Preparation method of ultra-light bright green chromium oxide green pigment with low hexavalent chromium content

A chromium oxide green, hexavalent chromium technology, applied in chromium oxide/hydrate, chemical instruments and methods, chromium compounds, etc., can solve the problem of poor quality of chromium oxide green pigments, hidden dangers in production processes, high water-soluble hexavalent chromium, etc. problem, to achieve the effect of bright color, reducing environmental damage and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] S1, select Cr 2 o 3 ≥25% powdered basic chromium sulfate;

[0043] S2. After the powdery basic chromium sulfate is sucked into the silo through the vacuum pump, it is sent into the rotary kiln through the blower through the rapid conveying dragon;

[0044] S3. Control the temperature of the rotary kiln at 1000-1150°C, and calcine at a high temperature in the rotary kiln for 2.5 hours;

[0045] S4. The fired material is sent to a cold water mixing tank for rinsing in a ratio of 1:3 by a conveyor, and rinsed 4 times to 0.5% of water-soluble salt. After filtering, drying, and crushing, chromium oxide green pigment is obtained, which is recorded as HSG4109;

[0046] Among them, the rinsing water is backwashed twice for the first time, backwashed for the second time three times, and so on, which can reduce the amount of new water, and the final hexavalent chromium content of the rinsed water is 912ppm;

[0047] The tail gas sulfur dioxide produced in the process is recove...

Embodiment 2

[0049] S1, select Cr 2 o 3 ≥25% of vitamin K3 by-product basic chromium sulfate;

[0050] S2. After the powdery basic chromium sulfate is sucked into the silo through the vacuum pump, it is sent into the rotary kiln through the blower through the rapid conveying dragon;

[0051] S3. Control the temperature of the rotary kiln at 1000-1150° C., and calcine at a high temperature in the rotary kiln for 3 hours;

[0052] S4. The burned material is sent to the cold water mixing tank for rinsing in a ratio of 1:3 by the conveyor, and rinsed 5 times to a water-soluble salt level of 0.3%. By analogy,) obtain chromium oxide green pigment after filtering, drying, pulverizing.

experiment example

[0054] The chromium oxide green pigment of the present invention exhibits data and effects such as brightness, depth, hue, and color difference through DL*Da*Db*DE*. The data detection is completed by color measurement with Konica Minolta colorimeter.

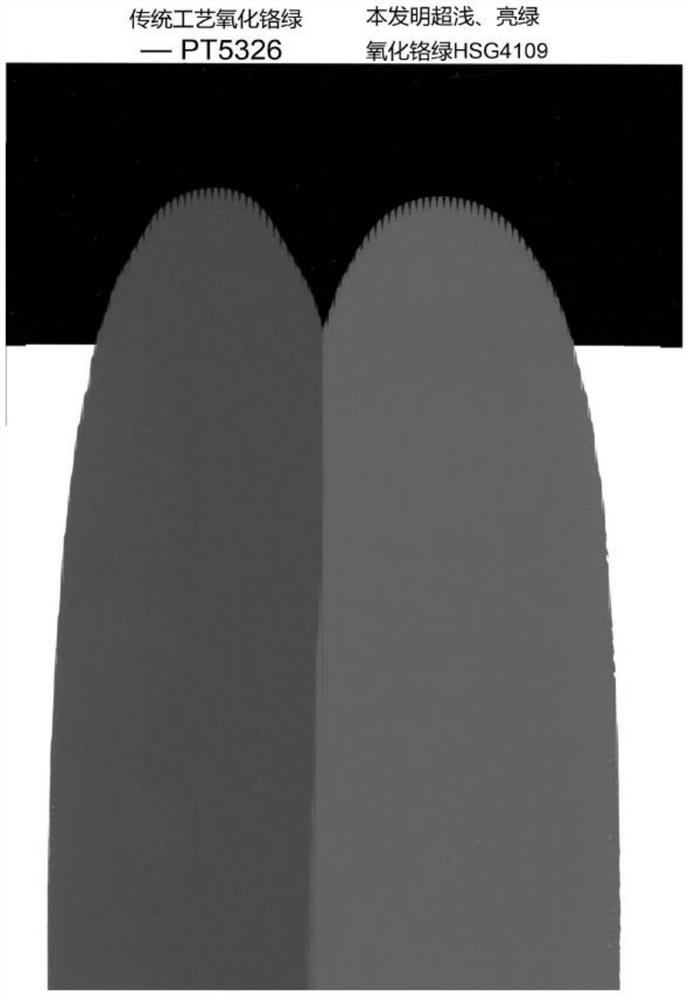

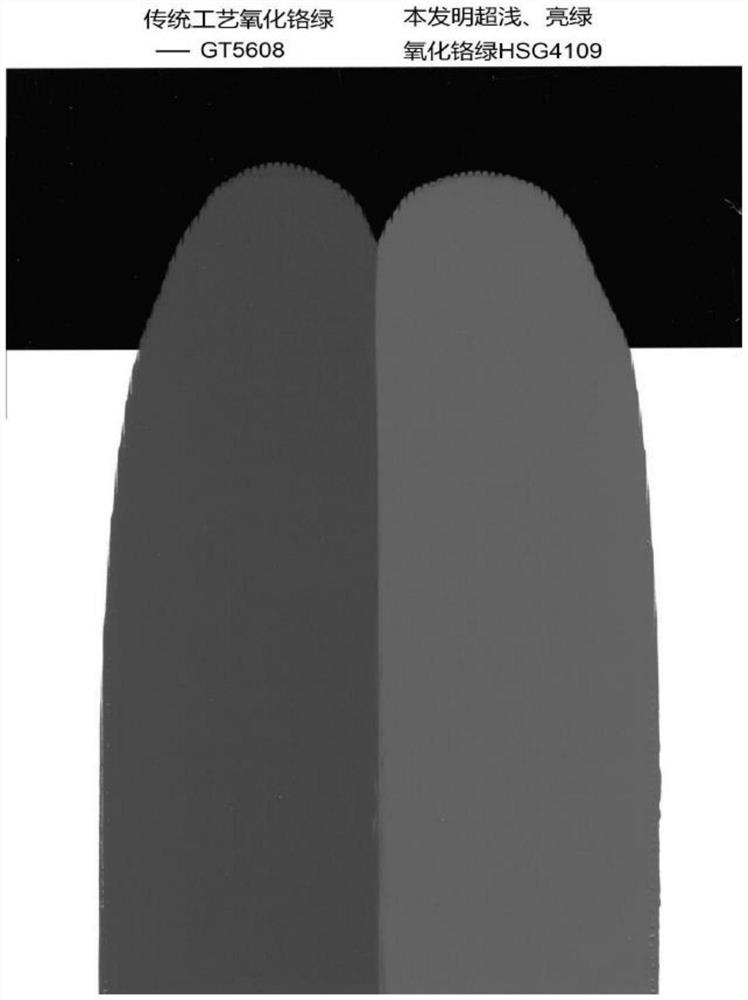

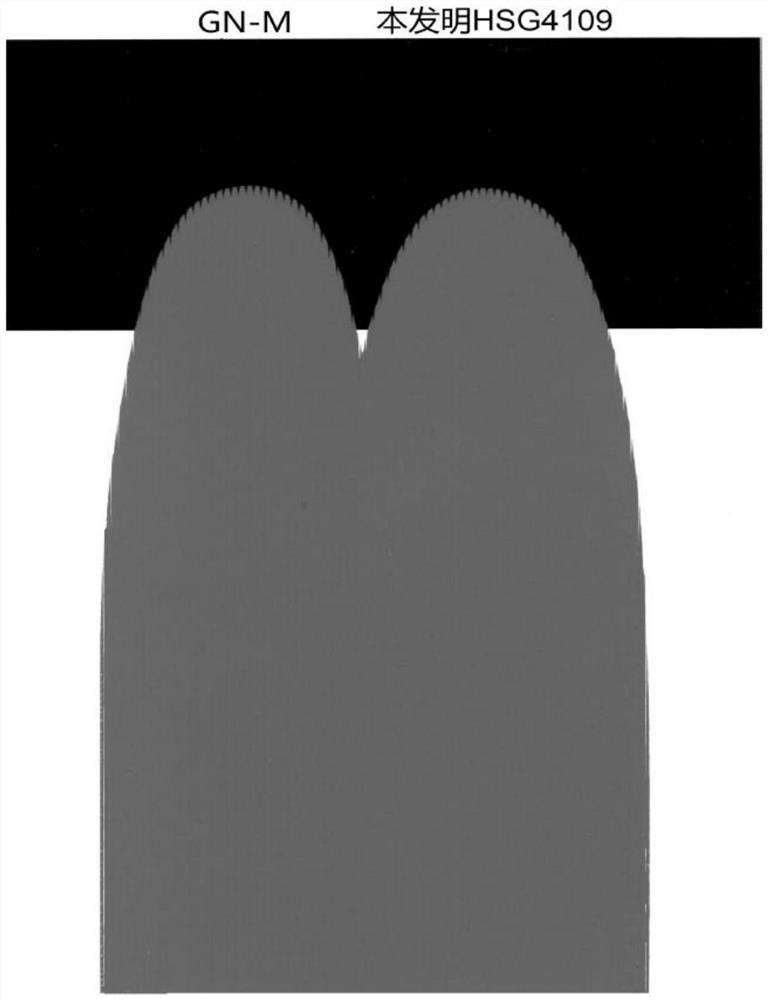

[0055] Specific method: that is, according to the proportion of 1g of pigment and 1mL of linseed oil, mix and grind the paint in PM240-2 flat grinder, and then prepare the color card according to the GB5211.19-88 standard operation, and use the Konica Minolta CR-10 color difference meter to measure and calculate Results, the results are shown in Table 1-6, and the full-color color card is shown in Figure 1-3 . The higher the DL value relative to the comparison sample, the greater the brightness value of the color, the higher the brightness, the DA value is relative to the comparison sample. kind of greener. Compared with the control sample, the positive value of DB value is more yellowish, and the negative value is more blu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com