium slag to obtain chromium phosphate and then extending preparation of the basic chromium sulfate. The method is characterized by sequentially comprising the following steps: (1) adding water into a chromic phosphate raw material for mixing slurry; (2) adding a reducing agent for reducing processing; (3) adding an alkali for phosphate radical removal reaction; (4) filtering to obtain chromium hydroxide and alkali liquid; (5) redissolving the chromium hydroxide with sulfuric acid; (6) adding NaOH alkali solution into redissolving solution to adjust solution pH, aging to obtain basic chromium sulfate solution; and (7) evaporating and crystallizing to obtain basic chromium sulfate. The method is a simple-process short-flow environmentally-friendly high chromium value utilization hydrometallurgy technology, and is suitable for application in the field of resource utilization of chromium phosphate in electroplating sludge, chromium phosphate slag and waste slag sludge.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

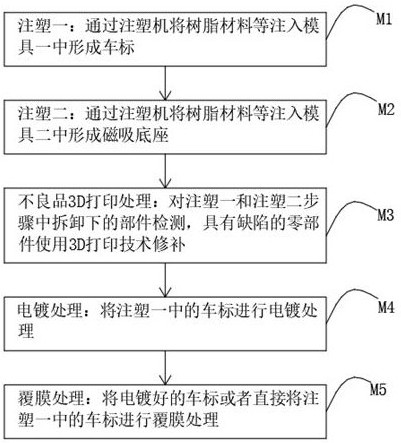

Trivalent chromium electroplating solution formula for automobile logo production and trivalent chromium electroplating process

Owner:上原汽车铭牌(惠州)有限公司

Preparation method of heavy-metal-free dye

The invention relates to a preparation method of a heavy-metal-free dye. The method comprises the following steps: 4-tert-amyl-2-amino-6-nitrophenol is added to a sodium hydroxide solution, sodium nitrite is added, and a solution A is obtained; the solution A is added dropwise to water, ice and hydrochloric acid, and a diazonium salt is obtained; 1,3,5-pyrazolone is dissolved in sodium carbonate and sodium hydroxide, a coupled liquid is obtained, the diazonium salt is added to the coupled liquid for reaction, and an azo dye is obtained; basic chromium sulphate is dissolved in water, a salicylic acid solution after dissolution with sodium hydroxide is added, and a chromaking agent is prepared; the azo dye and the chromaking agent are mixed, pH is regulated to 10-11, disappearance of the azo dye is taken as a reaction endpoint, a reaction liquid is cooled to 65-70 DEG C, the dye is precipitated, cooled to the temperature lower than 45 DEG C, filtered, washed and dried, and the heavy-metal-free dye can be obtained. The dye prepared with the preparation method is free of heavy metal, has little harm to a human body and can reduce environmental pollution.

Owner:HUBEI WEIQING POLYMER TECH CO LTD

Preparation method of anti-migration dye

InactiveCN105482489AImprove migration resistanceMeet the requirements of high-quality end marketComplex metal azo dyesNitrophenolSalicylic acid

The invention relates to a preparation method of anti-migration dye. The preparation method includes the following steps that 4-amyl-2-amino-6-nitrophenol is added into a sodium hydroxide solution, and sodium nitrite is added so that a solution A can be obtained; the solution A is dropwise added into water, ice and hydrochloric acid so that diazonium salt can be obtained; 1,3,5-pyrazolone is dissolved in sodium carbonate and sodium hydroxide so that coupled liquid can be obtained, diazonium salt is added into the coupled liquid to react, and azo dye is obtained; basic chromium sulfate is dissolved in water, a salicylic acid solution dissolved through a sodium hydroxide solution is added, and a chromizing agent is prepared; the azo dye and the chromizing agent are mixed, the pH value is adjusted to be 10-11, a reaction solution is cooled to 65-70 DEG C with disappear of the azo dye as a reaction end point, the dye is precipitated and cooled to 45 DEG C or below, and filtering, washing and drying are performed so that the anti-migration dye can be obtained. The dye prepared through the preparation method is high in migration resistance and can meet the requirement of a high-quality terminal market.

Owner:HUBEI WEIQING POLYMER TECH CO LTD

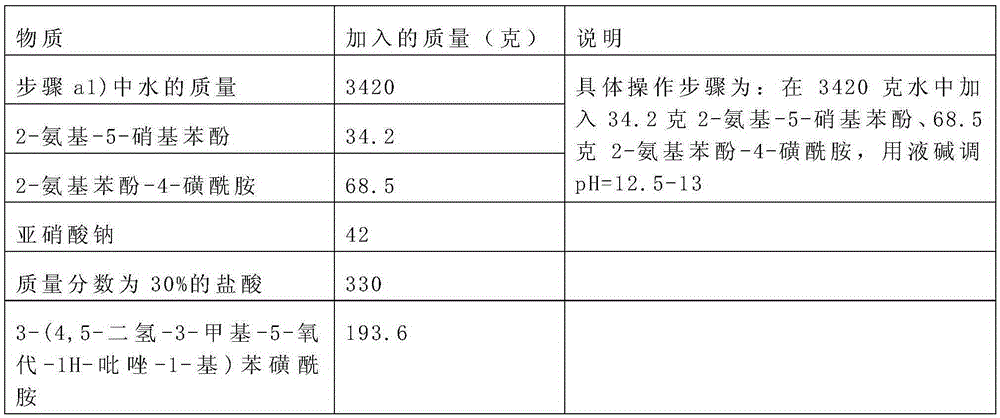

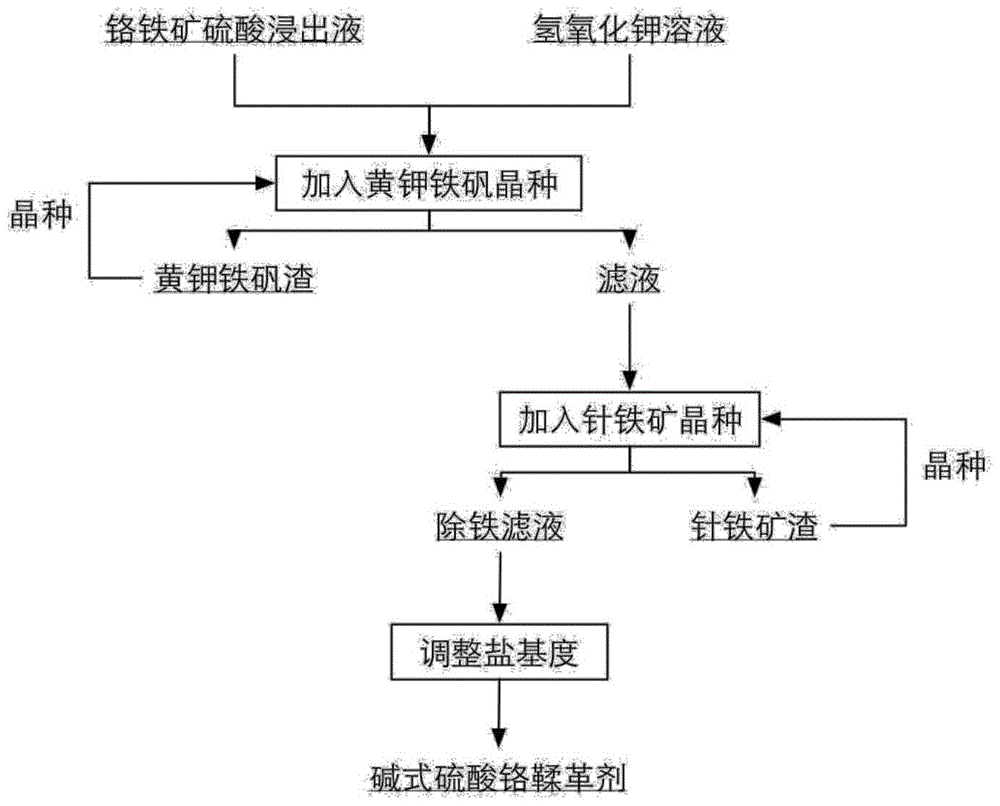

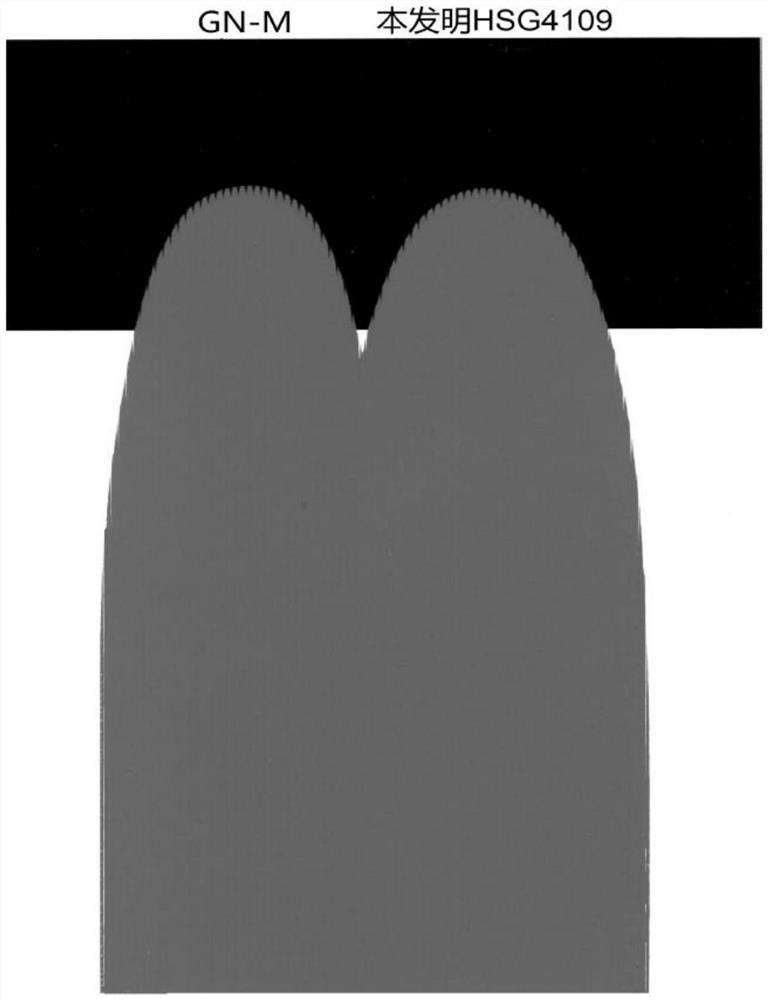

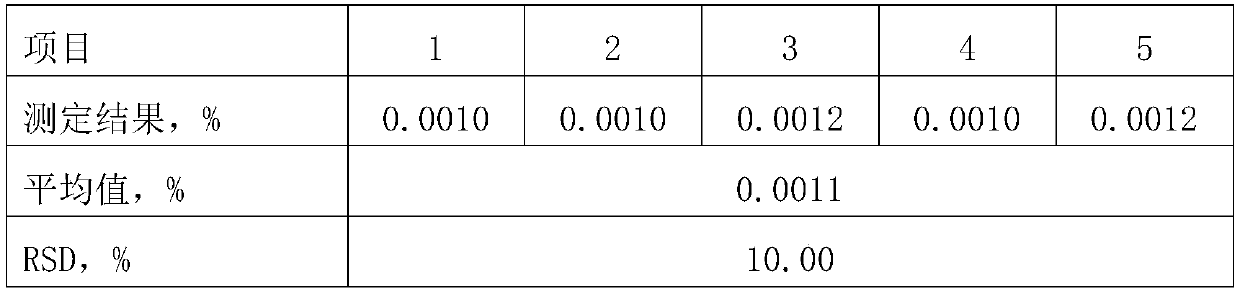

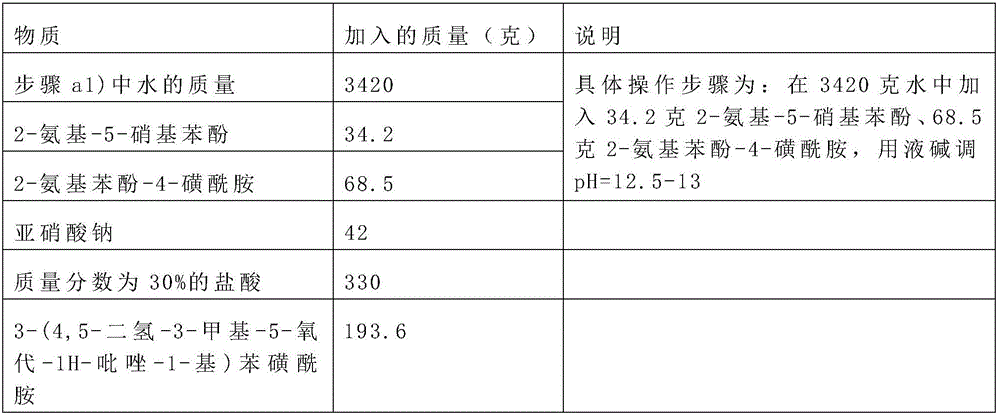

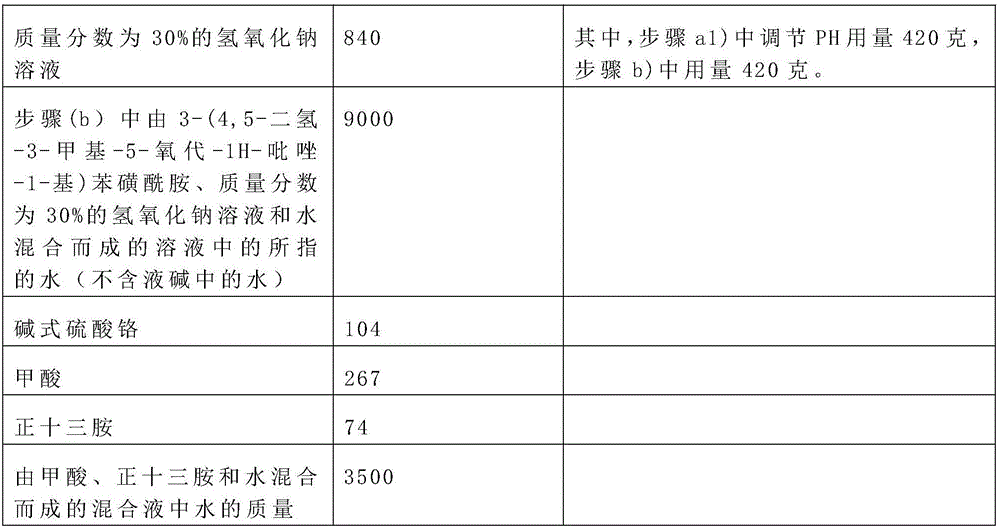

Migration-resistant red dye, preparation method therefor and application thereof

The present invention relates to a migration-resistant red dye, a preparation method therefor and application thereof. The preparation method for the dye comprises the following steps: (a) mixing 2-amino-5-nitrophenol, 2-aminophenol-4-sulfamide, sodium nitrite, hydrochloric acid and water to react, and obtaining a diazonium product; (b) adding a mixed solution of 3-(4,5-dihydro-3-methyl-5-oxo-1H-pyrazol-1-yl) benzenesulfonamide, caustic soda liquid and water to a vessel to react with the resulting diazonium product in the step (a), and obtaining a coupling product; (c) performing chromium complexation on basic chromium sulfate and the resulting coupling product in the step (b); (d) reacting a product obtained from the chromium complexation with a mixed solution of formic acid, n-tridecyl amine and water; and (e) after completion of the reaction, filtering and drying. The dye is resistant to a high temperature, is relatively inexpensive, and has good migration resistance.

Owner:GUANGZHOU WEIQING CHEM TECH CO LTD

Process for preparing basic chromium sulfate by using waste chromium material

ActiveCN102432067BReasonable optimizationAvoid pollutionSolid waste disposalChromium compoundsLiquid wasteFiltration

The invention relates to a process for treatment of heavy metal and recovery of an inorganic salt and especially to a process for preparing basic chromium sulfate by using a waste chromium material. In the process, a waste chromium liquid storage tank, an acidifying device, a reduction device, a reaction vessel, a condensation kettle, a press filtration device, a spray drying device and a gas purifying device are utilized; the process comprises the following steps: collecting electroplating and other chromium-containing waste liquid and waste residue, adding the collected waste liquid and waste residue into an acidifying reaction vessel, optimizing a formula for reagents, removing other impurity components except chromium components through addition and reaction of the reagents and press filtration, carrying out further dehydration by adjusting the condensation kettle for further reaction and preparing the product of basic chromium sulfate by using a centrifugal spray drier. The process provided in the invention is optimized, reasonable, simple and easy, makes the most of natural resources and natural conditions, has the advantages of low production cost, small investment and high yield and enables the problem of waste chromium pollution to be effectively overcome and the waste chromium material to be processed into inorganic chemical products, thereby producing remarkable environmental and economic benefits.

Owner:无锡金品环境技术有限公司

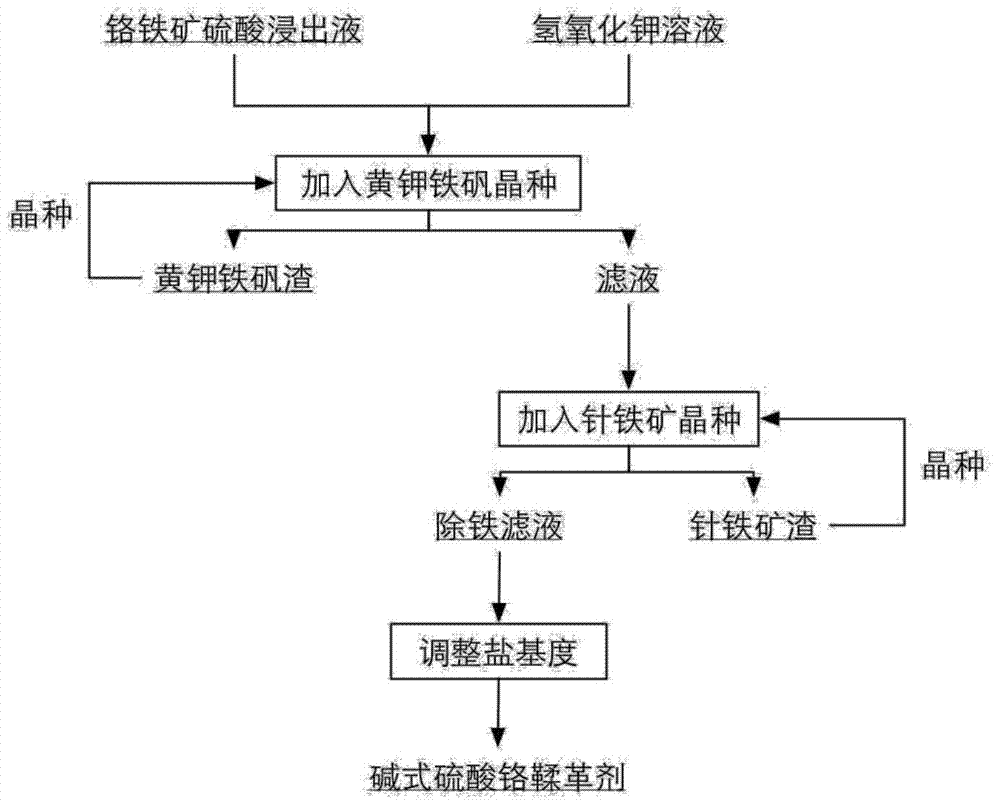

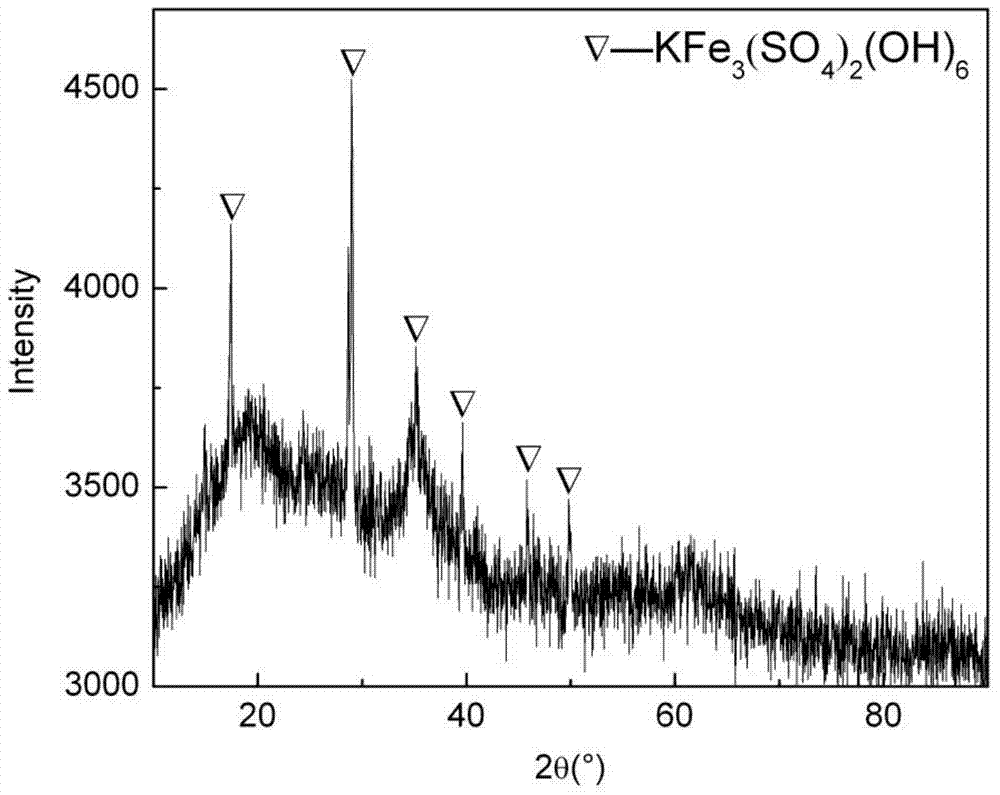

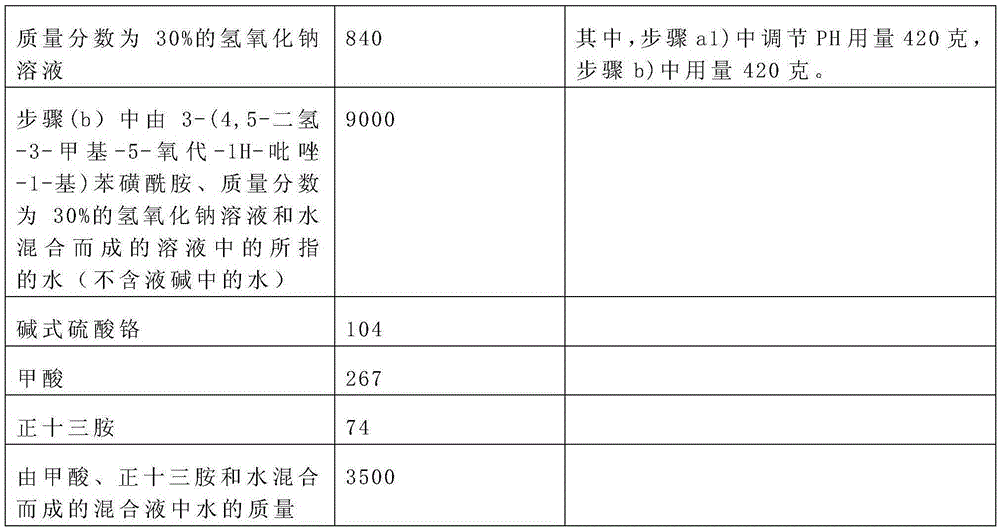

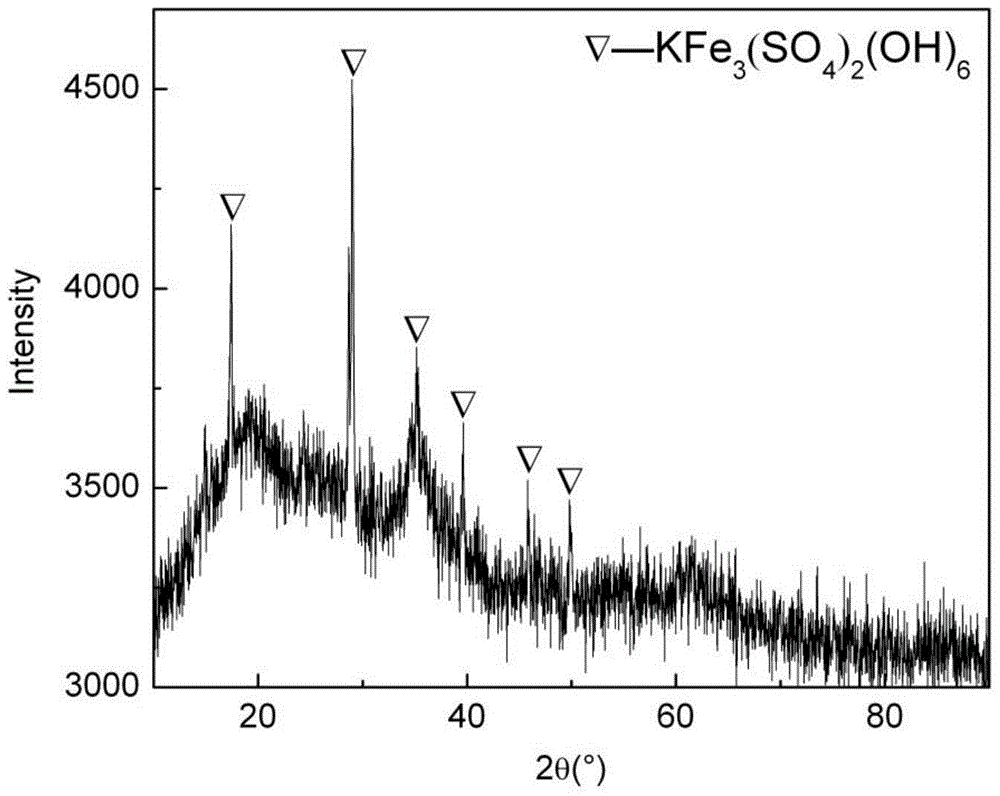

A method for preparing basic chromium sulfate tanning agent from chromite ore sulfuric acid leaching solution

In view of the existing problem of difficulty in removing iron from chromite sulfuric acid leachate, the present invention provides a method for preparing basic chromium sulfate tanning agent from chromite sulfuric acid leachate, which belongs to the field of mineral processing technology. The method includes controlling the temperature of the chromite sulfuric acid leach solution at 60 to 100°C, adjusting the pH value of the solution to between 1 and 3, adding pyrosite crystal seeds and crystallizing; filtering to obtain pyrosite crystals and filtrate; Keep the temperature of the filtrate, adjust the pH value of the solution to between 2 and 4, add goethite crystal seeds and crystallize; filter to obtain goethite crystals and filtrate; add diluted alkali solution to the filtrate to neutralize the solution. The salinity is 33±1%; the solution is then dried to obtain a basic chromium sulfate tanning agent. This process does not produce highly toxic Cr(Ⅵ). It is a clean and non-toxic tanning agent preparation method. Through two iron removal processes, more complete iron removal can be achieved, and the basic chromium sulfate tanned leather obtained The mass percentage of iron in the agent is less than 0.1%.

Owner:NORTHEASTERN UNIV LIAONING

A kind of method that chromium phosphate prepares basic chromium sulfate

ActiveCN104609473BBroaden sources of raw materialsNo secondary pollutionChromium sulfatesPhosphodiesteraseSludge

The invention discloses a method for preparation of basic chromium sulfate from chromium phosphate, relates to a method for preparation of the basic chromium sulfate from chromium-containing material chromium phosphate, particularly relates to a method for extraction and separation of chromium in mixed electroplating sludge and phosphorus chromium slag to obtain chromium phosphate and then extending preparation of the basic chromium sulfate. The method is characterized by sequentially comprising the following steps: (1) adding water into a chromic phosphate raw material for mixing slurry; (2) adding a reducing agent for reducing processing; (3) adding an alkali for phosphate radical removal reaction; (4) filtering to obtain chromium hydroxide and alkali liquid; (5) redissolving the chromium hydroxide with sulfuric acid; (6) adding NaOH alkali solution into redissolving solution to adjust solution pH, aging to obtain basic chromium sulfate solution; and (7) evaporating and crystallizing to obtain basic chromium sulfate. The method is a simple-process short-flow environmentally-friendly high chromium value utilization hydrometallurgy technology, and is suitable for application in the field of resource utilization of chromium phosphate in electroplating sludge, chromium phosphate slag and waste slag sludge.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for preparing basic chromium sulfate-chrome tanning agent by using lignite wax as reducing agent

InactiveCN103613134BImprove performanceReduced neutral salt contentTanning treatmentChromium sulfatesWaxReaction temperature

The invention discloses a method for preparing a basic chromium sulfate-chrome tanning agent by using lignite wax as a reducing agent. The method comprises the processes of primary oxidation, secondary oxidation and oxidation liquid modulation, wherein the primary oxidation comprises the steps of acidizing the lignite wax for 1 hour and then stirring and oxidizing for 4-6 hours; the secondary oxidation comprises the steps of acidizing the primary oxidation liquid for 20-40 minutes and then stirring and oxidizing for 2-3 hours; the method further comprises the steps of adding the primary oxidation liquid and the secondary oxidation liquid into a reaction kettle, determining the adding amount of an oxidizing agent and a reducing agent, adding the oxidizing agent and the reducing agent into the reaction kettle sequentially and slowly, strictly controlling the reaction temperature at 105-115 DEG C, stirring and oxidizing for 1-2 hours, standing, ageing, spray-drying and forming to obtain the basic chromium sulfate-chrome tanning agent. Compared with the pure sugar reducing agent, the neutral salt content of the basic chromium sulfate-chrome tanning agent is reduced by above 30 percent, the chrome absorption quantity of leather is enhanced, and the plumpness and humidity-resistant and heat-resistant stability of the leather are improved. The basic chromium sulfate-chrome tanning agent comprises organic micromolecular acid with a good masking effect, particularly sulfonated phthalic acid, so that the leather is plump and soft, and has elasticity, natural brightness and wax feel.

Owner:南通金庆美术图案设计有限公司

Clean regeneration method for chromium-containing waste acid

InactiveCN114105105AMeet recycling standardsIncreased chromium ion precipitation rateSulfur-trioxide/sulfuric-acidChromium sulfatesEnvironmental engineeringChromium(III) sulfate

The invention relates to a clean regeneration method of chromium-containing waste acid, which comprises the following steps: (1) mixing chromium-containing waste acid and an additive to enable the oxidation-reduction potential to be less than or equal to 250mV; (2) carrying out hydrolysis reaction on the mixed solution obtained in the step (1); and (3) carrying out solid-liquid separation on the product obtained in the step (2) to obtain regenerated sulfuric acid and basic chromium sulfate. According to the method, the process flow is simplified while the chromium-containing waste acid is efficiently treated, the treatment cost is reduced, the regeneration cycle of the acid liquor and the reutilization of metal precipitates are realized, and the emission pollution of waste residues and waste liquor is eliminated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

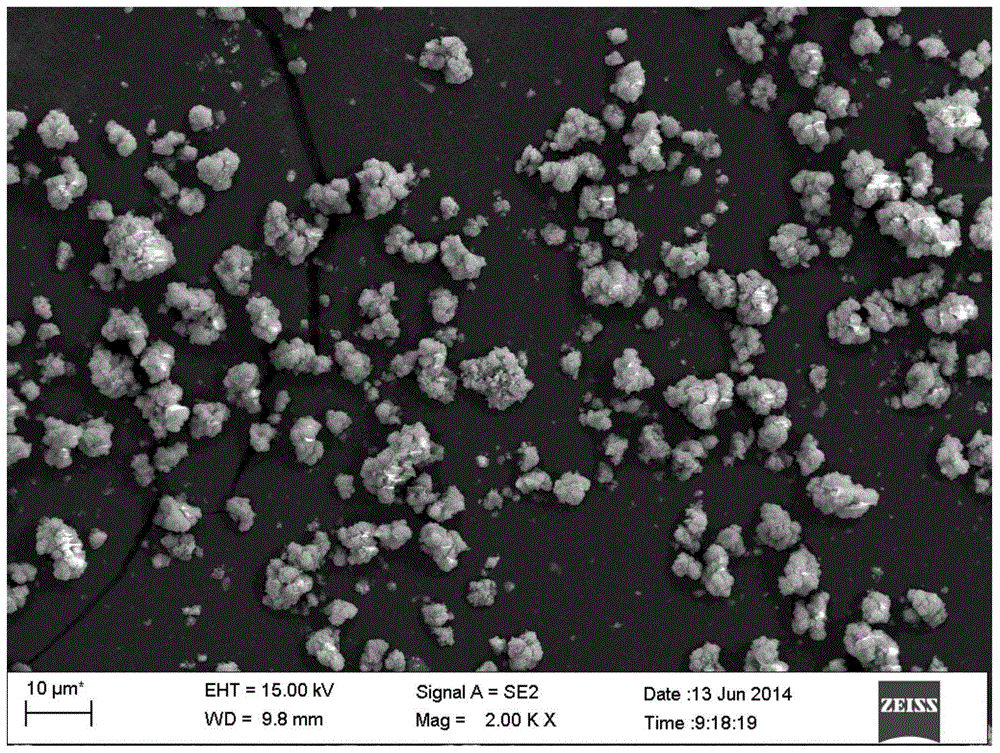

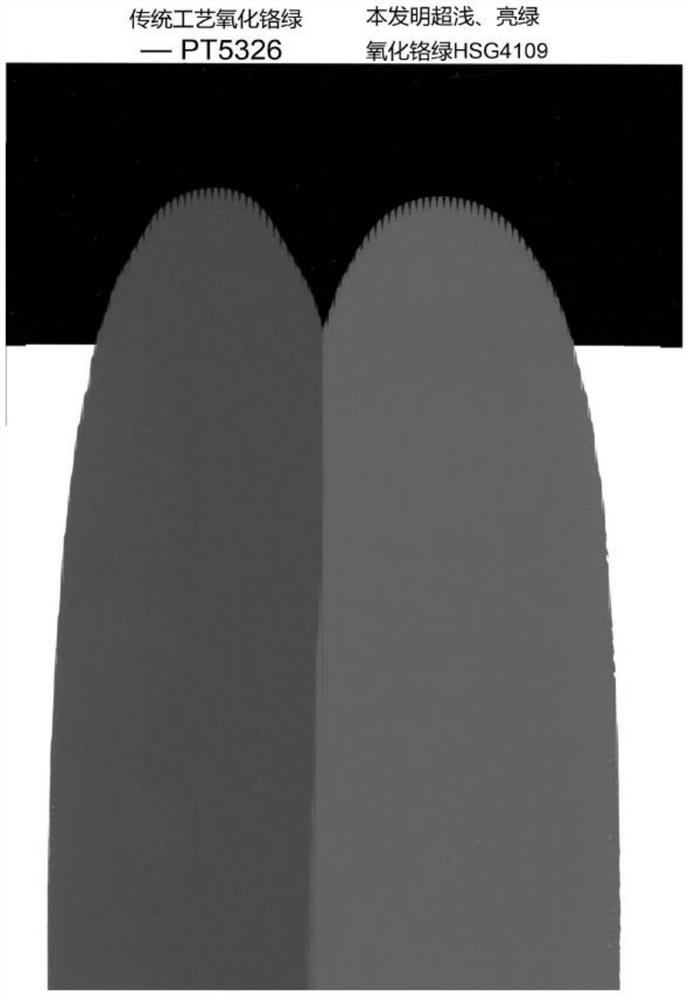

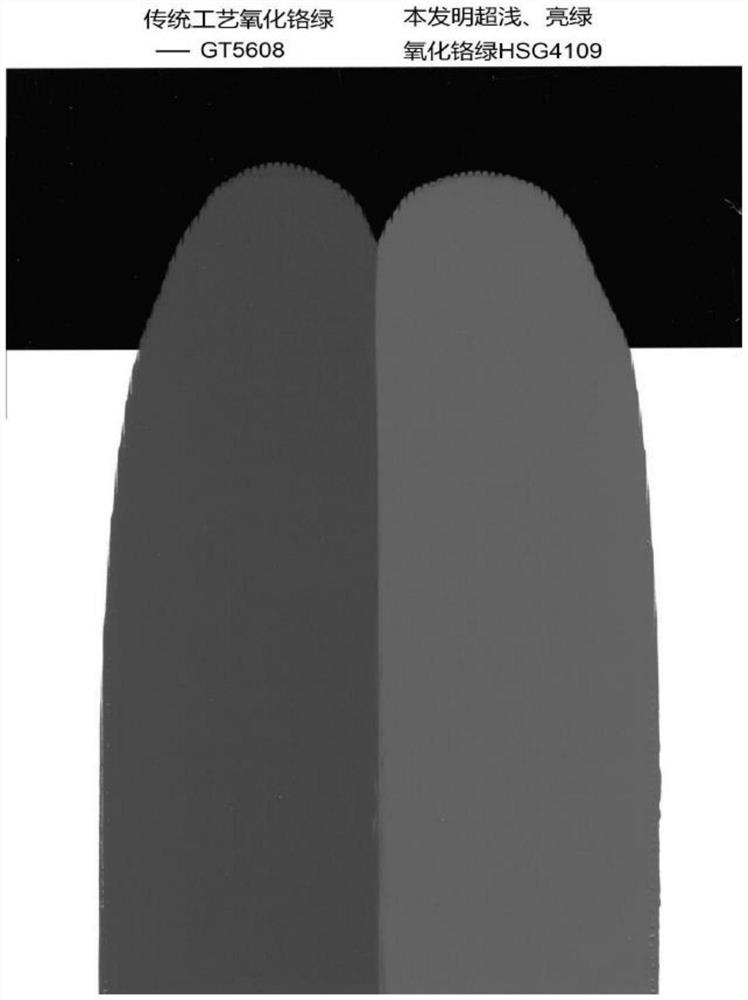

Preparation method of ultra-light bright green chromium oxide green pigment with low hexavalent chromium content

PendingCN114436331AImprove qualityHarm reductionChromium oxides/hydratesChromium sulfatesWarm waterPhotopigment

The invention relates to the technical field of pigment preparation, and provides a preparation method of an ultra-light bright green chromium oxide green pigment with low hexavalent chromium content, which comprises the following steps: S1, selecting powdery basic chromium sulfate with Cr2O3 greater than or equal to 25%; s2, feeding the powdery basic chromium sulfate into a rotary kiln; s3, performing high-temperature calcination in a rotary kiln; and S4, stirring and rinsing the sintered material with cold water, and drying to obtain the chromium oxide green pigment, or crushing the sintered material, rinsing with warm water, and spray-drying to obtain the chromium oxide green pigment. According to the technical scheme, the technical problems that in the prior art, a chromium oxide green production process has the complex conditions of potential risks and the like, the chromium oxide green pigment is poor in quality, and the water-soluble hexavalent chromium content is high are solved.

Owner:衡水友谊新材料科技有限公司

Method for preparing basic chromium sulfate tanning liquor by using tanning chromium sludge

ActiveCN102965455BWill not sputterMild chemical reactionSludge treatmentTanning treatmentChemical reactionSludge

The invention discloses a method for preparing basic chromium sulfate tanning liquor by using tanning chromium sludge, and solves problems in existing method for preparing tanning liquor by using tanning chromium sludge, such as violent reaction, high operation risk coefficient, incomplete organic compound hydrolysis, poor infiltration of the obtained tanning liquor and complex preparation process and steps. The method comprises the following steps: (1) homogenization; (2) leaching; (3) filter pressing; (4) pressure reduction; and (5) cooling and depressurization. The invention has beneficial effects of mild chemical reaction, easily controlled reaction, capability of completely reducing hexavalent chromium to trivalent chromium, low production cost, no introduction of new impurity, simple processing steps, high purity of the finally obtained chrome tanning liquor, high reduction rate of hexavalent chromium, small consumption amount of ethanol or industrial alcohol, deep hydrolysis of organic small molecules, further enhancement of purity and tanning property of the finally obtained tanning liquor.

Owner:ZHEJIANG TELI RECYCLING RESOURCES

Determination method of hexavalent chromium in basic chromium sulfate

ActiveCN106525740BEliminate distracting elementsImprove accuracyColor/spectral properties measurementsBasic chromium sulfateHexavalent chromium

The invention relates to a method for determination of hexavalent chromium in basic chromium sulfate and belongs to the technical field of chemical analysis. The method comprises dissolving a sample to be measured, immediately adding MgCl2 and FeCl3 into the solution, adjusting pH to about 10 so that chromium hydroxide precipitates completely, filtering and washing the precipitates to completely separate hexavalent chromium from trivalent chromium, and detecting the hexavalent chromium in the filtrate by a diphenylcarbazide spectrophotometry to obtain the content of hexavalent chromium. The method realizes elimination of interfering elements and complete separation of trivalent chromium and hexavalent chromium, prevents too high hexavalent chromium content caused by oxidation of trivalent chromium into hexavalent chromium in separation and has high accuracy and a good precision.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of migration-resistant red dye, preparation method and application

The present invention relates to a migration-resistant red dye, a preparation method therefor and application thereof. The preparation method for the dye comprises the following steps: (a) mixing 2-amino-5-nitrophenol, 2-aminophenol-4-sulfamide, sodium nitrite, hydrochloric acid and water to react, and obtaining a diazonium product; (b) adding a mixed solution of 3-(4,5-dihydro-3-methyl-5-oxo-1H-pyrazol-1-yl) benzenesulfonamide, caustic soda liquid and water to a vessel to react with the resulting diazonium product in the step (a), and obtaining a coupling product; (c) performing chromium complexation on basic chromium sulfate and the resulting coupling product in the step (b); (d) reacting a product obtained from the chromium complexation with a mixed solution of formic acid, n-tridecyl amine and water; and (e) after completion of the reaction, filtering and drying. The dye is resistant to a high temperature, is relatively inexpensive, and has good migration resistance.

Owner:GUANGZHOU WEIQING CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com