Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

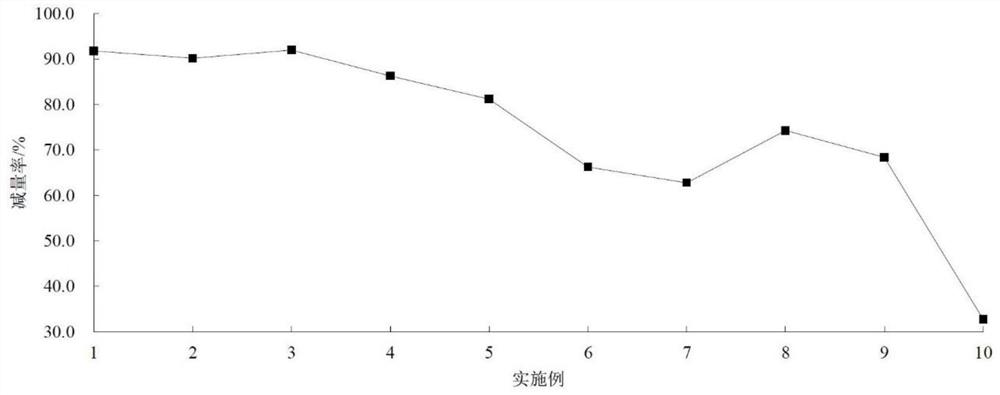

32results about How to "Strong adsorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color-deepening finishing agent for dyed polyester textiles

The invention relates to a color-deepening finishing agent for dyed polyester textiles. Nano-titanium dioxide particles serving as solids and an amino modified polyorganosiloxane microemulsion serving as a film-forming material are compounded to form the color-deepening finishing agent for the polyester textiles. Due to the small grain size effect and the large specific surface area of the nanoparticles, the contact of the nanoparticles with fibers is increased and a relatively high adsorption rate can be formed; due to the flexibility and the film-forming property of the organic silicon junction fragment of the film-forming material covering the nanoparticles, the color-deepening finishing agent is capable of forming an uneven thin film capable of generating scattering reflection on the surface of the treated fabric, and consequently, the absorptive amount of the fabric to the incident light can be greatly increased, the reflected light can be reduced and the effect of enhancing the color depth of the fabric can be achieved. The dyed polyester textiles treated by use of the color-deepening finishing agent are deepened in color under the circumstance that the inherent characteristics of the dyed fiber products are not damaged; besides, the treated dyed polyester textiles have good color fastness and also have antibacterial property.

Owner:科凯精细化工(上海)有限公司

Microcrystal and bamboo charcoal composite pottery material and preparation method thereof

InactiveCN104402519AExpand sourceLow costCeramic materials productionCeramicwareMetalMaterials science

The invention provides a microcrystal and bamboo charcoal composite pottery material, which is composed of the following components in percentage by weight: 20 to 50% of bamboo charcoal powder, 30 to 60% of porous non-metal mineral powder, 10 to 30% of clay, and 2 to 5% of binder. The porous non-metal ore is used to replace the purple sand, the raw material resources are greatly enlarged, and the cost is reduced. Moreover, the different porous non-metal ores have different chemical components and colors, thus the produced potteries are suitable for various occasions and environments, more specially, light color or even white potteries can be prepared from the provided composite pottery material. Compared to the potteries produced by the prior art, the potteries prepared from the provided microcrystal and bamboo charcoal composite pottery material have more pores and micro holes, a larger specific area, and a better water-absorbing and gas-absorbing performance. The invention also relates to a preparation method of the provided microcrystal and bamboo charcoal composite pottery material.

Owner:桂林新竹大自然生物材料有限公司

Ceramic composite with high absorptive property and preparation method of ceramic composite

InactiveCN104355600AStrong adsorption rateEfficient purificationClaywaresCeramic compositeMicroparticle

The invention provides a ceramic composite with high absorptive property. The ceramic composite is composed of the following components in percentage by weight: 9.3 to 74.5 percent of bamboo charcoal powder, 0.2 to 0.5 percent of graphene, 0.5 to 5 percent of tianium dioxide, 10 to 80 percent of tourmaline crystal particles and 10 to 80 percent of clay. The ceramic composite with high absorptive property has the advantages of large specific surface area and light self-cleaning capability, and is capable of effectively absorbing harmful gases such as formaldehyde and benzene, thereby purifying air; the preparation method is simple and suitable for industrial production.

Owner:华文蔚

Preparation method and application of modified ZSM-22 molecular sieve

InactiveCN110330033AImprove structural strengthImprove adsorption capacityOther chemical processesMolecular-sieve and base-exchange compoundsMolecular sieveHigh concentration

The invention relates to a preparation method and application of a modified ZSM-22 molecular sieve. According to the preparation method, a suitable silicon source, an aluminum source and a template agent are selected, preparation parameters are debugged without adding seed crystals, and a relatively pure ZSM-22 molecular sieve is prepared with a static hydrothermal synthesis method; and the titanium-loaded modified ZSM-22 molecular sieve is prepared by dispersing the ZSM-22 molecular sieve in butyl titanate, drying and calcining; the modified ZSM-22 molecular sieve provided by the invention has stronger adsorption than that of a unmodified ZSM-22 molecular sieve, and has relatively strong adsorption effect on toluene with low, medium and high concentrations, and the adsorption rate on toluene is as high as 98% or more.

Owner:JIANGSU UNIV OF TECH

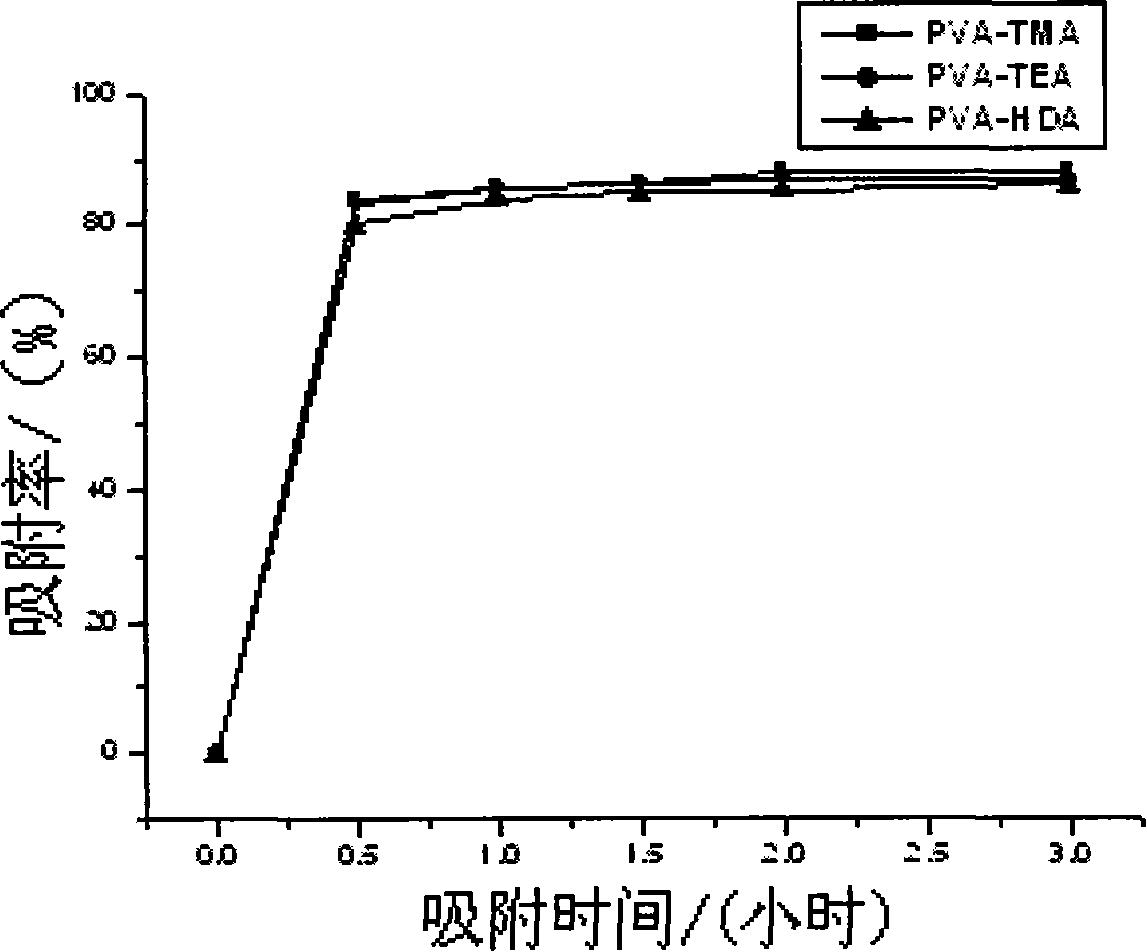

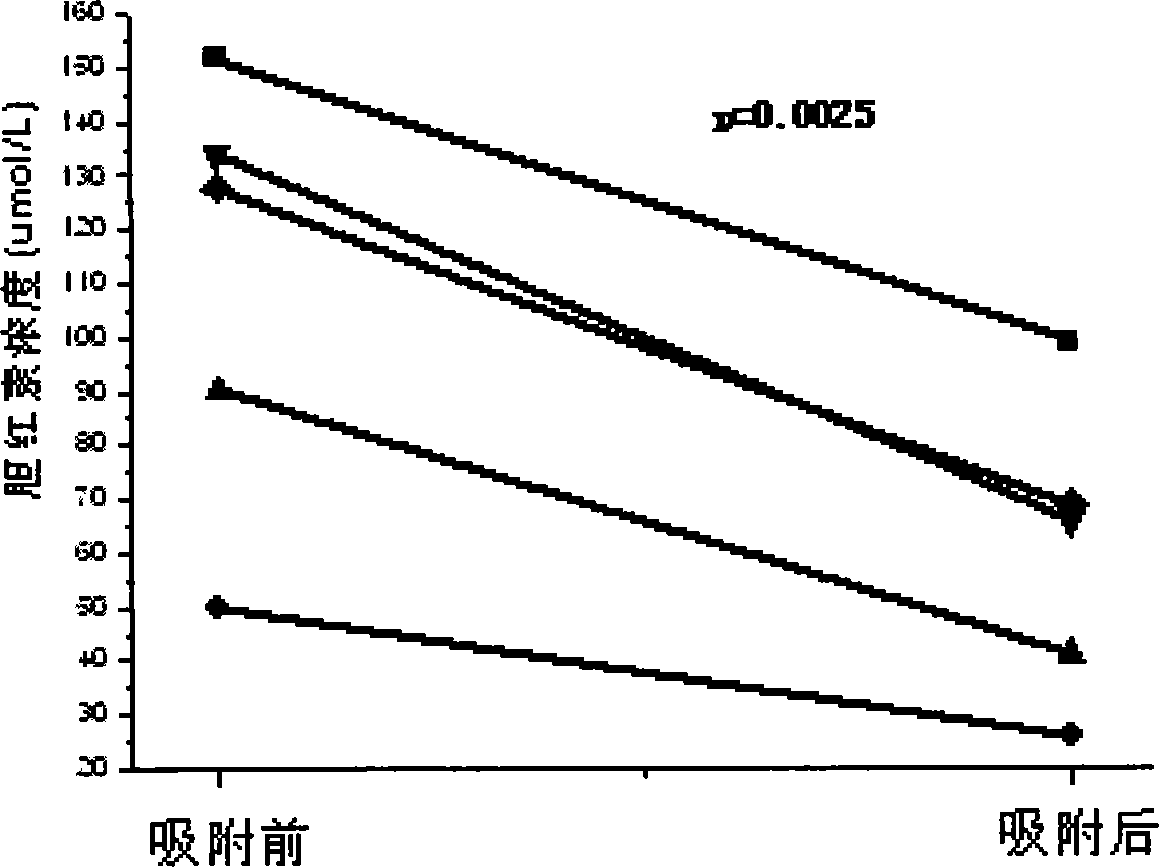

Production method of bilirubin adsorbent

InactiveCN109277085AGood mechanical strengthGood blood compatibilityIon-exchange process apparatusOther chemical processesChemistryPerfusion

The invention provides a production method of a bilirubin adsorbent, in which a polyvinyl alcohol microsphere having excellent biocompatibility serves as a carrier and is activated by epoxy chloropropane; then an amination reagent is immobilized as a functional group to form the bilirubin adsorbent. The bilirubin adsorbent carries a large number of positive charges on the surface, which is beneficial to generate adsorption effect with the bilirubin that carries negative charges on the surface. The bilirubin adsorbent has good biocompatibility and adsorption effect, is low in production cost, has simple synthetic process, is large in adsorption quantity and is high in adsorption speed. The bilirubin adsorbent can be used for treating hyperbilirubinemia through in-vitro whole blood perfusion.

Owner:山阳县恒桓生物科技有限公司

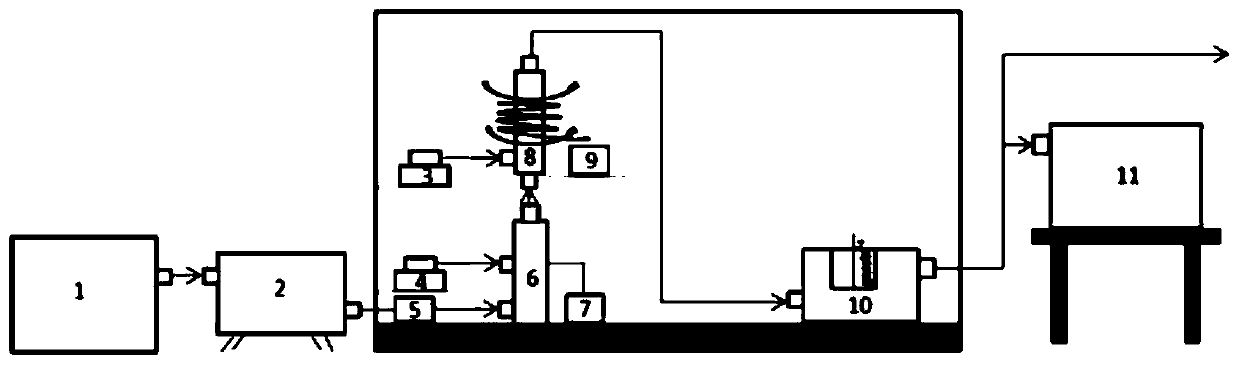

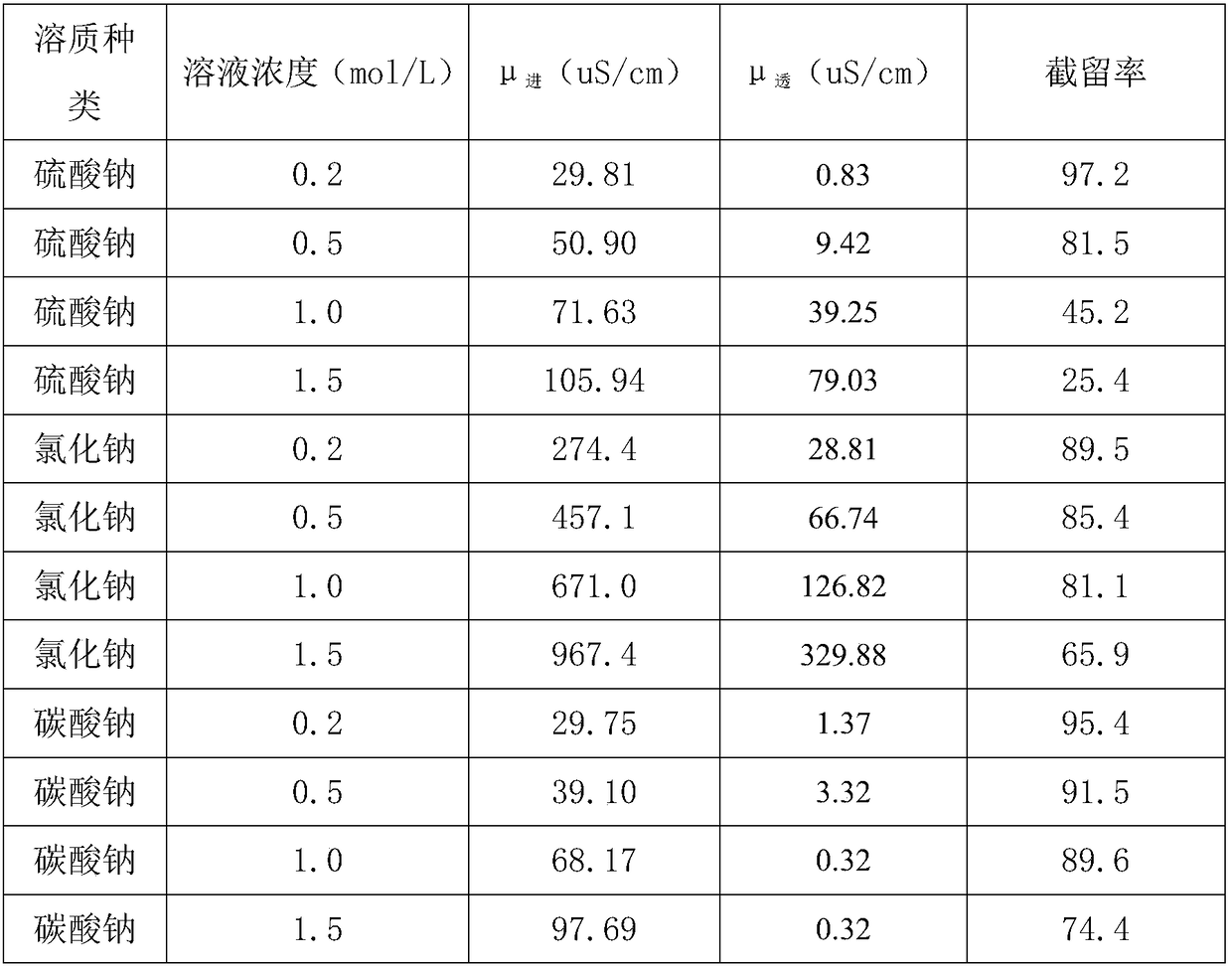

Method and system for recycling residual liquid in dye vat

InactiveCN109336270AAvoid cloggingIncrease water pressureTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisTreatment burdenWastewater

The invention relates to the field of sewage treatment and recycling and discloses a method for recycling residual liquid in a dye vat. The method comprises the following steps: S11, collecting the residual liquid; S12, filtering the residual liquid to remove impurities; S13, introducing the residual liquid into a special membrane separation system to obtain produced water and concentrated water;S14, recycling the produced water and collecting and discharging the concentrated water. The residual liquid in the dye vat is decolorized by the special membrane separation system, salt in the residual liquid is retained in the produced water, the salt in the residual liquid is recycled while dyeing sewage is purified and treated, and accordingly, treatment burden of a sewage plant is reduced, energy is saved, the environment is protected, and the production cost is reduced.

Owner:ZHEJIANG JINMO ENVIRONMENT TECH CO LTD

Blast furnace slag modification method

InactiveCN106994327ASimple methodRaw materials are convenient and cheapOther chemical processesWater contaminantsSlagHydrothermal reaction

The invention discloses a blast furnace slag modification method, and relates to the technical field of material modification. According to the method, hydrochloric acid is dropwise added into blast furnace slag original soil; full stirring is performed; a mixture is obtained; a template agent CTBA is added into the obtained mixture and is fully stirred till the dissolution; then, the mixture dissolved with the CTBA is put into a reaction kettle for hydrothermal reaction; the mixture subjected to hydrothermal reaction is cooled; then, suction filtration, washing and drying are performed; modified blast furnace slag is obtained. The blast furnace slag modification method has the advantages that the method is simple; the raw materials are convenient and cheap; the blast furnace slag original soil can be modified at low temperature; the energy consumption is low; the absorption performance of the modified blast furnace slag is better improved.

Owner:INNER MONGOLIA NORMAL UNIVERSITY

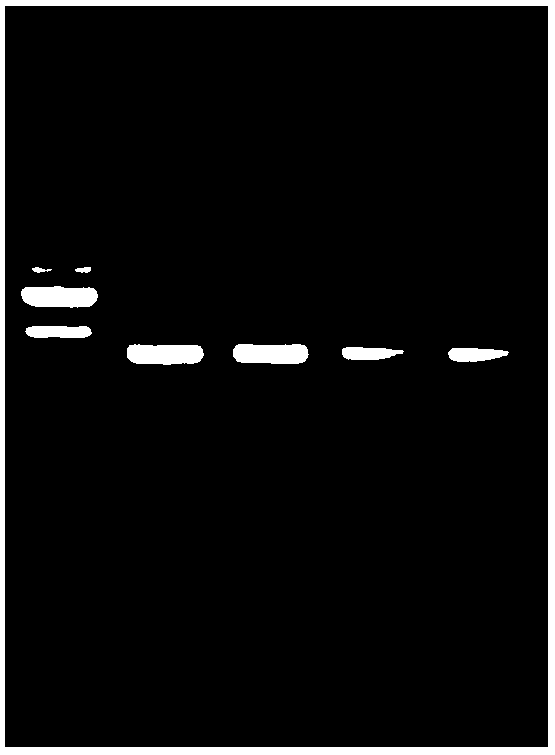

DNA methylation detection kit and application thereof

InactiveCN108130359AImprove integrityImprove recycling efficiencyMicrobiological testing/measurementDNA preparationDNA methylationModified dna

The invention relates to the field of molecular biology and discloses a DNA methylation detection kit and an application thereof. The DNA methylation detection kit comprises a CT conversion solution,an antioxidant, a binding solution, a washing solution, a desulfonation solution, an eluent and a magnetic bead suspension. According to the DNA methylation detection kit, DNA fragments are recoveredfrom a modified DNA solution with a magnetic separation technology, the kit has high recovery efficiency, the completeness of the recovered fragments is good, the kit can be matched with an automaticnucleic acid extractor to realize high-throughput methylation detection, a plenty of time is saved, and the detection efficiency is improved.

Owner:生工生物工程(上海)股份有限公司

Preparation method of foam with purifying material adhered thereto

InactiveCN105944669AImprove adsorption capacityStrong adsorption rateOther chemical processesAlkali metal oxides/hydroxidesSocial benefitsRespirator

The invention discloses a preparation method of foam with a purifying material adhered thereto. The preparation method includes: preparing a graphene dispersion solution and a diatomite-sepiolite purifier solution respectively; mixing the two solutions, performing ultrasonic dispersion, calcining, and grinding to obtain the powdery purifying material; processing the powdery purifying material into particles; mixing the particles with a foaming polymer and a foaming auxiliary in a foaming die for foaming, curing and forming to obtain blocky purifying foam with purifying effect. Graphene is organically combined with diatomite and sepiolite which have natural adsorption characteristics to obtain the purifying material having extremely high adsorption capability and adsorption rate, the purifying material is organically combined on soft polyurethane foam to obtain a purifying material block which is reusable and convenient to carry and cut, and the purifying material block can be widely applied in various existing purifying equipment and purifying masks and has great social benefit.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

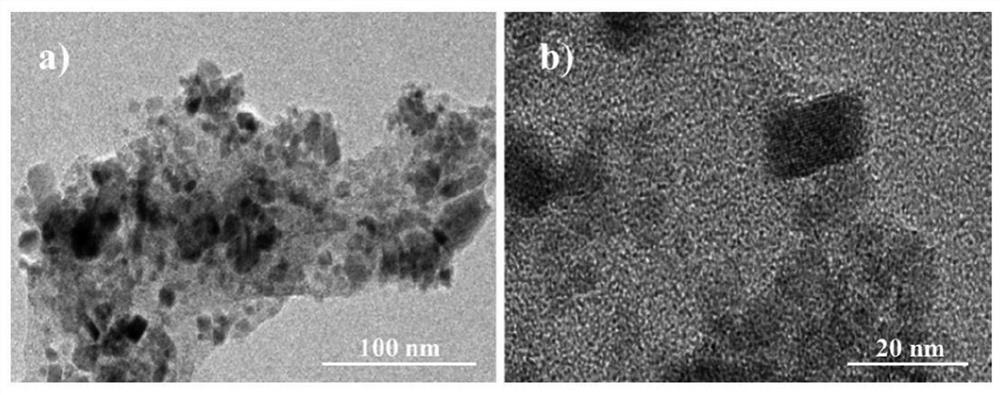

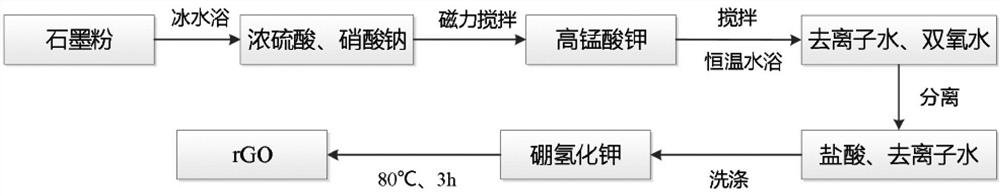

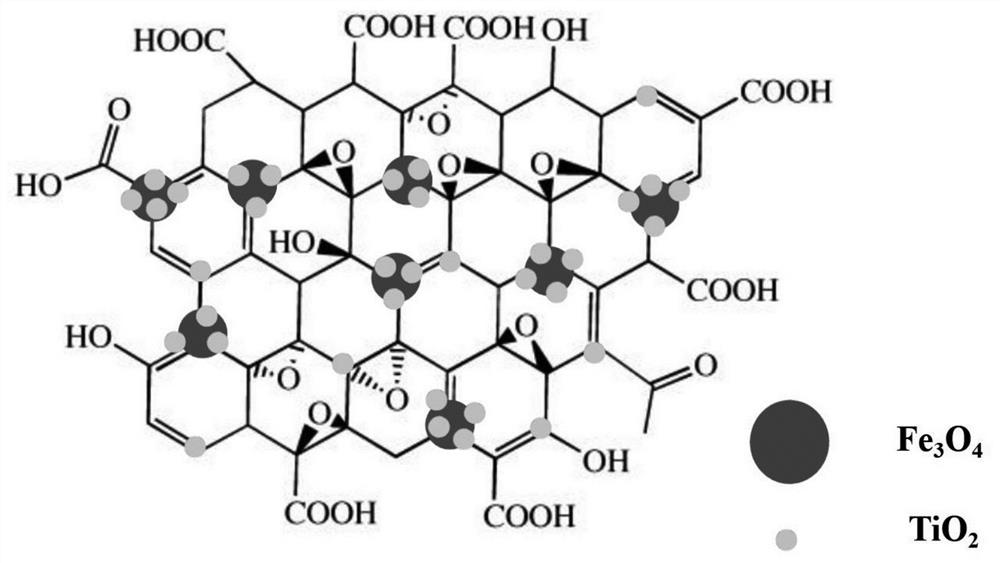

Treatment method of thallium-containing wastewater

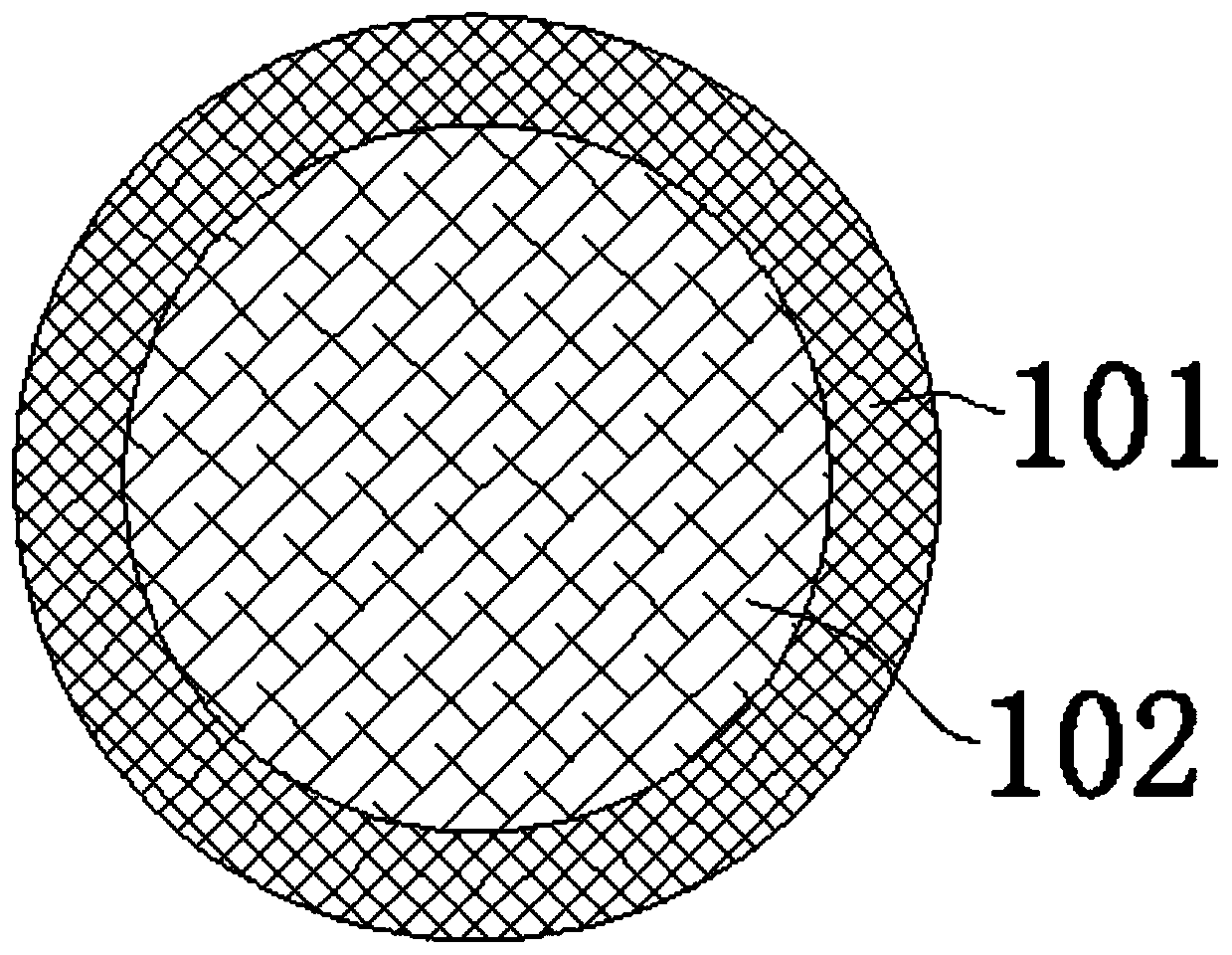

InactiveCN112979008ARenewable and recyclableReduce processing costsOther chemical processesWater contaminantsComposite structureSorbent

The invention discloses a treatment method of thallium-containing wastewater. The method comprises the following steps: A) respectively preparing magnetic adsorbents rGO-Fe3O4@TiO2 and PS; B) obtaining a thallium-containing wastewater sample, and measuring the concentration and pH value of thallium in the sample; C) calculating and verifying the optimal adding amount of the rGO-Fe3O4@TiO2 and PS; D) adding rGO-Fe3O4-coated TiO2 and PS into the wastewater according to the optimal adding amount. The rGO-Fe3O4@TiO2 material effectively activates PS to generate SO4 free radicals through -COOH groups of the rGO-Fe3O4@TiO2 material and Fe (II) in magnetic particles, Tl (I) is quickly adsorbed and oxidized into Tl (III), the Tl (III) is precipitated, and the Tl (I) in wastewater is efficiently removed. According to the invention, a novel magnetic adsorbent is adopted, and is a composite structure rGO-Fe3O4@TiO2 formed by taking Fe3O4 as a core, coating core-shell solid particles with TiO2 nanoparticles on the surface, taking an rGO nanosheet with mesopores as a carrier and combining the core-shell solid particles and the carrier with the nanosheet. According to the thallium-containing wastewater treatment method provided by the invention, the adopted adsorbents are few in variety and total amount, high in thallium adsorption capacity, large in capacity, high in efficiency, low in cost and easy to popularize.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

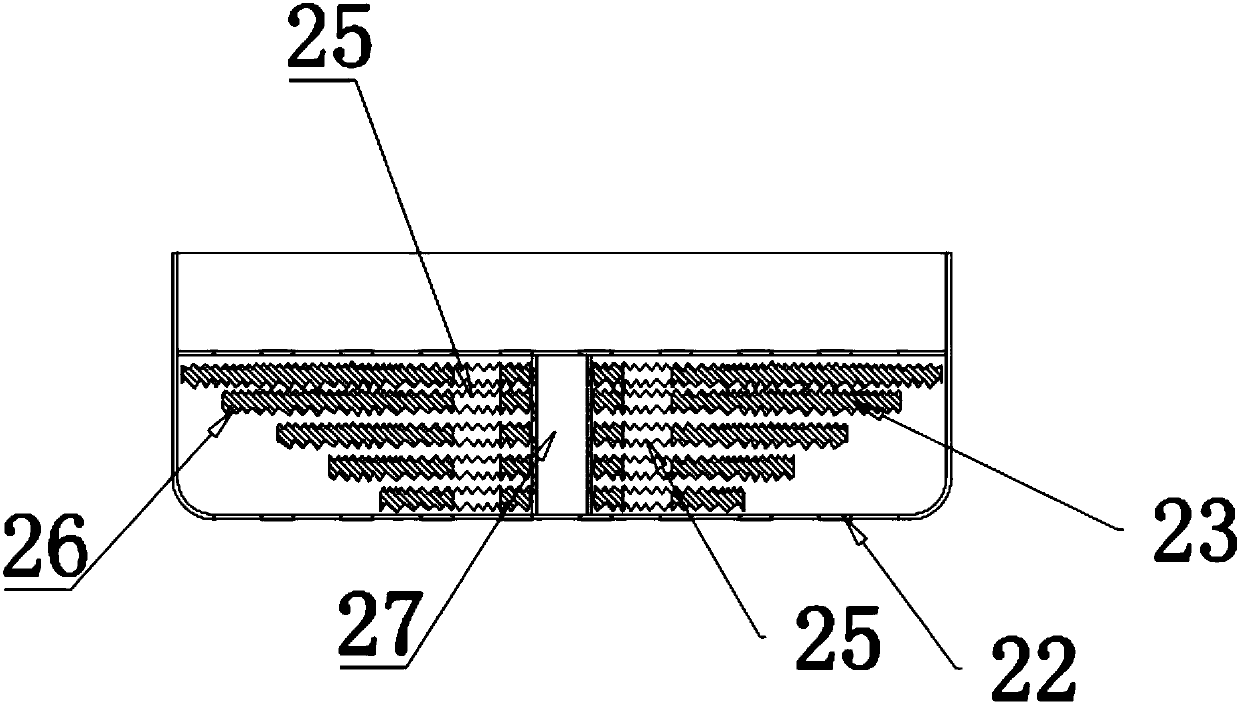

Nitrogen and phosphorus removal composite filler and preparation method thereof

The invention discloses a nitrogen and phosphorus removal composite filler and a preparation method thereof, which belong to the field of environmental protection and material science, the composite filler comprises the following raw material components by mass: 20-40 parts of steel slag powder; 40 to 60 parts of zeolite particles; 5-10 parts of pearl expansive rock powder; 10 to 15 parts of clay;and 10-20 parts of dolomite dust; the preparation method comprises the following steps: crushing: crushing the steel slag, the pearl expansive rock and the dolomite by virtue of a crusher, and sieving by virtue of a 100-mesh sieve so as to obtain the steel slag powder, the pearl expansive rock powder and the dolomite powder; crushing the zeolite through the crusher and sieved through a 10-mesh sieve, and obtaining the zeolite particles; and performing the steps of weighing, stirring, forming, drying and firing. The product disclosed by the invention has the advantages of high strength, lightweight, porosity and large specific surface area.

Owner:HUNAN QUANZHIYUAN ENVIRONMENTAL PROTECTION SCI & TECH

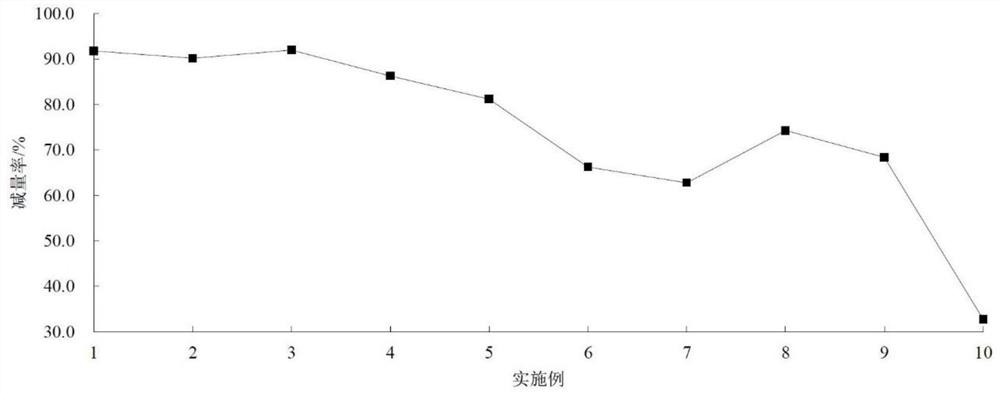

Preparation method of composite high-activity demercuration adsorbent

InactiveCN106423061AIncrease oxidation rateStrong adsorption rateOther chemical processesDispersed particle separationSorbentCopper chloride

The invention relates to a preparation method of a composite high-activity demercuration adsorbent, and belongs to the technical field of an demercuration adsorbent. Straw fly ash is subjected to acid soaking modification and is then subjected to soaking modification by copper chloride solution, so that the modified fly ash has good adsorbability; after the treatment and modification on attapulgite, copper oxide is loaded on the attapulgite, so that the loaded attapulgite has good catalyst performance; the mercury oxidation rate is improved. The demercuration adsorbent prepared by the invention has high oxidization rate on mercury and good adsorption rate; physical adsorption and chemical adsorption are combined, so that the demercuration activity is high; compared with the conventional active carbon, the high-activity demercuration adsorbent has the advantages of high mercury adsorption capability and long effective adsorption time.

Owner:吴迪

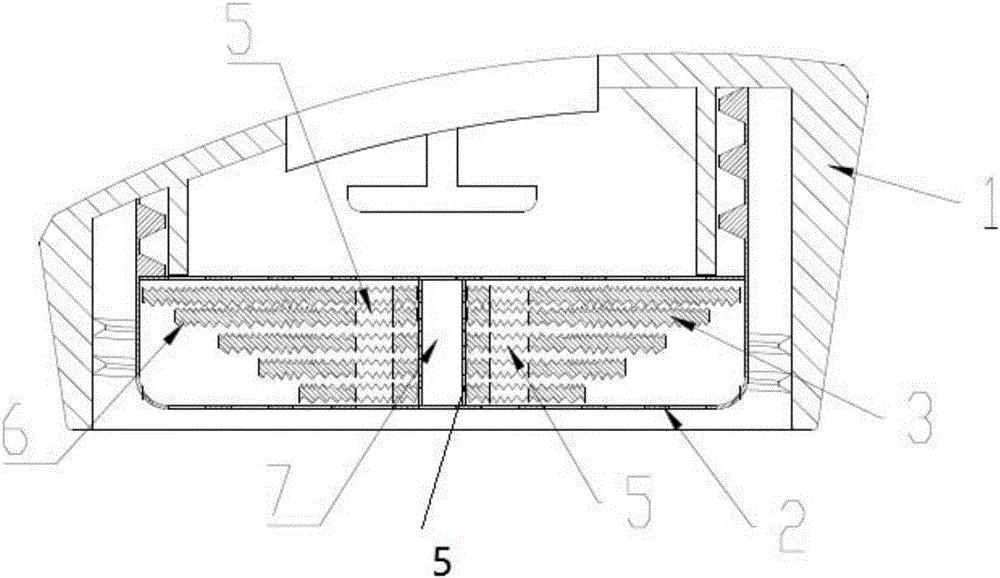

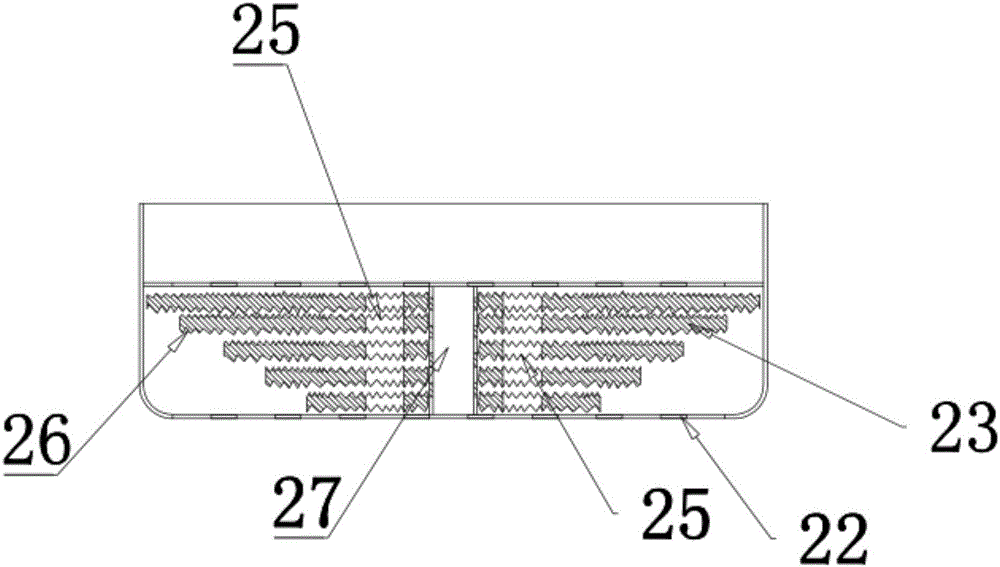

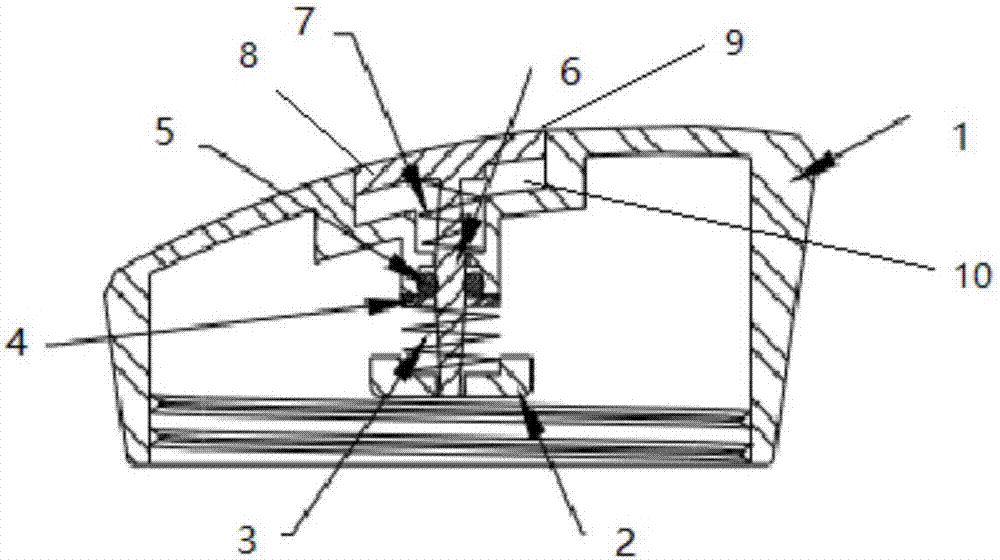

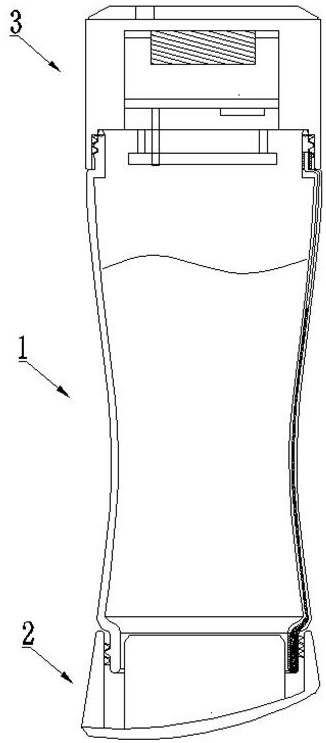

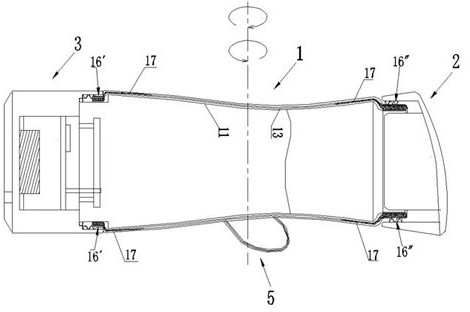

Hydrogen-rich water cup cap with filter element

InactiveCN106073391AAchieve dechlorinationAchieve electrolysisTreatment involving filtrationWater/sewage treatment by substance additionHydrogenHoneycomb Pattern

The invention relates to a hydrogen-rich water cup cap with a filter element. The hydrogen-rich water cup cap comprises a cup cap shell and a filtering device connected with the cup cap shell in a threaded or clamped mode. The filtering device comprises a stainless steel shell and a filter element device which is arranged in the stainless steel shell and can generate electrolyte and remove chlorine. The filter element device is formed by a plurality of sheet material layers in a stacked mode or a honeycomb-shaped composite formed by combining a plurality of spherical particles.

Owner:FUZHOU PINXING TECH DEV

Hydrogen-enriched cup facilitating medicine taking

The invention relates to a hydrogen-enriched cup facilitating medicine taking. The hydrogen-enriched cup comprises a cup body, a cup cover and a base, the inside of the cup body is divided into a first cavity and a second cavity, a hydrogen production electrode is arranged in the first cavity, the first cavity is communicated with the second cavity through a one-way valve, and a groove for containing medicines is formed in the cup cover.

Owner:上海波浦新材料科技有限公司

A kind of method and application of preparing heavy metal adsorbent by using blast furnace slag

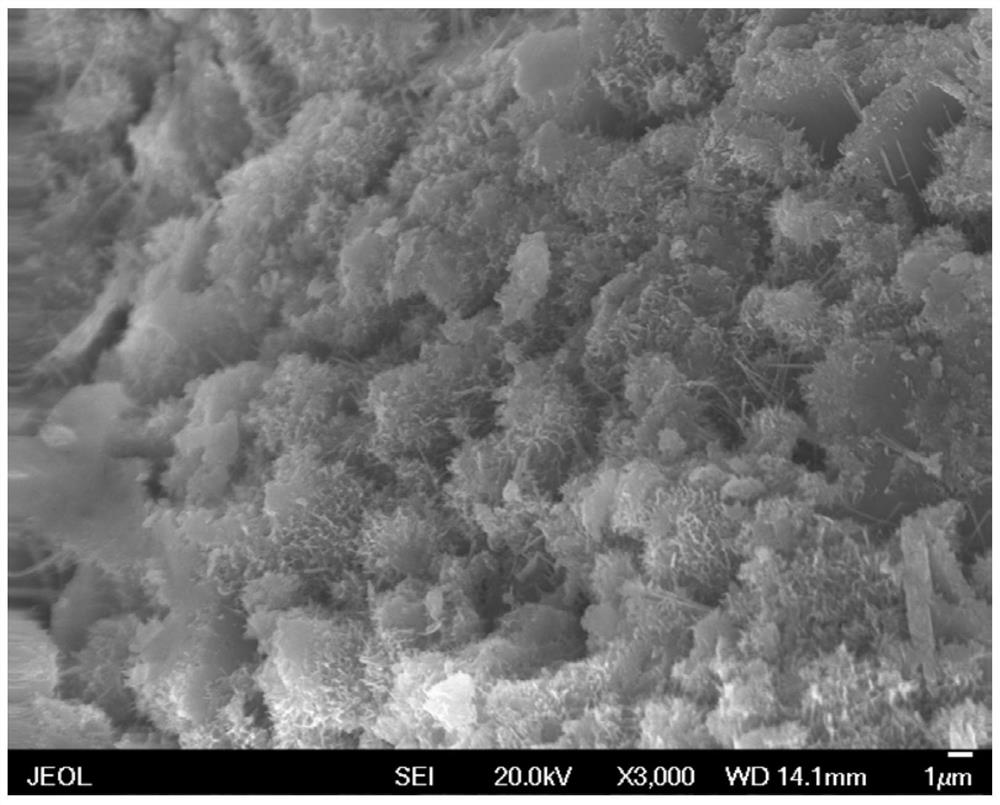

ActiveCN113231007BLarge specific surface areaStrong adsorption rateOther chemical processesWater contaminantsAluminum IonAluminate

A method and application for preparing a heavy metal adsorbent using blast furnace slag, the method comprises: soaking blast furnace slag in water, filtering, drying, and grinding; Record solid 1; adjust the pH of solution 1, suction filtration, and record the filtrate as solution 2; add the filter residue to lye 2, and react to obtain clear solution 3; ultrasonically disperse solid 1 in water to obtain suspension 1, and add solution to suspension 1 3, ultrasonically disperse to obtain suspension 2, then add solution 2, and finally centrifuge to obtain adsorbent. In the present invention, aluminum ions and silicate ions are separated from blast furnace slag, then the two are mixed with the treated blast furnace slag skeleton, and the dosage and curing conditions of the three are controlled to prepare a fluffy, granular skeleton, At the same time, the surface of the skeleton is covered with a layer of convex and "wrinkled" aluminosilicate rough gel adsorbent, which has a large specific surface area and a good adsorption rate for heavy metals.

Owner:UNIV OF SCI & TECH BEIJING

A hydrogen-rich water cup that is convenient for taking medicine

The invention relates to a hydrogen-enriched cup facilitating medicine taking. The hydrogen-enriched cup comprises a cup body, a cup cover and a base, the inside of the cup body is divided into a first cavity and a second cavity, a hydrogen production electrode is arranged in the first cavity, the first cavity is communicated with the second cavity through a one-way valve, and a groove for containing medicines is formed in the cup cover.

Owner:上海波浦新材料科技有限公司

A hydrogen-rich water cup

ActiveCN106073392BAchieve dechlorinationAchieve electrolysisTreatment involving filtrationMultistage water/sewage treatmentHydrogenEngineering

Owner:上海波浦新材料科技有限公司

Ceramic composition and preparation method thereof

InactiveCN107324763AStrong adsorption rateEfficient purificationCeramicwareClaywaresBenzeneZinc borate

The invention provides a ceramic composition and a preparation method thereof. The ceramic composition is prepared from the following components in parts by weight: 1 to 8 parts of bamboo charcoal powder, 10 to 15 parts of sepiolite, 1 to 5 parts of zinc borate, 1 to 5 parts of tourmaline crystal particle and 40 to 60 parts of clay. The ceramic composition with high adsorption performance, which is prepared by the preparation method, has a larger specific surface area and higher illumination self-cleaning capacity, can be used for effectively adsorbing harmful gases of formaldehyde, benzene and the like, and is used for improving air quality; moreover, the preparation method is simple and is suitable to the industrialized production.

Owner:周远华

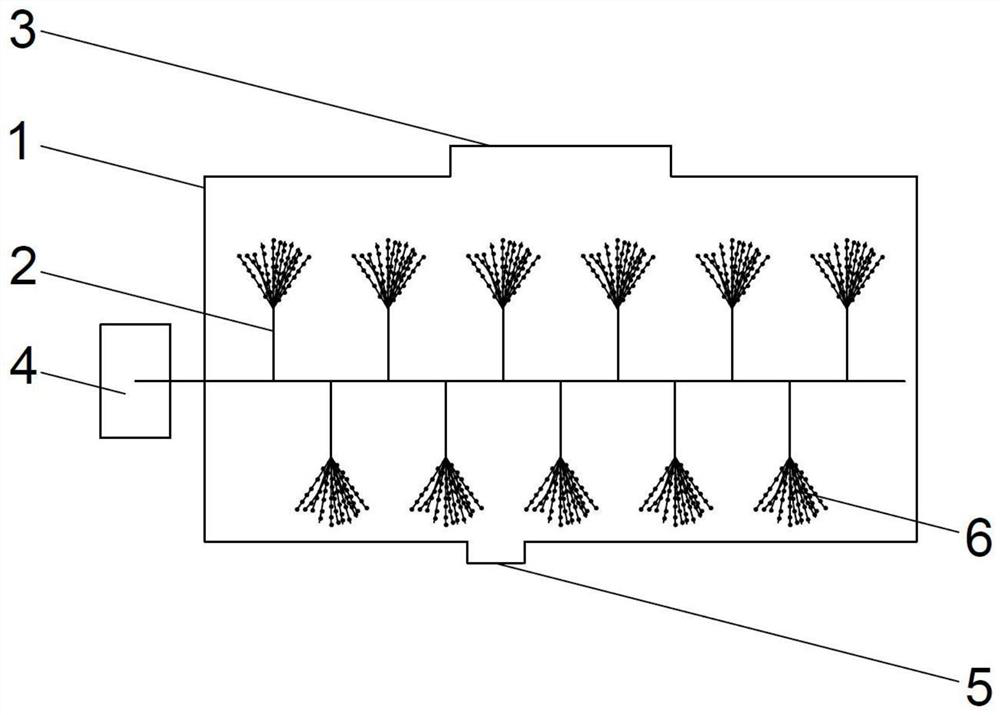

Perishable Garbage Rapid Degradation Method and Its Application

ActiveCN113151248BIncrease roughnessGood adhesionFungiBio-organic fraction processingElectric machineryEnvironmental engineering

The invention relates to the technical field of perishable garbage treatment, in particular to a method for rapidly degrading perishable garbage and its application. Firstly, a degradation bin with a stirring rod inside is provided. The stirring rod can be driven by a stirring motor arranged outside the degradation bin. There is a discharge port that can discharge the degradation products of perishable garbage; detachably fix the fast-degrading bacterial agent of perishable garbage to the stirring rod; pick out non-degradable substances from perishable garbage, crush them to pass through a 10-mesh sieve, and place them in the In the degradation chamber, the stirring motor is turned on to drive the stirring rod to rotate at 30-120r / min, and the aerobic degradation takes 24-36 hours; after the degradation is completed, the degradation products are discharged through the discharge port, and the slag liquid is separated and processed separately. The method can complete a relatively large amount of degradation treatment of perishable garbage in a short period of time, and degrade it into water and carbon dioxide, and no obvious peculiar smell is generated during the degradation process.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

A kind of gallium-germanium adsorbent, its preparation method and application, and the method for enriching gallium-germanium from the zinc hydrometallurgy leaching solution

InactiveCN105177321BEasy to prepareLow costOther chemical processesProcess efficiency improvementSorbentHydrometallurgy

The invention discloses a gallium and germanium absorbent, a preparation method and application of the gallium and germanium absorbent, and a method for enriching gallium and germanium from a zinc hydrometallurgy leaching agent. The gallium and germanium absorbent is capable of simultaneously absorbing the gallium and the germanium effectively and specifically, and the gallium and germanium absorbent is simple in preparation method and low in cost. When the gallium and germanium absorbent is used for absorbing the gallium and the germanium in the zinc hydrometallurgy leaching agent, the absorbing effect is good, and the pertinence is high; the follow-up process of zinc electrolytic can be effectively conducted, and the cost is low. The used absorbent and stripping liquid can be recycled and reused, and a good absorbing effect on the gallium and the germanium can still be achieved after the absorbent and the stripping liquid are recycled and reused for many times. The requirement for industrial production is met.

Owner:CENT SOUTH UNIV

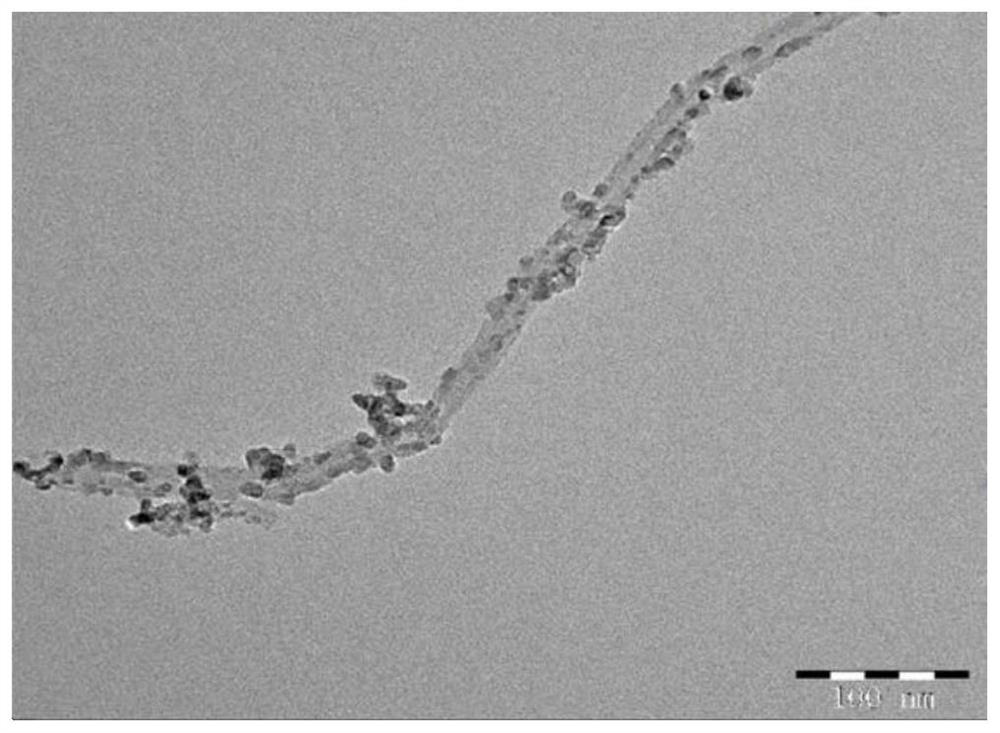

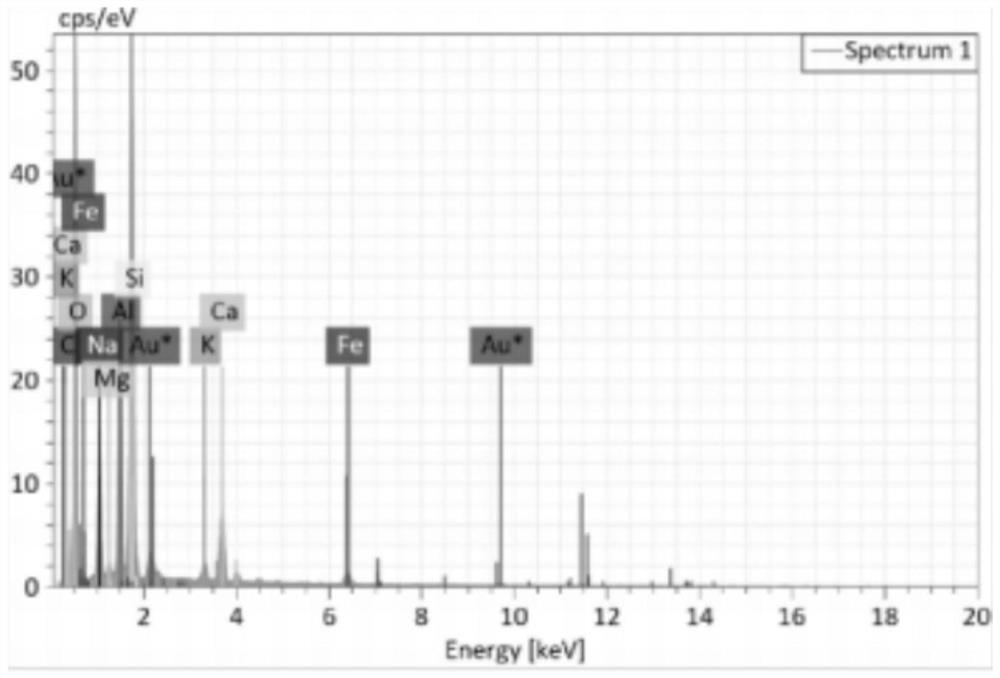

Preparation method of nano-gold modified titanium dioxide-carbon nanotube composite photocatalyst

ActiveCN108579737BImprove bindingEffective and excellent catalytic degradation effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOrganic solvent

The invention provides a method for preparing a nanogold-modified titanium dioxide-carbon nanotube composite photocatalyst, which includes the following steps: using an alcohol aqueous solution and a stable gas as a medium, and processing with a micro-nano bubble generator to obtain micro-nano bubble water ; Mix and disperse the micro-nano bubble water, carbon nanotubes and titanium salt to obtain a dispersion; mix and hydrolyze the dispersion with an ammonia solution to obtain a hydrolyzate; d) mix the hydrolyzate with gold salt and micron After the nanobubble water is mixed, light reduction and heating reactions are performed sequentially to obtain the reaction product; the reaction product is heat treated to obtain Au-TiO 2 -CNTs composite photocatalyst. The preparation method provided by the invention is simple and easy to implement, which greatly simplifies the preparation process; and the composite photocatalyst produced is stable in combination and has effective and excellent catalytic degradation effect; at the same time, the preparation process does not require the use of toxic organic solvents and template agents, which greatly improves the efficiency of the preparation process. Reduce costs and harm to the environment.

Owner:GUANGDONG UNIV OF TECH

Rapid perishable garbage degradation method and application thereof

ActiveCN113151248AIncrease roughnessGood adhesionFungiBio-organic fraction processingBiochemical engineeringElectric machinery

The invention relates to the technical field of perishable garbage treatment, in particular to a rapid perishable garbage degradation method and application thereof. Firstly, a degradation bin internally provided with a stirring rod is provided, the stirring rod can be driven by a stirring motor arranged outside the degradation bin, a feeding port capable of feeding perishable garbage is formed in the top of the degradation bin, and a discharging port capable of discharging perishable garbage degradation products is formed in the bottom of the degradation bin; a rapid perishable garbage degradation bacterial agent is detachably fixed to the stirring rod; non-degradable substances are selected from perishable garbage, the perishable garbage is crushed until the perishable garbage passes through a 10-mesh sieve, the perishable garbage is put into the degradation bin, the stirring motor is started to drive the stirring rod to rotate at 30-120 r / min, and aerobic degradation is performed for 24-36 hours; and after degradation is finished, the degradation products are discharged through the discharging port, and residues and liquid are separated and then are treated separately. According to the method, a relatively large amount of the perishable garbage can be degraded in a short time, the perishable garbage is degraded into water and carbon dioxide, and no obvious peculiar smell is generated in the degradation process.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

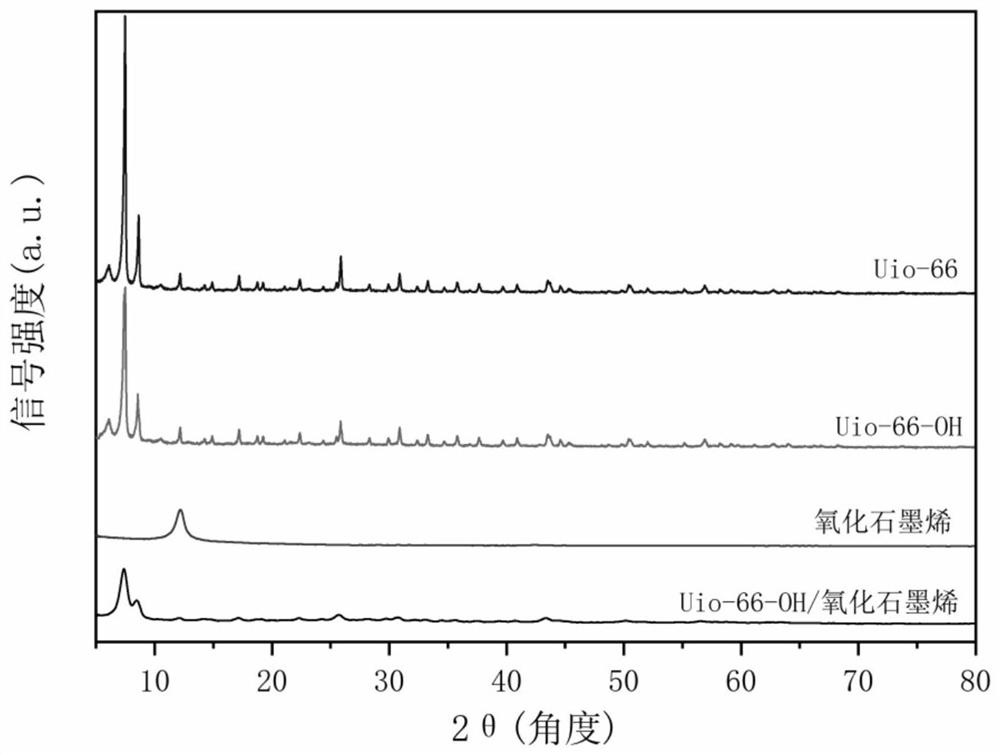

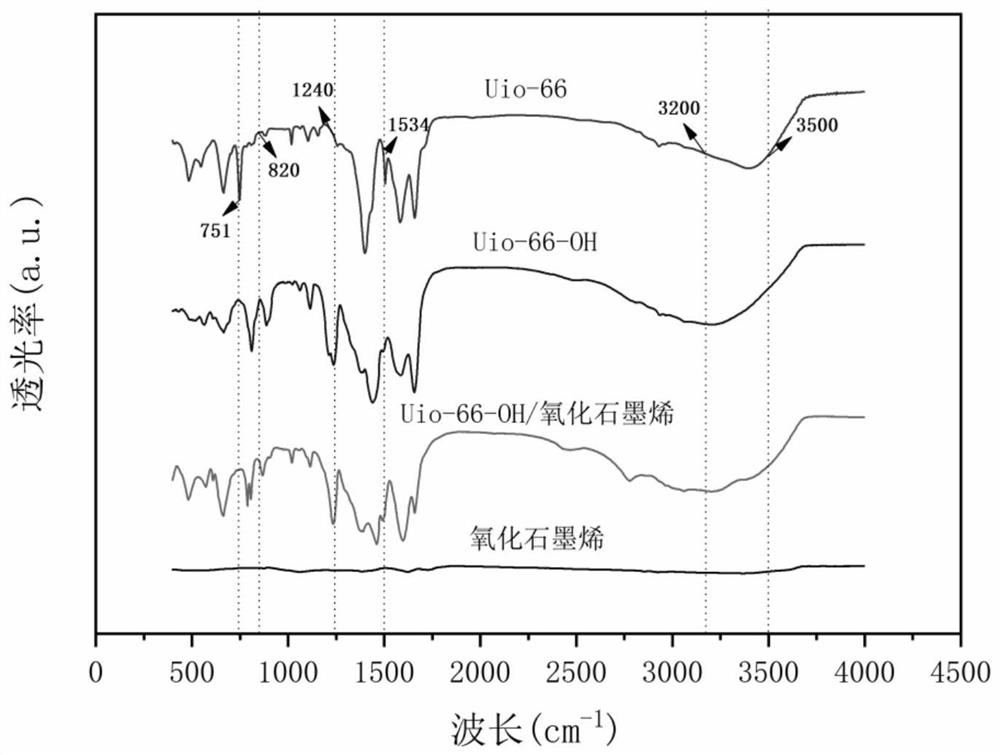

A functionalized zirconium-based metal-organic framework/graphene oxide composite material and its preparation method and application

ActiveCN110170308BSpecial structureStable structureOther chemical processesWater contaminantsOxide compositeMetal-organic framework

The invention discloses a functional zirconium-based metallic organic framework / graphene oxide composite material as well as a preparation method and application thereof. The composite material comprises Uio-66-OH as a carrier which is doped with graphene oxide. The preparation method comprises the following steps: preparing a reaction substrate solution from an organic ligand, a soluble zircon salt, an organic solvent, a high-boiling-point organic solvent and a graphene oxide solution, carrying out a reaction on the reaction substrate solution, repeatedly soaking and centrifuging the reactionproduct, washing, and drying, thereby obtaining the composite material. The composite material disclosed by the invention has the advantages of being low in cost, stable in structure, good in adsorption capability, high in adsorption velocity, and the like, can be widely applied to dye wastewater treatment, has a good removal effect and has high use values and good application prospects, and thepreparation method of the composite material has the advantages of being simple in process, simple in operation condition, easy to control, convenient to operate, easy in raw material obtaining, low in preparation cost, short in synthesis cycle, and the like.

Owner:HUNAN UNIV

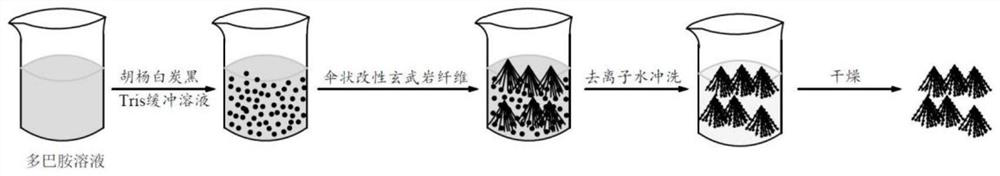

Method for preparing heavy metal adsorbent from blast furnace slag and application

ActiveCN113231007ALarge specific surface areaStrong adsorption rateOther chemical processesWater contaminantsAluminum IonSlag

The invention discloses a method for preparing a heavy metal adsorbent from blast furnace slag and application, and the method comprises the following steps: soaking blast furnace slag in water, filtering, drying and grinding; reacting the ground product with alkali liquor, carrying out suction filtration, retaining the filtrate as solution 1, and recording the filter residue as solid 1; adjusting the pH value of the solution 1, performing suction filtration, and recording filtrate as solution 2; adding filter residues into alkali liquor 2, and reacting to obtain a clear solution 3; and performing ultrasonic dispersion on the solid 1 in water to obtain a suspension 1, adding the solution 3 into the suspension 1, performing ultrasonic dispersion to obtain a suspension 2, adding the solution 2, and finally performing centrifugal separation to obtain the adsorbent. According to the invention, aluminum ions and silicate ions are separated from blast furnace slag, then the aluminum ions and the silicate ions are mixed with a treated blast furnace slag skeleton, and the use amounts and curing conditions of the aluminum ions, the silicate ions and the treated blast furnace slag skeleton are controlled, so that the adsorbent which has a fluffy and granular skeleton and covers a layer of bulges and wrinkles on the surface of the skeleton is prepared, the specific surface area is large, and the adsorption rate on heavy metals is good.

Owner:UNIV OF SCI & TECH BEIJING

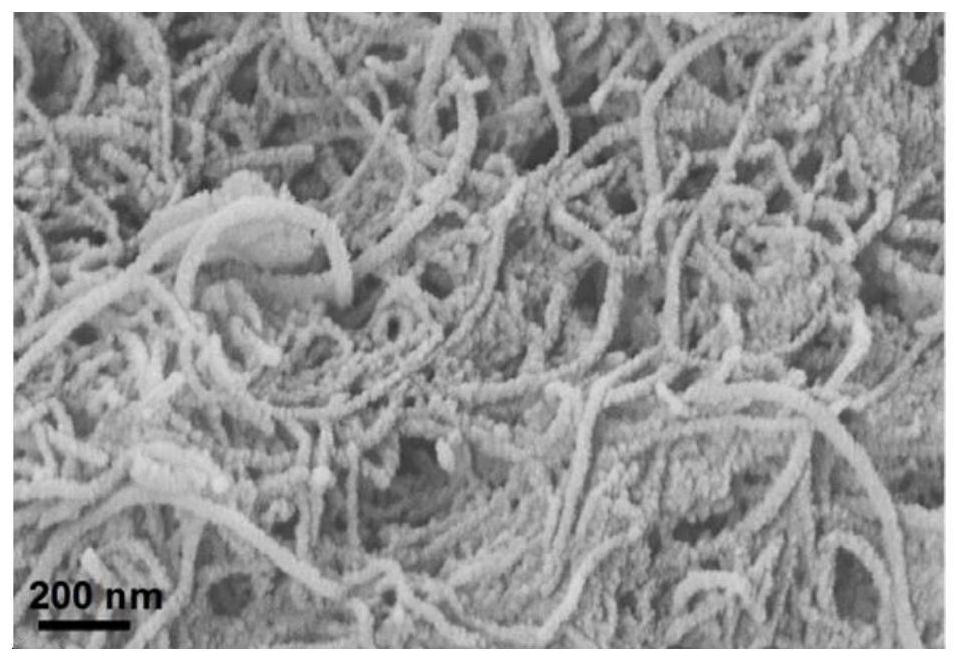

A kind of graphene microsheet with network structure and preparation method thereof

ActiveCN106044920BIncrease throughputStrong water absorption functionSeawater treatmentWater/sewage treatment by sorptionWastewaterNetwork structure

Disclosed are a graphene micro-sheet having a mesh structure and a preparation method therefor. According to the present invention, by adding a grafted functional group to a graphene micro-sheet, and generating micropores in the graphene micro-sheet during grafting, a graphene micro-sheet having a regular three-dimensional mesh structure, good stability, high adsorption rate, and great composite performance is obtained. The graphene micro-sheet having a mesh structure has super strong adsorbability, is applied to heavy metal adsorption, wastewater treatment, oil pollution collection, seawater desalination, and drink water purification, and can be used in a wide temperature range, a wide pH range, and a wide range of ion components.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

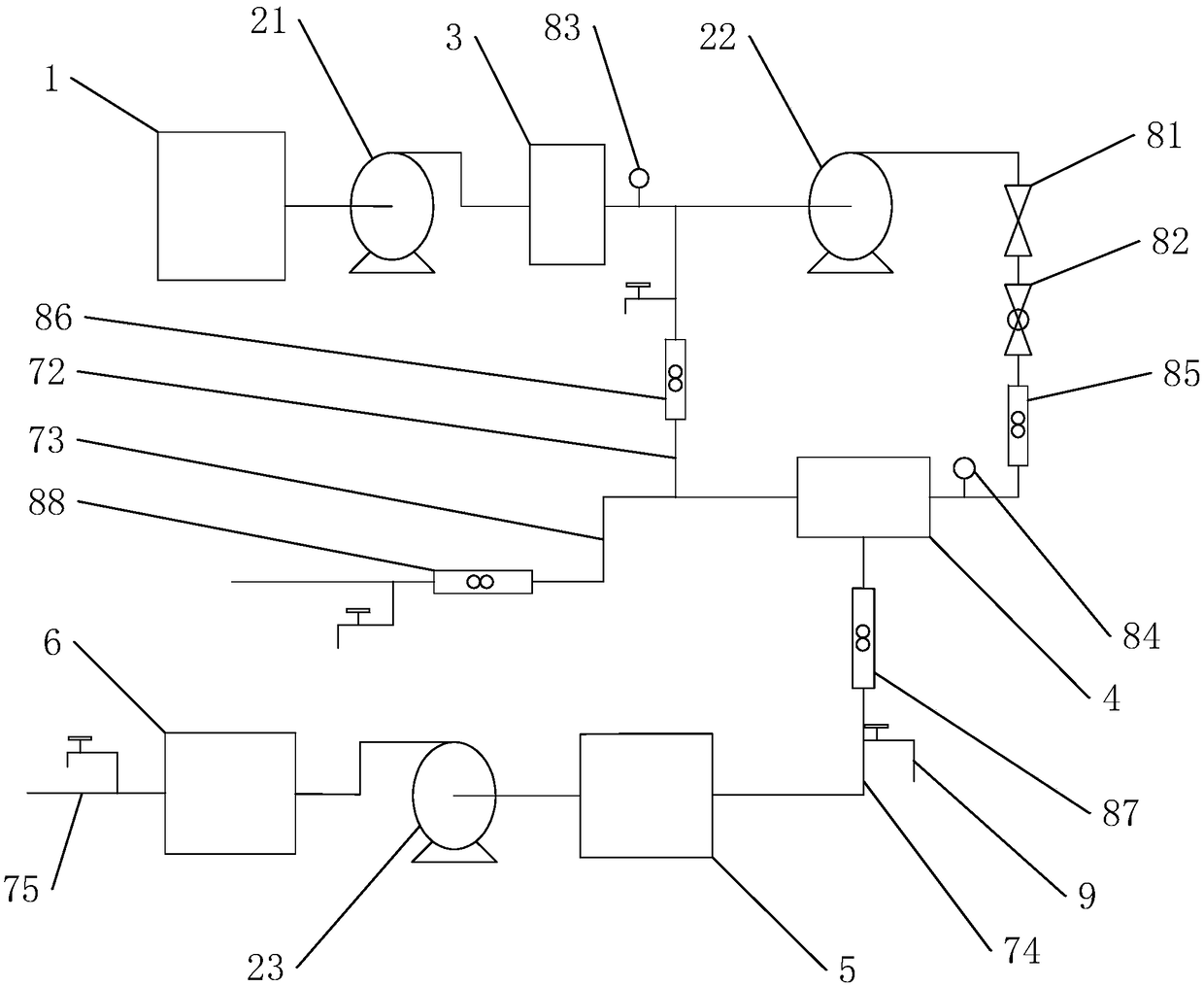

A sugar-based/sulfonated modified affinity polymer hollow fiber separation membrane, its preparation method and application

ActiveCN103252177BLittle side effectsHigh selectivityIon-exchange process apparatusSemi-permeable membranesHollow fibrePolymer science

The invention discloses a glycosyl / sulfonated modified affiliative polymer hollow fiber separating membrane and a preparation method thereof. The membrane is composed of polymer resin, sulfonated polymer resin and saccharide polymer, has a good specificity adsorption effect on LDL (low-density lipoprotein) under optimized raw materials and proportion, is good in stability and biocompatibility, reusable and low in cost, and can be put into large-scale clinical application. The preparation method comprises the following processes of: dissolving the polymer resin, sulfonated polymer resin, saccharide polymer and a pore-foaming agent for the membrane in a dissolvent according to a certain proportion to prepare a uniform spinning membrane-preparing solution, filtering the spinning membrane-preparing solution, defoaming the filtered spinning membrane-preparing solution in vacuum, spinning through a immersion-precipitation phase transformation method to prepare the hollow fiber membrane, and then sufficiently rinsing the prepared hollow fiber membrane in deionized water and ultrapure water in order. The blending dissolving preparation method adopted by the invention has the advantages that the operation is simple and safe and the raw materials are cheap and easily available.

Owner:ZHEJIANG UNIV

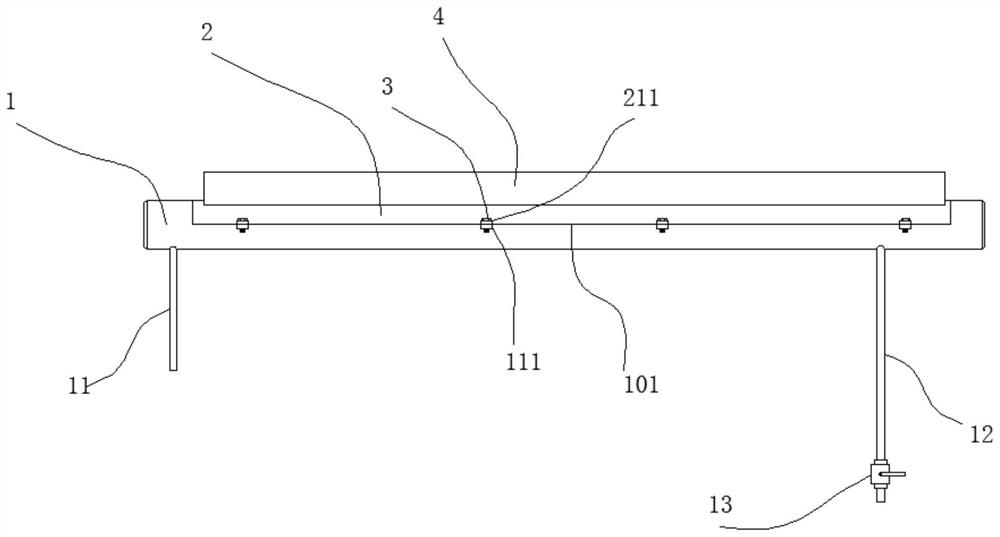

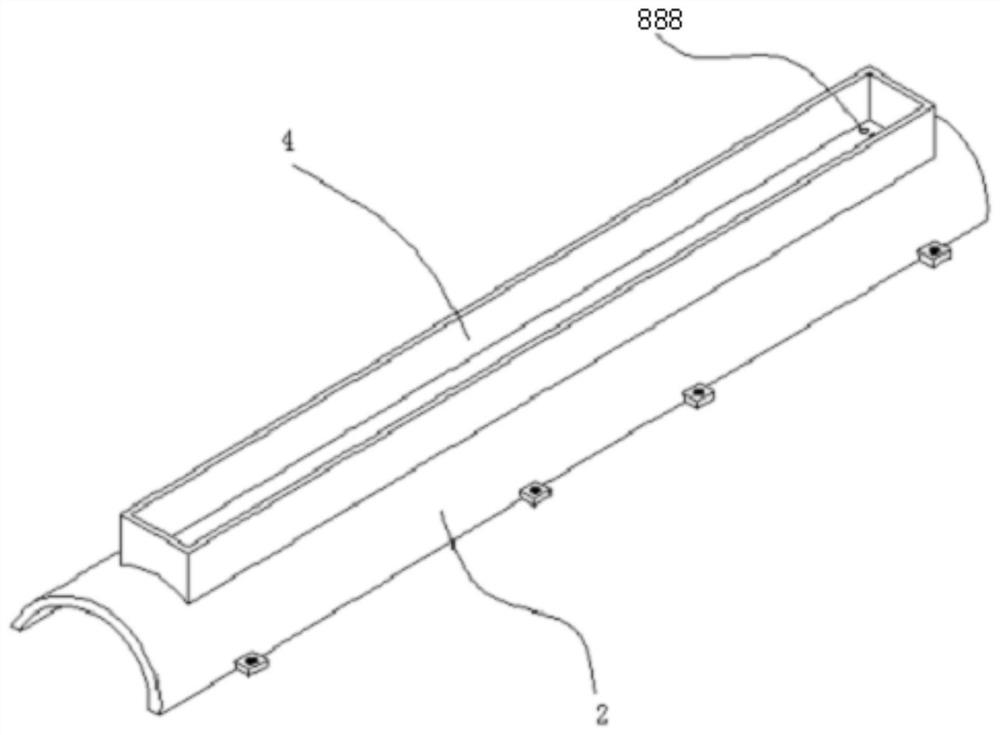

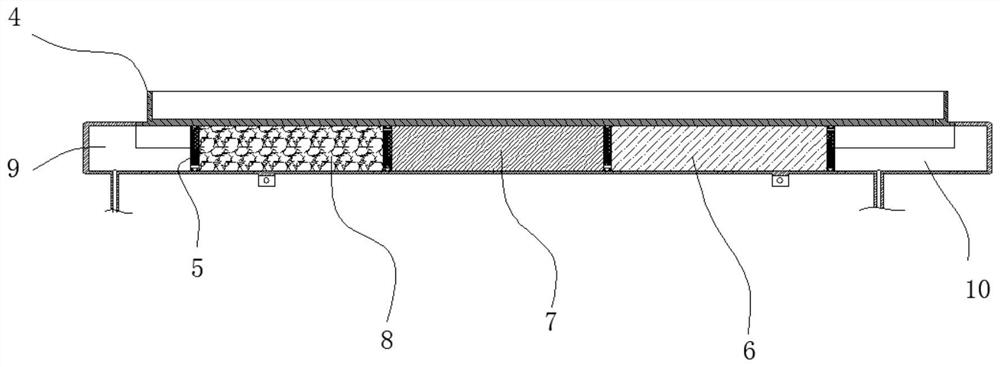

A rainwater collection and treatment pipeline

ActiveCN109778990BDon't worry about the smellEffectMultistage water/sewage treatmentSewer pipelinesPipe fittingStructural engineering

The invention discloses a rainwater collection and treatment pipeline, comprising a PVC pipe fitting. Two ends of the pipe fitting are sealed during injection molding. An upward open groove is formedin the outer wall of the pipe fitting; a cover plate is mounted at the open groove; the open groove is sealed by the cover plate; and a water collecting tank is formed at the upper end of the cover plate through injection molding. When the product is installed, a water collecting tank is positioned below an eave, water drops falling along the eave are collected into the water collecting tank, fourpartition plates are arranged in the pipe fitting and can move in the axial direction of the pipe fitting, a first cavity, a second cavity and a third cavity are formed among the four partition plates, the first cavity is filled with medium sand, the second cavity is filled with fine sand, and the third cavity is filled with a particle mixture. The product can collect natural rainwater and filterthe natural rainwater, and the filtered water can be used for direct drinking.

Owner:杭州建通塑业有限公司

High adsorption ceramic composition and preparation method thereof

InactiveCN107200601AStrong adsorption rateEfficient purificationGas treatmentOther chemical processesZinc borateTitanium dioxide

The invention provides a high adsorption ceramic composition and a preparation method thereof. The ceramic composition is prepared from the following components in parts by weight: 1-8 parts of bamboo charcoal powder, 10-15 parts of titanium dioxide, 1-5 parts of zinc borate, 1-5 parts of tourmaline crystal particle, and 40-60 parts of clay. The high adsorption ceramic composition has high specific surface area and light self-cleaning performance, can effectively adsorb formaldehyde, benzene and other harmful gases, can purify air so as to improve the air quality, is easy to prepare and is suitable for industrial production.

Owner:朱燕萍

Adsorbing agent for blood perfusion adsorbing bilirubin in vitro and preparation

InactiveCN101298041BStrong adsorption rateSafe and effective treatmentOther chemical processesSuction devicesBILIRUBINAEMIAPolyvinyl alcohol

The invention relates to an adsorbent used for adsorbing cholerythrin in extra corporeal blood perfusion and a preparation method thereof. The method takes polyvinyl alcohol microspheres with good biological compatibility as a carrier, adopts epoxy chloropropane for activation and fixes an amination agent as a functional group to form the cholerythrin adsorbent. The surface of the adsorbent is provided with a plurality of positive charges, which is beneficial to action with with the cholerythrin provided with negative charges on the surface to generate absorption effect. The adsorbent prepared by the invention has good biological compatibility and good adsorbing capacity, and is characterized by low manufacturing cost, simple synthesis process, large adsorbing volume, and high adsorbing speed, etc., and can be used in extra corporeal blood perfusion for curing hyperbilirubinemia.

Owner:TIANJIN DEOUTE BIOLOGY MEDICINE SICENCE & TECH +1

A motion-sensing hydrogen-rich water cup

InactiveCN106745535BTurn on the implementationPrevent openingElectrolysis componentsWater/sewage treatment by substance additionElectrolysisElectrical connection

Owner:FUZHOU PINXING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com