Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Meet recycling standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

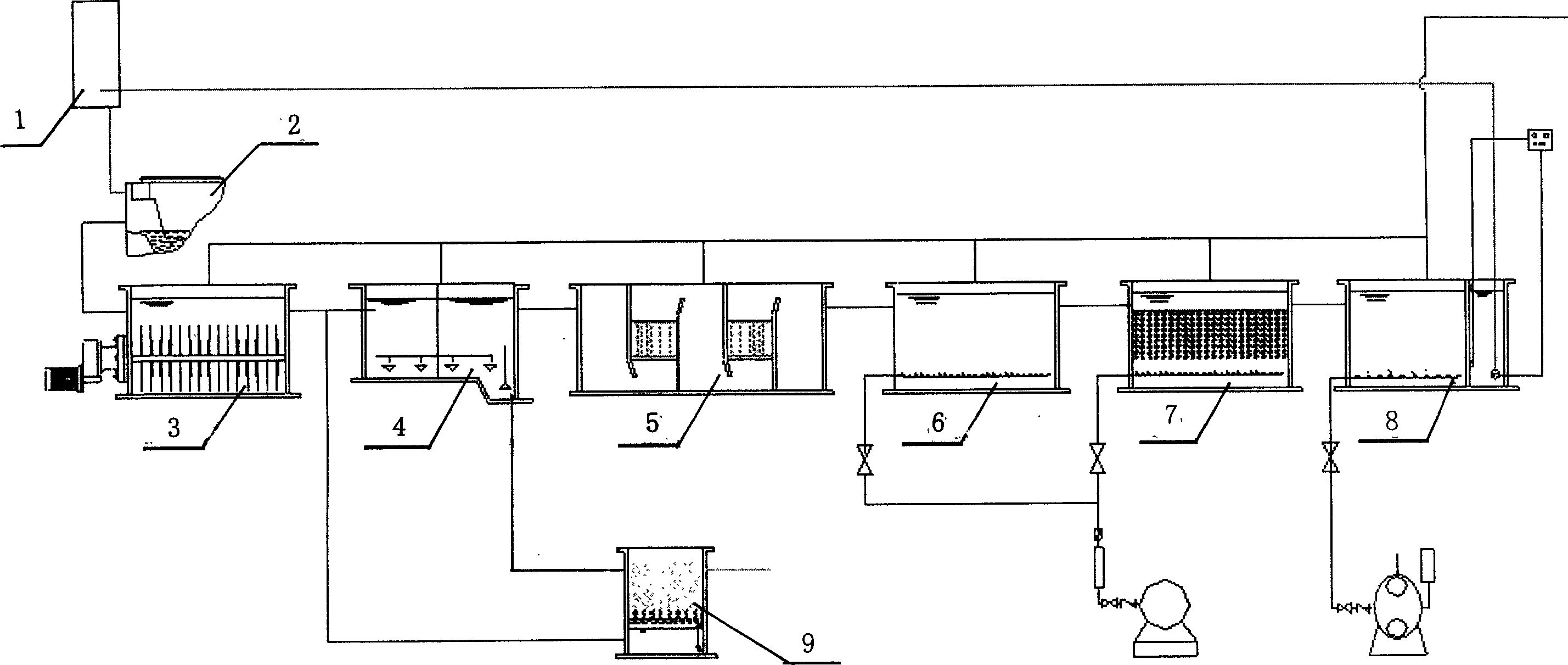

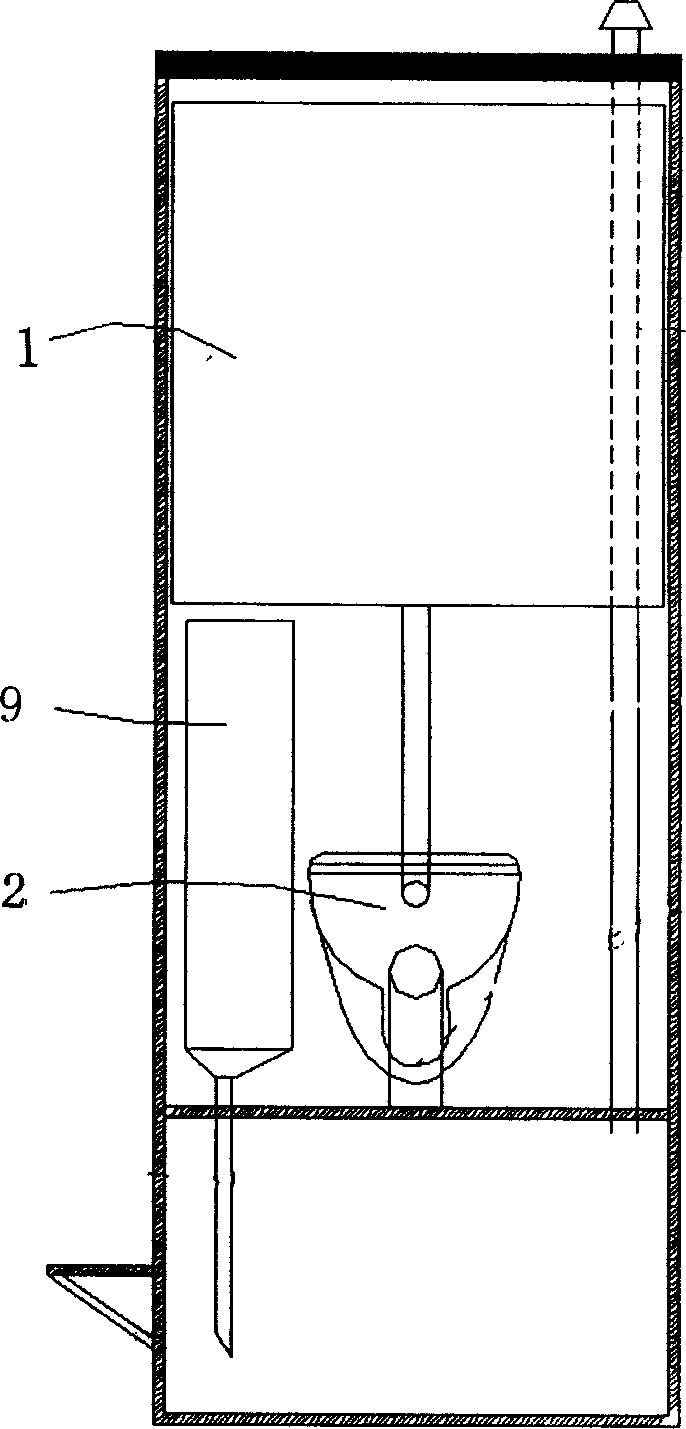

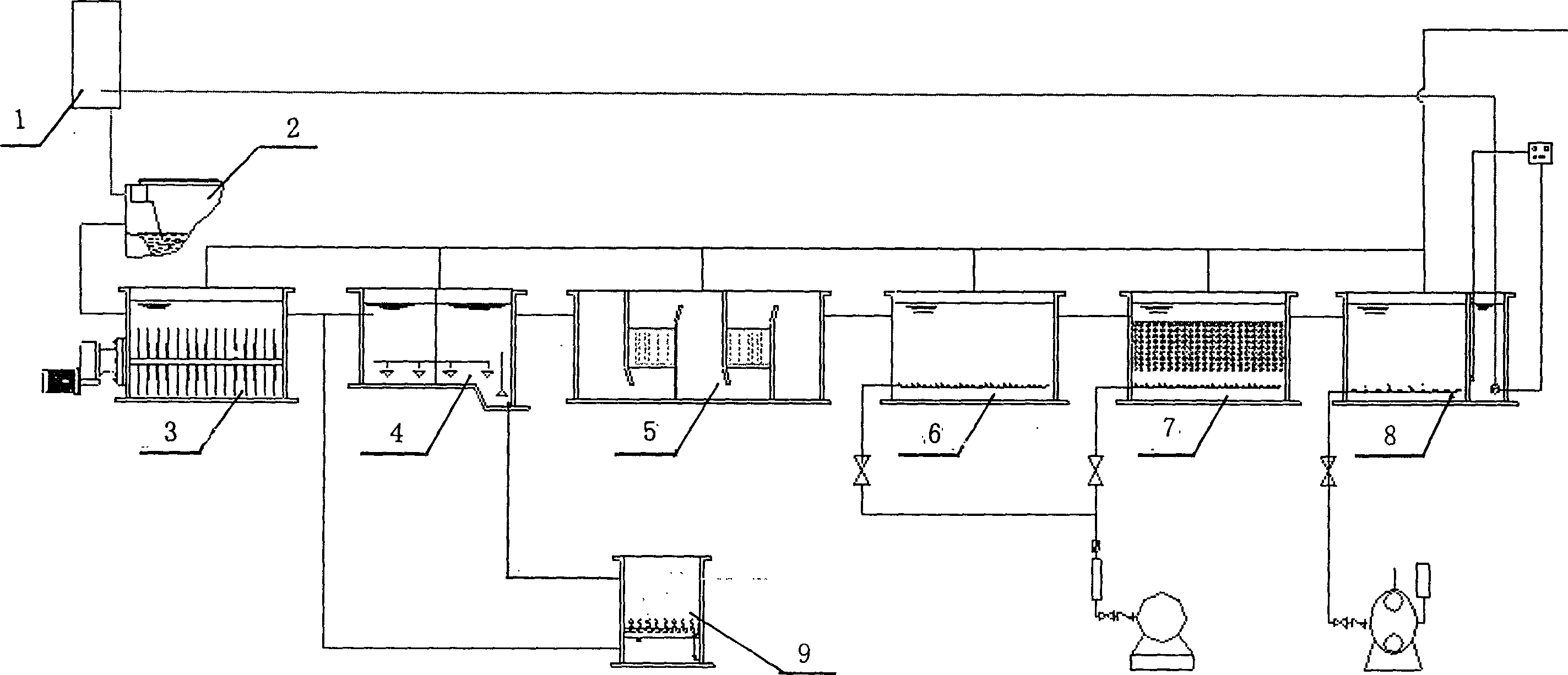

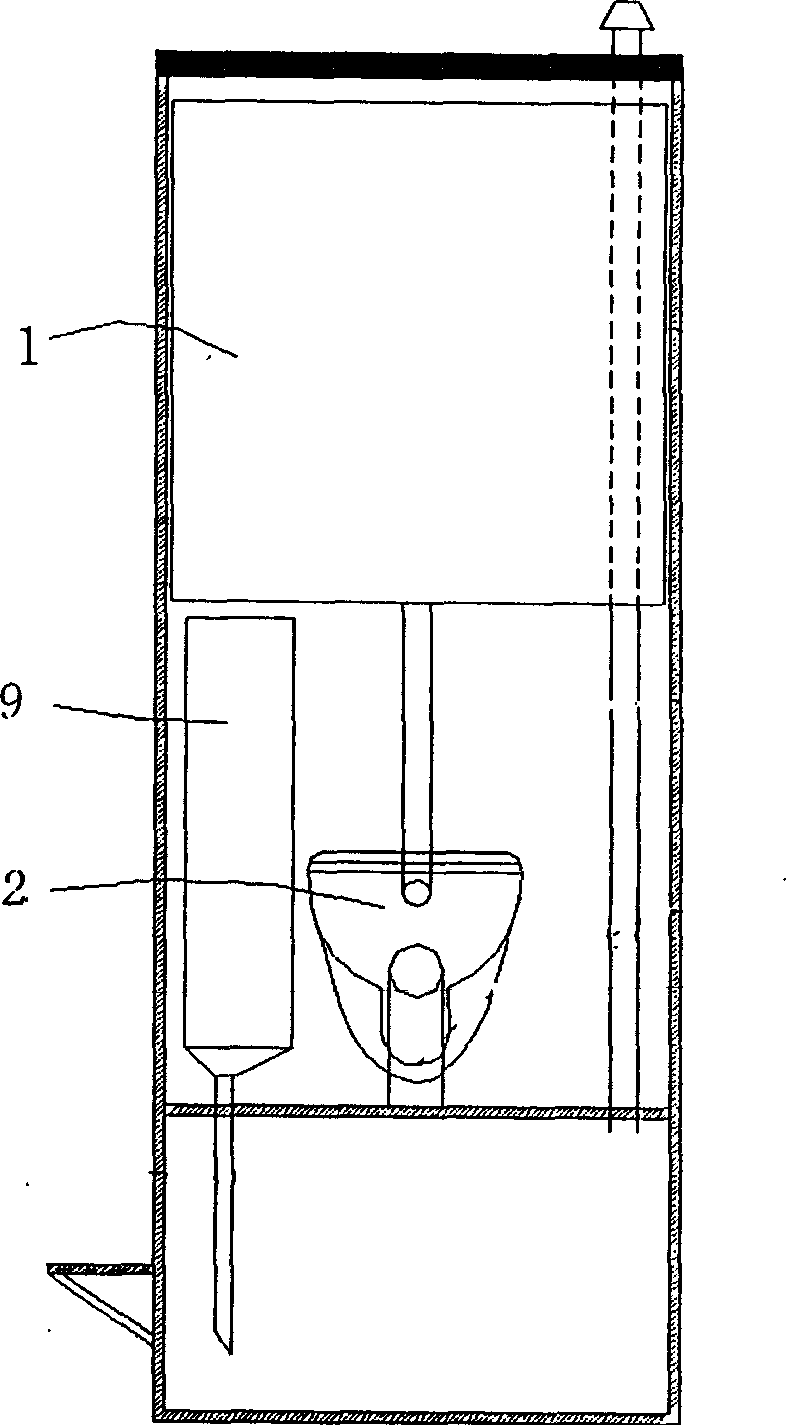

Circulating water flushing ecological toilet and sewage treatment method thereof

InactiveCN1594763AExpand conceptBroaden the field of applicationFlushing devicesLavatory sanitoryHuman wasteFeces

The invention discloses a circulating water flushing ecological toilet and sewage treatment method thereof. The high-position water tank orderly connects to the latrine, grinder-mixer, solid and liquid separator, anaerobic reacting device, facultative reacting device, aerobic reacting device and ozone disinfection device. The ozone disinfection device connects to the high-position water tank by water pump. The invention breaks the localization that the toilet depends on the water and the ecological toilet contaminant is treated elsewhere, conquers the secondary pollution of the transporting, collecting and packing materials for ecological no water toilet, improves the efficiency of the dejection treatment in situ and innocuous treatment degree, fully applies the abundant microbe resource in the dejection.

Owner:NANJING UNIV

Recycling treatment method for feces and wastewater in large-scale livestock and poultry breeding farm

InactiveCN106242162ANo need to addReduce aerationSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAnimal fecesEnergy recovery

A recycling treatment method for feces and wastewater in a large-scale livestock and poultry breeding farm includes the following steps: (1) pre-treating the feces and wastewater in the large-scale livestock and poultry breeding farm in a pretreatment unit to form slurry; (2) feeding the slurry into an energy recovery unit, and performing solid anaerobic digestion in a solid anaerobic reactor to obtain an energy gas, methane; (3) performing solid-liquid separation to the digested slurry to generate wastewater, which is then fed into a UASB reactor to perform further anaerobic fermentation to remove organic pollutants from the wastewater; (4) feeding the treated wastewater into a nitrogen and phosphorus removal unit to perform nitrogen and phosphorus removal treatment; (5) separating and purifying a precipitate, which is generated in the nitrogen and phosphorus removal unit and mainly includes magnesium ammonium phosphate, to obtain an organic fertilizer additive, wherein the nitrogen removal process is autotrophic nitrogen removal and can reduce aeration quantity by 62.5% without addition of any carbon sources, thus saving large quantity of operation cost; and (6) feeding the treated wastewater into a deep-treatment unit to remove bio-refractory substances and disinfect the wastewater so as to finally reach emission and recovery standards of wastewater.

Owner:SOUTH VENTURE TIANJIN TECH DEV CO LTD

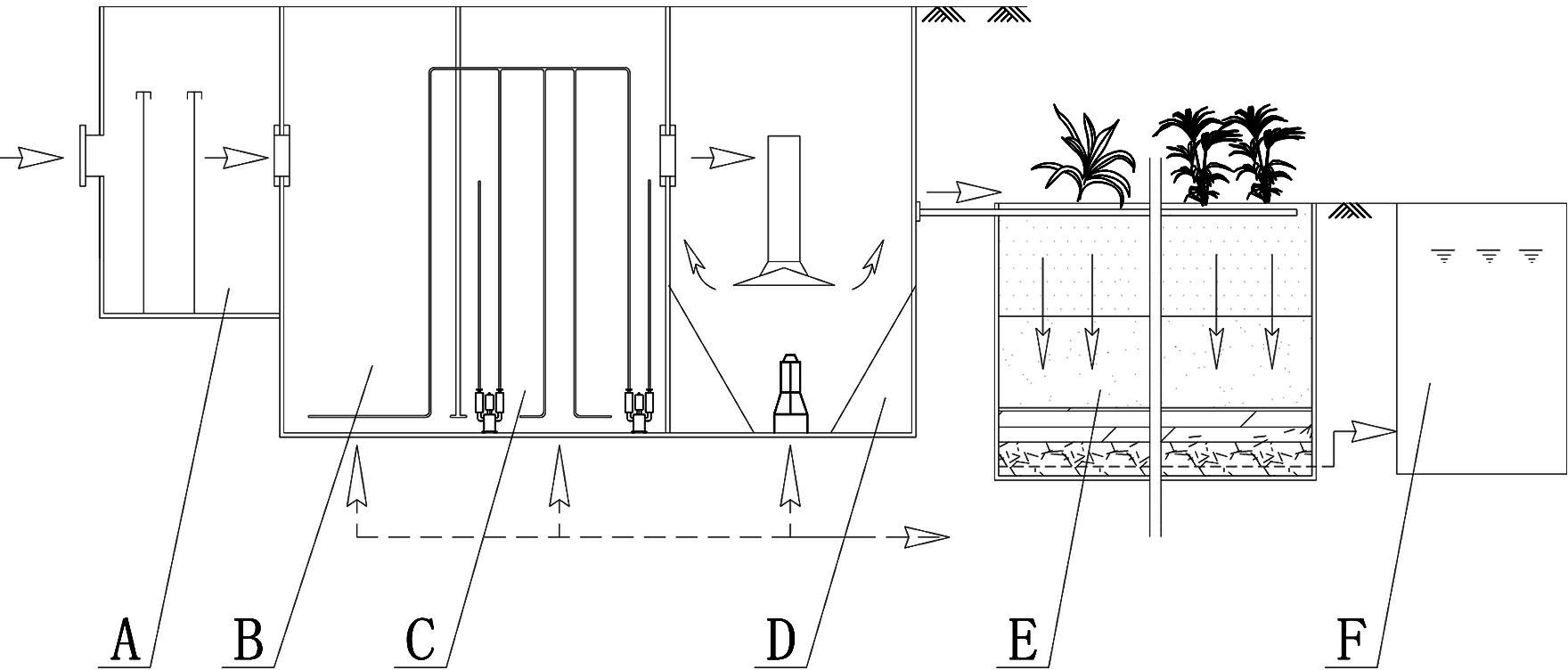

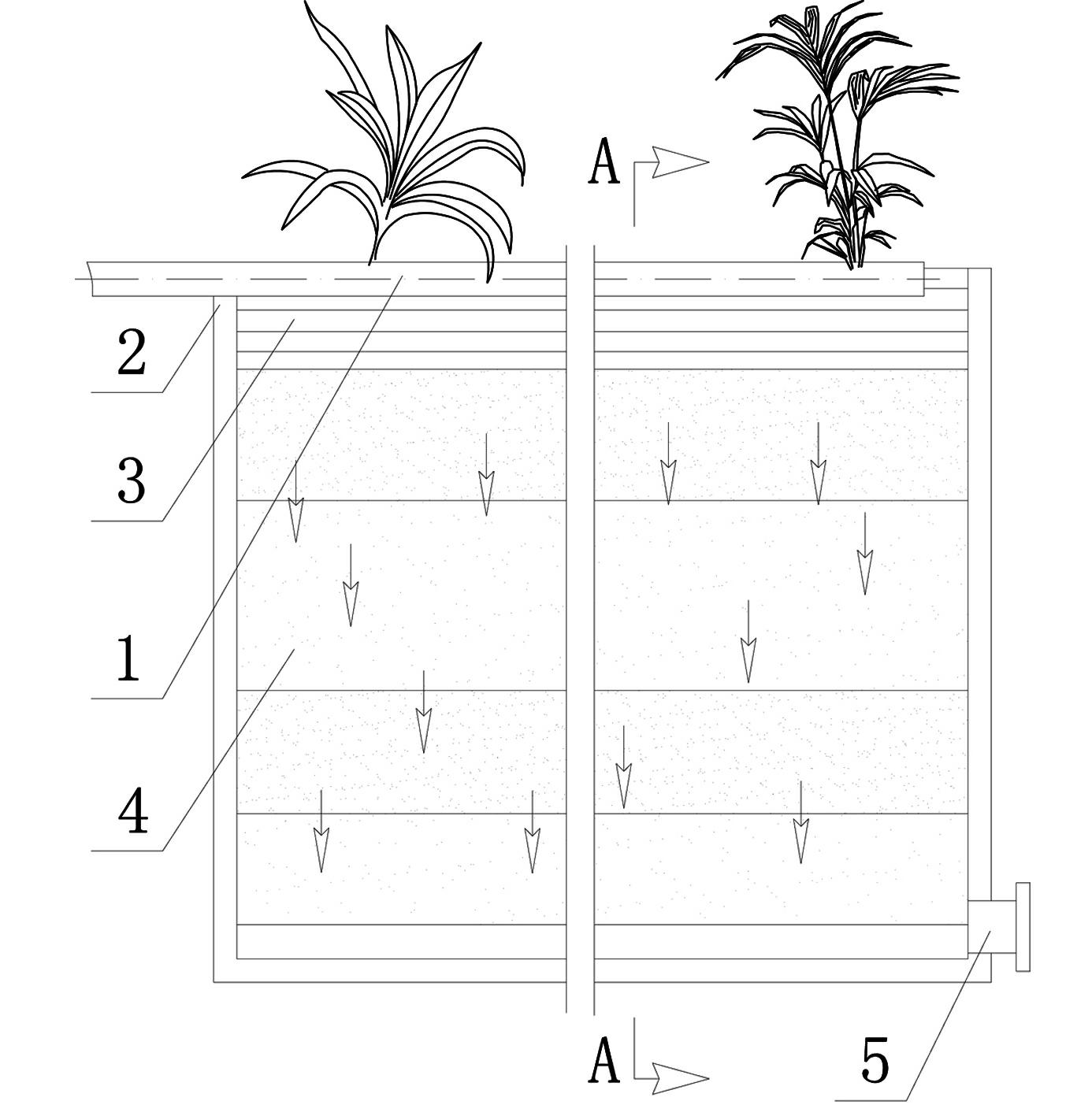

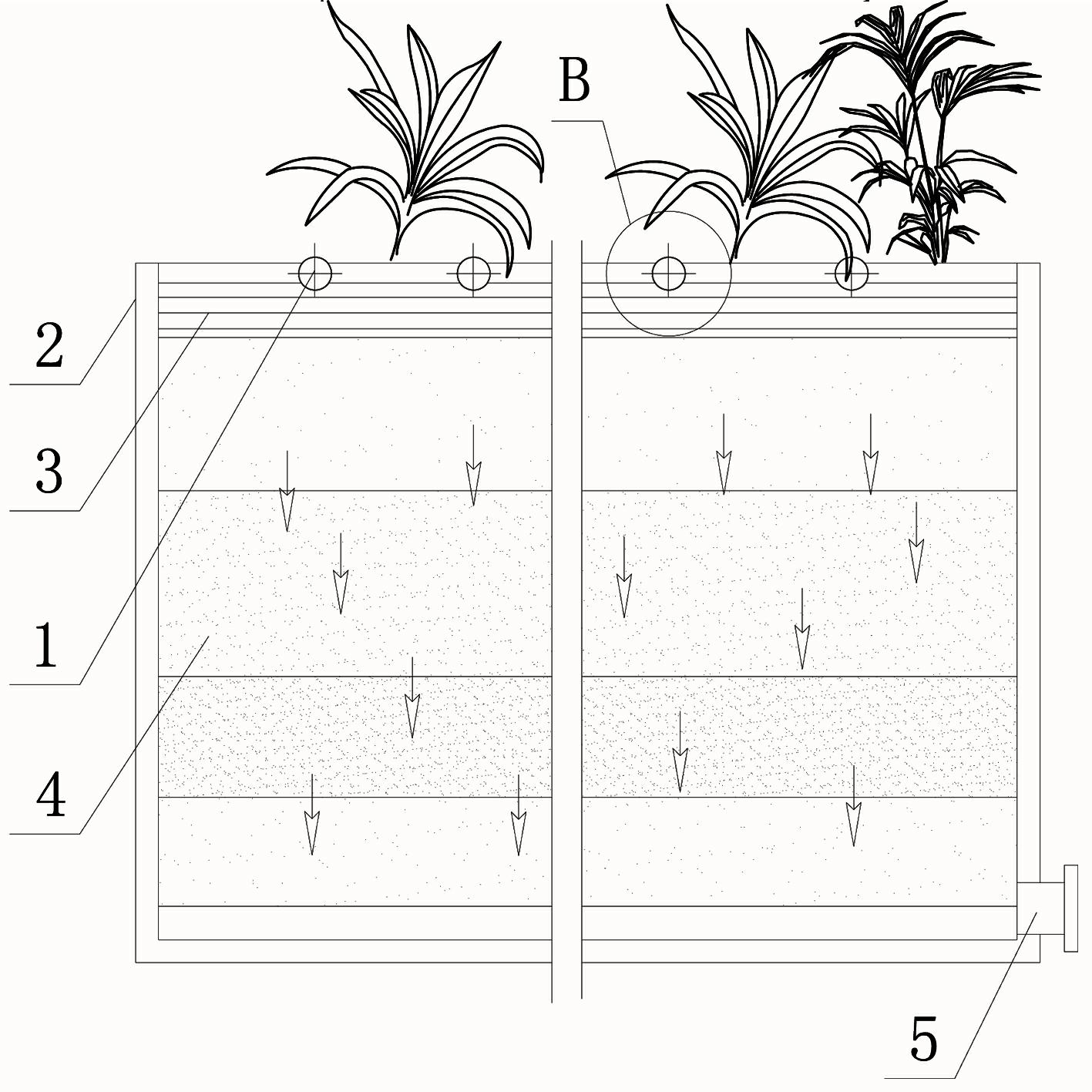

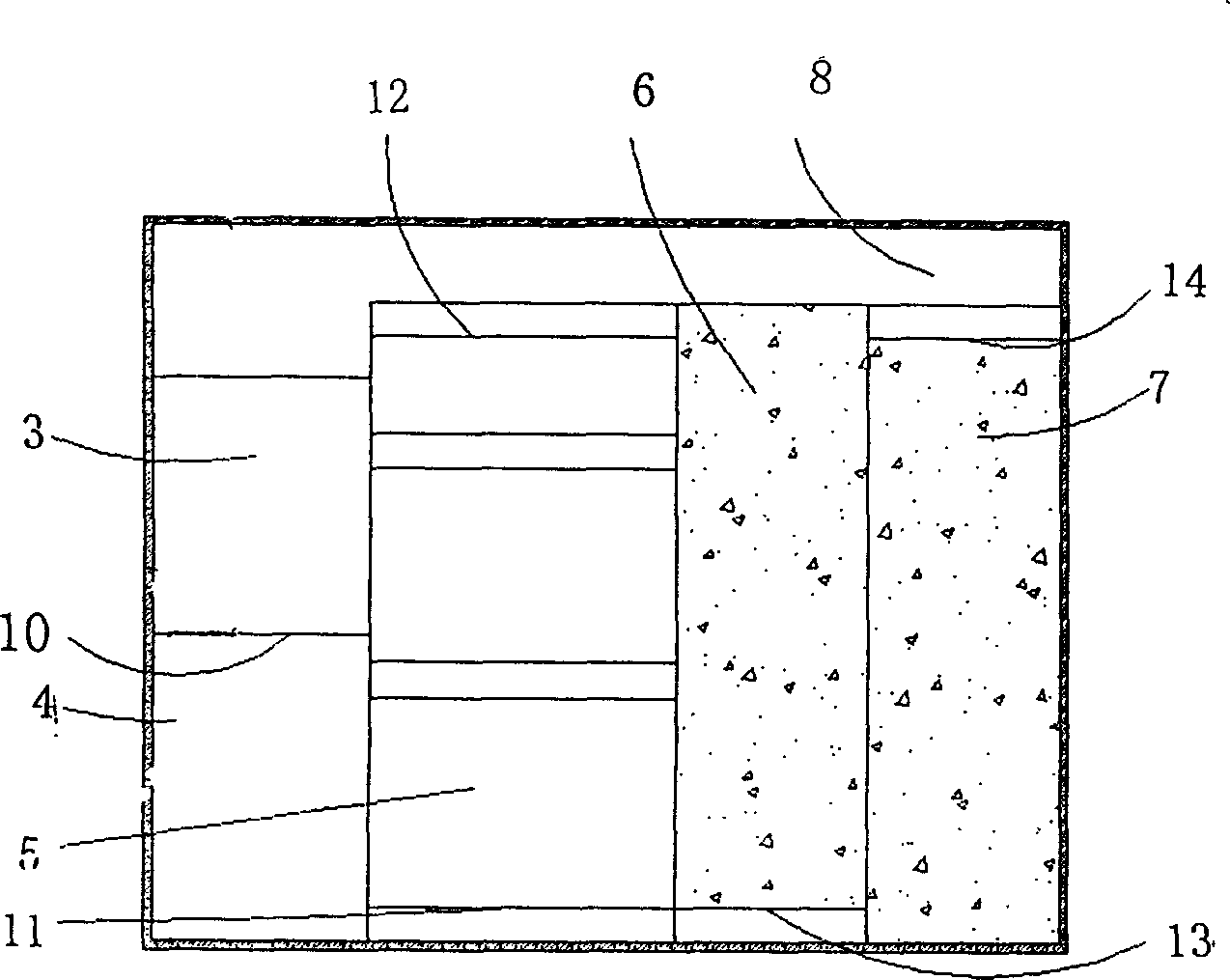

Method for advanced treatment of sewage and artificial wetland structure

ActiveCN102249496AMeet recycling standardsImprove water treatment effectMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandActivated carbon

The invention discloses a method for advanced treatment of sewage and an artificial wetland structure to solve the technical problems of low denitrification and dephosphorization effect and high capital construction and operating cost of the traditional sewage treatment system. The treatment method comprises the following steps that: sewage is intercepted by a grate, is subjected to hydrolysis acidification, aeration oxygenation and sedimentation, enters the top of artificial wetland, flows through a sand and gravel filler treatment layer, a lime stone treatment layer, a volcanized rock treatment layer, an oyster shell treatment layer, an active carbon treatment layer and a gravel treatment layer, which are arranged in the artificial wetland, from top to bottom in turn, is collected by a bottom pipeline of the artificial wetland and enters a recycling water tank. The internal structure of the artificial wetland is that: a group of sewage inlet pipes are horizontally arranged at the upper end of a treatment tank and are arranged in a filler reinforced treatment layer in the treatment tank, the sand and gravel filler treatment layer is arranged below the filler reinforced treatment layer, and a sewage outlet pipe is arranged at the bottom of the treatment tank. The invention has the advantages that: the treatment effect is good, the sewage recycling standard is met and the operating cost is low.

Owner:SHENZHEN BIYUAN ENVIRONMENTAL PROTECTION TECHNIC CO LTD

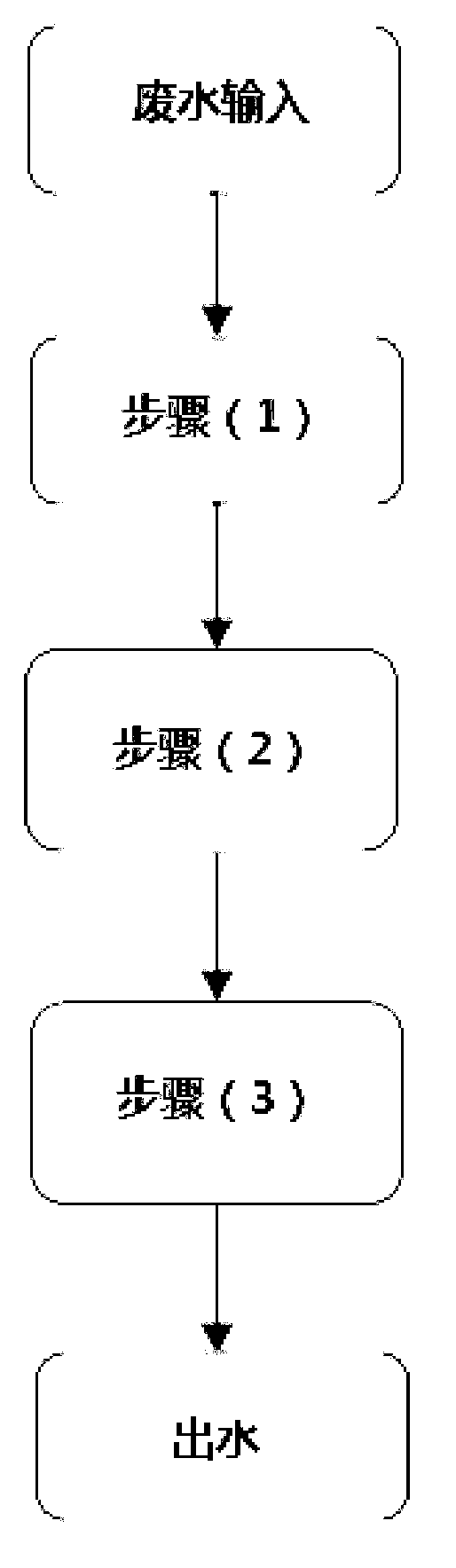

Treating and recycling method for waste water of lead-acid battery industry

InactiveCN102976510ATo the point of reuseTo the extent that it can be reusedEnergy based wastewater treatmentMultistage water/sewage treatmentUltrafiltrationHazardous substance

The invention relates to the technical field of water treatment and specifically to a treating and recycling method for waste water. The treating and recycling method for waste water of the lead-acid battery industry comprises the following steps: (1) pretreatment: a step of controlling the pH value of plumbic acid waste water to be in a range of 8 to 9 by using alkali lye and then adding a flocculating agent and a coagulant aid; (2) treatment with an ultrafiltration membrane: a step of conveying supernatant liquid which is obtained after deposition of the waste water treated in step (1) to an ultrafiltration membrane treatment system for treatment; and (3) treatment with a reverse osmosis membrane: a step of conveying supernatant liquid which is obtained after deposition of the waste water treated in step (2) to a reverse osmosis membrane treatment system for treatment. With such a technical scheme, the method provided in the invention has the advantages of simple steps and low investment cost and can not only effectively filter harmful substances in the waste water but also control water quality to allow the water quality to reach standards for recycling and reusing.

Owner:SHANGHAI WENDING WATER TREATMENT ENG +2

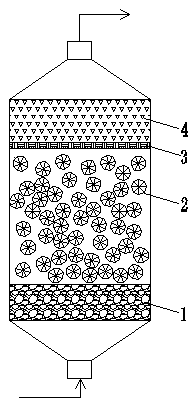

Treatment device and method for removing heavy metals out of sewage

ActiveCN103979749AOvercome costsOvercome operational complexityWater contaminantsMultistage water/sewage treatmentFiltrationSewage

The invention provides a treatment device and method for removing heavy metals out of sewage. The treatment device comprises a tank body, wherein a water inlet pipe is connected to the bottom of the tank body, a water outlet pipe is connected to the upper end of the tank body, a sandstone initial filter layer, a microbial adsorption layer, filter cloth and a granular activated carbon adsorption layer are sequentially arranged in the tank body from bottom to top, and the microbial adsorption layer is provided with spheres of which the surfaces are attached with microbes. By the treatment device and the treatment method, the disadvantages of the traditional metal ion removal methods that the cost is high, the operation is complicated, low-concentration wastewater is difficult to treat are overcome, and treated water can reach reuse standards by using a microbial treatment manner and adopting a multi-stage filtration and adsorption manner; meanwhile, potential heavy metal resources are recycled.

Owner:FUZHOU UNIV

Process for refining wheat-straw pulp by hydrogen peroxide enzyme method

InactiveCN103174047ASolve pollutionMeet recycling standardsPulping with inorganic basesPulp beating/refining methodsFiberPeroxidase

The invention relates to a process for refining wheat-straw pulp by a hydrogen peroxide enzyme method. A technology combining biological enzyme cold soaking catalytic decomposition with a mechanical mehtod is adopted for forming paper pulp from wheatgrass, grass is softened and dissociated at normal temperature, and fiber with physical indexes which meet the requirements of a conventional papermaking standard is formed through the mechanical mehtod. The process is as follows: soaking and softening the wheatgrass by adopting sodium hydroxide and sodium sulfite for cold soaking, then extruding a soaking solution in the wheatgrass through a screw extruder, washing, dehydrating, then enabling the wheatgrass to react with disodium edetate, sodium borohydride and hydrogen peroxidase in a thread rolling machine for fibrillation, and further forming the wheat-straw pulp required for production through a medium-concentration grinding machine and a high-concentration grinding machine. According to the process, the following raw materials in percentage by weight are used for the absolute dry wheatgrass: 16%-20% of sodium hydroxide, 0.6%-0.9% of sodium sulfite, 0.5%-2% of disodium edetate, 0.1%-0.3% of sodium borohydride and 0.5%-1.39% of hydrogen peroxidase. According to the process disclosed by the invention, biological bleaching and pulping is adopted, black liquor is not produced, a biological dissolution solution for soaking the wheatgrass can be reused for a long time, pulping water can be reused, and the production and the emission of the black liquor can be avoided during the pulping process.

Owner:ZAOZHUANG HONGRUN PAPER IND

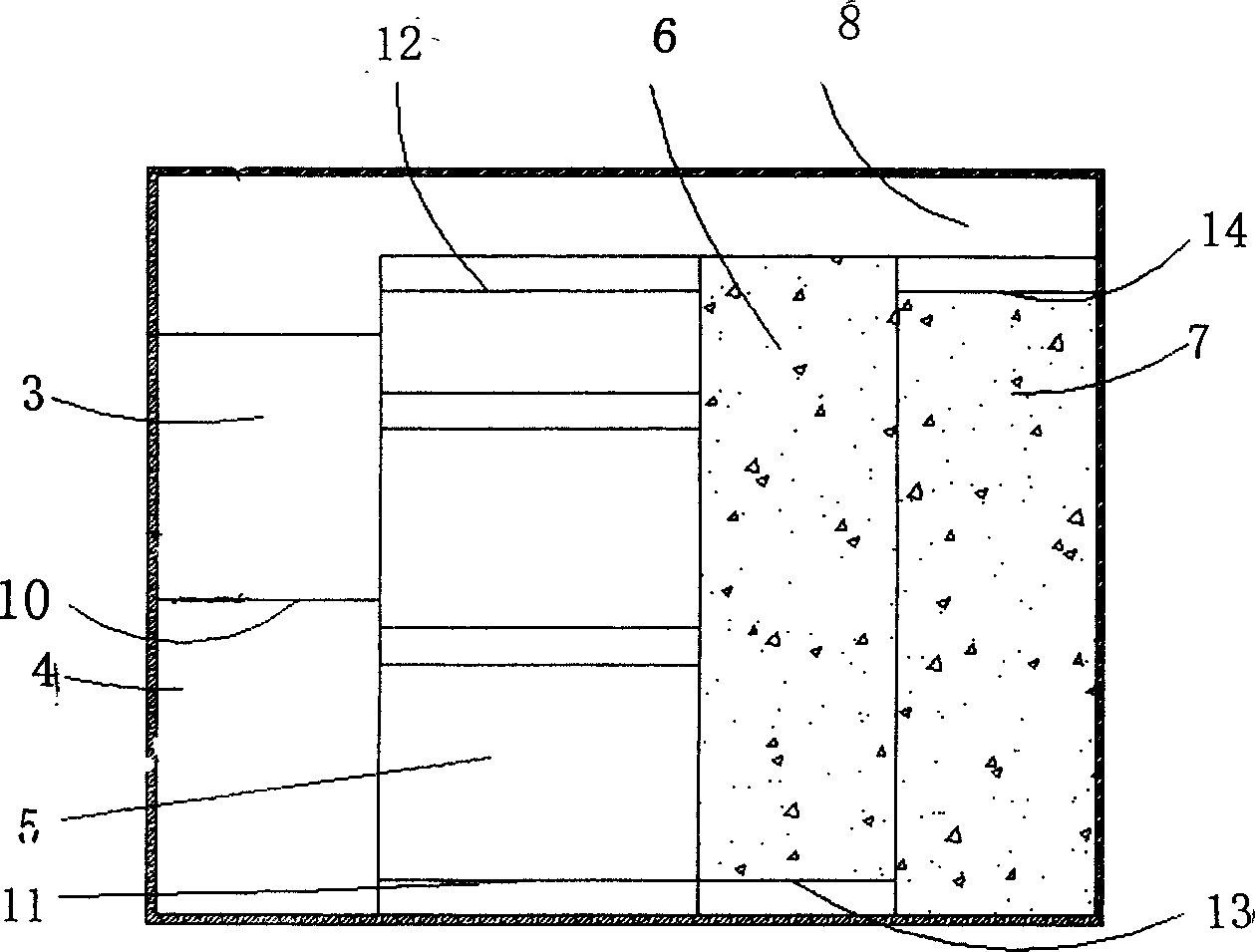

Filter tank type membrane bioreactor

InactiveCN101391833AReduce membrane foulingReduce replacement frequencyTreatment using aerobic processesSustainable biological treatmentWater pipeFilter material

A filter type membrane bioreactor comprises a biofilter, a receiving pool and a membrane module, and the biofilter is divided into a filter layer and a supporting layer; the filter layer is made from active filter material with high absorbability and biological adhesiveness and the filter material is a mixture made up of zeolite, granular activated carbon and aged refuse; the supporting layer comprises net sand cloth, a gravel layer and a porous backing plate from top to down, the grain size of the gravel layer gradually increases from top to down; the top of the biofilter is provided with a water supply pipe, on which a pump is arranged and which is connected with a pretreatment basin and provided with a weeper or connected with a sprayer; the receiving pool is arranged below the biofilter, the water pipe of the receiving pool is connected to the membrane module by the pump, a clean water pipe is connected above the membrane module, facilitating the discharge or reuse of clean water, and a backflow pipe is connected below the membrane module and connected with the water inlet of the biofilter, thus forming a cycling treatment system. The device of the invention is characterized by rich filter material sources, big filter flux, the reduction of membrane fouling and energy consumption, as well as high denitrification and dephosphorization efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Calcium hardness reducing method of recycle water of non-ferrous metallurgical acid waste water

InactiveCN107010739AMeet recycling standardsSimple processing methodWater softeningCalcium bicarbonateAfter treatment

The invention provides a calcium hardness reducing method of recycle water of non-ferrous metallurgical acid waste water. The method includes steps of neutralizing and settling acid waste water by lime milk, and then adjusting pH value of clear liquid firstly; charging carbon dioxide and calcium ion to react and generate calcium carbonate sediment, removing calcium ion; in order to further reduce the calcium content in the recycle water, continuing to charge carbon dioxide, and reversely dissolving the calcium carbonate sediment under the function of hydrogen ion to generate calcium bicarbonate; at the moment, adding sodium hydroxide in the solution, and rapidly generating a lot of sediments again; using the clear liquid after filtering for production. After treatment by the calcium hardness reducing method, the content of calcium ion can be reduced to 20 mg / L-35 mg / L, and the standard of industrial recycle water is completely reached. The method is simple in technique, the pH value is easy to control, the calcium hardness of the recycle water is effectively reduced, the cost is saved, and the method is economic and environment-friendly.

Owner:YANTAI UNIV

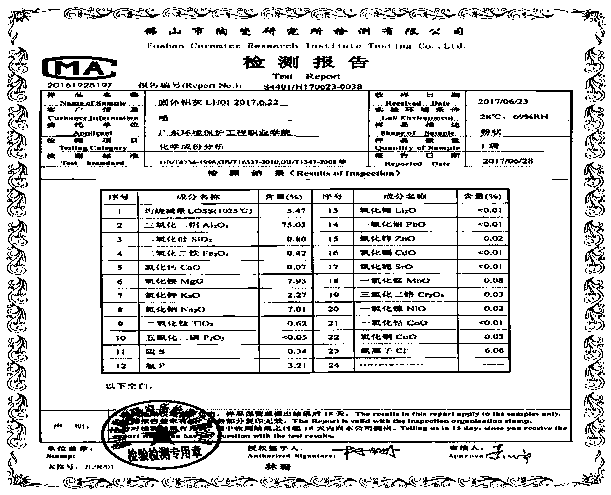

Aluminum sludge composite filler for constructed wetland and preparation method of filler

InactiveCN108996691ALow costWide variety of sourcesWater/sewage treatment apparatusBiological water/sewage treatmentConstructed wetlandSlag

The invention provides aluminum sludge composite filler for constructed wetland and belongs to the technical field of water treatment. The surface of the aluminum sludge composite filler is a porcelainized layer with adsorption micropores, the porcelainized layer is formed by covering the surface of zeolite or steel slag with aluminum sludge and performing high-temperature roasting. The inventionalso provides a preparation method of the composite filler. The composite filler is prepared from raw materials through stirring, granulation, drying, roasting and other steps, the prepared aluminum sludge composite filler has a remarkable removal effect on N and P in sewage, the filler can be repeatedly used for a long time and has the advantages of low cost and good purification effect.

Owner:JIANGSU LONG LEAPING ENG DESIGN

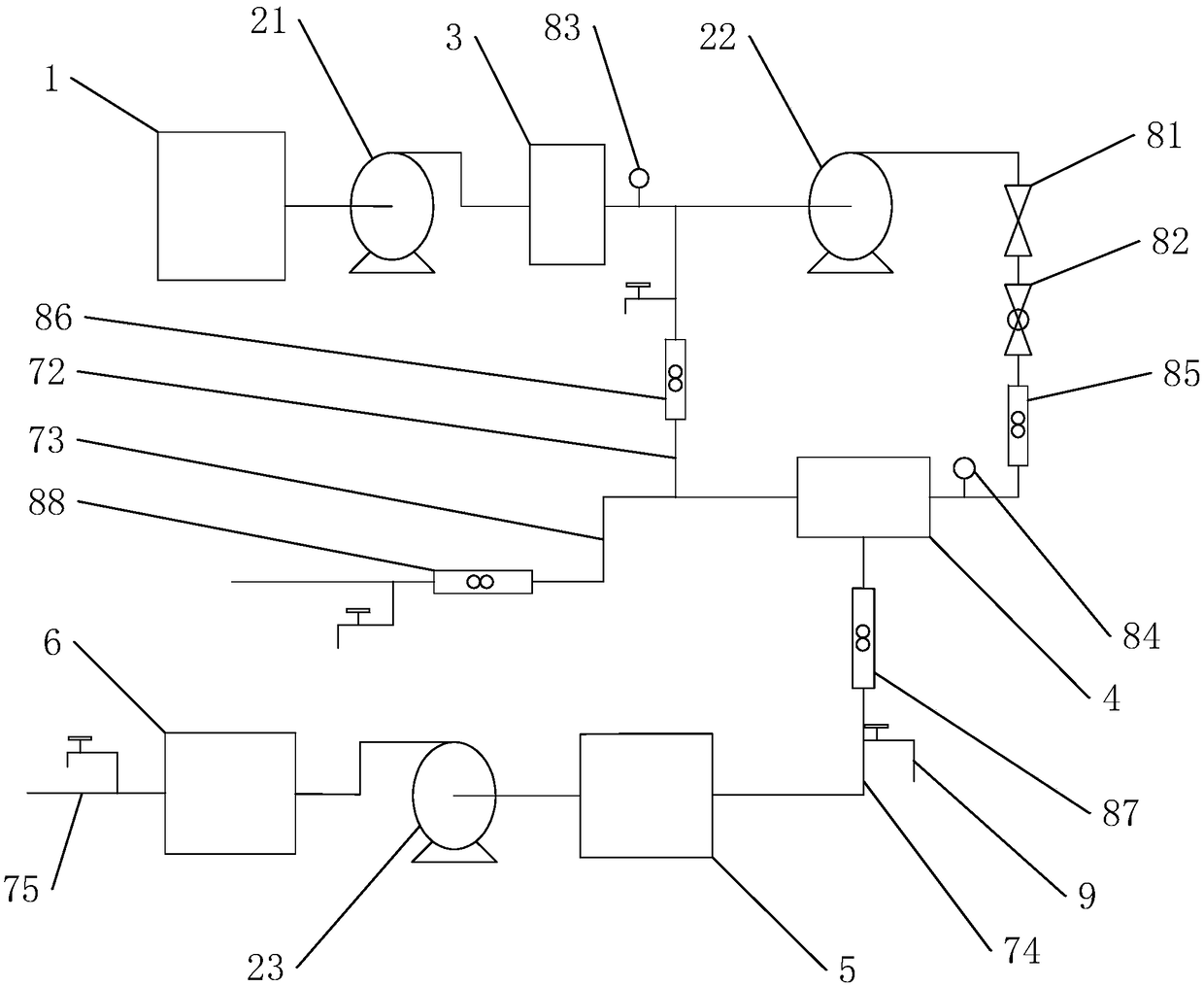

Industrial waste water recycling process and system thereof

PendingCN106115980AStable waterImprove effluent qualityMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processIndustrial waste waterReverse osmosis

The invention discloses an industrial waste water recycling process. A sewage pretreatment unit, an MCR (Membrane Coagulation Reactor) treatment unit and an RO (Reverse Osmosis) treatment unit which are connected in sequence are adopted. The industrial waste water recycling process comprises the following steps: pretreatment: introducing industrial waste water into the sewage pretreatment unit, removing cyanogen in water through an oxidizing or reducing method, and removing a complex in water through a de-complexing agent; MCR treatment: introducing the pretreated sewage into the MCR treatment unit, adding PAC (Poly Aluminum Chloride) into a pre-posed coagulation reaction pond in the MCR treatment unit to perform a coagulation reaction: RO treatment: introducing the effluent subjected to the MCR treatment into the RO treatment unit to perform reverse osmosis deep treatment to obtain recycled water. In the process, the MCR treatment is performed before the RO treatment, so that the quality of the water in the RO treatment unit is ensured, damage to an RO membrane component is reduced, and the reaction speed is increased; the industrial waste water recycling process can be applied to the field of industrial waste water treatment.

Owner:GUANGDONG SHUIQING ENVIRONMENTAL PROTECTION TECH CO LTD

Medical waste treatment device

InactiveCN109454090AGood removal effectEasy to sendSolid waste disposalTransportation and packagingMegasonic cleaningMedical waste

The invention relates to the field of waste treatment, in particular to a medical waste treatment device. The medical waste treatment device comprises a shell. A feeding port is formed in the top endof the shell. The feeding port communicates with a smashing device. A cleaning pool is fixedly installed at the lower end of the smashing device. Water spraying rows and a material collecting device are arranged in the cleaning pool. A filtering net is arranged below the cleaning pool. A gas spraying row and a hot melting furnace are arranged below the filtering net. By means of the medical wastetreatment device, water flow is used for transmission, and the energy utilization rate is increased. Ultrasonic cleaning is adopted, material cleaning is thorough, and the vibrating filtering net is used so that water disengaging and material conveying can be facilitated. Hot airflow is used for drying jittering materials, the drying effect is improved, and the work efficiency is improved. Hot airis used for preheating materials, and meanwhile a sterilizing and disinfecting effect is achieved. Materials enter the hot melting furnace to be melted, the materials can be thoroughly sterilized anddisinfected by the high temperature, and recycling standards are achieved. The medical waste treatment device is simple in structure, easy to operate, high in automation degree, high in sterilizing strength and capable of recycling waste materials.

Owner:霸州市辉月网络技术有限公司

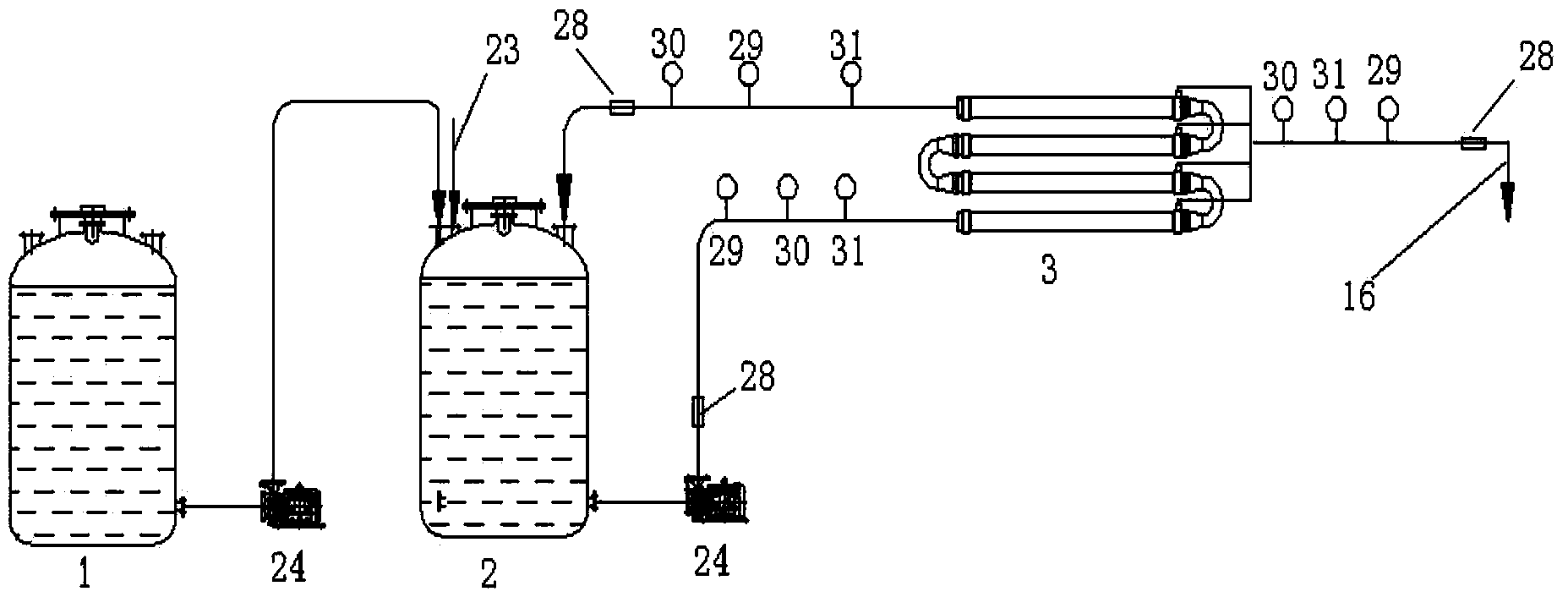

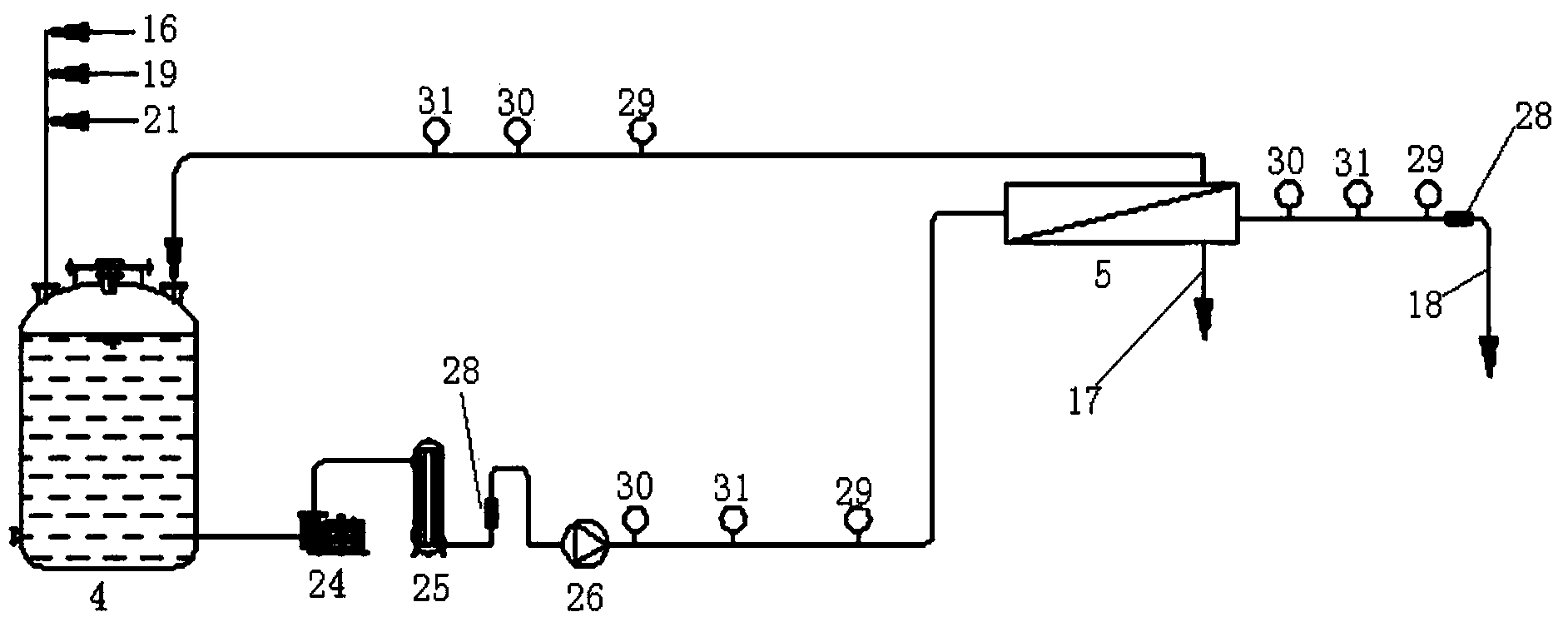

Fracturing backflow liquid finely-filtering device and method

InactiveCN104826381AMeet recycling standardsHigh precision retentionFiltration circuitsWater dischargeFiltration

The invention relates to a fracturing backflow liquid finely-filtering device and method. The device comprises a liquid storage tank, a lifting pump, a primary filter, two parallelly-arranged secondary filters, and a storage tank; the liquid storage tank is connected to the water suction pipe of the lifting pump, the water discharge pipe of the lifting pump is connected to the water inlet pipe of the primary filter, the water discharge pipes of the primary filter are respectively connected to the water inlet pipes of two secondary filters, and the water discharge pipes of the secondary filters are connected to the storage tank. The primary filter is arranged vertically, the secondary filters are horizontally arranged, the water inlet pipe of the primary filter is arranged on the upper part, and the water discharge pipe is arranged on the lower part. The filter device is used to finely filter the recyclable fracturing liquid, after the fine filtration, the fracturing liquid can be reused and applied to liquid preparation; and the fracturing liquid which cannot be recycled, can be applied to a post treatment after the suspended impurities are removed by the fine filtration. The provided filter device and method have the advantages that the filter area is large, the processing efficiency is high, the operation is simple and convenient, the maintenance is convenient, and solved is the technical problem that the recovery is difficult due to the high content of suspended impurities in the fracturing backflow liquid.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Mixed sewage treating agent and preparation method thereof

InactiveCN106517382AGood removal effectRaw materials are easy to getWater treatment parameter controlSpecific water treatment objectivesChemical oxygen demandDisinfectant

The invention discloses a mixed sewage treating agent which is prepared from the following raw materials in parts by weight: 10-20 parts of pomelo peel, 5-10 parts of attapulgite, 8-15 parts of dodecyldimethylbenzyl ammonium chloride, 5-15 parts of graphene, 5-10 parts of polyferric sulfate, 0.5-1 part of butyl acetate, 5-10 parts of sodium carbonate, 5-10 parts of sodium xylene monosulfonate, 3-10 parts of sodium tripolyphosphate, 2-8 parts of tall oil fatty acid, 5-18 parts of peroxyacetic acid disinfectant, 2-5 parts of lauryl betaine, 2-5 parts of octadecyltrimethyl ammonium chloride and 10-15 parts of fly ash. The sewage treating agent can effectively lower the contents of heavy metal ions, COD (chemical oxygen demand) and SS (suspended sediment) in the sewage. The preparation method is simple, and the product cost is lower. The mixed sewage treating agent has the advantage of short sewage treatment period, and the treated sewage can reach the cyclic utilization standard. The sewage treating agent is free of toxic substances, and has favorable decolorization effects; and the treated water does not have any stink.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Distillation system and technology of ethylene glycol and diethylene glycol in polyol waste liquid

PendingCN109179542AReduce manufacturing costAchieve recyclingWater contaminantsWater/sewage treatment by heatingReboilerDiethylene glycol

The invention discloses a distillation system of ethylene glycol and diethylene glycol in a polyol waste liquid. The system comprises first and second rectification columns and a vacuuming device. Thefirst rectification column comprises a first column body, a first reboiler, a first condenser, a first separator and a first pump. The second rectification column comprises a second column body, a second reboiler, a second condenser, a second separator and a second pump. The system has a simple structure and is easy to operate. Through two valves, a reflux ratio of ethylene glycol and diethyleneglycol is controlled so that high-purity ethylene glycol and diethylene glycol are separated and have purity of 99.7% or more. The distillation system satisfies recycling standards of enterprises, effectively reduces the recovery and recycling cost of ethylene glycol and diethylene glycol, effectively reduces the load to the environmental protection equipment and reduces the environmental protection expenses of enterprises.

Owner:CHONGQING HUAFON CHEM +2

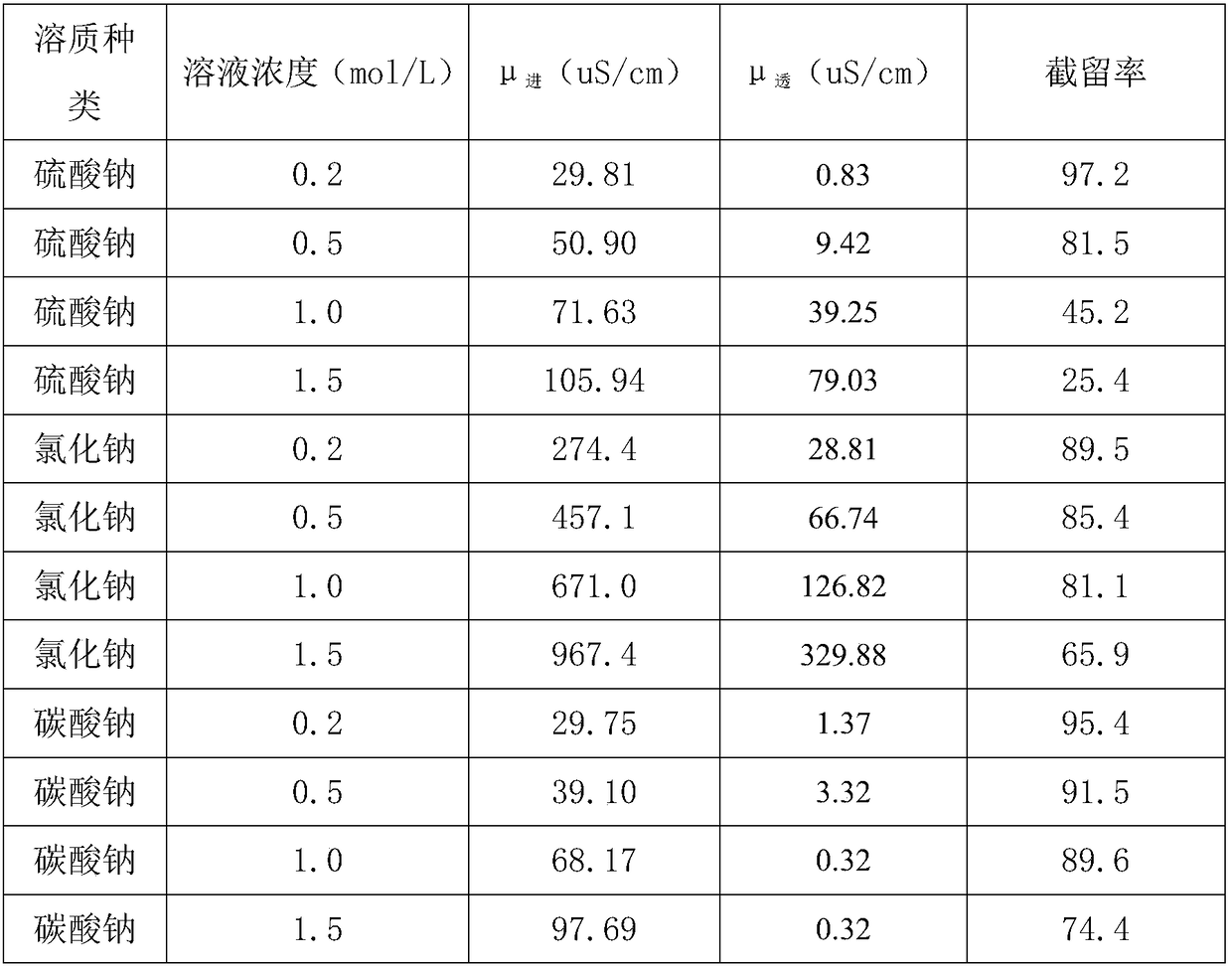

Method and system for recycling residual liquid in dye vat

InactiveCN109336270AAvoid cloggingIncrease water pressureTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisTreatment burdenWastewater

The invention relates to the field of sewage treatment and recycling and discloses a method for recycling residual liquid in a dye vat. The method comprises the following steps: S11, collecting the residual liquid; S12, filtering the residual liquid to remove impurities; S13, introducing the residual liquid into a special membrane separation system to obtain produced water and concentrated water;S14, recycling the produced water and collecting and discharging the concentrated water. The residual liquid in the dye vat is decolorized by the special membrane separation system, salt in the residual liquid is retained in the produced water, the salt in the residual liquid is recycled while dyeing sewage is purified and treated, and accordingly, treatment burden of a sewage plant is reduced, energy is saved, the environment is protected, and the production cost is reduced.

Owner:ZHEJIANG JINMO ENVIRONMENT TECH CO LTD

Waste incinerator fly ash heat treatment system

PendingCN109812818AIncreased chance of collisionReduce energy consumptionIncinerator apparatusHeavy metalsFlue gas

The invention discloses a waste incinerator fly ash heat treatment system. A flue gas sintering and melting furnace is included, and communicates with a flue gas outlet pipeline of a grate furnace anda fuel gas pipeline; a melting chamber is arranged on the lower portion of the flue gas sintering and melting furnace, and the side wall of the melting chamber is provided with a flue gas inlet and asupplemented fuel gas inlet; a cyclone hearth is above the melting chamber which communicates with the cyclone hearth; the side wall of the cyclone hearth is provided with a secondary air inlet; thetop of the flue gas sintering and melting furnace is provided with a flue gas outlet which is connected with a flue gas discharging pipeline; a slag discharging port is formed in the bottom of the flue gas sintering and melting furnace; flue gas and supplemented fuel gas are combusted in the melting chamber, for particles in fly ash in the high temperature environment, being 1300 DEG C or above, of the sintering and melting furnace, the volume is reduced, and residues such as heavy metal are stabilized. The molten ash content becomes slag and can be recycled as a roadbed material, a building material and the like; and meanwhile, due to decomposing under high temperature, dioxin in the fly ash can be substantially lowered.

Owner:HUANENG CLEAN ENERGY RES INST

Sewage purification device

PendingCN110746017AImprove purification effectExtended service lifeWater/sewage treatment by irradiationSpecific water treatment objectivesActivated carbonRaw water

The invention discloses a sewage purification device. The device comprises a pretreatment component, a sterilization component, a purification component, a water storage tank, a water outlet, a liquidometer and an electric control cabinet. According to the device, through the arrangement of the pretreatment component, sewage enters the device from a raw water inlet pipe, a pretreatment filter screen pretreats impurities in the sewage, the impurities fall into a waste box, thus, the purpose of pretreatment is achieved, subsequent purification of the sewage is benefited, the purification effectof the purification device is improved, and the service life of the purification device is prolonged; a second valve is opened regularly to discharge the impurities in the waste box from a blow-off pipe, and thus normal running of the pretreatment component is guaranteed; and through the arrangement of the sterilization component and the purification component, when a button switch is pressed, a UV lamp performs sterilization on the sewage, then the sewage enters a purification box and is purified after passing through a primary filter screen, an activated carbon filling layer and a nanofiltration membrane layer, thus, the purpose of thoroughly purifying the sewage is achieved, purified water reaches a recycling standard, and waste of water resources is avoided.

Owner:新晃县污水处理有限责任公司

Two-stage fine filter device and two-stage fine filter method for fracturing flow-back fluid

InactiveCN105413305AMeet recycling standardsHigh precision retentionWaste water treatment from quariesTreatment involving filtrationFiltrationFracturing fluid

The invention provides a two-stage fine filter device for fracturing flow-back fluids. The device includes a liquid storage tank, a lifting pump, a primary filter, and two secondary filters arranged in parallel. The liquid storage tank is connected to a water suction pipe of the lifting pump. A water outlet pipe of the lifting pump is connected to a water inlet pipe of the primary filter. The water outlet pipe of the primary filter is respectively connected to the water inlet pipes of the two secondary filters. The water outlet pipes of the two secondary filters are connected to the liquid storage tank. When the fracturing flow-back fluid is subjected to filtration in two precision stages, suspension solids in the fracturing flow-back fluid are effectively removed. For recyclable fracturing fluids, when being finely filtered, the fracturing fluids can be regenerated and reuse. For non-recyclable fracturing fluids, when being subjected to fine filtration to remove the suspension solids, the fracturing fluids can be sent to subsequent treatment. The device is large in filtration area and high in treatment efficiency and filtering precision, is simple in operation, is convenient to repair, and solves the technical problem that the fracturing flow-back fluids are difficult to recycle since content of the suspension solids is high in the fracturing flow-back fluids.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Purification process of electroplating waste liquid

InactiveCN105540916AImprove adsorption capacityEfficient removalCellsTreatment involving filtrationLiquid wasteEvaporation

The invention provides a purification process of an electroplating waste liquid; the purification process comprises the following steps: firstly, filtering the electroplating waste liquid to obtain a filtered electroplating waste liquid; then adsorbing the filtered electroplating waste liquid obtained in the step one with a first resin column, to obtain a primary treated waste liquid; next adsorbing the primary treated waste liquid obtained in the step two with a second resin column, to obtain a secondary treated waste liquid; and finally, adsorbing the secondary treated waste liquid obtained in the step three with a third resin column, to obtain a purified waste bath liquid. Under conditions without heating, pressurization, drug adding or evaporation and the like, impurity ions in the electroplating waste chrome acid anhydride bath liquid are effectively removed, the recycling use standard is reached, recycling use is performed anew, the externally-discharged pollution is reduced, and a lot of raw material costs and pollutant treatment costs are saved.

Owner:CHONGQING QINGTIAN ENVIRONMENTAL PROTECTION MATERIAL

Organic waste gas recovery method based n condensation-extraction process

InactiveCN105344201AHigh recovery rateReduce fugitive volatilizationGas treatmentMultiple-effect/fractional condensationSystem safetyAir volume

An organic waste gas recovery method based n condensation-extraction process comprises steps of waste-gas concentration adjusting, stepped precooling, deep cooling, circulating, deicing or defrosting, extraction and extractant recovery. The method is characterized in that in the waste-gas concentration adjusting step, a manner of increasing or reducing the blast capacity is employed for adjusting the concentration of organic waste gas at a client side based on the client-side organic waste gas concentration and the waste-gas concentration safety standard prescribed by national standard, the organic waste gas concentration is guaranteed to be in the concentration scope limited by national standard and the system safety is guaranteed. The organic waste gas recovery method based n condensation-extraction process gives play to protrude recovery effect on high-, middle- and low-boiling-point organic waste gases by utilizing a relatively-closed circulation system for waste gas recovery and extractant cyclic utilization.

Owner:GUANGDONG CODE OF ENVIRONMENTAL PROTECTION ENG CO LTD

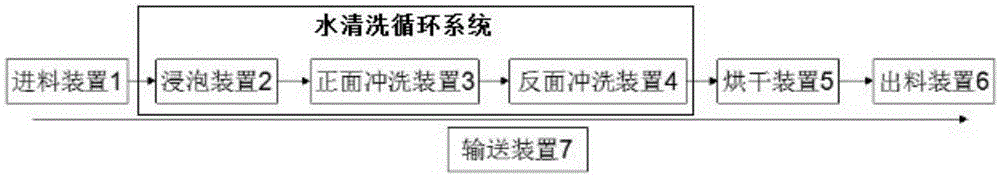

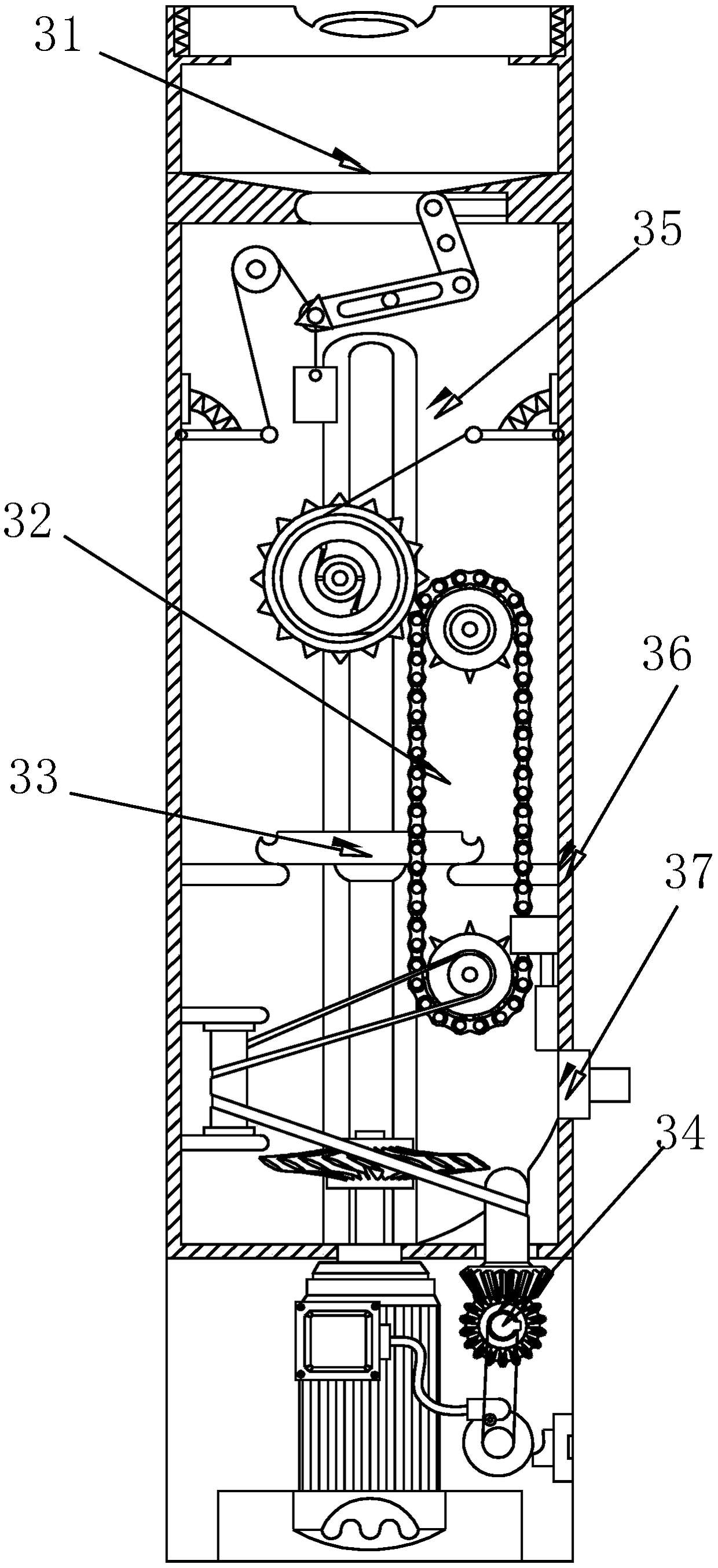

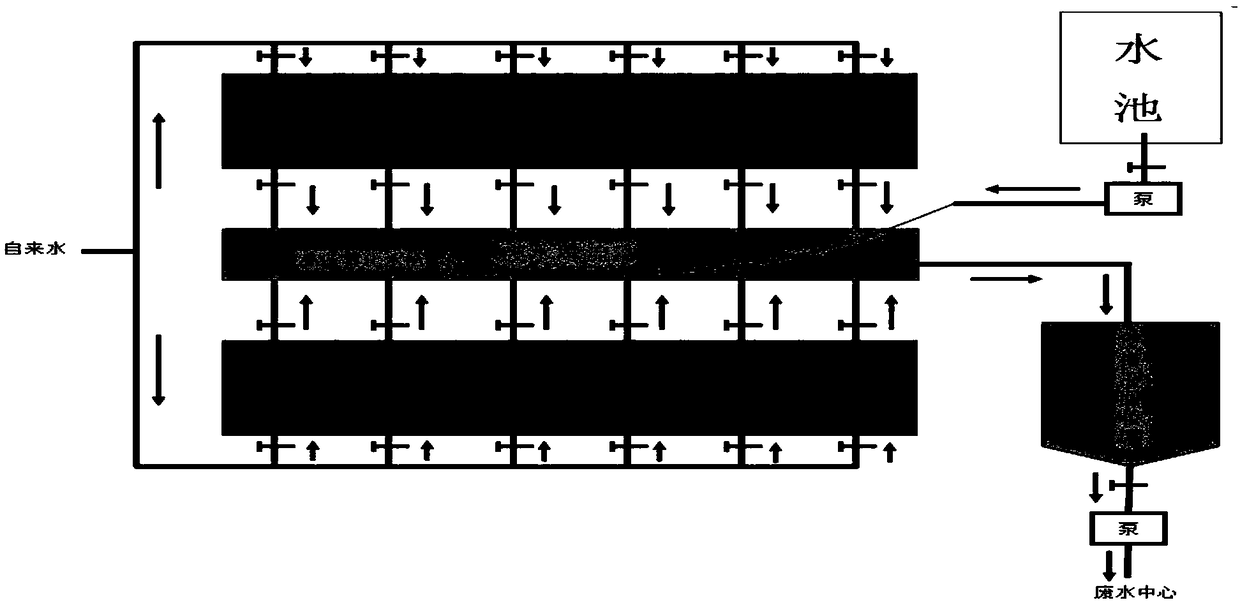

Water-cleaning circulating system and production line for substandard sheets produced in silk-screen printing

ActiveCN105428219AImprove filtering effectEasy to cleanSemiconductor/solid-state device manufacturingScreen printingProduction line

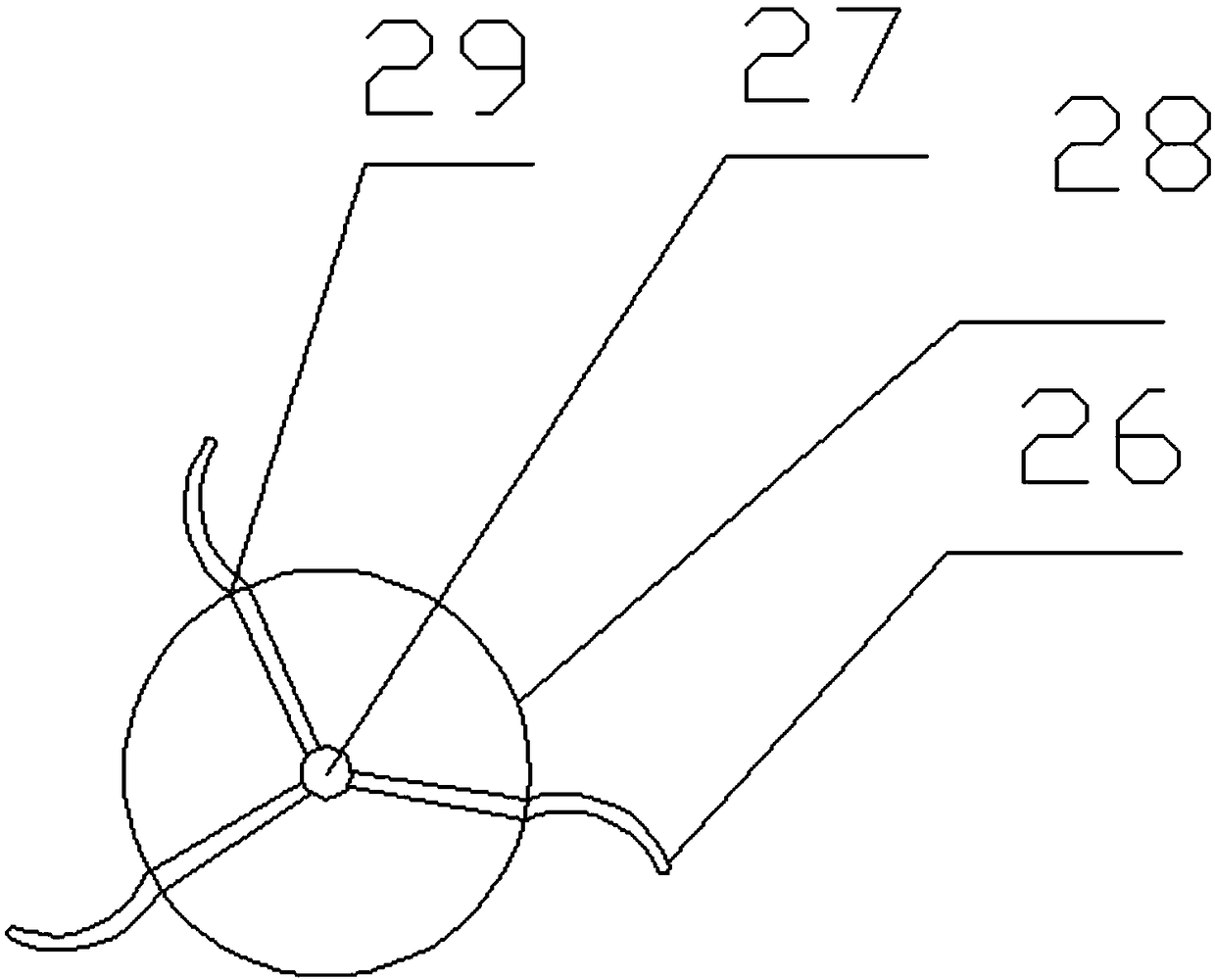

The invention discloses a water-cleaning circulating system for substandard sheets produced in silk-screen printing. The water-cleaning circulating system comprises a soaking apparatus (2), a front surface flushing apparatus (3) and a back surface flushing apparatus (4); a first solution circulating apparatus (29) is arranged in a first liquid outlet (26); the outlet of the first solution circulating apparatus (29) is connected with a first liquid inlet (28); a second solution circulating apparatus (34) is arranged in a second liquid outlet (31); the outlet of the second solution circulating apparatus (34) is connected with a second liquid inlet (33); and filtering apparatuses for filtering solid precipitate are arranged in the first liquid outlet (26) and the second liquid outlet (31). Before the front surface and the back surface of the substandard sheets are cleaned, the substandard sheets are soaked for one time to remove a part of aluminum paste from the surfaces of the substandard sheets as well as to permeate a part of water to the aluminum paste; therefore, the aluminum paste is easy to fall off in the front surface flushing process and the back surface flushing process; the requirement on the water flow speed is lowered; and the separate recycling for aluminum and silver is realized.

Owner:重庆蟠龙印务有限公司

Composite sewage treatment agent

InactiveCN106395939AReduce CODGood removal effectSpecific water treatment objectivesWater contaminantsChemical oxygen demandToxic material

The invention discloses a composite sewage treatment agent. The composite sewage treatment agent is prepared from raw materials in parts by weight as follows: 10-20 parts of exocarpium, 5-10 parts of attapulgite, 8-15 parts of dodecyl dimethyl benzyl ammonium chloride, 5-15 parts of activated carbon, 5-10 parts of polyferric sulfate, 0.5-1 part of n-butyl acetate, 5-10 parts of sodium carbonate, 5-10 parts of sodium xylene sulfonate, 3-10 parts of sodium tripolyphosphate, 2-8 parts of tall oil fatty acid, 5-18 parts of a peracetic acid disinfection solution, 2-5 parts of lauryl betaine, 2-5 parts of octadecyl trimethyl ammonium chloride and 10-15 parts of fly ash. The sewage treatment agent can effectively reduce content of heavy metal ions, COD (chemical oxygen demand) and SS (suspended solids) of sewage; the preparation method is simple, and the product cost is lower; the sewage treatment period is short, and treated sewage can meet the cyclic utilization standard; the sewage treatment agent is free of toxic substances and is good in decoloration effect, and treated water is odorless.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

System and method for recovering hole sealing agent and utilizing reclaimed water through single nickel salt coloring

InactiveCN109160627AAvoid pollutionRealize recycling of resourcesWater contaminantsAlkali orthophosphate fertiliserNickel phosphateNickel salt

The invention relates to a system and a method for recovering a hole sealing agent and utilizing reclaimed water through single nickel salt coloring. The system comprises a nickel-containing wastewater collecting unit, a nickel hydroxide recovering unit, a nickel phosphate recovering unit and an N-P composite fertilizer recovering unit; the nickel-containing wastewater collecting unit comprises acolored nickel-containing wastewater collecting tank and a pump 1; the nickel hydroxide collecting unit comprises a pump 2, a pump 3, a nickel hydroxide recovering tank, a liquid ammonia tank and a 1#filter press; the nickel phosphate recovering unit comprises a nickel phosphate recovering tank, a pump 4, a phosphoric acid tank and a 2# filter press; the N-P composite fertilizer recovering unit comprises a composite fertilizer recovering tank, a pump 5 and a filter; by the classifying and recovering method and by virtue of the system configuration, water for coloring cleaning is intercepted and collected and then is recovered and converted into a hole sealing medicament, and the reclaimed water is recycled and converted into liquid N-P composite fertilizer, so that resource recycling of toxic waste is realized.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Recycling box for electronic products

InactiveCN107719857AExtended service lifeImprove recycling efficiencyContainers preventing decayExternal fittingsCouplingEngineering

The invention discloses a recycling box for electronic products, and belongs to the technical field of electronic products. The recycling box comprises a box body, the top of the box body is fixedly connected with a transmission device, and a bracket penetrates through the bottom of the transmission device; the bottom of the bracket penetrates through the top of the box body and is fixedly connected with a heater, the bottom of the heater is fixedly connected with an air-outlet cover, and an air blower is fixedly connected to the right side of the top of the box body; an air outlet of the airblower communicates with a long hose, and the other end of the long hose penetrates through the top of the box body and communicates with an air inlet of the heater; and the transmission device comprises a shell, the left side of an inner cavity of the shell is fixedly connected with a motor, and an output shaft of the motor is fixedly connected with a rotary shaft through a coupling. According tothe recycling box for the electronic products, the problem that a traditional recycling box is not provided with a drying dehumidification device is solved, the situation that recycling materials inthe box body cannot realize the recycling purpose due to dampness is avoided, meanwhile, the service life of the recycling box is prolonged, and the recycling efficiency of the recycling box is improved.

Owner:合肥棠凯科技有限公司

Industrial wastewater purifying treatment device for reducing wastewater discharge

InactiveCN108640246AEmission reductionMeet recycling standardsWater/sewage treatment by neutralisationWater/sewage treatment apparatusSurface phaseAlkalinity

The invention discloses an industrial wastewater purifying treatment device for reducing wastewater discharge. The device structurally comprises a base, a support plate, a wastewater purifying treatment unit, a water outlet, a monitor, a water inlet pipe, a display screen and a main console. The device is characterized in that the upper surface of the base and the lower surface of the support plate are welded with each other and perpendicular to each other, and the lower surface of the wastewater purifying treatment unit and the upper surface of the support plate are welded with each other andperpendicular to each other; the back of the water outlet is embedded and mounted in the front end of the wastewater purifying treatment unit, the water inlet pipe is embedded and mounted in the backof the wastewater purifying treatment unit, and the left end of the monitor is embedded and mounted in the right end of the wastewater purifying treatment unit. According to the industrial wastewaterpurifying treatment device for reducing wastewater discharge, with full automatic low-cost and high-efficiency treatment as a core, the acidity and alkalinity of wastewater are effectively neutralized, so that only low-cost treatment is needed, the standard of recycling can be reached, and the wastewater discharge is reduced through recycling.

Owner:安徽摩塔营造环境设计有限公司

Heavy metal wastewater treatment agent

The invention discloses a heavy metal wastewater treatment agent which is composed of, by weight, 10-20 parts of exocarpium citris grandis, 5-10 parts of sodium carboxymethylcellulose, 8-15 parts of sodium dichloro isocyanurate, 5-15 parts of activated carbon, 5-10 parts of polymerized iron sulfate, 0.5-1 part of butyl acetate, 5-10 parts of sodium carbonate, 5-10 parts of sodium cumenesulfonate, 3-10 parts of sodium tripolyphosphate, 2-8 parts of tall oil fatty acid, 5-18 parts of peracetic acid disinfectant, 2-5 parts of lauryl betaine, 2-5 parts of octadecyl trimethyl ammonium chloride and 10-15 parts of coal ash. The heavy metal wastewater treatment effect can effectively lower content of heavy metal ions, COD and SS in wastewater; a preparation method is simple, and product cost is low; the wastewater treatment agent is short in wastewater treatment period, and wastewater treated by the agent can reach recycling standards; the wastewater treatment agent is free of toxic substance and good in discoloring effect, and water treated by the agent is free of undesirable smell.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

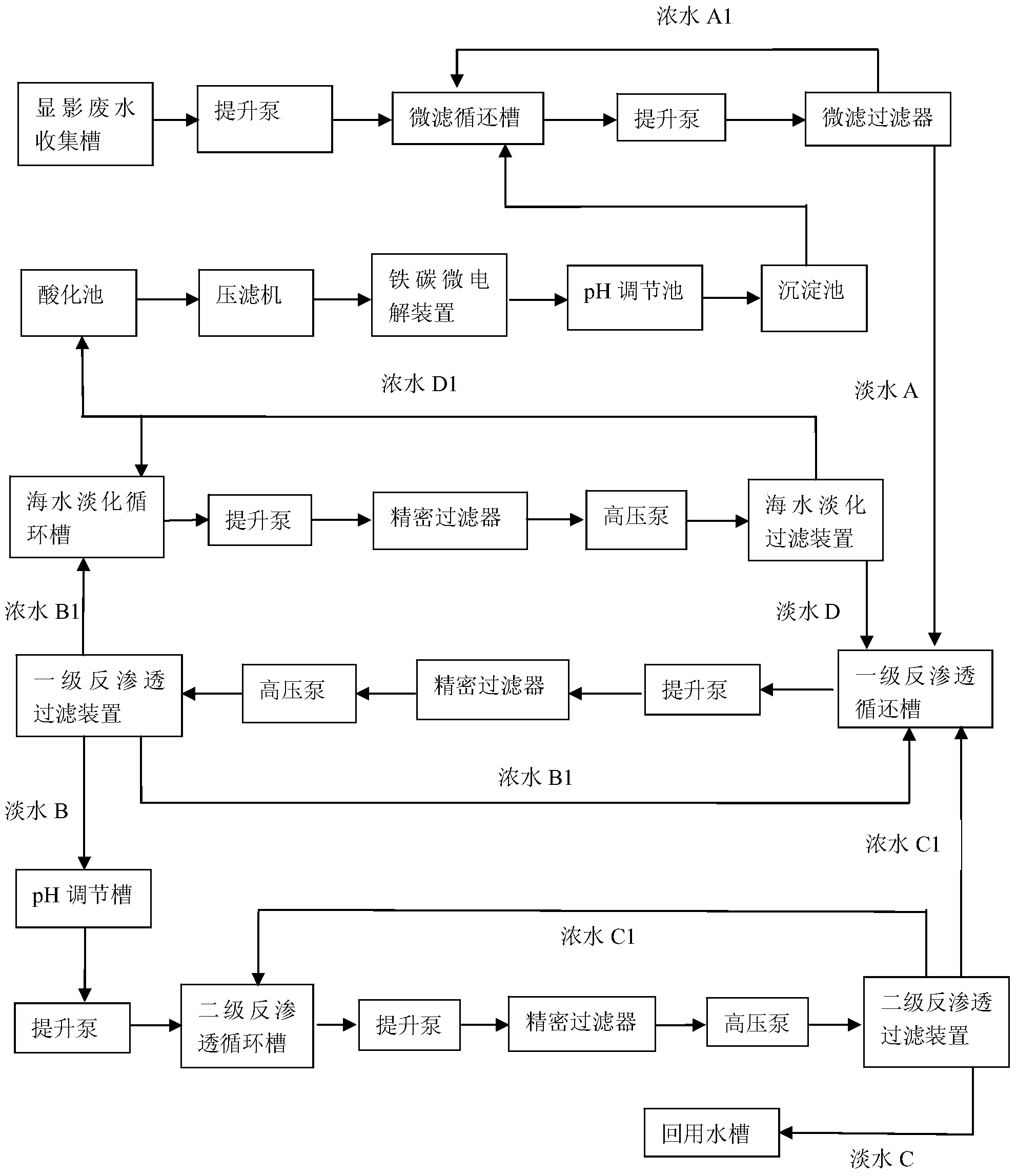

Zero-discharge treatment process and device for printed circuit board developing wastewater

ActiveCN104261598AImprove biodegradabilityAvoid pollutionGeneral water supply conservationSeawater treatmentEnvironmental resistanceElectrolysis

The invention belongs to the technical field of sewage treatment and discloses a zero-discharge treatment process and device for printed circuit board developing wastewater. The treatment device is composed of a microfiltration device, a primary reverse osmosis device, a secondary reverse osmosis device, a sea water desalting device and an acidification-iron-carbon micro-electrolysis device. The device is adopted to treat printed circuit board developing wastewater mainly in a physical separation way and basically no agent is utilized in the whole process; the whole device is integrated by connecting the filtering devices in a series connection or parallel connection way, is capable of operating continuously and automatically, and has excellent economic benefit; and the treatment process is capable of realizing wastewater zero discharge and has excellent environmental protection benefit.

Owner:YANGZHOU INGREENTREE ENVIRONMENTAL TECH CO LTD

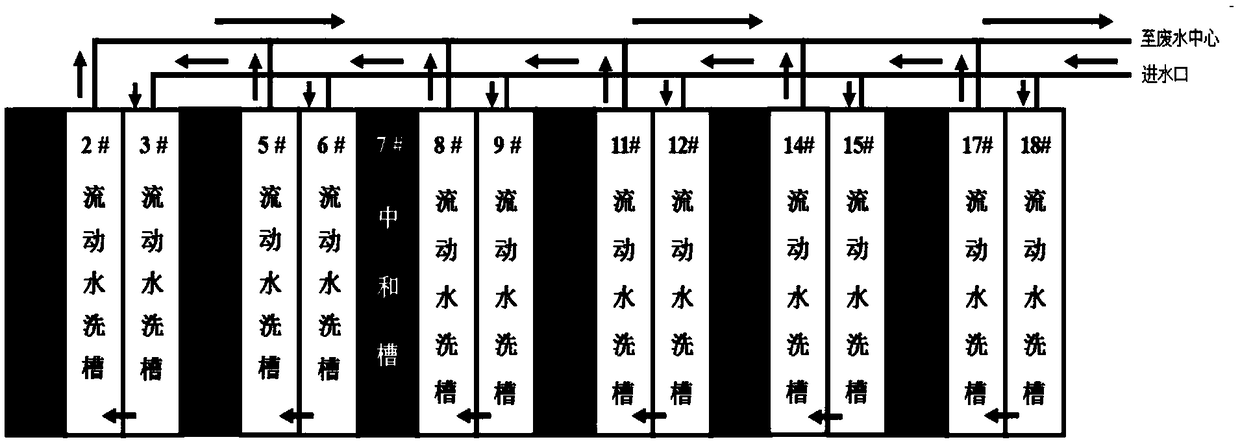

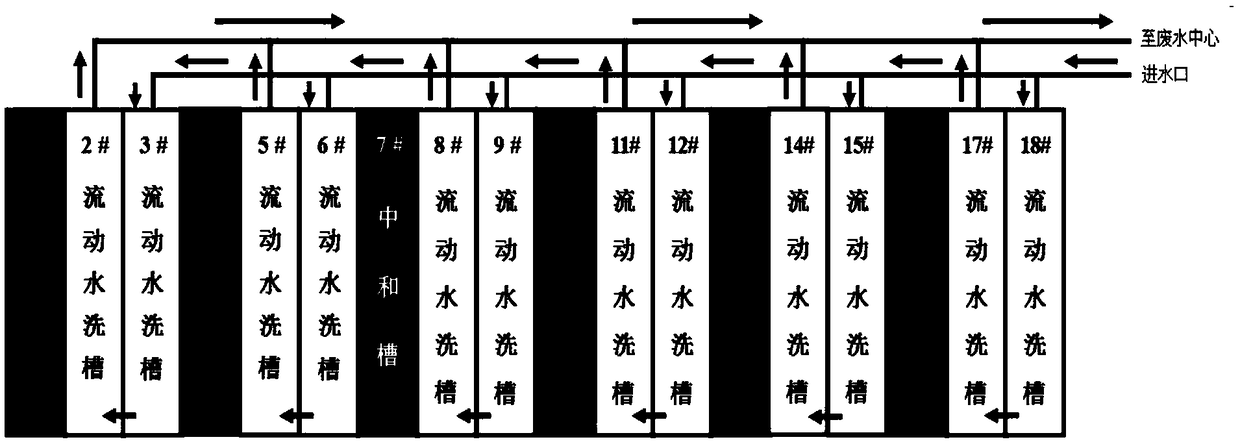

On-line system and method for recovering hole sealing agent and utilizing reclaimed water through single nickel salt coloring

InactiveCN109160628AAvoid pollutionRealize recycling of resourcesWater contaminantsAlkali orthophosphate fertiliserNickel phosphateNickel salt

The invention relates to an on-line system and an on-line method for recovering a hole sealing agent and utilizing reclaimed water through single nickel salt coloring. The system comprises a nickel-containing wastewater intercepting unit, a nickel-containing wastewater collecting unit, a nickel hydroxide recovering unit, a nickel phosphate recovering unit and an N-P composite fertilizer recoveringunit; the nickel-containing wastewater intercepting unit comprises a 13# single nickel salt coloring tank, a 14# flowing pure water cleaning tank and a 15# pure water cleaning tank which are sequentially configured; the nickel-containing wastewater collecting unit comprises a colored nickel-containing wastewater collecting tank and a pump 1; the nickel hydroxide recovering unit comprises a pump 2, a pump 3, a nickel hydroxide recovering tank, a liquid ammonia tank and a 1# filter press; the nickel phosphate recovering unit comprises a nickel phosphate recovering tank, a pump 4, a phosphoric acid tank and a 2# filter press; the N-P composite fertilizer recovering unit comprises a composite fertilizer recovering tank and a filter; and by the on-line system configuration, the nickel-containing wastewater and residues are recovered and converted into a hole sealing medicament, and the reclaimed water is recycled and converted into N-P composite liquid fertilizer, so that resource recycling of toxic waste is realized.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

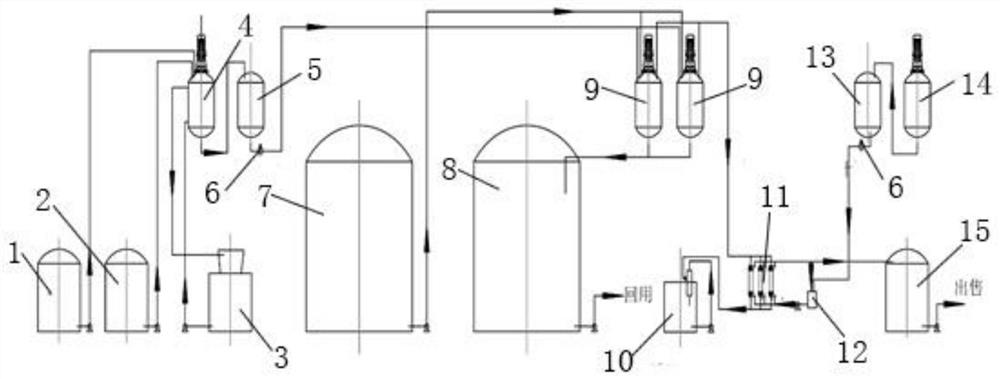

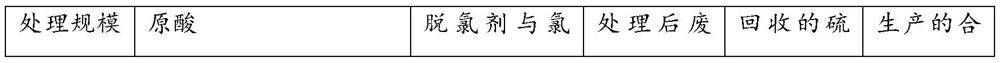

Treatment device and method for recycling chlorine-containing waste acid

PendingCN113526467AAvoid it happening againImprove qualitySulfur-trioxide/sulfuric-acidHypochloriteEnvironmental engineeringSodium hypochlorite

The invention relates to a treatment device and method for recycling chlorine-containing waste acid. The treatment device for recycling the chlorine-containing waste acid comprises a sulfuric acid supply device, a hydrogen peroxide supply device, a dechlorinating agent reaction device, a waste acid dechlorination regeneration device and a chlorine gas absorption device. The sulfuric acid supply device and the hydrogen peroxide supply device are respectively connected with the dechlorinating agent reaction device through conveying pipelines, the dechlorinating agent reaction device is connected with the waste acid dechlorination regeneration device through a conveying pipeline, and the waste acid dechlorination regeneration device is connected with the chlorine gas absorption device through a conveying pipeline. When the device is used for treating the chlorine-containing waste acid, gypsum-free treatment of the waste acid is realized, a series of problems caused by a large amount of dangerous gypsum residues generated when the waste acid is treated by a conventional neutralization method are solved, secondary pollution is thoroughly eliminated, waste is turned into wealth, a high-purity sodium hypochlorite product is obtained, the treated acid liquor is completely recycled, and the device and method have huge environmental, social and economic benefits.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Circulating water flushing ecological toilet and sewage treatment method thereof

InactiveCN1280490CMeet recycling standardsRealize the purpose of circular flushingFlushing devicesLavatory sanitoryDigestionOzone Sterilization

The invention discloses an ecological toilet for flushing with circulating water. Its structure is that a high-level water tank is sequentially connected with a toilet, a stirring and crushing device, a solid-liquid separation device, an anaerobic reaction device, an aerobic reaction device, an aerobic reaction device and an ozone disinfection device through a water pipe. The device is connected, and the ozone disinfection device is connected to the high-level water tank through the water pump. The present invention has the advantages of breaking through the dependence of toilets on water and the limitation that other types of ecological toilet pollutants need to be harmlessly treated in different places; Potential defects of secondary pollution of packaging materials; improve the in-situ treatment efficiency and harmless treatment degree of feces; expand the concept and application field of ecological toilets; make full use of the rich microbial resources in excrement and strengthen its functional digestion Effect: The degree of humanized design has been improved, and the new concept of ecological sanitation unit has been updated.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com