Method for preparing acid black 172

A technology of acid black and sulfonic acid, applied in chemical instruments and methods, dyeing methods, compound metal compounds of azo dyes, etc., can solve the problem of product abrasion resistance, low washing and light fastness, and low concentration of only 8- 10%, long product production cycle and other problems, to achieve the effect of speeding up the chromization reaction, increasing the product yield and reducing the cost of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

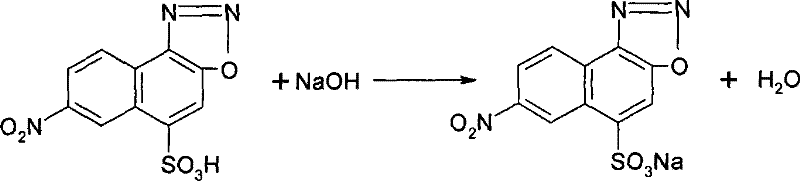

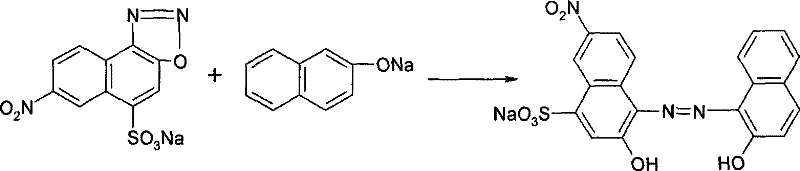

[0031] A preparation method of Acid Black 172, wherein the steps of the preparation method are:

[0032] (1). Put 295g of 100% 6-nitro-1,2-diazooxynaphthalene-4-sulfonic acid into dissolving tank A and add 1000ml of water to dissolve it, and add concentration to tank A while stirring It is a 30% sodium hydroxide solution to control the PH value of 5, and at the same time control the temperature of the solution to 18°C, the specific method of controlling the temperature of the solution can be adding ice;

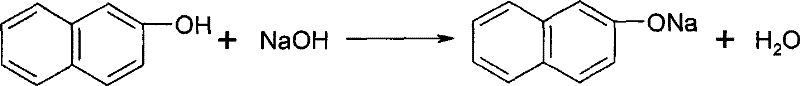

[0033] (2). Put 151g of 2-naphthol into dissolving tank B and add 400ml of water to dissolve it, add 95ml of 30% sodium hydroxide solution to tank B, stir and heat up to 80℃, when 2-naphthol is completely dissolved , Add 3g dispersant NSO (β-naphthalenesulfonic acid and formaldehyde condensate) and 8g ethylene glycol monobutyl ether, stir;

[0034] (3). Under the condition of rapid stirring, quickly pour the liquid in dissolving tank B into dissolving tank A to form a mixed liquid,...

Embodiment 2

[0038] A preparation method of Acid Black 172, wherein the steps of the preparation method are:

[0039] (1). Put 295g of 100% 6-nitro-1,2-diazooxynaphthalene-4-sulfonic acid into dissolving tank A and add 1000ml of water to dissolve, add to tank A under stirring conditions Sodium hydroxide solution with a concentration of 30%, control the PH value to 4, and at the same time control the temperature of the solution to 20°C, the specific method of controlling the temperature of the solution can be adding ice;

[0040] (2). Put 151g of 2-naphthol into dissolving tank B and add 400ml of water to dissolve it, add 95ml of 30% sodium hydroxide solution to tank B, stir and heat up to 85℃, when 2-naphthol is completely dissolved , Add 3g of dispersant ethoxylated nonylphenol and 8g of propylene glycol and stir;

[0041] (3). Under the condition of rapid stirring, quickly pour the liquid in dissolving tank B into dissolving tank A to form a mixed liquid, control the temperature of the mixed l...

Embodiment 3

[0045] A preparation method of Acid Black 172, wherein the steps of the preparation method are:

[0046] (1). Put 295g of 100% 6-nitro-1,2-diazooxynaphthalene-4-sulfonic acid into dissolving tank A and add 1000ml of water to dissolve, add to tank A under stirring conditions Sodium hydroxide solution with a concentration of 30%, control the PH value to 6, and at the same time control the temperature of the solution to 12°C, the specific method of controlling the cooling of the solution can be by adding ice;

[0047] (2). Put 151g of 2-naphthol into dissolving tank B and add 400ml of water to dissolve it, add 95ml of 30% sodium hydroxide solution to tank B, stir and heat up to 75℃, when 2-naphthol is completely dissolved , Add 3g dispersant sodium lignosulfonate and 8g ethylene glycol monomethyl ether, stir;

[0048] (3). Under the condition of rapid stirring, quickly pour the liquid in dissolving tank B into dissolving tank A to form a mixed liquid, control the temperature of the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com