Cast aluminum alloy for automobile metal casting and processing technology of cast aluminum alloy

A technology for casting aluminum alloys and metal castings, which is applied in the field of mechanical parts processing, and can solve problems such as coarse grains, decreased comprehensive performance of aluminum alloys, and reduced yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

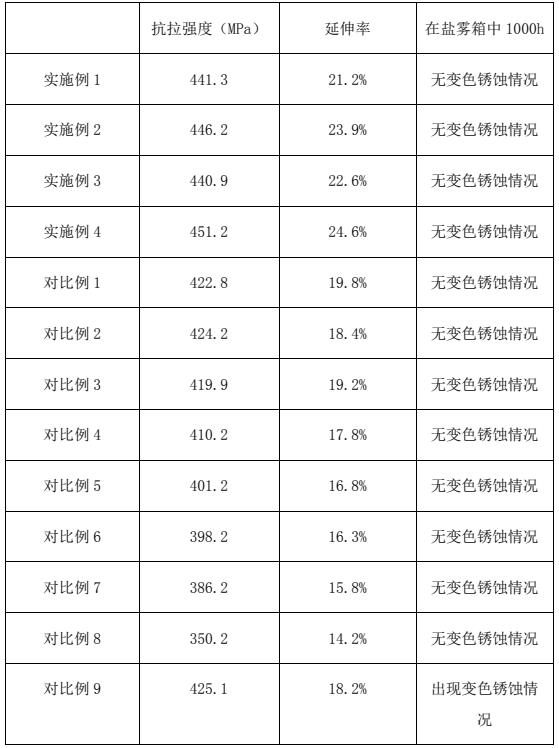

Examples

Embodiment 1

[0049] A cast aluminum alloy for automotive metal castings. In terms of percentages, the composition of the aluminum alloy is: Si 0.5%, Mg2%, Cu 2%, Mn 0.25%, Fe 0.2%, Y 0.08%, Zn 0.4%, Yb 0.1 %, Er 0.1%, Sr 0.1%, the total amount of unavoidable impurity elements does not exceed 0.3%, and the balance is Al;

[0050] A processing technology for casting aluminum alloys for automobile metal castings, comprising the following steps:

[0051] S1: Preheat the crucible to 400°C, put in an aluminum block, raise the temperature until the aluminum block is completely melted, heat to 730°C, remove slag and gas, stir and keep warm for 60 minutes, put yttrium aluminum alloy, magnesium aluminum alloy, zinc sheet, copper The flakes and ytterbium aluminum alloy are crushed, ball-milled into powder and wrapped in aluminum foil, pressed into the melt with a bell jar, stirred by a graphite rod to discharge gas;

[0052] S2: Dip the preheated ultrasonic horn into the melt surface at 15mm for ult...

Embodiment 2

[0061] A cast aluminum alloy for automotive metal castings. In terms of percentages, the aluminum alloy components are: Si 1%, Mg 2.3%, Cu 2.5%, Mn 0.42%, Fe 0.35%, Y 0.08%, Zn 0.6%, Yb 0.2%, Er 0.2%, Sr0.22%, the total amount of unavoidable impurity elements does not exceed 0.3%, and the balance is Al;

[0062] A processing technology for casting aluminum alloys for automobile metal castings, comprising the following steps:

[0063] S1: Preheat the crucible to 405°C, put in an aluminum block, heat up until the aluminum block is completely melted, heat to 745°C, remove slag and degassing, stir and keep warm for 50 minutes, put yttrium aluminum alloy, magnesium aluminum alloy, zinc sheet, copper The flakes and ytterbium aluminum alloy are crushed, ball-milled into powder and wrapped in aluminum foil, pressed into the melt with a bell jar, stirred by a graphite rod to discharge gas;

[0064] S2: Dip the preheated ultrasonic horn into the melt surface at 16mm for ultrasonic trea...

Embodiment 3

[0072] A cast aluminum alloy for automotive metal castings. In terms of percentages, the aluminum alloy components are: Si 1.5%, Mg 2.5%, Cu 3%, Mn 0.65%, Fe 0.5%, Y 0.08%, Zn 0.9%, Yb 0.3%, Er 0.25%, Sr0.3%, the total amount of unavoidable impurity elements does not exceed 0.3%, and the balance is Al;

[0073] A processing technology for casting aluminum alloys for automotive metal castings, characterized in that it comprises the following steps:

[0074] S1: Preheat the crucible to 410°C, put in the aluminum block, raise the temperature until the aluminum block is completely melted, heat to 750°C, remove the slag and gas, stir and keep it warm for 40 minutes, put the yttrium aluminum alloy, magnesium aluminum alloy, zinc sheet, copper The flakes and ytterbium aluminum alloy are crushed, ball-milled into powder and wrapped in aluminum foil, pressed into the melt with a bell jar, stirred by a graphite rod to discharge gas;

[0075] S2: Immerse the preheated ultrasonic horn at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com