Method and system for recycling residual liquid in dye vat

A technology of residual liquid and resource utilization, which is applied in the field of resource utilization of residual liquid in dyeing vats, can solve the problems of increasing the processing load of the sewage treatment system, increasing the difficulty of the advanced treatment system, and affecting the normal operation of the biochemical system. Good effect and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

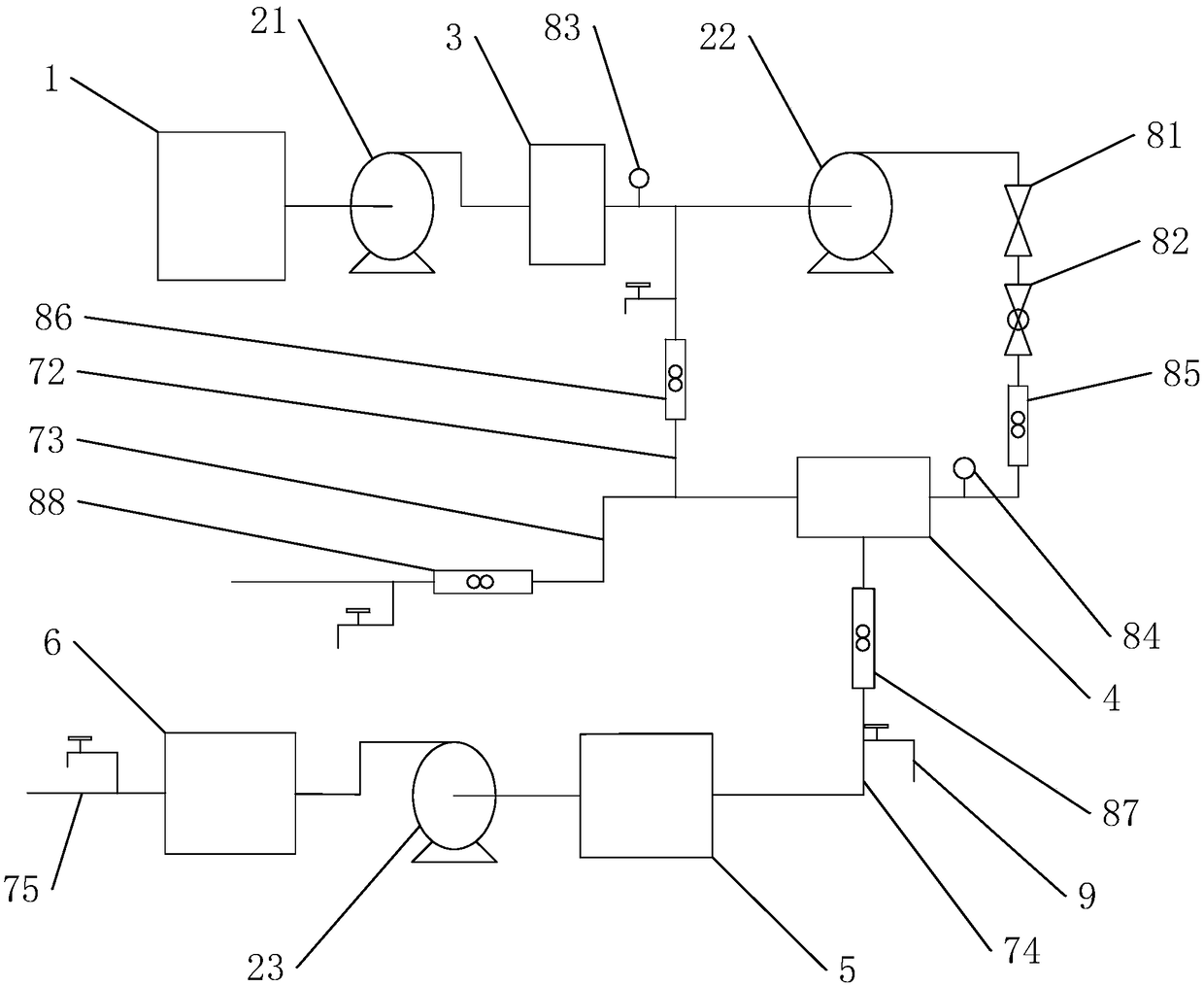

[0031] Embodiment 1: a method for recycling dye vat residual liquid, comprising the following steps:

[0032] S11. Residual liquid collection: collect the residual liquid that flows down from dyeing vats, dyeing machines and other equipment after dyeing;

[0033] S12. Filter the residual liquid to remove impurities: pass the residual liquid into a security filter for filtration, and the filter aperture of the security filter is 5 microns;

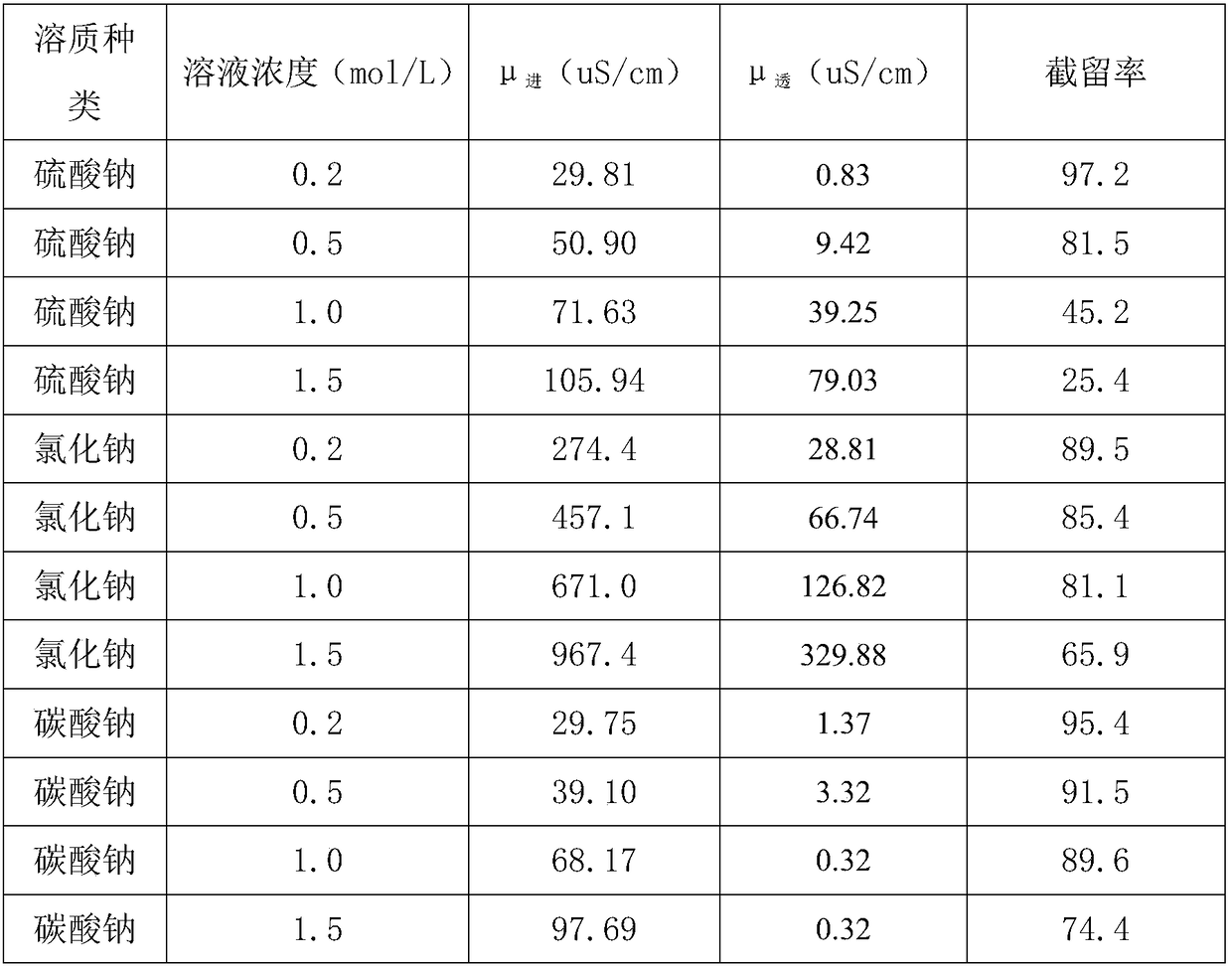

[0034] S13. Pass the raffinate into the special membrane separation system to obtain product water and concentrated water: pass the raffinate filtered in S12 into the special membrane separation system through a high-pressure pump, the operating pressure is 0.5-1Mpa, and the special membrane separation The removal rate is greater than or equal to 95%, the salt permeability rate is greater than or equal to 50%, the liquid passing through the special membrane separation system is produced water, and the retained liquid is concentrated water. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com